Page 1

O

PERATOR’S

M

ANUAL

Model 1825-C

Power/Energy Meter

Page 2

Model 1825-C

Power/Energy Meter

Page 3

Warranty

Newport Corporation warrants this product to be free from defects in material

and workmanship for a period of 1 year from the date of shipment. If found to

be defective during the warranty period, the product will either be repaired or

replaced at Newport’s option.

To exercise this warranty, write or call your local Newport representative, or

contact Newport headquarters in Irvine, California. You will be given prompt

assistance and return instructions. Send the instrument, transportation

prepaid, to the indicated service facility. Repairs will be made and the instrument returned, transportation prepaid. Repaired products are warranted for

the balance of the original warranty period, or at least 90 days.

Limitation of Warranty

This warranty does not apply to defects resulting from modification or misuse

of any product or part. This warranty also does not apply to fuses, batteries,

or damage from battery leakage.

This warranty is in lieu of all other warranties, expressed or implied, including any implied warranty of merchantability or fitness for a particular use.

Newport Corporation shall not be liable for any indirect, special, or consequential damages.

Statement of Calibration

This instrument has been inspected and tested in accordance with specifications published by Newport Corporation.

The accuracy and calibration of this instrument and photodetector (where

applicable) is traceable to the National Institute for Standards and Technology

through equipment which is calibrated at planned intervals by comparison to

the certified standards maintained at Newport Corporation.

Copyright 1997, Newport Corporation

Part No. 19572-01, Rev. F

IN-04925 (07-97)

ii

Page 4

EC DECLARATION OF CONFORMITY

Active Isolation Module Set Series

We declare that the accompanying product, identified with the

" " mark, meets the intent of the Electromagnetic Compatability

Directive, 89/336/EEC and Low Voltage Directive 73/23/EEC.

Compliance was demonstrated to the following specifications:

EN50081-1 EMISSIONS:

Radiated and conducted emissions per EN55011, Group 1,

Class A

EN50082-1 IMMUNITY:

Electrostatic Discharge per IEC 1000-4-2, severity level 3

Radiated Emission Immunity per IEC 1000-4-3, severity level 2

Fast Burst Transients per IEC 1000-4-4, severity level 3

Surge Immunity per IEC 1000 4-5, severity level 3

IEC SAFETY:

Safety requirements for electrical equipment specified in

IEC 1010-1.

Model 1825-C

Alain Danielo Jeff Cannon

VP European Operations General Manager-Precision Systems

Zone Industrielle 1791 Deere Avenue

45340 Beaune-la-Rolande, France Irvine, Ca. USA

iii

Page 5

Table of Contents

Warranty ...........................................................................................................ii

EC Declaration of Conformity ........................................................................ iii

List of Figures .................................................................................................. vi

List of Tables ................................................................................................... vi

Safety Symbols and Terms ............................................................................ vii

General Warnings and Cautions ................................................................... vii

Abbreviations ................................................................................................ viii

Specifications................................................................................................... ix

Section 1 – General Information

1.1 System Overview ................................................................................... 1

1.2 Scope of this manual ............................................................................. 1

1.3 Unpacking and Inspection .................................................................... 2

1.4 Preparation for Use ............................................................................... 2

1.5 Optional Accessories and Services ..................................................... 2

Section 2 – System Operation

2.1 Introduction ........................................................................................... 3

2.2 Display .................................................................................................... 3

2.3 Front and Rear Panel Controls ............................................................. 4

2.3.1 RANGE ........................................................................................... 5

2.3.2 ZERO ............................................................................................. 5

2.3.3 AVERAGE ...................................................................................... 6

2.3.4 MODE ............................................................................................ 6

2.3.5 CAL Slide Switch .......................................................................... 6

2.3.6 SETUP Dip Switches .................................................................... 7

2.3.7 EXP. ADJ. Rotary Dip................................................................... 7

2.4 Using the System ................................................................................... 7

2.4.1 Battery Charging ......................................................................... 7

2.4.2 Power Up ...................................................................................... 8

2.4.3 Detector Connection and Setup ................................................ 8

2.4.4 Setting the Detector Calibration Factor ................................... 8

2.4.4.1 Calibration Factor Mantissa Entry ................................... 9

2.4.4.2 Calibration Factor Exponent Entry................................... 9

2.4.5 Signal Averaging .......................................................................... 9

2.4.6 Signal Integration ...................................................................... 10

2.4.7 Peak-to-Peak Power Measurement .......................................... 11

2.4.8 Pulse Energy Measurement...................................................... 11

2.4.9 Detector Acceleration Time Constant .................................... 12

2.4.10 Analog Output ............................................................................ 13

Page

iv

Page 6

Section 3 – Principles of Operation

3.1 Introduction ......................................................................................... 14

3.2 Functional Description ........................................................................ 14

3.3 Measurement Considerations ............................................................ 15

3.3.1 Detector Calibration and Accuracy ........................................ 15

3.3.2 Quantum Detector Temperature Effects ................................ 16

3.3.3 Thermopile Detector Temperature Effects ............................ 16

3.3.4 Energy Detector Temperature Effects .................................... 16

3.3.5 Ambient and Stray Light ........................................................... 16

3.4 Performing Basic Measurements ....................................................... 17

3.4.1 Making a CW Power Measurement ......................................... 17

3.4.2 Making a Signal Integration Measurement ............................. 18

3.4.3 Making a Pulse Energy Measurement ..................................... 18

3.4.4 Common Measurement Errors ................................................ 19

3.5 System Accuracy ................................................................................. 19

Section 4 – Test, Maintenance and Troubleshooting

4.1 Maintenance Procedures .................................................................... 20

4.2 Troubleshooting Guide ....................................................................... 20

Section 5 – Factory Service

5.1 Introduction ......................................................................................... 21

5.2 Obtaining Service................................................................................. 21

5.3 Service Form......................................................................................... 23

v

Page 7

List of Figures

Figure 1 Model 1825-C and Accessories.......................................................... 1

Figure 2 Model 1825-C Display ......................................................................... 4

Figure 3 Model 1825-C Front Panel Detail ....................................................... 5

Figure 4 Model 1825-C Rear Panel Detail ........................................................ 5

Figure 5 Detector Setup Table.......................................................................... 8

Figure 6 Integrated Energy from Exposure to an Optical Power ............... 10

Figure 7 Integrated Energy from a Pulse Energy Optical Source ............... 10

Figure 8 Peak-to-Peak and Other Signal Types............................................. 11

Figure 9 Pulse Signal Detection ...................................................................... 12

Figure 10 Detector Time Constant ACCEL. ADJ. Setting ............................... 13

Figure 11 Simplified Model 1825-C Functional Block Diagram ..................... 14

Figure 12 Typical Energy Detector Signal Waveform .................................... 15

List of Tables

Table 1 Model 1825-C Display Annunciators ................................................. 3

Table 2 Model 1825-C Front Panel Controls .................................................. 4

Table 3 MODE Switch Position and Detector Compatibility ....................... 6

Table 4 CAL Slide Switch Functions ............................................................... 6

Table 5 SETUP Dip Switch Functions ............................................................. 7

Table 6 EXP. ADJ. Rotary Dip Switch Settings .............................................. 9

Table 7 Common Measurement Errors ........................................................ 19

Table 8 Symptom/Fault Troubleshooting Guide ........................................ 20

vi

Page 8

Safety Symbols and Terms

The following safety terms are used in this manual:

The Warning heading in this manual explains dangers that could result

in personal injury or death.

The Caution heading in this manual explains hazards that could damage

the instrument.

In addition, a Note heading gives information to the user that may be

beneficial in the use of this instrument.

