Page 1

1830-C

Optical Power Meter

I

NSTRUCTION

M

ANUAL

Page 2

1830-C Optical Power Meter

Page 3

Warranty

Warranty

Newport Corporation warrants this product to be free from defects in material and workmanship for a period of 1 year from the date of shipment. If

found to be defective during the warranty period, the product will either be

repaired or replaced at Newport’s option.

To exercise this warranty, write or call your local Newport representative, or

contact Newport headquarters in Irvine, California. You will be given prompt

assistance and return instructions. Send the instrument, transportation

prepaid, to the indicated service facility. Repairs will be made and the

instrument returned, transportation prepaid. Repaired products are warranted for the balance of the original warranty period, or at least 90 days.

Limitation of Warranty

This warranty does not apply to defects resulting from modification or misuse

of any product or part. This warranty also does not apply to fuses, batteries,

or damage from battery leakage.

This warranty is in lieu of all other warranties, expressed or implied, including

any implied warranty of merchantability or fitness for a particular use.

Newport Corporation shall not be liable for any indirect, special, or consequential damages.

Statement of Calibration

This instrument has been inspected and tested in accordance with specifications published by Newport Corporation.

The accuracy and calibration of this instrument and photodetector (where

applicable) is traceable to the National Institute for Standards and Technology through equipment which is calibrated at planned intervals by comparison to the certified standards maintained at Newport Corporation.

© 1994 Newport Corporation

P/N 20372-01, Rev. H

IN-07941 (07-00)

ii

ii

Page 4

EC DECLARATION OF CONFORMITY

Model 1830-C

We declare that the accompanying product, identified with the

" " mark, meets the intent of the Electromagnetic Compatibility

Directive, 89/336/EEC and Low Voltage Directive 73/23/EEC.

Compliance was demonstrated to the following specifications:

EN50081-1 EMISSIONS:

Radiated and conducted emissions per EN55011, Group 1,

Class A

EN50082-1 IMMUNITY:

Electrostatic Discharge per IEC 1000-4-2, severity level 3

Radiated Emission Immunity per IEC 1000-4-3, severity level 2

Fast Burst Transients per IEC 1000-4-4, severity level 3

Surge Immunity per IEC 1000 4-5, severity level 3

IEC SAFETY:

Safety requirements for electrical equipment specified in

IEC 1010-1.

Alain Danielo Jeff Cannon

VP European Operations General Manager-Precision Systems

Zone Industrielle 1791 Deere Avenue

45340 Beaune-la-Rolande, France Irvine, CA USA

iii

Page 5

Table of Contents

Warranty ................................................................................................................ ii

EC Declaration of Conformity .............................................................................iii

List of Figures ...................................................................................................... vii

List of Tables ....................................................................................................... vii

Safety Symbols and Terms ................................................................................ viii

Definitions ............................................................................................................. ix

Specifications......................................................................................................... x

Section 1 — General Information

1.1 System Overview ...................................................................................... 1

1.2 Scope of this Manual ................................................................................ 2

1.3 Unpacking and Inspection ....................................................................... 2

1.4 Preparation for Use .................................................................................. 2

Section 2 — Initial Setup

2.1 Introduction .............................................................................................. 3

2.2 Setting the Line Voltage Selector Switch ............................................... 3

2.3 Detector Connection and Setup ............................................................. 4

2.4 Configuring the Computer Interface ...................................................... 4

2.5 Power Up / Auto-Calibration ................................................................... 5

Section 3 — System Operation

3.1 Introduction .............................................................................................. 6

3.2 Digital Display ........................................................................................... 6

3.3 Front Panel Key Functions ...................................................................... 8

3.3.1 LOCAL (R/S) Local Mode & Run / Stop ......................................... 9

3.3.2 ZERO Offset Subtraction .................................................... 9

3.3.3 UNITS Display Units ............................................................. 9

3.3.4 STOREF Store Reference Value ........................................... 10

3.3.5 AVG Numerical Averaging ............................................. 10

3.3.6 λ䉱 Wavelength Increment .......................................... 10

3.3.7 λ䉲 Wavelength Decrement ......................................... 11

3.3.8 Power ....................................................................... 11

3.3.9 ATTN Optical Attenuator ................................................. 11

3.3.10 BKLT Backlight .................................................................. 11

3.3.11 BEEP Audible Beeper ....................................................... 11

3.3.12 AUTO Automatic Gain Ranging ........................................ 11

3.3.13 RANGE䉱 Manual Range Up ................................................... 12

3.3.14 RANGE䉲 Manual Range Down .............................................. 12

3.4 Default Meter Configuration.................................................................. 12

iv

Page 6

Section 4 — Performing Measurements

4.1 Introduction ............................................................................................ 13

4.2 Photodetector Considerations ............................................................. 13

4.2.1 Detector Calibration and Accuracy............................................ 13

4.2.2 Quantum Detector Temperature Effects ................................... 14

4.2.3 Ambient and Stray Light .............................................................. 14

4.3 Setting the Wavelength .......................................................................... 15

4.4 Setting the Attenuator Mode ................................................................. 15

4.5 Performing Basic Measurements.......................................................... 16

4.5.1 Power Measurements .................................................................. 16

4.5.2 Logarithmic Measurements (dB and dBm) ............................... 16

4.5.2.1 Logarithmic Measurements Using Reference Powers (dB) . 17

4.5.2.2 Logarithmic Measurements Using 1 mW Reference (dBm) . 17

4.5.3 Relative Measurements ............................................................... 18

4.6 Common Measurement Errors ............................................................. 19

Section 5 — Computer Interfacing

5.1 Introduction ............................................................................................ 20

5.2 Computer Interface Terminology ......................................................... 20

5.3 Entering Remote Computer Interface Mode ....................................... 21

5.4 RS-232C Communication........................................................................ 22

5.4.1 Setting the Baud Rate .................................................................. 23

5.4.2 RS-232C Command Termination ................................................. 23

5.4.3 General Guidelines for Using the RS-232C Port ........................ 24

5.5 GPIB Communication ............................................................................. 24

5.5.1 Setting the GPIB Address ............................................................ 24

5.5.2 GPIB Command Termination ...................................................... 25

5.5.3 General Guidelines for Using the GPIB Port ............................. 26

5.5.4 Procedure for Reading Only New Measurements .................... 26

v

Page 7

Section 6 — Remote Command Set

6.1 Summary of Command/Query Set ........................................................ 27

6.2 Detailed Description of Commands and Queries ............................... 29

An Attenuator on/off ................................................................ 29

A? Attenuator query................................................................. 29

Bn Beeper on/off ........................................................................ 30

B? Beeper query ....................................................................... 30

C Clear Status Byte Register .................................................. 30

D? Data query............................................................................ 31

En Echo mode on/off—( RS-232C interface only) .................. 31

E? Echo mode query ................................................................ 31

Fn Filter ( same as averaging ) Slow, Medium, Fast .............. 32

F? Filter (same as averaging) status query .......................... 32

Gn Go on/off (Run/Stop signal acquistition) .......................... 33

G? Go query ............................................................................... 33

Kn Keypad / Display Backlight on/off ..................................... 34

K? Keypad / Display Backlight intensity level query ............ 34

Ln Local-lockout on/off ............................................................. 35

L? Local-lockout query ............................................................ 35

Mn Service Request Enable Register (mask) .......................... 36

M? Service Request Enable Register query ............................ 37

O Auto-Calibration ................................................................... 37

Q? Status Byte Register query ................................................. 38

Rn Range setting ........................................................................ 39

R? Range query .......................................................................... 40

S Store reference ..................................................................... 40

Un Units....................................................................................... 41

U? Units query ........................................................................... 41

Wnnnn Set wavelength to nnnn ....................................................... 42

W? Wavelength query ................................................................ 42

Zn Zero on/off ............................................................................ 43

Z? Zero function query ............................................................. 43

Section 7 — Troubleshooting and Maintenance

7.1 Troubleshooting Guide .......................................................................... 44

7.2 Cleaning Procedure ................................................................................ 45

7.3 Re-Calibration Schedule ........................................................................ 45

Section 8 — Factory Service

8.1 Introduction ............................................................................................ 46

8.2 Obtaining Service ................................................................................... 46

Appendices

A Status Reporting System ....................................................................... 49

B Sample Programs .................................................................................... 52

B.1 Example Program for RS-232C Communication ....................... 52

B.2 Example Program for IEEE 488 Communication ...................... 55

C Simplified 1830-C Functional Block Diagram....................................... 58

vi

Page 8

List of Figures

1. 1830-C Power Meter and Compatible Detectors................................... 1

