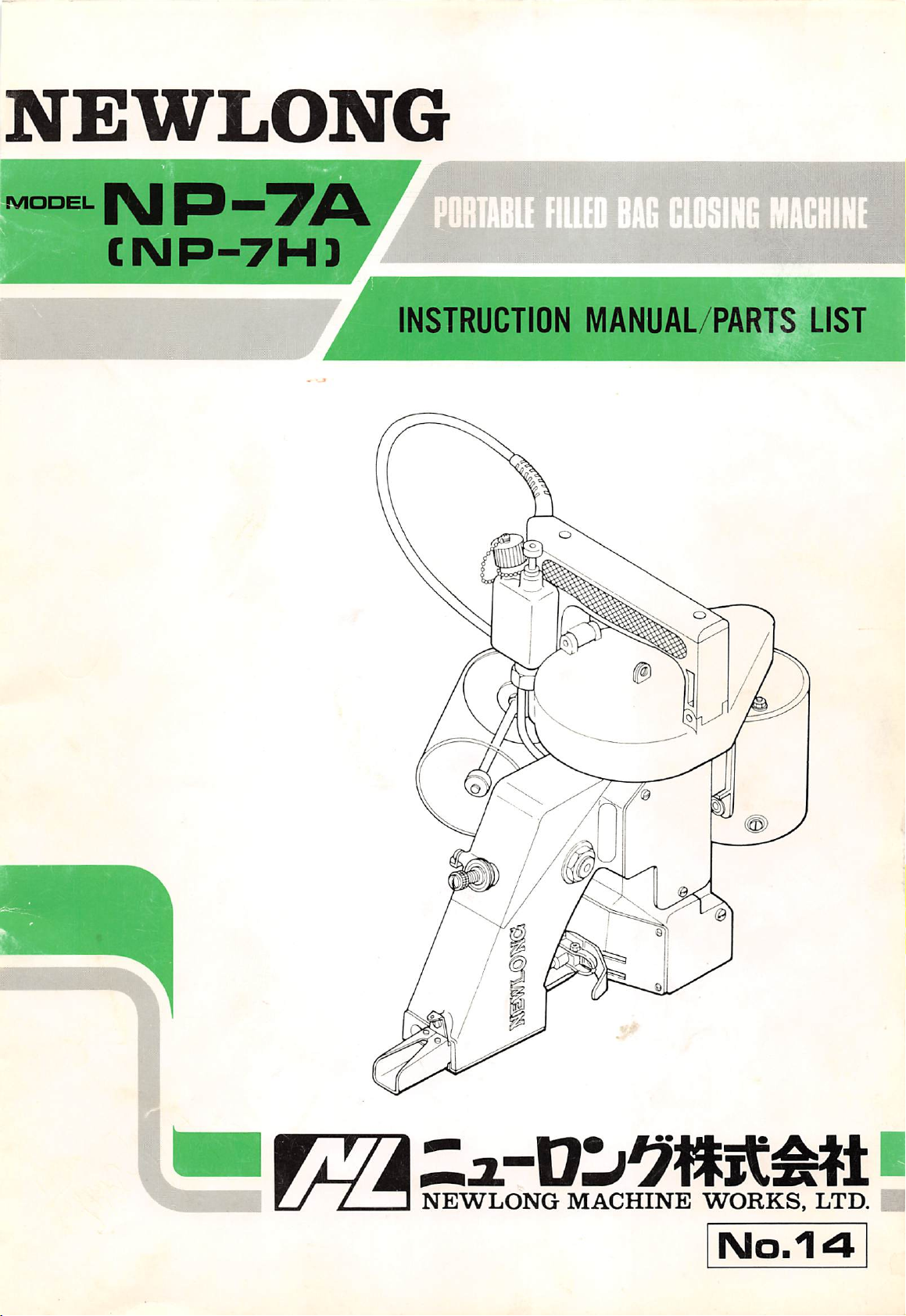

Newlong NP-7A User Manual

NEWLON6

MODEL

NP-7A

CNP-7H1

PORTABLE

INSTRUCTION

FILLED

BAG

MANUAL/PARTS LIST

CLOSING

MACHINE

NEWLONG

MACHINE

WORKS,

No.14

LTD.

CONTENTS

1.

SPECIFICATIONS

2.

PREPARATION

1. Oiling 3

2. Needle Setting 3

3. Threading 3

3.

START

4.

ADJUSTMENTS

1.

Thread

2.

PositionofNeedle

Tension

FOR

and

START

Looper

2

3

4

5

5

5

3.

PositionofFeed Dog 5

4.

5.

REPLACING

6.

MAINTENANCE

7.

LUBRICATOR

PressureofPresser

PARTS

&

Foot

LUBRICATION

1. Operation 7

2.

Maintenance

3.

Troubleshooting

8.

ORDERING

NUMERICAL

DIAGRAM

PARTS

INDEX

OF

OF SCREW. NUT &

PARTS

WASHER

5

6

7

7

7

8

9

26

28

- 1 -

1.