General Warnings and Cautions

The following general warnings and cautions are applicable to this instrument:

Warning

This instrument is intended for use by qualified personnel who

recognize shock hazards or laser hazards and are familiar with

safety precautions required to avoid possible injury. Read the

instruction manual thoroughly before using, to become familiar

with the instrument’s operations and capabilities.

Warning

The American National Safety Institute (ANSI) states that a shock

hazard exists when probes or sensors are exposed to voltage levels

greater then 42VDC or 42V peak AC. Do not exceed 42V between

any portion of the Model 1825-C (or any attached detector or

probe) and earth ground or a shock hazard will result.

Caution

There are no user serviceable parts inside the Model 1825-C. Work

performed by persons not authorized by Newport may void the

warranty. For instructions on obtaining warranty repair or service

please refer to section 5 of this manual. Do not operate this unit via

its AC Adaptor without the included rechargeable battery pack

installed. Use only the AC Adapter provided with the Model 1825C by Newport.

vii

Page 9

Abbreviations

A amps

AC alternating current

ADC analog-to-digital converter

BAT battery

BIC biconic fiber connector

BNC standard coaxial connector type

°C degrees Centigrade

DC direct current

°F degrees Fahrenheit

Hz hertz (cycles per second)

I-V current-to-voltage converter

kHz kilohertz

kΩ kiloOhms

LSD least significant digit

mA milliamps

mV millivolts

nA nanoamps

nF nanofarads

nm nanometers

P-P peak-to-peak

RH relative humidity

S/N serial number

µA microamps

µs microseconds

V volts

W watts

viii

Page 10

Specifications

Physical Specifications

Dimensions: 3.75 × 7.5 × 9.25 in. (95 × 191 × 235 mm)

Weight: 5 lb (2.3 kg)

Enclosure: Metal case, painted

Connectors: Signal Input BNC; Signal Output BNC;

Power 2.5 mm Phone Jack

Power: 12 VDC, 200 mA unregulated

Battery Life: 20 hours

Battery Type: Lead acid rechargeable, 1000 cycles

Display: 3.5 digit annunciated LED and analog

meter

Reading Rate: 12 Hz Max.

Range Switch: 12 position, 6 decades of gain

Operating Environment: <90 % RH Noncondensing. 5 to 40°C

Storage Environment: <90 % RH Noncondensing. -25 to 60°C

Compatible Detectors: Low-Power Detectors; Except 818-F-SL and

818-F-IR

High-Power Detectors

Energy Detectors; Except 818J-S10

ix

Page 11

Electrical Specifications:

(0)

Position 7

Position 8

Position 9

Position 10

Position 11

Position 12

Position 5

Position 4

Position 3

Position 2

Position 1

Position 6

Range Knob Positions

Range Switch Position 1 & 2 3 & 4 5 & 6 7 & 8 9 & 10 11 & 12

Full scale measurement (divide value by calibration factor mantissa)

Semiconductor 200nA 2µA 20µA 200µA 2mA 20mA

Thermopile 2mV

(2)

2mV 20mV 200mV 2V 20V

Pyroelectric 20mV 200mV 2V 20V 200V 2kV

(1)

(3)

(4)

Relative noise factor (peak-to-peak, measured relative to full scale)

Semiconductor 0.2% 0.02% 0.1% 0.01% 0.01% 0.01%

Thermopile 0.03% 0.03% 0.2% 0.02% 0.02% 0.01%

Pyroelectric 0.3% 0.09% 0.2% 0.02% 0.01% 0.01%

Analog Output Bandwidth

(7)

Semiconductor 150Hz 150Hz 25kHz 25kHz 150kHz 150kHz

Thermopile 5Hz 5Hz 20kHz 20kHz 100kHz 100kHz

Pyroelectric 75kHz 75kHz 75kHz 75kHz 200kHz 200kHz

Full scale analog output ................ 2V

Analog output drift ........................ <0-2% / 1 hour at constant temperature

Analog output offset ...................... <10mV

(5)

Analog output noise

Calibration accuracy ..................... <0.1% + 1% / calibration factor mantissa

.................. <0.1% + relative noise factor × calibration factor

mantissa

(6)

(6)

DC accuracy .................................... <0.2% + calibration accuracy

Analog output accuracy................ <0.3% + DC accuracy

Peak-to-Peak accuracy .................. <0.5% + DC accuracy + analog output noise / 2

Pulse accuracy ............................... <0.5% + DC accuracy + analog output noise / 2

Integration accuracy ..................... <0.7% + DC accuracy + analog output noise / 2

Display resolution.......................... full scale measurement / 2000

Minimum pulse slope .................... 10V / sec

Allowed detector responsivity limits:

2

Semiconductor .......................... 1 × 10

Thermopile ................................ 1 × 10

A/W to 1 × 10-8 A/W

5

V/W to 1 × 10-5 V/W

Pyroelectric ............................... 1 × 107 V/J to 1 × 10-3 V/J

(0)

Guaranteed after 30 min. warm up period.

(1)

Maximum measurable current is 10mA.

(2)

In Thermopile mode, ranges 1 & 2 are identical to 3 & 4.

(3)

Maximum measurable voltage in Thermopile mode is 2V.

(4)

Maximum measurable voltage in Pyroelectric is 200V.

(5)

Measured with 818-SL, 818T-10 or 818J-25 detector, respectively.

(6)

Calibration factor mantissa range is 1 to 10.

(7)

Amplifier bandwidths are higher internally.

