Newport Oriel MS260i, Oriel MS260i 74085, Oriel MS260i 74055, Oriel MS260i 74050, Oriel MS260i 74086 User Manual

Page 1

M-74050

OORRIIEELL PPRROODDUUCCTT LLIINNEE

150 Long Beach Boulevard

Stratford, CT 06615

Phone: (203) 377-8282

(800) 714-5393

Fax (203) 378-2457

E-MAIL: oriel.sales@newport.com

MS260i

IMAGING ¼ M SPECTROGRAPH

MODELS 74050, 74055, 74085, 74086

`

USER MANUAL

Please read these instructions completely before operating this equipment. The specification and operating

instructions apply only to the model(s) covered by this manual. If there are any questions or problems regard ing the

use of this equipment, please contact Newport or the representative from whom this equipment was purchased.

Rev: 04-24-09

Page 2

™

MS260i

1/4M IMAGING SPECTROGRAPH

M-74050

TABLE OF CONTENTS

I. INTRODUCTION........................................................................................................................................ 3

I.1 OPTICAL CONFIGURATION..........................................................................................................................3

I.2 DESIGNED FOR MULTI-TRACK SPECTROSCOPY.....................................................................................3

I.3 NEGLIGIBLE STRAY LIGHT ..........................................................................................................................3

I.4 EXCELLENT SPECTRAL RESOLUTION.......................................................................................................3

I.5 WAVELENGTH DRIVE...................................................................................................................................3

II. UNPACKING AND SETTING UP .............................................................................................................4

II.1 SOFTWARE INSTALLATION ........................................................................................................................5

II.2 USB INSTALLATION FOR THE 74125.............................................ERROR! BOOKMARK NOT DEFINED.

II.3 UTILITY PROGRAM INSTALLATION............................................................................................................6

III. SAFETY ...................................................................................................................................................8

IV. 15 MINUTE BASICS................................................................................................................................9

IV.1 GETTING STARTED WITH THE HAND CONTROLLER.............................................................................9

IV.2 GETTING STARTED WITH IEEE-488........................................................................................................12

IV.3 GETTING STARTED WITH RS-232 COMMUNICATIONS.........................................................................13

V. FUNCTIONS AND CONTROLS.............................................................................................................15

V.1 COMMAND AND QUERY SYNTAX............................................................................................................15

V.2 HANDSHAKING MODE...............................................................................................................................16

V.3 BRIEF COMMAND REFERENCE ORGANIZED ALPHABETICALLY.........................................................17

V.4 DETAILED COMMAND REFERENCE ORGANIZED BY FUNCTION.........................................................18

V.5 ERROR CODES WITH DESCRIPTIONS....................................................................................................23

VI. MS260i UTILITY PROGRAM .............................................................................................................24

VI.1 SOURCE CODE.........................................................................................................................................25

VI.2 IEEE-488 VERSION...................................................................................................................................25

VI.3 RS-232 VERSION ......................................................................................................................................26

VI.4 USB VERSION 74085/74086 .....................................................................................................................26

VII. OPTIONAL ACCESSORIES ................................................................................................................ 27

VII.1 MICROMETER DRIVEN SLIT...................................................................................................................27

VII.2 FILTER WHEEL.........................................................................................................................................27

VII.3 ADDITIONAL GRATINGS- WAVELENGTH CALIBRATION......................................................................27

VII.4 MEMORY LOSS (LARGE WAVELENGTH CALIBRATION ERRORS) .....................................................31

VIII. DECLARATION OF CONFORMITY....................................................................................................32

IX. WARRANTY AND RETURNS............................................................................................................... 33

Page 3

M-74050

MS260i

™

1/4M IMAGING SPECTROGRAPH

I. INTRODUCTION

This new spectrograph is in answer to your requests for an economical, fully automated, multi-grating, ¼

m imaging spectrograph. For those familiar with our popular MS257 ¼ m Spectrograph, the MS260i

meets many of the performance standards in a simplified design, and is more eco nomical.

The MS260i offers the best performance to price ratio of any spectrograph on the market.

The MS260i is an F/3.9 instrument with a single flat, 28 x 10 mm output port for multichannel detectors.

Stray light is negligible, throughput is high and spatial and spectral resolution are impressive. Three

communication interfaces are available via two versions of the board; one with RS232 and IEEE488 and

one with USB only. Control via optional Hand Controller is available.

This manual applies to the:

74050 MS260 MS260 (single output port) which has RS232 and GPIB communications inte rface

74085 MS260 MS260 (single output port) which has a USB communications interface

74055 MS260 MS260 (dual output port) which has RS232 and GPIB communications interface

74086 MS260 MS260 (dual output port) which has a USB communications interface

I.1 OPTICAL CONFIGURATION

The MS260i features an asymmetrical in-plane Czerny-Turner optical configuration. The input F/# is

F/3.9, and the input and exit focal lengths are unequal 220 and 257 mm. A set of computer designed

toroidal mirrors produce accurate images of the input slit in the flat output plane.

I.2 DESIGNED FOR MULTI-TRACK SPECTROSCOPY

Multi-track Spectroscopy is the simultaneous recording of multiple spectra. You can’t find a better

Multi-track Spectroscopy instrument combination than Oriel’s Imaging CCD Detectors and MS260i.

One of the factors limiting the number of spectra, which can be recorded simultaneously, is the

spectrograph’s magnification. MS260i uses two toroidal mirrors to achieve optimum imaging. These

mirrors have different horizontal and vertical radii. The result is a 1.1x horizontal and 1.6x vertical

magnification.

I.3 NEGLIGIBLE STRAY LIGHT

One of the design criteria for MS260i was to eliminate light scatter inside the instrument, one of the

main contributors to stray light. It is important that diffracted light not be allowed to reflect from the

mirrors, or from the face of a focal plane detector, back onto the grating. This light could then be

re-diffracted and cause ghost images or stray light at the detector. The wide open optical layout and

exaggerated tilt of the exit focal plane of the MS260i ensure that there is zero re-entrant spectra.

I.4 EXCELLENT SPECTRAL RESOLUTION

Resolution of 0.25 nm, with a 0.25 µm slit and a 1200 l/mm grating, is possible with the MS260i!

This compares to 0.4 nm with a 25 µm slit for the MS127i, 1/8 m Imaging Spectrograph.

I.5 WAVELENGTH DRIVE

The MS260i uses a high speed stepping motor drive for rapid wavelength changes. This same drive

is used to change the grating; a grating change takes only 10 seconds.

