NEWLONG

MODEL

DS-10^^

PRESSURIZED

MACHINE

Fi

if

INSTRUCTION

/•y

FISCHBEIN

MNUAL/PARTS

looooj

MODEL

DS-10A

•S-1

LIST

O C

§

L.

ty

/ I

NEWLONG

MACHINE

WORKS.

No.n

LTD

Identifying and Ordering

Where

the construction permits, each part is

with

itspart

number,

number.Onall

part

name

and

orders,

model

nameofmachine.

please

Parts

stamped

include

part

Safety

To prevent personalinjury:

•

All

power

beforethreading,

•

AU

cover

operating machine.

•

Do

not

machine is in operation.

Maintenance

Please keep in mind

andtomaintain

•

Thread

brush on throat plate, in the

around looper after the day's work.

Rules

sourcestothe

oiling,

and

guards

tamper

fuzz

with

the

machineingood

or

dust

machine

adjusting or

must be in

safety

to

handle

must

mustbeturned

cover,

guards,

the

condition.

be

cleaned

groove

off

replacing

position

machine carefully

parts.

before

etc.,

while

with

air

of feed dog or

1

MODEL

or

DS-1

O

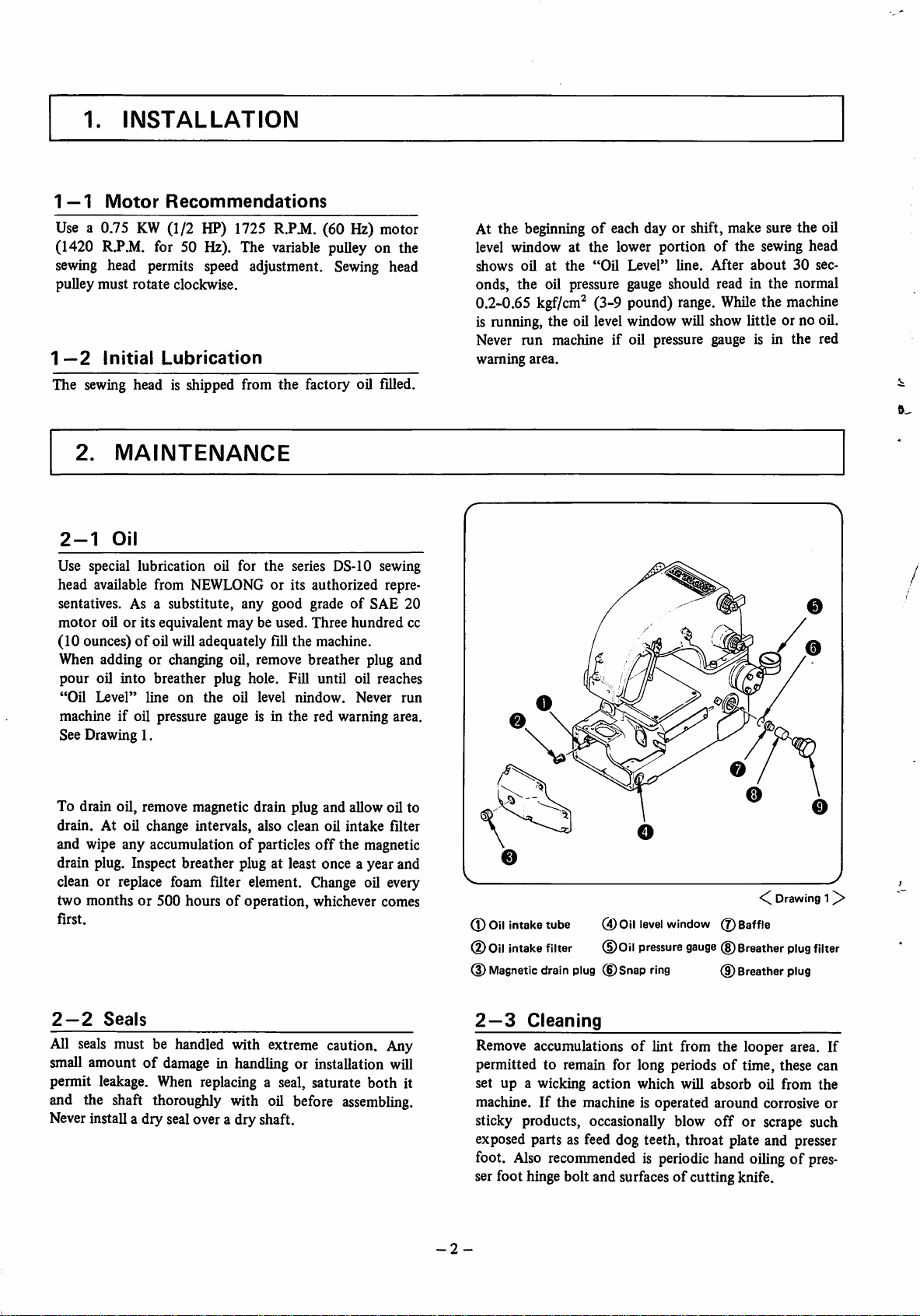

CONTENTS

1. INSTALLATION 2

1—1

Motor

Recommendations

1—2 Initial Lubrication 2

2.

MAINTENANCE

2-1

Oil 2

2-2

Seals 2

2—3

Cleaning

2—4 ColdAreaOperation 3

2—5 RunningAfter Prolonged Shot-Down 3

2—6

Threading

2

2

2

3

2—7 Tensions 4

2—8

2—9 Stitch Length 4

2-10

2—11 Looper 4

3.

TROUBLE

3—1

Needle

Replacement

Needle

Thread

2—12 Looper Holder 4

2—13

Needle

Guard

2—14 Presser Foot Spring Pressure 5

2—15

Feed

Dog

SHOOTER

Pull-Off 4

Height

Synchronization

4

5

5

5

5

3-2

3—3

Oil 5

Thread

3—4

FailureToChain

3—5

Uneven

3—6

Excessive

BreakageOrSkipping

Off

After

BagIsSewn

Stitch

LengthOrPoor

Needle

Breakage

Stitches

Feeding

- 1 -

5

5

5

5

1.

INSTALLATION

1—1

Use a 0.75

(1420

sewing

pulley

1

Motor

RJ*.M.

Recommendations

KW

(1/2 HP) 1725 R.PJ^. (60 Hz) motor

for 50 Hz). The variable pulley on the

head permits speed adjustment.

must

rotate

clockwise.

—2

Initial

Lubrication

Sewing

head

The sewing head is shipped from the factory oil filled.

2.

