I

I

SEWING

FIEAD

*trffi=i)

MODEL

9A

9G

9P

=gAW

:gcw

O

nm:ililirn

Iz-I7}?.IXil*rt+ft

t.:.,

For

Operator

Safety

Thank

you

for

purchasing the NLI

Model

DS-9

Bag

Closing

Machine

Head.

o

This manual contains

the

instructions

and

precautions

for

using the

Model DS-9

Bag Closing

Machine

Head. Be

sure

to read and

understand

this manual

before use and

use

the machine correctly.

o

Keep

this manual

near the

sewing machine

for easy

reference.

Be sure

to attach this

manual

to the machine

when lending

or transferring

it

to another

person

or

company.

o

Please orderthis

manual from

the nearest

NLI

office if it is

1ost.

O

The contents

ofthis

manual

are subject

to change

without

prior

notice for improvement

and safety

purpose.

Instructions

with this

mark are

especially

important

for operator

safety.

Be sure to

observe these marked

instructions.

??lc)l,\<

=

= -

E

Y

trTx(ffi)ts-g

4#

n

fiE

i

vvAfs

HL

\tlJL rlc.ldB

6

D

Wi

i

3t,''Ef.

.

.d)WWnnEE=it

DS-e

4*

trfil{-vYary51'filtL

fEH

t

oitH+trr\--E#8iu(v.*f

"

l'&ffi

tfrir:o

WWilf"Fn=?Z.

f

fc

-6fi

4 <

fa

3

L'.

fr

Et + hwWv<

EL<:"fEH(r.3v

''"

.

aaww#,ry

gi*:vyoz

if

i..

v.-crbl'f,uffi

v.r-rd

ir6&i.

{*€L((/d8v'.

DS-e4# tr

F#:v

v

bHL

H

L. EIc t*#Eo E d

tt*.

a

WW;nFfi E

affitfrltffit

L

( (

r. 3

v''

"

.

.DfuWifr.ffi

gAflr^3

tt

t:Edt*==-vY

/T-#-

(ffi)AtrEf6rtr

i.:'ill <

/l'3

v''.

.

.aWW=,nEE

g

iJ&HE Fl

L*ir-l** 4.at:d>

.

a E

tV

F-4E.fatLrt\bD*-tr"

fiav-,

ttEe-t'++l=EEE/JrH E

t'

t

"

il't.t;tuJ(EEut"

ElWfe,B.

o

DS-ec

4 E #Dt

y

I

-

|l:v/

b lfr.H

F

tilt

v

F

-

a

'ff

9rf

.

ffiEDl

t-tr 6*tr1fi\br9*f"

:v)' l.&ft

ffr-"-rb\fia(v\*f.

)t

v

I

-

VJ

a[(

[196

g

$

/31

ta'(/3f

$1,

t"

8iAtrH

o iv), l.# tffi

^t

6F+,lt.

iEHL/rv

t

&flt#F-&

i

rffi

1r

63

6

*tLA k

Z t1$\bD

*t

"

o

:

J/y

t. i*#iAiIH'.v-

2

LEE->

<

v,*f

.

ffi

iti

y>,

DT

l[\bi66& i.

+

tj:v)/

l.

EEs

t2 b

/rl/'I

i

l.

ilHL((/dst,.'"

A*"=rd

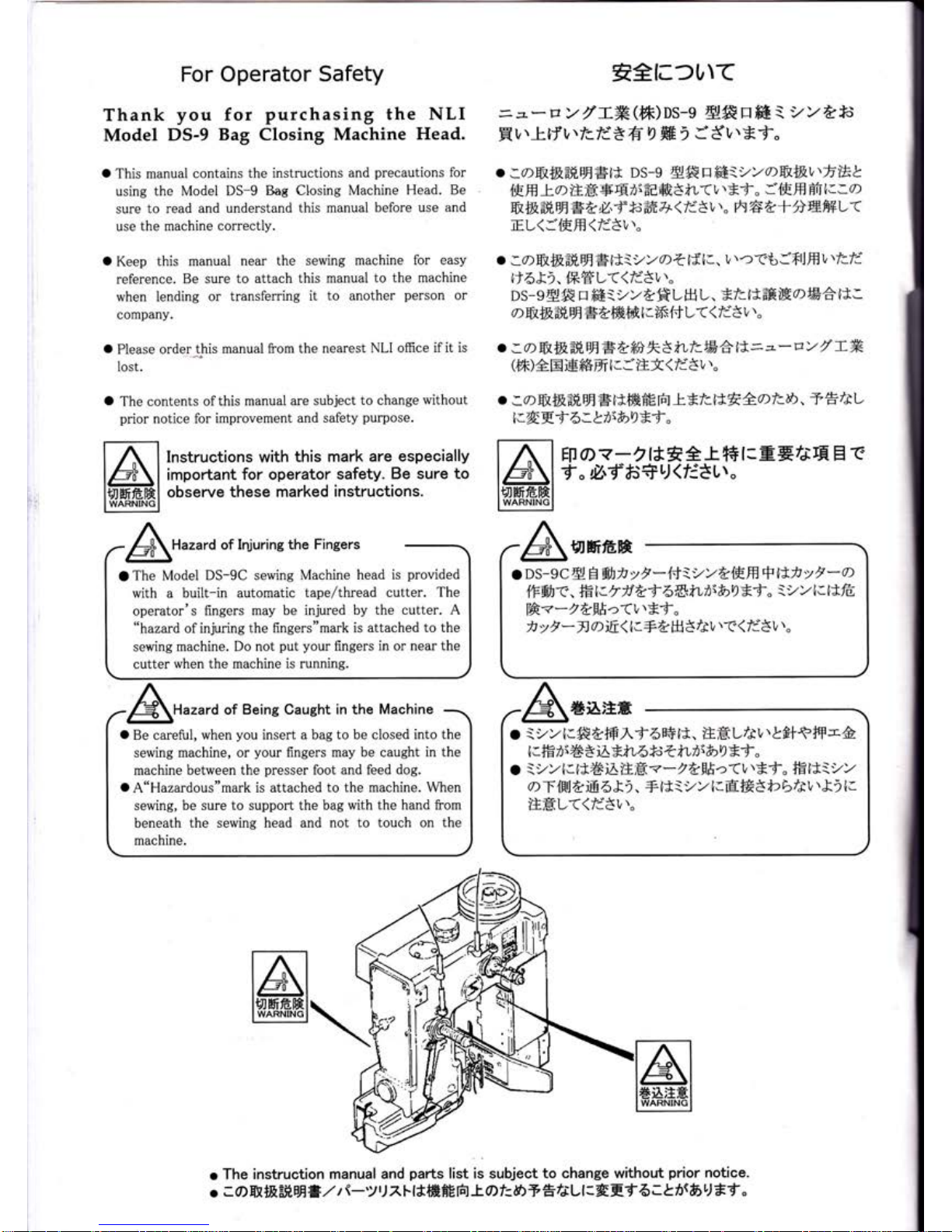

of Injuring

the Fingers

O

The Model

DS-9C sewing Machine

head is

provided

with a built-in

automatic tape/thread

cutter.

The

operator's

fingers

may be injured

by the cutter.

A

"hazard

ofinjuring

the

flngers"mark is

attached to the

sewing

machine. Do not

put your

flngers

in

or

near the

cutter

when the machine is running.

Hazard of

Being Caught in the

Machine

o

Be careful,

when

you

insert

a bag to be closed

into the

sewing

machine, or

your

fingers

may be caught in

the

machine

between the

presser

foot

and feed dog.

O

A"Hazardous"mark

is attached to

the machine. \Mhen

sewing,

be sure to support the bag

with the hand from

beneath

the sewing head and not

to touch on the

machine.

o

The

instruction

manual and

parts

list is subject

to change without

prior

notice.

o

; 0)

ffi *E

-#

flfr#,2

t

\-y'J

7.

F

ltffi

HE frt

-t-

A t=

&>

A fr

/i

L

I

:

4 E

t 6

z

t hrbu

tt

"

l.

WARNING

PERSONAL

INJURY

rvlAY

RESULT

IF THE FOLLOl|llING

SAFETY

PRECAUTIONS

ARE

NOT

OBSERVED.

BE SI'RE

IHE

AREA SURRflJNDING

I|ACHINE

IS

FREE

F

AI-I HAZARDS

SU$I

AS FIRE,

WATER,

OIL,

RUBISH

OR

AIIYTHING

THAT CAN

CAUSE

IIIJI'RI?

D0

NOT 0PERATE

ITACHINE

ll'l

AN EXPL0SIVE

AREA OR

UNDER

IIET

CONDITIONS.

THE

IIACHINE

IS

NOT

N

EXPLOSION_PROOF

TYPE

NOR I{ATER-PROOF

TYPE.

DO NOT

OPERATE

IIACHINE

BEFORE

READING

I NSTRUCT

IOII

IIANUAL.

DO

NOT

OPERATE

I|ACHINE ON

VOLTAGES OTHER

THAI{

SPECIFIED

FOR THE

HACHINE.

BE SURE

iIACHII{E

IS CONI{ECTED

TO BUILDTNG

ELECTRICAL

SAFETY

GROUIID

(EARTH).

Br

sunr

PowER

(ND

AtR

suppln

ts oFF

BEF0RE

PERF0RIilll'lG

MACHINE

iilAII'ITENAI'ICE,

PARTS

REPLACETENT,

ADJUSTMENTS

OR

CLEAI.IING.

DO

].IOT

OPERATE

IIACHINE

IIITH

GUARDS

ND

COVERS

REIIIOVED.

D0

NOT

T0UCH

Kl,llFE,

NEEDLE,

PULLEY,

BELT

AllD

ilOvltlc

PARTS

I{HEI'I

IIACHIItE

lS

It{

OPERAT

I ON.

BE SURE

IIACHINE

IS

PLACED

ON

A SIIIOOTH

(LEVEL)

SURFACE

ITHEN

PERFORiIIIIG

li|AINTENANCE,

PARTS

REPLACE[lEl'IT,

ADJUSTIIEiITS,

CLEANING

OR

STORAGE.

BE SURE

THE

MATERIAL

TO BE SE[{N

OR

CLOSED

COIPLIES

I{llH

THE I'lA$llNE

SPECIFICATIOI{S.

DO

NOT USE

SPARE

PARTS OTHER

THAN

.ilLI'

GET'IUINE

PARTS.

7.

3.

5.

10.

11.

1.

=#

TEts0)EAE

EI

EilH+

L

Tj75\

ct=EA

l: r*FfifoHtr

t

ti

L)

tf

o r;tH

t

((EtL'r"

ffi {fr

CIE

izt:gg

tfrE

;

f

H

tr

t.

re

6

!<

fi.

zk.

iH. EIffi+A/e Ez5rtL\fr\fiEf\d5(

(

f;*

ur"

R#@ftWa

b

6ffiffi

.

zl<;ffi

nttrf*#fift t:

i'z5r6ffiHr{*{HH

LfjL\r

(

fi*

ur"

;offifif;r*.

[fr,84

'

tffiffi4rr*6r.J *rf

/v"

m+e#,Ef

=

eil'E--fr/vti\

6ffiffieE+E

t

((E*ur"

ffififioEEEElJrt

Et*EFa

LfJr\r

< ri

t

u\.

7

-^

fi*6r+*ffi

* fL(

L\

5=F

effiffi

L

<

<

Et

Lr"

ffiffi@#ffi

-

#rrffi

El&

-

EEl#

-

xrtffimo)

Hf{:Z.f

E;If,

(&(.[rV-til

ttJtcT

(

fi81r,

H {5,

z t-z5ift*rf:

Ut

ffi

t

t*ffi

ffi

e

E+A

L

/JLrrS

(

Ett,r"

ffiffioiEFi+lt,

y

f

-,

8t.

a-.)

-.

,t/1,

l-

t

o

lfrgJL\

(

L\

6

ffi ffi

t=t*+

tffi)rL

fJLrC (

E8 Ur"

ffiiffi,a#ffi.