SPECIFICATIONS

TECHNICAL

DETAILS

Speed (sec/bag) 5—6

Seam

Stitch

Range (mm.) ,

Revolution

Needle

(rpm.)

Thread (vinylon, synthetic or

Drive

Motor

Power

Supply

cotton)

Single

Thread

7.2

(fixed)

1,600±125

DNx1-#25

20/6

60W

110,

220

12V,

24V.,

50—6OH2,

Chain

Stitch

or 240V., A.C.

D.C.

(specify

Single

Phase

Net Weight (kg) 5.2 Including Thread Cone,

Machine Dimension (mm.)

Packing Dimension (eft.)

STANDARD

1.

Needles

2.

Thread

3.

Screw

4.

Needle

5.

Oil

6.

Carbon

ACCESSORIES

DN X

1-#

Vinylon

Driver 1

Bar

20/6

Spanner

brush 2 pcs.

25

360(L)

2.5

5 pcs.

1 roll

pee.

1

pee.

1

can

x 245(W) x 315(H)

one.)

Shoulder

Belt.

- 2 -

2.

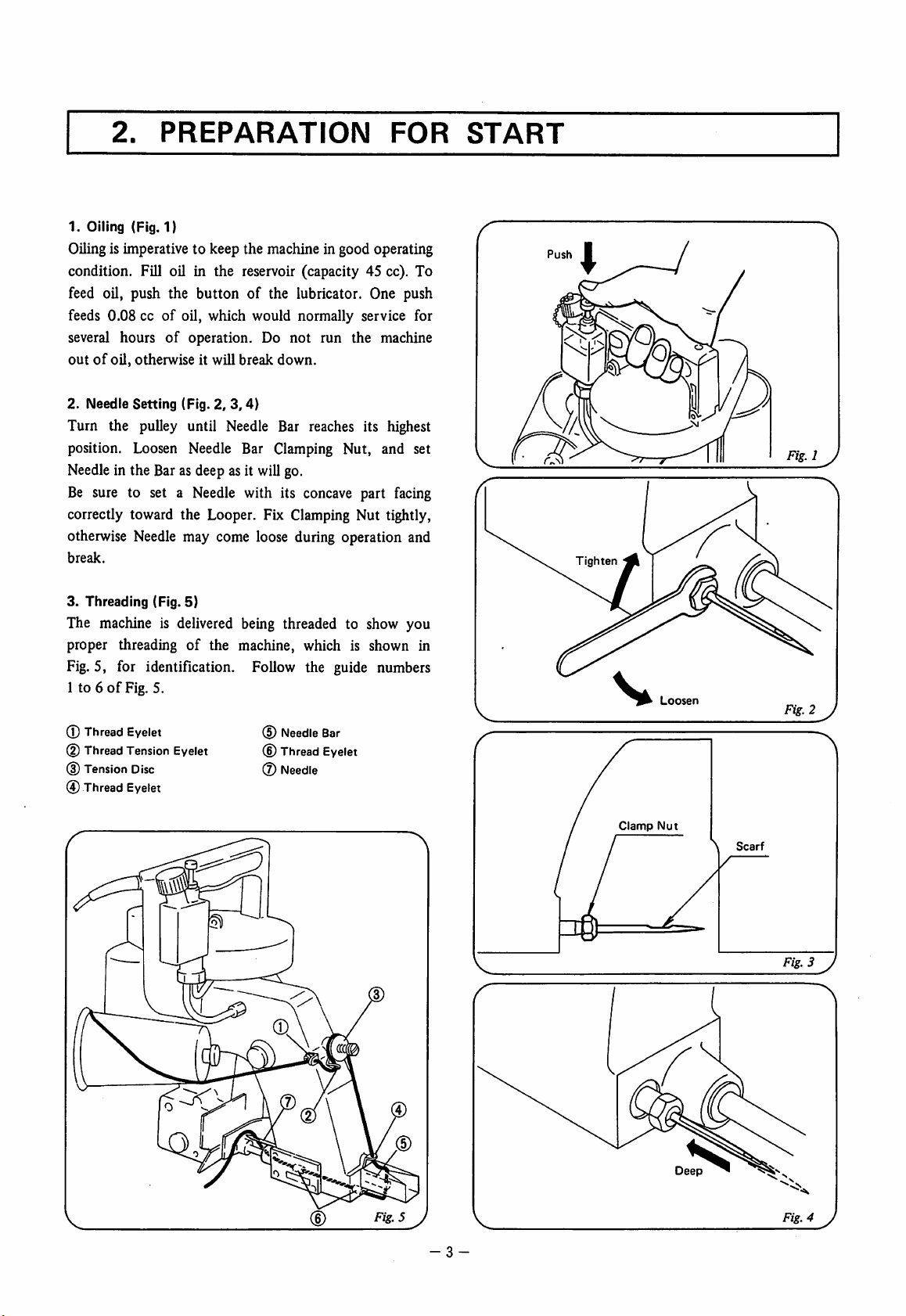

1. Oiling (Fig. 1)

PREPARATION

FOR

Oilingis imperative to keep the machine in good operating

condition. Fill oil in the reservoir (capacity 45 cc). To

feed oil, push the button of the lubricator. One push

feeds 0.08 ccofoil, which would normally service for

several hours

outofoil, otherwise it will break

of

operation. Do not run the machine

down.