3

Page 4

M-74050

MS260i

™

1/4M IMAGING SPECTROGRAPH

II. UNPACKING AND SETTING UP

Carefully unpack the MS260i Spectrograph and its accessories. The packaging is molded to your

instrument and therefore provides optimal protection. You should save the packaging in case you ever

need to transport or ship this instrument.

Your MS260i comes completely assembled with up to three gratings installed. Your fixed slit housings, or

micrometer driven slits, are mounted at our factory. The instrument is closed and the optical ports are

covered to prevent contamination of the optics during shipment. Included with the MS260i you should

also find:

1. this manual

2. a tabletop power supply (universal input)

3. a line cord for your country

4. any additional gratings you ordered

5. a CD-ROM containing your MS260i software

Since the MS260i is aligned and calibrated at our factory, there is no need to remove the top. You can

get started immediately by connecting the 5 pin DIN connector of the power supply to the MS260i back

panel, connect the line cord to both the power supply and the wall, and then turn on the MS260i power

switch. You will hear the monochromator drive to its home position, then any accessories like Filter Wheel

and/or Motorized Slits will home, finally the wavelength drive will position to the previous grating and

wavelength position.

The external BNC on the chassis is to facilitate external TTL control of the Shutter. A TTL low (or short)

will activate (Open) the Shutter. Control can be overridden by the shutter commands from a computer or

the shutter key on the hand controller.

4

Page 5

™

MS260i

1/4M IMAGING SPECTROGRAPH

II.1 SOFTWARE INSTALLATION

Newport provides an elementary software package with your Cornerstone MS260. To load and run

the software you must have a PC compatible computer (with CDROM drive) running Microsoft

Windows XP SP1or above. For the 74085/74086 a USB2 port is required. To successfully complete

the Install of the MS260 USB driver or the Utility software you must have Administrator

privileges on the PC which you are performing th e install.

The CD contains the installation for the Utility program, LabView VIs and the USB drivers. The Utility

Program provides easy access to almost all Cornerstone functions and is discussed in Section VI

CORNERSTONE UTILITY PROGRAM. Additionally, you can use the LabView VIs when writing your

own LabView software for Cornerstone (National Instruments LabView 8.5 required). The source

code for both Utility program is included with the 74100 VIs to be used as an example.

There are three versions of the basic Cornerstone software. The first version is for IEEE-488

communications. This version requires that you have a National Instruments IEEE-488 controller card

and the corresponding software drivers installed in your PC. The second version is for RS-232

communications. There is also a USB version for the 74125 version of the MS260, the USB driver

must be installed for that version to function. In all cases, the software looks the same, and has the

same functionality.