2. Line Voltage Selector Switch................................................................... 3

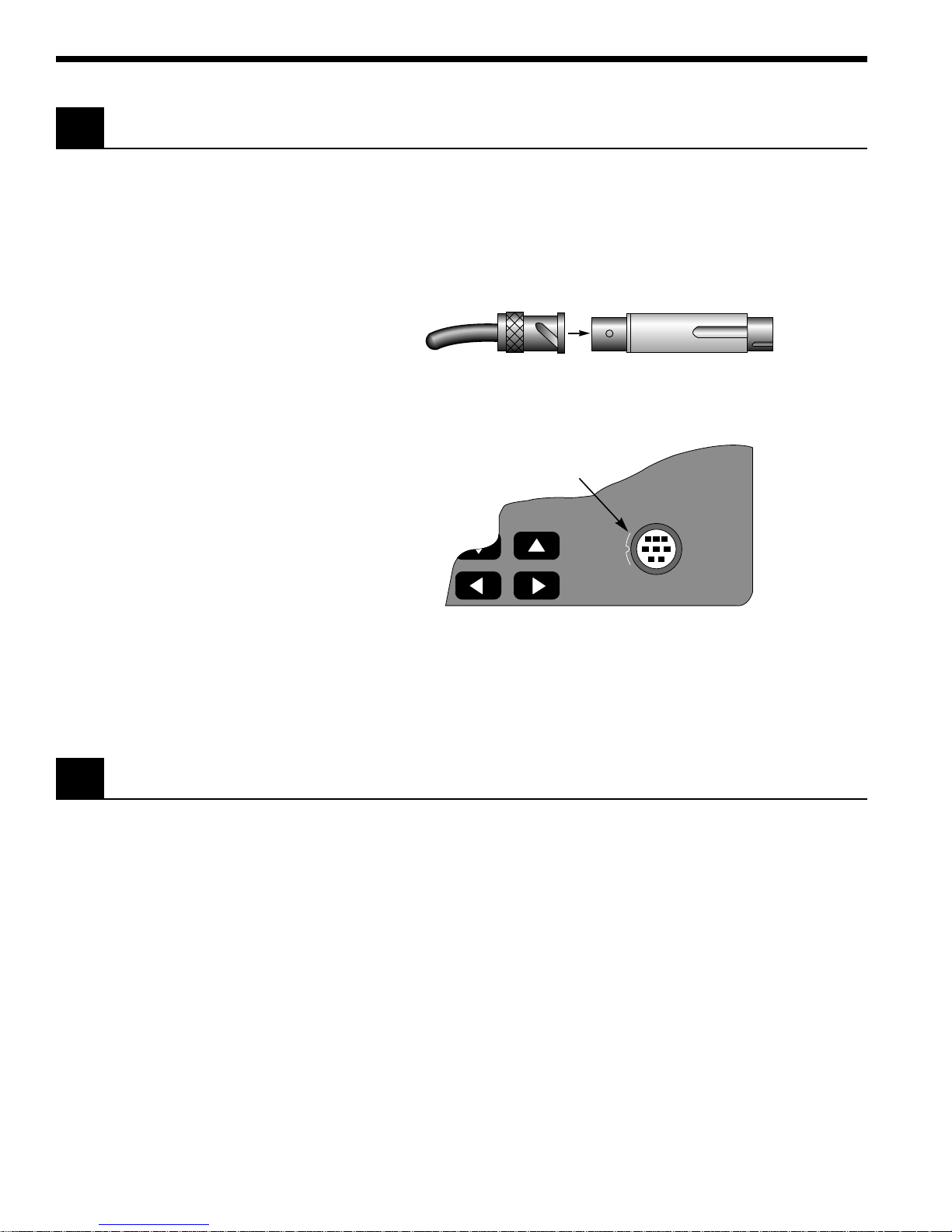

3. Connecting a Detector with its Calibration Module............................. 4

4. Calibration Module Connector Port ....................................................... 4

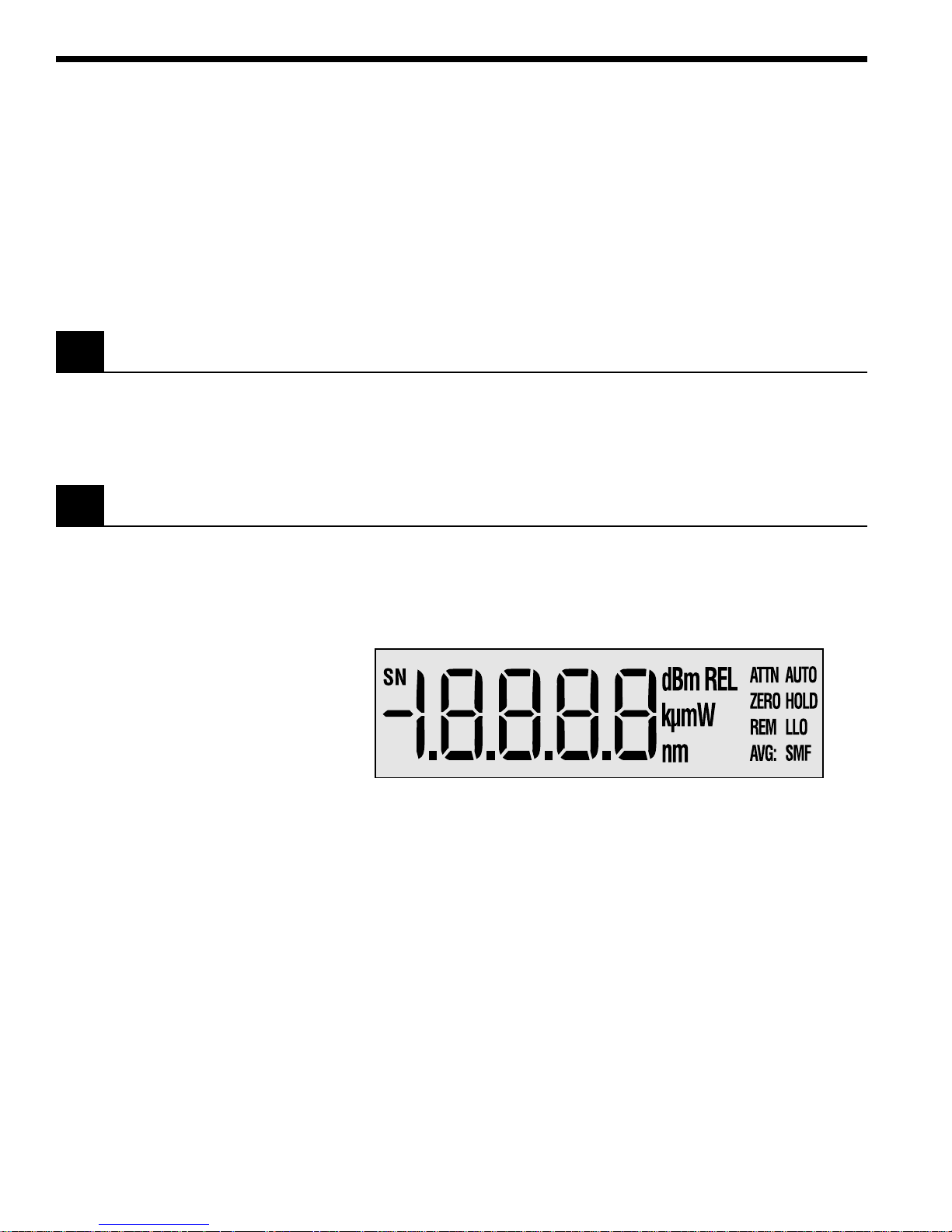

5. The 1830-C Liquid Crystal Display ......................................................... 6

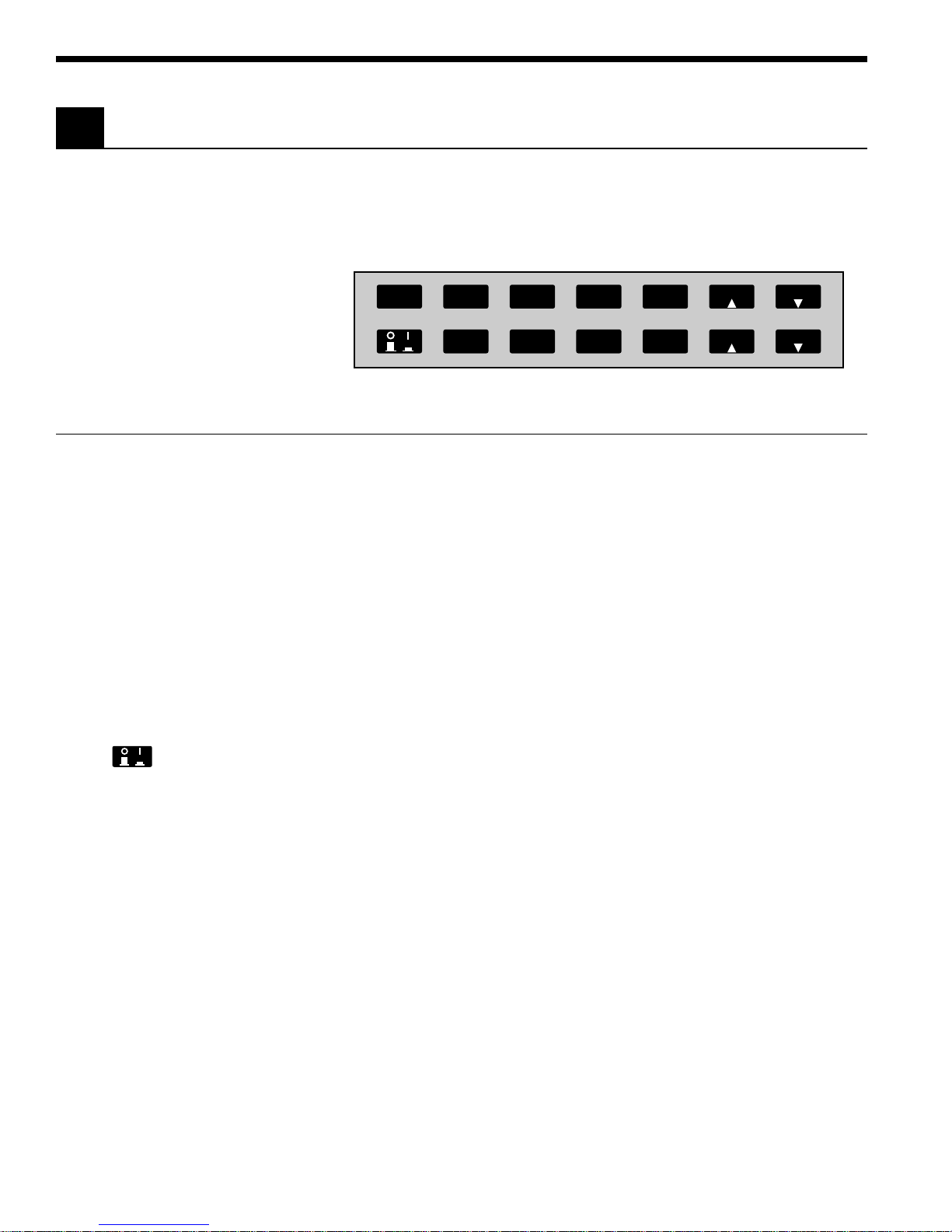

6. Front Panel Key Pad ................................................................................. 8

7. RS-232C Cable Connections................................................................... 22

8. RS-232C Baud Rate Selector Switches.................................................. 23

9. GPIB Address Selector Switches .......................................................... 25

10. The 1830-C’s Status Reporting System for the GPIB Bus ................... 49

11. Simplified Functional Block Diagram ................................................... 58

List of Tables

1. Measurement Modes ................................................................................ x

2. 1830-C Display Annunciators/Messages ................................................ 7

3. 1830-C Key Functions and Associated Remote Commands ................ 8

4. 1830-C Default Power-up Conditions.................................................... 12

5. Common Measurement Errors ............................................................. 19

6. Symptom/Fault Troubleshooting Guide .............................................. 45

vii

Page 9

Safety Symbols and Terms

The following safety terms are used in this manual:

The WARNING heading in this manual explains dangers that could result in

personal injury or death.