START

2. Needle Setting (Fig. 2,

3,4)

Turn the pulley until Needle Bar reaches its highest

position. Loosen Needle Bar Clamping Nut, and set

Needle in the Bar as deep asit will go.

Be sure to set a Needle with its concave part facing

correctly toward the Looper.

otherwise

break.

3. Threading (Fig. 5)

Needle

may come loose during operation and

Fbc

Clamping Nut tightly,

The machine is delivered being threaded to show you

proper threading

of

the machine, which is shown in

Fig. 5, for identification. Follow the guide numbers

1 to 6ofFig. 5.

® Thread Eyelet

(D Thread Tension Eyelet

(3)

Tension

@ Thread Eyelet

Disc

d)

Needle

Bar

(6) Thread Eyelet

(7) Needle

Tighten

Clannp

Loosen

Nut

Fig-i y

\

Scarf

(D

Fig.4 J

3.

START

Before starting, make sure that the supply voltage accords

with the specification

of

the motor.

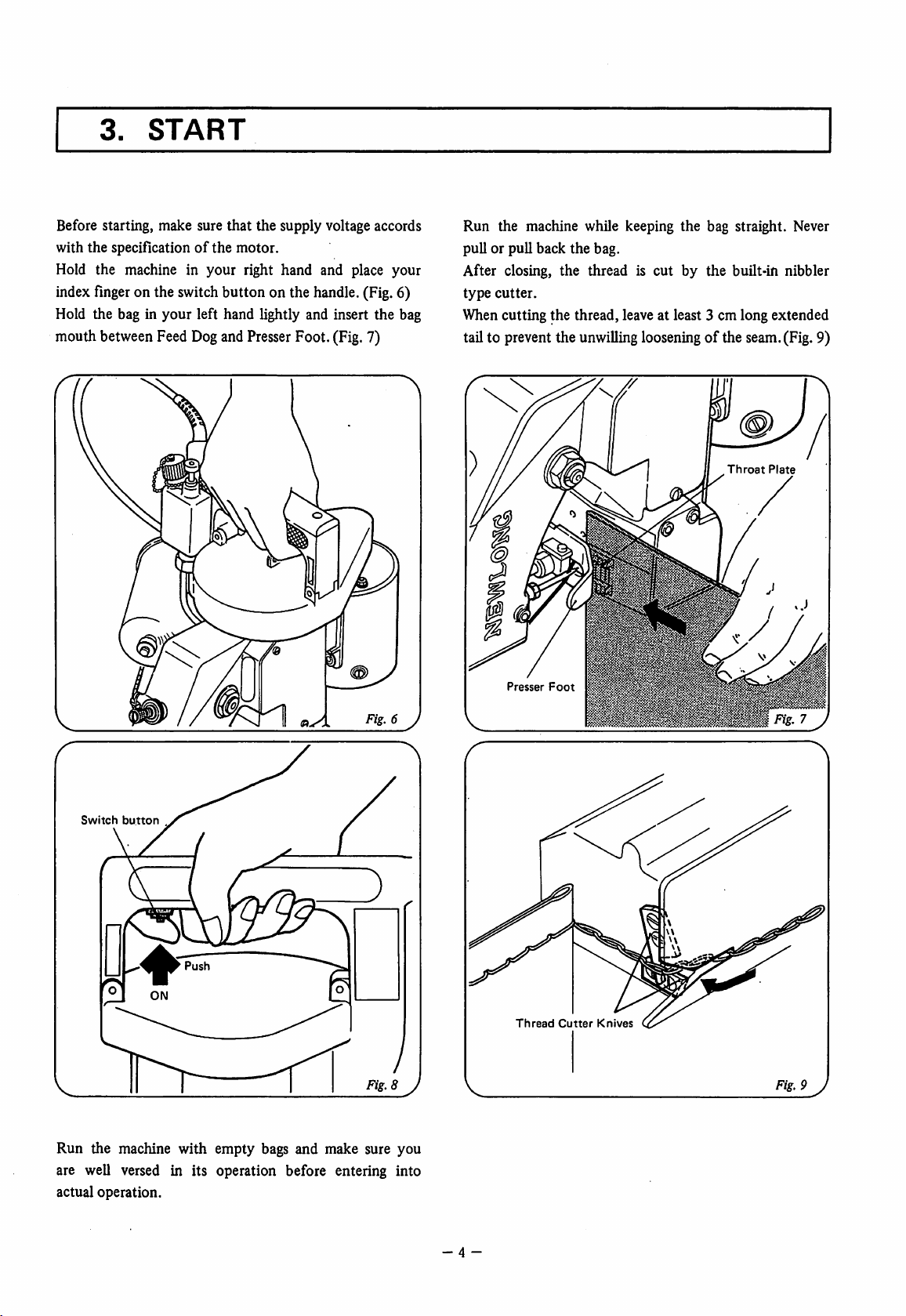

Hold the machine in your right hand and place your

index

finger

on the switchbutton on the handle.(Fig. 6)

