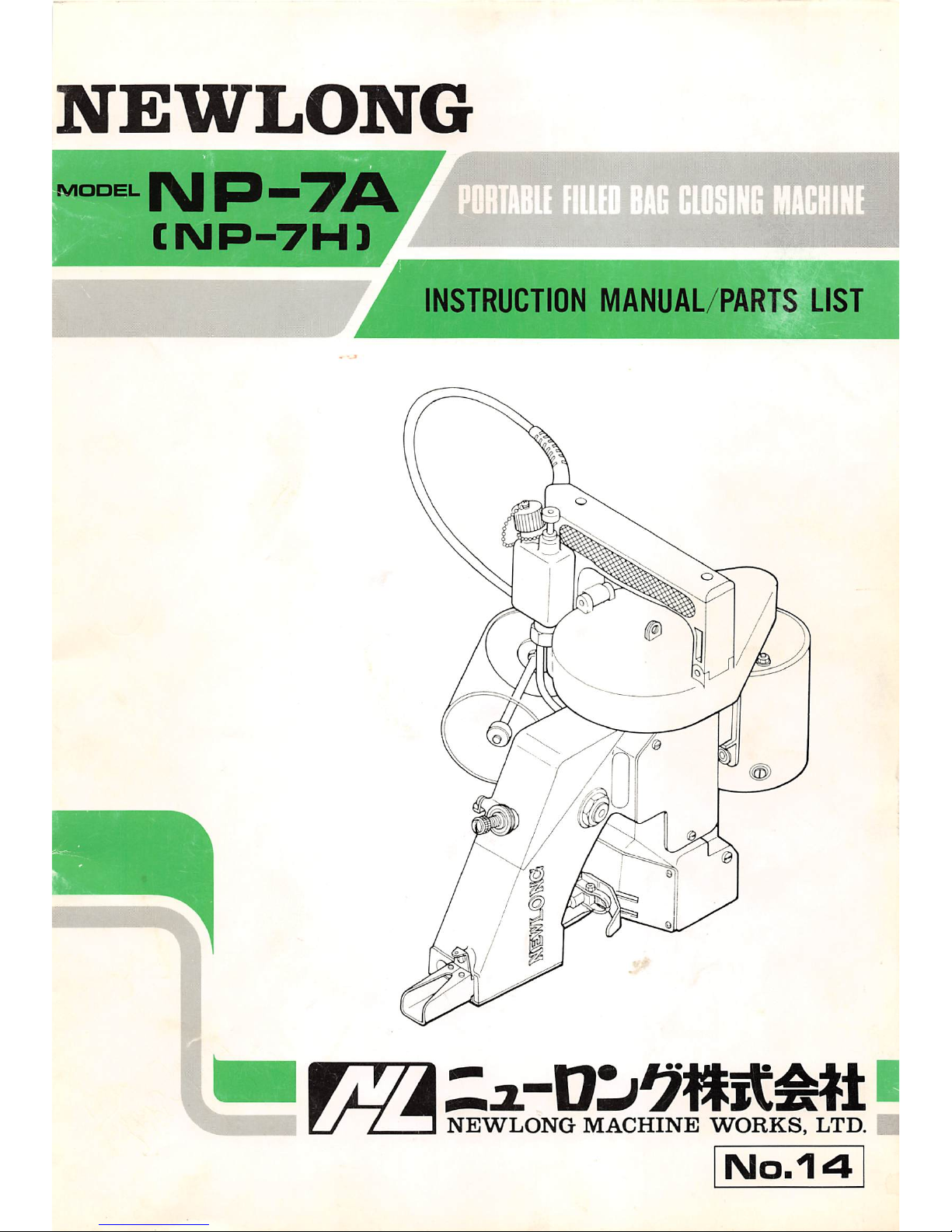

NEWLON6

MODEL

NP-7A

CNP-7H1

PORTABLE

FILLED

BAG

CLOSING

MACHINE

INSTRUCTION

MANUAL/PARTS LIST

NEWLONG

MACHINE

WORKS,

LTD.

No.14

CONTENTS

1.

SPECIFICATIONS

2

2.

PREPARATION

FOR

START

3

1. Oiling 3

2. Needle Setting 3

3. Threading 3

3.

START

4

4.

ADJUSTMENTS

5

1.

Thread

Tension

5

2.

PositionofNeedle

and

Looper

5

3.

PositionofFeed Dog 5

4.

PressureofPresser

Foot

5

5.

REPLACING

PARTS

6

6.

MAINTENANCE

&

LUBRICATION

7

7.

LUBRICATOR

7

1. Operation 7

2.

Maintenance

7

3.

Troubleshooting

8

8.

ORDERING

PARTS

9

NUMERICAL

INDEX

OF

PARTS

26

DIAGRAM

OF SCREW. NUT &

WASHER

28

- 1 -

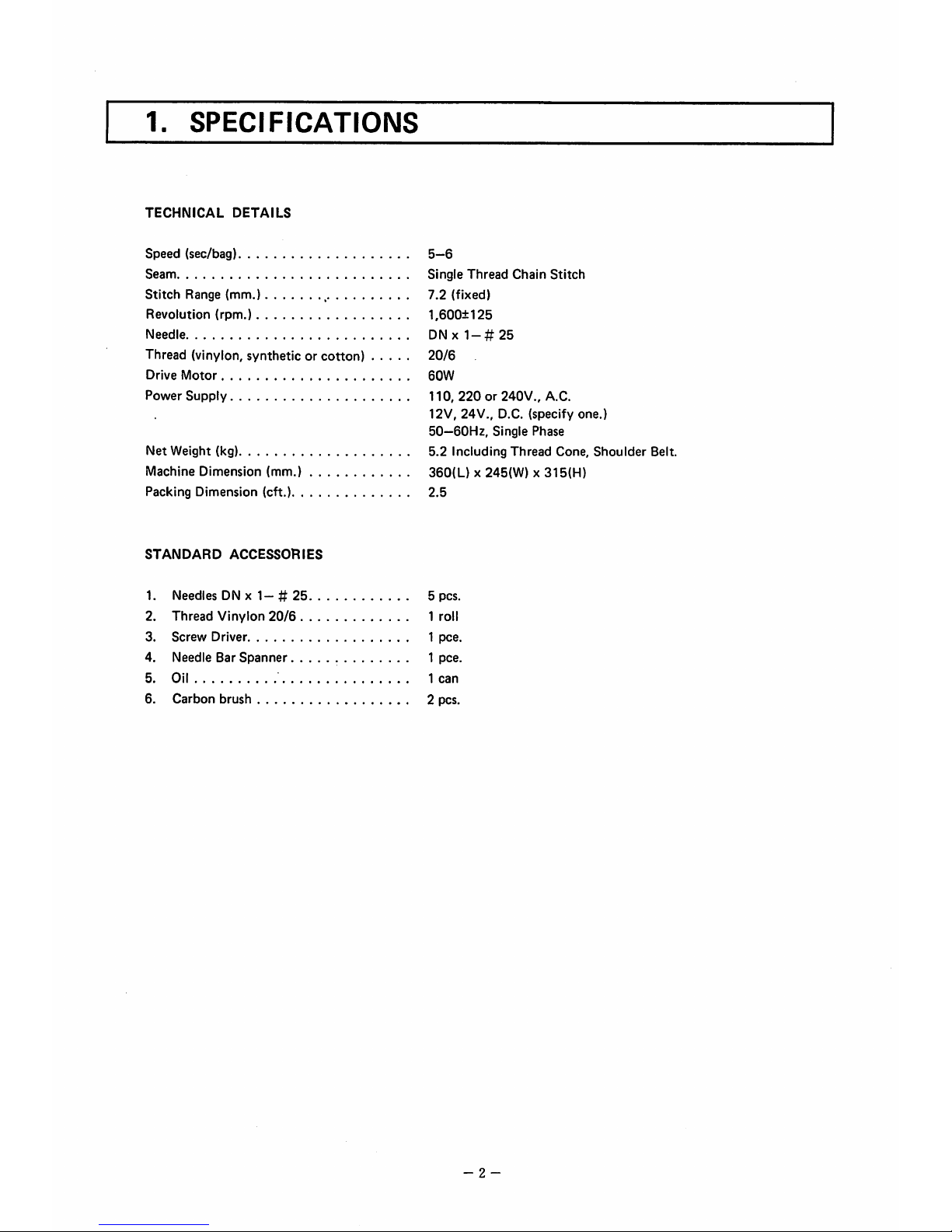

1.

SPECIFICATIONS

TECHNICAL

DETAILS

Speed (sec/bag) 5—6

Seam

Single

Thread

Chain

Stitch

Stitch

Range (mm.) ,

7.2

(fixed)

Revolution

(rpm.)

1,600±125

Needle

DNx1-#25

Thread (vinylon, synthetic or

cotton)

20/6

Drive

Motor

60W

Power

Supply

110,

220

or 240V., A.C.

12V,

24V.,

D.C.

(specify

one.)

50—6OH2,

Single

Phase

Net Weight (kg) 5.2 Including Thread Cone,

Shoulder

Belt.

Machine Dimension (mm.)

360(L)

x 245(W) x 315(H)

Packing Dimension (eft.)

2.5

STANDARD

ACCESSORIES

1.

Needles

DN X

1-#

25

5 pcs.

2.

Thread

Vinylon

20/6

1 roll

3.

Screw

Driver 1

pee.

4.

Needle

Bar

Spanner

1

pee.

5.

Oil

1

can

6.

Carbon

brush 2 pcs.

- 2 -

2.

PREPARATION

FOR

START

1. Oiling (Fig. 1)

Oilingis imperative to keep the machine in good operating

condition. Fill oil in the reservoir (capacity 45 cc). To

feed oil, push the button of the lubricator. One push

feeds 0.08 ccofoil, which would normally service for

several hours

of

operation. Do not run the machine

outofoil, otherwise it will break

down.

2. Needle Setting (Fig. 2,

3,4)

Turn the pulley until Needle Bar reaches its highest

position. Loosen Needle Bar Clamping Nut, and set

Needle in the Bar as deep asit will go.

Be sure to set a Needle with its concave part facing

correctly toward the Looper.

Fbc

Clamping Nut tightly,

otherwise

Needle

may come loose during operation and

break.

3. Threading (Fig. 5)

The machine is delivered being threaded to show you

proper threading

of

the machine, which is shown in

Fig. 5, for identification. Follow the guide numbers

1 to 6ofFig. 5.

