Page 1

1919-R

1919-R

Laser Power/Energy Meter

1919 - R

User Manual

Newport Corporation

www.newport.com

Page 2

Table of Contents

1 Introduction ................................................................................................................... 5

1.1 This Document ............................................................................................................... 5

1.2 Related Documentation ................................................................................................ 5

1.3 Support .......................................................................................................................... 6

2 Quick Reference ............................................................................................................. 7

2.1 Getting Started .............................................................................................................. 7

2.2 Thermopile Sensors ....................................................................................................... 8

2.2.1 Using 1919-R with Thermopile Type Sensors .................................................... 8

2.2.2 Using 1919-R to Measure Laser Power.............................................................. 8

2.2.3 Using 1919-R to Measure Single Shot Energy ................................................... 8

2.3 Photodiode Sensors ....................................................................................................... 8

2.3.1 Using 1919-R with Photodiode Type Sensors .................................................... 8

2.3.2 Setting the Measurement Parameters .............................................................. 9

2.3.3 Measuring Average Power or Exposure ............................................................ 9

2.4 Pyroelectric or Photodiode Energy Sensors .................................................................. 9

2.4.1 Using 1919-R with Energy Sensors .................................................................... 9

2.4.2 Zeroing Instrument against Sensor .................................................................. 10

2.4.3 Setting the Measurement Parameters ............................................................ 10

2.4.4 Measuring Energy, Average Power, or Exposure ............................................ 11

2.5 Graphical Displays ....................................................................................................... 11

2.6 Math Functions ............................................................................................................ 13

2.7 Logging Data to a File for Upload to PC ....................................................................... 13

3 Using the 1919-R Display Unit ....................................................................................... 14

3.1 General Description ..................................................................................................... 14

3.2 1919-R Display Unit Components ................................................................................ 15

3.3 1919-R Hardware Components/Interfaces ................................................................. 16

3.3.1 Sensor Input ..................................................................................................... 16

3.3.2 LCD Display and Backlight ................................................................................ 17

3.3.3 Soft Keys .......................................................................................................... 17

3.3.4 Navigation Keys ............................................................................................... 17

3.3.5 On-Off Switch/Backlight Control ..................................................................... 17

3.3.6 Charger Input ................................................................................................... 18

3.3.7 Analog Output ................................................................................................. 19

3.3.8 RS232 and USB Outputs ................................................................................... 20

3.4 1919-R Functions – Independent of Sensor Type ....................................................... 20

3.4.1 Instrument Settings ......................................................................................... 20

3.4.2 Field Upgrade – Updating the 1919-R Firmware ............................................. 23

3.4.3 Clock Settings ................................................................................................... 23

3.4.4 Zero Adjustments ............................................................................................ 24

3.4.5 Line Frequency ................................................................................................. 25

3.4.6 Language .......................................................................................................... 25

3.4.7 Measurement Screens (Graph Types) ............................................................. 26

3.4.8 Color Scheme ................................................................................................... 27

3.5 1919-R Screen Layout .................................................................................................. 29

1919-R User Manual 1

Page 3

4 Points to Consider ........................................................................................................ 30

5 Thermopile Sensors ...................................................................................................... 31

5.1 Operation of 1919-R with Thermopile Absorber Sensors ........................................... 32

5.2 Measuring Laser Power with Thermopile Sensors ...................................................... 32

5.3 Measuring Laser Energy with Thermopile Sensors ..................................................... 33

5.3.1 Measuring Pulses of Very Low Energy ............................................................. 34

5.3.2 Measuring Energy of Rapidly Repeating Pulses ............................................... 35

5.4 Measuring Laser Pulsed Power with Thermopile Sensors .......................................... 35

5.4.1 Pulsed Power Limitations ................................................................................ 36

5.5 Supported Models ....................................................................................................... 36

6 Photodiode Sensors...................................................................................................... 37

6.1 Operation of 1919-R with Photodiode Sensors ........................................................... 38

6.2 Measuring Laser Power with Photodiode Sensors ...................................................... 38

6.3 Averaging and Measuring Very Low Power Measurements ....................................... 40

6.4 Measuring Total Exposure ........................................................................................... 40

6.4.1 Exposure Limitations ....................................................................................... 41

7 Pyroelectric and Photodiode Energy Sensors ................................................................. 42

7.1 Pyroelectric Sensors – Method of Operation .............................................................. 42

7.2 Photodiode Energy Sensors – Method of Operation .................................................. 42

7.3 Measuring Pulses of High Energy Density ................................................................... 43

7.4 Operation of 1919-R with Pyroelectric and Photodiode Energy Sensors.................... 43

7.4.1 Zeroing the Energy Sensor Against the 1919-R Meter .................................... 44

7.4.2 Setting Measurement Parameters When Using Energy Sensors .................... 44

7.4.3 Energy, Average Power, or Exposure Measurement ....................................... 46

7.4.4 Measuring Laser Energy................................................................................... 46

7.4.5 Measuring Average Power............................................................................... 47

7.4.6 Measuring Total Energy Exposure ................................................................... 47

8 Graphical Displays ........................................................................................................ 49

8.1 Display Settings............................................................................................................ 50

8.2 Bargraph ...................................................................................................................... 51

8.2.1 Modes .............................................................................................................. 51

8.2.2 Zoom ................................................................................................................ 52

8.2.3 Offset ............................................................................................................... 52

8.2.4 Measuring Loss Using the dB Offset Function ................................................. 53

8.2.5 Bargraph Style .................................................................................................. 54

8.3 Analog Needle ............................................................................................................. 56

8.3.1 Modes .............................................................................................................. 57

8.3.2 Persist .............................................................................................................. 57

8.4 Line Graph ................................................................................................................... 58

8.4.1 Modes .............................................................................................................. 58

8.4.2 Percentage Range (Y-Axis Scale) ...................................................................... 59

8.4.3 Horizontal Sweep Time (X-Axis Scale) ............................................................. 59

8.4.4 Reset ................................................................................................................ 60

8.5 Statistics ....................................................................................................................... 60

8.5.1 Modes .............................................................................................................. 61

1919-R User Manual 2

Page 4

8.6 Pass/Fail ....................................................................................................................... 61

8.6.1 Modes .............................................................................................................. 62

8.6.2 Upper/Lower Limits ......................................................................................... 62

8.7 Exposure (for Pyroelectric Sensors)............................................................................. 63

8.7.1 Modes .............................................................................................................. 64

8.7.2 Manual/Timeout/Pulses .................................................................................. 64

8.7.3 Exposure for Photodiode Sensors ................................................................... 64

8.8 Pulse Chart ................................................................................................................... 65

8.8.1 Modes .............................................................................................................. 66

8.9 Other Display Settings ................................................................................................. 66

8.9.1 Show/Hide Settings ......................................................................................... 67

8.9.2 Color Scheme ................................................................................................... 67

9 Math Functions ............................................................................................................ 70

9.1 Display on Main Measurement Screen ....................................................................... 70

9.2 Functions Screen ......................................................................................................... 71

9.3 Average ........................................................................................................................ 71

9.4 Fixed Offset .................................................................................................................. 72

9.5 Scale Factor.................................................................................................................. 72

9.6 Normalize .................................................................................................................... 74

9.7 Density ......................................................................................................................... 75

9.8 Function Limitations .................................................................................................... 76

10 Logging Data to a File for Upload to PC ......................................................................... 77

10.1 Launching the Log Setup ............................................................................................. 77

10.2 Setting Logging Parameters for the Various Stop Modes ........................................... 78

10.2.1 Manual Mode .................................................................................................. 79

10.2.2 After Timeout .................................................................................................. 80

10.2.3 After Measurements ........................................................................................ 82

10.3 Start Logging ................................................................................................................ 83

10.4 Displaying Logged Data ............................................................................................... 84

10.5 Viewing the Log File on Your Computer ...................................................................... 87

11 Circuit Description ........................................................................................................ 88

11.1 Analog Module ............................................................................................................ 88

11.1.1 Analog Circuit ................................................................................................... 88

11.1.2 Fast Analog Input ............................................................................................. 88

11.1.3 Analog Output ................................................................................................. 88

11.2 Processor Board ........................................................................................................... 88

11.2.1 Power Supply ................................................................................................... 88

11.2.2 EMI Protection ................................................................................................. 89

12 Calibration, Maintenance, and Troubleshooting ............................................................ 90

12.1 Updating Sensor Calibration Factors ........................................................................... 91

12.2 Calibration of Thermopile Sensors .............................................................................. 91

12.2.1 Surface Absorbers ............................................................................................ 91

12.2.2 Volume Absorbers ........................................................................................... 92

12.2.3 Linearity and Accuracy of Newport Thermopile Sensors ................................ 92

12.2.4 Updating Thermopile Sensor Calibration Factors ............................................ 93

1919-R User Manual 3

Page 5

Introduction

12.3 Calibration of Photodiode Sensors .............................................................................. 98

12.3.1 Method of Factory Calibration ........................................................................ 98

12.3.2 Accuracy of Calibration .................................................................................... 98

12.3.3 Updating Photodiode Sensor Calibration Factors ........................................... 99

12.4 Calibration of Pyroelectric Sensors............................................................................ 100

12.4.1 Absorber Types Used in Newport Pyroelectric Measuring Sensors .............. 100

12.4.2 Calibration ..................................................................................................... 101

12.4.3 Accuracy of Calibration .................................................................................. 101

12.4.4 Updating Pyroelectric Sensor Calibration Factors ......................................... 102

12.5 Error Messages .......................................................................................................... 104

12.6 Troubleshooting ........................................................................................................ 104

12.6.1 1919-R Meter ................................................................................................. 104

12.6.2 Thermopile Sensors, Energy Measurements ................................................. 104

12.6.3 Thermopile Sensors, Power ........................................................................... 105

12.6.4 Pyroelectric Sensors....................................................................................... 105

12.7 Maintenance .............................................................................................................. 106

12.7.1 Maintenance of Thermopile Sensors ............................................................. 106

12.7.2 Battery Replacement ..................................................................................... 106

13 1919-R Specifications .................................................................................................. 107

13.1 System/Meter Specifications..................................................................................... 107

13.2 Sensor Specifications ................................................................................................. 109

1919-R User Manual 4

Page 6

1 Introduction

The Newport 1919-R is a microprocessor-based Laser Power/Energy Meter that provides a broad

range of measurements, displays, and data handling options. It operates with Thermopile,

Pyroelectric, and Photodiode sensors. Taking advantage of smart connector technology, it is easyto-use—simply connecting the sensor configures and calibrates the 1919-R to operate with that

sensor. The sensor configuration and calibration information is stored in an EEROM in the sensor

connector plug. This means that when the sensor is plugged in, 1919-R automatically identifies the

sensor type, calibration, and configuration. The user does not have to adjust anything.