M-74050

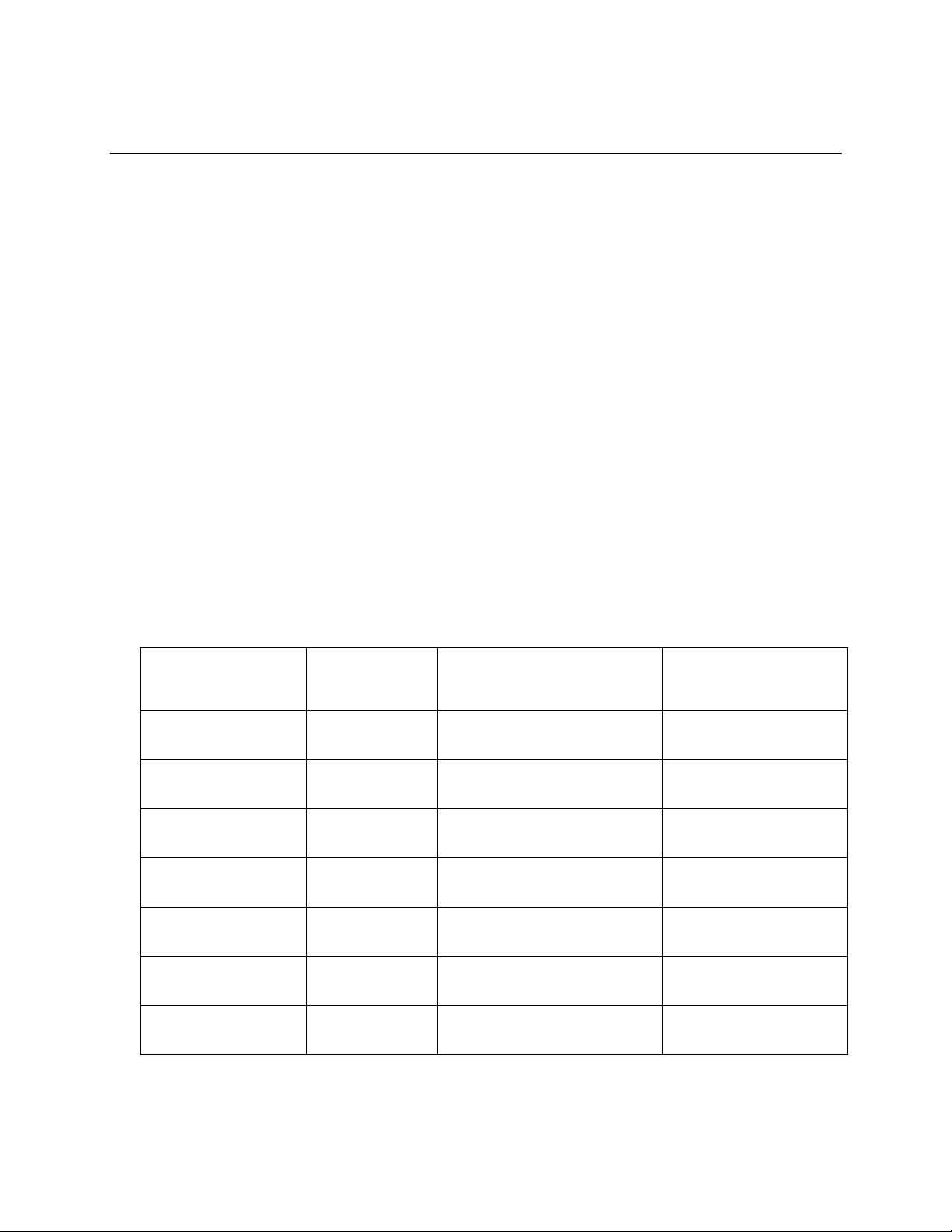

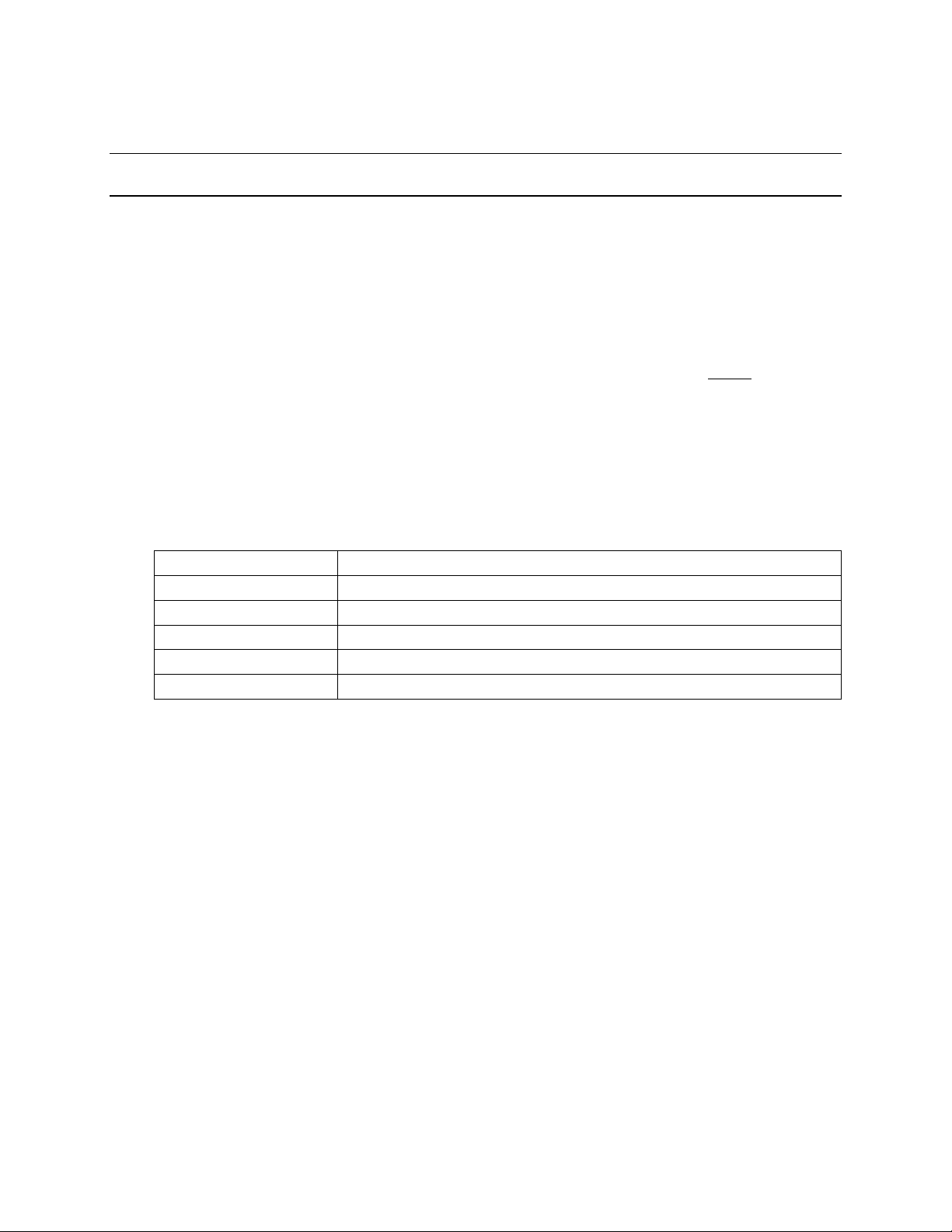

See the Table I below f or where to find the Utility install program, the VIs and the USB drivers.

Table I(Cornerstone Utility CD 74050/74055 74085/74086 relevant directories)

Directory on

Utility CD

Sub-directory containing

Install Program (Setup.exe)

Sub-directory containing

LabView VIs

for the Utility application

MS260 using RS232

\740500RS232\ \74050RS232\Utility\Installer \74050RS232\

Single output port

MS260 using GPIB

\74050GPIB\ \74050GPIB\Utility\Installer \74050GPIB\

Single output port

74085 CS260 USB

\74085\ \74085\ Utility\Installer \74085\

Single output port

MS260 using RS232

\74055RS232\ \74055RS232\Utility\Installer \74055RS232\

Dual output port

MS260 using GPIB

\74055GPIB\ \74055GPIB\ Utility\Installer \74055GPIB\

Dual port output port

74086 CS260 USB

74086\ \74086\ Utility\Installer \74086\

Dual output port

74085/74086 USB

\USB DRIVERS -- --

drivers and install file

5

Page 6

ontrols i

t t

ntrols i

t t

trols i

t t

rols i

t t

ols i

t t

ls i

t t

s i

t t

i

t t

i

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t t

t

t

M-74050

II.2 UTILITY PROGRAM INSTALLATION

MS260i

™

1/4M IMAGING SPECTROGRAPH

IMPORTANT: Do not connect any USB Cornerstone™ to the computer unless the USB

driver has been installed, or until prompted to do so.

Note: If the Utility software will not be installed with USB Model 74085/74086, please

skip to §II.3 , p. 7.

1. Put the Cornerstone

2. Select R

controls in the Browse dialog box to select the Cornerstone™ CD, browse to the folder for your

instrument as shown in Table I above. Inside the folder you will find “Setup.exe”. Double-click on this

program and then press the OK button in the Run di alog box.

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

b

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

d

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

f

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

3. The Installation program will appear, follow the prompts to install the Utility software on you PC. The

default directories and Start Menu groups will work on most machines and should be used if

possible. This simplifies the installation as you only need to click the “Next” button a few times.

4. Another install program will run and you should be able to use the default values again. Simply click

“Finish” to complete the installation.

5. If using USB Model 74085/74086, follow the connection procedure in §II.3 , p. 7 starting at Step #6.

6. You are now ready to work with the Cornerstone

before proceeding to the 15 Minute Basics.

For the software to send proper numeric format to the instrument, Windows Regional Settings in

Control Panel must be set to English (United States).

un... from the Windows Start Menu. Then click on the Browse...button. Now use the

™ CD-ROM into your computer drive.