Hold the bag in your left hand lightly and insert the bag

mouthbetweenFeed

Dog

and

Presser

Foot.(Fig.7)

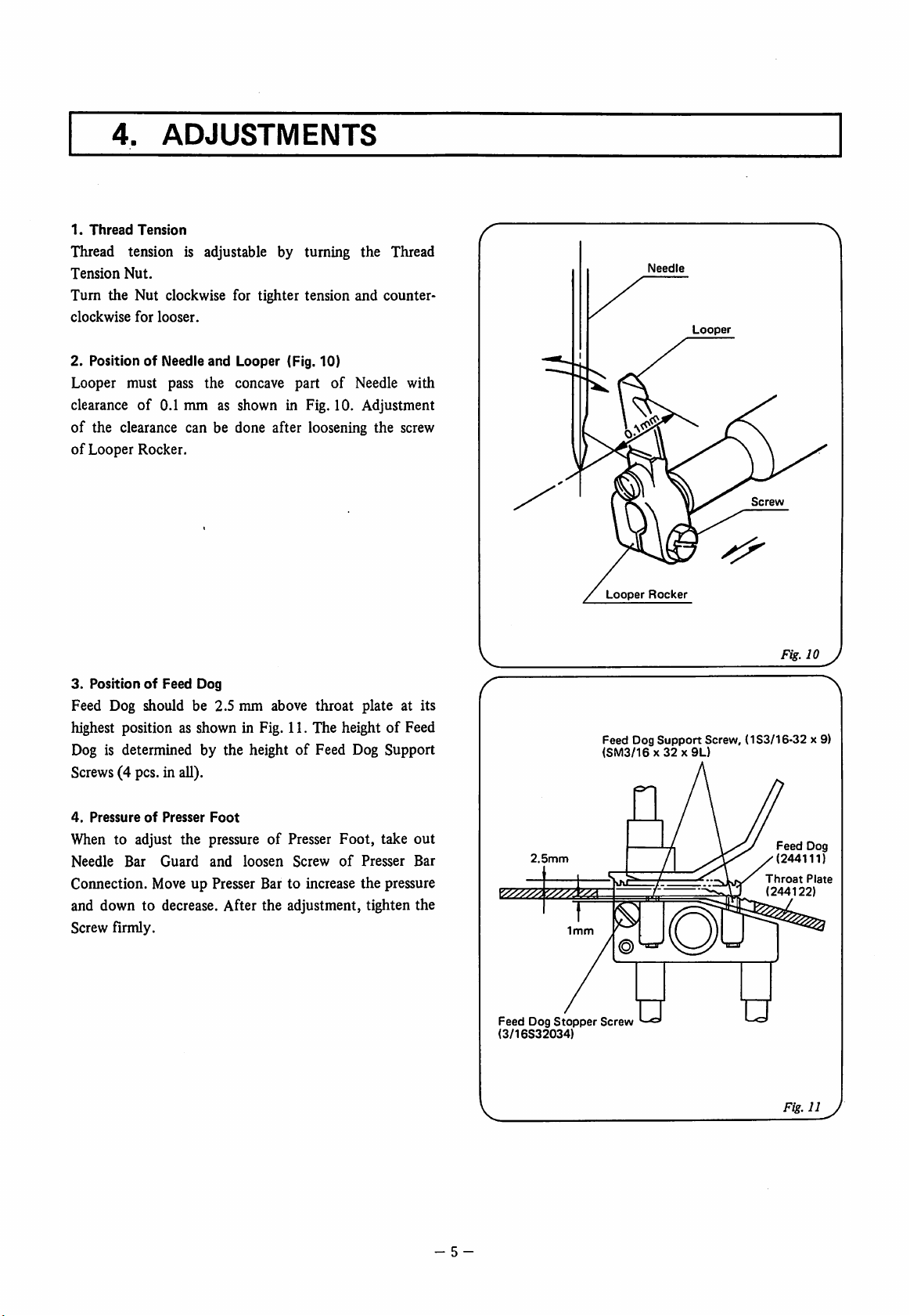

Run the machine while keeping

pull or pull back the bag.

the

bag straight. Never

After closing, the thread is cut by the built-in nibbler

type

cutter.

When cutting the thread, leave at least 3 cm long extended

tail to prevent the unwillinglooseningofthe seam.(Fig. 9)

Throat

Plate

I®

Switch

button

Fig.

6 J

Presser

Thread

Foot

Cutter

Knives

Fig.

9J

Run the machine with empty bags and make sure you

are well versed in its operation before entering into

actual operation.

- 4 -

1.

4.

Thread

ADJUSTMENTS

Tension

Thread tension is adjustable by turning the Thread

Tension

Nut.

Turn the Nut clockwise for tighter tension and counter

clockwise

for

looser.