® Thread Eyelet

(D Thread Tension Eyelet

(3)

Tension

Disc

@ Thread Eyelet

d)

Needle

Bar

(6) Thread Eyelet

(7) Needle

(D

Tighten

Fig-i y

Loosen

Clannp

Nut

\

Scarf

Fig.4 J

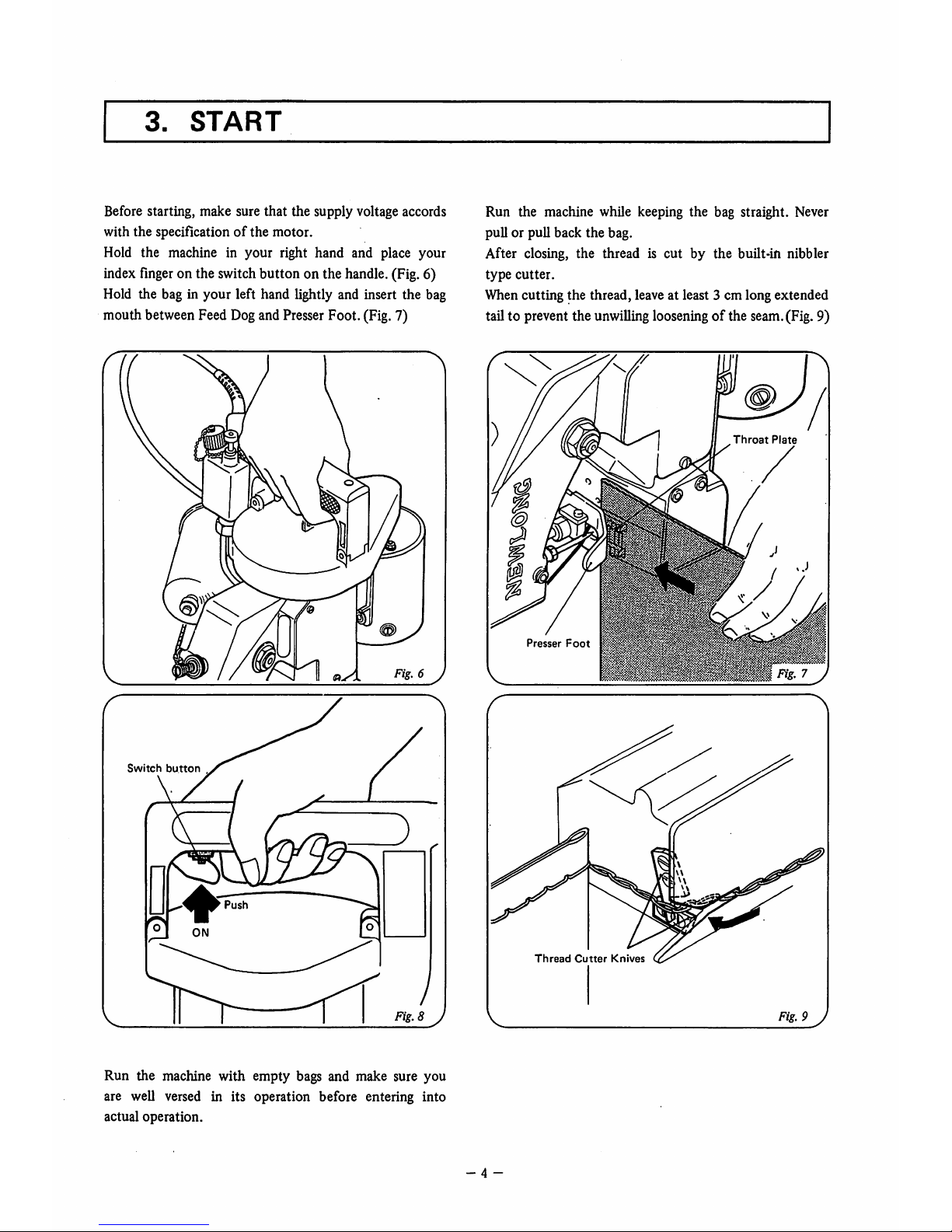

3.

START

Before starting, make sure that the supply voltage accords

with the specification

of

the motor.

Hold the machine in your right hand and place your

index

finger

on the switchbutton on the handle. (Fig. 6)

Hold the bag in your left hand lightly and insert the bag

mouthbetweenFeed

Dog

and

Presser

Foot.(Fig.7)

Fig.

6 J

Switch

button

Run the machine with empty bags and make sure you

are well versed in its operation before entering into

actual operation.

Run the machine while keeping

the

bag straight. Never

pull or pull back the bag.

After closing, the thread is cut by the built-in nibbler

type

cutter.

When cutting the thread, leave at least 3 cm long extended

tail to prevent the unwillinglooseningofthe seam.(Fig. 9)

Throat

Plate

I®

Presser

Foot

Thread

Cutter

Knives

Fig.

9J

- 4 -

4.

ADJUSTMENTS

1.

Thread

Tension

Thread tension is adjustable by turning the Thread

Tension

Nut.

Turn the Nut clockwise for tighter tension and counter

clockwise

for

looser.

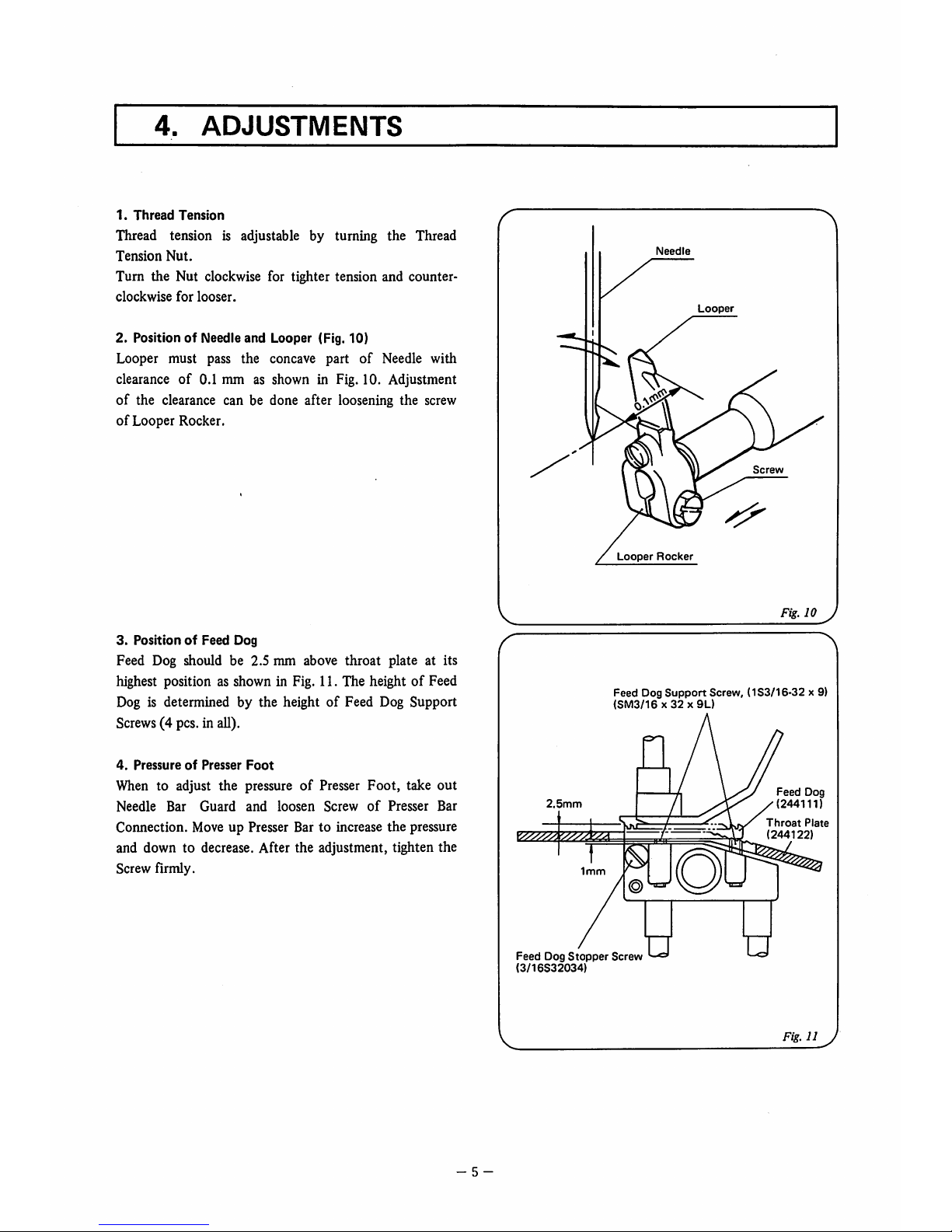

2. PositionofNeedle

and

Looper (Fig. 10)

Looper must pass the concave part

of

Needle with

clearanceof0.1 mm as shown in Fig. 10. Adjustment

of

the clearance can be done after loosening the screw

of

Looper Rocker.

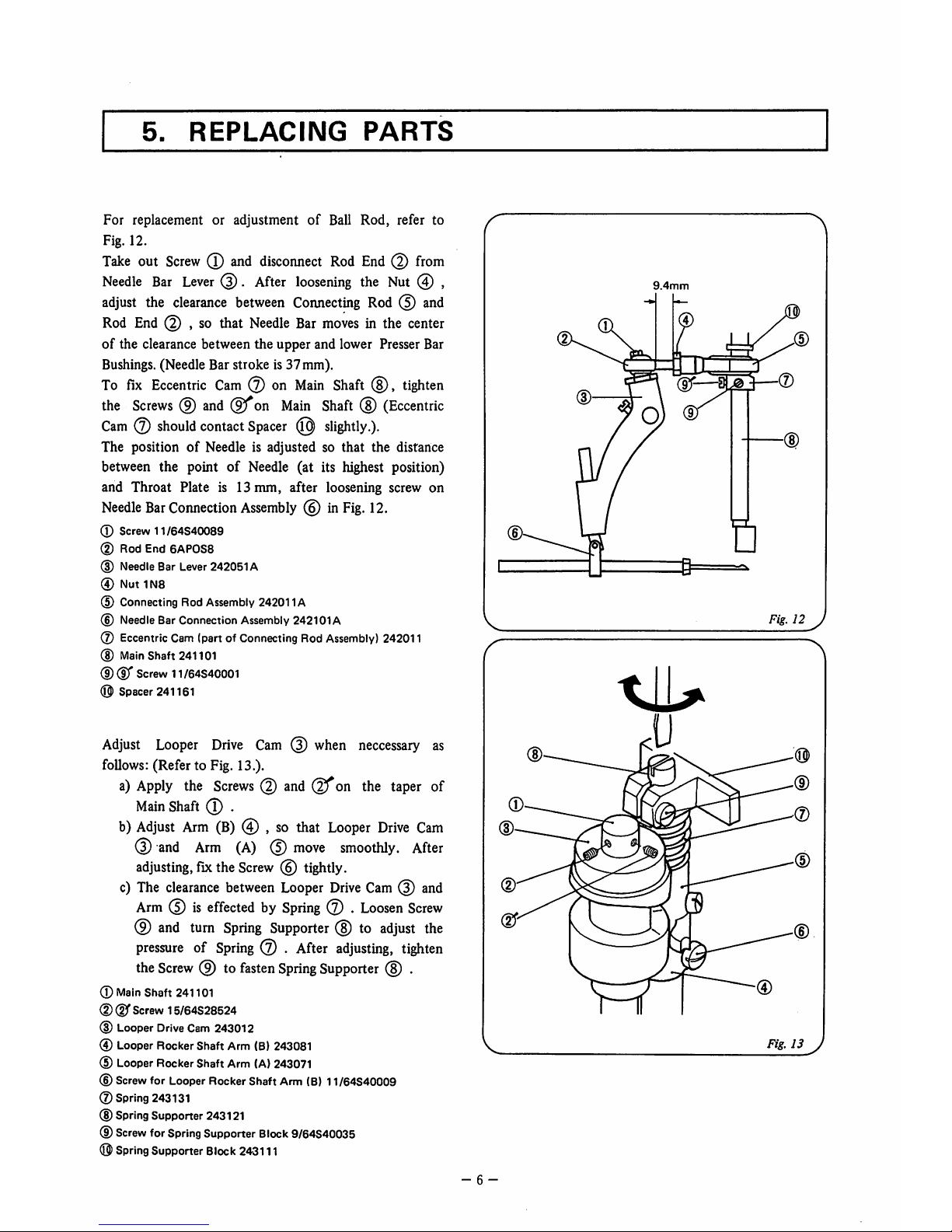

3.