™. Please review the Safety section in detail

<< IMPORTANT NOTE >>

7. Put the Cornerstone

8. Select R

c

o

instrument as shown in Table I above. Inside the folder you will find “Setup.exe”. Double-click on

this program and then press the OK button in the Ru n dialog box.

9. The Installation program will appear, follow the prompts to install the Utility software on you PC.

The default directories and Start Menu groups will work on most machines and should be used if

possible. This simplifies the installation, as you only need to click the “Next” button a few times.

10. Another install program will run and you should be able to use the default values again. Simply

click “Finish” to complete the installation. You are now ready to work with the Cornerstone

Please review the Safety section in detail before proceeding to the 15 Minute Basics.

un... from the Windows Start Menu. Then click on the Browse...button. Now use the

n

t

r

o

l

s

i

n

t

h

e

™ CD-ROM into your computer drive.

n t he Bro wse di al og box t o selec

n t he Bro wse di al og box t o selec

n t he Bro wse di al og box t o selec

n t he Bro wse di al og box t o selec

n t he Bro wse di al og box t o selec

n t he Bro wse di al og box t o selec

n t he Bro wse di al og box t o selec

n t he Bro wse di al og box t o selec

n t he Bro wse di al og box t o selec

n t he Bro wse di al og box t o selec

the Bro wse d i al og box t o selec

the Bro wse d i al og box t o selec

he Bro wse di al og box to selec

e Bro wse d i al og box t o selec

Bro w se di al og box t o selec

Bro wse d i al og box t o selec

ro wse di al og box to selec

owse dialog box t o selec

wse d i al og box t o selec

se di al og box t o selec

e di al og box t o selec

di al o g box t o selec

B

r

o

w

s

e

d

i

a

l

o

g

b

o

x

t

o

s

e

l

e

c

t

t

h

6

di al o g box t o selec

ialog box t o selec

al og box to selec

log box t o selec

og box t o selec

g box t o selec

box t o selec

box t o selec

ox t o selec

x t o selec

to selec

to selec

o selec

selec

selec

elec

lec

ec

c

e

C

t

o

e

r

n

•

o

C

n

r

e

s

D

d

o

o

,

b

r

w

t

s

h

e

t

e

r

f

o

e

f

o

r

y

o

l

u

™.

Page 7

M-74050

II.3 DRIVER INSTALLATION FOR USB MODEL 74085/74086

MS260i

™

1/4M IMAGING SPECTROGRAPH

IMPORTANT: Do not connect any USB Cornerstone™ to the computer unless the USB

driver has been installed, or until prompted to do so.

Note: If the monochromator(s) will be used with the optional TRACQ Basic™ software,

follow its installation procedure now and disregard the remainder of this section.

Perform the following steps to install the USB driv er for use with OEM or any other applications:

1. Log into a Wi ndows user account with Administrator privileges.

2. Insert the Cornerstone™ CD-ROM into a CD or DVD drive and locate the USB drivers folder from

Table I (§Error! Reference source not found., p . Error! Bookmark not defined.).

3. Right-click on the file “oriel_cs_usb.inf” and select the I

Note: If filename extensions are not displayed, two files will appear as “oriel_cs_usb”. If the menu

does not display the I

4. If any warning dialogs appear stating that the driver is “not signed” or “has not passed Windows

Logo testing”, click “Continue Anyway” to proceed.

5. Driver installation will complete silently if successful.

Note: If an “Installation failed” dialog appears, the logged-in Windows user account may not have

Administrator privileges required for installation. Please consult with your system manager and

repeat from Step #1 before contacting Newport/Oriel Customer Service.

6. Power-on one Cornerstone™ monochromator, then connect its USB cable to the computer. Do not

connect any additional devices yet.

7. When the “Found New Hardware” wizard appears, select the option “Install the software

automatically (Recommended)”, then click the “Next >” button. (It is not necessary to have the

CD-ROM in the drive at this point.)

8. If any warning dialogs appear stating that the driver is “not signed” or “has not passed Windows

Logo testing”, click “Continue Anyway” to proceed.

9. After the wizard completes, click the “Finish” button.

10. Repeat from Step #6 for any additional monochromators.

nstall option for one file, use the other one.

nstall option from the pop-up context menu.

Note: If a Cornerstone™ is connected to a different USB port on the same computer at

a later time, it may be necessary to repeat installation Steps #7 through #9.

7

Page 8

M-74050

MS260i

™

1/4M IMAGING SPECTROGRAPH

III. SAFETY

Electrical

The MS260i requires only DC voltages for operation. These voltages are provided by an external power

supply. This universal input power supply accepts 110/220 VAC for operation and has no user serviceable

parts. Do not attempt to open the external power supply. Do not attempt to work in the MS260i’s

electrical compartment without first disconnecting the power cord, since you may contact live voltage

areas inside the compartment even with the power switch in the “off” position.

MS260i has an internal microprocessor and should be installed with appropriate surge/EMI/RFI

protection on all power lines. Dedicated power lines or line isolation may be required for some extremely

noisy sites. The circuits used in MS260i are extremely sensitive to static electricity and radiated

electromagnetic fields. Operation of MS260i close to intense pulsed sources (lasers, xenon strobes or

arc lamps, etc.) may compromise performance, if shielding is inadequate, and may cause permanent

damage to the microprocessor. Note: This instrument conforms to European CE standards for both safety

and EMC.

Mechanical

Avoid dropping, sudden shocks, or rough handling of the spectrograph since this may cause the system to

lose its calibration and may destroy the high precisi on drive components or optics.

Do not use more than finger force in tightening down the grating mounts, since this may cause damage to

the drive assembly.

Optical

Do not touch any optical surfaces since this is likely to cause irreparable damage. Do not attempt to clean

any optical surface except by blowing off dust or lint particles with a stream of dry clean air or nitrogen.

8

Page 9

™

MS260i

1/4M IMAGING SPECTROGRAPH

IV. 15 MINUTE BASICS

IV.1 GETTING STARTED WITH THE HAND CONTROLLER

The 74009 Hand Controller is a fast and easy way to begin immediate communications with the

MS260i. Although the Hand Controller does not provide access to all the functions of this

instrument, it does provide a simple interface to the m ost commonly used parameters and controls.

Physical Connections

Please note: None of the MS260i accessories are designed to be connected or disconnected with

power on. Always turn off the instrument using the power switch on the back panel before

you connect

or remove the filter wheel or any communications cabl e (including the Hand Controller).