*{tFott4

.

FEH

.

tf;EF{p{*E0)

E+t:t*+

bfeBfrt-EL\(

(

E3 Lr.

ffi#j;

Lt

6#fr75rffiffiottt*r:a:

(

Lr

6/t#hr&>(<EtL\"

"=1-p

>rlf,x(ffi)

"

f,fiiE*ftfrDjrll*ffi

H

LfJL\-C

(

E8

Ur"

4.

7.

9.

10.

11.

Where

the construction

permits,

each

part

is stamped with

*lIft*fqfJ,EtlO;1H

its

part

number. On all orders,

please

include

part

number,

part

name

and

model name of rnachine.

o

=z*vYfT#(ffi)

AElEffiffilaitDs-9d)ftfi8*fJ#

tffi.{ffiL<*c9*f.

Safety

Rules

To

prevent

personal

injury:

.

:'tstOffiil.

zt*)!xl'Ozi*)*ElAf6(lffim

o

All

power

sources to the machine

must

be

turned offbefore

(li'3V

t.

threading,

oilins, adjusting or

replacing

parts.

o

{Effi

l:j6

EE

/r,F.X.

${EE

+

a)&HtT.#/r,f;

.

t

o

A1l

cover

and

guards

must

be

in

position

before

operating

D{&#lffitf

Etfi49

lc(

V

t

&6^lJ.

f.

H

L

\Ilf

L

tfcld*

machine.

*Llc.=,,.-vYr''f#(*)eEig*6trl.aB*F<fl3

u\"

BitDm,ffiffi*. ffiffi66.

ii/)/@fi5#.

:i/)/

t

Do

not

tamper

with

safety

cover,

guards,

etc.,

while

6ts4:ffim(ld8t,t*f&)*sffiV'.'vtlcL*-d-"

maehllre

is

in operation.

ldentifying ond Ordering

Pqrls

Coulions

When Using

ihe Mochine

Mqintenonce

tt-

t'xr:EEf

6 fjF6L\et

EHl'OtrH

gffi

Safety Precautions tA{:eUtf

1)Always turn

po$rer

off

before threadins, oilins, and

1)f;E=#X9'iAEJtLatZDXiiEL,

X\D*&,ffi&.ffi#.

adjusting the

machine

or replacins

parts.

*tJffit&. {*+,f;&{f#a-ffii.Z,fE,ffi&9lc((Id3

l/\"

2) Wear safety

srasses.

2)ffi*{F#0>}SEAAlrrz^alFHt*;ffDLEf"

3) Make

sure, before starting the machine,

that

all covers

3)A(O#'iz\-itZ'fIEEBfrlaffiD((fl5v''"

and shields are in

place

and closed.

4) Do not touch

on

the

machine when it

is run.

4)

f

zr*fta*iiffiEa(lrr6:LAffiffiL(r)BiEEL(<

fd8u."

5)

Turn

power

off

and make sure the cutter

does

not operate

5)

ffl)Tla+b^tLbL*lt.

/'f€rHt9]-a((Idttr

''"

before

you put your

fingers

under the

cutter blades

and

l6E.ffi*.Ctelt.

Z.f€ffitgJ0:yy7)rfi7)r/3trta|

the needles to adjust.

&ffiffiL(i.btF#.t'fr">((ld3tr\"

6) Do

not

touch on the machine

when

it is run. 6):y)/OiEE$lclt.

iyyl.mful31ta47351rt"

o

Please keep in mind to handle the machine

carefirlly and to

o

iyvEF*t5ltffiffi/ed.3/e*Ilffii.bH*trrr<L\*f.

maintain the machine in

good

condition.

ilHW<&$RiL&6tlHt:Effitl,L.fSiJ((li3V',.

o

Thread tuzz or

dust

must be cleaned with air

or brush on

o

-

E

A+FXrtrK-f

L*Llcb.

fi+ffi"D k,

*9&.0>l#0>

throat

plate,

in the

groove

of feed dog

or

around

looper

F,

tL-z{*a*bDIaR*aftl8LDS}*B*t,U\la}fi'9

after

the day's work.

ffiL\(T$L\"

o

Wipe

the area easy to rust with

oil cloth.

.

ZD{frffiDL\ffiEtr}*lH&'gaffiVt((fd8Vl"

o

Check the machine for loose screws and tighten

them,

if

o

E

lc-Eltt-rDffi.\fiiltL\r\,F,ffrL((ld3v''.

any,

once a month,

o

Good maintenance

will

prolong

the machine life.

o

+y'.fi,ORLHLttt#ffia#frIc**#L*fOfa'igH

(li8v''"

CONTENTS/

flYK

1

.Specifications/tlffi

2.The Points

Before

Operation/trEBta>ffiffi

2

S.Threadins/XiiEL

a.oiline/#iH

1. oil

Filline

EiH.

.......4

2.

Exchaneins Oil

mot&-..

.......4

5.A{iustine/ffiW

1 .

Thread Tension

fnffi+Offi#.

....

.

.

....

s

2. Presser

Foot

Pressure

fF-&OffiW....

......

s

3.

Looper tv*t\*61EHH.

.....6

4. Feed

Mechanism

E9&OAEB

. ...

........

8

5. Thread

cutter

f47Dffi#(ps-ge)

....

10

6. Cutter

)tyV*0tiffi#Os-9c)

....t0

7.

Adjustmentfor,

Single

Thread

Sewing

HffiffirrlOflfi|B.

...L2

o.Trouble

shooting/\yyoh,77*a76ElL*ffe

13,

14

Parts

List/ffiffi*

15-39

List

of Screw,

Nut

& Washer/i9.

fyl..,VyVf--HEl

40, 4l

Numerical Index

of Parts/z{-)ffiE

42-44

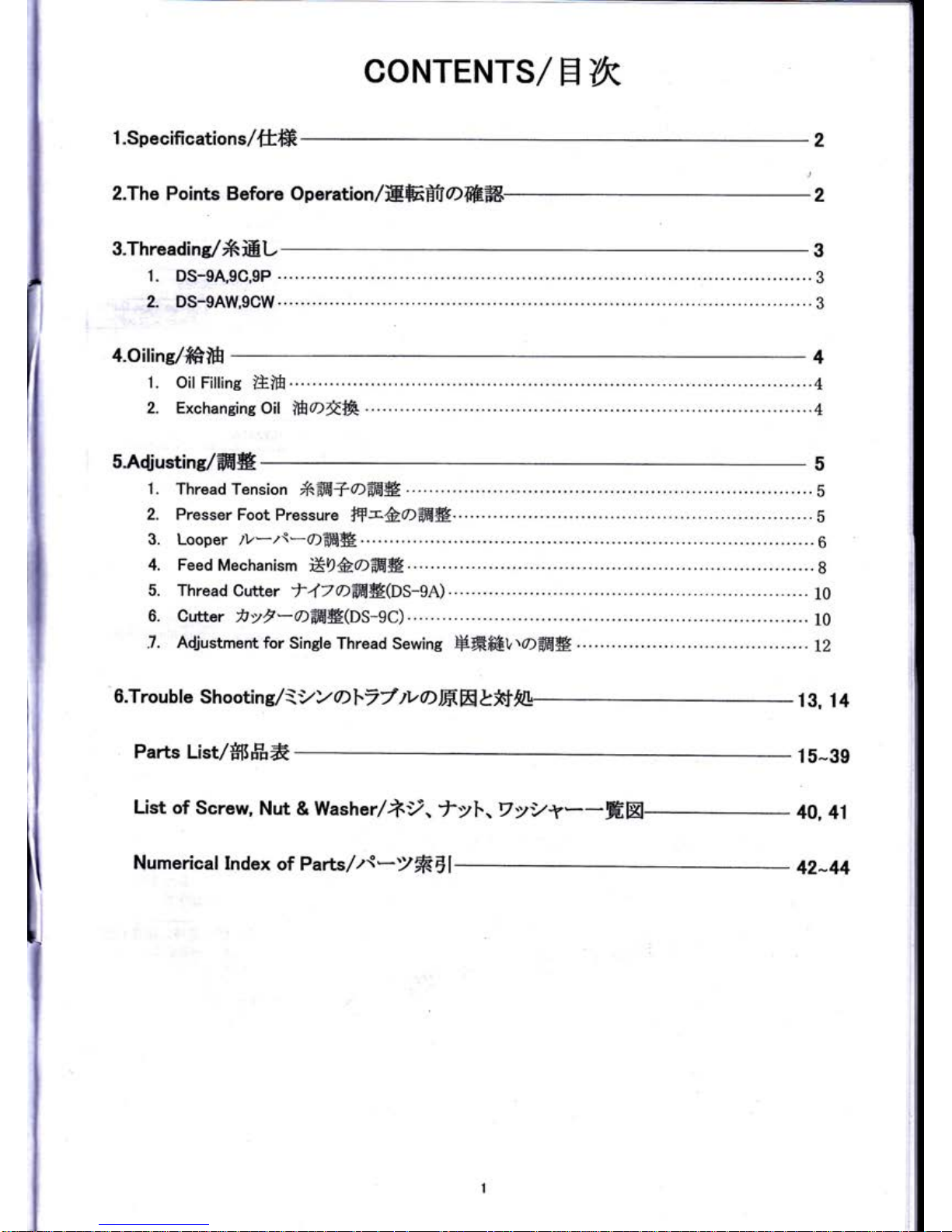

1. Specification/ftffi

2.

The Points

Before

Operation/EffitfrOffiffi

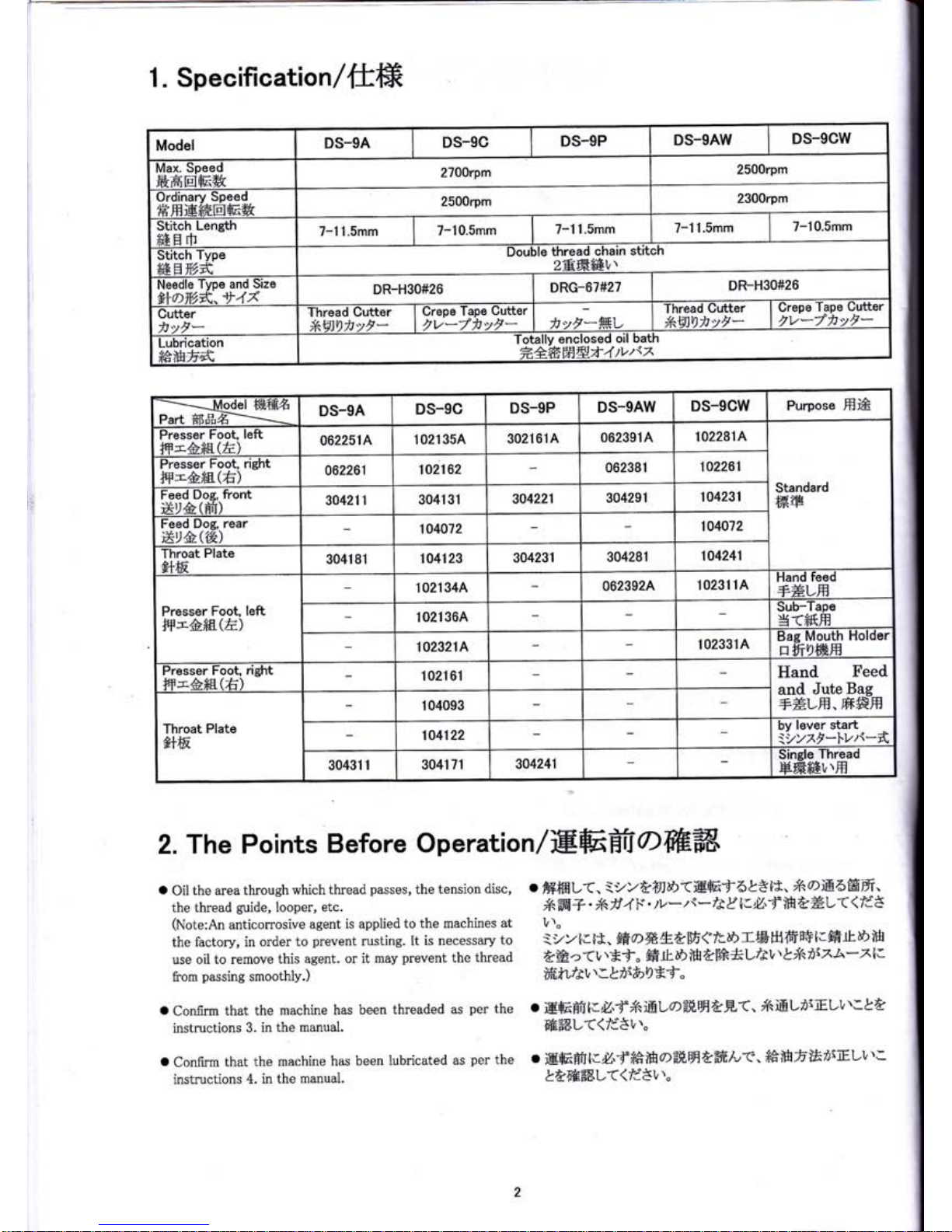

o

Oil

the

area

through

which

thread

passes,

the tension

disc,

the

thread

guide,

Iooper,

etc.