x

Page 12

Section 1

General Information

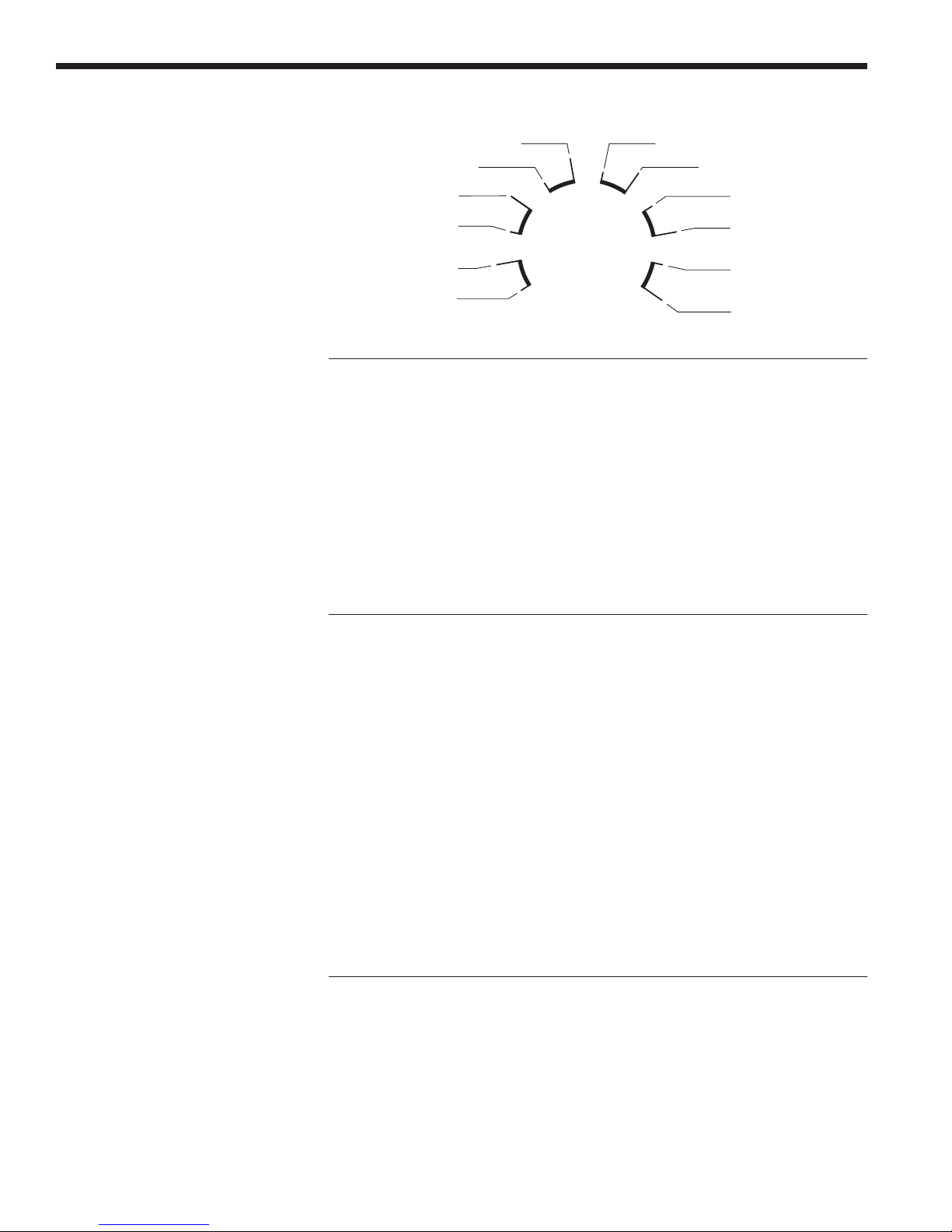

System Overview

1.1

The Model 1825-C is an accurate and flexible optical power and energy measuring instrument that provides features typically found only on advanced

single purpose optical meters: Simple front panel controls, annunciated digital

and analog displays, and compatibility with Newport’s full line of detector

families allow the Model 1825-C to meet almost any DC, AC peak-to-peak,

pulsed or integrated exposure measurement requirement with minimum fuss.

Compatible with Newport’s Low-Power, High-Power, and Energy detector

families, the Model 1825-C provides the features you need without the expense

of purchasing multiple single purpose optical meters. The Model 1825-C

Power/Energy Meter and its accessories are presented in Figure 1. Section 1.5

of this manual presents a brief description of compatible Newport detectors.

HIGH-POWER

818T-10

818T-10V

818T-30

818T-30V

818T-150

818T-150X

818T-300

ENERGY

818J-25Q

818J-50Q

818JA-YAG25

818JA-YAG50

818JA-NG254

818JA-NG504

818JA-NG251

818JA-NG504

818JA-9Q

818J-09

818J-09B

818J-25

818J-25B

818J-50

818J-50B

LOW-POWER

FP3-CA1

FP3-CA2

FP3-CA3

FP3-CA4

FP3-CA5

FP3-CA6

818-FA 818-

818-UV

818-SL

818-IR

FP3-FH1

FA2

818-ST

Scope of this manual

1.2

Needle Acc.±2% FS

Figure 1 — Model 1825-C and Accessories

Please carefully read this instruction manual before using the Model 1825-C

Power/Energy Meter. Be especially careful to observe the warnings and

cautions throughout this manual. If any operating instructions are not clear,

contact Newport Corporation.

This instruction manual contains the necessary information for operation and

maintenance of the Newport Model 1825-C Power/Energy Meter as well as

information for troubleshooting and obtaining service if necessary. This

information is divided into the following sections:

• Section 1 provides general information about this manual and the

Model 1825-C.

• Section 2 explains System Operation procedures for the Model 1825-C

and accessories.

1

Page 13

• Section 3 discusses the Principles of Operation of the Model 1825-C.

• Section 4 provides for Test, Maintenance and Adjustment of the Model

1825-C.

• Section 5 provides instructions for obtaining factory service.

Unpacking and

1.3

Inspection

Preparation for Use

1.4

Optional Accessories

1.5

and Services

All Model 1825-C Power/Energy Meters are carefully assembled, tested and

inspected before shipment. Upon receiving this instrument, check for any

obvious signs of physical damage that might have occurred during shipment.

Report any such damage to the shipping agent immediately. Retain the

original packing materials in case reshipment becomes necessary.

The Model 1825-C Power/Energy Meter should have some operations performed before measurements are made. These include:

• Charging the batteries (Section 2.4.1)

• Connection and calibration of the detector (Section 2.4.4)

Many detectors and detector accessories are available for use with the Model

1825-C Power/Energy Meter. In addition, detector accessories are available.

Refer to Figure 1 for the Model 1825-C Power/Energy Meter family tree. For

more information, please refer to the Newport Catalog.

2

Page 14

Section 2

System Operation

Introduction

2.1

Display

2.2

This section contains the information needed to prepare and operate the

Model 1825-C Power/Energy Meter. Operation consists of using the Model

1825-C to perform basic optical power or energy measurements using one of

Newport’s compatible detectors.

The Model 1825-C combines a fast response 3.5 inch analog display with a 3.5

digit annunciated LED display, see Figure 2. The full scale reading of the

analog display alternates between 2 and 5 as the RANGE knob is rotated so

that it can display signals below 2.00 with higher resolution. The analog

display matches the digital display (within ±1 division typ.) and the annunciators always indicate the current measurement units. The digital display is

more accurate than the analog display.

To facilitate measurements of integrated, AC peak-to-peak or pulsed signals,

both the analog and digital displays hold their last value for about 20 seconds

before falling back to zero. If a new signal arrives before the display has reset

itself to zero, the new signal is acquired and displayed.

The BAT annunciator lights when the battery voltage reaches 7 volts and

indicates that recharging is needed. See Section 2.4.1, Battery Charging. To

increase battery life, the digital display dims while the analog display backlight

brightens as ambient light levels decrease. Avoid prolonged operation when

the BAT annunciator is lit, measurement accuracy can degrade. The batteries

are protected from deep discharge damage and will automatically disconnect

when they are discharged below 6V.

If one needs to operate the meter even after the battery discharge protection

is activated, there is no need for waiting for batteries to be charged up. You

can operate the 1825-C as soon as the charger is plugged into it.

Table 1 — Model 1825-C Display Annunciators

Annunciator Comment

BAT Battery voltage has reached 7 volts

(approx. 10% battery life left).

CAL Indicates that the Calibration Factor decimal

number is being displayed

TRIG Indicates that a signal has crossed the

threshold that triggers the meter to take a

reading, (INTG, PULSE and peak-to-peak

modes).

READ Indicates that the meter is showing a valid

reading.

W, J Watt and Joule units annunciators,

respectively.

n, µ, m, k Exponent prefixes for the Watt and Joule

annunciators.

3

Page 15

1

.5

1.5

Front and Rear

2.3

Panel Controls

0

Needle Acc. ±2% FS

READ

1

CAL

2

BATTRIG

Figure 2 — Model 1825-C Display

Operating controls and settings for the Model 1825-C are found on both the

front and rear panels. For general operation, only the front panel controls are

used. The rear panel controls and settings are primarily used for meter/

detector setup. The front panels of the Model 1825-C are shown in Figure 3.

The following table gives a short description of each control:

Table 2 — Model 1825-C Controls

Control Description Comment

POWER Push Button Turns the Model 1825-C on and off

Meter Adjust 1 Turn Trim Pot Unlabeled. Calibrates the analog

CAL 10 Turn Pot Sets the Calibration Factor decimal

3

needle zero, (factory set).

number.

4

m

n

kWJ

2

5

ZERO 10 Turn Knob Zeros the display. Used to elimi-

nate ambient signals and electronic offsets.

AVERAGE 1 Turn Click-Off Knob Turns on and adjusts PULSE/P-P

averaging time.

RANGE 12 Position Knob Adjusts the meter’s signal gain, 12

positions, 6 decades.

MODE 3 Position Knob Sets the meters signal measure-

ment mode: CW, INTEGRATE or

PULSE/P-P.

CAL Slide Switch Selects between CAL, NORMAL

and BEEP operation.

SETUP 8 Switch Dip Bank Configures the meter to the type of

detector being used.