Needle

Looper

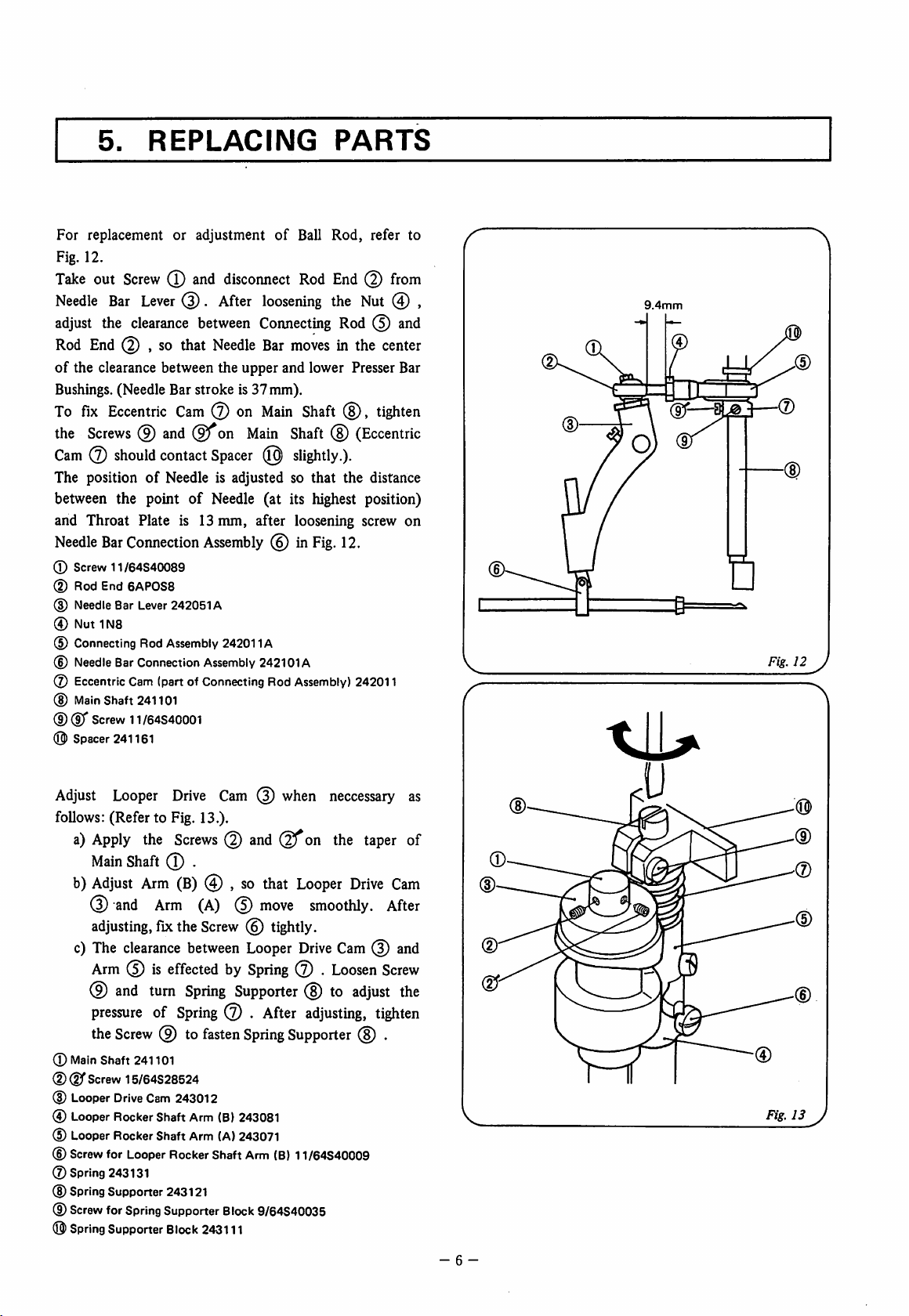

2. PositionofNeedle

Looper must pass the concave part

clearance

of

of

Looper Rocker.

3.

PositionofFeed

of

the clearance can be done after loosening the screw

Feed Dog should be 2.5 mm above

and

Looper (Fig. 10)

of

Needle with

0.1 mm as shown in Fig. 10. Adjustment

Dog

throat

plate at its

highest position as shown in Fig. 11. The height of Feed

Dog is determined by the heightofFeed Dog Support

Screws(4 pcs. in all).

Looper

Rocker

Feed Dog

(SM3/16x32x9L)

Support

Screw

Fig.

10 y

Screw, (1S3/16-32 x 9)

4.

PressureofPresser

Foot

When to adjust the pressure of Presser Foot, take out

Needle

Bar

Guard

and

loosen

Screw

of

Presser

Bar

Connection. Move up Presser Bar to increase the pressure

and down to decrease. After the adjustment, tighten the

Screw firmly.

- 5 -

2.5mm

Feed

Dog

(3/16S32034)

Stopper

Screw

Feed

(244111)

Throat

(244122)

Fig.11J

Dog

Plate

5.