MAINTENANCE

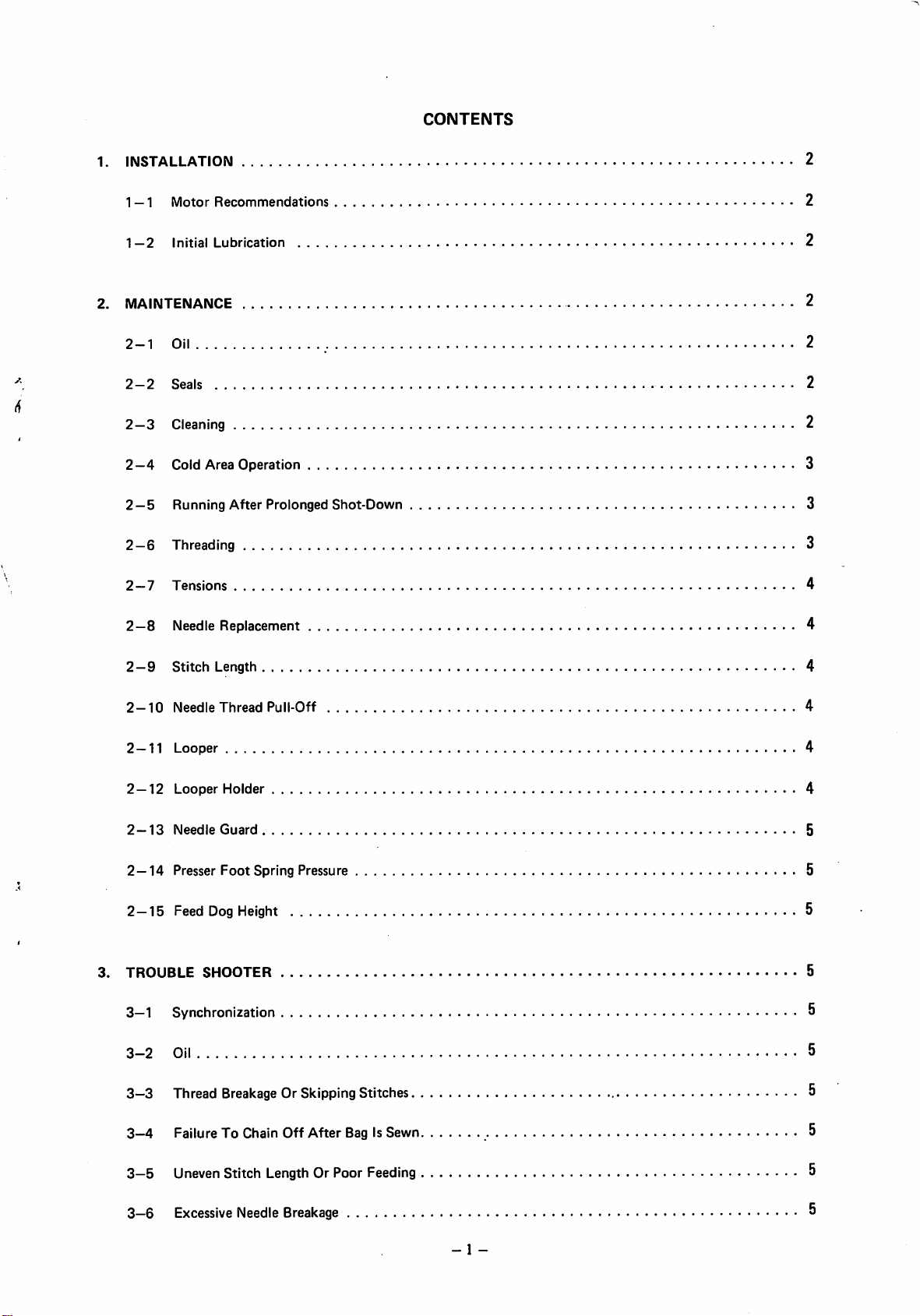

2-1

Use special lubrication oil for the series DS-10 sewing

head available from NEWLONG or its authorized repre

sentatives. As a substitute, any good gradeofSAE 20

motor oil or its equivalent may be used. Three hundred cc

(10 ounces)

When adding or changing oil, remove breather plug and

pour oil into breather plug hole. Fill until oil reaches

"Oil

Oil

Level"

of

oil will adequately fill the machine.

line

on

the

oil

level

nindow.

Never

machine if oil pressure gauge is in the red warning area.

See Drawing 1.

run

At the beginning of each day or shift, make sure the oil

level window at the lower portion of the sewing head

shows

oilatthe

"Oil

Level"

line.

After

about

30

sec

onds, the oil pressure gauge should read in the normal

0.2-0.65

kgf/cm^

(3-9

pound)

range.

While

the

machine

is running, the oil levelwindow will show little or no oil.

Never run machine if oil pressure gauge is in the red

waming

area.

To drain oil, remove magnetic drain plug and allow oil to

drain. At oil change intervals, also clean oil intake filter

and wipe any accumulationofparticles

off

the magnetic

drain plug. Inspect breather plug at least once a year and

clean or replace foam filter element. Change oil every

two months or 500 hoursofoperation, whichever comes

first.

2—2

All

small amountofdamage

Seals

seals

must be handled with extreme caution. Any

in handling or installation will

permit leakage. When replacing a seal, saturate both it

and the shaft thoroughly with oil before

Never install a dry seal over a dry shaft.

assembling.

(D Oilintake tube 0)01!

0

Oil

intake

filter

0 Magneticdrain plug (jDSnap ring

2—3

Cleaning

(DOil

level

window0Baffle

pressure

gauge

(g)

Breather

(D Breather plug

Remove accumulationsoflint from the looper area. If

permitted to remain for long periodsoftime, these can

set

up

a wicking

action

which

will

absorb

machine.Ifthe machine is operated around corrosive or

sticky products, occasionally blow

off

or scrape such

exposed parts as feed dog teeth, throat plate and presser

foot.

Also

recommended is periodic hand

ser foot hingebolt and surfacesof cutting knife.

-2-

<C

oil

oiling

Drawing

plug

from

of pres

1^

filter

the

2—4

In very cold areas allow machine to warm up by miming

steadily for a

ure to do this,

phase

the

the speed of the

badly scuff tape and

sewing

Cold

current,

sewing

headand motor

Area

few

can

head. This

Operation

minutesbefore

especially

with units mnning on

resultinslow

causes

conveyor

cause

warm

closing

starting

mis-synchronization with

belt which

sewing

up and attain proper

any

and

will

break thread,

problems

bags.

mnning

Fail

single

until the

speed.

of

2—BiRunnlng

After

prolonged

should be

motor

accomplished

second cycles until the oil pressure gauge reads in the

normal

pumping

warmed

0.2-0.65

After

shut-down

up before

by mnning the

kgf/cm^

Prolonged

properly and the

closing

(3-9

periods,

any bag. This is

sewing

pound)

Shut-Down

the

sewing

sewing

head in short 2-3

range.

head oil

head and

easily

2—6

Follow the threading diagram below for proper thread

ing.

the

Threading

Be sure looper thread

looper.

Threading

passes

through both holesof

Diagram

Needle

Looper

Thread

Thread

CD

Needle

lever

tension

assembly(DNeedle

thread

pull-off

(3)

-3

Needle

thread

-

tension

(4)

Looper

thread

tension

<C.Drawing

2^

2—7

The looper tension must be very light, barely discernible

when pulling thread by hand. The needle thread tension

Tensions

should be very firm and put a noticeable drag on the

thread. The tension assembly located on

must

put

looper

only light pressure,

tension,onthe

thread.

about

the

the

needle lever

same as

the

§

2—8

Be

sure

Needle

new

needleisinserted

Replacement

into

the

needle

chuck

far as it will go. Lock needle set screw against flat

needle

provided with the machine.

set screw can damage screw or needle chuck.

2—9

To adjust stitch length, remove the magnetic drain plug

on the

with a 4.8 mm. (3/16 inch) Allen wrench and loosen

the

pletely remove cap screw. To shorten stitch length, slide

loosened cap screw towards the throat plate. To length

en stitch, slide away from

sure adjusting screw is securely re-tightened. For stitch

shank.

Stitch

bottom

socket cap screwonthe

Caution:

Use

Length

cover. Reach through the drain plug hole

the

small

Excessive

feed rocker. Do

throat

pressure on needle

plate. Always make

needle

wrench

not

com

length of two stitches/inch, use optional throat plate

(C-10018)

See drawing 3.

and feed dog (A-10079).