The 1919-R’s 320x240 full color screen enhances measurement readouts in ways that simple

monochrome displays cannot. The 1919-R can graph power or energy versus time. It displays

power measurements in both digital and analog form simultaneously and also has a needle type

display. It will also autorange, so you do not have to set scales; or it can manual range if you wish.

It will remember what mode you were using before you turned it off and will return to that mode

when turned on. You can zoom in on the present reading, or subtract background. Although the

calibration information is stored in the smart connector, you can recalibrate from the screen and

store the new calibration in the sensor. You can also zero the 1919-R at the touch of a button.

1919-R is capable of logging data onto a USB Flash Drive (Disk On Key), as well as real-time

reporting of data via USB to Newport’s PMManager application to display and process the

information. 1919-R has RS232 capabilities as well. 1919-R also has the infrastructure for field

upgrading of the embedded software, should the need arise.

Above all, the 1919-R has advanced circuitry and digital signal processing for excellent sensitivity,

signal to noise ratio, accuracy, and response time. It also has special circuitry to reject

electromagnetic interference.

1919-R’s User Interface is intuitive. The keypad functionality is context-sensitive and functions

according to the needs of the present screen. Where necessary, on-screen help is provided as well,

so you should not have to refer to this manual very often.

1.1 This Document

This document covers everything you need to know to make full use of the 1919-R for all your

laser measurement needs. It includes a Quick Reference (Chapter 2) to allow you to perform basic

measurements immediately, without reading the whole manual.

1.2 Related Documentation

Newport takes pride in the wealth of laser measurement information that we provide including

FAQ’s, Catalogs, Spec Sheets, and more. Go to https://www.newport.com/Optical-

Meters/6770532/1033/section.aspx.

1919-R User Manual 5

Page 7

Introduction

North America

Europe

Asia

Newport Corporation Service

Dept.

1791 Deere Ave. Irvine, CA 92606

Telephone: (949) 253-1694

Telephone: (800) 222-6440 x31694

Newport/MICRO-CONTROLE S.A.

Zone Industrielle

45340 Beaune la Rolande, FRANCE

Telephone: (33) 02 38 40 51 56

Newport Opto-Electronics

Technologies (Wuxi) Co., Ltd

理波光电科技(无锡)有限公司

江苏省无锡市新区出口加工区

J3-8厂房 204028

Lot J3-8, Wuxi Export Processing

Zone, New District,

Jiangsu China 204028

Telephone: +86-510-8113 2999

Fax: +86-510-8526 9050

1.3 Support

If you have a question or require further assistance, contact Newport customer support:

1919-R User Manual 6

Page 8

2 Quick Reference

This section provides a quick reference for performing basic measurements with the 1919-R Laser

Power/Energy Meter.

2.1 Getting Started

The 1919-R is equipped with "soft keys." That is, the functions of the keys change as indicated by

the legend above each key. It is also equipped with 4 navigation keys and a round Enter key in the

center.

To connect sensor to the 1919-R meter:

Insert the 15 pin D type connector of the measuring sensor cable into the socket

marked Sensor Input on the rear panel of the 1919-R meter.

To switch the 1919-R on:

1. To switch on, briefly press the On/Off/Backlight switch. The unit will switch on, and the display

will appear.

2. The backlight for the 1919-R’s LCD can be configured to toggle between full, half, and low

illumination. This toggling will be performed by briefly pressing the On/Off switch after the

1919-R has been switched on.

3. To switch the 1919-R off, press the On/Off switch and hold it for ~ 2 seconds until the display

blanks.

To set general instrument settings:

1. Disconnect the sensor. Use the Navigation keys to select the parameter to change and press

the Enter key. Change the setting with the Navigation keys. Press the Enter key to save.

2. RS232 Baud: Set baud rate for PC communication through its COM port.

3. Max An. Output: Set desired max analog output.

4. Language: Set to desired language.

5. Line Frequency: Set to 50Hz or 60Hz, depending on the electrical power grid of the area that

you are in.

6. Date and Time: Set to correct date and time.

The 1919-R automatically saves the current settings for next power up.

To zero the instrument:

1. Disconnect the sensor.

2. Make sure the instrument is not in an electrically noisy environment and is undisturbed.

3. Press Zero and Start. Zeroing takes about 30 seconds. Wait until “Zeroing completed

successfully” appears.

1919-R User Manual 7

Page 9

Quick Reference

2.2 Thermopile Sensors

2.2.1 Using 1919-R with Thermopile Type Sensors

1. Plug in the Thermopile sensor. 1919-R will reconfigure itself to work with the attached sensor.

2. All of the sensor’s measurement parameters are shown on the main screen. Use the

Navigation keys to select and change the parameters.

3. Use the Navigation keys to select the parameter to change and press the Enter key. Change

the setting with the Navigation keys. Press the Enter key to save.

4. 1919-R saves the changes automatically for next startup of the instrument.

Warning: Do not exceed maximum sensor limits for power, energy, power density, and energy

density as listed in Sensor Specifications. Otherwise, there is a risk of damaging the absorber.

2.2.2 Using 1919-R to Measure Laser Power

1. Set Mode to Power.

2. Set Range to AUTO or one of the manual ranges. The correct manual range is the lowest one

that is larger than the expected maximum power of the laser.

3. Set Laser to the appropriate laser setting.

4. Set Average to the period you wish to average power over or set to NONE to disable.

2.2.3 Using 1919-R to Measure Single Shot Energy

1. Set Mode to Energy.

2. Set Range to the appropriate manual range. (In Energy mode, there is no autoranging.) The

correct range is the lowest one that is larger than the expected maximum pulse energy of the

laser.

3. Set Laser to the appropriate laser setting.

4. Set Threshold if you wish to change the energy threshold.

5. When the 1919-R screen flashes READY on and off, fire the laser.

2.3 Photodiode Sensors

2.3.1 Using 1919-R with Photodiode Type Sensors

1. Plug in the Photodiode sensor. 1919-R will reconfigure itself to work with the attached sensor.

2. All of the sensor’s measurement parameters are shown on the main screen. Use the

Navigation keys to select and change the parameters.

3. Use the Navigation keys to select the parameter to change and press the Enter key. Change

the setting with the Navigation keys. Press the Enter key to save.

4. 1919-R saves the changes automatically for next startup of the instrument.

Warning: Do not exceed maximum sensor limits for power, energy, power density, and energy

density as listed in Sensor Specifications. Otherwise, there is a risk of damaging the absorber.

1919-R User Manual 8

Page 10

Quick Reference

2.3.2 Setting the Measurement Parameters

1. Set Range to the appropriate manual range, AUTO, or dBm (logarithmic scale). Note that

when selecting a manual range, the correct range is the lowest one that is larger than the

expected maximum power of the laser.

2. Set Laser to the appropriate laser setting. If the wavelength you want is not among the

wavelengths listed, select one and press the arrow key that is next to it to open the Modify

screen. Using the up/down Navigation keys to change each number and the right/left keys to

move to the next number, key in the wavelength you want. When finished, press the Enter

key.

3. Set Filter to IN or OUT as physically configured on the sensor. Not necessary for sensors with

built-in filter state detection.

4. Set Average to the period you wish to average power over or set to NONE to disable.

2.3.3 Measuring Average Power or Exposure

To measure average power:

1. Set Mode to Power.

2. Set measurement parameters as described above.

To measure exposure:

1. Set Mode to Exposure.

2. Set measurement parameters as described above.

3. Set Stop Mode to Manual or Timeout period.

4. Accumulated energy exposure will be displayed on the screen, as well as the elapsed time.

2.4 Pyroelectric or Photodiode Energy Sensors

2.4.1 Using 1919-R with Energy Sensors

1. Plug in the Pyroelectric/Photodiode energy sensor. 1919-R will reconfigure itself to work with

the attached sensor.

2. All of the sensor’s measurement parameters are shown on the main screen. Use the

Navigation keys to select and change the parameters.

3. Use the Navigation keys to select the parameter to change and press the Enter key. Change

the setting with the Navigation keys. Press the Enter key to save.

4. 1919-R saves the changes automatically for next startup of the instrument.

Warning: Do not exceed maximum sensor limits for power, energy, power density, and energy

density as listed in Sensor Specifications. Otherwise, there is a risk of damaging the absorber.

1919-R User Manual 9

Page 11

Quick Reference

2.4.2 Zeroing Instrument against Sensor

For most accurate calibration, you should zero the energy sensor against the 1919-R it is being

used with:

1. Make sure the sensor is in a quiet environment and not subject to pulsed radiation.

2. Press Menu and select Instrument.

3. Press Zero and Start. Wait until “Zeroing completed successfully” appears.

2.4.3 Setting the Measurement Parameters

1. Set Range to the lowest one that is larger than the expected maximum pulse energy of the

laser.

2. Set Laser to the appropriate laser setting. If this sensor is a metallic type and if the wavelength

you want is not among the wavelengths listed, select one and press the arrow key that is next

to it to open the Modify screen. Using the up/down keys to change each number and the

right/left keys to move to the next number, key in the wavelength you want. When finished,

press the Enter key.

3. Set Pulse Length to the shortest time that is longer than the expected pulse length.

Warning: Incorrect readings will result if pulse length is not set up correctly.

4. For sensors with the diffuser option, set Diffuser to IN or OUT as physically set on the sensor.

5. Set Threshold as necessary to screen out false triggers due to noise.

6. Set Average to the period you wish to average power over, or set to NONE to disable.

1919-R User Manual 10

Page 12

Quick Reference

2.4.4 Measuring Energy, Average Power, or Exposure

With the Pyroelectric sensor, you have been supplied a test slide with the same coating as on your

Pyroelectric detector. You can also obtain this slide from your dealer. You should use this slide to

test the damage threshold with your laser pulses. If the slide is damaged, then either enlarge your

beam, or lower the laser energy until damage is no longer seen.

To measure energy:

1. Set Mode to Energy.

2. Set measurement parameters as described above.

3. Energy will be displayed on the screen as well as the laser’s frequency.

To measure average power:

1. Set Mode to Power.

2. Set measurement parameters as described above.

3. Average power will be displayed as a function of “Energy x Frequency” on the screen as well as

the laser’s frequency.

To measure exposure:

1. Set Mode to Exposure.

2. Set measurement parameters as described above.

3. Set Stop Mode to Manual, Timeout period, or Pulse count.

4. Accumulated energy exposure will be displayed on the screen, as well as elapsed time and

number of pulses measured.

