NEWLONG

/

•'

Industml

Sewing

Machine

INSTRUCTION

PORTABLE

MODEL

SACK

MANUAL

P-7

SEWING

MACHINE

V.

NSWLONG

Kr

MACHINE

TOKYOV

s.

N.

Vj^O^KS,

JAPAN.

LTD.

INDEX

SPECIFICATIONS 1

I.

GENERAL DESCRIPTION 1

II.

DRIVE

MECHANISM

m.

HOW

TO

OPERATE 2

1. Oiling 2

2. Needle Selling 2

3.

Threading

IV.

START

V.

GENERAL

VI.

ADJUSTMENT

CARE

2

2

3

3

3

1.

Thread

2. Position of

Tension

Needle

Bar

and

Looper 3

3. Position of Feed Dog 4

4.

VE.

MAINTENANCE

Vin.

HOW

Pressure

TO

of

Presser

CHANGE

Foot

& LUBRICATION 5

PARTS

3

5

6

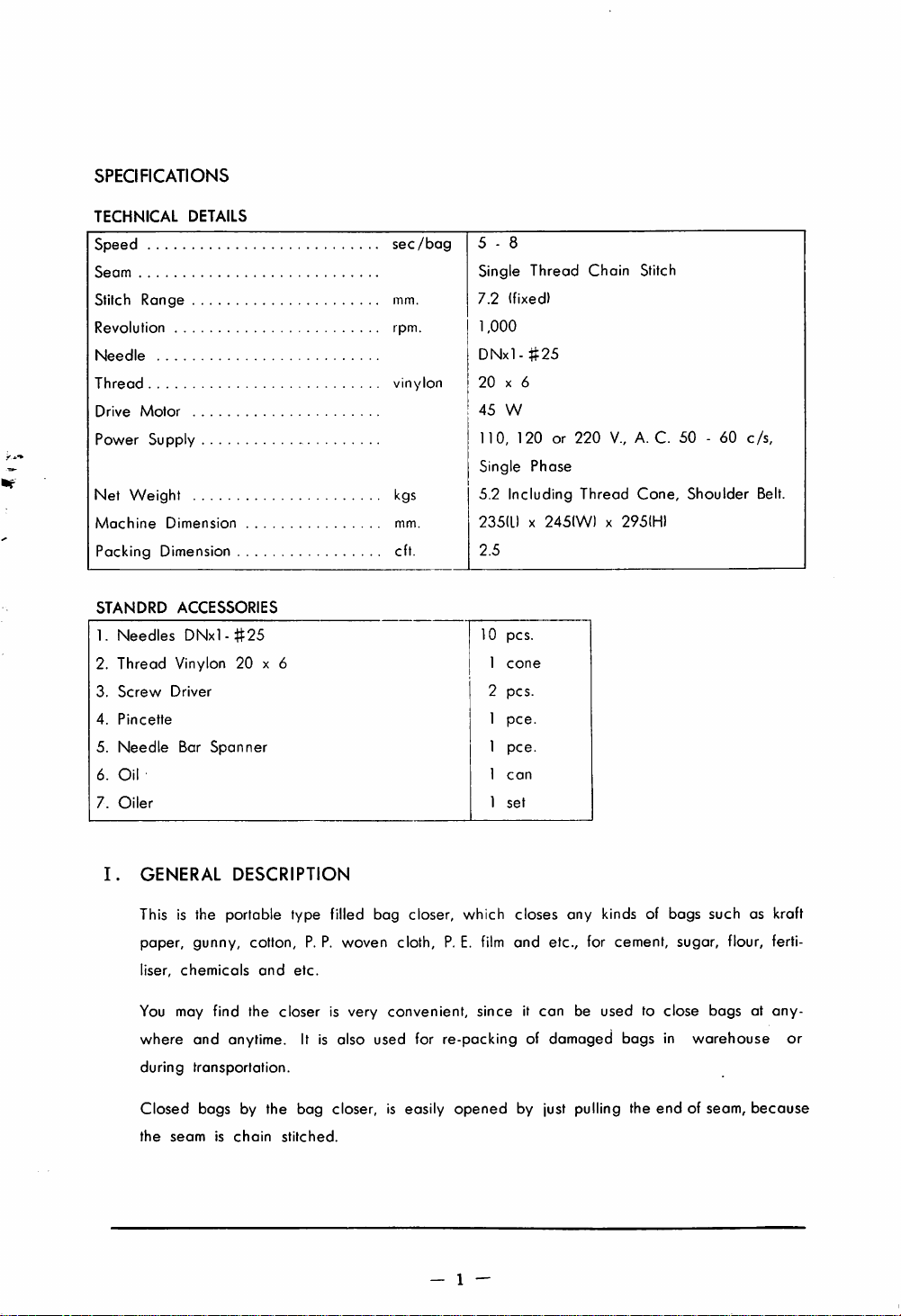

SPECIFICATIONS

TECHNICAL

Speed

Seam

Stitch

Range

DETAILS

sec/bag

mm.

Revolution rpm.

Needle

Thread

Drive

Po\wer

Net

Machine

Motor

Supply

Weight

Dimension

vinylon

kgs

mm.

Packing Dimension eft.

STANDRD

1.

Needles

2.

Thread

3.

Screw

4.

Pincette

5.

Needle

6.

Oil

7.

Oiler

ACCESSORIES

DNxl-#25

Vinylon 20 x 6

Driver

Bar

Spanner

5 - 8

Single Thread Chain Stitch

7.2

(fixed!

1,000

DNxl-

#25

20

X 6

45

W

110,

120or220

Single

Phase

5.2 Including

235(1)X245(W)X295(HI

2.5

v., A. C. 50 -60c/s.

Thread

Cone,

10 pcs.

1

cone

2

pcs.

1

pee.

1

pee.

1

can

1

set

Shoulder Belt.

I.

GENERAL

DESCRIPTION

This is the portable type filled bag closer, which closes any kinds of bags such as kraft

paper, gunny, cotton,

liser,

chemicals

You may find the closer is very convenient, since it

and

P. P.

woven cloth, P.E.film