as

of

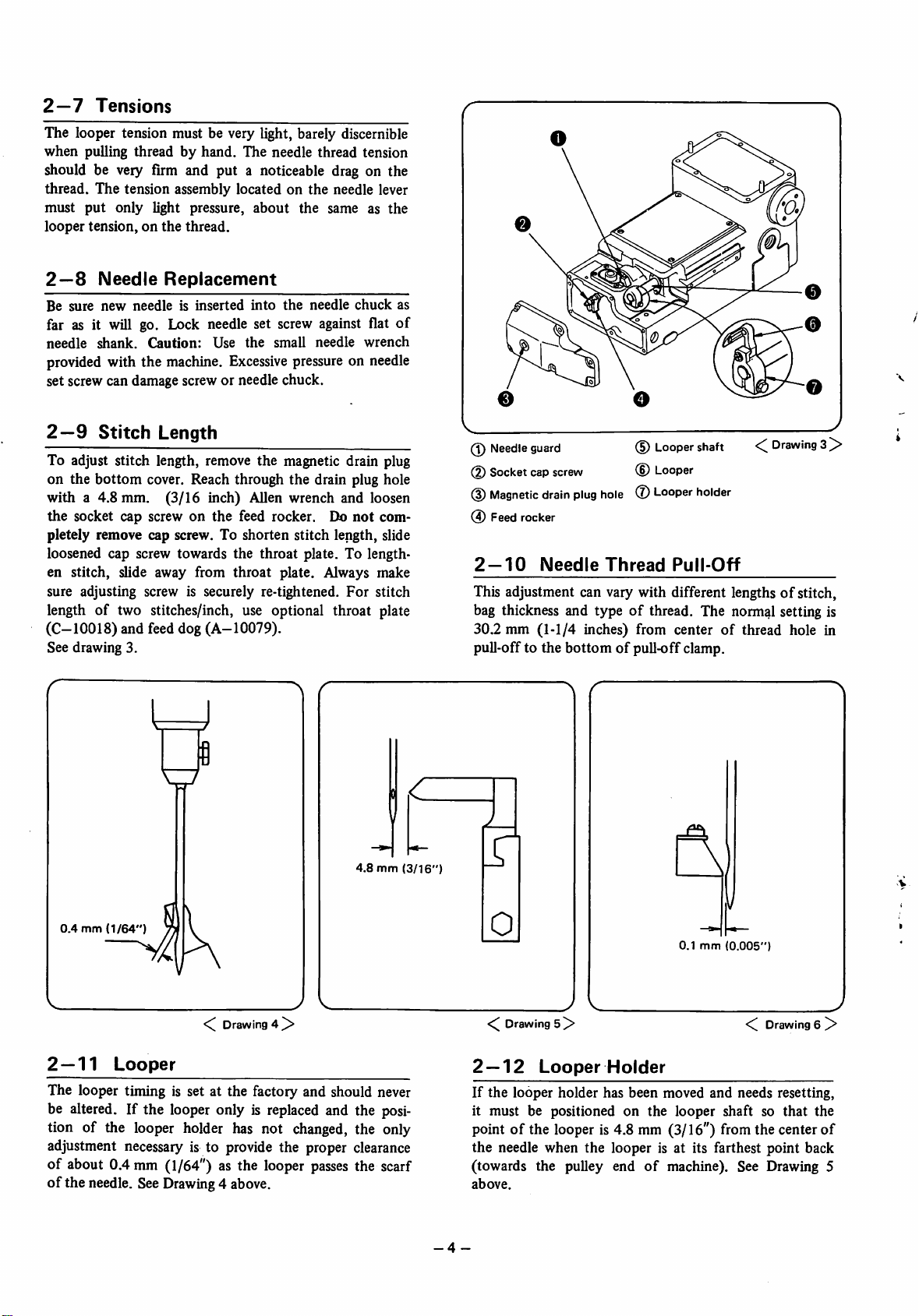

(1)

Needle

(2)

Socket

(3)

Magnetic

(4)

Feed

guard

cap

drain

rocker

screw

plug

hole

(§)

(D

(l)

Looper

Looper

Looper

shaft

holder

Drawing

3^

2—10 NeedleThread Pull-Off

This adjustment can vary with different lengthsofstitch,

bag thickness and typeofthread. The normal setting is

of

30.2 mm (1-1/4 inches) from center

pull-off to the bottomofpull-off clamp.

thread hole in

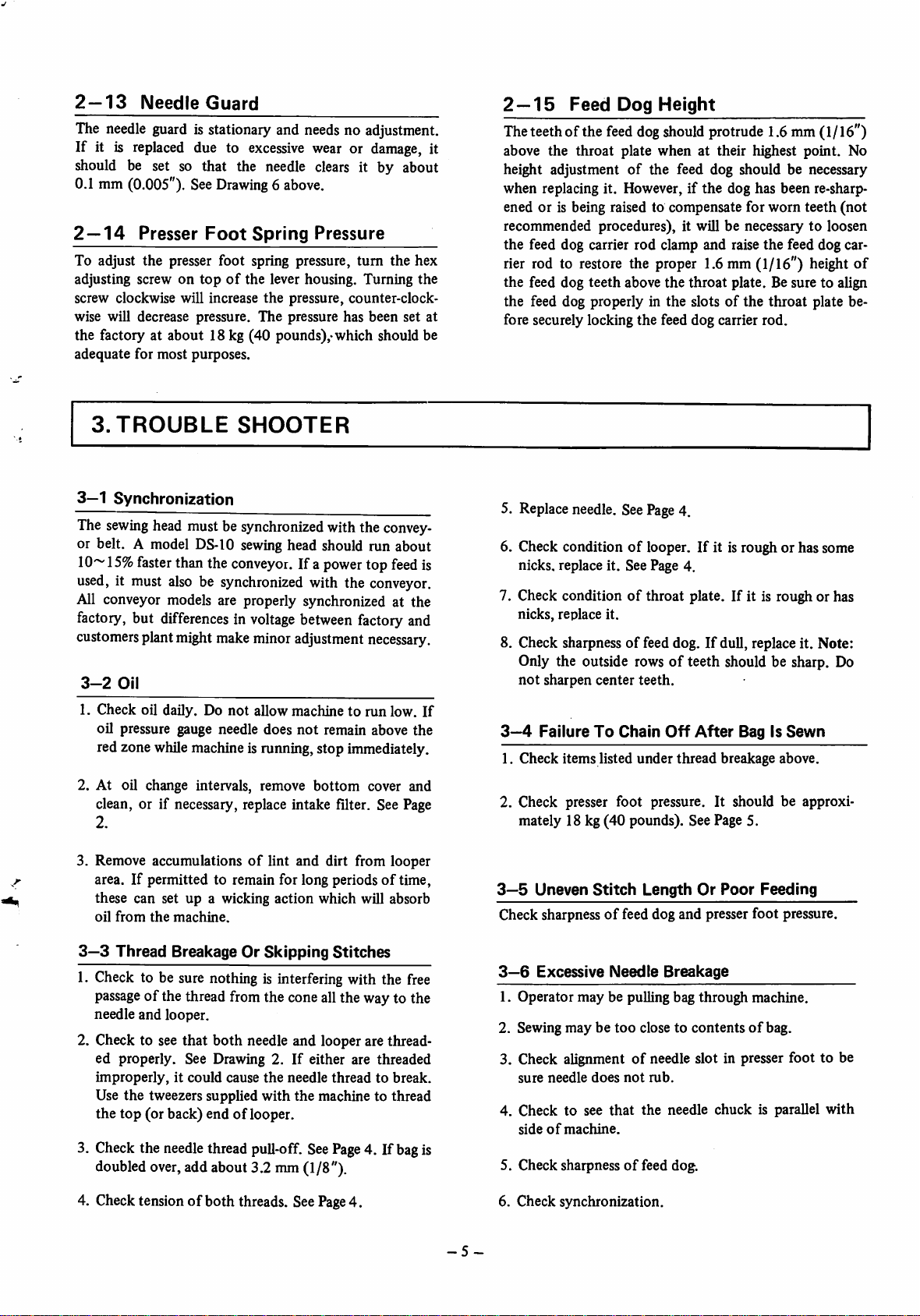

4.8

mm

0.4

mm

2 —

11

Drawing

Looper

4 ^

The looper timing is set at the factory and should never

be altered. If the looper only is

tion of the looper holder has not

replaced

changed,

and the posi

the only

adjustment necessary is to provide the proper clearance

of about 0.4 mm (1/64") as the looper

of

the needle. See Drawing 4 above.

passes

the scarf

(3/16")

1

0

0.1

mm

(0.005")

Drawing

2 —

12

If

the

it must be positioned on the looper shaft so

point of the looper is4.8 mm (3/16") fromthe centerof

the needle when the looper is at its farthest point back

(towards the pulley end

above.