REPLACING

PARTS

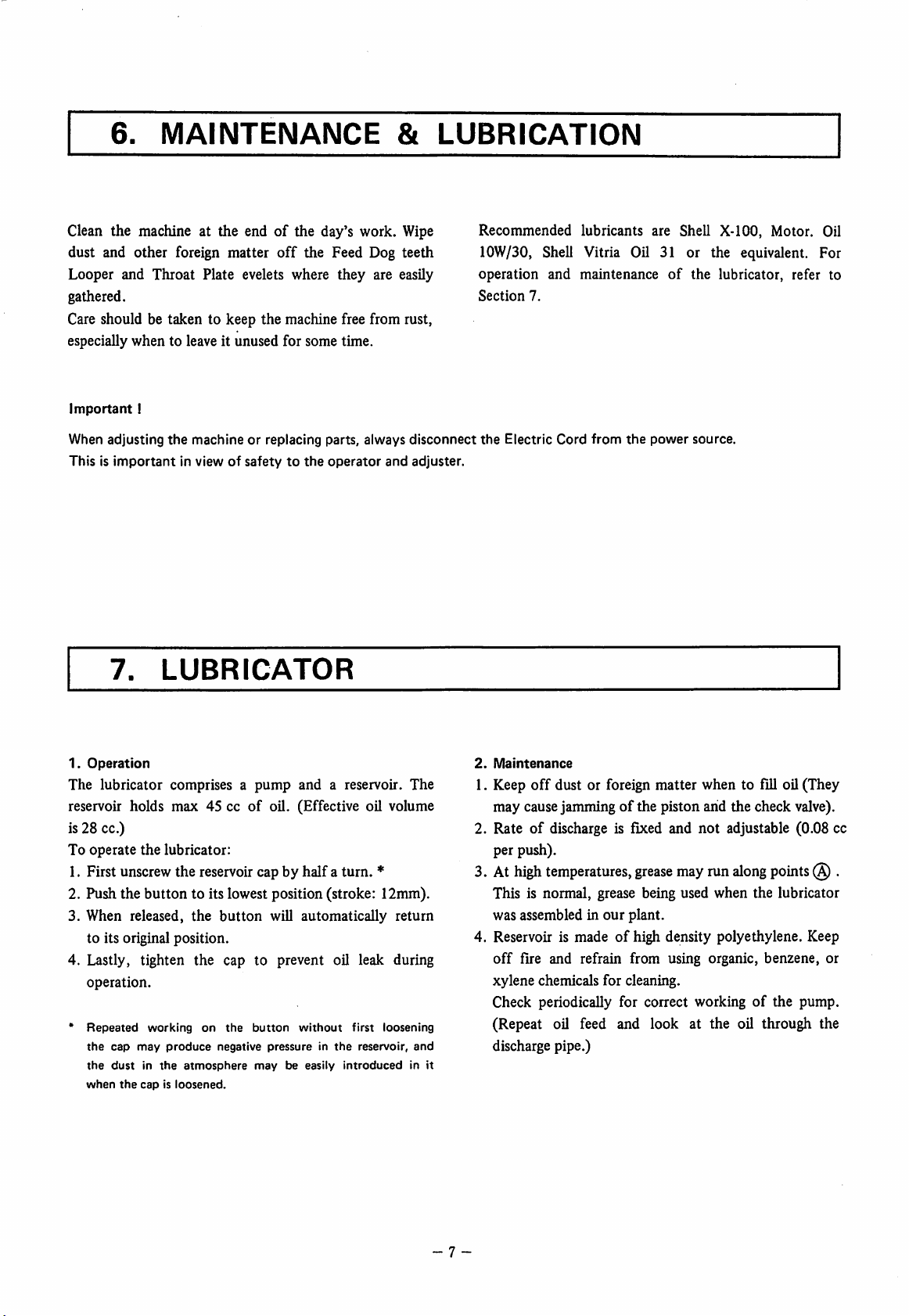

For replacement or adjustment

Fig. 12.

Take

out

Screw

(T)

and

disconnect

Needle

adjust

Rod

of

Bushings.(Needle Bar stroke is 37 mm).

To

the

Cam0should

The positionofNeedle is adjusted so that the distance

between the point of Needle (at its highest position)

and Throat Plate is 13 mm, after loosening screw on

Needle

® Screw 11/64S40089

(D Rod End

(D

® Nut 1N8

(5) Connecting Rod Assembly 242011A

(D

(7) EccentricCam (part of ConnectingRod

(D

CD®'

O Spacer 241161

Bar

Lever

the

clearance

End

(5) , so that

the clearance between the upper and lower Presser Bar

fix

Eccentric

Screws

Needle

Needle

Main

(9)

Bar

Connection

6APOS8

Bar

Lever

BarConnection

Shaft 241101

Screw

11/64S40001

between

Cam

and

contact

242051A

.

After

Needle

0 on

on

Spacer

Assembly

Assembly

of

loosening

Connecting

Bar

moves

Main

Main

Shaft

(0)

slightly.).