To get started with 74009 Hand Controller, simply connect the black communications cable by

snapping the RJ-11 connector into the receptacle on top of the controller and snapping the other end

into the matching connector on the back panel of your MS260i.

Color Coding

The functional keys on the Hand Controller are divided into various color-coded groups as follows:

Red key at top left “Abort” wavelength motion in progress, also clears pending commands.

Blue keys at the top Control wavelength motion.

Red frame in row #2 Pertain to constant rate scanning.

Orange frame in row #2 Grating position and parameters.

Green frame on left side Control accessories including filter, shutter, output port (when available).

Blue frame on left side Toggle local/remote communications and sets operating units (shifted).

M-74050

Activating the Hand Controller

With the Hand Controller connected, turn on power to the MS260i. You will see a horizontal cursor

in the upper left corner of the display. Press the LOCAL key to activate communications through the

Hand Controller. Please note that if the Hand Controller is active (the display is lit and information fills

the screen), you cannot command the MS260i via either RS-232, IEEE-488 or USB. Press the

LOCAL key again to deactivate the Hand Controller, allowing PC communications.

Yellow “Shifted” Keys

Some keys are divided into top and bottom halves. The function for the yellow top half is called a

“shifted” function. To activate these commands press the SHIFT key in the bottom left corner and then

press the function key.

Entering Parameters- the Numeric Keypad

Many of the MS260i commands require a numeric parameter. First press the function key for your

command. The bottom line of the LCD display will then show an abbreviated form of the command

and the current parameter. There is no need to erase this number, simply typing the first key for your

desired parameter will overwrite the current value. To execute the command press the ENTER key in

the bottom right corner.

While entering parameters, if you mistype one digit press SHIFT and then DEL (above the decimal

point in the numeric keypad); this will move backward one display position and delete that character.

9

Page 10

™

MS260i

1/4M IMAGING SPECTROGRAPH

Key Reference

(From Top of the Controller to the Bottom, Left to Right)

ABORT If you accidentally press a function key or enter a bad parameter you may press the

ABORT key to clear that command before it executes. The ABORT key has no effect

on most functions once the command is executed (by pressing ENTER). However,

wavelength motion will stop immediately upon ABORT and the display will update to

show the wavelength where motion was halted.

STEP DOWN Press this key once to move the MS260i to shorter wavelengths by the smallest

possible increment. Holding this key causes rapid single stepping toward lower

wavelengths. Press SHIFT and then STEP DOWN, you can use the keypad to define

a number of steps to move at once. Press ENTER to execute this larger move.

STEP UP Press this key once to move the MS260i to higher wavelengths by the smallest

possible increment. Holding this key causes rapid single stepping toward higher

wavelengths. Press SHIFT and then STEP UP, you can use the keypad to define a

number of steps to move at once. Press ENTER to execute this larger move.

GO WAVE This key induces wavelength motion to a specified position. Press GO WAVE, then

use the keypad to enter the desired wavelength, and finally press ENTER to execute

the move.

M-74050

GO SCAN Pertains to constant rate motion. This function is not available in the current version.

SCAN λ Pertains to constant rate motion. This function is not available in the current version.

SHIFT SPEED Pertains to constant rate motion. This function is not available in the current version.

GRAT Press this key to move to the other grating position. Press GRAT, then press either 1,

2 or 3 on the numeric keypad, and finally press ENTER to execute the change. The

display will update to show the correct parameters for the new grating.

SHIFT LABEL This key (located directly above GRAT) provides access to the grating label. The

label is an eight character alpha-numeric field that is used for information only.

Newport sets the grating blaze wavelength as the label during calibration. However,

you can use the keypad to type any number, then press ENTER to accept that new

value. The Hand Controller display only shows the first four digits of the label, and

you can only enter numbers.

LINES Press this key to change the lines/mm of the grating. This value is used for

wavelength calculations and will affect your calibration. This parameter should be

changed only when adding a new grating.

SHIFT CALIB This button is used to change the wavelength calibration of the current grating. Use

the GO WAVE, STEP DOWN, and STEP UP keys to move to a known wavelength

(often the intensity peak for a spectral calibration lamp). If the wavelength shown in

the top row of the display does not match the known value, press SHIFT CALIB and

use the numeric keypad to enter the known wavelength. Then press ENTER to

change the calibration. The current grating is thus calibrated over its entire range.

SHUTTER Alternately open and close the shutter by pressing this button. The shutter position is

shown in the display as “OPN” for open and “CLS” for closed.

10

Page 11

™

MS260i

1/4M IMAGING SPECTROGRAPH

SHIFT PORT- Use this key to alternate between the two output ports. This feature is only available

on Model 74055. The active port is shown in the upper right corner of the display; “A”

indicates the axial port (adjacent to the power switch) while “L” indicates the lateral

port (opposite the input port).

FILTE- Move the 74010 Filter Wheel accessory to the specified position. Press FILTER, then

type the number 1, 2, 3, 4, 5, or 6 indicating the desired position, then finally press

ENTER to execute the move.

SHIFT LABEL This key (located directly above FILTER) provides access to the filter label. These

labels are eight character alpha-numeric fields, used for information only. You can

use the keypad to type any number, then press ENTER to accept that new value.

The Hand Controller display only shows the first four digits of the label, and you can

only enter numbers.

LOCAL Use this key to toggle between “local” communications through the Hand Controller

and “remote” communication with a computer. Please note that if you press LOCAL

to activate the Hand Controller (the display is lit and information fills the screen), you

also lock out PC communications. You cannot command the MS260i via either RS232, IEEE-488 or USB while the Hand Controller is active.

SHIFT UNITS To change the wavelength units press this key, followed by either 1, 2, or 3 and then

press ENTER. Those three number keys are labeled with the corresponding units: 1

is nanometers (nm), 2 is micrometers (µm), and 3 is wave numbers (cm

-1

) shown as

“”.

M-74050

1 Pressing the 1 key when not in a function parameter edit mode brings ups the

“Slit1um>” prompt to edit/enter the slit 1 size, (the slit at the input port), the integer

parameter is the open size specified in microns. Slit range is 6-3000 microns, in 6

micron resolution steps; for values larger than 3000 the slit goes to 3000, for values

0-6 the slit goes to 6.

SHIFT 1- Pressing the SHIFT-1 key when not in a function parameter edit mode brings ups the

“Bandpass>” prompt. The floating point parameter is the wavelength resolution to

automatically adjust slits for. If Bandpass is not set at zero the 74100 will be adjust all

slits to maintain the Bandpass resolution at wavelength moves and grating changes.