-4-

5]>

Looper

looper holder has been moved and needs resetting,

Holder

of

machine). See Drawing 5

Drawing

that

6 ^

the

2—13

The

If it is

should be set so that the needle clears it by about

0.1 mm (0.005"). See

2 —

To adjust the presser foot spring pressure, turn the hex

adjusting screw on

screw clockwise will increase

wise will decrease pressure. The pressure has been set at

the factory at about 18 kg (40 pounds),-which should be

adequate for most purposes.

3.

3—1

The

or belt. A model

10~15%

used,

Needle

needle

guard

is stationary and

14

replaced

Presser

due to

TROUBLE

Synchronization

sewing

head

mustbe

faster

thanthe

it must

also

Guard

needs

no adjustment.

excessive

wear or

damage,

Drawing6above.

Foot

topofthe lever housing. Turning the

Spring

the

Pressure

pressure, counter-clock

SHOOTER

synchronized

DS-10

sewing

conveyor.

be synchronized with the

withthe

convey

head should run about

If a

power

top

feed

conveyor.

is

All conveyor models are properly synchronized at the

factory,

customers plantmight makeminoradjustment

3-2

1. Check oil daily. Do

2. At oil change intervals, remove

but

differencesinvoltage

between

factory

and

necessary.

Oil

not

allow machine to

oil pressure gauge needle does

red zone

clean, or if necessary, replace intake filter. See Page

2.

while

machine isrunning, stop immediately.

not

bottom

run

low.

remain above the

cover and

If

2 —

15

Feed

it

Theteethofthe

above

the

height adjustmentofthe feed dog should be necessary

when replacing it. However, if the dog has been re-sharp

ened or is being raised to compensate for worn teeth

recommended procedures), it will be necessary to loosen

the

feed dog carrier rod clamp and raise

Dog

Height

feed

dog

should

protrude1.6mm(1/16")

throat

plate when at their highest point. No

the

feed dog car

(not

rier rod to restore the proper 1.6mm(1/16") heightof

the feed dog teeth above the throat plate. Be sure to align

the feed dog properly in the slots of the throat plate be

fore securely locking

5.

Replace

6. Check conditionoflooper.Ifit is rough or has some

nicks, replace it. See Page 4.

7. Check conditionofthroat plate. If it is rough or has

nicks, replace it.

8. Check sharpnessoffeed dog.Ifdull, replace it. Note:

Only the outside rowsofteeth should be sharp. Do

not

3—4

1. Check items listed

2. Check presser foot pressure. It should be approxi

mately 18 kg (40 pounds). See Page5.

needle.

sharpen center teeth.

FailureToChain

the

feed dog carrier rod.

See

Page

4.

Off

under

thread

After

Bag Is

breakage above.

Sewn

3. Remove accumulationsoflint and dirt from looper

area. If permitted to remain for long periodsoftime,

these can set up a wicking

oil

from

the

machine.

3—3

Thread

Breakage Or

1. Check to be sure nothing is interfering with the

passage

needle and looper.

2. Check to see that both needle and looper are thread

ed properly. See Drawing 2.Ifeither are threaded

improperly,itcould

Use

the

of the thread from the cone allthe wayto the

cause

the

tweezers supplied

top

(or back) endoflooper.

3. Check the needlethread pull-off. See

doubled

over,

addabout3.2 mm(1/8").

4. Checktensionofboth threads. See

action

Skipping

the

needle

with

the

which will absorb

Stitches

free

threadtobreak.

machine to thread

Page

4. If bagis

Page

4.

-5

3—5

Uneven

Check sharpnessoffeed dog and presser foot pressure.

Excessive

3—6

1. Operator may be pulling bag through machine.

2. Sewing may be

3. Check alignmentofneedle slot in presser foot to be

sure

needle

4. Check to see

sideofmachine.

5. Check sharpnessoffeed dog.

6. Check synchronization.

-

Stitch

Needle

too

does

that

LengthOrPoor

Breakage

close to

not

the

contentsofbag.

rub.

needle chuck is parallel

Feeding

with

Memo

ORDERING

(1)

«Rp"p«liDS-l

g|5p°n^rttS:wKU.

(2)

mi£:S:<nmi,

(3)

ISLH#

(1)

Descriptionofeach

parts list.

parts.

nameofpart.

(Ref. No.) WEAA'i:v>gBp'?.(i,

Screws

When

ordering

(2) Part that has no Ref.

always

order

it as an assembly.

(3)

This

part

list

(refer to columnofQuantity.)

^ Information included in this part list is subject to change without

prior

notice.

OA,

DS-10C«^«Sr*fflL*t<7)-C-,

S#p°#-t.

part

and

its

and nuts for parts are

parts,

describe

Number

covers

parts

of not

gRo°«lii-..

<

^wti

stamp

numberisdescribedinthis

shown

clearly

can not be

only

DS—lOA

fflSc4:WeT#t>,

ztti't)

adjacentto the relevant

stamp number with its

delivered

PARTS

#«:8S^t-§

nit.

independently;

but

also

DS—IOC.