The CAUTION heading in this manual explains hazards that could damage

the instrument.

In addition, a NOTES heading gives information to the user that may be

beneficial in the use of this instrument.

GENERAL WARNINGS AND CAUTIONS

The following general warnings and cautions are applicable to this instrument:

This instrument is intended for use by qualified personnel who recog-

nize shock hazards or laser hazards and are familiar with safety

precautions required to avoid possible injury. Read the instruction

manual thoroughly before using, to become familiar with the

instrument’s operations and capabilities.

WARNING

WARNING

The American National Safety Institute (ANSI) states that a shock

hazard exists when probes or sensors are exposed to voltage levels

greater than 42VDC or 42V peak AC. Do not exceed 42V between any

portion of the Model 1830-C (or any attached detector or probe) and

earth ground or a shock hazard will result.

CAUTION

There are no user serviceable parts inside the Model 1830-C. Work

performed by persons not authorized by Newport may void the

warranty. For instructions on obtaining warranty repair or service

please refer to Section 8 of this manual.

viii

Page 10

Definitions

A amps

ADC analog-to-digital converter

BNC standard coaxial connector type

degree C degrees Centigrade

Hz Hertz (cycles per second)

k kilo (103)

kHz kilohertz

kΩ kilo-ohms

µ micro (10

m milli (10-3)

mA milliamps

mV millivolts

n nano (10-9)

nA nanoamps

nm nanometers

RH relative humidity

S/N serial number

µA microamps

µs microseconds

V volts

W watts

--6

)

ix

Page 11

Specifications

Dimensions: 3.7 x 7.5 x 9.0 in. (94 x 191 x 229 mm )

Weight: 5 lb ( 2.3 kg )

Enclosure: Metal case, painted

Connectors: Calibration Module: 8-Pin Sub Mini DIN

Analog Output: BNC

RS-232: 9 pin D-Sub

GPIB: 24 Conductor D

Power : 100-120, 220-240 VAC ±10%, 50/60 Hz

Absolute Maximum Line

Current Rating: 200 mA

Signal Ranges: Up to 8 decades (dependent on detector type)

Display: 4.5 digit, annunciated, backlit, wide angle view LCD

Display Update Rate: 75 ms

Auto-Ranging Time: 200 ms (typical)

GPIB Bus Transfer Time: 10 ms (typical)

Operating Environment: 0 to +40 degree C; < 70% RH noncondensing

Storage Environment: −20 to +60 degree C; < 90% RH noncondensing

Compatible Detectors: Low-Power (Semiconductor) Family

Signal Range

Full-Scale Current

1, 2

12345678

3

2 nA 20 nA 200 nA 2 µA 20 µA 200 µA 2 mA 5 mA

Gain 1000 M 100 M 10 M 1 M 100 k 10 k 1 k 100

Resolution 0.1 pA 1 pA 10 pA 100 pA 1 nA 10 nA 100 nA 1 µA

Analog Bandwidth 35 Hz 35 Hz 1.5 kHz 1.5 kHz 5 kHz 15 kHz 10 kHz 20 kHz

Full-Scale Accuracy

4

0.2 % 0.2 % 0.2 % 0.2 % 0.2 % 0.2 % 0.2 % 0.2 %

(Typical)

Full-Scale Accuracy

4

0.4 % 0.4 % 0.4 % 0.4 % 0.4 % 0.4 % 0.4 % 0.4 %

(Worst Case)

1

Listed signal ranges specify meter capability. Available signal ranges are detector dependent.

2

Maximum measurable signal is detector dependent. See description of detector saturation message “SA” in Table 2.

3

Full scale current may vary due to the Auto-Calibration compensation of amplifier DC offsets.

4

After 60 minute warm-up, followed by execution of an Auto-Calibration. See Section 2.5 and Section 6.2 (“O” Command).

Analog Output

Full-Scale Voltage: 2V into 1MΩ

Full-Scale Accuracy: ±1%

Maximum AC Noise: Range 1: <4 mV

(open input) Ranges 2-8: <1 mV

p-p

p-p

x

Page 12

Display Display

Calculation Unit Comment

I/R W ZERO Disabled

(I-Iz)/R W ZERO Enabled

101log

/IR

mW

dBm ZERO Disabled

(

101log

10 log

I

STOREF

10 log

II

STOREF Z

I

I

STOREF

II

−

Z

II

−

STOREF Z

−

Z

mW

I

−

II

/II R

)

Z

−

dBm ZERO Enabled

dB ZERO Disabled

dB ZERO Enabled

REL ZERO Disabled

REL ZERO Enabled

Where I = detector current

Iz= detector background current defined when the

ZERO key was pressed

R = responsivity of the detector (A/W)