2.5 Graphical Displays

To present measurements on a graduated scale (bargraph):

1. In Power or Energy mode, press Menu and enter Display.

2. Go to Graph Type and select Bargraph. Return to the main display screen.

3. To expand the bargraph scale ±5x of the present reading, press the Zoom button. Press Zoom

again to return the bargraph to full scale.

4. To subtract the background and set the current reading to zero, press the Offset button. Press

Offset again to cancel.

To simulate an analog needle:

1. In Power or Energy mode, press Menu and enter Display.

2. Go to Graph Type and select Needle. Return to the main display screen.

3. To expand the needle graph ±5x of the present reading, press Zoom. Press Zoom again to

return the needle range to full scale.

1919-R User Manual 11

Page 13

Quick Reference

4. To subtract the background and set the current reading to zero, press the Offset button. Press

Offset again to cancel.

5. Press Persist to keep older measurements on the screen and to display numerically the Min

and Max values measured. Press Persist again to cancel.

To graph laser output over time:

1. In Power or Energy mode, press Menu and enter Display.

2. Go to Graph Type and select Line. Return to the main display screen.

3. Set the percentage range of the scale to be displayed to the desired setting.

4. Set the horizontal sweep time as necessary.

5. Press Reset to clear the Min/Max tracking and to restart the graph.

6. This is especially useful to fine-tune the laser power.

To display real-time statistics:

1. In Power or Energy mode, press Menu and enter Display.

2. Go to Graph Type and select Statistics. Return to the main display screen.

3. Displays Maximum, Minimum, Average, Standard Deviation, Total Readings, and Number

Overrange.

4. To subtract the background and set the current reading to zero, press the Offset button. Press

Offset again to cancel.

5. Press Reset to clear the statistics.

To set pass/fail tracking:

1. In Power or Energy mode, press Menu and enter Display.

2. Go to Graph Type and select Pass/Fail. Return to the main display screen.

3. Press the Upper and Lower buttons to set tolerance limits. If reading is out of range, an

appropriate warning will be displayed on the screen.

To display readings as bars with lengths proportional to the measurement:

1. In Power or Energy mode, press Menu and enter Display.

2. Go to Graph Type and select Pulse Chart. Return to the main display screen.

3. Set the percentage range of the scale to be displayed to the desired setting.

4. Set the number of readings to display as necessary.

5. Press Reset to clear the Min/Max tracking and to restart the graph.

6. This is especially useful when measuring pulses of low frequency lasers.

1919-R User Manual 12

Page 14

Quick Reference

2.6 Math Functions

To apply a fixed offset to measurements:

1. Press Menu and enter Functions. Go to Fixed Offset.

2. Set the value to subtract from all subsequent measurements.

To apply a Scale Factor to measurements:

1. Press Menu and enter Functions. Go to Scale Factor.

2. Set to value by which to multiply all subsequent measurements.

3. Useful when working with beam splitters.

To normalize against a reference measurement:

1. Press Menu and enter Functions. Go to Normalize.

2. Set to reference value by which to normalize all subsequent measurements.

To display as power/energy density:

1. Press Menu and enter Functions. Go to Density.

2. Select beam shape and size.

3. Measurements will be shown as cm².

2.7 Logging Data to a File for Upload to PC

You can log your measurement data to a file for upload to PC by connecting an external storage

device to the USB port of the 1919-R meter. For details, see Logging Data to a File for Upload to

PC.

1919-R User Manual 13

Page 15

3 Using the 1919-R Display Unit

This section describes the 1919-R display unit, its components, its functions independent of sensor

type, hardware functions, GUI, and keypad settings.

Topics include:

General Description

1919-R Display Unit Components

1919-R Hardware Components/Interfaces

1919-R Functions – Independent of Sensor Type

1919-R Screen Layout

3.1 General Description

The Newport 1919-R is a microprocessor-based Laser Power/Energy Meter that provides a broad

range of measurements, displays, and data handling options. It operates with Thermopile,

Pyroelectric, and Photodiode sensors. Taking advantage of smart connector technology, it is easyto-use—simply connecting the sensor configures and calibrates the 1919-R to operate with that

sensor. The sensor configuration and calibration information is stored in an EEROM in the sensor

connector plug. This means that when the sensor is plugged in, 1919-R automatically identifies the

sensor type, calibration, and configuration. You do not have to adjust anything. Sensors are hot

swappable. Even after the meter is switched on, you can remove one sensor and insert a different

one. 1919-R will recognize the switch and reconfigure itself according to the settings of the new

sensor.

The 1919-R’s 320x240 full-color screen enhances measurement readouts in ways that simple

monochrome displays cannot. The 1919-R can graph power or energy versus time. It displays

power measurements in both digital and analog form simultaneously and also has a needle type

display. It will also autorange, so you do not have to set scales; or it can manual range if you wish.

It will remember what mode you were using before you turned it off and will return to that mode

when turned on. You can zoom in on the present reading, or subtract the background. Although

the calibration information is stored in the smart connector, you can recalibrate from the screen

and store the new calibration in the sensor. You can also zero the 1919-R at the touch of a button.

1919-R is capable of logging data onto a USB Flash Drive (Disk On Key), as well as real-time

reporting of data via USB to Newport’s PMManager application to display and process the

information. 1919-R has RS232 capabilities as well. 1919-R also has the infrastructure for field

upgrading of the embedded software, should the need arise.

Above all, the 1919-R has advanced circuitry and digital signal processing for excellent sensitivity,

signal-to-noise ratio, accuracy, and response time. It also has special circuitry to reject

electromagnetic interference.

1919-R’s User Interface is intuitive. The keypad functionality is context-sensitive and functions

according to the needs of the present screen. Where necessary, on-screen help is provided as well,

so you should not have to refer to this manual very often.

1919-R User Manual 14

Page 16

Using the 1919-R Display Unit

3.2 1919-R Display Unit Components

Figure 3-1 below displays the 1919-R display unit, displaying the main screen with some sample

measurements.

Figure 3-1 1919-R Meter/Display Unit – Front View

The 1919-R is equipped with:

LCD Display screen

Soft keys (under the display screen): The functions of the keys change as indicated by the

legend above each key. (The Menu key enables you to access Sensor, Display, Functions,

Instrument, Log, and Calibration settings. For sensor-specific details, see Thermopile Sensors,

Photodiode Sensors, Pyroelectric and Photodiode Energy Sensors.)