EXP. ADJ. Rotary Dip Switch Sets the Calibration Factor expo-

nent.

ACCEL. ADJ. 10 Turn Trim Pot Sets the thermopile acceleration

time constant.

4

Page 16

0

READ

POWER

1 0 0 0 0 0

0 0 1 1 0 0

0 0 1 0 1 1

0 1 1 0 1 1

O

N

1

0

1 2 3 4 5 6 7 8

■

.5

1

Needle Acc.±2% FS

Power/Energy Meter ■

1

2

1.5

3

4

Model 1825-C

2

5

CAL

BATTRIG

(I )

(O )ONOFF

nmkWJ

CAL

Figure 3 — Model 1825-C Front Panel Detail

- -

LOW-POWER, (SEMICONDUCTOR)

- -

HIGH-POWER, (THERMOPILE)

- -

ENERGY 1 M

- -

ENERGY 50

-

1

PROCESSED OUTPUT

-

0

UNPROCESSED OUTPUT

ACCELERATED

1

NOT ACCELERATED

0

INPUT

Ω

, (PYROELECTRIC)

Ω

, (PYROELECTRIC)

NORMAL

BEEP

CAL

OFF

BEEP

ON

ACCEL

ADJ

EXP

ADJ

RANGE

AVERAGE

OFF MAX

ANALOG

OUTPUT

MODE

INTEGRATE

CW

ZERO

—-

12–18V

- - -

PULSE

P-P

Figure 4 — Model 1825-C Rear Panel Detail

2.3.1 RANGE

The RANGE knob adjusts the signal gain of the Model 1825-C. It has twelve

positions covering 6 decades of signal gain. Intermediate gain positions only

change the full scale reading of the analog display and do not effect either the

digital display or the analog output. Turn the RANGE knob clockwise (counter

clockwise) to decrease (increase) signal gain. The RANGE positions 1 thru 12

with position 1 being the furthest CCW postion, are illustrated in the figure on

page ix.

2.3.2 ZERO

This knob will adjust the display and analog output values down to zero. It is

used to zero the display to remove the effects of ambient signals before

making a measurement. The ZERO function has the capability of offsetting

signals over a 5 decade range. Turn the ZERO knob CW to decrease the

negative (offsetting) signal that is injected.

Always use the ZERO knob to eliminate ambient and/or offset signals to insure

accurate readings.

5

Page 17

2.3.3 AVERAGE

This front panel knob adjusts the PULSE/P-P signal averaging of the Model

1825-C’s display and analog output between off and maximum averaging. Use

this knob to slow down the response of the display when observing noisy

signals. A soft detent indicates the signal averaging “off” position. Averaging

only works in INTEGRATE and PULSE/P-P modes.

2.3.4 MODE

The front panel MODE knob sets the method of signal acquisition that the

Model 1825-C will use with a given detector. Not every mode can be used with

every detector. Table 3, below, indicates which modes are compatible with

the various Newport detector types.

Table 3 — MODE Switch Position and Detector Compatibility

MODE Position Compatible Detectors Comment

CW Low-Power, High-Power Measures average optical

power.

INTEG Low-Power, High-Power Measures energy resulting

from integrated power.

†

P-P

†

PULSE

†

While P-P and PULSE are the same position on the MODE switch, the meter’s

operation will differ due to the settings of the SETUP dip switches for the

different detector types. See Section 2.3.6.

Low-Power Measures peak-to-peak

optical power.

Energy Measures pulse energy.

2.3.5 CAL Slide Switch

The rear panel CAL slide switch performs the functions described in the table

below:

Table 4 — CAL Slide Switch Functions

Switch Position Function

CAL Display the Calibration Factor mantissa.

NORMAL, BEEP OFF Take readings normally.

NORMAL, BEEP ON Take readings normally but beep with each

pulse triggering. (INTEGRATE & PULSE/P-P

modes only)

6

Page 18

2.3.6 SETUP Dip Switches

The rear panel SETUP dip switches configure the meter to the type of Newport

detector that the meter will be used with. The following table identifies the

function each SETUP switch position performs:

Table 5 — SETUP Dip Switch Functions

SETUP Switch Switch Position Function

O

N

1

0

1 2 3 4 5 6 7 8

1 Selects current amplification (1) other-

wise (0).

2 Selects voltage amplification (1) other-

wise (0).

3 Selects 50Ω (1) or 1 MΩ (0) voltage

input impedance for Energy detectors.

4 Selects for the type of detector; High-

Power (1) otherwise (0).

5&6 Selects for the type of detector; Energy

(11) otherwise (00).

7 Selects processed analog output (1) or

unprocessed output (0).

8 Selects accelerated voltage response (1)

or unaccelerated response (0).

2.3.7 EXP. ADJ. Rotary Dip

The rear panel EXP. ADJ. rotary dip adjusts the display annunciator units to

properly account for the sensitivity of a detector’s calibration factor exponent.

This allows the display to adjust between different detectors even when the

responsivities of the two detectors may differ by many decades.

Using the System

2.4

The Model 1825-C Power/Energy Meter does not have a microprocessor. It

relies on the user to properly install the calibration factor describing the

detector and wavelength in use. In order to assure that measurements are

accurately calibrated, please carefully read and follow the instructions regarding the Detector Calibration Factor. See Sections 2.4.4, 2.4.4.1 and 2.4.4.2.

2.4.1 Battery Charging

The lead-acid battery pack in the Model 1825-C is designed to provide many

years of reliable operation before any need of replacement. The battery pack

can be recharged by the AC Adaptor at any time and may be charged indefinitely without damage. The batteries will not discharge through the adaptor if

power is removed. With the meter off, a full charge will be reached after 15

hours. With the meter on, the wall mount power supply will trickle charge the

batteries. If you keep the Model 1825-C continuously connected to wall power,

then it will always have a full charge ready for any portable use measurements.

1. Turn the Model 1825-C off and insert the charging plug into the rear

panel 12V DC input.

2. Plug the AC adaptor into the wall. You may now turn the Model 1825-C

back on.

7

Page 19

NOTE

The battery pack is capable of 1000 to 2000 charge/discharge cycles

before factory replacement is needed. If the battery is continuously

charged, no charge/discharge cycles are accumulated.

NOTE

Prolonged operation after the BAT annunciator lights can cause

inaccurate measurements. Eventually the meter disconnects the

batteries to prevent deep discharge damage.

2.4.2 Power Up

Turn on the Model 1825-C by depressing the POWER button located on the

front of the meter. The digital display should light indicating that the meter is

operating. If the BAT annunciator is lit, operate the meter from the AC adaptor

so the batteries can recharge. See Section 2.4.1.