I

STOREF

= referenced detector current defined when the

STOREF key was pressed

Table 1. Measurement Modes

xi

Page 13

xii

Page 14

Section 1

General Information

1.1 System Overview

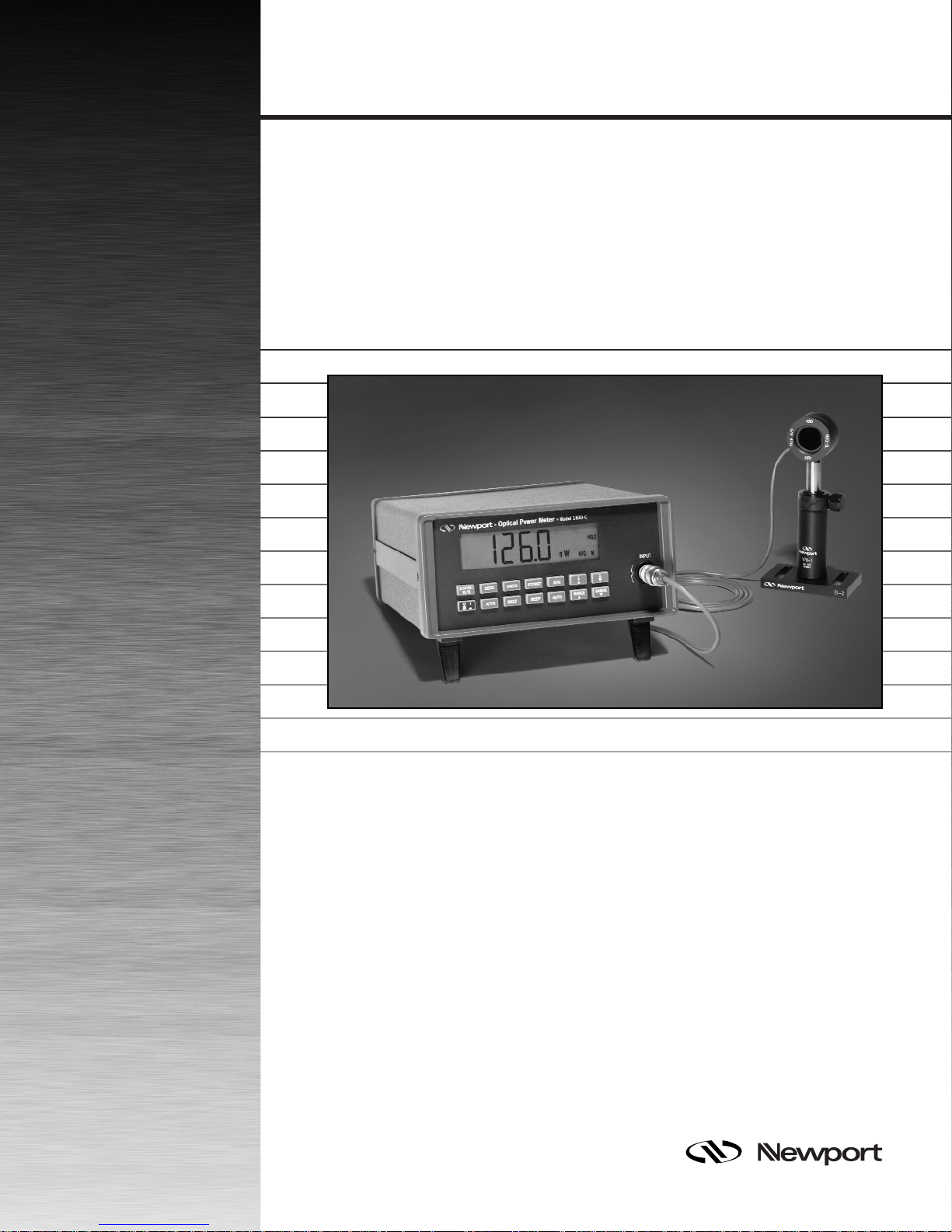

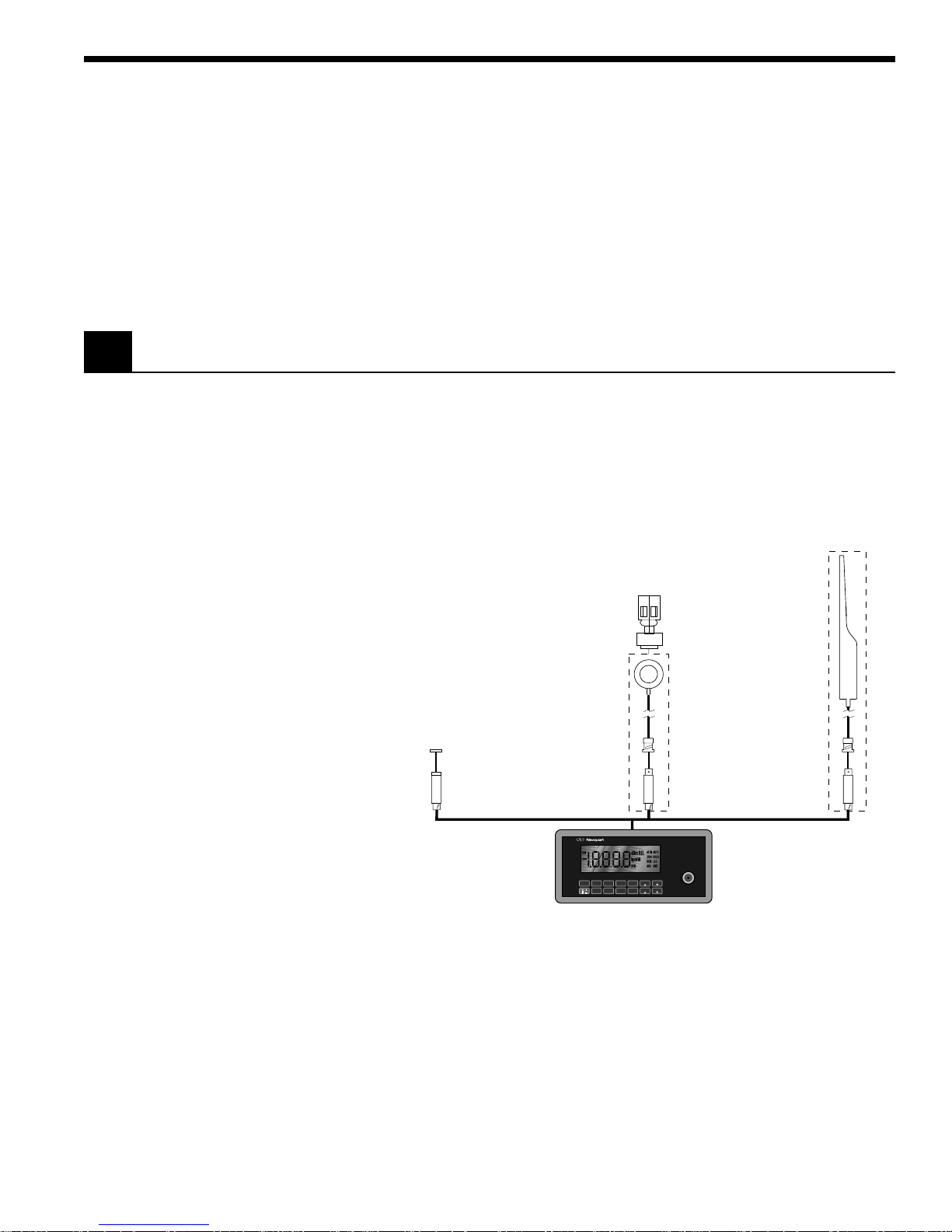

The 1830-C Optical Power Meter is a ±20,000 count A/D resolution, autoranging picoammeter. Measurements are displayed on a large 4 1/2 digit

liquid crystal display (LCD) and can also be taken remotely via the RS-232C

port or the IEEE 488 GPIB bus. The 1830-C is designed to take continuous

wave optical power measurements and is compatible with all of Newport’s

Low-Power Semiconductor photodetectors. A family tree of the 1830-C

compatible detectors and accessories is shown in Figure 1 below.

FP3-FH1

818-FA2

818-UV/CM

818-SL/CM

818-IR/CM

818-FA3-SMA

818-FA3-ST

818-FA3-FC

818-F-SL

818-F-IR

■

Optical Power Meter ■

Model 1830-C

(LOCAL)

R/S

AVG

STOREF

UNITSZERO

BEEPBKLT

ATTN

AUTO

INPUT

RANGEλλRANGE

818-ST/CM

Figure 1. 1830-C Power Meter and Compatible Detectors

Detectors connect to the 1830-C through a calibration module, in which the

responsivities and other information unique to the detectors is stored.

Calibration modules are ordered with the detectors at the time of purchase

and are labeled with the detectors’ model number and serial number.

Detectors with calibration modules have a “/CM” appended to their model

number.

EXAMPLE: 818-SL (no calibration module)

818-SL/CM (with calibration module)

1

Page 15

1.2 Scope of this Manual

1.3 Unpacking and Inspection

Please carefully read this instruction manual before using the 1830-C. Be

especially careful to observe the warnings and cautions throughout this

manual (see Safety Symbols and Terms). If any operating instructions are

not clear, contact Newport Corporation.

This instruction manual contains the necessary information for operation

and maintenance of the 1830-C, as well as information for troubleshooting

and obtaining service if necessary. This information is divided into the

following sections:

Section 1 General Information

Section 2 Initial Setup

Section 3 System Operation

Section 4 Performing Measurements

Section 5 Computer Interfacing

Section 6 Remote Command Set

Section 7 Troubleshooting and Maintenance

Section 8 Factory Service

1.4 Preparation for Use

All 1830-C meters are carefully assembled, tested and inspected before

shipment. Upon receiving this instrument, check for any obvious signs of

physical damage that might have occurred during shipment. Report any

such damage to the shipping agent immediately.

NOTE

Retain the original packing materials in case reshipment becomes necessary.

The 1830-C should have some basic operations performed before measurements are made. These include:

Setting the Line Voltage Selector Switch ( Section 2.2)

Detector Connection and Setup ( Section 2.3)

2

Page 16

Section 2

LINE SELECT

230V

115 V

100–120V 50–60 Hz, 0.25A, SLO- BLO, 250V

220–240V 50–60 Hz, 0.25A, SLO- BLO, 250V

FUSE

Initial Setup

2.1 Introduction

This section contains information on how to configure the 1830-C to your

local line voltage and how to connect the detector and calibration module

to the meter. It also includes a short discussion about the remote interface

and the 1830-C’s power-up and auto-calibration.

2.2 Setting the Line Voltage Selector Switch

The 1830-C can be configured to operate with line voltages of 100-120 VAC

and 220-240 VAC, and line frequencies between 50-60 Hz. Before turning the

meter on, configure it to the local voltage by setting the voltage selection

switches on the 1830-C back panel to match the nominal local voltage. See

Figure 2. Plug the AC line power cord to the rear of the 1830-C and then

connect the cord to AC power.

Figure 2. Line Voltage Selection Switch

WARNING

This product is equipped with a 3 wire grounding type plug. Any

interruption of the grounding connection can create an electric shock

hazard. If you are unable to insert the plug into your wall plug receptacle, contact your electrician to perform the necessary alterations to

assure that the green (green-yellow) wire is attached to earth ground.

3

Page 17

2.3 Detector Connection and Setup

Connect the detector to its calibration module as shown in Figure 3. The

detector’s model and serial numbers must match the model and serial

numbers found on the calibration module. Insert the calibration module,

with its groove facing left, into the connector port on the front panel of the

1830-C, as shown in Figure 4. An alignment pin assures the proper orientation of the calibration module.

Detector Cable BNC Calibration Module

Figure 3. Connecting a Detector with its Calibration Module

Plug calibration

module into this port.

INPUT

Always power off the meter before removing or inserting the calibration

module.

2.4 Configuring the Computer Interface

The RS-232C baud rate and the IEEE 488 GPIB address must be properly set

via the back panel system switches if either interface is to be used. Please

refer to Section 6 for detailed instructions.

Figure 4. Calibration Module Connector Port

NOTE

4

Page 18

2.5 Power Up / Auto Calibration

Turn on the 1830-C by depressing the red power switch, located in the lower

left-hand corner of the front panel, until it clicks and remains in its depressed

position. At power-up, the 1830-C will perform the following sequence:

1) Momentarily display all the segments on the display

2) Display the software version number

3) Perform an Auto-Calibration, designated by displaying CAL on the

4) Display the serial number of the detector/calibration module

5) Display the wavelength to which the meter is set (If no calibration

The auto-calibration process involves measuring amplifier offset voltages

which arise from aging and temperature effects. These offsets are then

appropriately corrected for during normal operation. The 1830-C will

automatically disconnect the input signal from the amplifier during the

auto-calibration mode. To achieve stable readings at the specified accuracy, auto-calibration should be executed after a minimum 60 minute warmup period. This can be done either by resetting the 1830-C with the RESET

button on the back of the meter, or by sending the auto-calibration remote

command, O.

display

(If no calibration module is installed, the meter will display 000 as the

serial number.)

module is installed, the meter will display 0257nm as the wavelength.)

NOTE

The 1830-C must be powered-up with the calibration module connected to

the meter in order for the calibration data to be downloaded into the 1830-C.

Always power off the meter before removing or inserting the calibration

module.

5

Page 19

Section 3

System Operation

3.1 Introduction

3.2 Digital Display

This section contains the information needed to operate the 1830-C power

meter, via the front panel key pad. The meanings of the display annunciators and the operation of all keys are discussed later in this section.

The 1830-C has a large 4-1/2 digit, back-lit liquid crystal display (LCD)

which can be seen at large angles of view. Figure 5 illustrates the layout of

the 1830-C’s display. Table 2, on the following page, explains the meaning of

the various annunciators and messages on the display.

Figure 5. The 1830-C Liquid Crystal Display

6

Page 20

Annunciator/Message Comment

SN This annunciator denotes serial number and is displayed at turn-on when

the detector’s serial number is displayed.

dBm This annunciator specifies that either dB or dBm measurements are being

displayed.

REL This annunciator specifies that relative measurements are being displayed.

k µ m Only one of the characters of this annunciator will light at any time to specify

engineering prefixes of kilo, micro, nano, or milli. The “m” in this annunciator

serves as both “m” and “n”.

W This annunciator specifies that measurements in units of watts are being

displayed.

nm This annunciator indicates nanometer whenever the wavelength is displayed.

ATTN The responsivity in use includes the effect of the detector’s OD3 attenuator.

AUTO Automatic signal ranging is activated.

ZERO Background signal subtraction (zeroing) is activated.

HOLD No new readings will be displayed, nor be available on the remote interface bus.

REM The meter has received a command/query either through the IEEE 488 or

the RS-232C bus.

LLO The meter has been set to local-lockout from the remote interface bus and

will not respond to any front panel keys.

AVG: S M F Either Slow, Medium, or Fast numerical averaging for the displayed

measurement is activated.