4 Navigation Keys and round Enter Key (under the soft keys, in the center of the unit)

Power On/Off/Backlight button

1919-R User Manual 15

Page 17

Using the 1919-R Display Unit

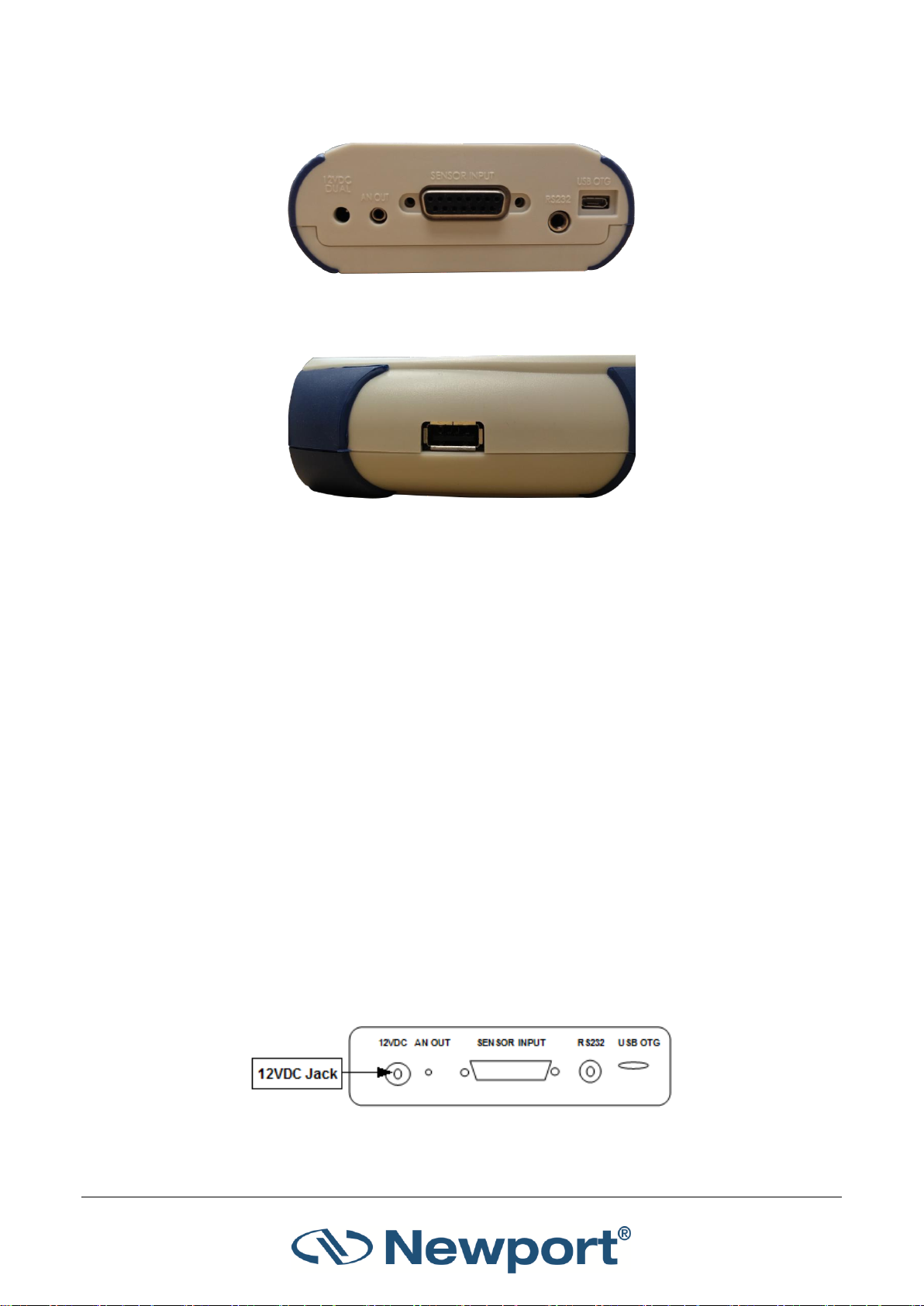

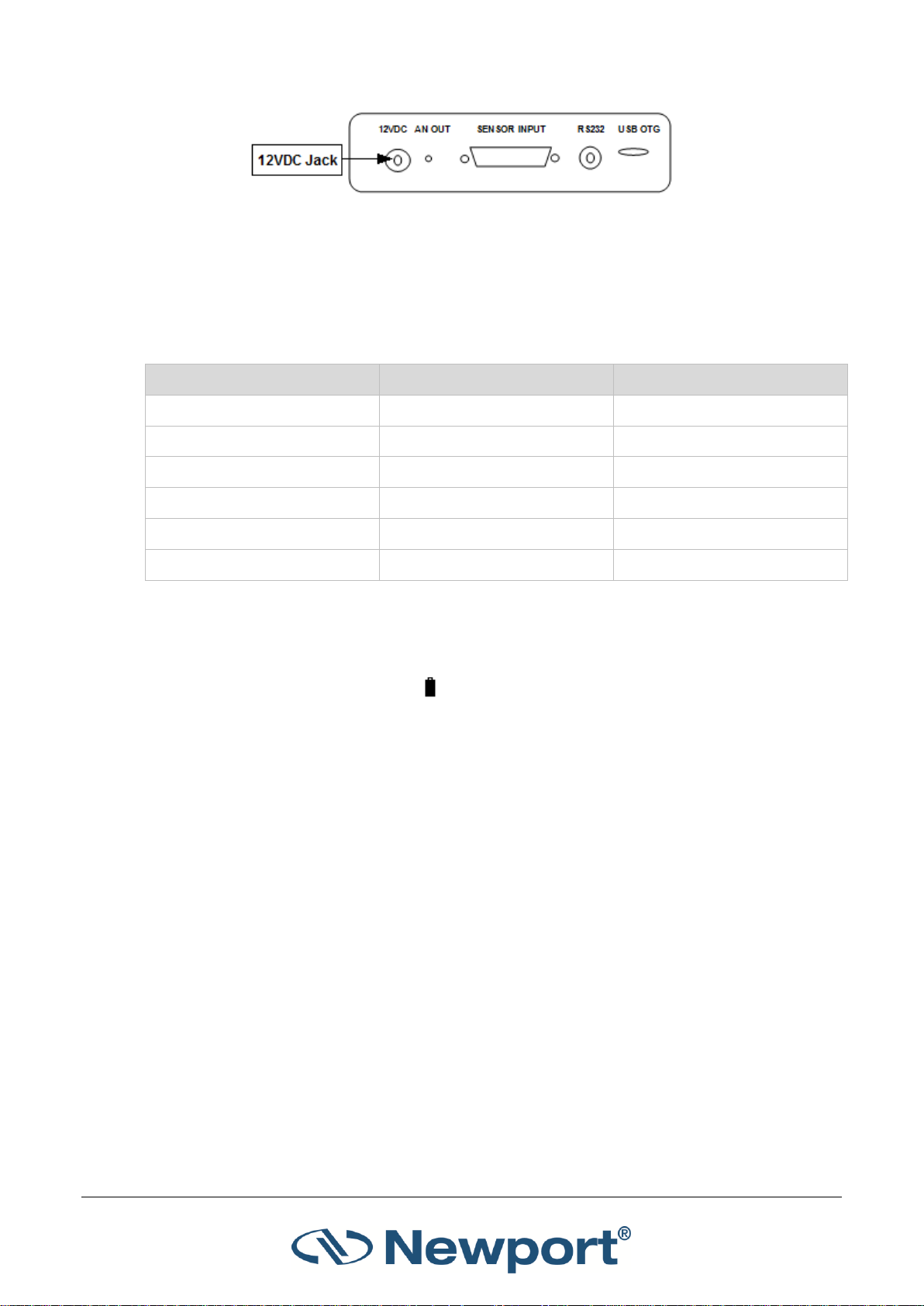

Rear Panel with the following sockets: 12VDC, AN OUT, Sensor Input, RS232, USB OTG

Figure 3-2 1919-R Rear Panel

USB Port (on left side of the 1919-R meter)

Figure 3-3 USB Port (on Left Side) of 1919-R Meter

3.3 1919-R Hardware Components/Interfaces

This section describes the 1919-R hardware components and interfaces.

Topics include:

Sensor Input

LCD Display and Backlight

Soft Keys

Navigation Keys

On-Off Switch/Backlight Control

Charger Input

Analog Output

RS232 and USB Outputs

3.3.1 Sensor Input

The Sensor Input, located in the center of the 1919-R real panel, is the socket where you insert the

15 pin D type connector of the measuring sensor cable in order to connect the sensor to the

meter, as shown in Figure 3-4 below.

Figure 3-4 1919-R Rear Panel View

1919-R User Manual 16

Page 18

Using the 1919-R Display Unit

3.3.2 LCD Display and Backlight

The 1919-R screen is a QVGA 320x240 pixel color TFT LCD. It can be driven in one of two full color

modes or in one.

The LCD backlight is actually a set of LEDs that illuminate the display from behind. Because the

1919-R uses a TFT color display, the backlight must be constantly on. It can be operated at full

intensity for full illumination; or at low or half-level to conserve power consumption

(recommended). The backlight level is toggled by a short press on the On/Off switch.

The 1919-R backlight consumes considerably less power than competing instruments, and

therefore it can operate from the battery even when the charger is not plugged in. Nevertheless,

since it does shorten the time between charges, it is recommended to set the backlight to less

than full intensity when the instrument is operated without the charger. (For further details, see

On-Off Switch/Backlight Control.)

3.3.3 Soft Keys

The Soft keys, located under the 1919-R screen, have functions defined by

the legend above each key. The legend usually indicates what will happen

when pressing the key. For example, if "Zoom" appears above a key, pressing that key will display

a zoom view of the screen. Some functions operate when the key is pressed and are canceled

when the key is pressed again. Those keys show reverse highlighting when operational. Pressing

the same key again cancels the operation and the highlighting.

Key Functions

The 1919-R has certain conventions as to the meaning of standard key strokes, including:

Highlighted item: The item that is presently active.

Menu: Provides access to Sensor, Display, Functions, Instrument, Log, and Calibration settings.

Start: Launches the active item.

Exit: Returns to the previous screen.

Cancel: Cancels the selection and returns to the previous screen, leaving the settings

unchanged.

3.3.4 Navigation Keys

The Navigation keys move to the next active item—left, right, up, and down. The round

button in the center is an Enter key to enter the screen of the item selected or when

finished, to leave that screen. Pressing the Enter key to leave the screen will save the

newly selected value for immediate use and will also save the change permanently.

3.3.5 On-Off Switch/Backlight Control

This section describes how to switch on/off the 1919-R and how to toggle the state of the

backlight.

To turn the 1919-R on:

Briefly press the On/Off switch (located under the Navigation keys, at the bottom

of the front panel). See Figure 3-1 above.

1919-R User Manual 17

Page 19

Using the 1919-R Display Unit

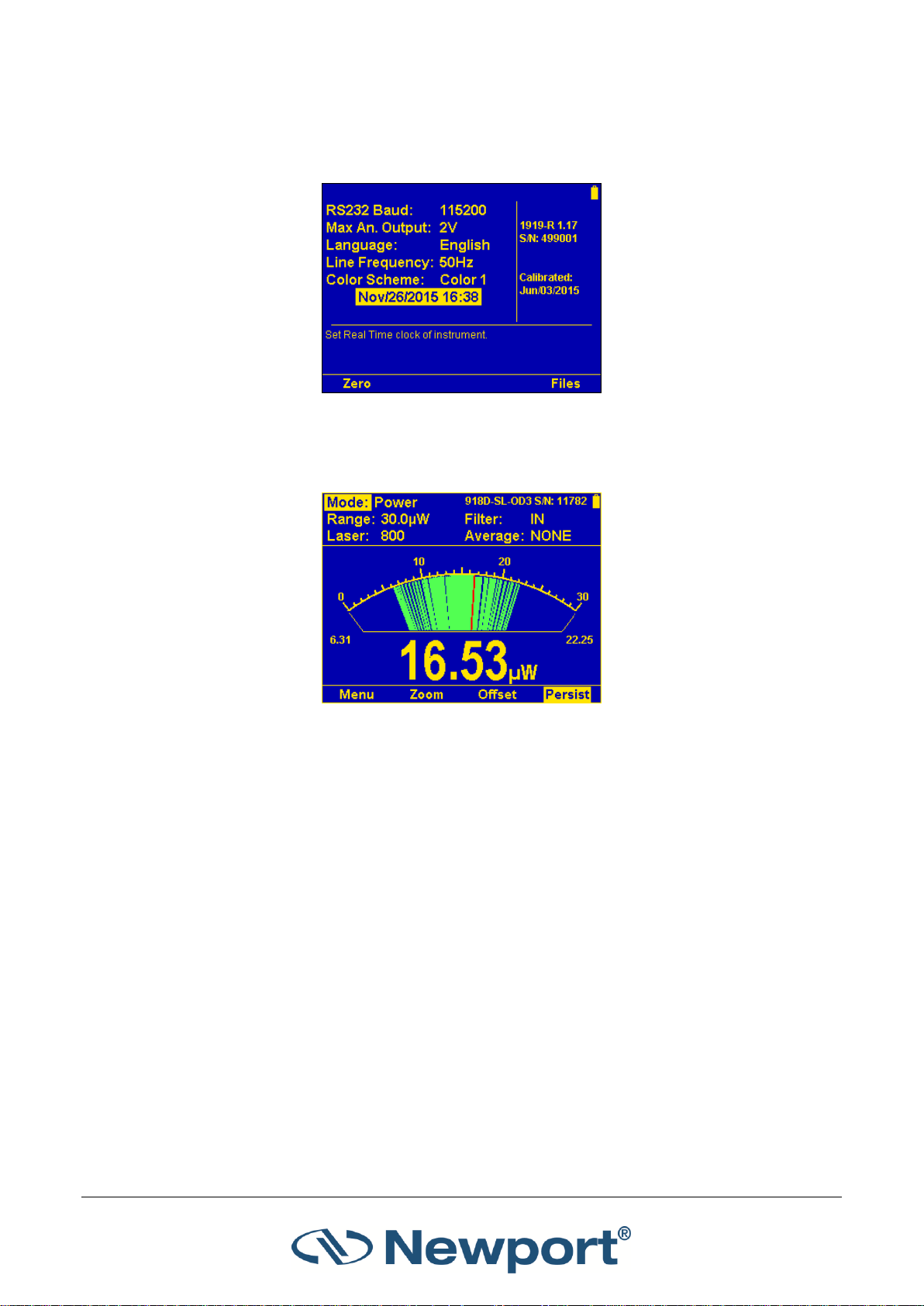

The unit switches on, and the display appears. If no sensor is connected, the Instrument

Settings screen appears, displaying the configurations saved from the previous session (see

Instrument Settings). For example:

Figure 3-5 Instrument Settings Screen

If a sensor is connected, the appropriate default measurement screen will appear. For

example:

Figure 3-6 Needle Display with Persistence Enabled

To switch the 1919-R off:

Press the On/Off switch and hold it for ~ 3 seconds until the display blanks.