CONTENTS

a

-k

01 Tape Clipper 8

02

Oil

Pump&Counterweight

03

Main Housing 14

04

Lever Housing 18

Assembly 12

05 Needle & Presser Foot LeverAssemblies 20

06

Feed

07

Assembly

ji'J

Main

Shaft&Knife

Assembly

24

26

08

Looper

;u—

Assembly

Numerical IndexofParts 29

-7-

28

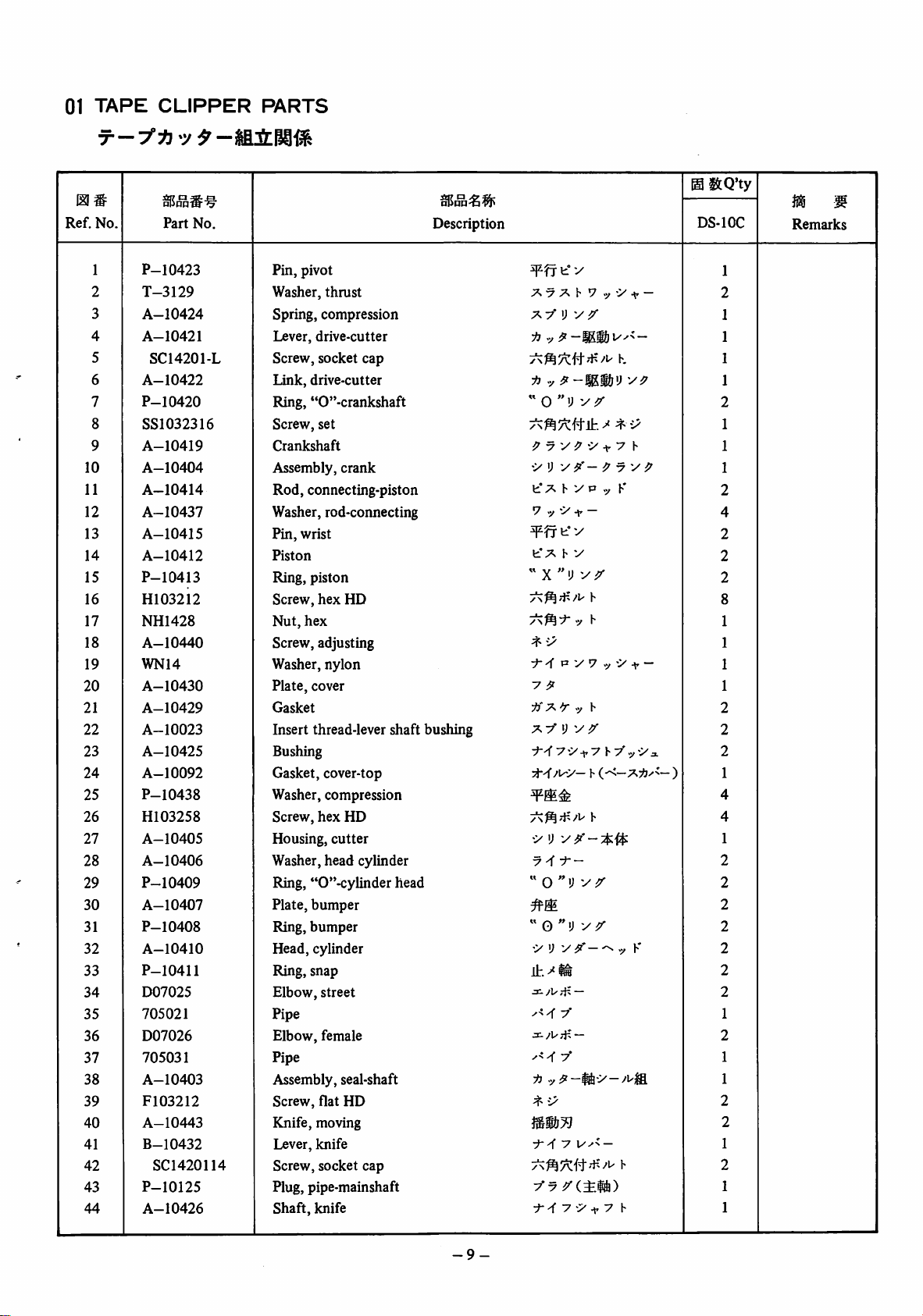

01

TAPE

CLIPPER

PARTS

CD

CD

33

29

fa.

-8-

01

Ref.

El#

TAPE

No.

CLIPPER

ni^qq##

Part

No.

PARTS

nBqq^$5^

Description

@

litQ'ty

DS-IOC

Remarks

20

21

22

24

26

27

28

10

11

12

13

14

15

16

17

18

19

23

25

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

1

2

3

4

5

6

7

8

9

P-10423

T-3129

A-10424

A-10421

SC14201-L

A-10422

P-10420

SSI032316

A-10419

A-10404

A-10414

A-10437

A-10415

A-10412

P-10413

H103212

NH1428

A-10440

WN14

A-10430

A-10429

A-10023

A-10425

A-10092

P-10438

H103258

A-10405

A-10406

P-10409

A-10407

P-10408

A-10410

P-10411

D07025

705021

D07026

705031

A-10403

F103212

A-10443

B-10432

SC1420114

P-10125

A-10426

Pin, pivot

Washer,

Spring, compression

Lever,

Screw, socket cap

link,

Ring,

Screw,

Crankshaft

Assembly,

Rod, connecting-piston

Washer, rod-connecting

Pin,

Piston

Ring,

Screw,

Nut,

thrust

drive-cutter

drive-cutter

"0"-crankshaft

set

crank

wrist

piston

hex

HD

hex

yj

V

if

fi

-y

K

ii

y

Vi;

" 0 " V V

9 =7 V ^

y i; V ip =7 y 9

t'

b V P .y K

7 .y •> + —

b V

'7

" X " V ^

b

y b

Y

Screw, adjusting

Washer,

nylon

Plate, cover

Gasket

Insert thread-lever shaft bushing

Bushing

Gasket, cover-top

P V 7 .y V' + —

7 ^

if

^'r

y b

7.

y y V y

•T'i

7-7-^7

My—

b7'.y-73.

b )

Washer, compression 4

Screw,

hex

HD

Housing,

Washer,

Ring,

Plate,

Ring,

cutter

head

cylinder

"0"-cylinder

bumper

bumper

Head, cylinder

Ring, snap

Elbow,

street

Pipe

Elbow,

female

Pipe

Assembly, seal-shaft

Screw,

Knife,

flat

HD

moving

Lever, knife

head

•7

7 ^

" 0 " V y y

" G " y 7 y

•7 V

it.

:x./V

ii

mW}7^

y^

b

i; 1

y—

y^

.y

b*

^

7°

PC-

—

y

'y

7

Screw, socket cap

y7

Plug, pipe-mainshaft

Shaft,

knife

y

y-f7 7 7 b

1

2

1

1

1

1

2

1

1

1

2

4

2

2

2

8

1

1

1

1

2

2

2

1

4

2

2

2

2

2

2

2

1

2

1

1

2

2

1

2

1

1

-9-

01

TAPE

x—^

CLIPPER

PARTS

OCt)

29

-10-

01

Ref.

TAPE

No.

CLIPPER

Part

No.

PARTS

Description

m IgcQ'ty

DS-IOC

Remarks

45

46

47

48

49

P-10428

A-10427

SSI032316

WN8

B103214

Washer,

Shaft,

Screw,

thrust

thrust

socket

set

Washer, nylon

Screw, binding HD

t*

V

P y 7 .y + —

1

1

4

4

4

-11

-

02

OIL

PUMP

&

COUNTERWEIGHT

ASSEMBLY

PARTS

-^x-f

h/<7VXSaiBII#

A

\ 1 24 23

26

9

-12-

02

OIL

PUMP

&

COUNTERWEIGHT

ASSEMBLY

PARTS

Ref.

m #

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

No.

1

2

3

4

5

6

7

8

9

Part

No.

A-10191

P-10192

A-10204

B103212

WN8

NJIO

A-10105

P-10107

SC63278

A-10178

P-10104

A-10103

A-10061

SS142038

SS142038CP

A-10101

A-10102

SS1032316

A-10106

NH1420

P-10107

A-10169

P-10051

A-10130

A-10053

P-10084

B-10167

HI03212

A-10168

A-10049

B-10050

H1032114

H10321

A-10127

A-10052

Description

Ass'y,

filter-intake

Ring,

Retainer,

"0"-intake

tube-intake

filter

7^

0 " V V

Screw, binding HD

Washer,

Nut

Ass'y,

Ring,

Screw,

Insert,

Link

Pin, pivot-pump drive V y

Eccentric,

Counterweight &

Link,

Ass'y,

Nut,

Ring,

Piston, pump

Ball, valve

Spring, relief-oil pressure

Plug, spring-valve

Ring,

Body,

Screw,

Cyhnder,

Gasket, block-valve

Block,

Screw, hex HD (long)

Screw, hex HD (short)

Spring, block-valve

Seal, washer-valve

nylon

^ V 7 y-y^ —

y V 1

tube-intake

"0"-intake

socket

body-pump

connecting-pump

Screw,

set

Screw, set-cone

control-pump

Screw,

set

tube

HD cap

stroke-pump

point

Pump

drive

drive

Drive

0"v

V^

-•t;

yy't)

y —

V V ^

if

\L y

y y ^ ^ b 1 1

tube-pressure 1 1

hex

"0"-tube

"0"

pump

hex

pump

valve

terminal

HD

plug

.y b

" 0 " •; V ^

h y

-/u

C )

v>5'*(y

y'y^

" 0 " V y

7i-:yy°:^i$.

V y -

jivy—

A/vy'%^

•'^/uy

yy'

o y 7

y-7>'vuy)

b

b

b

b

V y

.y-yj^~

y'

@ ^

DS-lOA

1

1

1 1

1

1

1

1

1 1

1

1 1

1 1

1

1

1

1

1 1

1 1

1

1 1

1 1

2 2

1 1

2 2

2 2

Q'ty

DS-IOC

1

1

1

1

1

1

1

2

2

2

1

1

2

1

2

1

3

1

3

2

1

Remarks

(14,15)

(18)

-13-

eo

niviai

0NisnoH

siavd

OOl-SQ

^

/•

Tl>^

^

-Wyi

301-sa

03

m #

Ref.

MAIN

No,

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

HOUSING

Part

No.