(Note;An

anticorrosive

agent

is

applied to

the machines

at

the

factory, in order

to

prevent

rusting. It

is necessary

to

use oil to remove

this

agent. or it

may

prevent

the

thread

from

passing

smoothly.)

o

Conirm

that

the machine

has

been

threaded

as

per

the

instructions

3. in

the

manual.

o

Confirm

that the

machine

has

been

lubricated

as

per

the

instructions

4. in

the

manual.

o

fi+mL<.

-vY

trylh<trEf

6LE

l*' *\'0)i&6ffifr

'

X\ffi+.

*il

4 F'

tv

-z{-

/r

D

lrfl.f

$

aEL(

<

fd

I

v\o

ivvt.

tt.

ffi

aXEtW

{

ir.d>Tffi

frffi

ffi

lrffi

rL D

ffi

?6a

(1,'Ef"

ffi

Lt.E

iH

&[A*L/ev''t/A

rixA-x

l.

Sfifu/rvl:Lrr&)!*f"

ffiffiL((/d5v''.

o

iEEBtl.U'ff€'lHoil

H

tffi/-<, f#ffif,EntrEuv

'':

&AaEffi'L(<fd3l,\"

1

I

l

l

Model

DS-9A

DS-gC

DS-9P

DS.gAW

DS_gCW

Max.

Speed

frHtr]E&

2700rpm

2500rpm

Ordinary

Speed

HffiEffiEffi&

2500rpm

2300rpm

Stitch

Length

ffiH

rfr

7-11.5mm

7-10.5mm

7-11.Smm

7-11.5mm

7-10.5mm

Stitch

Type

fi48#"2fr

Fouble

thread chain

stitch

28ffiffi1,'

Needle

Type and

Size

#laY,,*^ t4A

DR-H30#26

DRG-67#27

DR-H30#26

Cutter

itvF*

Thread Cutter

*,VJDtvl*

Crepe

Tape

Gutter

,v"/fiyr-

tt"rrylfl.tv

Thread

Gutter

*<6lD)tvF-

Grepe

Tape

Gutter

tv*/)tvF-

Lubrication

ffitH6fr

resedoilbath

frAffif'f,Ht4tv"sz

--..-_Modet

ffifEft

Part*IIfr#i--i

-

DS-9A

DS-gC

DS-9P

DS_gAW

DS-9GW

Purpose HE

Presser

Foot,

left

#-&#s.(E)

062251A

102135A

302161A

062391

A

1022814

Standard

ffiry

Presser

Foot, right

ffi-&*tr(fi)

a62261

102162

062381

1A2261

Feed

lfog,

tront

Er&(Et)

304211

3041

31

304221

304291

104231

Feed Dog,

rear

Xt&.(th)

104072

104072

Throat

Plate

AFfiE

3041 81

104123

304231

304281

104241

Presser

Foot,

left

ffi-A*E(la)

1 021 34A

062392A

10231

1A

Hand

feed

+#Lffi

102136A

Sub-Tape

g<ffiffi

1023214

t02s31A

Bag

Mouth

Holder

affiu)wH

Presser

Foot,

right

#-6ffi(E)

1021

61

Iland

Feed

and

Jute

Bag

+ELH.

ffi#H

Throat

Plate

e+ffi.

1 04093

104122

by

lever staft

iyyxt-1.1.,/\-{

30431

1

3041 71 304241

Single

Thread

HffiffiVTH

3. Threadins/friEL

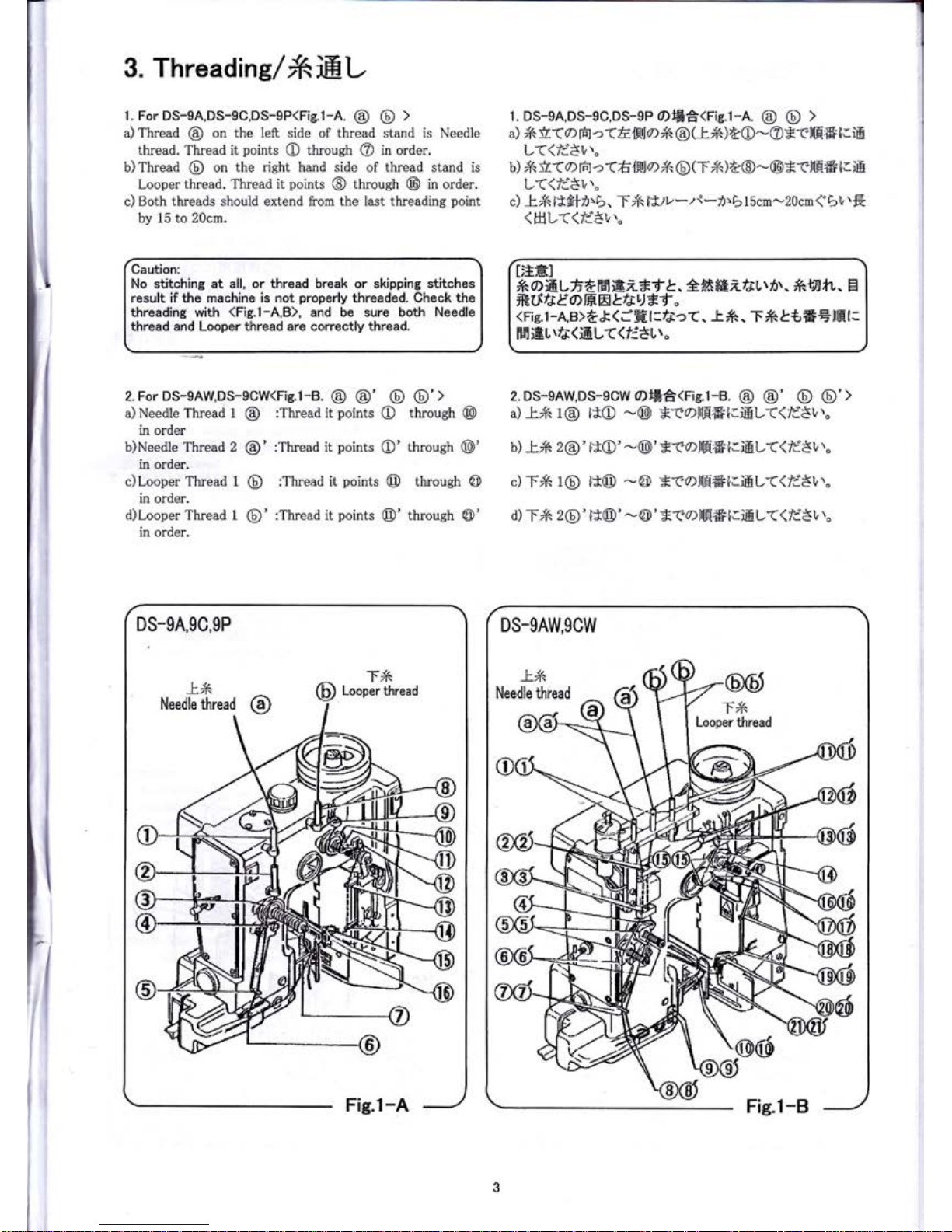

1. ForDS-9A,DS-9C,DS-9P(Fig.1-A.

@ @

>

a) Thread

@

on the left side

of

thread

stand is Needle

thread. Thread it

points

O

throueh @ in order.

b) Thread

@

on the

right

hand

side

of thread stand is

Looper

thread. Thread it

points

@

through @ in order.

c) Both

threads should

extend

from the last threading

point

by 15

to 20cm.

1. DS-eA,DS-e0,DS-9P 0)Efi<rie.l-A.

@ @

>

a)

i6

ir(

o

rto

->a

El$lo

*<@

G'tr ) AO

-@Erl[F6

E iE

L(<fa'8v\"

b) iA

ir

(

o

rFJ

c\

h lill

0)

*,

@

(

T

i6

)

A@

-

@

E

tllF6

I

r

iE

L((/i8v',"

c)

t i6

l*fi

n'

6.

T/A

li.tv

-

f

*

71.

b

1 5cm-20cm

{ b

t,'E

(HL((/dEv',"

Caution:

No stitching at all, or thread break or skipping stitches

result if

t}te

machine is

not

properly

threaded.

Check the

threading

with

(Fis.l-A,B),

and be sure both Needle

thread and Looper thread are correctly thread.

DEH]

lRaiEVfi

*F"1

EZ*f

t. A*ffi er*u

tit.

*fl

*t.

El

fttXfa&"0>lHtrbfsL)*t

"

(Fig.l

-A,B)f &

(f

H

l:/au

(.

-t.

#.

T

#

&t,iFEllLE

l:

FpliEtrfa(iEL<<EtL\"

2.DS-eAW,DS-9CW

@l6d/.Gie.t-B.

@

@' @

o'>

a)

-L.i6

1@

t*O

-@

*reol|[FE{.rEL((IdSv''.

b)

tX

2@'

i*O'

-@'

*tolllH6[.iEL((fd3v''"

c)

T/6

1@

lt@

-@

*<"olrF#l.iEL<(li'3t,."

d)

TX

2O)'

lt@'

-@'E-eol{E6t.iEL<(li3t,

''"

2.

For DS-9AW,DS-9GW(Fig.1-8.

@ @'

a)

Needle

Thread 1

@

:Thread it

points

in order

b)Needle

Thread 2

@'

:Thread it

points

in order.

c)Looper Thread 1

@

:Thread it

points

in

order.

d)Looper

Thread I

@'

:Thread

it

points

in order.