To toggle the state of the backlight of the 1919-R’s LCD:

Briefly press the On/Off switch after the 1919-R has been switched on. You can toggle

the backlight between full, half, and low illumination.

3.3.6 Charger Input

The 1919-R can be operated either by the internal battery or from an AC source with the charger

plugged in all the time. Plug the charger into the jack labeled "12VDC" on the rear panel (see

Figure 3-7 below). The battery will be charged at the same rate whether the 1919-R is switched on

or off, and whatever the backlight level. The battery will fully recharge in around 4-5 hours.

1919-R User Manual 18

Page 20

Using the 1919-R Display Unit

Sensor Type

Backlight Level

Time Between Charges

Thermopile and Photodiode

Low

19 hours

Thermopile and Photodiode

Half

17 hours

Thermopile and Photodiode

Full

15 hours

Pyroelectric

Low

16 hours

Pyroelectric

Half

15 hours

Pyroelectric

Full

13 hours

Figure 3-7 1919-R Rear Panel View

Note: The charger circuit of the 1919-R is designed to allow the charger to be plugged in for an

extended period without causing damage to the battery.

The approximate time between charges is given in Table 3-1 below for various configurations:

Table 3-1 Sensor Charging Times

Note: Battery charge will be depleted faster if a USB Flash Drive (Disk on Key) is left plugged into

the 1919-R meter.

The battery charge is indicated by the icon. The battery charge is shown approximately by each

segment of the icon, for example, when 2 segments are shown, the battery is ½ full. When the

battery is charging, the segments turn on in sequence. When the battery is low, the charger should

be plugged in. While the unit will charge even while on and even with the backlight on, it will

charge fastest if the charger is left in while the unit is off.

3.3.7 Analog Output

The 1919-R provides an analog voltage output via the 2.5mm mono jack socket on the rear panel

marked “AN OUT” (see Figure 3-7 above). The 1919-R is supplied with the mating adapter plug

that connects to this socket. The analog output is useful for driving chart recorders and other

analog devices. The voltage is proportional to the reading on the display and scaled such that full

scale equals 1, 2, 5, or 10 volts as selected during setup.

To set the analog output voltage:

1. Use the up (↑) /down (↓) Navigation keys to select Max An. Output and press the Enter key.

2. Select the relevant voltage setting (1V, 2V, 5V, 10V).

3. Press the Enter key to exit this selection screen and save the new setting.

The analog output is driven through an impedance of 100ohm. For best accuracy, is recommended

to limit the external load to 100K (or larger). A smaller load (down to 1K) is possible, but may

result in loss of accuracy.

1919-R User Manual 19

Page 21

Using the 1919-R Display Unit

For Thermopile and Photodiode sensors in power mode, the analog output is continually updated

15 times per second with the latest power measurement. For Thermopile sensors in single shot

energy mode, the analog output is held until the next pulse is measured. For Pyroelectric sensors,

the analog output is updated at up to 10 times per second with the latest pulse energy.

3.3.8 RS232 and USB Outputs

The 1919-R is equipped for either RS232 or USB communications with PC. The Unit is supplied with

a standard cable for USB communications and a custom cable for RS232 (see Figure 3-7 above).

You can change the RS232 baud rate with or without the sensor connected.

To set the RS232 baud rate for RS232 PC communication:

1. Disconnect the sensor and change the setting in the Instrument Settings screen.

Alternatively, when the sensor is connected to 1919-R, the RS232 Baud Rate can be configured

in the Instrument Settings screen, accessed by pressing the Menu button and selecting

Instrument.

2. Use the Navigation keys to select RS232 Baud Rate and press the Enter key to display the

options (115200, 57600, 38400, 19200).

3. Change the setting with the up (↑) /down (↓) Navigation keys and press the Enter key to

save.

3.4 1919-R Functions – Independent of Sensor Type

This section describes the functions available when no sensor is connected to the 1919-R.

Topics include:

Instrument Settings

Field Upgrade

Clock Settings

Zero Adjustments

Line Frequency

Language

Measurement Screens (Graph Types)

Color Scheme

3.4.1 Instrument Settings

When no sensor is connected, the 1919-R Instrument Settings screen is displayed. This gives you

the opportunity to change instrument settings including the RS232 baud rate, maximum analog

output, language, line frequency, color scheme, and date and time of the real time clock. The

Instrument Settings screen also shows the firmware version, serial number of the instrument, and

last calibration date. You can also re-zero the instrument. (Click the links to view more details.)

1919-R User Manual 20

Page 22

Using the 1919-R Display Unit

To configure the instrument settings:

1. Disconnect the sensor.

The Instrument Settings screen is displayed.

Figure 3-8 Instrument Settings Screen

2. Use the up (↑) /down (↓) Navigation keys to select the parameter to change and press the

Enter key to display the options, as described in Table 3-2 below. (These instrument settings

are also available when a sensor is connected, and you press the Menu button and select

Instrument.)

3. Change the setting with the up (↑) /down (↓) Navigation keys and press the Enter key to

save.

The 1919-R automatically saves the current settings for the next power up.

1919-R User Manual 21

Page 23

Using the 1919-R Display Unit

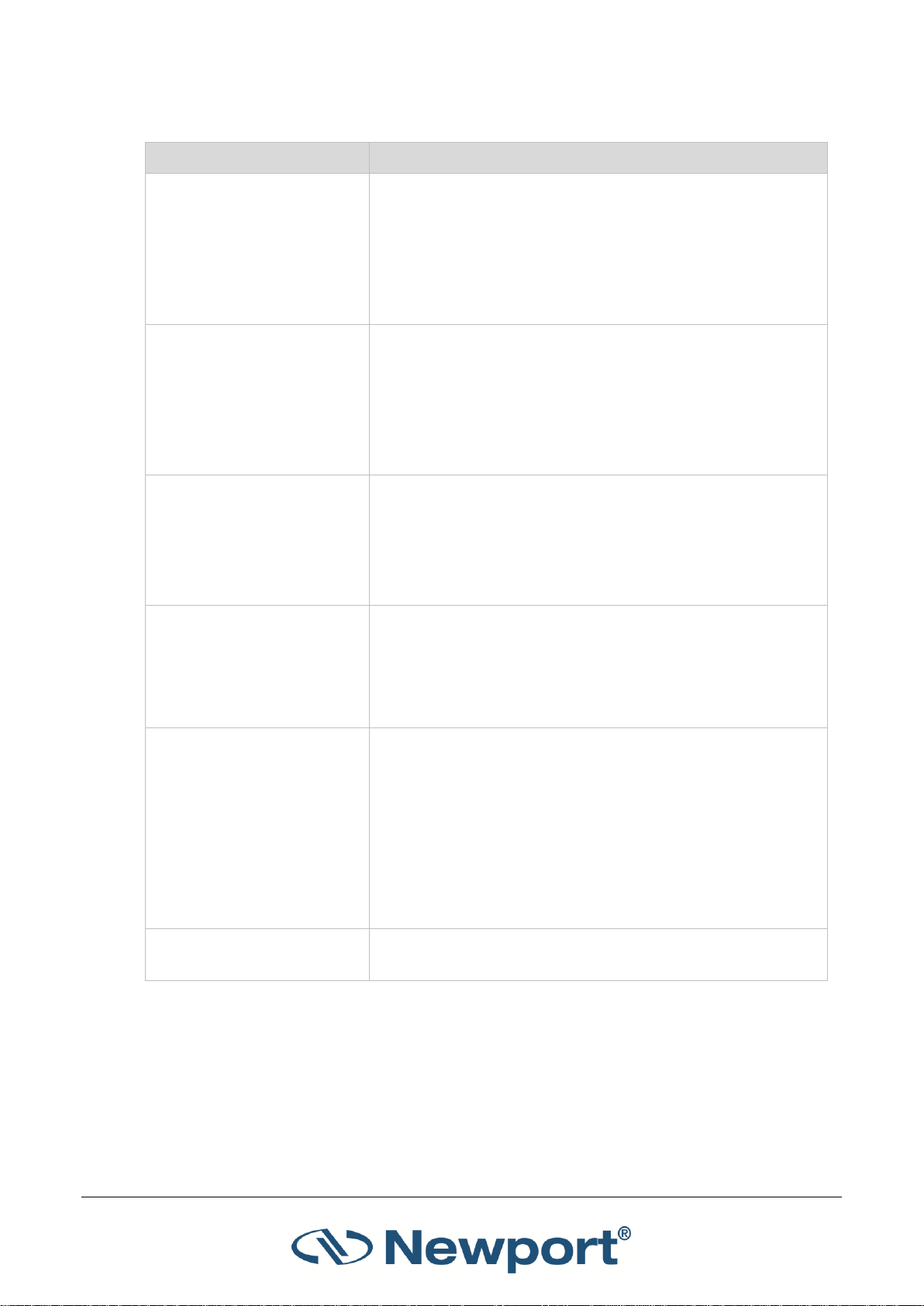

Parameter

Description

RS232 Baud

Set the baud rate for RS232 PC communication. Options

include:

115200

57600

38400

19200

Max An. Output

Select the voltage of analog output for full scale measurement.

Options include:

1V

2V

5V

10V

Language

Set desired instrument startup language. Options include:

English

Japanese

Russian

Chinese

Line Frequency

Set local line frequency to screen out electrical noise from the

mains supply (to prevent any impact on the measurements).

Options include:

50Hz

60 Hz

Color Scheme

Set to full color functionality or to color pair that best matches

the protective goggles in use. Options include:

Black/White

Blue/Black

Red/Black

Green/Black

Color 1

Color 2

Date and Time

Set the real-time clock of the instrument, in date/time format:

MM/DD/YYYY H:mm.

Table 3-2 1919-R Instrument Settings

1919-R User Manual 22

Page 24

Using the 1919-R Display Unit

3.4.2 Field Upgrade – Updating the 1919-R Firmware

1919-R has all of the necessary infrastructure for field upgrading of the embedded software,

should the need arise. This is done through the USB OTG port that is found on the rear panel of

the instrument (see Figure 3-7 above).