OL This message indicates that the input signal level exceeds the capability of

the present signal range. Either use auto-ranging or increment the signal

range until the OL message goes away.

SA This message indicates that the input signal level exceeds the specified

saturation current of the detector being used with the meter. This level is

detector dependent.

CAL This message indicates that the meter is currently performing an auto-

calibration. The auto-calibration process involves measuring amplifier offset

voltages. See Section 2.5 for more details.

Table 2. 1830-C Display Annunciators/Messages

7

Page 21

3.3 Front Panel Key Functions

The front panel key pad of the 1830-C, Figure 6, provides access to all the

basic measurement functions. Table 3 and Sections 3.3.1 through 3.3.14 list

and describe in detail each key function. For power-up default conditions,

please see Table 4 at the end of this section.

(LOCAL)

R/S

ZERO

ATTN

UNITS

BKLT

STOREF

BEEP

AVG

AUTO

RANGE RANGE

λλ

Figure 6. Front Panel Key Pad

Keypad Remote Command Description

(LOCAL) L0 Enables local mode.

R/S G0, G1 Run/Stop signal acquisition.

ZERO Z0, Z1 Zero the display by subtracting the present reading from all

subsequent readings.

UNITS U1-U4 Cycles between the four available measurement units (Watt, dB,

dBm, Relative).

STOREF S Stores last measurement for future dB or relative measure-

ments.

AVG F1-F3 Cycles between Slow, Medium, or Fast numerical averaging of

readings that are within a certain percentage of each other.

λ 䉱 Wnnnn Increments the calibration wavelength in use.

λ 䉲 Wnnnn Decrements the calibration wavelength in use.

None Turns the meter on/off.

ATTN A0, A1 Sets the responsivity value for either:

BKLT K0, K1, K2 Cycles the display backlight brightness between Off, Medium,

BEEP B0, B1 Turns the variable frequency beeper on/off.

AUTO R0, R1-R8 Turns the automatic signal ranging on/off.

RANGE 䉱 Rx Increments the signal range and disables the automatic signal

RANGE 䉲 Rx Decrements the signal range and disables the automatic signal

Table 3. 1830-C Key Functions and Associated Remote Commands

1) detector alone, or

2) detector and OD3 optical attenuator.

or High.

ranging.

ranging.

8

Page 22

3.3.1

(LOCAL)

R/S

Local Mode

Run / Stop

This key serves two purposes:

1) When the meter receives a command through either the RS-232C or the

IEEE 488 GPIB interface, the meter is automatically put into remote

mode and the REM annunciator is displayed. Now all front panel keys

are disabled except this (LOCAL) key which, when pressed, puts the

meter back into the local mode. The meter can also be put in the local

mode by sending the remote command, L0.

2) When the meter is in the local mode, pressing this key will toggle

between run/stop acquisition modes. The HOLD annunciator is displayed when the meter is in the stop acquisition mode.

3.3.2

ZERO

Offset Subtraction

This key turns the offset subtraction on and off. When turned on, the ZERO

annunciator is displayed and the last measurement is saved as Pz and

subtracted from all subsequent measurements P. This causes subsequent

measurement calculations shown on the display and available on the

remote interface to use the value ( P− Pz) instead of P.

Offset subtraction allows one to remove the effects of ambient DC signals,

by zeroing the display before making a measurement. A second ZERO key

press turns off the ZERO annunciator and stops offset subtraction.

3.3.3

UNITS

Display Units

Measurements can be displayed in units of watts W, decibels dB or dBm,

and relative REL. Pressing the UNITS key repeatedly cycles the display

through these four units.

The W mode is a straightforward measurement which converts the current

from the detector into a power reading via the responsivity of the detector

at the set wavelength.

The dB mode uses the relationship dB = 10 * log( P / P

most recent measurement and P

is the reference measurement. At power-

ref

), where P is the

ref

up the reference for the dB mode is a level equivalent to 1mW. This can be

changed by pressing STOREF, which makes the most recent measurement

the new P

.

ref

The dBm mode uses the relationship dBm = 10 * log( P / 1mW ), where P is

the most recent measurement.

The REL mode uses the relationship ( P / P

measurement and P

is the reference measurement. At power-up the

ref

), where P is the most recent

ref

reference for the REL mode is a level equivalent to 1mW. This can be

changed by pressing STOREF, which makes the most recent measurement

the new P

.

ref

When the engineering prefixes n, µ, m and k are displayed in the REL

mode, they multiply the reading on the display by their appropriate

weights. For example, a display of 1.8300µ

REL

means ( P/ P

) * 10−6.

ref

9

Page 23

3.3.4

STOREF

Store Reference Value

Pressing STOREF causes the most recent measurement P to be stored as P

ref

for subsequent use in relative measurement calculations. When the units

are dB and STOREF has been pressed, the displayed value is the function

10 * log( P/P

displayed value is the ratio P/P

P

is always a power reading stored in the units of Watts. Pressing STOREF

ref

causes a new P

3.3.5

). When the units are REL and STOREF has been pressed, the

ref

to overwrite the existing P

ref

AVG

Numerical Averaging

.

ref

value.

ref

Pressing AVG causes the numerical averaging feature to cycle through

slow S, medium M, and fast F modes. The slow mode takes the last 16

measurements that are within ±9 counts of the oldest measurement and

averages them for the displayed reading. The medium mode averages the

last 4 measurements, and the fast mode does no averaging.

The averaging buffer is a sliding buffer that always maintains 16 or 4

measurements, depending on the mode. Initially the buffer is completely

filled with the same measurement, and thereafter subsequent measurements replace the older measurements in the buffer. If, at any time, a single

measurement is acquired that is not within ±9 counts of the oldest measurement, the averaging algorithm starts over, not retaining any of the

previous measurements.

3.3.6

λ

Wavelength Increment

Pressing this key once causes the wavelength to be displayed. If the key is

pressed again or held down, the wavelength will increment or scroll,

respectively.

The detector calibration module contains responsivity data at discrete

wavelengths for its associated detector. By entering the wavelength which

is being measured, the correct responsivity value is used by the 1830-C in

calculating the measured power. When a wavelength falls between two

calibration points, linear interpolation is used to approximate the true

responsivity value.

Upon the initial power-up on a new calibration module, the meter defaults

to the shortest wavelength available for that specific detector. Whenever

the calibration wavelength is changed, this new wavelength is written to the

PROM in the calibration module and is used as the default wavelength at

subsequent power-ups.

NOTE:

If the detector and calibration module are changed to a different set, the

power meter must be powered-up again to allow for the downloading of

the new calibration data into the power meter. Always remember to

power off the meter before removing or inserting the calibration module.

10

Page 24

3.3.7

Same as λ except that this key decrements the wavelength.

λ

Wavelength Decrement

3.3.8 Power

This key turns the power to the 1830-C on and off. To turn the meter on,

depress the key until it clicks. To turn the meter off, press the key again

until it clicks and rebounds to its original position.

3.3.9

This key selects whether the responsivity value for the detector-alone, or

the value for the detector-with-attenuator is used. When the attenuator

mode is on, the ATTN annunciator is lit and the responsivity value for the

detector-with-attenuator is used. When the attenuator mode is off, the

ATTN annunciator is off and the detector-alone responsivity value is used.

3.3.10

This key cycles the brightness level of the LCD backlight between off,

medium, and high.

3.3.11

This key turns the variable frequency beeper on and off. The frequency of

this tone varies as a function of the optical power being measured. The

real-time audible feedback is very helpful when trying to maximize optical

through-put.

3.3.12

This key enables and disables the auto-range feature. When auto-range is

enabled, the AUTO annunciator is displayed and the amplifier gain in the

1830-C will be automatically controlled to maximize the analog-to-digital

converter resolution. When auto-range is disabled, the AUTO annunciator

is turned off and the signal range is left in its present state. Signal ranging

can be manually controlled by the RANGE(䉱) and RANGE(䉲) keys, as

described below.

ATTN

BKLT

BEEP

AUTO

Optical Attenuator

Backlight

Audible Beeper

Automatic Signal Ranging

NOTE

The 1830-C has 8 signal ranges (R1-R8) which are one decade apart. The

ranges available are detector dependent. For example, when using the

1830-C power meter with Newport’s 818-IR, the lowest available range is

R3. This is due to the fact that this germanium detector inherently has a

large noise equivalent power (NEP).

11

Page 25

3.3.13

RANGE

Manual Range Up

This key enables the user to manually decrease the amplifier gain by one

decade, allowing the input of larger optical signals without saturating the

amplifier. If the meter is in the auto-range mode just prior to pressing this

key, the meter will be forced into the manual-range mode and the range will

be incremented.

3.3.14

This key enables the user to manually increase the amplifier gain by one

decade. If the meter is in the auto-range mode just prior to pressing this

key, the meter will be forced into the manual-range mode and the range will

be decremented.

3.4 Default Meter Configuration

Upon power-up or pressing the RESET button on the back of the meter, the

1830-C will configure itself as listed in Table 4.

RANGE

Manual Range Down

Keypad Function Default Power-Up Condition

(LOCAL) Local

R/S Signal Acquisition is on. (Run)

ZERO ZERO is off.

UNITS Watts

STOREF 1 mW

AVG Medium Averaging

λ 䉱 Lowest available, or last set wavelength

λ 䉲 Lowest available, or last set wavelength

ATTN ATTN is off. (Detector Alone)

BKLT Medium Brightness

BEEP BEEP is off

AUTO Auto-Ranging enabled

Table 4. 1830-C Default Power-Up Conditions

12

Page 26

Section 4

Performing Measurements

4.1 Introduction

This section contains detailed information on how to make various optical

power measurements with the 1830-C.

4.2 Photodetector Considerations

This section describes detector and attenuator characteristics, optical and

electrical considerations, and environmental influences on optical measurements. In general, the accuracy of measurement with the 1830-C is limited

by the calibration accuracy of the detector calibration. Making accurate

measurements of optical power is however, also dependent upon properly

setting up the 1830-C, controlling temperature and illumination conditions,

and understanding the factors that affect power measurement.