PositionofFeed

Dog

Feed Dog should be 2.5 mm above

throat

plate at its

highest position as shown in Fig. 11. The height of Feed

Dog is determined by the heightofFeed Dog Support

Screws(4 pcs. in all).

4.

PressureofPresser

Foot

When to adjust the pressure of Presser Foot, take out

Needle

Bar

Guard

and

loosen

Screw

of

Presser

Bar

Connection. Move up Presser Bar to increase the pressure

and down to decrease. After the adjustment, tighten the

Screw firmly.

- 5 -

Needle

Looper

Screw

Looper

Rocker

Fig.

10 y

Feed Dog

Support

Screw, (1S3/16-32 x 9)

(SM3/16x32x9L)

2.5mm

Feed

Dog

Stopper

Screw

(3/16S32034)

Feed

Dog

(244111)

Throat

Plate

(244122)

Fig.11J

5.

REPLACING

PARTS

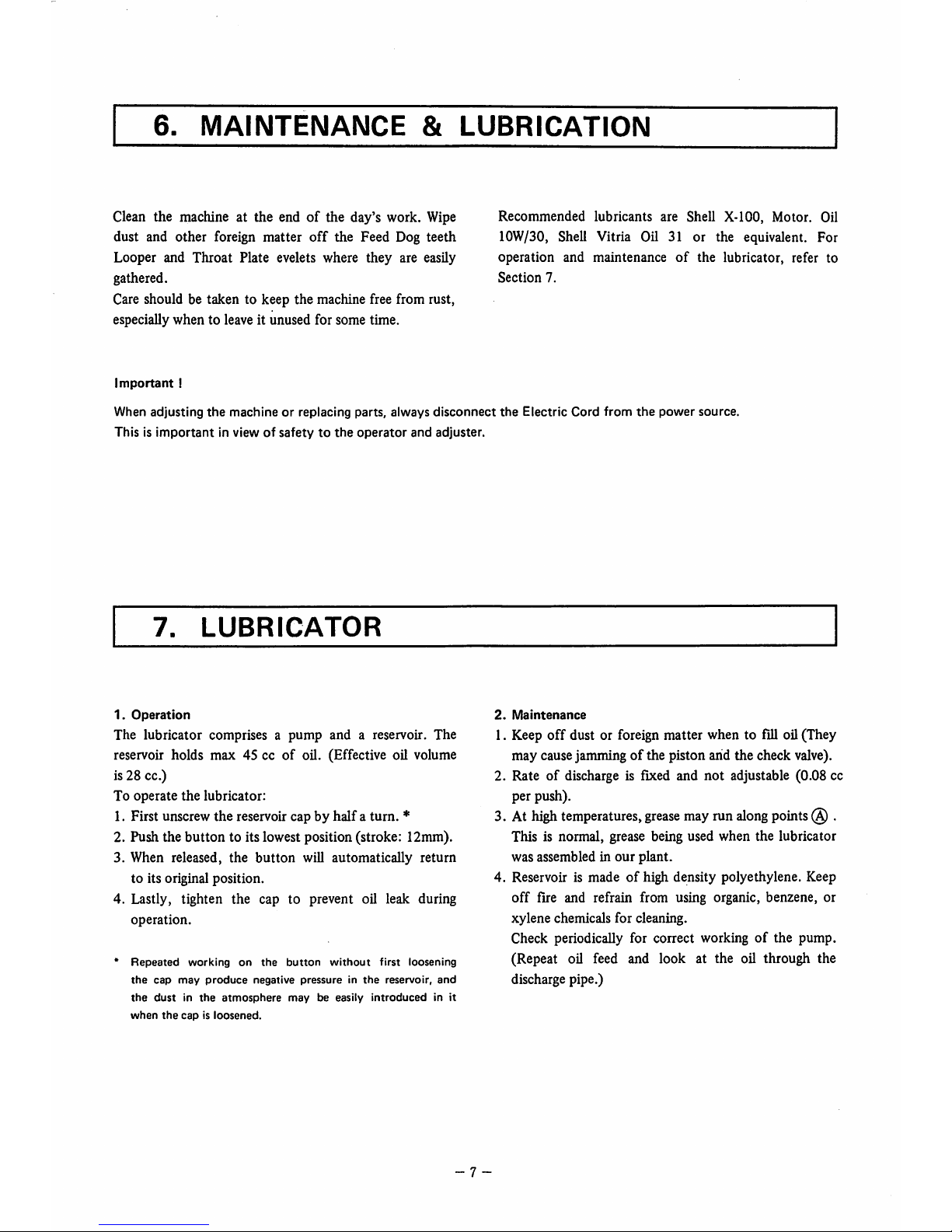

For replacement or adjustmentofBall Rod, refer to

Fig. 12.

Take

out

Screw

(T)

and

disconnect

Rod

End

(2)

from

Needle

Bar

Lever

.

After

loosening

the Nut 0 ,

adjust

the

clearance

between

Connecting

Rod0and

Rod

End

(5) , so that

Needle

Bar

moves

in the

center

of

the clearance between the upper and lower Presser Bar

Bushings.(Needle Bar stroke is 37 mm).

To

fix

Eccentric

Cam

0 on

Main

Shaft

(8),

tighten

the

Screws

(9)

and

on

Main

Shaft

(8)

(Eccentric

Cam0should

contact

Spacer

(0)

slightly.).

The positionofNeedle is adjusted so that the distance

between the point of Needle (at its highest position)

and Throat Plate is 13 mm, after loosening screw on

Needle

Bar

Connection

Assembly

0 in

Fig.

12.

® Screw 11/64S40089

(D Rod End

6APOS8

(D

Needle

Bar

Lever

242051A

® Nut 1N8

(5) Connecting Rod Assembly 242011A

(D

Needle

BarConnection

Assembly

242101A

(7) Eccentric Cam (part of ConnectingRod

Assembly)

242011

(D

Main

Shaft 241101

CD®'

Screw

11/64S40001

O Spacer 241161

Adjust

Looper

Drive

Cam0when

neccessary

as

follows: (Refer to Fig. 13.).

a)

Apply

the

Screws0andQfon

the

taper

of

Main

Shaft

0 .

b)

Adjust

Arm

(B)

0 ,sothat

Looper

Drive

Cam

0

and

Arm

(A)

0

move

smoothly.

After

adjusting,

fix

the

Screw0tightly.

c)

The

clearance

between

Looper

Drive

Cam0and

Arm0is

effectedbySpring

0 .

Loosen

Screw

0

and

turn

Spring

Supporter

0 to

adjust

the

pressureofSpring

0 .

After

adjusting,

tighten

the

Screw

0 to

fasten

Spring

Supporter

0 .

(D

Main

Shaft 241101

®

(D"

Screw

15/64S28524

® Looper

Drive

Cam243012

® Looper Rocker Shaft Arm (B)243081

® LooperRocker Shaft Arm (A)243071

®

Screw

for

Looper

RockerShaft Arm

(B)

11/64S40009

©Spring 243131

® SpringSupporter 243121

®

Screw

for

Spring

Supporter

Block

9/64S40035

®

Spring

Supporter

Block

243111

(D

(D

m-

- 6 -

(D

(D

9.4mm

(D

Fig.

12 J

U

(0)

(D

(D

CD

Fig.

13 J

6.

MAINTENANCE

&

LUBRICATION

Clean the machine at the endofthe day's work. Wipe

dust and other foreign matter

off

the Feed Dog teeth

Looper and Throat Plate evelets where they are easily

gathered.

Care should be taken to keep the machine free from rust,

especially when to leave it unused for some time.

Recommended lubricants are Shell X-100, Motor. Oil

lOW/30, Shell Vitria Oil 31 or the equivalent. For

operation and maintenanceofthe lubricator, refer to

Section

7.

Important

I

When adjusting

the

machineorreplacing parts, always

disconnect

the

Electric Cord

from

the

power

source.

Thisisimportantinviewofsafetytothe

operator

and

adjuster.

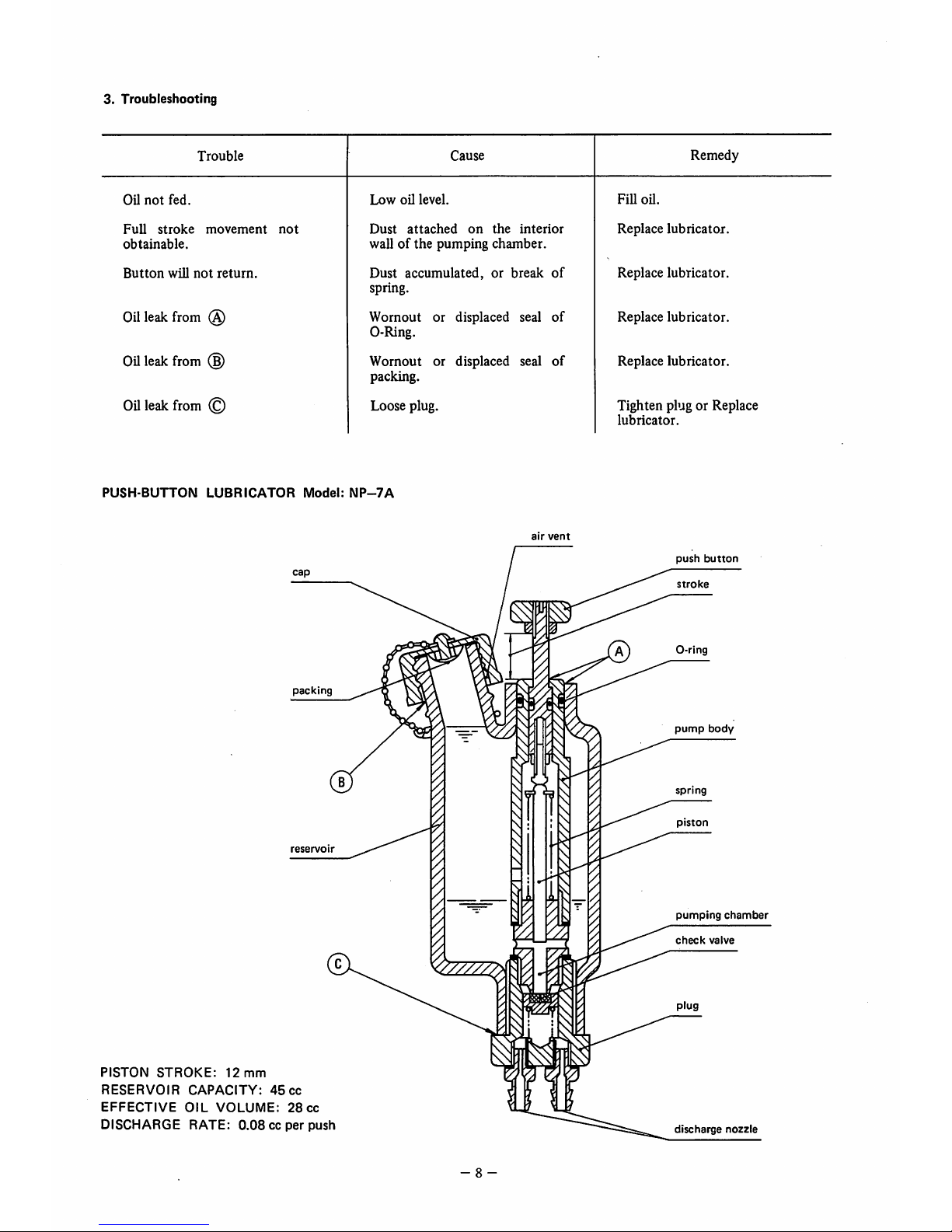

7.

LUBRICATOR

1.