Setting Bandpass to 0 turns off this automatic adjustment. Slit range is 6-3000

microns, in 6 micron resolution steps. For Bandpass adjustments requiring slit

openings larger than 3000 the slit goes to 3000, for values 0-6 the slit goes to 6.

Note; for Bandpass slit size calculations to function properly, Slit1 must be at the

input port.

2 Pressing the 2 key when not in a function parameter edit mode brings ups the

“Slit2um>” prompt to edit/enter the slit 2 size, the integer parameter is the open size

specified in microns. Slit range is 6-3000 microns, in 6 micron resolution steps; for

values larger than 3000 the slit goes to 3000, for values 0-6 the slit goes to 6.

3 Pressing the 3 key when not in a function parameter edit mode brings ups the

“Slit3um>” prompt to edit/enter the slit 3 size, the integer parameter is the open size

specified in microns. Slit range is 6-3000 microns, in 6 micron resolution steps; for

values larger than 3000 the slit goes to 3000, for values 0-6 the slit goes to 6.

11

Page 12

™

MS260i

1/4M IMAGING SPECTROGRAPH

IV.2 GETTING STARTED WITH IEEE-488

IEEE-488 communication (also called GPIB) offers the greatest versatility for integrating your

MS260i into a larger system since you may connect up to 30 different devices to the same controller

card. However, this versatility brings with it some complication in setting up each device.

Newport designs all of its IEEE-488 products to be completely compatible with National Instruments’

GPIB controller cards. Likewise, most of our IEEE-488 software requires National Instruments’ device

drivers to run on your PC. We strongly recommend National Instruments’ controller cards. Since there

are differences between IEEE-488 implementations among the various manufactures, we cannot

support them all. Therefore, Newport will only provide communication and software support for IEEE488 systems that use National Instruments controller cards.

Physical Connections

First, install your National Instruments control card and software in your PC computer. Run their

diagnostic tools to make sure the card is working properly.

Next, be sure the MS260i power switch is off, then attach your IEEE-488 cable to the appropriate

connector on the back panel. Attach the other end to the National Instruments’ control card and

secure the screws on both sides. Now turn on the MS260i. In order to limit possible address

conflicts, we recommend that you turn off all other IEEE-488 instruments while checking your

MS260i for the first time. Note: the MS260i default GPIB primary address is 4.

M-74050

Verify Communications

You can check your IEEE-488 communications by running the application Cornerstone Utility Program

. See software installation ( in section II. UNPACKING AND SETTING UP)

When this application runs, a dialog box will appear asking for the GPIB board index and

Cornerstone

you have multiple controller cards or if you have changed the Cornerstone

TM

260 address. The default values, 0 and 4 respectively, should work for most systems. If

TM

260 address fill in the

correct values. Click the OK button to establish communication and open the main application window.

If you get an error at this point you may have a connection problem. Check all the cables (including

the line cord), make sure the Cornerstone

off. PLEASE NOTE: if the Hand Controller is active (the display is lit and information fills the screen),

you cannot command the Cornerstone

on the Hand Controller to deactivate it, allowing PC communications. PLEASE ALSO NOTE:

Cornerstone

TM

260 selects either RS-232 or IEEE-488 communications based upon the first

command received after power up. When you send an IEEE-488 command, or initialize your IEEE488 software, the RS-232 link will be ignored until Cornerstone

TM

260 is turned on, and make sure the Hand Controller is

TM

260 via either RS-232 or IEEE-488. Press the LOCAL key

TM

260 power is turned off and on

again.

Low Level Communications

TM

It may be desirable to send commands directly to the Cornerstone

Instruments Interactive Control or through another simple interface. To establish low level

communications with Cornerstone

TM

260 you will have to first open the device. Using the National

260 through the National

Instruments’ drivers the correct co mmand is: ibdev 0 9 0 13 0 0x140a

The timeout code “13” allows 30 seconds to read responses back from Cornerstone

TM

260. In most

cases 300 ms is sufficient (timeout code 10), however, the longer period guarantees success on all

commands. The end of string code “0x140a” terminates a read when the linefeed character is

12

Page 13

™

MS260i

received from the instrument. All Cornerstone 260 responses end with carriage return and linefeed.

Likewise, all messages sent to Cornerstone

TM

260 must end with the linefeed ch aracter.

1/4M IMAGING SPECTROGRAPH

Again, refer to the detailed discussion of section V. FUNCTIONS AND CONTROLS for further

information on direct low level communications, message synta x, and parameters.

IV.3 GETTING STARTED WITH RS-232 COMMUNICATIONS

RS-232 connections are a simple means of communicating between your PC and your instruments.

However, you are limited in that each instrument must have its own dedicated communication port at

the computer. Most PC’s come standard with COM1 and COM2, although COM1 is occasionally used

by a serial mouse. Additional communication port hardware can be added and the corresponding

drivers must be added to your Windows software. Please review your computer setup to determine

what physical connections are available to you. Again, due to the variety of hardware and software

options that are availab le Newport cannot provide support for PC configuration.

Physical Connections

First, make sure that the COM port you would like to use for MS260i is recognized by Windows

and is working properly. Usually a simple check can be done with a serial mouse.

Next, be sure the MS260i power switch is off, then attach your RS-232 cable to the appropriate

connector on the back panel. Attach the other end to the COM port connection on your PC. Note that

RS-232 cables come in two types: modem and null-modem. The modem cable is a pin-to-pin cable.

That is, each pin at one end connects directly to the corresponding pin at the other end: 1 to 1, 2 to 2,

3 to 3, etc. The modem cable is the correct cable for communicating with MS260i.

M-74050

Now turn on the MS260i. You are ready to communicate with the instrument. The hardware

communication parameters, including baud rate, are fixed inside MS260i, so setup your COM port

as follows:

Baud Rate: 9600

Data Bits: 8

Parity: NONE

Stop Bits: 1

Flow Control: NONE

Verify Communications

Check your RS-232 communications by running the Cornerstone Utility application. See software

installation (in section II. UNPACKING AND SETTING UP).

When this application runs, a dialog box will appear asking for the COM port number. Fill in the

correct value, then click the OK button to establish communication and open the main application

window.

If you get an error at this point you may have a connection problem. Check all the cables (including

the line cord), make sure the Cornerstone is turned on, and make sure the Hand Controller is off.