0 in

242101A

Assembly)

Ball Rod, refer to

Rod

End

(2)

from

the Nut 0 ,

Rod

0

and

in the

center

Shaft

(8),

tighten

(8)

(Eccentric

Fig.

12.

242011

(D

9.4mm

Fig.

(D

12 J

Adjust

follows: (Refer to Fig. 13.).

(D

®

® Looper

® Looper Rocker Shaft Arm (B)243081

® LooperRocker Shaft Arm (A)243071

®

©Spring 243131

® SpringSupporter 243121

®

®

Looper

a)

Apply

Main

Adjust

b)

0

adjusting,

c)

The

the

Shaft

Arm

and

Arm

fix

clearance

Arm0is

0

and

turn

pressureofSpring

the

Screw

0 to

Main

Shaft 241101

(D"

Screw

15/64S28524

Drive

Cam243012

Screw

for

Looper

Screw

for

Spring

Supporter

Spring

Supporter

Drive

Cam

0

Screws0andQfon

0 .

(B)

0 ,sothat

(A)

0

move

the

Screw0tightly.

between

effectedbySpring

Spring

RockerShaft Arm

Block

0 .

fasten

Block

243111

Looper

Supporter

After

Spring

9/64S40035

when

Looper

smoothly.

Drive

0 .

0 to

adjusting,

Supporter

(B)

11/64S40009

neccessary

the

taper

Drive

Cam

After

Cam0and

Loosen

Screw

adjust

tighten

0 .

as

of

the

(D

(D

m-

(D

U

Fig.

(0)

(D

(D

CD

13 J

- 6 -

6.

MAINTENANCE

&

LUBRICATION

Clean the machine at the endofthe day's work. Wipe

dust and other foreign matter

off

the Feed Dog teeth

Looper and Throat Plate evelets where they are easily

gathered.

Care should be taken to keep the machine free from rust,

especially when to leave it unused for some time.

Important

When adjusting

Thisisimportantinviewofsafetytothe

7.

I

the

machineorreplacing parts, always

LUBRICATOR

operator

disconnect

and

adjuster.

Recommended lubricants are Shell X-100, Motor. Oil

lOW/30, Shell Vitria Oil 31 or the equivalent. For

operation and maintenance

Section

the

7.

Electric Cord

from

the

of

the lubricator, refer to

power

source.

1.

Operation

The lubricator comprises a

pump

and a reservoir. The

reservoir holds max 45 ccofoil. (Effective oil volume

is 28 cc.)

To operate

1. First unscrew

the

lubricator:

the

reservoir capbyhalfaturn.

*

2. Push the button to its lowest position (stroke: 12mm).

3. When released,

the

button

will automatically return

to its original position.

4. Lastly, tighten the cap to prevent oil leak during

operation.

*

Repeated

the

the

when

working

cap

may

dustinthe

the

capisloosened.

produce

atmosphere

on

the

negative

button

without

pressureinthe

maybeeasily

first

reservoir,

introduced

loosening

and

in it

2.

Maintenance

1. Keep

off

dust or foreign matter when to fill oil (They

may cause jammingofthe piston arid the check valve).

2. Rate of discharge is fixed and not adjustable (0.08 cc

per push).

3. At high temperatures, grease may run along points .

This is normal, grease being used when the lubricator

was assembled in our plant.

4. Reservoir is madeofhigh density polyethylene. Keep

off

fire and refrain from using organic, benzene, or

xylene chemicals for cleaning.

Check periodically for correct working of the pump.

(Repeat oil feed and look at the oil through the

discharge pipe.)