@ @'>

O

through

@

O'

through

@'

@

throush

@

@'

through

@'

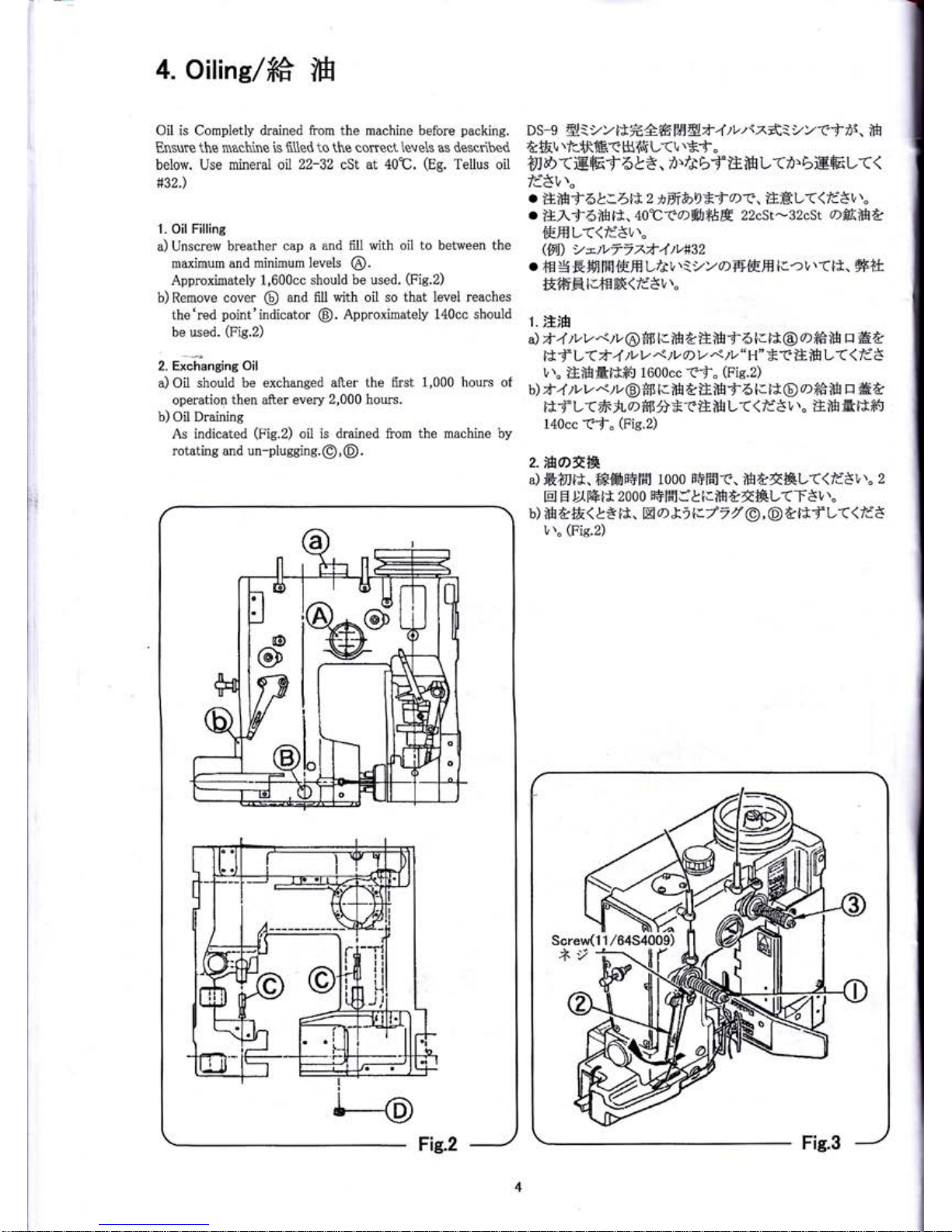

4.

oilin

g/t#

lH

Oil is

Completly

drained from the machine

before

packing.

Ensure the machrne

is fl1led to the correct

levels

as descdbed

below.

Use

mineral al

22-32

cSt

at 40"C.

(Eg.

Tellus oil

#32.)

1.

Oil Filling

a) Unscrew

breather cap

a

and fiIl

with oil

to

between

the

maximum and

minimum levels

@.

Approximately

1,600cc should

be used.

(Fig.2)

b)Remove

cover

@

and flll with oil so

that level reaches

the'red

point'indicator

@.

Approximately 140cc

should

be used.

(Fig.2)

2. Exchanging

Oil

a) Oil should

be exchanged

after the flrst

1,000

hours

of

operation

then

after

every

2,000

hours.

u)

Oit

oraining

As indicated

(n'ie.Z)

oil is drained ilom

the machine by

rotating and

un-pluggine.@,

@.

&f&t,

rfcfif

B< H{f

L<

l,

\Ef

"

AID

(rE6f

6&ts.

i'/ebf

iEffi

L(D'

biEEL(<

ld'St't.

.

iIiH9-6L.4t&2

*rt&>9*f

ar.

iEffiL<(/i3t,'"

.

lE,\f6iH

t*,

40'C(0)ffi

fEE

22cSt-32cSt

offilfrb

ffiffiL(<rd8u''"

(Frl)

y-tv77zft-4tvnzz

.

+E

g

EH f5t€,ffi

ur3p'1

vv

aFffi-Hlc-?u

\(l*.

#+t

&ffiElcfgff(A8vt.

1.

E'fi

a)

zt

4

tvv

*/r,

@

*11

[I.

ffi

&EH

16

l.lt

@

o

ffi

ffi

tr

HA

i*

f

L

-6

r--1'

)v

V'\

)v

q)

v'r'.rl,

"

H"

* T lI lH

L

(

<

fd 3

L\"

iEmEt**!

tooocc

-(f"

(Fie.2)

b)

*

4

tvv

*/L@

H3

t.m AiElHf 6

l. rtG)

o*a'ffi

tr

#a

it-d-L(#

JL

7)

ffi A*r&ifr

L(

<

rd8

r,',.

lI&

Et*ffr

140cc

Tf"

(Fig.2)

2.ifraf'+a

d &?nE. f*Eifl+Ffr

1000

F+FHl-f.

-{frt{,&t-<(fi3t,''.

z

El

E

D-lffilt 2000

ffiFfrSLlriHAt&L(T8t,."

b)

ffi&&<&tst*.

EXd)Xir.77f

@,€)AEf

L(<fi8

1,

r.

(Fig.2)

I

'-iM

Screw(1 1

/6454009)

5. Adjusting/Elf

H

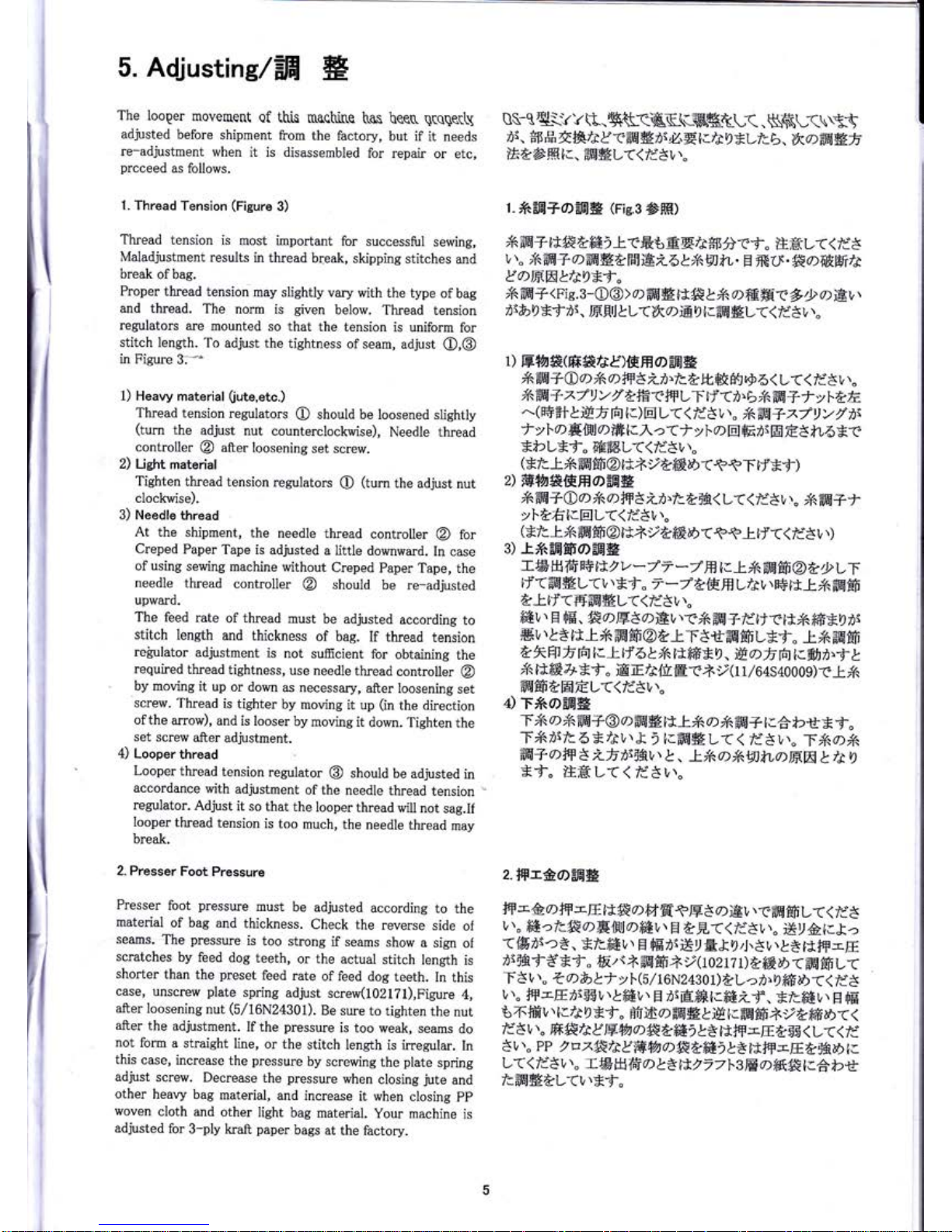

The

looper

movernent

of

this

rnaqh.i&e

tr-as

hee(r

qrcge(L\

adjusted

before

shiprnent

from the

factory,

but

if it

needs

re-adjustment

when

it is disassembled

for repair

or

etc,

prcceed

as

foilows.

1. Thread

Tension

(figure

3)

Thread tension

is

most important

for successful

sewing,

Maiadjustment

results

in thread

break,

skipping

stitches

and

break

ofbag.

Proper

thread

tension

may slightly

vary

with the

type

of bag

and thread.

The

norm

is

given

below.

Thread

tension

regulators

are mounted

so

that the

tension

is uniform

for

stitch length.

To

adjust the

tightness

of seam,

adjust

O,@

in

Figure

3:*

1) Heavy

material

fiute,etc.)

Thread tension

regulators

O

should

be loosened slightly

(turn

the

adjust

nut counterclockwise),

Needle thread

controller

@

after

loosening

set screw.

2)

Lisht material

Tighten

thread

tension

regulators

O

(turn

the adjust

nut

clockwise).

3) Needle

thread

At

the shipment,

the

needle

thread

controller

@

for

Creped

Paper

Tape is

adjusted

a iittle

downward.

In case

of using

sewing

machine

without

Creped

paper

Tape, the

needle

thread

controller

@

should

be re-adjusted

upward.

The feed

rate

of

thread

must

be adjusted

according

to

stitch

leneth

and

thickness

of bag.

If thread

tension

regulator

adjustment

is

not

sufficient

for

obtaining

the

required

thread

tightness,

use

needle

thread

controller

@

by moving

it

up

or down

as

necessary,

after

loosening

set

screw.

Thread

is tighter

by

moving

it up

(in

the direction

of the

arrow),

and

is looser

by

moving

it

down.

Tighten the

set

screw

after

adjustment.

4)

Looper

thread

Looper

thread

tension

regulator

@

should

be

adjusted

in

accordance

with

adjustment

of

the

needle

thread

tension

=

regulator.

Adjust

it

so that

the

looper

thread

will

not

sag.lf

looper

thread

tension

is too

much,

the

needle

thread

may

break.

2- Presser

Foot

Pressure

Presser

foot

pressure

must

be

adjusted

according

to

the

material

of bag

and

thickness.

Check the

reverse

side

o{

searns.

The

pressure

is too

strong

if seams

show

a sign

of

scratches

by

feed

dog teeth,

or the

actual

stitch

length

is

shorter

than

the

preset

feed

rate

of

feed

dog

teeth.

In

this

case,

unscrew

plate

spring

adjust

screw(102171),Figure

4,

after

loosening

nut

(5/16N24301).

Be sure

to tighten

the

nut

after

the

adjustment.

If the

pressure

is

too weak,

seams

do

not

form

a straight

line,

or

the

stiteh

length

is irregular.

In

this

case,

increase

the

pressure

by screwing

the

plate

spring

adjust

screw.