PLEASE NOTE: if the Hand Controller is active (the display is lit and information fills the screen), you

cannot command the Cornerstone via either RS-232 or IEEE-488. Press the LOCAL key on the

Hand Controller to deactivate it, allowing PC communications. PLEASE ALSO NOTE: Cornerstone

13

Page 14

™

MS260i

1/4M IMAGING SPECTROGRAPH

selects either RS-232 or IEEE-488 communications based upon the first command received after

power up. When you send an RS-232 command, or initialize your RS-232 software, the IEEE-488 link

will be ignored until Cornerstone power is turned off and on again.

Low Level Communications

In some cases, it may be desirable to send commands directly to Cornerstone through a terminal

emulation program, such as the HyperTerminal provided with Windows. Once your terminal

program is open and running you will have to first select a COM port and configure it according to the

parameters previously listed (9600, 8, N, 1, None). Additionally, you should set the terminal to “Send

line ends with line feeds”. There is no reason to turn on the local echo since Cornerstone will

automatically echo each character as it is typed. All Cornerstone responses end with carriage return

and linefeed. Likewise, all messages sent to Cornerstone must end with the linefeed character.

Again, refer to the detailed discussion of section V. FUNCTIONS AND CONTROLS for further

information on direct low level communications, message synta x, and parameters.

M-74050

14

Page 15

™

MS260i

1/4M IMAGING SPECTROGRAPH

V. FUNCTIONS AND CONTROLS

V.1 COMMAND AND QUERY SYNTAX

For the purposes of this discussion we will divide communications with the instrument into two parts.

First, the messages that you send to MS260i will be called “Statements”. Second, the messages

that you receive from MS260i will be called “Responses”. When communicating with MS260i you

will use two types of Statements: “Commands” and “Queries”. A Command causes some physical

action or sets an internal parameter. Quer ies ask some question of the instrument and automatically

return a Response. Fundamentally, the syntax is the same for all messages.

Termination

Both Statements and Responses end with a carriage return (ASCII character code 13 decimal) and

linefeed (ASCII character code 10 decimal). This manual will show the termination as [cr][lf]. Please

note, you may find it more convenient to end Statements with only the linefeed [lf]; this is also

acceptable.

Capitalization

Statements may be sent in upper case, in lower case, or in any combination of the two. Responses

will always be returned in upper case. For clarity throughout this manual, Statements will be shown in

upper case (ie. STATEMENT) and Responses will be shown in upper case italics (ie. RESPONSE).

M-74050

Parameters

Some Statements will require a parameter. In this manual numeric parameters will be shown as “XX”;

each X will fill a numeric position and decimals are used to indicate where floating point number

should be expected. Numeric notation is not strict and integers can be substituted for floating point

numbers as desired. There are some specific cases where alpha-numeric values or exponential

notation may be required; these special Statements will be detailed in the sections that follow.

Most normal communication with MS260i, especially communication handled inside closed

application software, is done in Standard Mode. This mode follows all of the rules on the previous

page plus there are some additional features for error handling.

MS260i stores errors internally in a status byte and an error byte, where each bit has a specific

meaning. Details of the status and error bytes can be found in this manual under section V-4 ERROR

CODES. For now, we will simply cover the syntax necessary to send Statements and receive

Responses in this communication mode.

In all cases, Statements must be terminated properly with [lf] for MS260i to take any action.

Statements that are not understood or parameters that are unacceptable will generate an error code

in the status byte, ie. status byte 0. Moreover, the status byte must be explicitly read, it is not

returned after general Statements. Correct Statements are handled as follows:

Commands

Under RS-232, Statements are echoed back to the PC. Thus, after sending a Command you should

read back this echo. There is no further response to a Command.

For example:

Send: GOWAVE 500[lf] Receive: GOWAVE 500[lf]

Under IEEE-488, there is no echo. There is no automatic response to a Command.

For example:

Send: GOWAVE 500[lf] Receive: {none}

15

Page 16

™

MS260i

1/4M IMAGING SPECTROGRAPH

Queries

Under RS-232, Statements are echoed back to the PC. Additionally, there will be an explicit response

to that query. Thus, after sending a Query you should read back the echo and the answer together.

For example:

Send : WAVE?[lf] Receive: WAVE?[lf]500[cr][lf]

Under IEEE-488, there is no echo. Thus, you can read back the Response by itself.

For example:

Send : WAVE?[lf] Receive: 500[cr][lf

V.2 HANDSHAKING MODE

This communications mode is most useful for methods development, troubleshooting, or in the early

stages of programming. Use the command: “HANDSHAKE 1[lf]” to put MS260i into Handshake

Mode. This mode follows the command syntax listed at the start of section V-1 in this manual, but in

addition every Statement is acknowledged. The “handshake” that you receive is the status byte.

MS260i stores errors internally in a status byte and an error byte, where each bit has a specific

meaning. Details of the status and error bytes can be found in this manual under section V-4 ERROR

CODES. For now, we will simply cover the syntax necessary to send Statements and receive

Responses.

In all cases, Statements must be terminated properly with [lf] for MS260i to take any action.

Statements that are not understood or parameters that are unacceptable will generate an error code

in the status byte, ie. status byte 0. This status byte will be reported immediately if it contains an

error, otherwise the status byte “00” will be returned upon completion of the Statement. Correct

Statements are handled as follows:

M-74050

Commands

Under RS-232, Statements are echoed back to the PC. Thus, after sending a Command you should

read back this echo. Additionally, the status byte is reported when the action is complete.

For example:

Send: GOWAVE 500[lf] Response: GOWAVE 500[lf]00[cr][lf]

Under IEEE-488, there is no echo. The only response will be the status byte.

For example:

Send: GOWAVE 500[lf] Response: 00[cr][lf]

Queries

Under RS-232, Statements are echoed back to the PC. Additionally, there will be an explicit response

to that Query, and the statues byte. Thus, after sending a Query you should read back a 3 part

answer.

For example:

Send : WAVE?[lf] Response: WAVE?[lf]500[cr][lf]00[cr][lf]

Under IEEE-488, there is no echo. Thus, you will read back the Response and the status byte.

For example:

Send : WAVE?[lf] Response: 500[cr][lf]00[cr][lf

16

Page 17

MS260i

™

V.3 BRIEF COMMAND REFERENCE ORGANIZED ALPHABETICALLY

ABORT [ABORT]

Command Query Hand Ctrl Key

ADDRESS XX ADDRESS?