Operation

The lubricator comprises a

pump

and a reservoir. The

reservoir holds max 45 ccofoil. (Effective oil volume

is 28 cc.)

To operate

the

lubricator:

1. First unscrew

the

reservoir capbyhalfaturn.

*

2. Push the button to its lowest position (stroke: 12mm).

3. When released,

the

button

will automatically return

to its original position.

4. Lastly, tighten the cap to prevent oil leak during

operation.

*

Repeated

working

on

the

button

without

first

loosening

the

cap

may

produce

negative

pressureinthe

reservoir,

and

the

dustinthe

atmosphere

maybeeasily

introduced

in it

when

the

capisloosened.

2.

Maintenance

1. Keep

off

dust or foreign matter when to fill oil (They

may cause jammingofthe piston arid the check valve).

2. Rate of discharge is fixed and not adjustable (0.08 cc

per push).

3. At high temperatures, grease may run along points .

This is normal, grease being used when the lubricator

was assembled in our plant.

4. Reservoir is madeofhigh density polyethylene. Keep

off

fire and refrain from using organic, benzene, or

xylene chemicals for cleaning.

Check periodically for correct working of the pump.

(Repeat oil feed and look at the oil through the

discharge pipe.)

7 -

3.

Troubleshooting

Trouble

Cause

Remedy

Oil

not

fed.

Low

oil

level.

FiU

oil.

Full

stroke

movement

not

obtainable.

Dust

attached

on

the

interior

wallofthe pumping chamber.

Replace

lubricator.

Button

will

not

return.

Dust

accumulated,orbreak

of

spring.

Replace lubricator.

Oilleak from (S)

Wornout or displaced seal

of

0-Ring.

Replace lubricator.

Oil

leak

from

(§)

Wornout or displaced seal

of

packing.

Replace lubricator.

Oil

leak

from

© Loose plug. Tighten plug or Replace

lubricator.

PUSH

BUTTON

LUBRICATOR

Model;

NP-7A

packing

reservo

r

PISTON

STROKE:

12

mm

RESERVOIR

CAPACITY:

45

cc

EFFECTIVE

OIL

VOLUME:

28

cc

DISCHARGE

RATE:

0.08ccper

push

air

vent

- 8 -

push

button

stroke

pump

body

spring

piston

pumping

chamber

check

valve

discharge

nozzle

8.

ORDERING

PARTS

The parts list showing all the parts used in the machine is included in this book.

Check the list, and specify parts numbers and quantities required clearly.

Send yourorder to the nearest agent, distributor or one of

our

branch offices.

1. Description of each part and its stamp number is describedin this parts list.

Screws and nuts for parts are shown adjacent to the relevant parts. When ordering parts, describe

clearly

stamp

number

with

its

nameofpart.

2. The parts which have no Ref. Number can not be delivered independently; always order it as an

assembly.

3. A

setofassembled

parts

is represented by

the

stamp

numberofits

main

parts.

4.

The

last figure in

the

parts stamp number advances on each improvementofthe parts.

5.

Part

No.

described

in [ ]ofRemarks

means

old

part

No.

*

The

part

list is

subjecttochange

without

prior

notice.

CONTENTS

(1) THREAD

TENSION

AND COVER PARTS 10

(2)

BUSHINGS,

OILINGS

AND

HANDLE

PARTS 12

(3)

NEEDLE

BAR,

PRESSER

BAR

AND

DRIVING

PARTS

14

(4)

LOOPER

DRIVING

PARTS

16

(5) FEED

DRIVING

AND

THREAD

CUTTER

PARTS

18

(6)

MOTOR

PARTS

(ForTotally

Enclosed

Type

Motor)

20

(7)

SPECIAL

PARTS

FOR NP-7H TYPE 22

(8) CREPE

TAPE

BINDING

AND

CUTTER

PARTS

(Special OrderParts) 24

NUMERICAL

INDEX

OF

PARTS

26

- 9 -

(1)

THREAD TENSION AND COVER PARTS

@

27

28

29

-10-

(1)

THREAD

TENSION

AND

COVER

PARTS

Ref.No.

Part

No.

Description

Q'ty

Remarks

1

245042

Thread

Stand

1

2

15/64S28028

Screw,

for

245042

2

3

1N6

Nut

2

4

3W6

SpringWasher

1

5

2W6

Washer

1

6

KOlOOl

Thread

7

245052

Thread Cone Clamping Rod

1

8

245201

Thread Cone Clamping Nut

1

9

245013

Top Cover

1

10

9/64S40043 Screw, for

245013

11

245261

Thread Eyelet

1

12

11/64S40005

Screw, for 245261

1

13

245071

Thread Tension Eyelet

1

14

245081A

Thread

Tension

Assembly

1

(15-19)

15

245081

Tension

Post

1

16

065261

Tension

Disc

17

245101

Tension Spring

1

18

245091

Tension

Nut

19

9/64S40011

Screw, for

245081A

1

20

245033

Needle

Bar

Guard

1

21

11/64S40005

Screw,

for

245033

1

22

9/64S40065

Screw, for

245033

23

245222

Looper Cover

1

24

9/64S40065

Screw, for

245222

25

245022

Side

Plate

1

26

9/64S40005

Screw, for

245022

27

245481

Gasket

1

28

245302

Inside

Cover

1

29

9/64S40005

Screw, for

245302

4

30

245181

Thread

Cone

Cover

(1)

Special Order

-11-

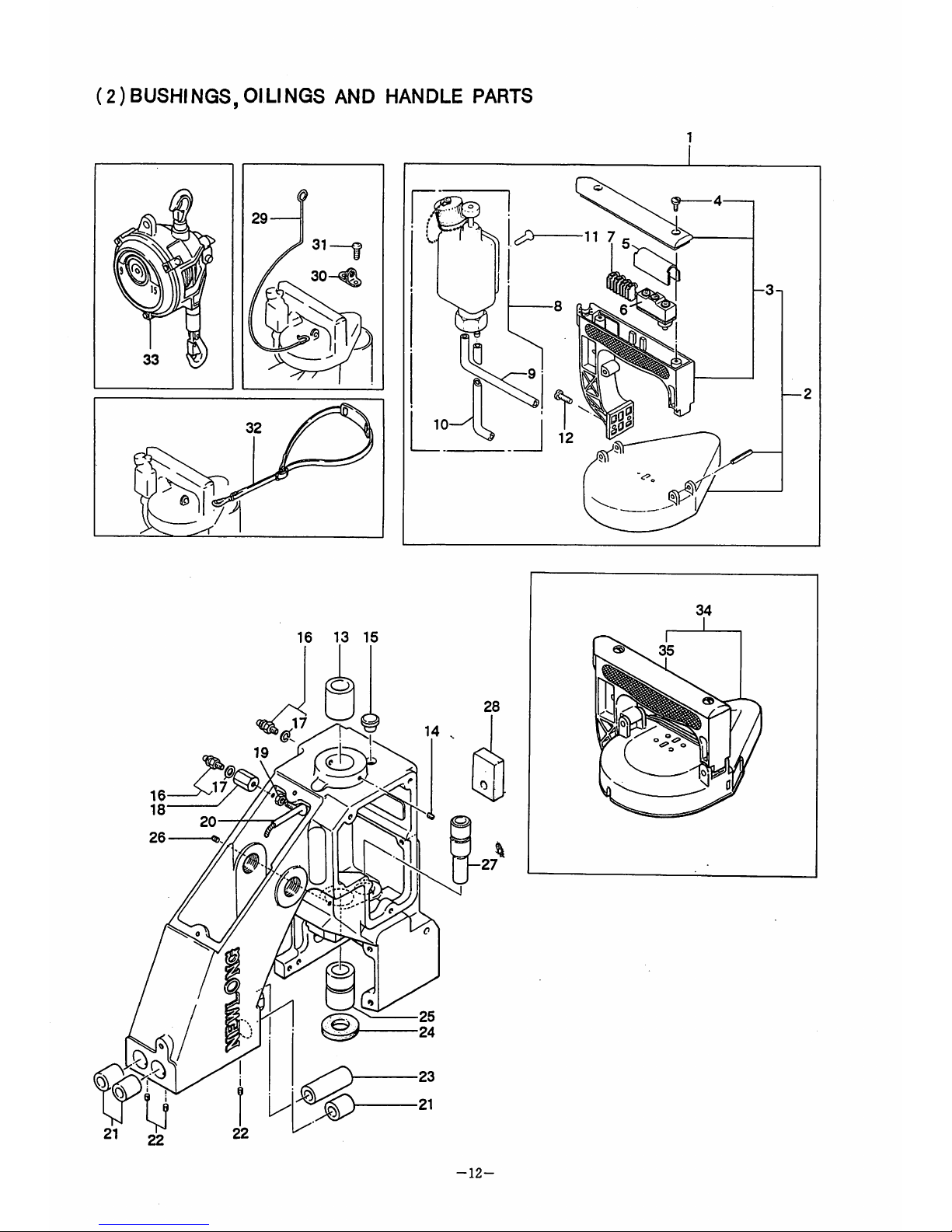

(2)BUSHINGS,01

LINGS

AND

HANDLE

PARTS

16 13

15

-12-

(2)

BUSHINGS,01LINGS

AND

HANDLE

PARTS

Ref.No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

Part

No.

241024AS

241024A

241024

9/64S40011

245132

C02001

C02006

C05008

D03003

8FU2-6x90F

8FU2-6x60F

685x15

15/64828021

241122

9/64840502

065401

D07021

E03014

245471

1N4

245461

242212

9/64840502

242222

205131

241111

9/64840502

243021

245162

245271

241151

1/8840006

245171

EW-6.5

241024BS

241024B

Description

Handle Assembly

Handle Assembly

Handle

8crew,

for

241024A

Micro

8witch

Cover

Micro8witch (Z-15GK655-B)

Micro

8witch

(X-IOGD-B)

FlexibleTerminalBlock(ML-8K-1,4?)

Oiler

Oil Tube,

with

oil felt

Oil Tube, with oil felt

8crew, for D03003

8crew, for

241024A

Main8haft Bushing,rear

8crew,for241122

Rubber Bushing

Joint

(BN-5-6)

Washer

Joint

Nut

Oil Pipe

Bushing for PresserBar&NeedleBar, upper

8crew,

for

242212

Presser Bar Bushing,lower

Oil

Felt

Main8haft Bushing,rear

8crew, for 241 111

Looper Rocker 8haftBushing

Oil

Felt

Hanger

Hook

8crew, for 241151

8houlder

Belt

^

8pring Balancer

Handle

Assembly

(Safety

type

with pulley

cover)

Handle

Assembly

(Safety

type

with pulley

cover)

-13-

Q'ty

)

(2)

Remarks

(2-11)

(3,4)

(4)

forDCmotor

(9,10)

(17)

-8pecial

Order

(2-11)

(3,4)

Ref.No.

m

Part

No.