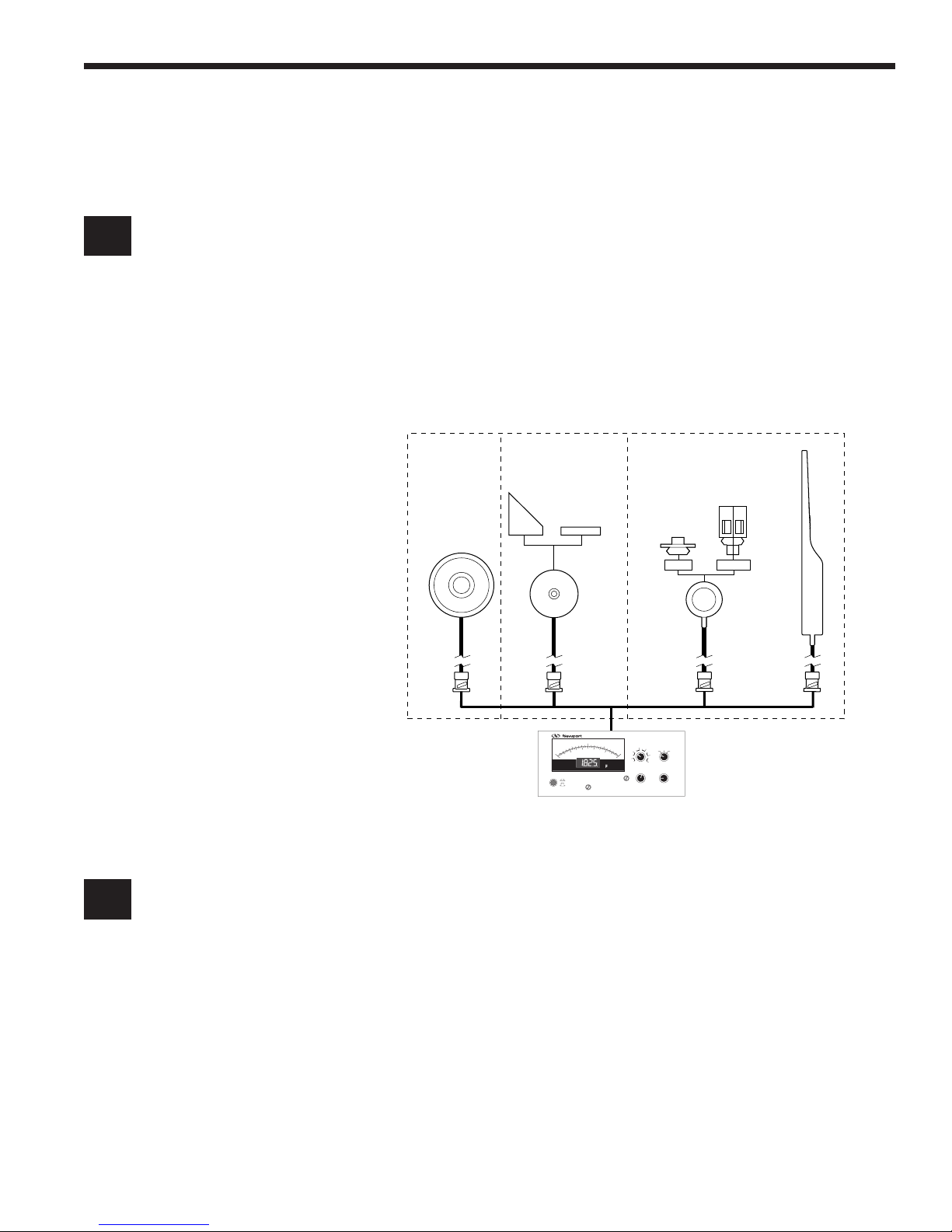

2.4.3 Detector Connection and Setup

Connect the detector to the INPUT BNC found on the rear of the Model 1825-C.

You may connect or disconnect any Newport Low-Power, High-Power or

Energy detector at any time without damage. Adjust the SETUP dip switches

to reflect the type of Newport detector that the Model 1825-C is being used

with. If you are not using a Newport detector, follow the figure below when

setting up the Model 1825-C. Information from this figure is reproduced on the

rear panel of the Model 1825-C, see Figure 4.

- -

1 0 0 0 0 0

0 0 1 1 0 0

0 0 1 0 1 1

0 1 1 0 1 1

LOW-POWER, (SEMICONDUCTOR)

- -

HIGH-POWER, (THERMOPILE)

- -

ENERGY 1 M

- -

ENERGY 50

-

1

PROCESSED OUTPUT

-

0

UNPROCESSED OUTPUT

ACCELERATED

1

NOT ACCELERATED

0

Ω

, (PYROELECTRIC)

Ω

, (PYROELECTRIC)

O

N

1

0

1 2 3 4 5 6 7 8

Figure 5 — Detector Setup Table

When using a Newport ENERGY ( or pyroelectric) detector check the detector

manual to determine if it should be operated with 50Ω or 1MΩ input impedance.

We recommend operating with UNPROCESSED OUTPUT and NOT ACCELERATED until you have read the manual sections explaining these features.

2.4.4 Setting the Detector Calibration Factor

The calibration factor tells the Model 1825-C how to account for a detector’s

responsivity at the measurement wavelength. Each Newport detector arrives

with a full spectrum calibration report with detector responsivities and

8

Page 20

calibration factors listed in 10 nm increments. A calibration factor is calculated from a responsivity by simply taking the inverse of the responsivity and

expressing it in scientific notation, i.e. “d.ddE±d”. Be sure to re-express the

responsivity value in units of A/W or V/W before calculating the inverse. See

Examples below.

Example 1: Responsivity R = 0.568 A/W thus the Calibration Factor =

1.76 E+0 W/A

Example 2: Responsivity R = 0.346 mV/W thus the Calibration Factor =

2.89 E+3 W/V

2.4.4.1 Calibration Factor Mantissa Entry

The calibration factor mantissa is the “d.dd” portion of the calibration factor

value “d.ddE±d”. The mantissa is the most frequent calibration adjustment

made when making measurements at various wavelengths. To set the mantissa, use the following procedure:

1. Slide the CAL switch to the CAL position.

2. Adjust the front panel CAL potentiometer until the display matches the

calibration factor mantissa.

Example: If the Calibration Factor = 2.89 E+3, then the display should

indicate 2.89.

3. Return the CAL switch to the NORMAL, BEEP OFF (or NORMAL, BEEP

ON) position.

2.4.4.2 Calibration Factor Exponent Entry

The calibration factor exponent is the ±d of the calibration factor value

d.ddE±d. The Model 1825-C accounts for this exponent through its EXP. ADJ.

rotary dip setting. The EXP. ADJ. rarely needs to be set more than once when

using the Model 1825-C with a particular detector. However, it is still wise to

check that the EXP. ADJ. does not need resetting when making measurements

at multiple wavelengths. To set the EXP. ADJ. rotary dip, use the following

lookup table:

Table 6 — EXP. ADJ Rotary Dip Switch Settings

Calibration Factor Exponent -7-6-5-4-3-2-101234567

Low Power Detectors –––––0123456789

High Power Detectors ––0123456789–––

EXP. ADJ.

Dip Setting

Energy Detectors 0123456789–––––

2.4.5 Signal Averaging

The Model 1825-C provides an adjustable low pass filter for signal averaging in

INTEG and PULSE/P-P modes. The effects of averaging cause the display to

slow down its response to changes in signal level. Average feature is disabled

in CW mode. It could be very useful when trying to observe noisy signals, or

signals whose value fluctuates when in PULSE or Peak-to-Peak mode. If

averaging is used in the INTEG mode, accuracy can be lost. We suggest

checking that the use of averaging does not effect the INTEG result in each

measurement situation.

9

Page 21

2.4.6 Signal Integration

The Model 1825-C provides a circuit which measures optical energy by

electronically integrating the signal from a power sensing detector. This mode

of operation is only compatible with Low-Power and High-Power detectors.

Signal integration is enabled when the MODE switch is set to INTEG.

The Model 1825-C uses a self-trigger-on-level method of integration. The TRIG

annunciator lights and remains lit for the length of the integration. After the

pulse integration is completed the READ annunciator lights indicate that the

display value now represents a final result. The display units will indicate

Joules as energy is the time integral of power:

t

EPdt

λλ

()=()

1

∫∫

t

0

Vt

t

()

1

=

t

0

R

λ

()

dt

where:

V(t) = detector signal

R(λ) = detector responsivity

One can measure the accumulated energy from exposure using the INTEG

mode. When a power, P(λ,t), is incident on a power detector, the integration

circuit behaves as is shown in Figure 6 below. The display then reflects the

total energy, E(λ), resulting from the detectors time exposure to the optical

power, P(λ,t).