CALIBRATE XXX.XXX [CALIB]

ERROR?

FILTER X FILTER? [FILTER]

FILTER1LABEL TTTTTTTT FILTER1LABEL? [SHIFT LABEL]

GOWAVE XXX.XXX WAVE? [GO WAVE]

GRAT X GRAT? [GRAT]

M-74050

1/4M IMAGING SPECTROGRAPH

GRAT1FACTOR XXX.XXX GRAT1FACTOR?

GRAT1LABEL TTTTTTTT GRAT1LABEL? [SHIFT LABEL]

GRAT1LINES XXXX GRAT1LINES? [LINES]

GRAT1OFFSET XXX.XXX GRAT1OFFSET?

HANDSHAKE X HANDSHAKE?

INFO? [LOCAL]

OUTPORT T

OUTPORT? [PORT]

SHUTTER T SHUTTER? [SHUTTER]

STB?

STEP XXX STEP? [STEP UP]

UNITS TT [SHIFT UNITS]

SLIT1MICRONS XXXX SLIT1MICRONS? [1]

SLIT2MICRONS XXXX SLIT2MICRONS? [2]

SLIT3MICRONS XXXX SLIT3MICRONS? [3]

BANDPASS XXX.XX BANDPASS? [SHIFT 1]

17

Page 18

™

MS260i

1/4M IMAGING SPECTROGRAPH

V.4 DETAILED COMMAND REFERENCE ORGANIZED BY FUNCTION

Recall from section V-1 of this manual that messages that you send to MS260i will be called

“Statements” and messages that you receive from MS260i will be called “Responses”. There are

two types of Statements: “Commands” and “Queries”. A Command causes some physical action or

sets an internal parameter. Quer ies ask some question of the instrument and automatically return a

Response. Also recall that all Statements must end in [lf], and [cr][lf] is acceptable. Likewise, all

Responses will end with [cr][lf]. Refer to section V-1 for detailed general syntax instructions. This

section describes the exact syntax, acceptable parameters, and functionality for every MS260i

Command. For each corresponding Query, in braces {}, we also list the type of Response you should

expect. Where appropriate the corresponding Hand Controller key, in brakets [ ], is also listed. Finally,

there are some warnings as to possible errors that could occur if a command is not used properly.

MS260i Motion Commands:

UNITS TT {UNITS?} [UNITS]

Specifies the operational unit designated by the mnemonic parameter “TT”. Possi ble parameters are:

“NM” for nanometers “UM” for micrometers “WN” for wavenumbers (cm

By default MS260i uses nanometers. Parameters for all motion Statements are handled in the

current units. Therefore, if you change from nanometers to micrometers GOWAVE parameters must

be entered in micrometers. Likewise, WAVE? answers will be returned in micrometers. The response

to UNITS? is always the two character mnemonic for the current units.

M-74050

-1

)

GOWAVE XXX.XXX {WAVE?} [GO WAVE]

Moves the wavelength drive at maximum speed to the step position closest to the specified

wavelength parameter. This parameter must be in the current units and may be either a floating point

number or an integer, ie. “GOWAVE 500.00[lf]” and “GOWAVE 500[lf]” will be understood the sam e

way. For each grating there is a maximum possible wavelength (approximately 1600 nm for a 1200

l/mm grating, thus 800 nm for a 600 l/mm, etc.) This command will generate an error if the parameter

is larger than the maximum wavelength. The response to WAVE? will be a floating point number

indicating the exact wavelength position. Current units are assumed and so no units are passed with

the floating point number.

CALIBRATE XXX.XXX [CALIB]

This command is used to make minor corrections to the wavelength calibration of MS260i. It is used

when installing new gratings, or at any point when the wavelength calibration is disrupted. Execute

this command to define the current position as the wavelength specified in the numeric parameter

XXX.XXX. This calculates a new OFFSET for the grating and saves it accordingly. Please Note: The

calibration is corrected for the entire range of the current grating and current output port; on a 74055

system, a separate calibration may be necessary if the output port is changed. A complete calibration

procedure is outlined in Section VII-4 ADDITIONAL GRATINGS- WAVELENGTH CALIBRATION.

ABORT [ABORT]

Simply stops any wavelength motion immediately, ie. GOSCAN, GOWAVE, STEP, etc.

STEP XXXX {STEP?} [STEP UP] / [STEP DOWN]

Move the wavelength drive by the integer number of steps indicated in XXXX. The parameter can be

positive or negative, however, one step is the smallest increment MS260i can move and so this

parameter must be an integer. The response to STEP? is the current step position as measured from

18

Page 19

™

MS260i

1/4M IMAGING SPECTROGRAPH

the physical home sensors.

MS260i Grating Commands:

GRAT X {GRAT?} [GRAT]

Move the wavelength drive to the grating specified in the integer parameter. The parameter should be

either “1”, “2” or “3”. Please note: whenever you change gratings, the wavelength drive will sweep

past zero order on grating #2. In order to prevent saturation of a detection system, it is wise to close

the shutter temporarily while changing gratings. When changing to grating #1 the instrument stops at

the maximum wavelength for that grating. When changing to grating #3, the system stops at the zero

order position for that grating. When changing to grating #2, the system will stop at the zero order

position or the maximum wavelength, whichever is closer. Therefore, this command is usually

followed by a GOWAVE command. The response to GRAT? contains three parameters separated by

commas without spaces. The first parameters is the grating number, then the lines/mm, then the label

for that grating. For example: “1,1200,BLUE[cr][lf]”.

GRAT1LABEL TTTTTTT {GRAT1LABEL?} [SHIFT LABEL]

Sets the user defined “label” for the grating #1 to the < 9 character parameter “TTTTTTTT”. The

parameter can letters or numbers. This label is for informational purposes only. Newport uses these

labels to indicate blaze wavelength for those gratings that are installed in MS260i at the factory.

Note: that the Hand Controller only displays four characters, however all eight may be entered. Also,

the Hand Controller only changes the current grating parameters.

M-74050

GRAT2LABEL TTTTTTT {GRAT2LABEL?} [SHIFT LABEL]

Sets the user defined “label” for the grating #2 to the < 9 character string parameter “TTTTTTTT”. The

parameter can letters or numbers. This label is for informational purposes only. Newport uses these

labels to indicate blaze wavelength for those gratings that are installed in MS260i at the factory.

Note: that the Hand Controller only displays four characters, however all eight may be entered. Also,

the Hand Controller only changes the current grating parameters.