241092

3/16S28001

241131

11/64S40502

241161

205131

241101

242011A

242011

3/16S28029

11/64S40001

1N8

Descnption

Synchro

Pulley

Screw, for

241092

Retaining

Collar

Screw,

for

241131

Spacer

Oil

Felt

Main

Shaft

Connecting Rod Assembly

Connecting Rod Sub-Assembly

Screw, for connecting rod cap

Screw, for eccentric

cam

Nut,

for

242011A

Q

ty

Remarks

(9-14)

(10,11)

(3)

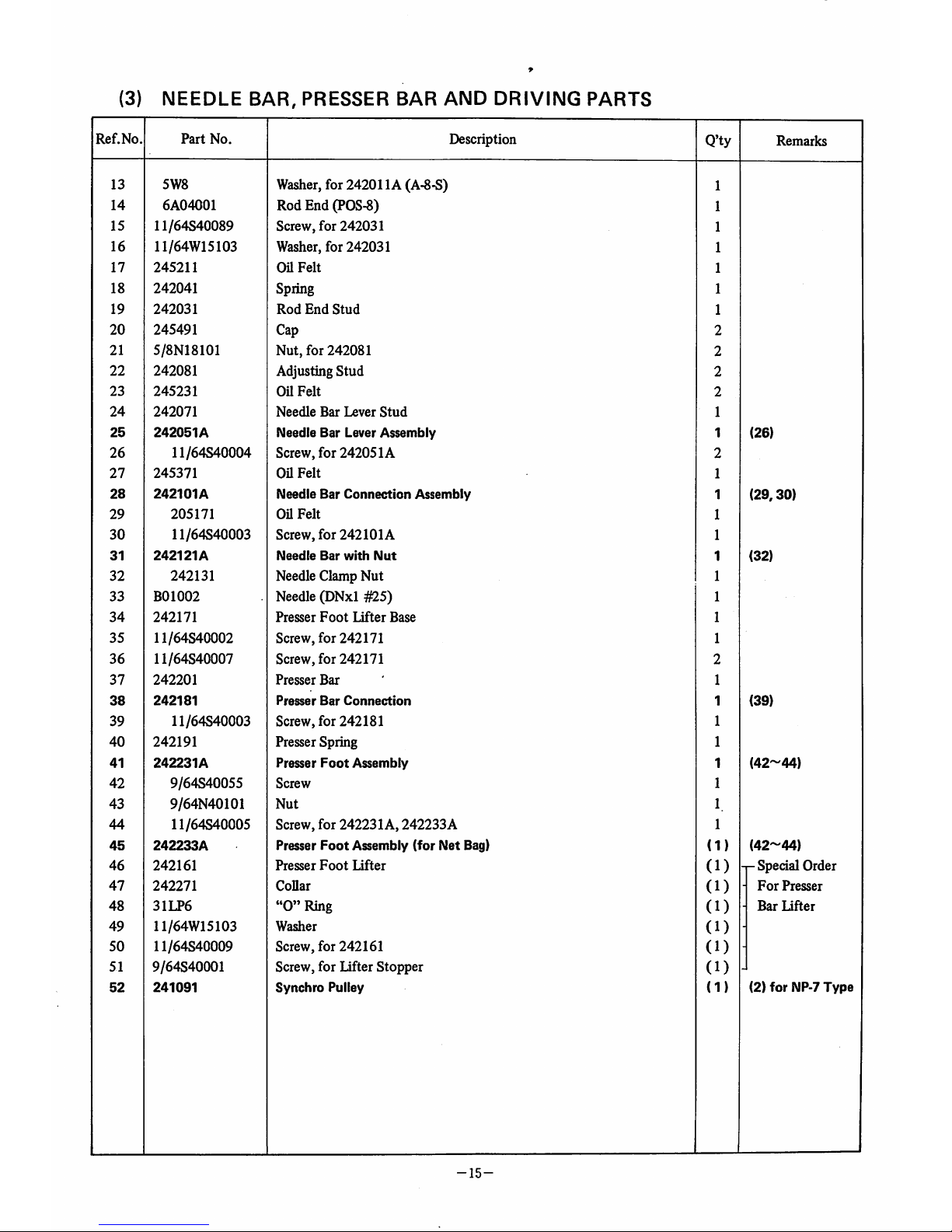

NEEDLE

BAR,

PRESSER

BAR AND

DRIVING

PARTS

Ref.No.

Part

No.

Description

Q'ty

Remarks

13

5W8

Washer,for 242011A (A-8-S)

1

14

6A04001

Rod End (POS-8)

1

15

11/64S40089

Screw, for 242031

1

16

11/64W15103 Washer,

for

242031

1

17

245211

Oil

Felt

1

18

242041

Spring 1

19

242031

Rod

End

Stud

1

20

245491

Cap

2

21

5/8N18101

Nut,

for 242081

2

22

242081

Adjusting

Stud

2

23

245231

GUFelt

2

24

242071

Needle

Bar

Lever

Stud

25

242051A

Needle

Bar

Lever

Assembly

1

(26)

26

11/64S40004 Screw,

for

242051A

27

245371

Oil

Felt

1

28

242101A

Needle

Bar

Connection

Assembly

1

(29,30)

29

205171

Oil

Felt

1

30

11/64S40003 Screw,

for

242101A

1

31

242121A

Needle

Bar

with

Nut

1

(32)

32

242131

Needle Clamp Nut 1

33

B01002

Needle (DNxl #25) 1

34

242171

Presser

Foot

Lifter

Base

35

11/64S40002 Screw, for 242171 1

36

11/64S40007 Screw, for 242171

37

242201

Presser

Bar

1

38

242181

Presser

Bar

Connection

1

(39)

39

11/64S40003 Screw,

for

242181

1

40

242191

Presser Spring 1

41

242231A

Presser

Foot

Assembly

1

(42-44)

42

9/64S40055

Screw

1

43

9/64N40101

Nut

1

44

11/64S40005 Screw, for 242231A,

242233A

1

45

242233A

Presser

Foot

Assembly (for

Net

Bag)

(1)

(42-44)

46

242161

Presser

Foot

Lifter

(1)

p

Special

Order

47

242271

Collar

(1)

•

For

Presser

48

31LP6

"0"

Ring

(1)

•

Bar

Lifter

49

11/64W15103

Washer

(1)

-

50

11/64S40009

Screw, for 242161

(1)

-

51

9/64S40001 Screw, for Lifter Stopper

(1)

52

241091

Synchro

Pulley

(1)

(2)

for

NP-7

Type

-15-

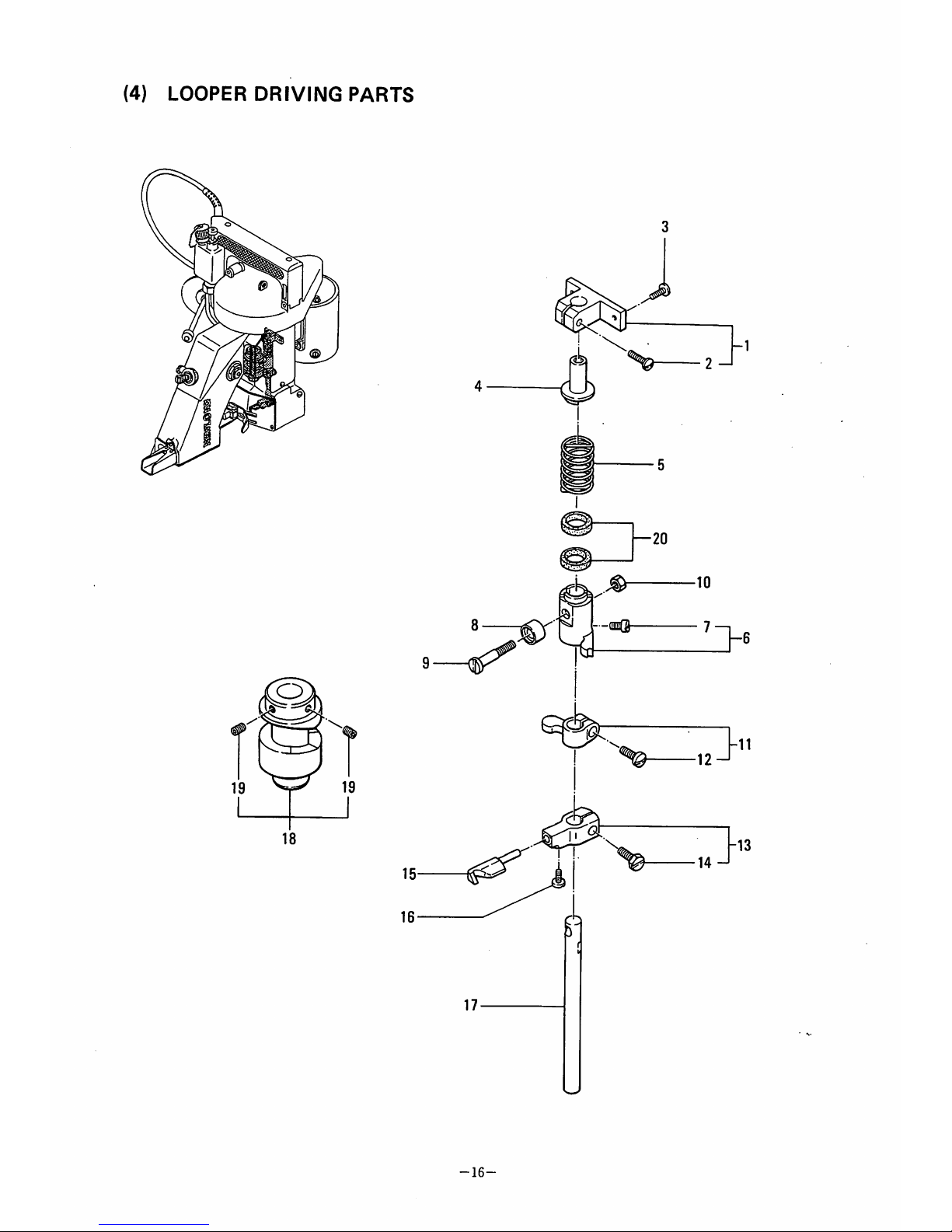

(4)

LOOPER

DRIVING

PARTS

17

-16-

(4)

LOOPER DRIVING PARTS

Ref.No,

4-1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Part

No.

243111

9/64S40035

9/64S40005

243121

243131

243071

11/64S40002

243041

243061

11/64N40201

243081

11/64S40009

243092

11/64S40089

243102

9/64S40001

243032

243012

15/64S28524

205131

Description

Spring

Supporter

Block

Screw, for 243111

Screw, for 243111

Spring

Supporter

Spring

Looper

Rocker

Shaft

Arm

(A)

Screw,

for

243071

Roller

Roller

Stud

Screw

Nut,

for 243061

Looper

Rocker

Shaft

Arm

(B)

Screw, for 243081

Looper

Rocker

Screw, for

243092

Looper

Screw, for

243102

Looper Rocker Shaft

Looper

Drive

Cam

Screw,

for

243012

Oil

Felt

-17-

Q'ty

Remarks

(2)

(7)

(12)

(14)

(19)

(5)

FEED

DRIVING

AND

THREAD

CUTTER

PARTS

31 ^

30

-18-

(5)

FEED

DRIVING

AND

THREAD

CUTTER

PARTS

Ref.No.

Part

No.

Description

Q'ty

Remarks

5-1

244011A

Feed

Dog

Carrier

Block

Assembly

1

(2,3)

2 183/16-32x9

Feed Dog8upport8crew (8M3/16x32x9)

4

3

245391

Oa

felt

1

4

244102

81ide

Block

Guide

8tud

1

5

9/64S40011 8crew, for

244102

2

6

246011

Knife

Bracket

Extension

1

7

3/16S32031 8crew, for 246011 2

8

244111

Feed Dog

1

9

3/16S32034 8crew, for 244111

1

10

244081

81ide

BlockAdjusting

1

11

3/16S32025 Lock Bolt, for 244091

2

12

11/64W15103

Washer, for 244091

2

13

244091

8tud

8Ude Block Adjusting 8upport

2

14

3/8N24201 .