Decrease

the

pressure

when

closing

jute

and

other

heavy

bag

material,

and increase

it when

closing

pp

woven

cloth

and

other

light

bag

material.

your

machine

is

adjusted

for

3-ply

kraft

paper

bags

at the

factory.

avtq\VvR.S$IK(\CnKKtL<.$\K\-;(\\g$'

7)r.

sl3

gil

tf4/r

D("ffi

E

n\il.

E

i./i

g

ELft.b. tkq)ffi*fi

'tEt

E ffit..

EEt*

L((

/i3

v''"

l.

#-EJA+odElB

(rie.s

6ffi1)

X

AH+

tt#&ffi

i

l^-eft684/r*[A-ef"

iIHL<<

fis

v

\"

Xffi

+

offi

Ha

HEi 6

LNrrrJtL.

E ft

Lrt.

#o ffiWtt

&"oFtr&la9*f.

#

ffi

+

<p'rs.3-o@>

o

ffi

#

i*# &

#

offi

ffic

&

D

a&v,

,s&)9E:f

,r.

trErJ&L(ltCIiE4 I.EE*L(<ra'8r,

\"

1)

tr{rr*(ffi

*A&)f€H o

3EI

*

*ffi

+

@

D

*r) fF 3 ii./c

t tu#fr\

vg

6( L

(

(

ti' 3

v

r"

X\ffi

+

^7

t)

y

I &ffi<frLT rf

(D.b

#ffi

7f

yltE

^(E+-=#&rEf

Ifi

lt)

g

1_a

a

Id8

r,..

#ffi+

^7

y

y

/

ti

t

ylaF.luoffi

t.

?(J-

yT.o

ElErr

En

€3

tu6E-e

**2L*f"

EEffiL(<fdSL\.

(*Ic-t.fr

EEfifi

@t

*i,

tffiD r++T

d*f

)

2)

ffi{a*ffiHo-dag

i6ffi

+Oo

X

o

ilfl

3 ii.f:Adfi

<

L(<fdtu

r.

5

p67*

vl-&fi[.81L((ldsr,r"

3)

r*EEffiof,aE

Tw

fiffi

E+

rX'

v

-

7

7

*7

fr

t.

.E'

X

ffi

fiF

@

t D

LT

LJ(=aE#L(L

\

Xf

"

7

*7

t

{F.ffiL/i

r,

\

H

ttt,if

aE€F

at'd(FffiBL(<rd3v\.

f6v'' H

fiE.

#otr8o)EL

\-e/A

aB+rdtrrE#

ffffE9

rr

ffi

r,

\I*

t*t*

ffi

€F@A-LT8tffiffi

LEf.

.E'tr

;EfiF

L

kW fr

fi

I.-t

tf

6 L

fi

t*ffi

*0. ttDfi

frit;.9173'j

I

*

t

Jffi

7t

*-t'"

iE

rE

/e

{f

E

r

+,

(

1 1

/64

s 40

0 0 9)

-e

t /A

ffi€FaEEL((/i8t''"

4)

T*o5Eg

T *\

a

#ffi+@

o

ffi

# lrt

*

a

;Affi+

tra t2it

*

f

.

T*i\tbtlir,\t

)

fc6g1_a<

fdSv.,"

T/60lA

ifr+

Dfr

3

iraitfi L

\

l,

-9/6

o,/A

gJtv,,t*W

L

tr

ut

*f"

iEHL<(

liSt'r'

z.lH-SoffiE

#F

-&

o

fF

-

'-tr,'tj.#

D

fi

H.tE 3

o

iel,

\

(.=*H

€F

L(

<

ri

3

r,

r"

ffi

cli#

0DFrftl,:.ffii,\

H AF,(<fi8L."

Elr&lrI->

A.

Ert\.>

*,

Elcffi

r,

r

E

fE-

rt*,

E&

g

4. 3

v.

LE

l*#F-E

,r

tfi

f

3- *?-.

fEu

s

*

ffi

frFR

y(l

02

I 7 1)

tfrX

O

<

ffiFtrV<

T

3

r,''

"

z

a

b t

-f

y

I.

(5/

1

6N243

0 L)

tt-

->

t1,

g

fr#E

r

<

rd

3

l,

t"

#f

-E

/i

$$

l,

r

|

ffi

!,

r

E

nl

Effi

lcffi

if

.

E/1fi6

L

\

El fiE-

66ffi

r,.

t:/r

D *f"

Bifi

,)=FlE#trE

lr;6664y

tffi

b><

<

ld5

t,

..

ffi!frfr E

EMz

a*tffi)

t*llffi

-E

&86

<

L(<

fd

3t''"

PP,

n

z$lt?Wryn

OXb{#2}B

i*ffi

-E

b*kd> tt

L((

ld8

t,

r"

TE

tr)ffi

D

L.Z

tX,

77 l.

sE

ofiS#

tlAbrt

t=ffi#tL<L\*,f.

5.

Adiustins/ffi

H

i

I

3.

Looper

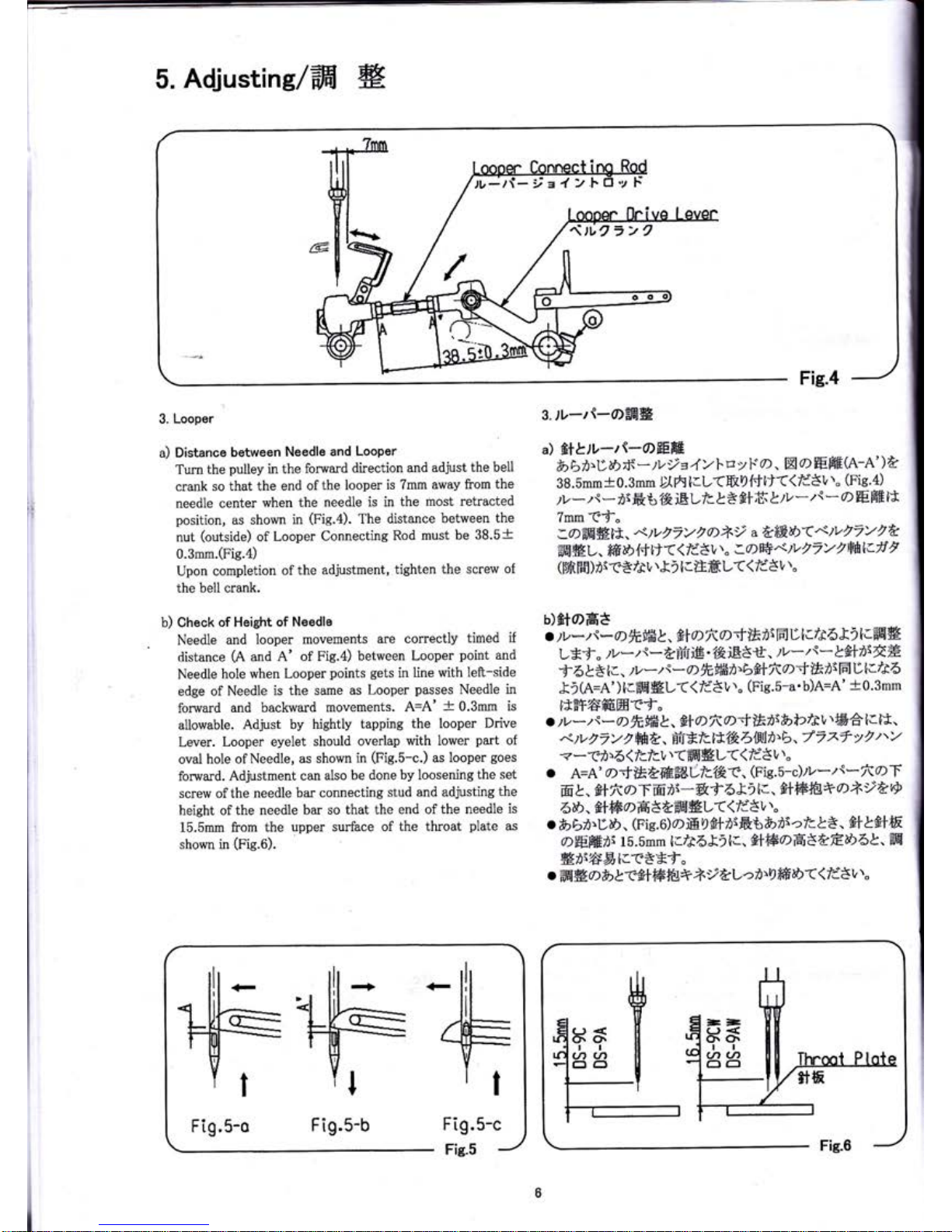

a)

Distance

between

Needle and

Looper

Turn

the

pulley

in the

forward

direction

and

adjust the

bell

crank so

that the

end ofthe

looper

is 7mm

away from

the

needle center

when

the needle

is in

the most

retracted

position,

as

shown

in

(Fie.4).

The

distance

between

the

nut

(outside)

of Looper

Connecting

Rod

must be

38.5+

0.3mm.(Fis.4)

Upon completion

of

the

adjustment,

tighten

the screw

of

the bell crank.

b) Gheck

of Height of Needle

Needle

and

looper movements

are correctly

timed

if

distance

(A

and A'

of Fie.4)

between

Looper

point

and

Needle

hole

when

Looper

points

gets

in line

with

left-side

edge

of

Needle is the

same

as Looper

passes

Needle in

forward

and backward

movements.

A-A'

+

0.3mm is

allowable.

Adjust by hiehtly

tapping the

looper

Drive

Lever.

Looper eyelet

should overlap

with lower

part

of

oval hole of

Needle, as shown

in

(Fig.5-c.)

as

looper

goes

forward. Adjustment

can

also

be done by loosening

the set

screw ofthe

needle bar

connecting

stud and adjusting

the

height of

the needle bar

so that

the end of

the needle

is

15.5mm

from

the

upper surface of

the throat

plate

as

shown in

(r'ig.o).

s.lt

-r{-oEEE

il fitL.tv-tt-ofEHfi

b bf.Dab

fi

-

tv)

e

4

YI'

r:

v

r*

o.

EX

o

ffi HE(A-A'

)A

3 8. Smm

+

0. 3mm

D[ 6t

llL<E

D

{'i

Lr((

ld8

v

r"

(Fis.

4)

/L-.,{

-

ir

ft

6 f&

ELfc

}

tsfif

Ifi

&zt,

*/{

-

a)

HEE

lt

?mm Tf"

ffi

#L. ffi

E{-t}r< <

Ii3t,',"

a0)W,9v, 7y

2

Wl.tl,

$'H

f6 )

rr

f

B

/*r,

r

&

)

I

cl},e.:

L(

(

li 3

t,

t.

b)ffoH8

o

)v*

t

\*

71trffi

&. t+

D

Ra;;f$-ri

IFJ

D

t./J6

&

2

t.EEg

L*f

.

)v

-

)

s-

?dfriE

"{&

nB3ii.

/lz-"

t

-

I &+rt\rt#

f

6 }*

tc.

)v

-

/

:-

D

fitffifi'E>fi+

fta'f

if

it

IEI

D

tI/r6

&i

[A=A' )

llffi EL<<

fi3l,''"

(Fic.s-a.

b)A=A'

+

0.3mm

itE-f6ffiEflTf"

.

)v*,,s-

o)

taffit,

&+

D

l<D=f #fi:fuN2fst,

tffi6

lclt'

.< p

r'

7

Y

2

ffit.

Ef

E/c tt

lkblW|fi'b,

7

2

zf

v

/

t'v

<

*(-i'6

(

Icrcv

r

(ffi

HL((

IdS

t,

t.

.

A=A'

Orfi**68&ti,Clkc.

(Fie.5-c)

)v*ts*fiqn

ffi

L

-

tI lr,)T ffi

,r-

&f

6

I

i

tr'

f*ffitr6'+

a

*,

L@

6ii.

t+BoH 3 AiE#L(

(

/c'3

t,''.

o

&)

EZ)>DE.

(Fie.

6)

o

rE 4

elD&6

&rnr

o

lc &3.