C-10017

C-10018

F103258

F103238

A-10091

F83214

A-10015

H103212

WN8

D208

B103214

WN8

P-10111

B-10022

F1032114

F103258

A-10170

NH1420

WF14

WN14

A-10093

A-10016

H103212

WN8

D208

A-10005

A-10021

F63234

A-10019

A-10020

D05003

A-10097

H103212

D208

A-10098

B632316

A-10164

H103234

A-10134

A-10179

A-10116

A-10121

P-10227

P-10226

H10321

A-10094

PARTS

Description

Plate,

throat

Plate,throat(Long Stitch)

Screw, flat HD (long)

Screw, flat HD (short)

Knife, stationary

Screw,

flat HD

Post,

short-throat plate

Screw,

hex

HD

Washer, nylon

Washer

Screw, binding HD

Washer

Plug, drain-magnetic K U V 7° 7

Cover,

bottom

Screw, flat HD (long)

Screw, flat HD (short)

Pull-Off-Looper Thread

Nut,

hex

Washer

Washer-Nylon

Gasket,

cover-bottom

Post, long-throat plate

Screw,

hex

HD

Washer-Nylon

Washer

Door, looper

Knob,

latch-looper

door

Screw, flat HD

Spring, latch-looper

door

Latch, door-looper

Window,

Plate, latch-looper

Screw,

Washer

oil level

hex

door

HD

Cover, groove-thread

Screw, binding HD

Eyelet,

Screw,

thread-short

hex

HD

Ring, snap-breather baffle retainer

Baffle, plug-breather

Ass'y, plug-breather

Filter,

plug-breather

Gauge, oil pressure 1

Adapter,

Screw,

Gasket,

gauge-oil pressure

hex

HD

main

shaft

seal

(

•>'

3 - b )

h

i-'i

n V 7 y -y —

P V 7 .y -v —

K

^ P V 7 .y V' —

/Uv'—

h )

P

77*

p V 7 .y •> -t- —

/U

— —

/ 7*

7.y'V V

7

^

7'

.y^

jL7

¥J^^

K

(/Jn)

h

7. .y 7* V y

7-7'

y

7 ^/u7 -

7

7'7*7-

/I'-y—

V

)

if

0

DS-lOA

1

(1)

1

1

1

1 1

1

1

1

1

1

1

1

1

1 1

1 1

1

1

1

1

1

1

1

1

1 1

1 1

1

1

1

1

1 1

1 1

1

1 1

1

1 1

4 4

1

Wl

Q'ty

DS-IOC

—

-

1

2

—

—

—

1

1

2

2

1

1

2

4

1

1

1

1

1

1

1

—

—

—

—

—

1

1

1

1

1

1

1

1

m m

Remarks

Special Order

(1#^)

-15-

03

MAIN

HOUSING

PARTS

DS-IOC

DS-IOC

-16-

03

Ref.

MAIN

No.

HOUSING

Part

No.

PARTS

Description

DS-lOA

15:

Q'ty

DS-IOC

Remarks

46

47

48

49

50

51

52

53

54

55

56

57

58

59

D-lOOOl

A-10095

A-lOlOO

H103212

A-10092

A-10014

F103238

B-10485

B103214

A-10449

F83212

A-10446

A-10434

NH832

Housing,

main

Gasket, cover-manifold

Cover,

manifold

Screw,

hex

HD

Gasket, cover-top

Plate, cover-top

Screw, flat HD

Plate,

throat

Screw, binding HD

Fence

Screw, flat HD

Knife,

bed

Post,

offset

Nut,

hex

.y K

^

/U-y— h

-V — — /U K ^

i-

y h

-17-

04

LEVERS

HOUSING

PARTS

-18-

04

LEVERS

HOUSING

PARTS

Ref.

m#

S^Q'ty

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

Part

A-10142

A-10161

H103278

WFIO

A-10188

SS1032516

B-10123

B103238

A-10146

P-10013

B-10145

HI03234

1-178

A-10144

A-10171

A-10172

HI03234

A-10164

HI03234

NH1428L

A-10114

A-10008

A-10120

A-10007

A-10115

D-120

P-10010

A-10165

HI03234

H3824134

WF38

D-10002

SC516181

WS516

A-10143

SS142038

SC5161858

A-10187

A-10186

A-10139

SS142014

B-10141

SC142034

No.

Description

Cam, lifter-presser

foot

Guide, lever-presser foot

Screw,

hex

HD

Washer

Guard,

Screw,

tension-needle

set

Cover, guard-levers

Screw, binding HD

Plate, presser foot spring-tapped

Pin,

roll

Spring, presser foot

Screw,

hex

HD h

Nut,

lock

Clamp, spring-presser foot

Pull-off, needle thread

Clamp, needle thread pull-off

Screw, hex HD

Eyelet,

Screw,

Nut

Sleeve,

thread-short

hex

HD

tension

Spring, tension-looper thread

Disc, tension-large

Spring, tension-needle

Stud,

tension

Washer,

lock

thread

Pin, retaining-tension disc

Eyelet, thread-long

Screw,

hex

HD

Screw, adjusting

Washer

Housing, levers

Screw,

socket

HD cap

Washer, spring

Shaft, spring-presser

Screw,

set

Screw,

stop-lifter

foot

lever

Spring, lifter lever

Liner, bushing-lifter lever

Bushing, lifter-presser

Screw,

set

Lever,

lifter-presser

Screw,

socket

HD cap

foot

foot

K

7 — A —

7.7°

7ti

b

4 K

(/J^)

b

p V .y b

X U -

7'

7.

7° V y 7" t* 7

K

b 4

b

r-M.

7.7'U V 7* 7

y

y—

y—zv

A

-f K

(T^)

y

'J 7

'J

J'

b

b

7'

vi/

y

if

DS-lOA

DS-IOC

1

1

2

2

1

2

1

2

1

1

5

2

2

1

1

1

2

1

1

2

4

1

4

1

2

2

2

2

1

1

1

4

4

1

1

1

1

1

1

1

1

1

m g

Remarks

(43)

-19-

05

NEEDLE

&

PRESSER

FOOT

LEVER

ASSEMBLIES

PARTS

58

-20-

05

NEEDLE

&

PRESSER

FOOT

LEVER

ASSEMBLIES

PARTS

Ref.

m#

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

@ ^ Q'ty

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Part

A-10031

H103234

NJIO

C-IOO-S

A-10011

A-10212

A-10211

SC63234

A-10166

F54038

A-10119

A-10009

A-10181

B632316

A-10231

H103212

A-10232

A-10113

A-10023

A-10025

SS1032316

SS103238

T3129

C-10003

SC1420114

A-10026

B-10137

F103238

A-10128

A-10028

A-10159

B-10047

SS142038CP

SS142014

HI03238

WSIO

A-10048

F103238

C-10004

SC1420114

A-10189

F63212

P-10193

A-10190

A-10163

No,

Description

Chuck, needle

Screw,

hex

HD

Nut,

hex

HD

Needle

Screw, clamp-needle

tf

tfjlr.

y h

^

Plug,clamp-tapped (needlelever) ^ V B )

y

Plug,clampdrilled(needlelever)

Screw, socket HD cap

V7*(

h

Guide, thread-needle lever

Screw, flat HD

Disc.,

tension-small

Spring, tension-needle lever

Collar,

tension-needle

lever

Screw, binding HD

Washer, heavy-needle lever

Screw,

hex

HD

Rod,

clamp-needle lever

Stud,

tension-needle

lever

^ 7 V y P .y K

Insert, thread-levers shaft bushing

Bushing, shaft-levers

-y 7 h

7*.y

Screw, set (short)

Screw, set (long)

Washer,

Lever,

thrust

needle

Screw, socket HD cap

Shaft,

levers

1/^N

— •y' —

—-y-

••/

/U

y—/l

y ^

—

KSi

h

Seal, levers

Screw, flat HD

Spring, garter-levers seal

Bushing, lever-presser foot

Spacer,

Rod,

Screw,

stud-ball

connecting-needle drive

Screw, set-cone

Screw,

set

hex

point

HD

^

iy

y. y* y y ^ —

lfp^^yy<-y'.y

jtP

Washer, spring

Restrainer, rod-connecting

4^ — /U ^ K

Screw, flat HD

Lever,

presser

foot

Screw,

socketHDcap

Cradle, pad-presser

foot

spring

Screw, flat HD

Pin,

roll

Pad, spring-presser

Clamp, bearing-sheet

foot

y>;y y t* y

y-

hit.y

A )

DS-lOA

1

1

1

1

1

1

1

1

1 1

1

1

1

1

1

1

1

2

2

2

2

3 3

1

2

1

1 1

4

2

1

1

1

1 1

1 1

1 1

1

1 1

2

1

2

1

1

2

1

1

DS-IOC

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

1

2

1

4

2

1

1

1

1

2

1

2

1

1

2

1

1

m w

Remarks

(14)

(25)

(33,34)

(40)

-21

-

05

NEEDLE

&

PRESSER

FOOT

LEVER

ASSEMBLIES

PARTS

58

-22-

05

Ref.