Lock

Nut,

for 244091

2

15

244122

Throat

Plate

1

16

9/64S40043 8crew, for

244122

3

17

246081

BaU

1

18

lB3xl2

Bolt, for 246081 (M3x0.5xl2 2)

1

19

1N3

Nut, for 246081 (M3x0.5)

1

20

1W3

Washer,for 246081 (M3)

1

21

11/64840049

8crew, for 246021

1

22

11/64W15103 Washer, for 246021

1

23

246021

Kiufe

Bracket

1

24

246032

Knife

Bracket

Pin

1

25

246042

Bushing,for 246032

1

26

246051

Knife Tension 8pring

1

27

9/64840502

8crew, for

246042

1

28

246061

Knife Moving

1

29

1/8840003 8crew, for 246061

30

246071

Knife 8tationary

1

31

1/8840003

8crev/, for 246071

32

3W3

8pring Lock

Washer

(M3)

1

-19-

I

11,25

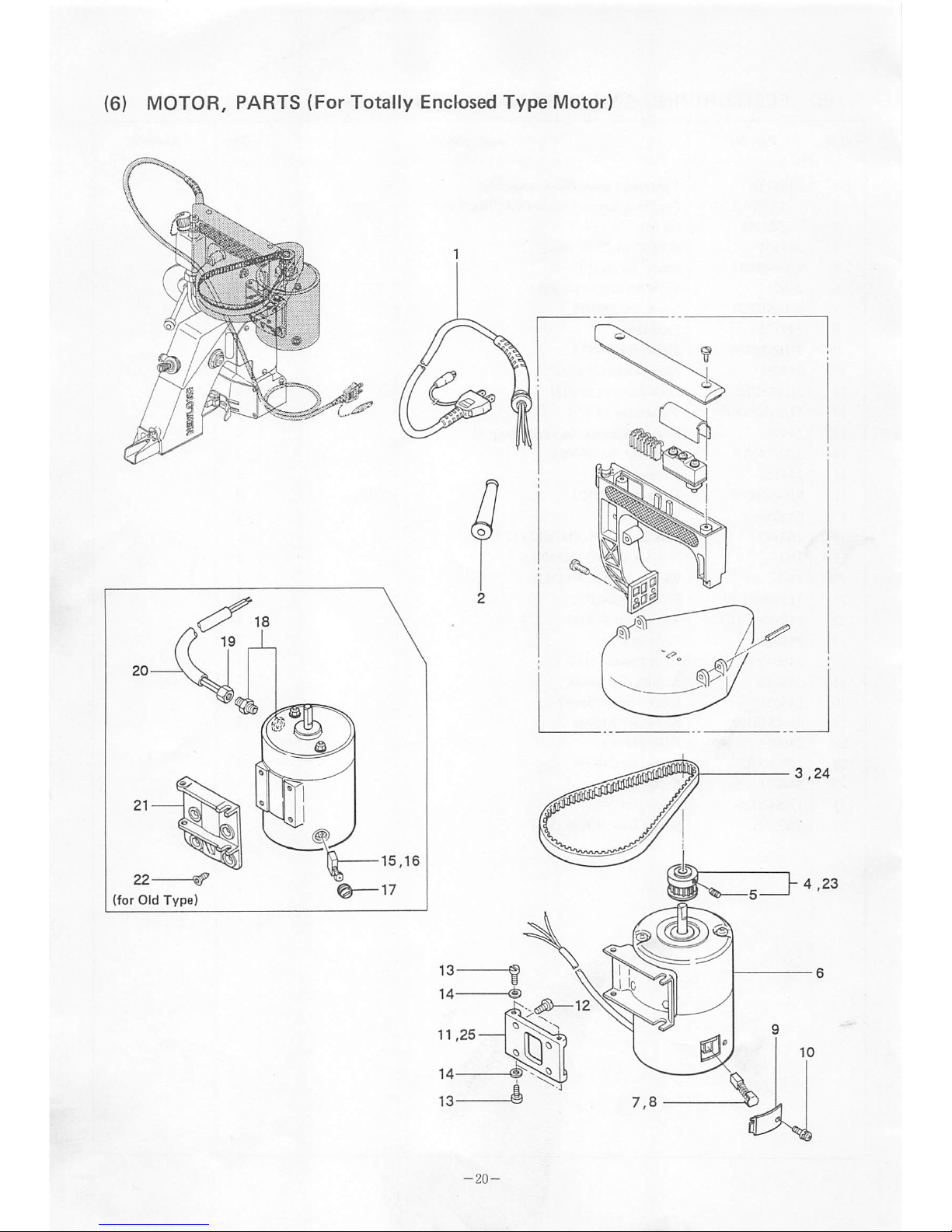

(6) MOTOR, PARTS (For Totally Enclosed Type Motor)

Ref.No

Part

No.

C04001

C04003

C04004

C04005

C04006

C04007

C04009

211151

FOlOOl

241083

11/64S40504

COlOlO

COlOll

C01012

C01013

C01014

7

C08004

8

C08005

9

C07003

10

4S3x6-W

11

241073

12

15/64S28021

13

11/64S40075

14

11/64W10101

15

C08001

16

C08003

17

C07001

18

245321

19

245501

20

245361

21

241062

22

FC103238

23

24

F01002

25

241072

Description

Cabtyer Cord, with Plug (Standard Type)

Cabtyer Cord, with Plug (American Type)

Cabtyer Cord, with Plug(British TVpe)

Cabtyer Cord, with Plug(German Type)

Cabtyer Cord,with Plug(French Type)

Cabtyer Cord, with Plug(Australian Type)

Cabtyer Cord, with Plug(for DCMotor)

Rubber Bushing(for C04003-C04007)

Timing Belt

Motor

Pulley

Screw, for

241083

UniversalMotor (1lOV)

Universal Motor (220V)

Universal Motor (240V)

UniversalMotor (24V)

UniversalMotor (12V)

Carbon Brush,for ACMotor (size 6x 8x 15)

Carbon Brush,for DC Motor (size 6x 8x 15)

Cap

Screw (with washer)

Motor

Base

B

Screw, for

241073

Screw, for Motor

Washer, for Motor

Carbon Brush,for ACMotor (size 5x8x 14)

Carbon Brush,for DC Motor (size 5x 8x 14)

Cap

Connector

B

Nut

Cord

Cover

Motor

Base

A

Screw, for

241062

Motor

Pulley

(for

Old

type)

Timing Belt (for Old type)

Motor

Base

B

-21-

Q'ty

2

2

2

2

1

4

4

4

(2)

(2)

(2)

(1)

(1)

(1)

(1)

(4)

(1)

(1)

(1)

Remarks

(5)

(7,9,10)

(7,9,10)

(7,9,10)

(8~10)

(8-10)

-r

for

Old

Part

(5)

for NP-7Type

(7)

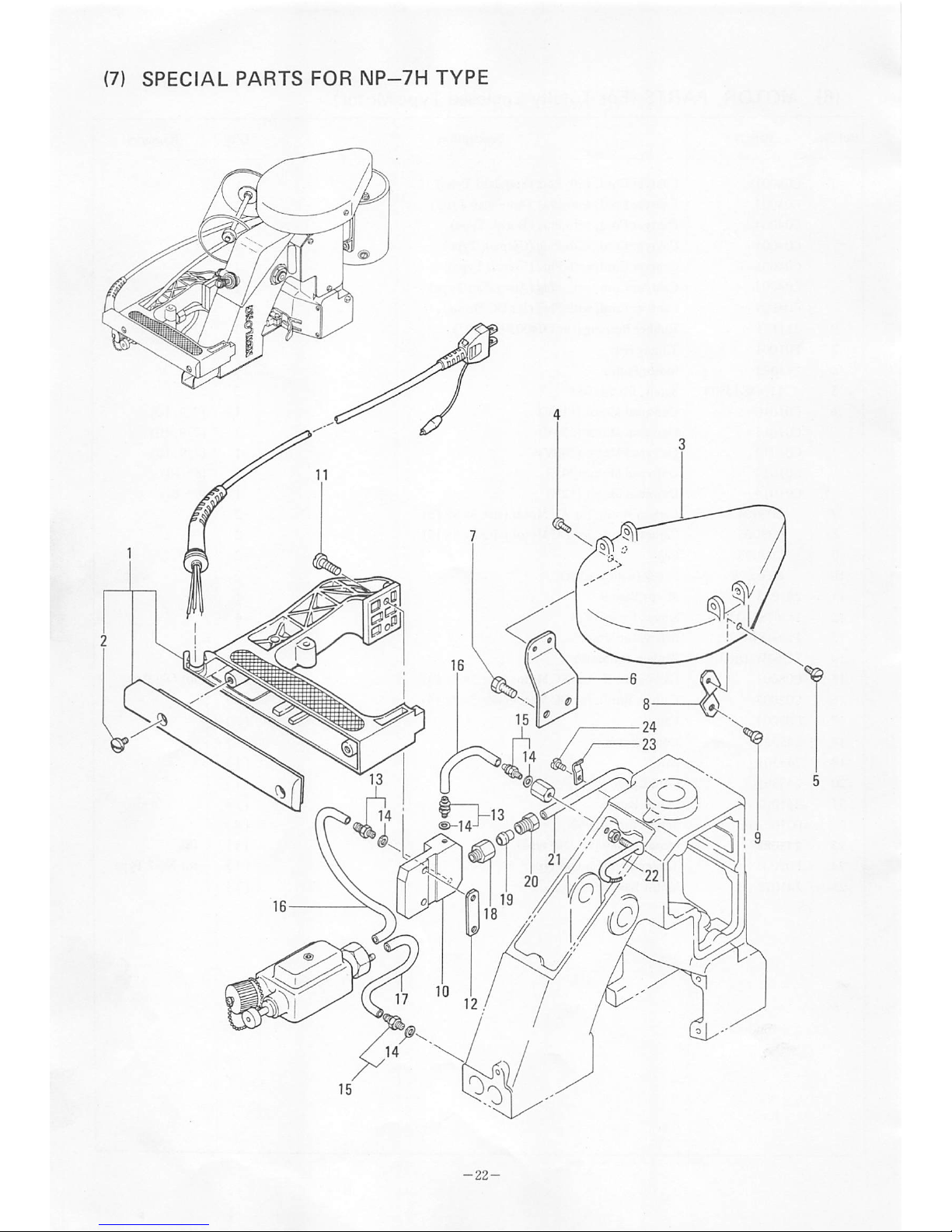

SPECIAL

PARTS

FOR

NP-7H

TYPE

Ref.No

7-1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Part

No.

241024

9/64S40011

241212

9/64S40004

9/64S40052

241242

15/64S28004

241231

9/64S40005

241223

15/64S28032

241253

D07021

E03014

D07021

8FU2-6x95F

8FU2-6x70F

D07022

D07023

D07024

8FN24xl35F

245462

D07009

9/64S40005

Description

Handle

Screw

Pulley Cover

Screw, for

241053

Screw, for

241053

Pulley Cover Holder A

Screw, for

241242

Pulley Cover Holder B

Screw,

for

241231

Handle

Base

Screw, for

241253

Handle

Base

Holder

Joint

(BN-5-6)

Washer

Joint

(BN-5-6)

OilTube (06x95 fi),with oil felt

Oil Tube (06x70 £), with oil felt

Joint

Compression Sleeve

Compression Bushing

OilTube (06x135

fi),

with oilfelt

Oil Pipe

Tube

CUp

(PC4-1)

Screw,

for

D07009

•23-

Q'ty

1

2

1

2

1

1

2

1

1

1

2

1

2

4

2

2

Remarks

(2)

(14)

(14)

(8) CREPE TAPE

BINDING

AND CUTTER PARTS (Special Order Parts)

11,37

13,38

17,39

-24-

(8) CREPE TAPE BINDING AND CUTTER PARTS (Special Order Parts)

Ref.No.