Input Optical

Power

Signaa

Resultant Detector

Signal

Resultant Integrated

Signal = Energy

P (λ,t)

S (

λ

,t)

1

E (

λ

) = P (λ,t) dt

∫

λ

)

R (

Figure 6 — Integrated Energy from Exposure to an Optical Signal

When a pulse of energy, E(λ), is incident on a High-Power detector’s surface, the

detector responds with a voltage signal reflecting the thermal effects of the

much slower heat pulse that the energy generates. The integration circuit then

measures the energy in the pulse by integrating the voltage pulse, Figure 7.

Input Optical

Pulse Energg

Resultant Voltage

Pulse

Resultant Integrated

Voltage

E (λ)

V (t)

1

E (

λ

) =

R (

V (t) dt

∫

λ

)

Figure 7 — Integrated Energy from a Pulse Energy Optical Source

10

Page 22

2.4.7 Peak-to-Peak Power Measurement

The Model 1825-C allows one to measure AC Peak-to-Peak power when the

MODE switch is set to P-P, (compatible with Low-Power detectors only). Peakto-Peak detection only occurs when the detector signal slope exceeds a

threshold. The result of this is that the Model 1825-C can measure the peak-topeak amplitude of square waves down to DC but cannot detect sinewaves

below 100 Hz. Figure 8 below illustrates the nature of a peak-to-peak signal.

DC Average

AC Peak-to-Peak

DC + AC Peak

Figure 8 — Peak-to-Peak and Other Signal Types

If the CAL slide switch is set to BEEP ON while in the P-P mode, the Model

1825-C will give a short “click” with the arrival of each trigger. This is particularly useful for infrared wavelengths and for listening for changes in the pulse

repetition rate.

2.4.8 Pulse Energy Measurement

The Model 1825-C can measure pulse energies with an Energy detector when

the MODE switch is set to PULSE. (This MODE of operation is only compatible

with Newport Energy detectors.) The Model 1825-C’s PULSE mode automatically accounts for the baseline drift inherent in pyroelectric detectors when

exposed to a pulse train (see Figure 9). As pulse acquisition is slope threshold

triggered, adjustments to the RANGE knob must be made until the TRIG

annunciator lights as each energy pulse arrives. Note that PULSE detection

only occurs when the detectors signal slope exceeds a threshold.

At very low pulse repetition rates, the Model 1825-C will capture and display

each pulse for about 20 seconds before the display falls back to zero. During

this display hold time, the READ annunciator will light to indicate that the

display holds a real reading rather than a signal offset arising from the ZERO

adjustment. If a new pulse arrives before the display has fallen back to zero,

the display simply captures and displays the new pulse.

If the CAL slide switch is set to NORMAL, BEEP ON while in the PULSE mode.

The Model 1825-C will give a short “click” with the arrival of each pulse. This

is particularly useful for infrared wavelengths and for listening for changes in

the pulse repetition rate.

11

Page 23

1.0

0.8

0.6

VOLTS

0.4

0.2

0.0

0.0 0.2 0.4 0.6 0.8 1.0

V

peak

TIME (sec)

Figure 9 — Pulse Signal Detection

2.4.9 Detector Acceleration Time Constant

The Model 1825-C provides a circuit to electronically accelerate the risetime of

Newport’s High-Power thermopile detectors. Acceleration occurs when the

SETUP switch position 8 is set to “1”. A back panel potentiometer, ACCEL

ADJ., is used to adjust the time constant of the acceleration circuit to match

the time constant of the detector. Since most of Newport’s High-Power

detectors have a 1 sec. time constant, the ACCEL ADJ. potentiometer is tuned

at the factory for this time constant. Good results are generally obtained

without having to readjust the ACCEL ADJ.

NOTE

Rise time acceleration is only compatible with Newport High-Power

(thermopile) detectors.

You can set or fine tune the ACCEL ADJ. to your particular detector. This is

especially useful if you are monitoring the processed analog output on an

oscilloscope or other time based or data logging instrument. This adjustment

is required if you are using a High-Power detector that does not have a 1 sec.

time constant. When the ACCEL ADJ. setting does not match the actual time

constant of the attached detector, you will see some overshoot or undershoot

on the processed analog output signal (see Section 2.4.10). To fine tune the

ACCEL ADJ. potentiometer use the following procedure:

1. Set the SETUP dip switch to “0, 0, 1, 1, 0, 0, 1, 1”. Connect your HighPower detector to the Model 1825-C and monitor the analog output on

an oscilloscope.

2. Introduce a step function (or sub-hertz square wave) of optical power to

the High-Power detector. You should observe a signal trace similar to

Figure 10 below.

3. Adjust the ACCEL ADJ. potentiometer on the rear panel until the overshoot or undershoot of the analog output signal is eliminated.

12

Page 24

Input Optical Signal

Actual Thermopile

Detector Signal

Overshoot

Undershoot

Accelerated

Analog Output Signal

Correct

Figure 10 — Detector Time Constant ACCEL. ADJ. Setting

2.4.10 Analog Output

The Model 1825-C provides a 0 to 2 volt BNC analog output for signal monitoring. The analog output voltage reflects actual measurement by being equal to

the digital display’s digits and ignores the decimal point position. Thus, if the

digital display indicates 1.560, then the analog output voltage will be 1.560

volts. If the display indicates 156.0 then the analog signal will still be 1.560

volts.

The analog output can be configured in two ways: “PROCESSED” or “UNPROCESSED”. PROCESSED analog output reflects the cumulative effects of any

signal conditioning such as signal averaging, integration and acceleration.

UNPROCESSED analog output allows one to monitor the natural unconditioned

signal response of the detector. In general, one normally uses the analog

output in its PROCESSED state.

NOTE

The effects of any signal processing always show up on the display.

The PROCESSED or UNPROCESSED degree of freedom in the analog

output is independent of whether signal conditioning is occurring in

the displayed value. For example: Signal averaging can be on and

affecting noise level of the display while the analog output can be

UNPROCESSED and still show the unaveraged noisy detector signal.

13

Page 25

Section 3

Principles of Operation

Introduction

3.1

The Model 1825-C is a multiple function optical meter whose electronics can

adapt to a number of signal measurement tasks. The Model 1825-C can be

configured to measure DC current or voltage, AC peak-to-peak current or

voltage, integrate DC current or voltage, or to accelerate exponential signals to

their final values. This versatility is required to handle the various signals that

Newport’s Low-Power, High-Power and Energy detector families generate.

These detector families are based on semiconductor, thermopile and pyroelectric detectors respectively.

A block diagram of signal flow through the Model 1825-C is shown in Figure 11.

The actual flow through the diagram depends upon the MODE and SETUP

switch settings.

Signal

Accelerator

IN

Voltage

Preamplifier

I

Amplification

Configurable

V

Amplification

Power

Management

Amplifier

Zero

Adjust

Calibration

External

Power

Supply

Adjust

Accel.Not Accel.

Pulse/p-p

Detector

Integrator

Logic

Pulse/p-p

Average

Integration

Pulse/p-p/Integration

Processed Output

CW

Output

Unprocessed

Analog

Output

Amplifier

A/D

Converter

&

Display

Amplifier

Analog

Meter

OUT

3.2

Functional

Description

Figure 11 — Simplified Model 1825-C Functional Block Diagram

The Model 1825-C Power/Energy Meter is a configurable current or voltage

measuring instrument optimized for use with semiconductor photodiodes

(current measurement), disk thermopiles (voltage measurement) or pyroelectric (peak voltage measurement) detectors.

Detector signals are introduced to the Model 1825-C by way of a BNC input

connector. A bank of dip switches found on the back of the Model 1825-C

configures the amplifier as either a transimpedance current amplifier, a 1 MΩ

input impedance voltage amplifier or a 50 Ω or 1 MΩ input impedance peak

reading voltage amplifier. The amplified signal is then further processed via a

Calibration Factor compensation (adjustable signal attenuator) stage and, if

appropriate, a signal averaging circuit, and/or a signal integration circuit and/

or Peak Detector and/or a signal accelerator circuit. The resulting signal is

then sent to the A-D converter and displayed.