4.2.1 Detector Calibration and Accuracy

Newport Corporation calibrates its detectors using secondary standards

directly traceable to the United States National Institute of Science and

Technology (NIST). The details and accuracy of the calibration procedure

vary with each detector model but a detailed description of the calibration

results is supplied with each individually calibrated detector.

In general, detector calibration accuracy ranges from 2% to 7% in absolute

terms and varies with wavelength. Each detector will have some variation

in the response over different sections of its surface. Therefore, for the

most reproducible measurements, light should illuminate the detector as

uniformly as possible over 80% of the detector’s active area.

CAUTION

Avoid focusing a light source onto the detector surface.

Inaccurate readings and possible detector damage may result.

Consult your detector manual for information on detector

saturation or damage thresholds.

NIST traceability requires that detectors be re-calibrated on one year

intervals. As individual detector responses change with time, especially in

the ultraviolet spectral range, re-calibration is necessary to assure confidence in the accuracy of the measurement. The same detector should

always be used for measurements which are to be directly compared, in

order to obtain reproducible results.

13

Page 27

4.2.2 Quantum Detector Temperature Effects

Semiconductor based photodiode detector characteristics (Newport

Corporation Low-Power detectors) are significantly affected by temperature. At longer wavelengths, these quantum detectors typically lose sensitivity with increasing temperature. However the detector dark current

increases exponentially with temperature. For silicon detectors, dark

current is generally on the order of a few picoamps at room temperatures.

With uncooled germanium detectors, however, this dark current is on the

order of a nanoamp, or typically 1,000 to 10,000 times greater than silicon.

These dark currents can be zeroed at any moment in time via the ZERO key

on the 1830-C. Since dark currents drift with temperature, the ZERO should

be adjusted just prior to taking any measurements. The noise or drift in the

dark current sets a lower bound on the measurement resolution which can

be achieved with any given detector.

If the detector temperature is constant, sensitivity changes and dark

current drifts are significantly reduced. In addition, if the detector is

cooled, the dark current and dark current noise will decrease. For the most

accurate measurements, particularly with germanium detectors, the user

can cool the detector to approximately 0 °C and control the temperature to

within ± 1 °C.

4.2.3 Ambient and Stray Light

Ambient and stray light striking the detector will be measured by the 1830C, and should be considered when making sensitive measurements. Ambient light can be distinguished from dark current (or the detector/meter

noise floor) by turning off or blocking the source and covering the detector

face with an opaque material such as a piece of black metal. Using the

human hand to cover the detector is not advised because it emits a significant amount of infrared radiation, and because it radiates a temperature

significantly different from ambient. With the detector covered, a reading of

the dark current may be made. Next, remove the material which is covering

the detector and take another reading. The difference is the ambient light

level.

The effects of ambient light are greatly reduced when using a fiberconnectorized signal input to the detector. If free-space beam measurements are desired, using an attenuator (Low-Power detectors have an OD3

attenuator included) will reduce stray light and often improve the source

signal to ambient signal noise level. Wavelength-specific filters, such as

optical cutoff, bandpass, or spike filters can also be used if the signal

wavelength spectrum permits. Other techniques to reduce stray light

include using apertures, placing the detector in a box or other housing to

shield the surface from light which is not coming from the source, and

turning off room and other lights.

NOTE

Changes in ambient light levels can occur from such factors as

turning room lights on or off, or by moving people or equipment. Remember, if you can see your detector element, then your detector can see the

light bouncing off your shirt!

14

Page 28

4.3 Setting the Wavelength

In order to obtain accurate optical power measurements, it is necessary to

set the calibration wavelength to the wavelength of the light incident upon

the photodetector. This calibration wavelength is indicated in nanometers

on the LCD display at power-up and whenever the λ䉱/λ䉲 keys are pressed.

Upon power-up, the calibration wavelength used will be the last value

entered into the meter (if this is the initial power-up on your calibration

module, the wavelength will default to the shortest available wavelength).

To change the wavelength, do the following:

Determine the wavelength of the light being measured to the nearest

nanometer. If the source is broadband, use either a value near the center

wavelength of the light or the wavelength with greatest intensity. Pressing

the λ䉱/λ䉲 keys will increase or decrease the calibration wavelength by

1nm. Wavelength will continue to change as long as the wavelength key is

depressed.

NOTE

Different detectors are sensitive over different wavelength ranges. See the

appropriate detector manual and calibration data to determine the range

of wavelengths available for the detector being used. The responsivities

stored in the calibration module span only the wavelength range appropriate for the detector and are specific to that detector.

4.4 Setting the Attenuator Mode

All Newport detectors are provided with calibrated optical attenuators.

The responsivities for an attenuator/detector combination are stored in the

calibration module. To measure optical powers above the saturation limit

of the detector (see appropriate photodetector manual), use the optical

attenuator that was shipped with your detector. When the attenuator mode

is selected, the following occurs:

a. The ATTN annunciator is displayed.

b. The responsivity for the detector-with-attenuator is used in calculating

If the attenuator is subsequently removed, the ATTN key should be pressed

to turn the attenuator mode off. All measurements will now be computed

using the responsivity for the detector-alone.

The transmission characteristics of each attenuator are slightly different;

the user must therefore be careful to use ONLY the attenuator and detector pair with the same serial numbers for which the particular calibration

module is calibrated.

the optical power being measured.

NOTE

15

Page 29

4.5 Performing Basic Measurements

4.5.1 Power Measurements

The 1830-C’s most basic measurement mode is in the units of Watts.

Power measurements may be made with background correction, which is

initiated by pressing the ZERO key. The following equation illustrates this

relationship:

a. Select the Watt measurement mode, auto-range, and a wavelength. Use

manual ranging if you want manual control of the range; over-range is

indicated by an OL message.

Watt reading = Net Applied Power

= ( I - Iz ) / R

where

I = detector input current

Iz= detector background current defined

when the ZERO key was pressed

R = responsivity of the detector (A/W)

(or detector with attenuator)

b. Block the light to be measured.

c. Initiate background correction by pressing the ZERO key. Display

should read approximately zero, but will fluctuate depending upon the

variations in the amount of light reaching the detector and the detector

dark current fluctuations.

d. Illuminate the detector with the optical signal to be measured.

e. Take the reading from the display.

4.5.2 Logarithmic Measurements (dB and dBm)

The 1830-C can make logarithmic measurements referenced to any measured power level or to a 1 mW power level by changing the measurement

units to dB or dBm, respectively.

NOTE

Log measurements should always be made on the lowest possible range

(without over-ranging). Readings on high ranges will not allow optimum

calculations of the logarithm. When in doubt, use auto-range.

NOTE

When using log measurements with background correction, the signal after

the subtraction of the stored offset power level may be negative. In this

case, OL will be displayed since the log of a negative number is not defined.

This will be automatically cleared when the signal becomes positive.

16

Page 30

4.5.2.1 Logarithmic Measurements Using Reference Powers (dB)

The dB measurement mode displays the absolute value of 10 times the

logarithm (base 10) of the input power, referenced to a power level which

is selected by pressing the STOREF key. The following equation illustrates

this relationship:

dB reading = 10 * log [Net Applied Power/Net Referenced

Power(=STOREF)]

= 10 * log [(( I - Iz )/R)/((I

STOREF

- IZ)/R)]

where

I = detector input current

Iz= detector background current defined when

the ZERO key was pressed

I

= referenced detector current defined when the

STOREF

STOREF key was pressed

R = responsivity of the detector (A/W)

(or detector with attenuator)

To make dB measurements with background correction, proceed as follows:

a. Select the dB measurement mode, auto-range, and a wavelength.

b. Block the light to be measured.

c. Initiate background correction by pressing the ZERO key. Display

should read approximately zero, but will fluctuate depending upon the

variations in the amount of light reaching the detector and the detector

dark current fluctuations.

d. Illuminate the detector with the optical signal to be used as the

reference signal.

e. Press the STOREF key.

f. Illuminate the detector with the optical signal to be measured.

g. Take the reading from the display.

4.5.2.2 Logarithmic Measurements Using 1 mW Reference (dBm)

The dBm measurement mode displays the absolute value of 10 times the

logarithm (base 10) of the input power, referenced to 1mW. The following

equation illustrates this relationship:

dBm reading = 10 * log [Net Applied Power/1mW]

= 10 * log [(( I - Iz )/R)/1 mW]

where

I = detector input current

Iz= detector background current defined when

the ZERO key was pressed

R = responsivity of the detector (A/W)

(or detector with attenuator)

Using this 1mW reference power, the dBm reading span is from −90 dBm to

+10 dBm (1 pW to 10 mW), when the detector responsivity equals 1.

17

Page 31

To make dBm measurements (relative to 1 mW optical power) with background correction, proceed as follows:

a. Select the dBm measurement mode, auto-range, and a wavelength.

b. Block the light to be measured.

c. Initiate background correction by pressing the ZERO key. Display

should read approximately zero, but will fluctuate depending upon the

variations in the amount of light reaching the detector and the detector

dark current fluctuations.

d. Illuminate the detector with the optical signal to be measured.

e. Take the reading from the display.

4.5.3 Relative Measurements

The relative mode REL is selected by pressing the UNITS key until the REL

annunciator turns on. The referenced power is selected at any time by pressing the STOREF key. The following equation illustrates this relationship:

REL reading = Net Applied Power/ Net

Referenced Power(=STOREF)

= (( I - Iz)/R)/((I

STOREF

- IZ)/R)

where

I = detector input current

Iz= detector background current defined

when the ZERO key was pressed

I

= referenced detector current defined when

STOREF

the STOREF key was pressed

R = responsivity of the detector (A/W)

(or detector with attenuator)

To make relative measurements with background correction, proceed as

follows:

a. Select the REL measurement mode, auto-range, and a wavelength.

b. Block the light to be measured.

c. Select background correction by pressing the ZERO key. Display should

read approximately zero, but will fluctuate depending upon the variations in the amount of light reaching the detector and the detector dark

current fluctuations.

d. Illuminate the detector with the optical signal to be used as the

reference signal.

e. Press the STOREF key.

f. Illuminate the detector with the optical signal to be measured.

g. Take the reading from the display.