7 -

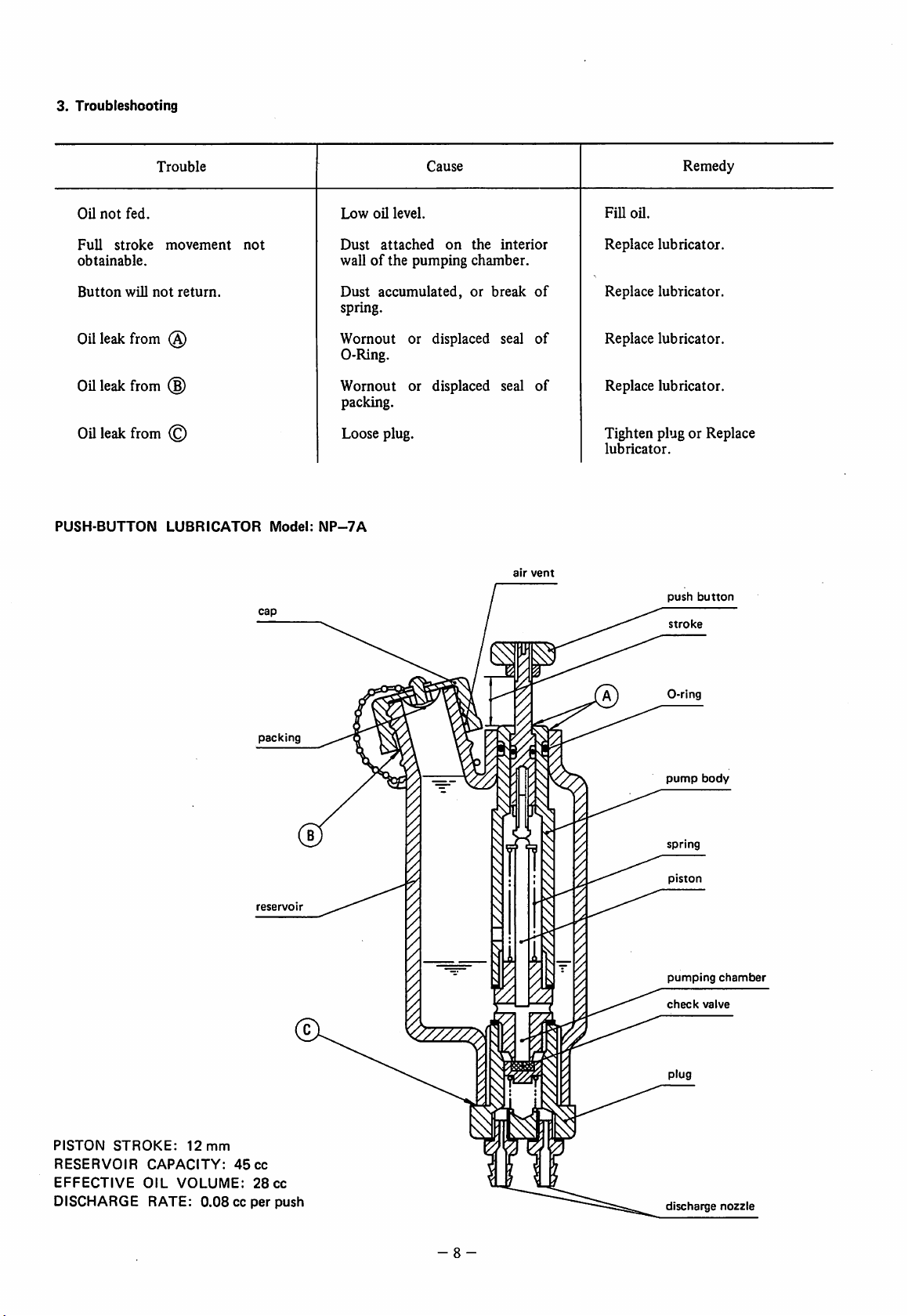

3.

Troubleshooting

Oil

not

fed.

Full

stroke

obtainable.

Button

will

Oilleak from (S)

Oil

leak

from

Oil

leak

from

PUSH

BUTTON

Trouble

movement

not

Low

Dust

oil

level.

attached

Cause

on

the

interior

FiU

oil.

Replace

Remedy

lubricator.

wallofthe pumping chamber.

not

return.

Dust

accumulated,

or

break

spring.

Wornout or displaced seal

of

of

Replace lubricator.

Replace lubricator.

0-Ring.

(§)

Wornout or displaced seal

of

Replace lubricator.

packing.

© Loose plug. Tighten plug or Replace

lubricator.

LUBRICATOR

Model;

NP-7A

air

vent

push

button

packing

reservo

stroke

pump

body

spring

piston

r

pumping

check

chamber

valve

PISTON

RESERVOIR

EFFECTIVE

DISCHARGE

STROKE:

CAPACITY:

OIL

RATE:

12

mm

VOLUME:

0.08ccper

45

28

cc

cc

push

- 8 -

discharge

nozzle

8.

ORDERING

PARTS

The parts list showing all the parts used in the machine is included in this book.

Check the list, and specify parts numbers and quantities required clearly.

Send yourorder to the nearest agent, distributor or one of

our

branch offices.

1. Description of each part and its stamp number is describedin this parts list.

Screws and nuts for parts are shown adjacent to the relevant parts. When ordering parts, describe

clearly

stamp

number

with

its

nameofpart.

2. The parts which have no Ref. Number can not be delivered independently; always order it as an

assembly.

3. A

4.

5.

*

The

setofassembled

The

last figure in

Part

No.

described

part

list is

subjecttochange

(1) THREAD

BUSHINGS,

(2)

(3)

NEEDLE

(4)

LOOPER

parts

is represented by

the

parts stamp number advances on each improvementofthe parts.

in [ ]ofRemarks

TENSION

OILINGS

BAR,

PRESSER

DRIVING

without

prior

AND COVER PARTS 10

AND

HANDLE

BAR

PARTS

means

notice.

AND

the

stamp

old

CONTENTS

PARTS 12

DRIVING

numberofits

part

No.

PARTS

main

parts.

14

16

(5) FEED

(6)

(7)

(8) CREPE

NUMERICAL

DRIVING

MOTOR

SPECIAL

PARTS

PARTS

TAPE

INDEX

AND

THREAD

(ForTotally

FOR NP-7H TYPE 22

BINDING

OF

AND

PARTS

CUTTER

Enclosed

CUTTER

Type

PARTS

- 9 -

PARTS

Motor)

(Special OrderParts) 24

18

20

26

Loading...

Loading...