14

Page 26

The flexibility of the Model 1825-C is required in order that it may properly

measure the signals that various types of detectors make. Optical power or

energy is related to a detector signal, Sd, in the following way:

S

PEor

()

d

=

R

λ

For semiconductor photodiodes (Newport Low-Power Detectors), Sd, is a

current, Sd=Id. The 1825-C must be able to make sensitive low noise current

measurements to be compatible with these detectors. For thermopile detectors (Newport High-Power Detectors), Sd, is a small voltage, Sd=Vd. The 1825-C

must be able to sense microvolt levels with a 1 MΩ input impedance to be

compatible with these detectors. For pyroelectric pulse energy detectors

(Newport Energy Detectors), Sd, is a peak voltage Sd=Vpk. The Model 1825-C

must be able to capture 2 µsec rise time voltage spikes using either a 50Ω or

1MΩ input impedance to be compatible with these detectors. A typical energy

detector signal in response to a pulse train is shown below in Figure 12.

< 5 µs

Measurements

3.3

Considerations

>10 msec

Figure 12 — Typical Energy Detector Signal Waveform

This section describes detector and attenuator characteristics, optical and

electrical considerations, and environmental influences on optical measurements. In general, the accuracy of measurement with the Model 1825-C is

limited by the calibration accuracy of the detector calibration. Making accurate

measurements of optical power or energy is, however, also dependent upon

properly setting up the Model 1825-C, controlling temperature and illumination

conditions and understanding the factors that affect optical measurements.

3.3.1 Detector Calibration and Accuracy

Newport Corporation calibrates its detectors using secondary standards

directly traceable to the United States National Institute of Science and Technology (NIST) or to Great Britain’s National Physical Laboratory, (NPL). The

details and accuracy of the calibration procedure vary with each detector

model but a detailed description of the calibration results is supplied with

each individually calibrated detector.

In general, detector calibration accuracy varies from 2% to 5% in absolute

terms. Each detector will have some variation in the response to wavelength

and over different sections of its surface. Therefore, for the most reproducible

measurements, light should illuminate the detector as uniformly as possible

over as large an area as practical.

15

Page 27

CAUTION

Avoid focusing a light source onto the detector surface. Inaccurate

readings and possible detector damage may result. Consult the

detector manual for saturation or damage thresholds.

NIST traceability requires that detectors be recalibrated on one year intervals.

As individual detector responses change with time, especially in the ultraviolet, recalibration is necessary to assure confidence in the accuracy of the

measurement. For the most reproducible measurements, the same detector

should always be used for measurements which are to be directly compared.

3.3.2 Quantum Detector Temperature Effects

Semiconductor based photodiode detector characteristics (Newport Corporation Low-Power detectors) are affected by temperature. At longer wave-

lengths, quantum detectors typically lose sensitivity with increasing temperature. Of special note, the detector dark current increases exponentially with

temperature. For silicon detectors, dark current is generally on the order of a

few picoamps at room temperatures. With uncooled germanium detectors,

however, this dark current is on the order of a nanoamp, typically 1,000 to

10,000 times greater than silicon. These dark currents can be zeroed by the

Model 1825-C’s ZERO knob. Since dark currents drift with temperature, the

ZERO should be adjusted just prior to taking any measurements. The noise or

drift in the dark current sets a lower bound on the measurement resolution

which can be achieved with any given detector.

If the detector temperature is constant, sensitivity changes and dark current

drifts are significantly reduced. In addition, if the detector is cooled, the dark

current and dark current noise will decrease. For the most accurate measurements, particularly with germanium detectors, the user should cool the

detector to approximately 0 °C and control the temperature to within ± 1 °C.

3.3.3 Thermopile Detector Temperature Effects

Disk thermopile based detector characteristics (Newport Corporation HighPower detectors) are significantly affected by temperature fluctuations arising

from air flow disturbances. As the detector element is a heat measuring

device, air flow disturbances often set a practical lower limit on the power that

a detector can measure. In order to get the most out of any thermopile

detector, be careful to shield the detector from air flow disturbances. Common sources of disturbance are air conditioners and people walking past the

detector. At small signal levels, thermopiles will also observe people as

radiating infrared sources.

3.3.4 Energy Detector Temperature Effects

Newport Energy detectors are AC coupled devices and thus are not suscep-

tible to temperature induced DC signal offsets or noise floor changes.

3.3.5 Ambient and Stray Light

Ambient and stray light striking the detector will be measured by the Model

1825-C, and should be considered when making careful measurements.

Ambient light can be distinguished from dark current (or the detector/meter

noise floor) by either turning off or blocking the source and covering the

detector face with opaque material such as a piece of black metal. Using the

human hand to cover the detector is not advised because it emits a significant

16

Page 28

amount of infrared radiation. With the detector covered, a reading of the dark

current may be made. Next, remove the material which is covering the

detector and take another reading. The difference is the ambient light level.

NOTE

Changes in ambient light levels can occur from such factors as turning

room lights on or off, or by moving people or equipment. Remember,

if you can see your detector element, then your detector can see the

light bouncing off your shirt!

The effects of ambient light are greatly reduced when using a fiberconnectorized signal input to the detector. If free-space beam measurements

are desired, using an attenuator (Low-Power detectors have an OD3 attenuator included.) will reduce stray light and often improve the source signal to

ambient signal noise level. Wavelength-specific filters, such as optical cutoff,

bandpass, or spike filters can also be used if the signal wavelength spectrum

permits. Other techniques to reduce stray light include using apertures,

placing the detector in a box or other housing to shield the surface from light

(or air currents when using Newport’s High-Power disk thermopile detectors)

which is not coming from the source, and turning off room and other lights.

Performing Basic

3.4

Measurements

Basic measurement techniques for using the Model 1825-C are covered in the

following sections. Also included are methods of background correction and

common measurement errors. In general, the absolute measurement accuracy

is limited by the accuracy of the detector calibration and environmental

factors affecting the detector. See the appropriate detector manual for

specific information on a particular detector model.

3.4.1 Making a CW Power Measurement

The following process describes the procedure for making a basic optical

power measurement while properly removing influence of ambient light and

other drift effects.

1. Set up the meter to reflect the Newport Low-Power or High-Power

detector, the calibration factor at the wavelength of light you will be

making your power measurement at. See Sections 2.4.4 through 2.4.4.2.

Set the MODE knob to CW.

2. Cover or otherwise block the source that you will be measuring and

adjust the RANGE knob until the ambient signal is displayed to three

significant figures.

3. Use the ZERO knob to remove the ambient signal by zeroing the display.

Increase the gain (RANGE knob) and re-zero until the display reaches its

noise floor.

4. Uncover the source and adjust the RANGE knob until the source power

is displayed at least to three significant figures of accuracy.

5. Record the display value and the appropriate units from that RANGE

knobs position. This reading is your optical power.

The process as detailed assumes that the ambient signal is not changing

between when you zero the display (step 3) and when you make your measurement, (step 5). Remember, though, if you can see your detector as you

move around, then your detector can see you as a changing ambient signal!

17

Page 29

3.4.2 Making a Signal Integration Measurement

The following process describes the procedure for making a basic signal

integration measurement while properly removing influence of ambient light

and other drift effects. The Model 1825-C’s self-trigger-on-pulse method of

signal capture requires that the source signal turn on to start the integration

and turn off to stop the integration. This constrains the signal to be some sort

of “pulse”.

1. Set up the meter to reflect the Newport Low-Power or High-Power

detector, the calibration factor at the wavelength of light you will be

making your energy measurement at. See Sections 2.4.4 through 2.4.4.2.