18

Page 32

4.6 Common Measurement Errors

The most common sources of optical power measurement errors are listed

in Table 5 below.

Type of Error What should be done?

Radiometry Check that all of the light is actually hitting the

Ambient Light Check that any ambient light was ZERO’ed

Wavelength Calibration Check that the proper wavelength has been set.

Detector Saturation Check that the optical power density remains

Meter Configuration Check that the 1830-C was powered-up with the

detector.

before the measurement was made.

below the detector’s saturation threshold.

calibration module properly connected.

Check that the optical attenuator mode (ATTN

annunciator) is properly enabled/disabled.

Table 5 — Common Measurement Errors

19

Page 33

Section 5

Computer Interfacing

5.1 Introduction

The 1830-C has two computer interface ports: GPIB and RS-232C. The GPIB

interface conforms with the IEEE 488.1 hardware standard. All commands

for the 1830-C are device dependent commands. In this manual, we interchangeably use either GPIB or IEEE 488 when referring to the IEEE 488 bus.

Please see the General Guidelines sections for using either the GPIB

(Section 5.5.3) or RS-232C (Section 5.4.3) interfaces. These sections

include important information on using these interfaces properly.

5.2 Computer Interface Terminology

Key abbreviations and concepts used in the command reference section of

this manual are listed below:

<EOI> End or Identify

An IEEE488.1 signal sent with the end-of-string character.

<CR> Carriage Return

The ASCII decimal “13” byte.

<LF> Line Feed

An ASCII decimal “10” byte.

<NL> New Line

Defined in the IEEE 488 standard as the ASCII decimal “10” byte.

20

Page 34

<SRQ> Service Request

The 1830-C generates an <SRQ> to tell the GPIB controller that a serial poll

is needed. Any device on the GPIB bus may assert the <SRQ> line. Bit 6

(decimal 64) will be high in the serial poll byte returned from a device

requesting service. To determine if a device has generated an SRQ, an

“AND” operation could be performed on the Status Byte :

IF ((serial poll) AND 64) = 64 THEN ⇒ device is requesting service,

where serial poll is the integer returned from a GPIB serial poll.

Whitespace

Optional between commands and between parameters. Whitespace is any

character with a binary value less than or equal to an ASCII space character

( except the <NL> character ).

Numerical types

Numerical parameters are passed and returned as the actual ASCII characters in the string representation of the number. The 1830-C accepts numeric values in decimal format only.

RS-232C Command Termination

Commands and queries sent to the 1830-C through the RS-232C port should

be terminated with a <LF>.

All responses sent by the 1830-C are terminated with a <LF>.

GPIB Command Termination

Commands and queries sent to the 1830-C through the GPIB must be

terminated with a <NL> <EOI> (<NL> is equivalent to an <LF>).

All responses sent by the 1830-C are terminated with a <NL> <EOI>.

5.3 Entering Remote Computer Interface Mode

When a command or query is received by the GPIB or RS-232C interface

ports, the 1830-C automatically goes into the remote interface mode. The

REM annunciator on the 1830-C display will light up to indicate that the

1830-C is in remote interface mode.

When in remote mode, the 1830-C can be issued a “L1” command. The LLO

annunciator on the 1830-C display will also light up to indicate that the

1830-C is in the local-lockout mode. This mode disables the 1830-C front

panel keypad from affecting system operation. Locking out the front panel

keys is useful in applications where the user does not want inadvertent key

presses to affect his application setup. “L0” command disables the locallockout feature. The local-lockout mode can also be disabled by poweringup the meter again, or by pressing the “RESET” button located at the back

of the meter.

21

Page 35

5.4 RS-232C Communication

Before communicating with 1830-C through the RS-232C port, proper cable

connections must be made. Figure 7 shows the cable connections for

communicating with the RS-232C port on the 1830-C.

TO 1835 TO COMPUTER

CABLE TERMINATORS (RS-232)

9 pin to 25 pin

9 PIN

PIN NO.

TO 1835 TO COMPUTER

CODE DESCRIPTION

1

DCD

2

RXD

3

TXD

4

DTR

5

GND

6

DSR

7

RTS

8

CTS

9

CARRIER DETECT

RECEIVE DATA

TRANSMIT DATA

DATA TERM. READY

SIGNAL GROUND

DATA SET READY

REQUEST TO SEND

CLEAR TO SEND

RI

RING IND.

25 PIN

PIN NO.

8

3

2

20

7

6

4

5

22

CABLE TERMINATORS (RS-232)

9 pin to 9 pin

9 PIN

PIN NO.

1

2

3

4

5

6

7

8

9

CODE DESCRIPTION

DCD

RXD

TXD

DTR

GND

DSR

RTS

CTS

CARRIER DETECT

RECEIVE DATA

TRANSMIT DATA

DATA TERM. READY

SIGNAL GROUND

DATA SET READY

REQUEST TO SEND

CLEAR TO SEND

RI

RING IND.

9 PIN

PIN NO.

1

2

3

4

5

6

7

8

9

Figure 7. RS-232C Cable Connectors

22

Page 36

5.4.1 Setting the Baud Rate

Once cable connections are made, the baud rate for communication must

be set. Valid baud rates are 9600, 4800, 2400 and 1200. The parity, data bits,

and stop bits are fixed at: no parity, 8 data bits, and 1 stop bit.

RS-232C Parameters

Baud Rate 9600, 4800, 2400, 1200

Parity none

Data Bits 8

Stop Bits 1

Choose the appropriate baud rate by setting the rear panel system

switches to the desired parameters, as shown in Figure 8.

GPIB Address

1

0

1 2 3 4 5 6 7 8

RS232C

0 0 Baud Rate = 9600

1 0 Baud Rate = 4800

0 1 Baud Rate = 2400

1 1 Baud Rate = 1200

Default RS-232C Baud Rate = 9600

Not

Used

Figure 8. RS-232C Baud Rate Selector Switches

NOTE

Cycle the power off and on or press the “RESET” button located at back of

the meter, whenever the 1830-C baud rate switch settings are changed.

5.4.2 RS-232C Command Termination:

Commands and queries sent to the 1830-C through the RS-232C port must

be terminated by a <LF> (line feed).

All responses sent by the 1830-C are terminated with a <LF> (line feed).

23

Page 37

5.4.3 General Guidelines for Using the RS-232C Port

• The RS-232C port can communicate with a dumb terminal or a personal

computer running any one of the many communications programs

available. You may also control your 1830-C using a personal computer

running high level programming languages such as Quick Basic or C and

lab automation software such as LabWindows and LabVIEW.

• When a dumb terminal type of device is used to communicate with the 1830-C

via the RS-232C, the echo mode is especially useful. When the “Echo Mode”

for the RS-232C port is enabled, all characters sent to the 1830-C and error

messages will be echoed. The 1830-C will generate a ‘>’ prompt for every

line. As the user enters commands, the line may be edited by using the

backspace key ( sending an ASCII decimal 08 code ) or by using the DEL

key ( sending an ASCII decimal 127 code ).

• When the 1830-C is being controlled by a high level programming language, the echo mode should be disabled. When the “Echo” mode is

disabled, the 1830-C does not generate a prompt or echo characters back

to the interface.

NOTE:

The 1830-C’s default mode for RS-232C communication is with echo

disabled.

• Since the 1830-C’s output buffer size is limited to ten bytes, it is recommended that when a query is made, the response to that query be read

before other commands are issued.

5.5 GPIB Communication

• Only one command/query may be sent to the 1830-C per bus transaction.

• 1830-C system errors can be identified by reading the 1830-C’s Status Byte

Register. (See Appendix A)

A variety of third party GPIB communication hardware and software, such

as plug-in GPIB computer boards and LabVIEW software from National

Instruments are available. The 1830-C should work with any of these as long

as they adhere to the IEEE 488.1 standard. This manual assumes the user is

familiar with one of these third party hardware/software packages. We refer

to GPIB and IEEE 488 interchangeably.

5.5.1 Setting the GPIB Address

The 1830-C GPIB interface port can be connected to the GPIB bus via a

standard IEEE 488 cable. Before communicating with the 1830-C GPIB port,

the 1830-C GPIB address must be set. Choose the appropriate 1830-C GPIB

address by setting the rear panel system switches to the desired address,

as shown in Figure 9.

NOTE

Cycle the power off and on or press the RESET button located at the back

of the meter whenever the GPIB address is changed.

24

Page 38

GPIB Address

1

0

1 2 3 4 5 6 7 8

RS232C

Not

Used

GPIB Bus SW SW SW SW SW

Address 1 2 3 4 5

1: 10000

2: 01000

3: 11000

4: 00100

5: 10100

6: 01100

7: 11100

8: 00010

9: 10010

10: 0 1 0 1 0

11: 1 1 0 1 0

12: 0 0 1 1 0

13: 1 0 1 1 0

14: 0 1 1 1 0

15: 1 1 1 1 0

16: 0 0 0 0 1

17: 1 0 0 0 1

18: 0 1 0 0 1

19: 1 1 0 0 1

20: 0 0 1 0 1

21: 1 0 1 0 1

22: 0 1 1 0 1

23: 1 1 1 0 1

24: 0 0 0 1 1

25: 1 0 0 1 1

26: 0 1 0 1 1

27: 1 1 0 1 1

28: 0 0 1 1 1

29: 1 0 1 1 1

30: 0 1 1 1 1

Default GPIB Address=4

Figure 9. GPIB Address Selector Switches

5.5.2 GPIB Command Termination:

Commands and queries sent to the 1830-C through the GPIB bus should be

terminated by sending an <NL><EOI> (<NL> is equivalent to an <LF>).

All responses sent by the 1830-C are terminated with the concurrent

transmission of a <NL><EOI>.

25

Page 39

5.5.3 General Guidelines for Using the GPIB Port

The GPIB port can communicate with computers and other devices that

have GPIB ports that follow the IEEE 488.1 standards. Third party add-on

boards and software can be used to allow a personal computer to communicate with the 1830-C through the IEEE 488 port. With these add-on boards

and software, high-level language programs, can also be written to control

the 1830-C through the IEEE 488 port. For those who wish to minimize the

need for conventional “programming”, Newport provides free instrument

driver software for plug-in-and-run compatibility with LabVIEW.