NEEDLE

No.

qilnm

Part

&

No.

PRESSER

FOOT

LEVER

Description

ASSEMBLIES

PARTS

DS-lOA

ffi:

Q'ty

DS-IOC

Remarks

46

47

48

49

50

51

54

52

53

55

56

57

58

F103258

A-10162

A-10214

A-10213

A-10155

HI03234

NJIO

A-10156

H103238R

A-10185

A-10182

NJIO

A-10484

Screw, flat HD

Sheet, bearing-presser

foot

lever guide

Plug,clamp-tapped(presserfoot)

Plug, clamp-drilled(presser foot)

Shank, presser foot

Screw,

hex

HD

Nut,

hex

Block, hinge-presser foot

Screw,

hex

HD

Presser

Foot

Bolt, hinging-presser foot

Nut

Presser

foot

V'-

h

^ u y t V

l:^

«y

-y h

^

-23-

06

FEED

DS-IOC

ASSEMBLY

PARTS

-24-

06

FEED

ASSEMBLY

PARTS

Ref.

mm

@ ^

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

Part

No.

A-10078

A-10079

SS1032516

A-10124

A-10177

F103238

B-10077

P-10075

A-10074

A-10073

A-10072

A-10070

SCI42078

A-10069

A-10071

A-10064

A-10062

A-10215

A-10063

SC54012

H103258

D208

A-10109

SS1032516

A-10066

B1035

A-10067

SCI42878

A-10068

A-10174

P540916

A-10486

Dog,

feed

Dog, feed (Long

Screw,

set

Stitch)

Ring, garter-feed dog seal 1 1

Holder, guard-needle

Screw, flat HD

Seal, dog-feed

Ring,

"0"

Rod,

slide-feed

Slide, feed

Rod,

carrier-feed dog 31 y t.*

Clamp,

Screw,

rod-feed

socket

dog

HD

Link, stroke-feed

Link,

lift-feed

Pin,

rod-feed

stroke

Rod, connecting-primary feed stroke

Washer,

Lever, pin-feed

Screw,

Screw,

Washer

thrust

rocker

socketHDcap

hex

HD

Bushing, shaft-feed rocker

Screw,

set

Lever,

slotted-feed

Key

Nut,

pivot-feed stroke adjusting

Screw,

socketHDcap

Pivot, adjusting-feed stroke

Guard,

needle K

Screw,

pan

HD.

Feed

dog

Description

carrier

connecting

rocker

31

y#

31

" 0 " y V >/

3iy±^

3i

y y V ^

31 y

-tT

y ^

t"

V

31 y ^-yK

3iy

31

y^

3|yi^®5#^y-y'

DS-lOA

(1)

f

Q'ty

DS-IOC

1

1 1

1

1 1

1

1 1

1 1

1 1

1 1

1

1 1

1 1

1 1

1 1

1

1

1 1

1

1 1

1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

-

-

1

1

1

1

1

1

1

1

Remarks

(2)

(2)

(13)

(19,20,21)

(2) Special

Order

mm

-25-

07

MAIN

1,

SHAFT

&

KNIFE

ASSEMBLY

PARTS

DS-IOC

-26-

07

MAIN

U

SHAFT

& KNIFE ASSEMBLY PARTS

Ref,

10

13

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

@15:

No.

1

2

3

4

5

6

7

8

9

11

12

14

Part

A-10076

H103212

A-10058

C-10045

B-1035

P-10125

A-10044

SSI032516

T-3129

A-10061

SS142038

SS142038CP

A-10158

SC103258

A-10043

SS1032516

A-10094

A-10035

H103212

A-10038

SS142038

A-10199

SS142038

F103258

A-10080

H103212

H103258

A-10082

SS540316

P-10084

A-10083

A-10085

H103212

A-10087

D-120

A-10086

A-10056

SS1032516

A-10088

A-10089

A-10090

A-10442

P-10441

No.

Assembly, seal-knife

Screw,

hex

HD

Gasket,

seal-knife

shaft

Shaft, main

Description

shaft

h

i.#

DS-lOA

Key

Plug, pipe-main shaft

Bushing, main shaft-needle end

Screw,

set

Washer,

Eccentric,

Screw,

Screw,

Collar,

Screw,

thrust

stroke-feed

set

set

lock-main

socket

shaft

HD cap

Tmy'

y y ^

Bushing, main shaft-drive end

Screw,

set

yf-l'

yu-y—

Gasket,

main

shaft

seal

h

Assembly, seal-main shaft

Screw,

Hub,

Screw,

Pulley,

Screw,

hex

HD

pulley

set

adjustable

set

y-u-a

h

Screw, fiat HD 3

Assembly, connecting rod-knife

Screw,

hex

HD

Screw,

hex

HD

Crank,

bell-knife

Screw,

set

Ring,

"0"

Shaft,

bell

crank-knife

Bracket, pivot-knife

Screw,

hex

HD

4-*—/u3'f

7^:^

,+:/!✓

" 0 " y V ^

•<;V y V V

y'y

fr y h

V h

h

7)

Screw, pivot-knife 1

Washer,

Link,

Bushing, shaft-knife

Screw,

Shaft,

lock

knife

set

knife

fV—^<—

y^

^y'

,y 3.

Spring, knife

Knife, moving y A 1 -

Plug -

Ring,

"0"

" 0 " y V

Q'ty

DS-lOB

1

1

1 1

1 1

1

1

1

1

1 1

1

1

1 1

1 1

1 1

1 1

1

1 1

1 1

1 -

1

1

1

1

1 1

1

1 1

1

1

1

1

1

2 -

m w

Remarks

1

1

1

1

1

1

1

2

—

—

—

—

—

4

—

-

—

—

-

-

1

1

(11,12)

(21)

(23)

(29)

-27-

08

LOOPER

ASSEMBLY

PARTS

121#

Ref.

plSnaS''^

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Part

C-10060

P540916

WF5

A-10059

H103234

D208

A-10076

H103212

A-10058

B1035

A-10055

A-10173

SC103212

WFIOS

A-10056

SS1032516

A-10150

SS103258CPL

SS103212L

No.

Looper (two thread)

Screw,

pan

HD

Washer

Holder,

Screw,

Washer

Ass'y, seal-looper

Screw,

looper

hex

hex

HD

shaft

HD

Gasket, seal-looper shaft

Key

Shaft, looper

Ass'y,

pivot-looper

Screw, socket HD cap

Washer

Bushing, shaft-looper

Screw,

set

Ass'y,

cam-looper

Screw, set-cone

Screw,

set

point

Description

/U—

—

Jl/—✓<—i-Q

/U— ^

/I'——.y

3.

@ ^

DS-lOA

Q'ty

DS-IOC

1

1

1

1

1

1 1

1

1 1

1

1 1

1 1

1

1

1

1

1

1 1

Remarks

1

1

1

1

(5,6)

1

1

1

(13,14)

1

1

1

1

(18,19)

1

-28-

NUMERICAL

INDEX

OF

PARTS

(^<—yig5|)

PART

A-10005

A-10007

A-10008

A-10009

A-10014

A-10015

A-10016

A-10019

A-10020

A-10021

A-10023

A-10025

A-10026

A-10028

A-10031

A-10035

A-10038

A-10043

A-10044

A-10048

NO.