Part

No.

Description

Q'ty

Remarks

8-1

247071

Crepe Tape Bracket

1

2

247091

Crepe Tape Hanger Stud

1

3

9/64S40035 Screw, for 247071

4

1N6

Nut, for 247091 (M6) 1

5

2W6

Washer,

for 247091 (M6) 1

6

247081

Crepe Tape Supporter 1

7

11/64S40015 Screw, for 247071 1

8

1/4W03205 SpringWasher,for 247071 1

9

1/4W15105

Washer, for 247071

1

10

11/64N40203 Nut,

for

247071 1

11

244132

Throat

Plate

1

12

9/64S40043

Screw, for

244132

3

13

247051

Holder, for crepe tape binder 1

14

9/64S40043

Screw, for 247051

2

15

9/64N40101

Nut, for 247051

2

16

2W4

Washer,for 247051 (M4)

2

17

247061

Crepe Tape binder 1

18

9/64S40054 Screw, for 247061 2

19

2W4

Washer,

for 247061 (M4)

2

20

247031

Cutter

Lever

1

21

11/64S40046 Screw, for 247011 2

22

11/64W10101 Washer, for 247011 2

23

247041

Screw, for 247031

1

24

15/64N28206

Nut,

for 247021 2

25

3W6

SpringLock

Washer,

for 247021, (M6) 2

26

2W6

Washer,

for 247021, (M6)

2

27

11/64S40029

Stopper Screw, for 247011

1

28

3/16S32026

Stopper Screw, for 247031

1

29

247021

Hinge Pin

1

30

247011

Knife, Moving

1

31

247001

Knife, Stationary 1

32

1/8S40003 Screw, for 247001

33

183261

Spring

Hook

1

34

247073

Crepe Tape Bracket

(1)

pfor

Crepe

35

247092

Crepe Tape HangerStud

(1)

-

Tape width

36

247082

Crepe Tape Supporter

(1)

-

70

mm

37

244133

Throat

Plate

(1)

•

38

247052

Holder, for crepe tape binder

(1)

-

39

247063

Crepe tape Binder

(1)

-

40

242261A

Presser

Foot

Assembly

(1)

-25-

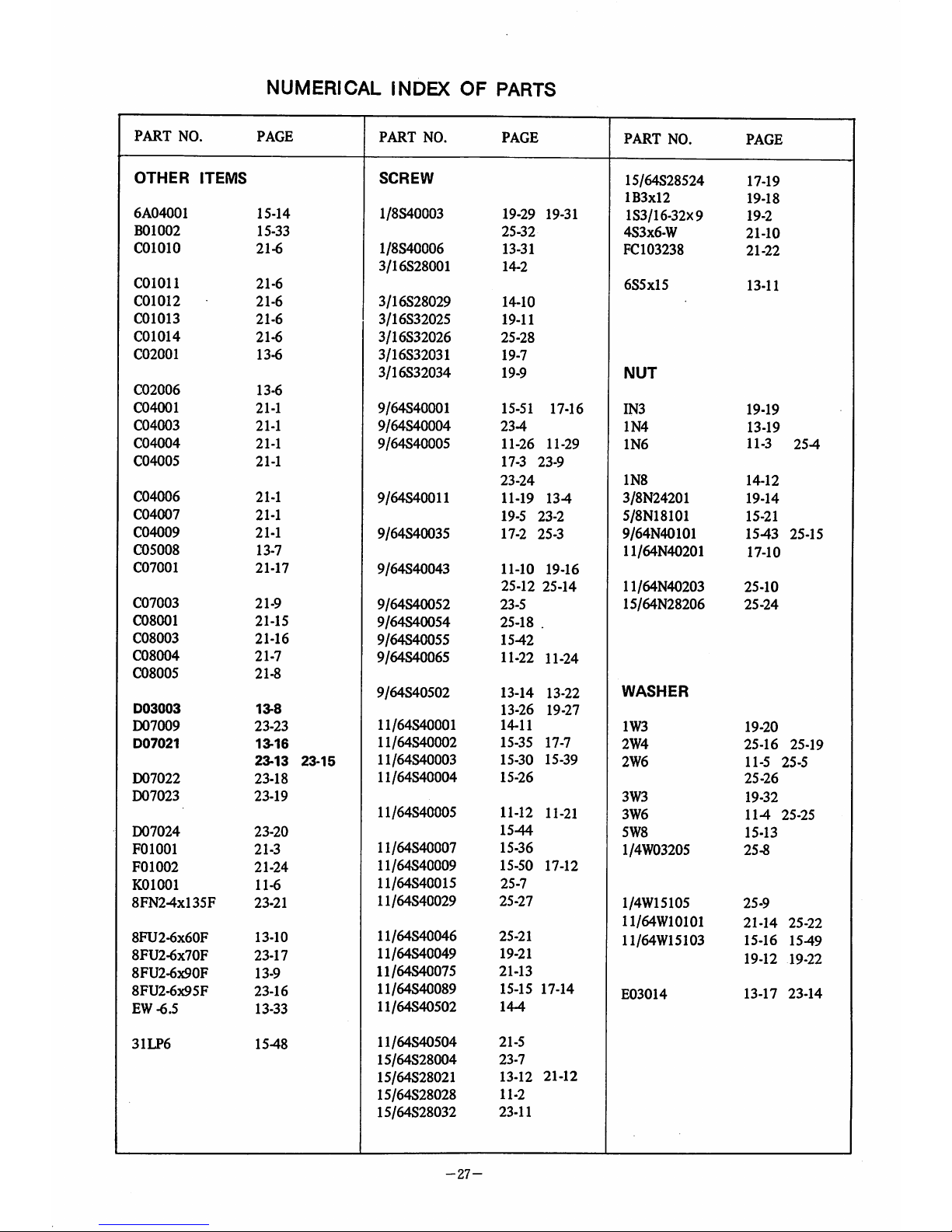

NUMERICAL

INDEX

OF

PARTS

PART

NO.

PAGE

PART

NO.

PAGE

PART

NO.

PAGE

065261

11-16

242212

13-21

245271

13-29

065401

13-15

242222

13-23

245302

11-28

183261

25-33

242231A

15-41

245321

21-18

205131

13-24

14-6

242233A

15-45

245361

21-20

17-20

242261A

25-40

245371

15-27

205171

15-29

242271

1547

2453^1

19-3

211151

21-2

243012

17-18

245461

13-20

243021

13-27

245462

23-22

241024

13-3

23-1

243032

17-17

245471

13-18

241024A

13-2

243041

17-8

245481

11-27

241024AS

13-1

243061

17-9

245491

15-20

241024B

13-35

243071

17-8

245501

21-19

241024BS

13-34

243081

17-11

246011

19-6

241062

21-21

243092

17-13

246021

19-23

241072

21-25

243102

17-15

246032

19-24

241073

21-11

243111

17-1

246042

19-25

241082

21-23

243121

174

246051

19-26

241083

21-4

243131

17-5

246061

19-28

241091

15-52

244011A

19-1

246071

19-30

241092

14-1

244081

19-10

246081

19-17

241101

14-7

244091

19-13

247001

25-31

241111

13-25

244102

194

247011

25-30

241122

13-13

244111

19-8

247021

25-29

241131

14-3

244122

19-15

247031

25-20

241151

13-30

244132

25-11

247041

25-23

241161

14-5

244133

25-37

247051

25-13

241212

23-3

245013

11-9

247052

25-38

241223

23-10

245022

11-25

247061

25-17

241231

23-8

245033

11-20

247063

25-39

241242

23-6

245042

11-1

247071

25-1

241253

23-12

245052

11-7

247073

25-34

242011

14-9

245071

11-13

247081

25-6

242011A

14-8

245081A

11-14

247082

25-36

242031

15-19

245081

11-15

247091

25-2

242041

15-18

245091

11-18

247092

25-35

242051A

15-25

245101

11-17

242071

15-24

245132

13-5

242081

15-22

245162

13-28

242101A

15-28

245171

13-32

242121A

15-31

245181

11-30

242131

15-32

245201

11-8

242161

1546

245211

15-17

242171

15-34

245222

11-23

242181

15-38

245231

15-23

242191

1540

245261

11-11

242201

15-37

-26-

NUMERICAL

INDEX

OF

PARTS

PART

NO.

PAGE

PART

NO.

PAGE

PART

NO.

PAGE

OTHER

ITEMS

SCREW

15/64828524

17-19

lB3xl2

19-18

6A04001

15-14

1/8S40003

19-29

19-31

183/16-32x9

19-2

B01002

15-33

25-32

483x6-W

21-10

COlOlO

21-6

1/8S40006

13-31

FC103238

21-22

3/16S28001

14-2

COlOll

21-6

685x15

13-11

C01012

21-6

3/16S28029

14-10

C01013

21-6

3/16S32025

19-11

C01014

21-6

3/16S32026

25-28

C02001

13-6

3/16S32031

19-7

3/16S32034

19-9

NUT

C02006

13-6

C04001

21-1

9/64S40001

15-51

17-16

IN3

19-19

C04003

21-1

9/64S40004

234

1N4

13-19

C04004

21-1

9/64S40005

11-26

11-29

1N6

11-3

254

C04005

21-1

17-3

23-9

23-24

1N8

14-12

C04006

21-1

9/64S40011

11-19

134

3/8N24201

19-14

C04007

21-1

19-5

23-2

5/8N18101

15-21

C04009

21-1

9/64S40035

17-2

25-3

9/64N40101

154325-15

C05008

13-7

11/64N40201

17-10

C07001

21-17

9/64S40043

11-10

19-16

25-12

25-14

11/64N40203

25-10

C07003

21-9

9/64S40052

23-5

15/64N28206

25-24

C08001

21-15

9/64S40054

25-18

C08003

21-16

9/64S40055

1542

C08004

21-7

9/64S40065

11-22

11-24

C08005

21-8

9/64S40502

13-14

13-22

WASHER

D03003

13-8

13-26

19-27

D07009

23-23

11/64S40001

14-11

1W3

19-20

D07021

13-16

11/64S40002

15-35

17-7

2W4

25-16

25-19

23-13

23-15

11/64S40003

15-30

15-39

2W6

11-5

25-5

D07022

23-18

11/64S40004

15-26

25-26

D07023

23-19

3W3

19-32

11/64S40005

11-12

11-21

3W6

114

25-25

D07024

23-20

1544

5W8

15-13

FOlOOl

21-3

11/64S40007

15-36

1/4W03205

25-8

F01002

21-24

11/64S4C009

15-50

17-12

KOlOOl

11-6

11/64S40015

25-7

8FN24xl35F

23-21

11/64S40029

25-27

1/4W15105

25-9

11/64W10101

21-14

25-22

8FU2-6x60F

13-10

11/64S40046

25-21

11/64W15103

15-16

1549

8FU2-6x70F

23-17

11/64840049

19-21

19-12 19-22

8FU2-6x90F

13-9

11/64840075

21-13

8FU2-6X95F

23-16

11/64840089

15-15

17-14

E03014

13-17

23-14

EW-6.5

13-33

11/64840502

144

31LP6

1548

11/64840504

21-5

15/64828004

23-7

15/64828021

13-12

21-12

15/64828028

11-2

15/64828032

23-11

-27-

NP-7A

SCREW.