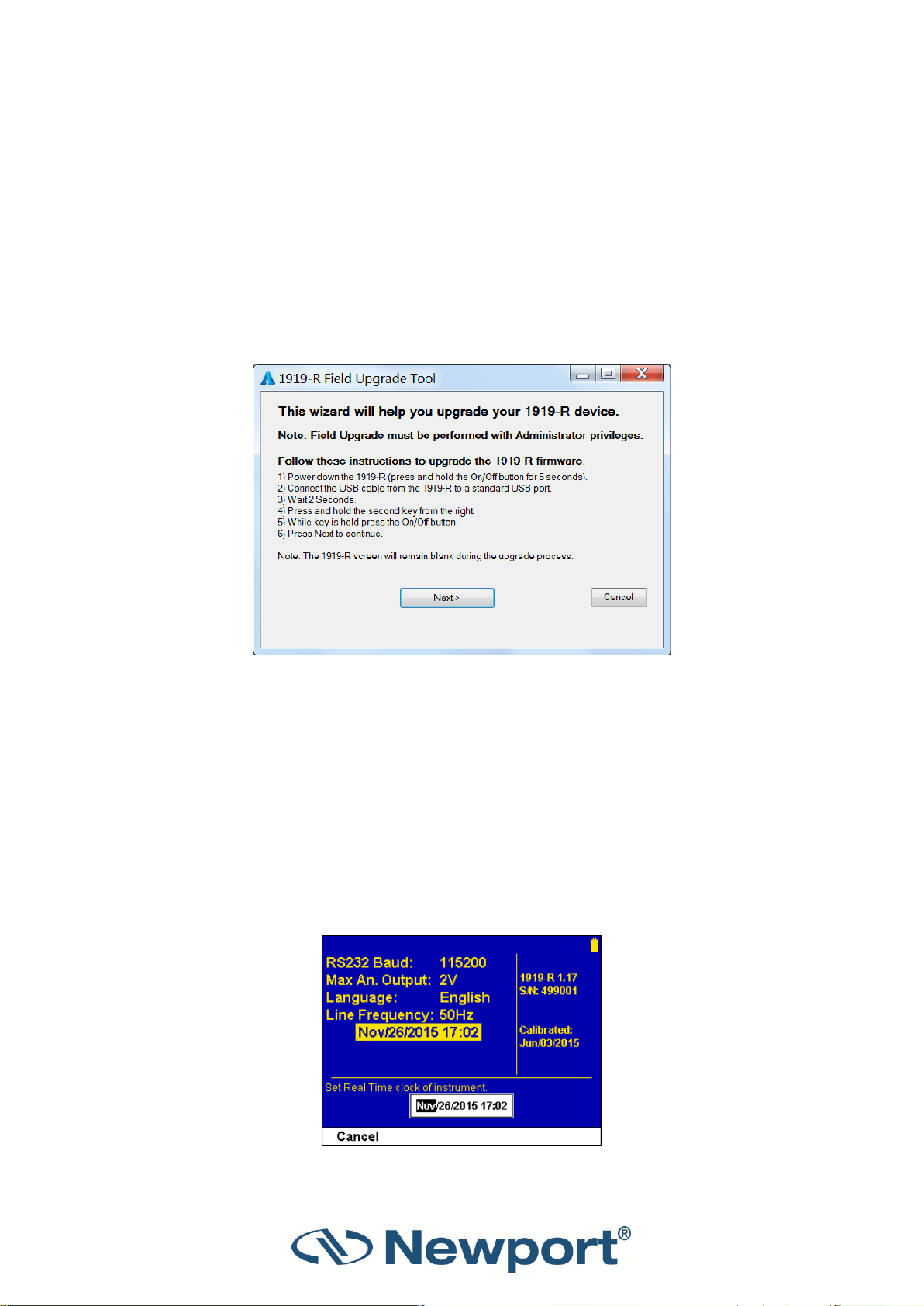

To update the 1919-R firmware:

1. Download the latest 1919-R firmware upgrade package from the Newport website:

http://www.newport.com/Handheld-Power-and-Energy-Meters/6770602/1033/category.aspx

and copy it to your target directory.

2. Run the upgrade executable and follow the on-screen instructions.

3.4.3 Clock Settings

The 1919-R is equipped with a real time clock which shows the date and time. This clock also

allows the 1919-R to query the sensor attached and notify you if the sensor is due for calibration.

You can change the date and time.

To set the real-time clock of the instrument:

1. Disconnect the sensor.

2. Use the up (↑) /down (↓) Navigation keys to select/highlight the Date and Time parameter

and press the Enter key.

Figure 3-9 1919-R Field Upgrade Wizard

Figure 3-10 Real Time Clock Settings

1919-R User Manual 23

Page 25

Using the 1919-R Display Unit

3. Use the left (←)/right (→) Navigation keys to scroll through and select/highlight each of the

Month, Day, Year, Hours, and Minutes fields (MM/DD/YYYY H:mm).

4. Change the setting with the up (↑) /down (↓) Navigation keys and press the Enter key to

save.

3.4.4 Zero Adjustments

In the 1919-R, all adjustments, including zeroing internal circuits, are done from the software. This

ensures simple and accurate realignment. It is recommended to re-zero the 1919-R every 2

months for best performance.

To zero the instrument:

1. Disconnect the sensor, turn the instrument off and then back on again, so the 1919-R can

identify that no sensor is connected. An "Initializing" message will be displayed.

2. Let the 1919-R run for at least 30 seconds before performing zero adjustment. Make sure the

sensor is in a quiet environment (without electrical noise) and not subject to pulsed radiation.

3. Press Zero and Start. Wait until “Zeroing completed successfully” appears.

4. Press Save to save the new zero values to the instrument.

5. Press Exit to return to the main screen.

For Thermopile Sensors only:

For best results with Thermopile sensors, it may be necessary to do the procedure once with the

sensor disconnected, then afterwards again with the sensor connected.

To zero the instrument against Thermopile sensors:

1. After completing steps 1-4 above, connect the sensor and make sure it is at room temperature

and well shielded from any stray thermal power. It is recommended to lay the sensor with the

absorber face down on the table.

2. Switch the instrument off then on again with the sensor connected.

3. Press Menu and select Instrument. Press Zero and Start. Wait until “Zeroing completed

successfully” appears.

4. Press Save to save the new zero values to the instrument.

5. Press Exit to exit this screen and return to the previous one.

For Pyroelectric and Photodiode Energy Sensors:

In addition to zeroing the meter, as described previously, it is important to zero the meter against

the sensor you are using the first time. After you have done zeroing, you do not have to do it again

when used with the same type of meter. If you have zeroed it against a different type of meter,

then a different value has been saved and therefore when used with this 1919-R, you should zero

it again.

1919-R User Manual 24

Page 26

Using the 1919-R Display Unit

3.4.5 Line Frequency

Setting Line Frequency correctly removes electrical noise that may impact the measurements.

To set line frequency:

1. In the main screen, use the Down (↓) Navigation key to select Line Frequency and press the

Enter key.

2. Set to 50Hz or 60Hz, depending on the electrical power grid of the area that you are in.

3. Press the Enter key to save the new setting.

3.4.6 Language

The 1919-R display can be configured to one of several languages (English, Japanese, Russian, or

Chinese).

To set the user interface language for the instrument:

1. In the main screen, use the Down (↓) Navigation key to select Language and press the Enter

key.

2. Set to English, Japanese, Russian, or Chinese.

3. Press the Enter key to save the new setting.

Note: If you mistakenly save the Japanese (or any foreign) language as the 1919-R startup

language, you can revert to English.

To revert to English (from a foreign language):

1. Disconnect the sensor from 1919-R.

2. Turn the 1919-R off and on again. The Instrument Settings screen appears (titled “head

disconnected” in Japanese).

3. Press the Down (↓) Navigation key 2 times to select/highlight the “Language” option.

4. Press the Enter key and select English (at the top of the language list).

Press the Enter key to save English as the startup language.

Note: The current settings are automatically saved for the next time 1919-R is turned on.