etc.

and etc., for cement, sugar, flour, ferti

can

be

used

to close

where and anytime. It is also used for re-packing of damaged bags in

during

transportation.

Closed

the

bags

by the

seamischain

bag

stitched.

closer, is easily

opened

— 1 —

by just pulling the

end

bagsatany

warehouse

of seam,

or

because

II.

DRIVE

MECHANISM

Main Shaft is driven by pulley which is

belt. The movement of Lower Shaft controls

Lower,

Main Shaft drives Looper directly

Shaft.

These

Needle

three

Bar

and

movements of

Needle

Needle,

by intermediary of Eccentric Cam. At the same time, the

end

connected

with motor pulley by means of timing-

Crank

Connecting

Rod,

Needle

also regulates movement of Feed Dog through Feed

Looper

and

Feed

Dog ore so controlled to

that Looper picks up thread which Needle is in its upward movement and chain stitch is

accomplished. At this instance, Feed Dog is protruded

bag

forward.

III.

HOW

TO

OPERATE

above

the

Needle

Plate

1. Oiling

Oiling is important and necessry treatment to keep the machine in good condition for

a long time. Put oil in oil hole of machine marked with

2.

Needle

Turn the pulley or knob located at the end of

highest

Loosen

go.

Be sure to set a

Looper

Fix

Setting

motor

position.

the Needle Bar Clamp Nut, and set Needle in the Needle Bar as

Needle

side.

the Clamp Nut

tightly,

so that the

concave

part of

otherwise Needle shall break during operation.

shaft

needle

"OIL"

before operation.