NUT &

WASHER

i-'y

h,

9'yv-V-

FULL

SIZE

(IS-^)

9/64840502

11/64840502 11/64340504

15/64828524

1/8840006

9/64840001

9/64840004

9/64840052

9/64840054

9/64840011

9/64840065

9/64840005

9/64840035

11/64840029

11/64840001

11/64840002

11/64840009

11/64840046

11/64840003

11/64840004

11/64840005

3/16832031

15/64828004

15/64828021

15/64828032

1/8840003

9/64840043

11/64840007

15/64828028

11/64840015

3/16828001

3/16832026

3/16828029

3/16832034

9/64840055

11/64840049

11/64840075

11/64840089

3/16832025

183x12

183/16-32x9

483x6-W

FC103238

685x15

9/64N40101

11/64N40201

11/64N40203

15/64N28206

3/8N24201

5/8N18101

1N3

1N4

1N6

1N8

11/64W10101

11/64W15103

1/4W03205 1/4W15105

1W3

2W4 2W6

3W3

3W6

5W8

E03014

: m

Si5

^ m E ^ ±

'110

6-4-14

TEL03-3843-73ll(H3

TLX

265-5306

FAX

03-3843-9998

I -

14-14

IEL03-3843-0269

III

TLX265-53C6

FAX03-3843-0260

Ai

Jlj^HIm7kOj5

Ife

4 T i TELOl66-47-3267

T078-02

FAXO 166 - 48 - 1654

H ^

5?lrfi:;*:?llfBa?S?Bai23

TEL0I77-66-269I

t030

FAXO

177-66-7082

iff M ^ jg m titOjai I

-109-5

TEL025-275-I45I

T950

FAX025-273-8488

SI5UJ|i?UjrfTM:^3-3-7

TEL0249-34-3I77

X963

FAX0249-32-7076

^ ^ ^ ^

rti

HI

ffl

fflj

280

- 3 TEL0282-23-398I

X328-0I

FAX0282-23-3809

m a 1

TEL0299-36-4612

X3I4-02

FAX0299-96-7359

.1

P.li^feMl^^Bl:^$±)gi;k490-l

TEL0270-65-0883

t370-

11

FAX0270

- 65 -

0889

M:

1?

TEL0268-64-269I

=f389-03

FAX0268-64-26I9

m I

-10-30

TEL0775-53-269I

X520-30

FAX0775-53-7846

a a m PI PE :1b fill 9 - 2

TEL0794-47-2570

X676-0I

FAX0794-47-2807

'J^ ?|5

lJjPm:^?:>iei§^;^J^3640-

I

TEL0839-89-269I

X754

FAX0839-89-4999

I - II - 10

TEL0992-68-3235

T89I-0I

FAX0992-67-6023

i\h

m

W W m Mil2 - 17 - 2

T047-02

^

flll^m^^^ESl-S3

-14-10

t982

« 4 - 3 - 17

TI20

m m m M JK s

-12-

2

t280

^j^mtSmETcl-

I

-17-3

t230

>9 tK ;t5 tk m

t424

5 0 3

«SMr!)4'JIIEW^BII3-

5

T454

S Oj

®UjmTMgl-l-36

t93I

± B5

:'^B5m7iJiE±Fj3

2 - I - 8

t553

IS) UJ

1844-5

T703

tS

til

15tllrtT>I^EBj

1460-4

T762

m &

/Aam4'Ei?iA0j7-28

X733

7i

151

7i!S9m?fiMSl??0fHBlT/Jt487

T8II-0I

IE

LO134-62-2691

(ffi

FAXO134-62-2682

TEL022-286-5I89

FAX022-286-8230

TEL03-3629-269l(Ha

FAX03-3629-2695

TEL0472-63-I542

FAX0472-66-6546

TEL045-584-269l(ft)

FAX045-584-9450

TEL0543-64-269l(ft)

FAX0543-65-2533

TEL052-35l-269l(ft)

FAX052-363-369I

TEL0764-4I

-2690

FAX0764-3I

-2691

TEL

06-462-435lira

FAX

06-465-5926

TEL0862-77-6527

FAX0862-77-6528

TEL0877-46-3659(fia

FAX0877-46-3662

TEL082-293-269l(ft)

FAX082-295-65I6

TEL092-962-4006(ft)

FAX092-963-0249

^ 4 - 8 - 14

TI25

+ 9 - I

=f277

m I5|

1S:t^lT«i5ag|?SI5|fflI0l5|4254

X349-I3

T0I8-57

± m

±>im4'4TBT

1322

t300

a

if

=f382

4 0 1

1-6

TEL03-3603-225l(m

FAX03-3603-9648

TEL047I

-33-2691

FAX047I

-33-2695

TEL0282-62-320l«t)

FAX0282-62-5400

TELO186-49-5201

FAXO

186-49-0759

TEL0298-4l-0805(f«

FAX0298-42-9I05

TEL0262-45-7223

FAX0262-48-0847

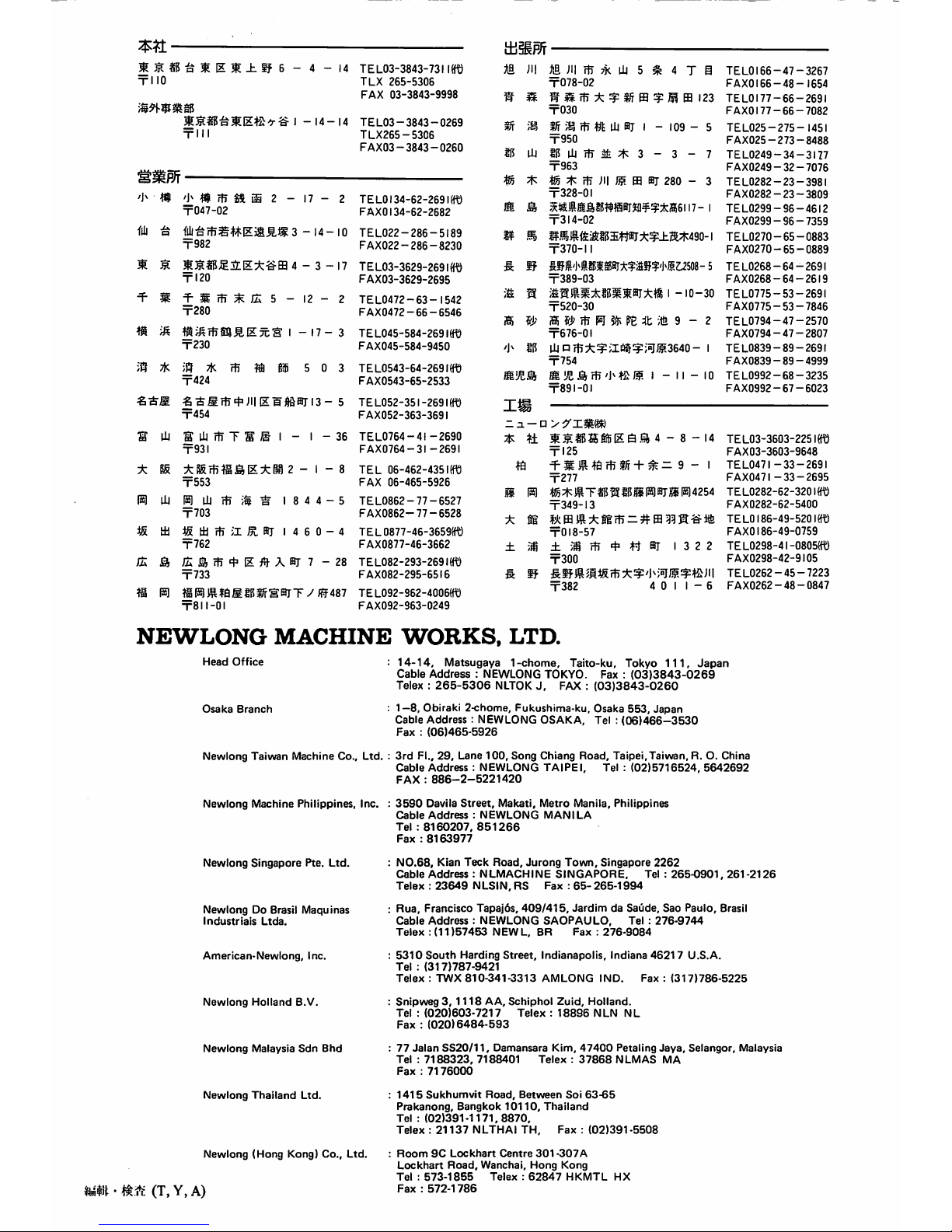

NEWLONG

MACHINE

WORKS.

LTD.

Head

Office

Osaka

Branch

Newlong

Taiwan

Machine

Co..

Ltd.

Newlong

Machine

Philippines,

Inc.

Newlong

Singapore

Pte.

Ltd.

Newlong

Do Brasil

Maquinas

Industrials

Ltda.

American-Newlong.

Inc.

Newlong

Holland

B.V.

Newlong

Malaysia

Sdn

Bhd

Newlong

Thailand

Ltd.

Newlong

(Hong

Kong)

Co..

Ltd.

t3^(T,Y,A)

14-14,

Matsugaya

1-chome,

Taito-ku, Tokyo

111,

Japan

Cable

Address

: NEWLONG TOKYO. Fax :

(03)3843-0269

Telex :

265-5306

NLTOKJ,FAX :

(03)3843-0260

1—8,Obiraki 2-chome, Fukushima-ku, Osaka

553,

Japan

Cable

Address

: NEWLONG

OSAKA,

Tel :

(06)466-3530

Fax:(06)465-5926

3rd

Fl.,

29,

Lane

100,

Song

Chiang

Road,

Taipei,Taiwan,

R. O. China

Cable

Address;NEWLONG

TAIPEI.

Tel :

(02)5716524,

5642692

FAX:886-2-5221420

3590

Davila

Street.

Makati.

Metro

Manila.

Philippines

Cable

Address:NEWLONG

MANILA

Tel:8160207.

851266

Fax:8163977

N0.68,

Kian

Teck

Road.

Jurong

Town.

Singapore

2262

Cable

Address:NLMACHINE

SINGAPORE.

Tel :

265-0901.

261

-2126

Telex:23649

NLSIN.

RS

Fax:65-265-1994

Rua.

Francisco

Tapaj6s.

409/415.

JardimdaSaude,

Sao

Paulo.

Brasil

Cable

Address:NEWLONG

SAOPAULO,

Tel :

276-9744

Telex:(11)57453

NEWL.

BR

Fax:276-9084

5310

South

Harding

Street.

Indianapolis,

Indiana

46217

U.S.A.

Tel:(317)787-9421

Telex:TWX

810-341-3313

AMLONG

IND.

Fax:(317)786-5225

Snipweg3,1118

AA.

Schiphol

Zuid,

Holland.

Tel:(020)603-7217

Telex:18896

NLN

NL

Fax:(020)6484-593

77

Jalan

SS20/11,

Damansara Kim,

47400

Petaling

Jaya,

Selangor,

Malaysia

Tel:7188323.

7188401

Telex:37868

NLMAS

MA

Fax:7176000

1415

Sukhumvit

Road.

Between

Soi

63-65

Prakanong.

Bangkok

10110.

Thailand

Tel:(02)391-1171.8870.

Telex:21137

NLTHAI

TH,

Fax:(02)391-5508

Room9CLockhart

Centre

301

-307A

Lockhart

Road.

Wanchai.

Hong

Kong

Tel:573-1855

Telex:62847

HKMTL

HX

Fax:572-1786

HA

14-14

MATSUGAYA

1-CHOME, TAITO-KU TOKYO, JAPAN TEL:

(3843)

0269

No.14

NO.IE3007H

92-03-1000F

PRINTEDINJAPAN

1985,

1991

NEWLONG

MACHINE

WORKS,

LTD.

Loading...

Loading...