Set the MODE knob to INTEG.

2. Cover or otherwise block the source that you will be measuring and

adjust the RANGE knob until the ambient signal is displayed to three

significant figures.

3. Use the ZERO knob to remove the ambient signal by zeroing the display.

Readjust the RANGE knob and re-zero until the display reaches its noise

floor on the lowest possible range.

4. Now “pulse” the source and adjust the RANGE knob until the TRIG

annunciator lights to indicate that the signal has exceeded the trigger

threshold. When the “pulse” is over, the READ annunciator will light to

indicate that the display contains a good final value. Continue “pulsing”

and adjusting the RANGE knob until the final value shows at least three

significant figures of accuracy.

5. Record the display value and the appropriate units. This reading is your

integrated signal “pulse” energy.

NOTE

The process as described above assumes that ambient “pulse” energy

signals are not changing between when you zero the display (step 3)

and when you make your measurement, (step 5). Fluorescent lamps

are a common source of ambient pulsed light.

3.4.3 Making a Pulse Energy Measurement

The following process describes the procedure for making a basic optical

pulse energy measurement while properly removing influence of ambient light

and other drift effects.

1. Set up the meter to reflect the Newport Energy Detector, the calibration

factor at the wavelength of light you will be making your energy measurement at. See Sections 2.4.4 through 2.4.4.2. Set the MODE knob to

PULSE.

2. Cover or otherwise block the source that you will be measuring and

adjust the RANGE knob until the ambient signal is displayed to three

significant figures.

18

Page 30

3. Use the ZERO knob to remove the ambient signal by zeroing the display.

Readjust the RANGE knob and re-zero until the display reaches its noise

floor at the lowest possible range.

4. Uncover the source and adjust the RANGE knob until the TRIG annunciator lights to indicate that the meter is capturing pulses. Continue

adjusting the RANGE knob until the source pulse energy is displayed to

at least three significant figures of accuracy.

5. Record the display value and the appropriate units from the RANGE

knobs position. This reading is your optical pulse energy.

NOTE

The process as described above assumes that ambient pulse energy

signals are not changing between when you zero the display (step 3)

and when you make your measurement, (step 5). Fluorescent lamps

are a common source of ambient pulsed light.

3.4.4 Common Measurement Errors

The most common sources of optical measurement error are listed in Table 8

below.

Table 7 — Common Measurement Errors

System Accuracy

3.5

Type of Error Type of Detector What should be done?

Radiometry Any Check that all of the light is

actually hitting the detector.

Ambient Light Any Check that any ambient light

was ZEROed before the measurement was made.

Wavelength

Calibration Any Check that the Calibration

Factor for the measurement

wavelength is properly set.

Low Battery Power Any Check that meter is not indicat-

ing low BAT.

Detector Saturation Low-Power Check that the optical power

density remains below the

detector’s saturation threshold.

Meter SETUP

Configuration Any Check that the SETUP dip

switch bank is properly set up

for the detector being used.

The system measurement accuracy of the Model 1825-C Power/Energy Meter

is primarily governed by the calibration accuracy of the attached detector.

The electronic accuracy of the Model 1825-C generally exceeds the calibration

uncertainties of a detector by a decade or more. However, as NIST calibration

capabilities improve, system accuracies will begin to experience the influence

of electronic accuracy uncertainties.

19

Page 31

Section 4

Test, Maintenance and Troubleshooting

Maintenance

4.1

Procedures

Troubleshooting

4.2

Guide

In cleaning the body of this instrument, use only a mild soap & water solution

on a damp cloth.

CAUTION

Do not use acetone or other organic solvents (other than alcohol)

on the Model 1825-C Power/Energy Meter. Organic solvents attack

the paint.

The following troubleshooting guide is intended to isolate and solve problems

with the power meter so that, to the greatest extent possible, the return of the

power meter/detector system to Newport will be unnecessary. For the

problems that cannot be resolved with information in this manual, or for other

situations that are not covered in this section, please see Section 5 for details

on returning your entire system to Newport for service.

Table 8 — Symptom/Fault Troubleshooting Guide

Symptom Possible Fault/Correction

Blank display. Power switch OFF. Turn switch ON.

Batteries drained. Recharge batteries per

Section 2.4.1.

BAT indicator lit. Batteries need charging. Recharge

batteries per Section 2.4.1.

Display value does not change. CAL slide switch set to CAL. Return

switch to center.

Display indicates – – – – Signal overflow. Adjust RANGE knob

clockwise.

Reading is different than expected. See Table 7 Common Measurement

Errors. Section 3.4.4.

20

Page 32

Section 5

Factory Service

Introduction

5.1

Obtaining Service

5.2

This section contains information regarding obtaining factory service for the

Model 1825-C Power/Energy Meter. The user should not attempt any maintenance or service of this instrument and/or accessories beyond the procedures

given in Section 4: Test, Maintenance and Troubleshooting. Any problems

which cannot be resolved using the guidelines listed in Section 4 should be

referred to Newport Corporation factory service personnel. Contact Newport

Corporation or your Newport representative for assistance.

The Model 1825-C contains no user serviceable parts. Its calibration accuracy

is warranted for a period of 1 year. After 1 year, the unit should be returned to

Newport Corporation for recalibration and NIST traceability recertification.

To obtain information concerning factory service, contact Newport Corporation or your Newport representative. Please have the following information

available:

1. Instrument model number (On front panel)

2. Instrument serial number (On rear panel)

3. Description of the problem.

If the instrument is to be returned to Newport Corporation, you will be given a

Return Number, which you should reference in your shipping documents.

Please fill out the service form, located on page 23, and have the information

ready when contacting Newport Corporation. Return the completed service

form with the instrument.

21

Page 33

22

Page 34

Service Form

5.3

Newport Corporation

U.S.A. Office: 949/863-3144

FAX: 949/253-1800

Name ____________________________________________________________________________________

Company ______________________________________________________________________________

Address ________________________________________________________________________________

Country ________________________________________________________________________________

P.O. Number _________________________________________________________________________

RETURN AUTHORIZATION # ______________________________

(Please obtain prior to return of item)

Date __________________________________________________________________

Phone Number __________________________________________________

FAX Number _____________________________________________________

Item(s) Being Returned:

Model # ________________________________________________________ Serial # __________________________________________________________________________________________

Description: _________________________________________________________________________________________________________________________________________________________

Reason for return of goods (please list any specific problems) ______________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________

Please complete the below, as appropriate.

List all control settings and describe problem: ______________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________ (Attach additional sheets as necessary).

Show a block diagram of your measurement system including all instruments connected (whether power is turned

on or not). Describe signal source. If source is a laser, describe output mode, peak power, pulse width, repetition

rate and energy density.

Where is the measurement being performed?

(factory, controlled laboratory, out-of-doors, etc.) ________________________________________________________________________________________________

What power line voltage is used? ______________________________________________ Variation? __________________________________________________________

Frequency? _____________________________________________________ Ambient Temperature? ________________________________________________________________

Variation? ________________________________________ °F. Rel. Humidity? __________________________________ Other? _________________________________________

Any additional information. (If special modifications have been made by the user, please describe below).

____________________________________________________________________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________________________________________________________________

23

Page 35

24

Page 36

25

Page 37

Visit Newport Online at: www.newport.com

Newport Corporation, Irvine,

California, has been certified compliant with ISO 9001 by the British

Standards Institution.

P/N 19572-01, Rev. F

IN-04925 (04-01)

Printed in the USA

Newport Corporation

Worldwide Headquarters

1791 Deere Avenue

Irvine, CA 92606

(In U.S.): 800-222-6440

Tel: 949-863-3144

Fax: 949-253-1680

Internet: sales@newport.com

Loading...

Loading...