until

Needle Bar reaches its

faces

correctly towards the

deep

Bar

each

Crank

and

as it

other

put

will

\

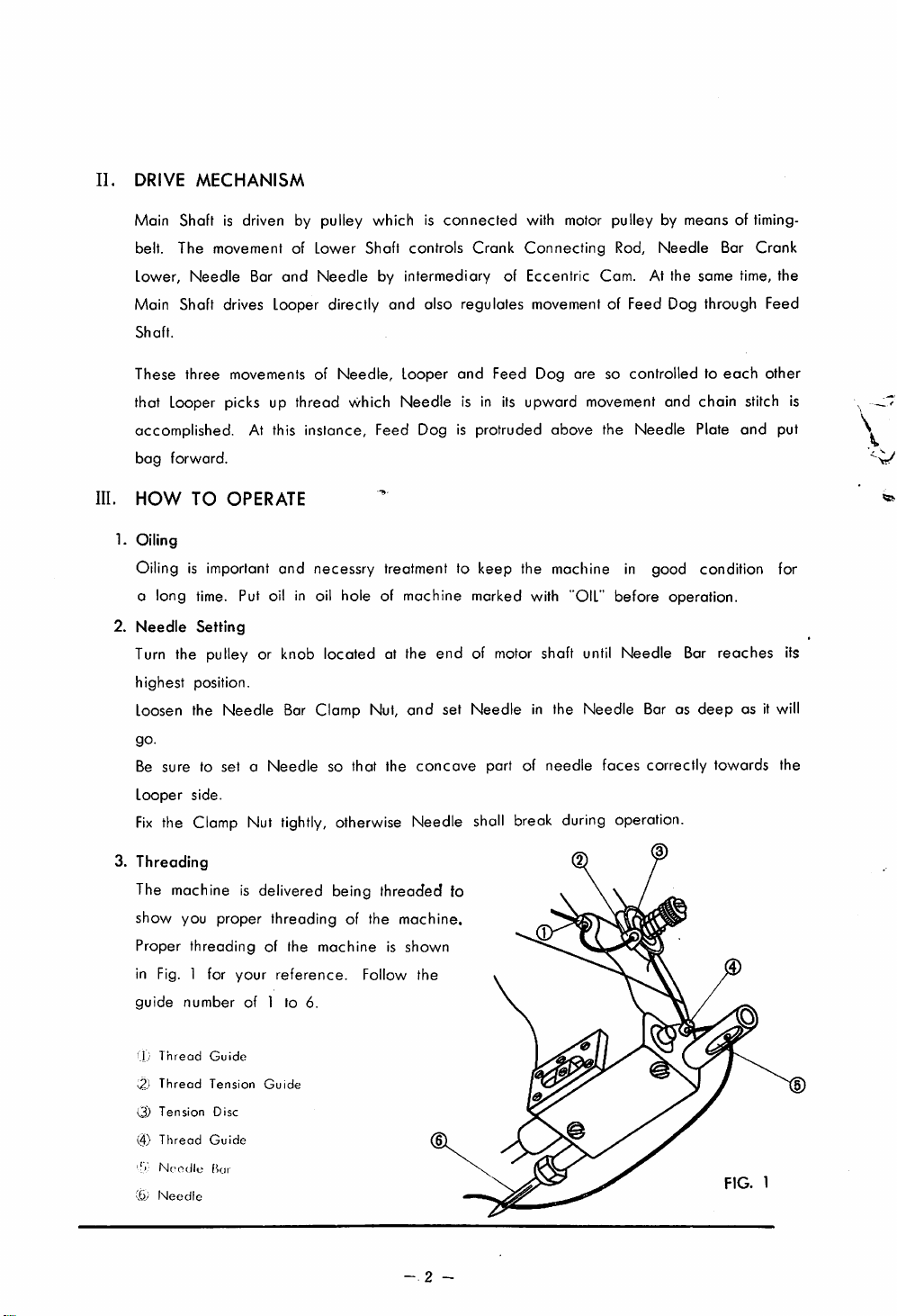

3. Threading

The machine is delivered being threaded to

show you proper threading of the machine.

Proper

threading

in Fig. 1 for

guide

number

1;

Thread

Guide

Thread

Tension

Q)

Tension

(3)

Thread

Guide

11

Needle

v6>

(NJeedle

your

Disc

(tar

of the

reference.

of 1 to 6.

Guide

machineisshown

Follow the

- 2 -

FIG.

1

Loading...

Loading...