PAGE

15

19

19

21

17

15

15

15

15

15

9,21

21

21

21

21

27

27

27

27

21

PART

A-10083

A-10085

A-10086

A-10087

A-10088

A-10089

A-10090

A-10091

A-10092

A-10093

A-10094

A-10095

A-10097

A-10098

A-lOlOO

A-10101

A-10102

A-10103

A-10105

A-10106

NO.

PAGE

27

27

27

27

27

27

27

15

9,17

15

15,27

17

15

15

17

13

13

13

13

13

PART

A-10163

A-10164

A-10165

A-10166

A-10168

A-10169

A-10170

A-10171

A-10172

A-10173

A-10174

A-10177

A-10178

A-10179

A-10181

A-10182

A-10185

A-10186

A-10187

A-10188

NO.

PAGE

21

15,19

19

21

13

13

15

19

19

28

25

25

13

15

21

23

23

19

19

19

PART

A-10426

A-10427

A-10429

A-10430

A-10434

A-10437

A-10440

A-10442

A-10443

A-10446

A-10449

A-10484

A-10486

B-10022

B-10047

B-10050

B-10077

B-10123

B-10137

B-10141

NO.

PAGE

9

11

9

9

17

9

9

27

9

17

17

23

25

15

21

13

25

19

21

19

A-10049

A-10052

A-10053

A-10055

A-10056

A-10058

A-10059

A-10061

A-10062

A-10063

A-10064

A-10066

A-10067

A-10068

A-10069

A-10070

A-10071

A-10072

A-10073

A-10074

A-10076

A-10078

A-10079

A-10080

A-10082

13

13

13

28

27,28

27,28

28

13,27

25

25

25

25

25

25

25

25

25

25

25

25

27,28

25

25

27

27

A-10109

A-10113

A-10114

A-10115

A-10116

A-10119

A-10120

A-10121

A-10124

A-10127

A-10128

A-10130

A-10134

A-10139

A-10142

A-10143

A-10144

A-10146

A-10150

A-10155

A-10156

A-10158

A-10159

A-10161

A-10162

.15

28

23

23

27

21

23

21

21

25

21

19

19

19

19

19

19

25

19

19

15

19

13

13

15

A-10189

A-10190

A-10191

A-10199

A-10204

A-10211

A-10212

A-10213

A-10214

A-10231

A-10232

A-10403

A-10404

A-10405

A-10406

A-10407

A-10410

A-10412

A-10414

A-10415

A-10419

A-10421

A-10422

A-10424

A-10425

21

21

13

27

13

21

21

23

23

21

21

9

9

9

9

9

9

9

9

9

B-10145

B-10167

B-10432

B-10485

B1035

C-IOO-S

C-10003

C-10004

C-10017

C-10018

C-10045

C-10060

DlOOOl

D10002

P-10226

P-10227

P-10413

P-10428

705021

705031

19

13

9

17

25,27,28

21

21

21

15

15

27

28

17

19

15

15

9

11

9

9

9

9

9

9

9

-29-

NUMERICAL

INDEX

OF

PARTS

PART

SCREW

A-10011

B103212

B103214

B103238

B632316

F1032114

F103212

F103238

F103258

F54038

F63212

F63234

F83212

F83214

H10321

H1032114

H103212

NO.

PAGE

m

21

13

11,15,17

19

15,21

15

9

15,17,21,25

15,23,27

21

21

15

17

15

13,15

13

9,13,15,17,

21,27,28

PART

SS103258CPL

SS142014

NO.

SS142038

SS142038CP

SS540316

NUT

(i-^yVm)

NH832

NH1420

NH1428

NH1428L

NJIO

1-178

PAGE

28

19,21

13,19,27

13,21,27

27

17

13,15

9

19

13,21,23

19

PART

OTHER

D05G03

D07025

D07026

P-10010

P-1C013

P-10051

P-10075

P-10084

P-10104

P-10107

P-10111

P-10125

P-10192

P-10193

P-10408

P-10409

P-10411

P-10420

NO.

PARTS

PAGE

15

9

9

19

19

13

25

13,27

13

13

15

9,27

13

21

9

9

9

9

PART

NO.

PAGE

V'

H103234

H103238

H103238R

H103258

H103278

H3824134

P540916

SC103212

SCI03258

SC14201-L

SC1420114

SCI42034

SCI42078

SC142878

SC516181

SC5161858

SC54012

SC63234

SC63278

SS103212L

SSI032316

SSI03238

SSI032516

15,19,21,23,

28

21

23

9,25,27

19

19

25,28

28

27

9

9,21

19

25

25

19

19

25

21

13

28

9,11,13,21

21

19,25,27,28

WASHER

A-10215

D-120

D-208

P-10438

WF5

WFIO

WFIOS

WF14

WF38

WN8

WN14

WSIO

WS516

25

19,27

15,25,28

9

28

19

28

15

19

11,13,15

9,15

21

19

P-10423

P-10441

T3129

9

27

9,21,27

-30-

NEWLONG

Head

Office

Osaka

Branch

Newlong Taiwan Machine Co., Ltd.

Newlong Machine Philippines, Inc.

Newlong

Newlong Do Brasil Maquinas

Industrials

American-Newlong,

Newlong

Newlong

Newlong

Singapore

Ltda.

Holland

Malaysia SDN BHD

Thailand

MACHINE

Pte.

Ltd.

Inc.

B.V.

Ltd.

WORKS.

:

4—14,

Higashi

Cable Address :

Telex

: 265-5306

:

1-8,

Obiraki

Cable

Address:NEWLONG

Telex :

: 3rd Fl., 29,

CableAddress :

FAX:886-2-5221420

: 3590

Davila

Cable

Address:NEWLONG

: No. 68, Kian Teck Road, Jurong Town, Singapore 2262

Cable

Address:NLMACHINE

Telex :

; Rua. Francisco Tapajos,409/415, Jardim daSaude,SaoPaulo,

Cable Address : NEWLONG SAOPAULO, Tel :

Telex:1121566

5310South

Tel:317-787-9421

Telex : TWX

C/0

World

1077XXAmsterdam,

Tel:020-575-3121

Telex : 18896 NLN NL FAX :

77 Jalan SS20/11, Damansara Kim, 47400 Petaling Jaya, Selangor Malaysia

Tel:7188323,

Telex:37868

25/1 Soi-16, Sukhumvit Road, Bangkok, Thailand.

Tel:258-1834

Telex:21137

Ueno

NEWLONG

2chome,

524-5680

Lane

NEWLONG

Street,

RS23649

Harding Street, Indianapolis,

810-341-3313

Trade CenterAmsterdam TowerB.9th FloorStrawinskylaan 929

7188401

NLMAS

NLTHAI

LTD.

6-chome,

NLTOKJ,FAX

NLOSAJ, FAX :

100,Song

Pasong

A/B:NLSIN,

NEWL

Taito-ku,

TOKYO, Tel :

Fukushima-ku,

OSAKA,

Chiang

TAIPEI, Tel : 02-5716524. 5642692

Tamo,

MANILA,

SINGAPORE,

BR

AMLONG IND. FAX :

Holland

MA

TH

Tokyo110,Japan

03-843-0269

: 03-843-0260, 9998'

Osaka

553,Japan

Tel: 06-466-3530,

06-465-5926

Road,

Taipei,

Makati,

Metro

Tel: 8160207,

FAX :

020-627-255

Tel : 2650901,

001-65-2651994

Indiana46217

C/0

7311

3531

Taiwan,

R. O.

China

Manila,

Philippines

882474,

891137

2612126,

Brasil

276-9744

317-786-5225

WORLD TRADE CENTER

2643942

(T,Y,A)

1 ^

4-14

HIGASHI-UEN0 6-CH0IV1E,TAIT0-KU TOKYO, JAPAN TEL:

m

(843)0269

IE3010A

PRINTED IN JAPAN

IMo.1

85-12-500®

Loading...

Loading...