1919-R User Manual 25

Page 27

Using the 1919-R Display Unit

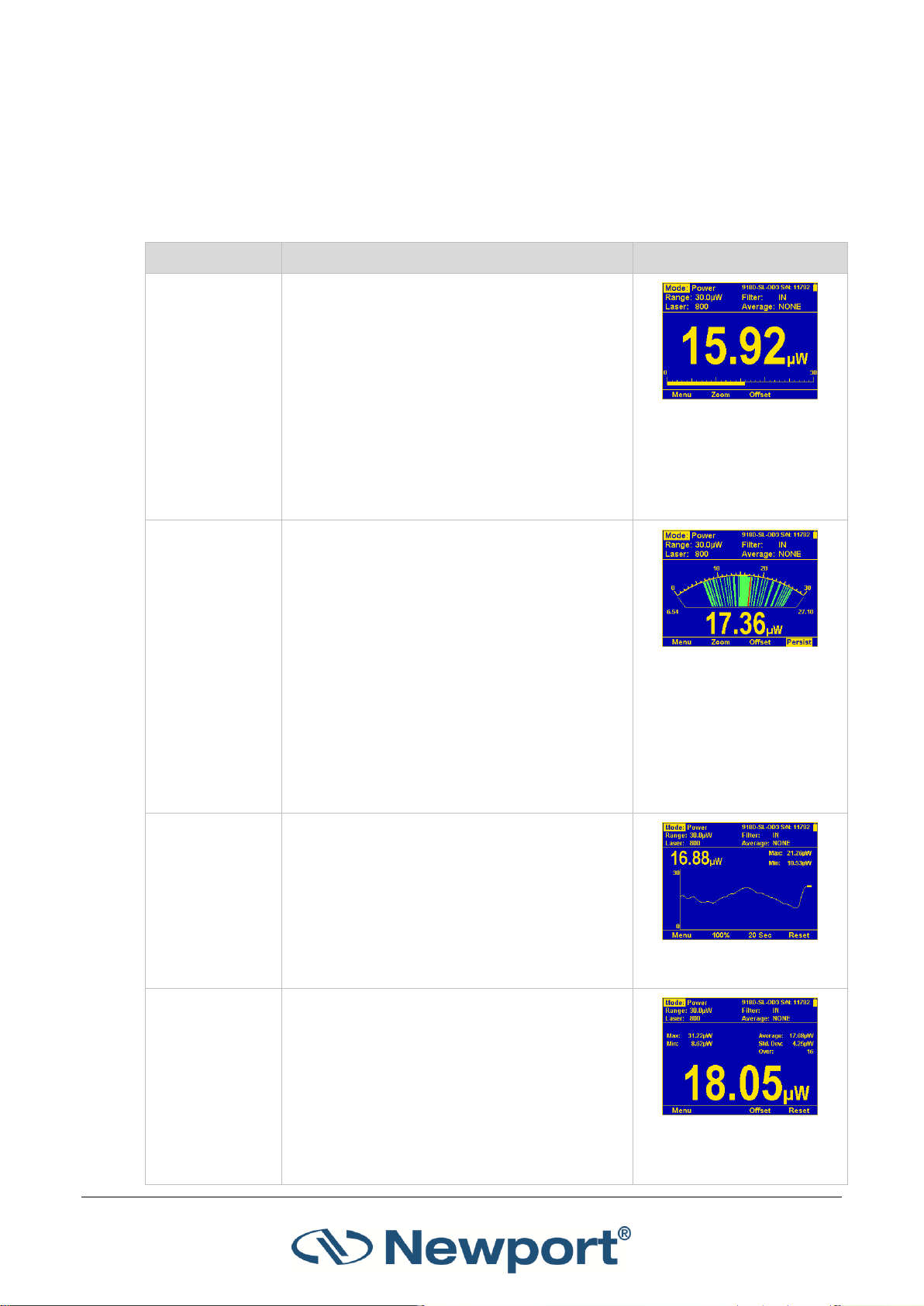

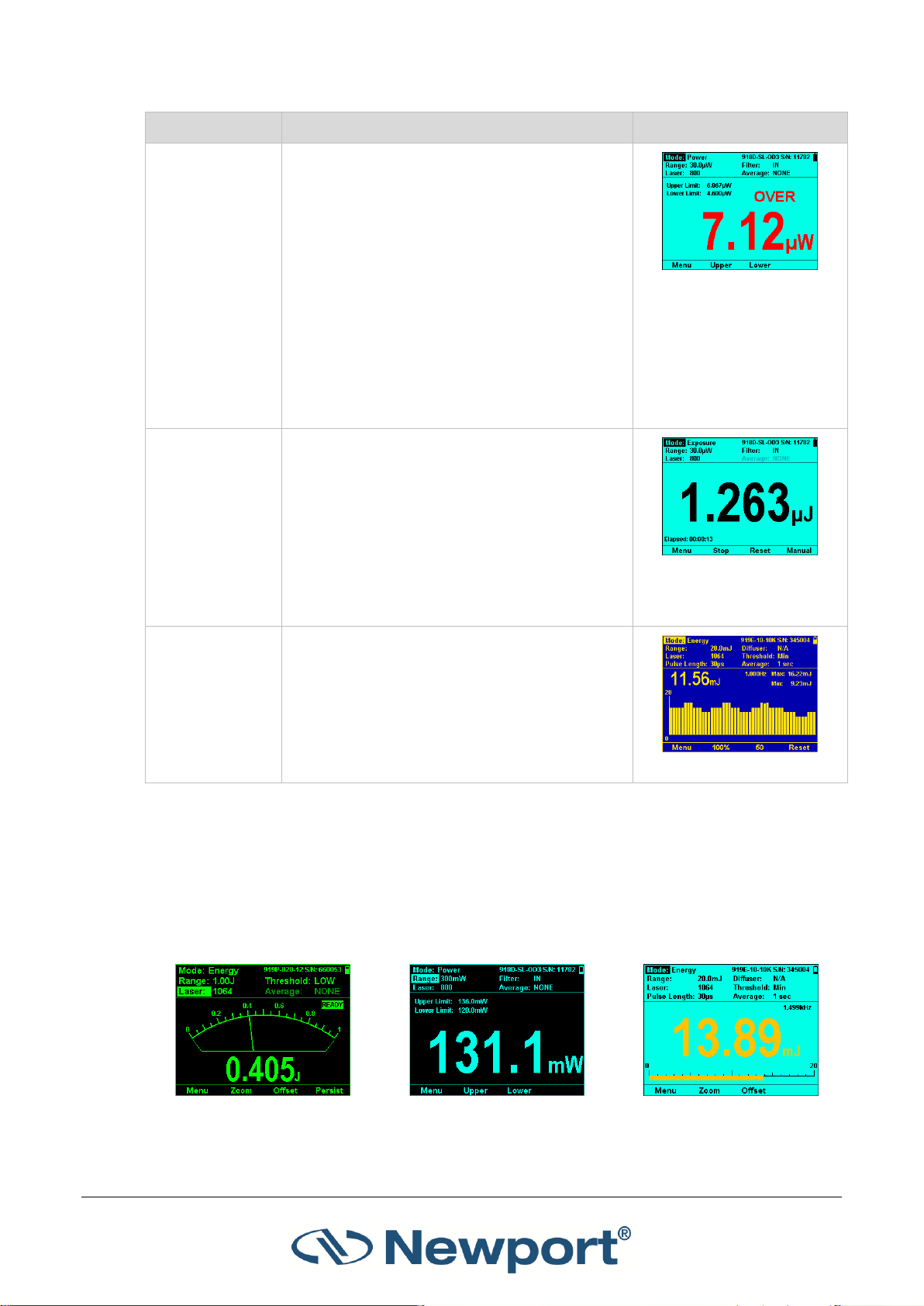

Graph Type

Description

Sample Figure

Bargraph

Ruler-like display in which the graph is filled

proportionally to the reading’s being a

percentage of full scale. Presents measurement

on a graduated scale. Available when measuring

laser power or energy.

Press the Zoom key to zoom in on a

smaller section of the range when

readings are fluctuating slightly.

If you notice that noise has impacted the

measurement, you can press the Offset

key to remove it from the measurement.

Figure 3-11 Bargraph

Needle

Simulates an analog display, similar to the style

of an analog voltmeter or a car’s speedometer.

Available when measuring power or energy.

Press the Zoom key to zoom in on a

smaller section of the range when

readings are fluctuating slightly.

If you notice that noise has impacted the

measurement, you can press the Offset

key to remove it from the measurement.

Press the Persist key to continue to

display previous readings as well as to

show the minimum and maximum

measurements.

Figure 3-12 Needle with

Persistence Enabled

Line

Graph laser output as a function of time. Useful

for technicians performing laser alignment that

want to see the results of their experimenting

graphically as well as to be shown the maximum

laser power attained.

Figure 3-13 Line Graph

Statistics

Large numeric readout with statistics displayed

as well.

Figure 3-14 Statistics

Display

3.4.7 Measurement Screens (Graph Types)

The 1919-R measurement screens are available in a variety of graphical displays, as described in

Table 3-3 below (click the links to view more details):

Table 3-3 1919-R Measurement Screens (Graph Types)

1919-R User Manual 26

Page 28

Using the 1919-R Display Unit

Graph Type

Description

Sample Figure

Pass/Fail

Test for measurements outside the user-defined

range of acceptable readings. Configurable

upper and lower limits. Useful for final

inspection testing, other aspects of Production

Q/A, or field inspection of equipment.

If the measurement is out of range, OVER or

UNDER will be displayed on the screen. If the

Color Scheme has been set to one of the full

color options, then this will be displayed in RED,

along with the reading itself. When within range,

the display will be normal, with the results

shown in GREEN, if one of the color options has

been selected.

Figure 3-15 Pass/Fail

Display

Exposure

Sum of the total energy of a series of

measurements over a given time period or

number of pulses (pulse count is relevant for

energy sensors only). This gives the total energy

"exposure" over that time period. For example,

if the laser is pulsing at 30 times/sec at 1mJ per

pulse and you measure the exposure over 20

seconds, then the total exposure is 30 x 1 x 20 =

600mJ.

Figure 3-16 Exposure

Measurement

Pulse Chart

Displays a graph of pulses as they occur. Displays

the readings as bars with lengths proportional to

the measurement. Not time based and is most

applicable when the data flow is not necessarily

periodic. Ideal when measuring low frequency

lasers.

Figure 3-17 Pulse Chart

Figure 3-18 Thermopile Sensor

(Monochrome)

Figure 3-19 Photodiode Sensor

(Monochrome)

Figure 3-20 Pyroelectric Sensor

(Full Color)

3.4.8 Color Scheme

You can configure the 1919-R for full color or monochrome functionality. Choose full color to make

use of special color enhancements. Choose one of the monochrome schemes for use with

protective goggles that filter out visible wavelengths.

Screen captures of the 1919-R in this manual are shown in the various color schemes. For example,

the following sensor displays:

1919-R User Manual 27

Page 29

Using the 1919-R Display Unit

Full Color

To set the color scheme of the main measurement displays to full color:

1. Connect the relevant sensor.

2. Press the Menu button, and use the Navigation keys to select Display and press the Enter key.

3. Use the Navigation keys to select Color Scheme and press the Enter key.

4. Select the relevant full color scheme option:

Color 1: Yellow text on dark blue background

Color 2: Black text on sky blue background

5. Press the Enter key to save the setting.

For both of these full color schemes, warnings will be displayed in red, selection windows (for

example, range, average, laser) will be pink, and modification windows will be white.

Figure 3-21 Sample Full Color Scheme Display with Pink “Range” Selections

Monochrome

Monochrome schemes are for use with lasers that demand protective glasses that filter out colors

in the visible part of the wavelength spectrum. These color schemes apply to all of the screens. All

color-enhanced features of the 1919-R will not be functional in any of the monochrome screens.

Follow the procedure above to set the color scheme and choose one of the following

monochrome schemes:

Black/White: Black text on white background

1919-R User Manual 28

Page 30

Using the 1919-R Display Unit

Blue/Black: Sky blue text on black background

Red/Black: Red text on black background

Green/Black: Green text on black background

See Figure 3-18, Figure 3-19, and Figure 3-20 above which show the sensors in monochrome and

full color displays.

3.5 1919-R Screen Layout

The 1919-R screen display is carefully designed to provide easy reading of the laser measurement,

quick access to configuration parameters, as well as the ability to set up for more advanced work.

Figure 3-22 below displays the layout of a typical 1919-R measurement screen.

Figure 3-22 1919-R Measurement Screen Layout

The 1919-R measurement screen comprises:

Configuration parameters for laser measurements (at the top), including “Mode” (on upper

left) for setting the measurement mode (for example, Power, Energy, and so on). The

configuration settings are sensor specific and saved in the sensor’s memory.

Measurement display area (in the middle), varies per the selected display type (for example,

large numeric readout with real-time statistics).

Sensor name and serial number (upper right).

Soft keys (on the bottom) for additional display functionality. (For example, press the Menu

key to access additional 1919-R functions including logging, pass/fail inspection, and math

processing. Press Offset to remove background noise from the measurement. Press Reset to

clear the statistics and start over.)

1919-R User Manual 29

Page 31

4 Points to Consider

Before using the 1919-R Laser Power/Energy Meter, consider the following points:

What is the specific laser you need to measure? Which sensor is suitable for this laser? Do you

need to measure laser power or laser energy?

What range and other measurement parameters do you need to set for your particular laser

(for example, laser setting, energy threshold, pulse length, and so on)?

What other instrument settings do you need to configure? Do you use the analog output and if

so, is it configured correctly for your needs?

How would you like to display the measurement data, as a bargraph, analog needle, or some

other format? Do you need real-time statistics or pass/fail tracking?