#+

tfr+

ffi

o)Hffiri

15.5mm

l:.ft635

0..

fr+W0 ttftr,Ab-

ffi

#fi;*D!i_zc8Ef"

.

ffi#Dblfarffiffi

+i

itl-->fi'9ffiD((ff

3

v

t"

]L

r

Fig.5-c

-

Fig.S

tv-tl- i = I

b9a"2

Fig.5-o

Fig.5-b

I

5. Adiustine/ffi

H

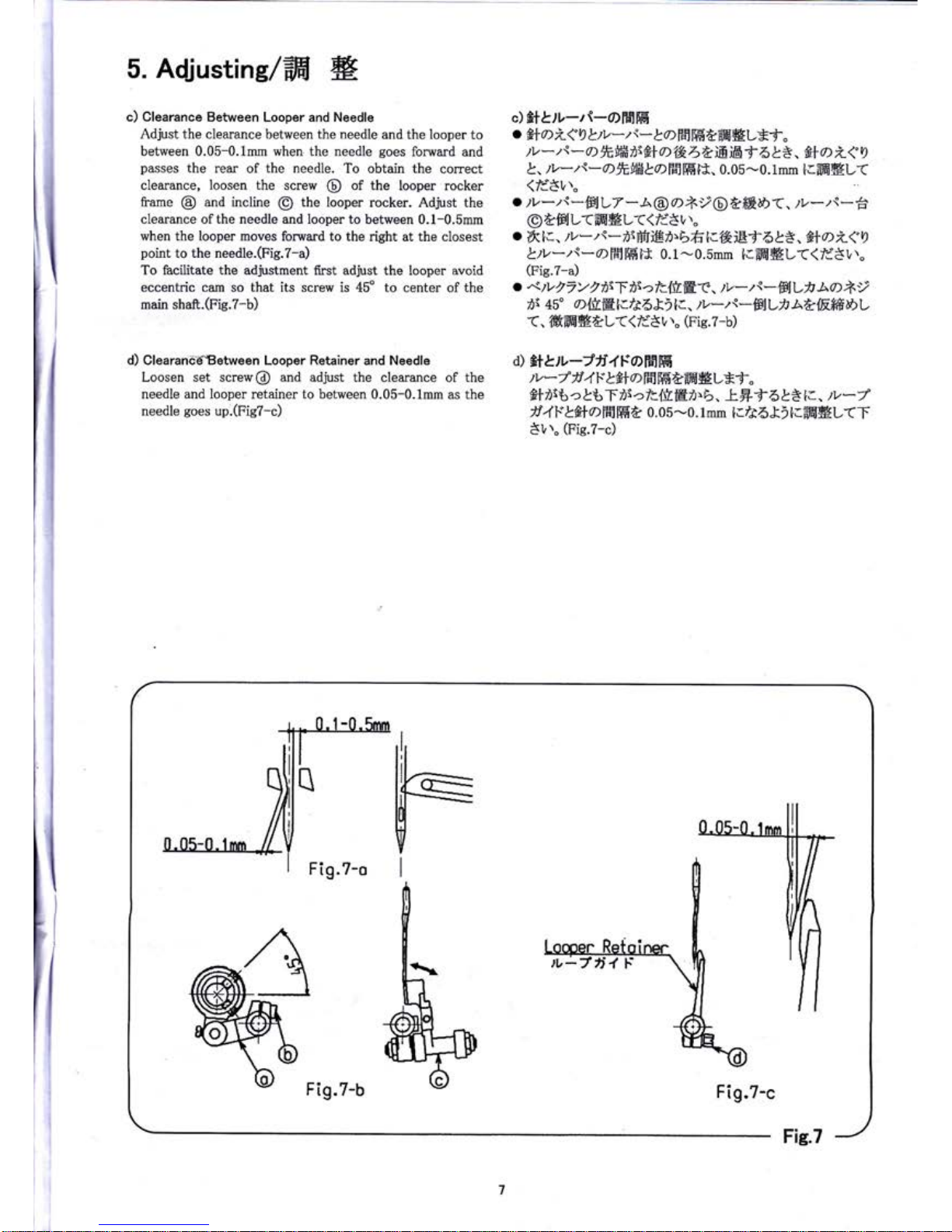

c) Clearance

Between Looper and

Needle

Adjust the

clearance between

the needle

and the looper

to

between 0.05-0.1mm when the needle

goes

forward

and

passes

the

rear of

the needle.

To

obtain

the

corect

clearance,

loosen the

screw

@

of the

looper rocker

frame

@

and incline

@

the looper

rocker. Adjust

the

clearance ofthe

needle and looper

to between 0.1-0.5mm

when the looper

moves fonnard to the

right at the closest

point

to the needle.(Fig.7-a)

To facilitate the adjustment

first adjust the looper avoid

eccentric cam

so that its

screw is 45" to center of the

main shaft.(Fie.7-b)

d) Clearande^Between Looper Retainer

and

Needle

Loosen set screw@ and adjust the

clearance of the

needle and looper

retainer

to between

0.05-0.1mm as the

needle

goes

up.(Fie?-c)

c)

fi+&rt

-/{-o)Fe1ffi

.

&l

D

Z<A b.)v-

t

s-

161ffi

ffi

&ffi

BL*f

"

)v

-

)

s

-

D 9tffi

rt\fr+

D'tk

4a

E iE

f

6 L8. f+o i

{

I

l,

.rl,-z{-

o

ftffit

o:-l1ffiilt.

0.05-0. t mm

t.ffi*L(

(ld$t,''.

.

)v-

):*ff.Ilt7

-

A

@

D+y@

Affi

E

(.

zt,-zt-6'

@AFJL(ffi#L(<rdSl,\"

o

ift

[:.

/r-.,{-

rrBfr ff_,fi)t>fr

ttth.iBf 6}8.

#

D

L< 9

L.tv*

ts-

61H

tffi

E

0.1-0.5mm

t.ffi#L<<li3v',"

(Fie.7-a)

.

,<)vVTYZirTi\ct{trEf

.

)v-/:-'F41-fi

Aa*,

,i

45" CI&E[:./361i

1..

)v-/s-FlL)J

ab{Effie>l-

<,'#\ffi*tL((ri'3

v''"

(Fic.

z-b)

a)

ft

L, tv

-Jli,f

ls

o)

Fpl lE

)v-/

)t

4

ts

l#o

rfi ffi

aaH

gL*f

"

Slir6c &6f

isaft'{trEi'b,

k*-l-

6}*

lr.

)v-7

)f

4

r* Lfi+

rr^lfrffi

t

0. os

-0.

lmm

l./r6Xi irffi

#LrT

Str''"

(Fig.7-c)

Fig.7-o

Fig.7-b

Fig.7-c

Fig.7

!-

I

L

5. Adjustins/ffi

W

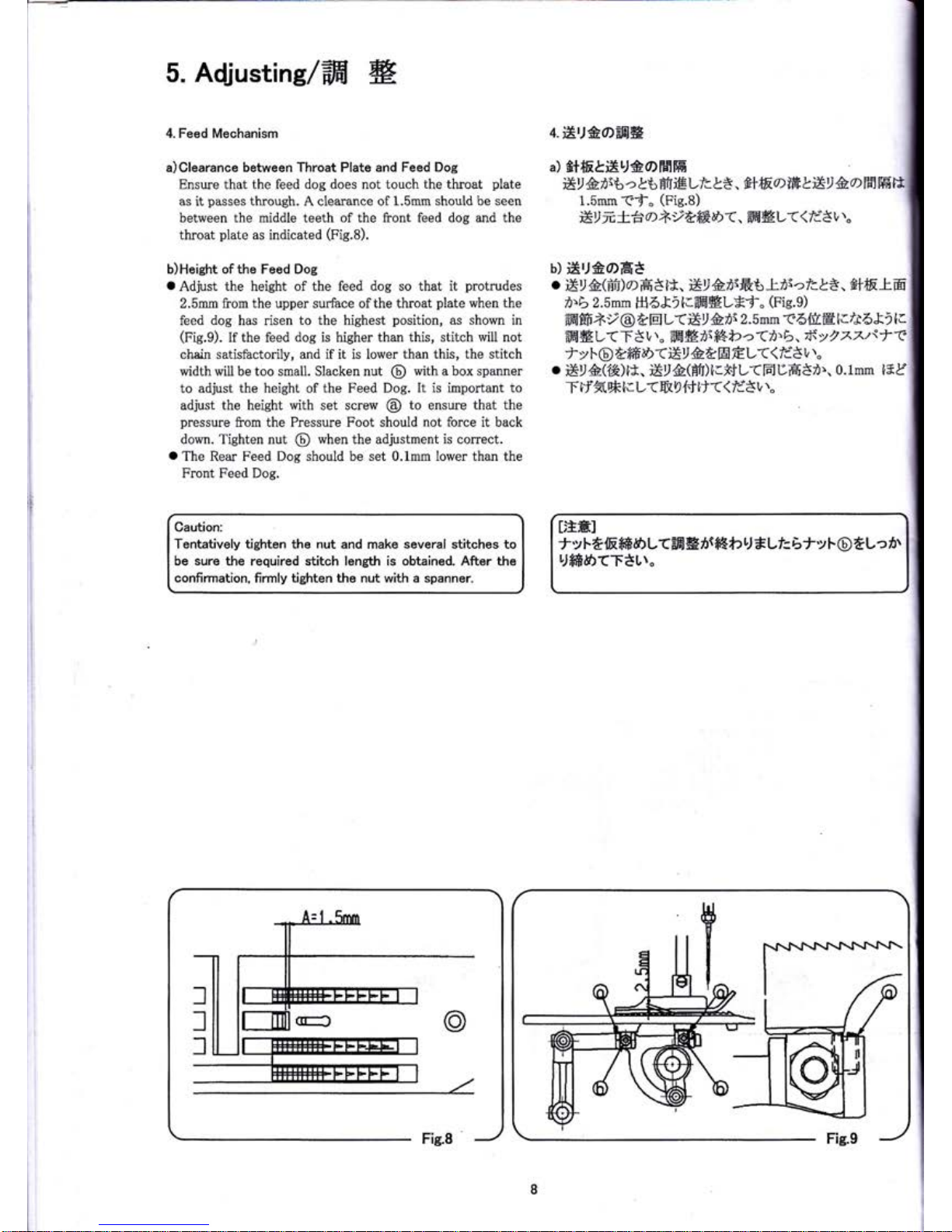

4. Feed

Mechanism

a)Clearance between Throat Plate and

Feed Dog

Ensure that

the feed

dog

does not touch

the

throat

plate

as it

passes

through. A clearance of

1.5mm

should

be seen

between the middle teeth

of the front feed dog and the

throat

plate

as

indicated

(p'k.A).

b)Height of the Feed Dog

o

Adjust

the

height

of the feed dog so that it

protrudes

2.5mm from

the upper surface ofthe throat

plate

when the

feed

dog

has risen

to the

highest

position,

as

shown

in

(p'ig.g).

If the feed

dog

is higher than

this, stitch will not

chain satisfactorily, and if it is lower

than this, the

stitch

width will be too smal1. Slacken nut

@

with a box spanner

to

adjust the height

of

the Feed Dog.

It is

important to

adjust the height with set screw

@

to

ensure that

the

pressure

from

the Pressure Foot should not force it back

down. Tighten nut

@

when

the adjustment

is

correct.

o

The

Rear Feed

Dog should

be

set 0.1mm lower than the

Front

Feed Dog.

Gaution:

Tentatively tishten the

nut

and make several stitches to

be sure the required stitch length is obtained.

After

the

confirmation,

firmly

tighten

the nut with

a spanner.

4-ix'JeOFla*

a)

St*E&iEtJ#oFslffi

E)

&is*:

c

*6 Efr trLf

L3. fltE@ffi

&X, &o

f5

1.5mmTf"

(Fig.B)

EINifo t

tffie><.

ffi*L((lddt,l.

b)

iXu#orat

o

Er#(Bfi)o H3

tt, i*,

&r\Eb

Iii->lcl*.