Call Newport for more information.

Some of the issues which should be kept in mind while developing the

IEEE 488 software interface for the 1830-C, are as follows:

• A query is a command that invokes a response from the 1830-C. All

queries are terminated with a question mark (?).

• Since the 1830-C’s output buffer size is limited to ten bytes, it is recommended that the response to a query be read before other commands

are issued.

• Before reading the response, the MAV bit in the status byte should be

checked by means of a serial poll to make sure that the data is available.

(See Appendix A, Status Reporting System)

• Only one command/query may be sent to the 1830-C per bus transaction.

5.5.4 Procedure for Reading Only New Measurements

When you want to retrieve only new measurements from the GPIB bus, use

the following sequence of commands, serial polls, and queries:

1) Send the Command: C

This will clear the status byte register.

2) Serial Poll the 1830-C until the Read Done bit goes high. (decimal 128)

3) Send the Query: D?

This is a Data Query and responds with the last signal acquisition.

4) Serial Poll until the Message Available (MAV) bit goes high. (decimal 16)

5) Perform a GPIB read.

26

Page 40

Section 6

Remote Command Set

6.1 Summary of Command/Query Set

The following commands and queries are case insensitive. No spaces are

allowed between the letter-command and the parameter or question mark

(?). Only one command/query allowed per bus transaction.

Command Description

A0 Attenuator off

A1 Attenuator on

A? Attenuator query ( returns: 0, 1 )

B0 Beep off

B1 Beep on

B? Beep query ( returns: 0, 1 )

C Clear Status Byte Register

D? Data Query

E0 Echo off

E1 Echo on

E? Echo query ( returns: 0, 1 )

F1 Filter S ( Slow )

F2 Filter M ( Medium )

F3 Filter F ( Fast )

F? Filter query ( returns : 1, 2, 3 )

G0 Hold

G1 Go

G? Go query ( returns: 0, 1)

K0 Keypad/Display backlight off

K1 Set the Keypad/Display Backlight to medium intensity

K2 Set the Keypad/Display Backlight to high intensity

K? Keypad/Display Backlight query ( returns: 0, 1, 2 )

L0 No local lockout

L1 Local lockout

L? Local lockout query ( returns: 0, 1 )

27

Page 41

M Service Request Enable Register (Mask)

M? Service Request Enable Register Query

O Auto-Calibration

Q? Status Byte Register Query ( returns: 0 – 255 )

Bits

7 6 5 4 3 2 1 0

Parameter Error

Command Error

Saturation

Over-Range

Message Available (MAV)

Busy

Service Request

Read Done

(See Appendix A

for details)

R0 Auto Range

R1 Signal Range 1 ( Highest signal range )

R2 Signal Range 2

R3 Signal Range 3

R4 Signal Range 4

R5 Signal Range 5

R6 Signal Range 6

R7 Signal Range 7

R8 Signal Range 8 ( Lowest signal range )

R? Signal Range query ( returns: 1 – 8 )

S Store Reference

U1 Units W

U2 Units dB

U3 Units dBm

U4 Units REL

U? Units Query ( returns: 1, 2, 3, 4)

Wnnnn Set wavelength to nnnn

W? Wavelength query ( returns: nnnn )

Z0 Zero off

Z1 Zero on

Z? Zero query ( returns: 0, 1)

28

Page 42

6.2 Detailed Description of Commands and Queries

An

Attenuator on/off

Function: Selects between the responsitivity values associated with

the photodetector alone or for the photodetector-attenuator

combination. These values are stored within the calibration

module.

Syntax: An or an

Parameter: n = 0 Use the calibration module’s responsitivity values

associated with the photodetector-alone.

n = 1 Use the calibration module’s responsitivity values

associated with the photodetector-attenuator

combination.

Type: integer

Related

Commands: A? – Attenuator query

A?

Attenuator query

Function: Reports whether the 1830-C is using the responsitivity

associated with the photodetector-alone or the

photodetector-attenuator combination.

Syntax: A? or a?

Returns: 0 photodetector-alone responsitivities are used.

1 photodetector-attenuator responsitivities are used.

Related

Commands: An – Selects the responsitivity associated with the

photodetector-alone or photodetector-attenuator combination

29

Page 43

Bn

Beeper on/off

Function: This command is used to turn the audio output on/off. The

audio output frequency is proportional to the intensity of the

input power signal.

Syntax: Bn

Parameter: n = 0 beeper is off

n = 1 beeper is on

Type: integer

Related

Commands: B?- Beeper query

B?

Beeper query

Function: This query informs the user whether the 1830-C’s beeper

is on or off.

Syntax: B? or b?

Parameter: none

Returns: 0 beeper is off.

1 beeper is on.

Related

Commands: Bn - Turn the beeper on/off.

C

Clear Status Byte Register

Function: This command is used to clear the status byte register. All

bits, except the MAV bit, are set low by sending this command. The status byte register contents are described in Q?

and Appendix A.

Syntax: C or c

Parameter: None

Related

Commands: Q? - Status Byte Register query

30

Page 44

D?

Data query

Function: This query responds with the power level of the input signal.

Syntax: D? or d?

Parameter: none

Returns: The format of the returned data string is: ±d.ddddE ±dd.

Example: Send: D?

Resp: 0.0000E-09

Related

Commands: An, A? - Set/Query the Attenuator setting

Rn, R? - Set/Query the Range setting

Un,U? - Set/Query the units of measurements

En

Echo mode on/off ( RS-232C interface only)

Function: This command is used to turn 1830-C’s echo mode on/off. The

echo mode applies to RS-232C communication only. In this

mode all the characters that are received over the RS-232C

are transmitted (“echoed”) back to the user. This mode is

useful when interfacing the 1830-C to a dumb terminal.

Syntax: En or en

Parameter: n = 0 Turn echo mode off

n = 1 Turn echo mode on

Type: integer

Related

Commands: E? - Echo mode query

E?

Echo mode query

Function: This query informs the user whether the 1830-C’s echo mode

is on or off. When the echo mode is on, then all the characters

that are received over the RS-232C are transmitted back to the

user.

Syntax: E? or e?

Parameter: none

Returns: 0 echo mode is off.

1 echo mode is on.

Related

Commands: En - Turn the echo mode on/off.

31

Page 45

Fn

Filter ( same as averaging ) Slow, Medium, Fast

Function: This command is used to set how many measurements are

averaged for the displayed reading. When the slow speed

filter is selected, the 1830-C displays the average of the last 16

measurements. When using the medium filter, the 1830-C

displays the average of the last 4 measurements. The fast

filter does no averaging.

Syntax: Fn or fn

Parameter: n = 1 use the slow filter to average the last 16 measurements

n = 2 use the medium filter to average the last 4 measurements

n = 3 no averaging is performed

Type: integer

Related

Commands: F? - Filter status query

F?

Filter (same as averaging) status query

Function: This query informs the user about the current settings for

the filter parameter. The filter setting dictates how many

measurements are averaged for the displayed reading. In the

slow mode, the reading is the average of the last 16 measurements, while in the medium mode the reading is the average

of the last 4 measurements. No averaging is done in the fast

mode.

Syntax: F? or f?

Parameter: none

Returns: 1 The readings are being averaged in slow mode

2 The readings are being averaged in medium mode

3 The readings are not being averaged

Related

Commands: Fn - Set how many measurements are averaged for the

displayed reading

32

Page 46

Gn

Go on/off

Function: This command is used to enable/disable the 1830-C from

taking new readings. During disable mode, no 1830-C parameters can be changed.

NOTE:

- “Run” and “Go “ words are used interchangeably and they

represent the same 1830-C function.

- “Stop” and “Hold” words are used interchangeably

and they represent the same 1830-C function.

Syntax: Gn or gn

Parameter: n = 0 1830-C is in Hold mode, i.e. does not take new readings

n = 1 1830-C is in Go mode, i.e. takes new readings

Type: integer

Related

Commands: G? - Go query

G?

Go query

Function: This query informs the user whether the 1830-C is in the Run

or Hold mode. If the meter is in the “Run” mode, the 1830-C

will continue acquiring new measurements. In the “Hold”

mode, it stops acquiring new measurements.

NOTE:

- “Run” and “Go “ words are used interchangeably and they

represent the same 1830-C function.

- “Stop” and “Hold” words are used interchangeably

and they represent the same 1830-C function.

Syntax: G? or g?

Parameter: none

Returns: 0 1830-C is in Hold mode.

1 1830-C is in Run mode.

Related

Commands: Gn - Set 1830-C to either Run/Hold mode.

33

Page 47

Kn

Keypad/Display Backlight on/off

Function: This command is used to set the keypad/display backlight to

various intensity levels. The backlight intensity levels may be

set to off, medium, or high.

Syntax: Kn or kn

Parameter: n=0 Turns the front panel backlight off

n=1 Turns the front panel backlight to medium intensity

n=2 Turns the front panel backlight to the highest intensity

level

Type: integer

Related

Commands: K? - Query the backlight intensity level

K?

Keypad/Display Backlight intensity level query

Function: This query responds with the current status of 1830-C’s

backlight intensity level. The backlight intensity level can be

either off, medium, or high.

Syntax: K? or k?

Parameter: none

Returns: 0 Backlight is off

1 Backlight intensity is set to medium intensity level

2 Backlight intensity is set to the highest intensity level

Related

Commands: Kn - Set the Backlight intensity to off/medium/high.

34

Page 48

Ln

Local lockout on/off

Function: This command is used to enable/disable the 1830-C’s local-

lockout function. When the local-lockout function is enabled,

any front panel key presses would have no effect on system

operation. The 1830-C’s front panel display has a “LLO”

annunciator, and it lights up when the local-lockout function

is enabled.

This feature is useful when conducting an experiment and the

user does not want inadvertent key presses to affect the

system operation.

Syntax: Ln or ln

Parameter: n = 0 Local-lockout is off

n = 1 Local-lockout is on

Type: integer

Related

Commands: L? - Query the current status of local-lockout function

L?

Local lockout query

Function: This query informs the user whether 1830-C’s local-lockout

function is enabled/disabled. The local-lockout function,