1919-R will help you implement the answers to these questions. The following chapters describe

the measurement functionality of the various sensor types, the graphical displays of the 1919-R

meter, as well as the data logging and math processing capabilities that make the 1919-R meter

the complete answer to your measurement needs.

1919-R User Manual 30

Page 32

Sensor Type

Liters per Minute at Full Power

Min Pressure Bar

US Gallons per Minute

919P-5KW-50

4.5

0.8

1.2

5 Thermopile Sensors

For a list of the available Thermopile Sensor models that can be used with 1919-R, see Sensor

Specifications.

Warning: Before using the Thermopile sensor for power or energy measurement, check that your

laser power, energy, and energy density do not exceed the sensor ratings. See Sensor

Specifications.

If the sensor is a water-cooled type, ensure that the cooling water is flowing at an adequate rate

(see Table 5-1 below). Also, note that the reflectance from the absorber could be as much as 10%

and with CO2 lasers, the reflected beam can be quite specular, so it is advisable to provide a beam

stop for the reflected beam with the highest power lasers.

Table 5-1 Minimum Flow Rates for Water-Cooled Sensors

When a radiant heat source, such as a laser, is directed at the absorber sensor aperture, a

temperature gradient is created across the Thermopile of the enclosed detector disc. This

generates a voltage proportional to the incident power.

The display unit amplifies this signal and indicates the power level received by the sensor. At the

same time, signal processing software causes the display unit to respond faster than the thermal

rise time of the detector disc, thus reducing the response time of the 1919-R. Energy of a single

pulse is measured on the 1919-R by digitally integrating the pulse power over time.

Most Thermopile sensors have somewhat different absorption at different wavelengths. To

compensate for this, each sensor has been calibrated by the laser at several wavelengths. When

you choose the correct laser setting, the correction factor for that wavelength is automatically

introduced. Note that the laser setting selected is displayed in the upper left section of the display.

The 1919-R can be set to various settings while operating. In addition, the 1919-R automatically

saves the settings for the next power up. This way the 1919-R will be in the desired configuration

when turned on the next time.

On power up, the 1919-R meter checks its own memory as well as the sensor’s to decide on the

measurement configuration. For example, if in the last session, the sensor was used to measure

power in the Bargraph screen in autoranging with a YAG laser and averaging for 10 seconds, this

will be the setup used the next time the system is powered up. These settings can all be easily

changed, as will be described fully in the following sections.

Topics include:

Operation of 1919-R with Thermopile Absorber Sensors

Measuring Laser Power with Thermopile Sensors

Measuring Laser Energy with Thermopile Sensors

Measuring Laser Pulsed Power with Thermopile Sensors

Supported Models

1919-R User Manual 31

Page 33

Thermopile Sensors

5.1 Operation of 1919-R with Thermopile Absorber Sensors

To use 1919-R with Thermopile sensors:

1. Connect the Thermopile sensor to the 1919-R meter: Insert the 15 pin D type connector of the

measuring sensor cable into the socket marked Sensor Input on the rear panel of the 1919-R

meter. 1919-R will reconfigure itself to work with the attached sensor.

2. All of the sensor’s measurement parameters are shown on the main screen. (These are also

available when you press the Menu button and select Sensor). Use the Navigation keys to

navigate to the parameter you want to change.

3. Use the up (↑) /down (↓) Navigation keys to select the parameter to change and press the

Enter key. Change the setting with the Navigation keys.

4. Press the Enter key to save the settings.

Note: The 1919-R automatically saves the current settings for the next power up.

Warning: Do not exceed maximum sensor limits for power, energy, power density, and energy

density as listed in Sensor Specifications. Otherwise, there is a risk of damaging the absorber.

5.2 Measuring Laser Power with Thermopile Sensors

When measuring laser power, center the laser beam carefully on the absorber surface and read

the power.

Power measurements can be displayed in Bargraph, Needle, Line, Statistics, or Pass/Fail graphical

formats (by pressing Menu > Display and choosing the Graph Type). Updating measurement

parameters is performed in the main measurement screen. A sample is shown in Figure 5-2 below

at the end of this procedure.

To measure laser power when using Thermopile sensors:

1. Set Mode to Power. The measuring mode is set to Power, and you can specify the expected

laser Range, Laser setting, and Average power period. (The power is measured 15 times per

second.)

Figure 5-1 Setting the Measurement Mode to Power

2. Set Range to AUTO or to one of the manual ranges, as follows:

AUTO: Select autoranging when the laser power is unknown or varies widely. In autorange,

you do not have to change scales. When the reading of the meter or bar is more than

100% of full scale, the range goes to the next higher one. The ranges are arranged in

factors of 1, 10, 100, and so on. When the reading falls below 9% of full scale, the range

changes to one range lower. This change only occurs after a few seconds delay. This

provides overlap (hysteresis) to keep the 1919-R from flipping back and forth when

reading close to the end of the scale.

Manual range: The correct manual range is the lowest one that is larger than the expected

maximum power of the laser. There are certain disadvantages to autorange, since it

changes scale even if you do not want it to do so. If you want to measure in the same

range all the time, it is better to use a manual range.

1919-R User Manual 32

Page 34

Thermopile Sensors

3. Set Laser to the appropriate laser setting.

4. Set Average to the period you wish to average power over or set to NONE to disable. This

feature is especially useful for lasers with unsteady output. (The Average can also be

configured in the Functions screen.)

Figure 5-2 below shows a sample bargraph showing laser power measurements.

Figure 5-2 Thermopile Power in Bargraph Display

Note: The soft key legend options such as Zoom, Offset, Persist, Reset vary per Graph Type.

5.3 Measuring Laser Energy with Thermopile Sensors

In addition to power, Thermopile sensors can be used to measure single shot energy as well,

where they integrate the power flowing through the disc over time and thus measure energy.

Since the typical time it takes for the disc to heat up and cool down is several seconds, these

Thermopile sensors can only measure one pulse every several seconds at most. Thus they are

suitable for what is called “single shot” measurement. Although the response time of the sensor

discs is slow, there is no limit to how short the pulses measured are since the measurement is of

the heat flowing through the disc as a result of the pulse.

Energy measurements can be displayed in Bargraph, Needle, Line, Statistics, or Pass/Fail graphical

formats (by pressing Menu > Display and choosing the Graph Type). Updating measurement

parameters is performed in the main measurement screen. A sample is shown in Figure 5-3 below

at the end of this procedure.

To measure single shot energy when using Thermopile sensors:

1. Set Mode to Energy. The measuring mode is set to Energy, and you can specify the expected

laser Range, Laser setting, and Threshold.

2. Set Range to the appropriate manual range. (In Energy mode, there is no autoranging.) The

correct range is the lowest one that is larger than the expected maximum pulse energy of the

laser.

3. Set Laser to the appropriate laser setting.

4. Set Threshold to change the energy threshold to LOW, MED, or HIGH to set the hardware

threshold in the sensor to screen out noise that would otherwise be seen as energy pulses.

(This screens out false triggers.) The factory setting of the energy threshold is Med for

medium. If the unit triggers on noise, set the threshold to High. If you are measuring small

energies and the unit does not trigger, set the threshold to Low.

If the 1919-R is used in a noisy environment or where there is a high level of background

thermal radiation, the instrument may trigger spuriously on the noise or background radiation.

1919-R User Manual 33

Page 35

Thermopile Sensors

It would then fail to measure the intended pulse. Since there is always some degree of noise

or background radiation, the instrument is designed not to respond to pulses below some

preset minimum size. This "Minimum Energy Threshold" is typically set to 0.3% of full scale of

the selected range. If this level is found to be too sensitive for the user's particular

environment, it may be altered by the user. The threshold should not, however, be raised

higher than necessary. This will cause a degradation in the accuracy of energy measurements

of pulses below about 4 times the threshold level.

5. When the 1919-R screen flashes READY on and off, fire the laser. The display will go blank

while the energy is being integrated. After about 2-4 seconds (depending on the sensor), the

correct energy will be displayed.

6. Return to Step 1 for the next measurement.

Figure 5-3 below shows a sample analog Needle display showing laser energy measurement

data with options for Zoom, Offset, and Persistence. (Click the above links for more details.)

Figure 5-3 Thermopile Energy in Needle Display

Note: The soft key legend options such as Zoom, Offset, Persist, Reset vary per Graph Type.

5.3.1 Measuring Pulses of Very Low Energy

When it is necessary to measure pulses of very low energy, i.e., less than 0.5% of the maximum

range of the instrument, the following two alternative methods allow greater accuracy to be

obtained.

A continuous train of pulses may be fired, and the average power measured using Power

mode. The energy per pulse can be calculated by:

Average Energy per pulse = Average power / Pulse Repetition Rate

A train of a known number of pulses may be fired, and the total energy measured in Energy

mode. This train should not exceed 5 seconds duration. The energy per pulse can be calculated

by:

Average Energy per pulse = Total Energy / Number of Pulses

In both of the above methods, the pulse repetition rate must exceed 3Hz. Higher rates will

generally give improved accuracy, but care should be taken not to exceed maximum power

ratings.

1919-R User Manual 34

Page 36

Thermopile Sensors

5.3.2 Measuring Energy of Rapidly Repeating Pulses

With a typical Thermopile sensor, 1919-R will only measure individual pulses every 5 seconds or

so. You can also calculate the average energy of rapidly repeating pulses by measuring average

power on the power setting and using the formula:

Average Energy per Pulse = Average Power / Pulse Repetition Rate

For rapidly repeating pulses, you can use one of the Newport Pyroelectric sensors, as long as the

pulse energies do not exceed the ratings of the Pyroelectric absorbers. The Pyroelectric sensors

are compatible with 1919-R and just have to be plugged in to be used.

5.4 Measuring Laser Pulsed Power with Thermopile Sensors

Thermopile Energy Sensor models are capable of measuring “Pulsed Power” in order to display

instantaneous power of a laser pulse. Power can be calculated from energy if you know the length

of the pulse.

Note: Accuracy of measurement will be dependent on your setting the pulse width correctly.

To measure laser pulsed power when using Thermopile sensors:

1. Set Mode to Pulsed Power. The measuring mode is set to Pulsed Power, and you can specify

the expected energy Range, Laser setting, and Threshold.

2. Set Range to the appropriate manual range. (In Energy mode, there is no autoranging.) The

correct range is the lowest one that is larger than the expected maximum pulse energy of the

laser.

3. Set Laser to the appropriate laser setting.

4. Set Pulse Length to the correct pulse length. Using the up/down Navigation keys to change

each number and the right/left keys to move to the next number, key in the pulse length you

want. (The range is 0.1 to 10 seconds in increments of 0.1. The default is 1.0 seconds.) When

finished, press the Enter key.

5. Set Threshold to change the energy threshold to LOW, MED, or HIGH to set the hardware