SitEt

ffi

D.b

2.5mm

H6&il.ffi#L*f"

(Fie.9)

ffiEF*-r@

&EIL(ErADI

2.5mm t6{tEl.A6&i l.

ffi

#L<TS

r,

\.

#l#

ri

ft€*>

cAfi'b,

if

>

2

z ztsaa

J'vF@ &ffi

E

()Xll

Aa

H

EL(<fd8

L

\"

.

E,

A('{&)t*.

Er&(BfI)

icf.f

L<

E

DHSi'.

0. 1mm

l* &"

T

}Jft,*

tr

u(

& I {-.}

!r((

fdsr,',"

ItrH]

ty

l-d

lRffi

a>L

(-aE

*

nrfi

I

b U

*Lt= b tv

F

@

t

L

z z5r

tJ*if,&)(T*t\"

5. Adiusting/ffi

W,

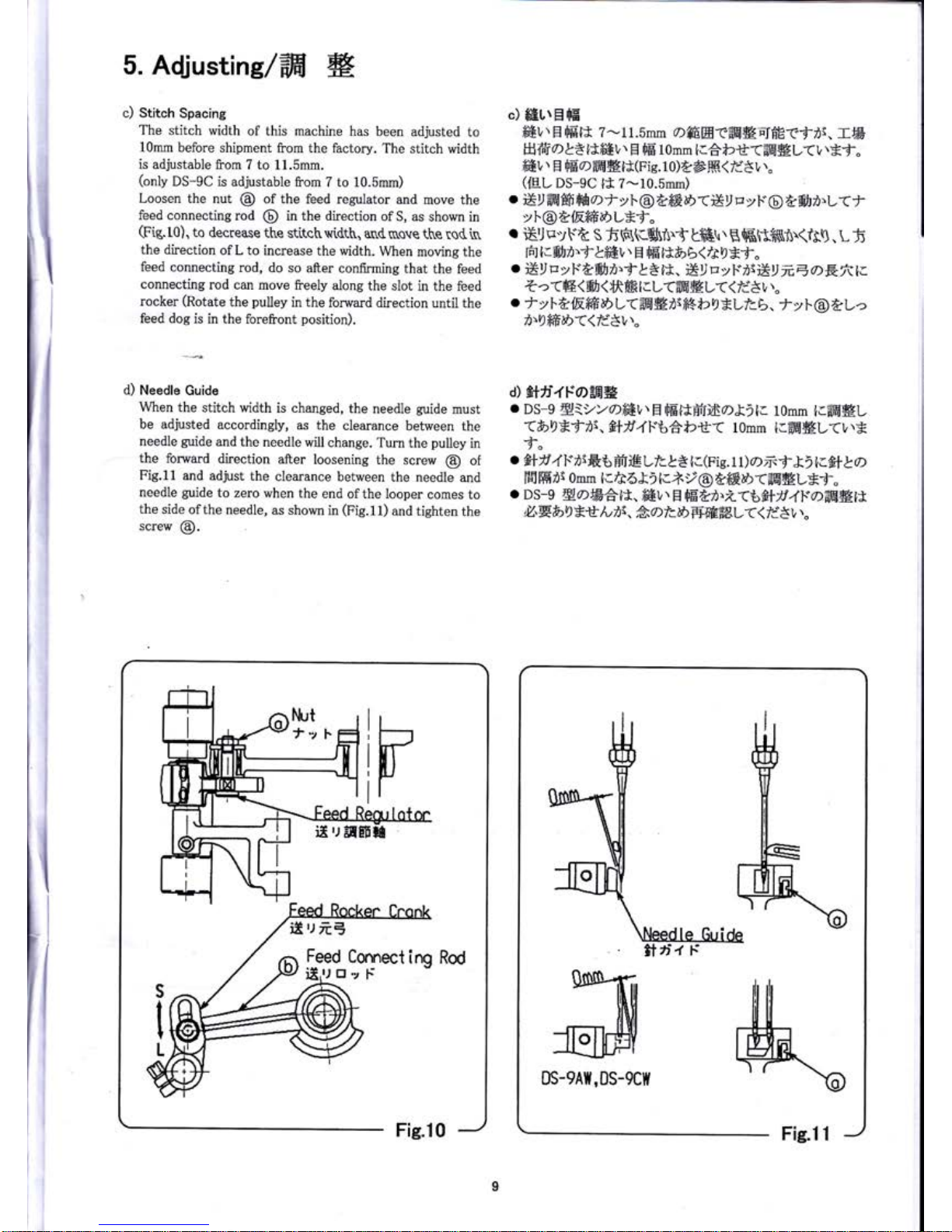

c) Stitcn

Spacins

The stitch

width

of this

machine has

been adjusted

to

10mm before

shipment

from the factory.

The

stitch width

is adjustable

from

7 to 11.5mm.

(only

DS-9C

is adjustable

from 7 to 10.5mm)

Loosen the

nut

@

of

the feed regulator

and

move the

feed connecting

rod

@

in the direction

ofS,

as shown

in

(p'is.tO).

to decrease

the

stitchwtdth,

an(ruove

the

ro(in

the direction

of L to

increase

the width.

When

moving the

feed connecting

rod,

do so after

confirming

that

the feed

connecting

rod can

rnove freely

along

the slot

in the feed

rocker

(Rotate

the

pulley

in the

forward

direction until

the

feed dog

is in the

forefront

position).

c)

#ELtEfE

fEL

\

El

fE-t*

z-1

r.Smm offiEfl

tEE#EI6E-cf

,i.

rB

Hffi

ol*l*mr,.

El

rFE

tomm

tl6i2rt'<ffi

HL<L

\*f.

fi6v'' H

fEod6*t*(Fis.

10)t8ffi

(

li3

v''.

(fE

L DS-9C

l*

7-10.5mm)

vl@tltrffiDL*f.

r

€'l

ttv\-'t

S

fi

H(rBi

S

gffi

r

gffififfiflr(ft9.

L

5

H

1ls31'j1#6v''

H

r[E-

tt&,

b

<

/r

I

*f

"

o

El/

p

y

r*&#rr.f

&* tt.

EI

rz

y

r."rtEll

N E

oE

It

tc

z

">Tw1#s(

ttFF

I

I

u<ffi

g

L(

<

/i3

L''"

o

f

vlL{EffiDl,<ffi#nr*$b9*LIc

b. f

yf@tl-o

i'9*ffiD((ldSvr"

d) Needle

Guide

When

the

stitch width

is changed,

the

needle

guide

must

be adjusted

accordingly,

as the

clearance

between the

needle

guide

and

the

needle

will change.

Turn the

puiley

in

the

forward

direction

after

loosening

the

screw

@

of

Fig.1l

and adjust

the

clearance between

the

needle

and

needle

guide

to zero

when the

end ofthe looper

comes to

the

side

ofthe needle,

as shown

in

(Fig.11)

and tighten

the

screw

@.

d)

fitti.fFoEE#

.

DS-g

ryiy)//)ffiI,

\

H

rFE=EHfrm

DX)|.

10mm

[.==Jfl#L

<b9*fri,

flf4F'66*2t(

10mm

lc.ffi#L<vr*

l"

.

flf4F'rsft

6

ffi

reLt.&3 lc(nig. t t

)

o>

zrf

l)

ir_fil

ta

f6 Hrr

omm

i.A6&

) ll-lnt

@tffi

aD

(-ilEHLBf

"

o

DS-e

Ha*AtJ.,

fi61\

H

r[E&n.i(6ffr4]."offigtj

U.E&)

I *rf

tu

i\.

Ao

/l.

E

Be'E=aE

L((

/i3

I',"

iI'l

ilEE

iX'J

ftE

5.

t-paffiH

(DS-eA)

t 4

7 A

tt,l

7 B

arffi

Tlebit

ttho

&'i

t.=EE

V\"

(Fis.12)

a)

t4z

A

i*ElErtaawlt,tt}ffiffittl-'

(t8v

r"

4ffiv

rft

ztst#O

+T8trb/et

t&i

,rln,

B

ttf47v,{-oi#rr,'fi,.

*)@-efnmt"

I

",

511;il;**,L(r,{7

BiitoLb*ii*LirL*.,

n,

I

A

o>:

fr

l.

2

mrntt'7t6iatruEf+r@4ffi

E<tr

€t<

|

il

-f47

ALt47

B

tDtyti(^zrflrD&'{EBD"f47

|

rzz\-2911<e6gL*i"

I

e) /n s

AAHi2<i47

A.B

o>ffitrr''fL.

/-y-t+<

|

*bt-TL)J.>trL*,

gJtt'ffi\

rt:*<9]

ffi

ffi

,r

E

fr

l.qJfi"

I

I

r.ffi@Ds-eAull

ffir nilr

ll

EJfl II]fl

ffil lfnk

*{q

*\

\Krilrl

b ll

t'(aA

Fis'12

)

|

6.

h'yl--.olefrr*

I

)tyF*o>ffiWb-f

6tr!E.

/,f-7

*{R't.j9J'>aara*

|

r,r"

-7*JRri@trr<1,''6:&&AEffiL((fd*v''"

I

]trfl.Tl]a-}.&'t'6LZi*,

v''.tbffilErrz.E-ef"

I

d S9]-e.E'll

t#trt'L=c,

LTJ LT

flbrffi

7*6t2rt*3-.

I

}.TJTT

tf

6&3(Fie.

t3)*r@,

@, @l:z

l'@,

@

ttffi

|

.

?;y+*;),

*r^*o*

rt(Fis.

14)o

&

)

t=iva*z+

|

-sii

0.1mm-0.2mm

{l/r61iO.*r@-eAEELEf"

:

I

o&ts'b'ItT

fl

flftffilultt.

Ef,fL(v''ari

icffiEL

I

((ldst,l

I

r tt

I

=az+<a&6&*(Fig.r4)o&il=.

t.l;LTTJaFeil=

I I

lrtztrw,t

+xtt*;tAr

(rrf:Etlf,.

ffiHt=H;F:Ff"

I I

I

rl

b) .CIffi#.Dfrrt

t,@t+ro

lrffi<&)(<.

trl@a

I

ffiD((ldsl""

5.

Adjustins/ffi W,

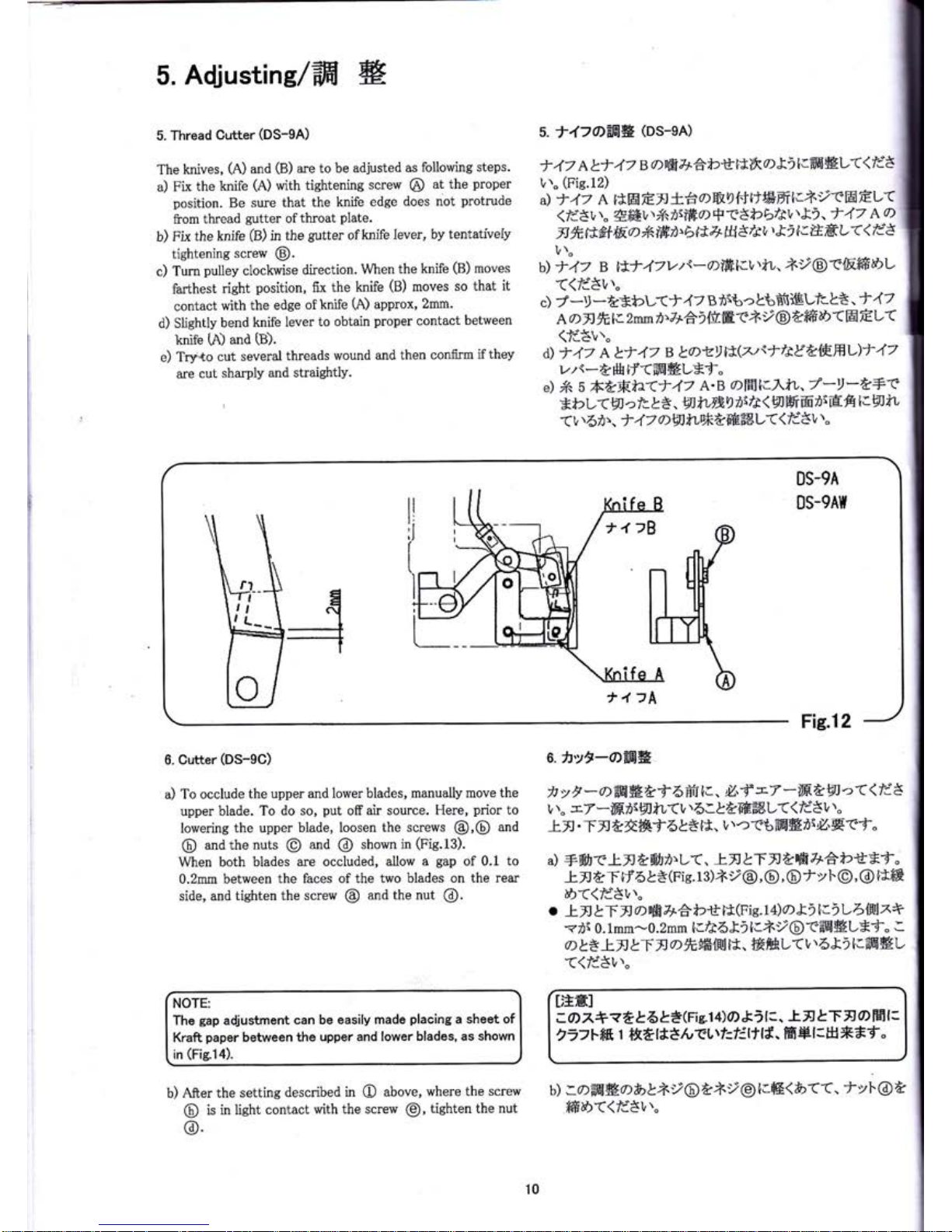

5.

Thread

Cutter

(DS-9A)

The

knives,

(A)

and

(B)

are to

be adjusted

as following

steps.

a)

pix

the

knife

(A)

with

tightening

scre\4r

@

at the

proper

position.

Be

sure that

the knife

edge

does not

protrude

from

thread

gutter

ofthroat

Plate.

b)

Fix

the knife

(B)

in

the

gutter

ofknife

lever,

bv

tentativelv

tightening

screw

@.

c) Tum

pulley

clockwise

direction.

When

the knife

(B)

moves

farthest

right

position,

fix

the knife

(B)

moves

so that

it

contact

with

the

edge

of

knife

L\)

approx,

2mm.

d) Sliehtly

bend

knife

lever

to obtain

proper

contact

between

knife

(A)

and

(D.

e)

Tr:nto

cut

several

threads wound

and then confirm

ifthey

are cut

sharply and

straightly.

6. Cutter

(DS-9C)

a) To

occlude

the upper and

lower blades, manually

move

the

upper

blade. To

do so,

put

off air

source. Here,

prior

to

lowering

the upper blade,

loosen the

screws

@,@

and

@

andthenuts

@

and

@

shownh(fie.tf).

When

both blades

are oecluded,

allow

a

gap

of

0.1 to

0.2mm between

the faces of the

two blades on the

rear

side, andtighten

the

screw

@

and the nut

@.

b) After

the

setting

described

in

O

above,

where the

screw

@

is

in light contact

with the screw

@,

tighten the

nut

@.

u*.,a1

;a 7+v

t&

6

&*(Fie.1

4)O

&5

l:,

-E.n

&T 5

o

Fe3

l:

,a7F*fr,

I

tfEl*t/-(Ltf:Elt{f,.

ffi+t:H*tf

"

NOTE:

The

gap

a{ustment

can be

easily made

placing

a

sheet of

Kraft,

paper

between

the

upper and lower

blades, as shown

in

(Fig.14).

10

5. Adiustins/ffi

W

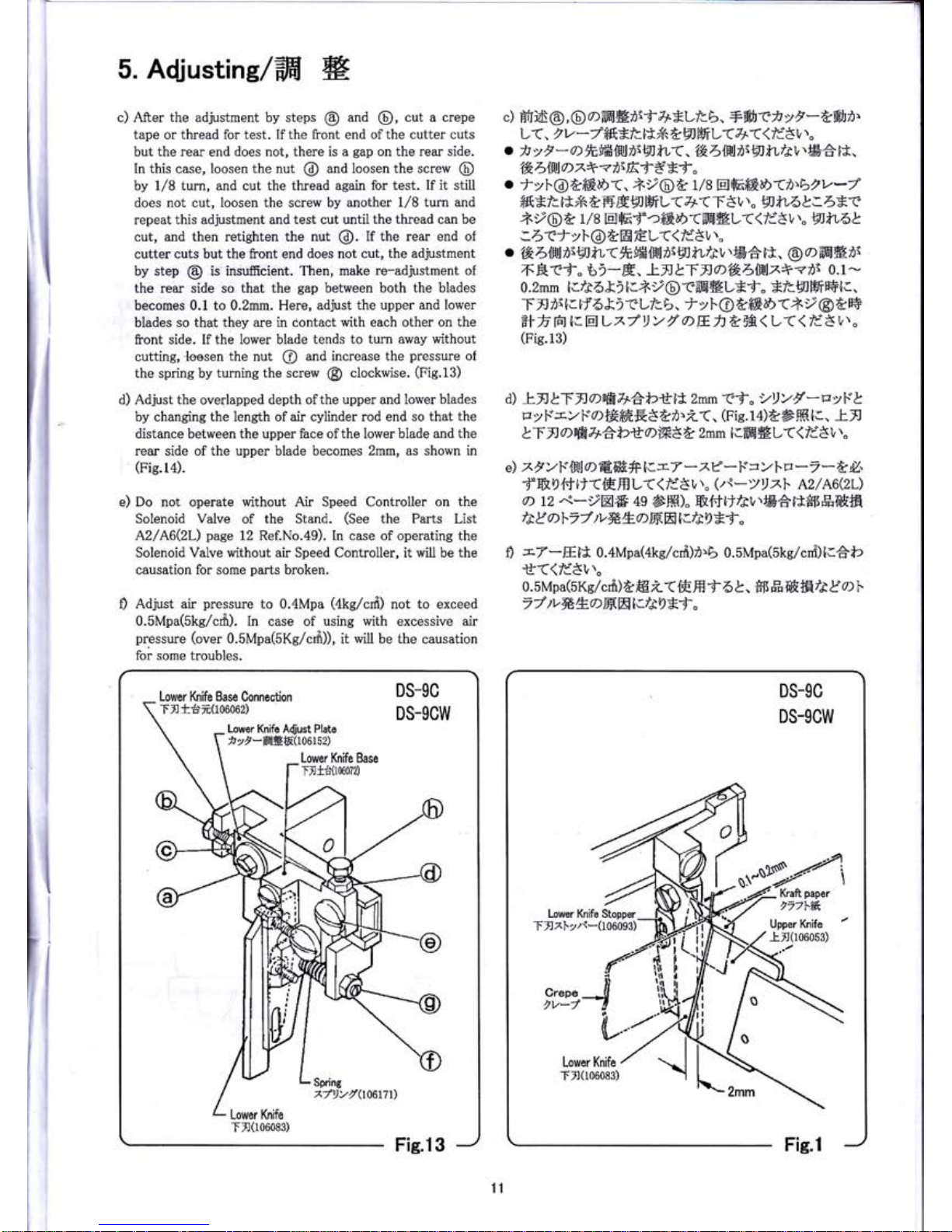

c) After the adjustment by steps

@

and

@,

cut a crepe

tape or thread for

test.

Ifthe

front

end

ofthe cutter cuts

but

the

rear end

does

not,

there is a

gap

on the rear

side.

In this case, loosen

the

nut

@

and loosen the screw

@

by l/8 turn, and

cut

the thread

again for test. If it still

does

not

cut,

loosen the screw by another 1/8

turn and

repeat

this adjustment and test cut until

the thread

can

be

cut, and then retighten the nut

@.

If

the

rear end of

cutter cuts but the front end does not cut,

the adjustment

by step @ is insufrcient. Then, make

re-adjustment of

the rear side so that the

gap

between both the blades

becomes 0.1 to 0.2mm. Here,

adjust the upper

and lower

blades so that they

are in contact

with

each other

on the

front side. If the lower blade

tends to turn

away without

cutting,

lsesen

the

nut

@

and increase the

pressure

of

the spring by turning

the screw @ clockwise.

(p'is.t3)

a) eajust the

overlapped

depth ofthe upper and lower blades

by changing the leneth ofair cylinder

rod end so that

the

distance between the upper face ofthe lower blade and

the

rear side of the upper blade becomes 2mm, as shown

in

(Pis.t+).

e) Do not operate without Air Speed Controller

on the

Solenoid Valve

of

the

Stand.

(See

the Parts List

A2/A6(2L)

pace

12 Ref.No.49). In case of operating

the

Solenoid Valve

without air

Speed Controller, it will be the

causation

for some

parts

broken.

0

eajust air

pressure

to 0.4Mpa

(ake/cfi)

not to exeeed

0.5Mpa(5kg/crf,).

in case of using with excessive

air

pressure

(over

0.5Mpa(5Kc/crfi)),

it

will

be the

causation

for some

troubles.

c)

Bfrs@,

@

rr-ffiWrt\f 7^*Lt6.

*qt1)t v

I

-t#9'

L<.,

v

*j*.fi*r..i**

&

\JWL<

7r<(

fd8

t,''.

.

fi

y

F

-

aft

'ffi

fiil

rlq

fu

<

.,tr4[ilrt\

@

il"ttv).E6 t*

-

,tk4l1lD^+?r\Efg*f.

o

fvl-@ &ffiE.<.

jir@

A

U

I

@*ffiE.art,b2v*7

*rG)

a

1/8

EEf,

fi*b<ffi#t-((td3

v',"

qttL6

t.

:,5<iyl.@AEEL(<fd8L

\"

.'&

6lillrt\gJ

tL<

fi,iHlillrti fl

fu

/3 t,

r

S.S

it.

@

a>

ffi

#

rr

6Rrf" 6

i-8.

.tIJ

LT

fl

a'rkbl\lT*<ri 0.1

-

0.2mm

tc/r5E5 O.*y@rAB#L*f"

*tc.9llfiffiic.

T>l

rr

[.

if

6&irLlc b. t vl

@

tftED

<+r@

&H

A+frfilttr4r7aY

Ytr DEh

Arf;<

L(( /dE

t,''.

(Fis.13)

d)

-trg&fIJ

arffi&eb:&i* 2mm

<t"

yy>.y

-pyr.^&

r:

y

5^-7f."d) t*ffiF.5?rt.Z(.

(Fig.

1 4)t

>ffil.,

-Lfl

LT

rJ

Dffi46i2tol#3

t

2mm

(cffi

#u<</i8v

t"

d

^,

vF

[H\o €ffi #

ic-7

-^c

*

i.^

av

Fv

-

7

*

t il,

f

mD{.f

[r<&ffi

L(<

fjg

1

r.

(z{

-yt)

z.l_

Az

/

A6(ZL)

a n

*-rEl6

+g

aK)"Wttt]lrv.#6Effi$tfiEH

ft

E

o>

17

7

tv

#

/fa'lilW.tr9

*f

"

0

-7-E

lt

o.4Mpa(4ks/crf)t.b 0. 5Mpa(5ks/cni)

trAt:

il(<fi8L\"

0.5Mpa(5Ke/ crk)t

ffiL<{E,ffi

f

6

}.

S

ft

fift H

/r

Do l.

7)turyhogEI[:699j"

Lower Knife

Base

Connection

Tnt6i(106062)

Kraft

paper

,77\ffi

Lower Knife Stopper

Tnxl.y/{-(106093)

11

Loading...

Loading...