NEWLONG INDUSTRIAL CO., LTD.

JUTE

BAG

SEWING

MACHINE

For Operator Safety

Thank you for purchasing the NLI Model

DR-3A Bag Sewing Machine Head.

• This manual contains

using the Model DR-3A Bag Sewing Machine

sure

to

read and understand this manual before use and

use the machine correctly.

• Keep this manual near

reference. Be sure

when

lending

company.

• Please order this manual

is lost.

• The contents of this manual are subject

without prior notice for improvement and safety

purpose.

~iazard

•

Be

careful, when you insert a bag to

the

sewing machine,

the

machine between the presser foot and feed dog.

•A•

Hazardous" mark is attached

sewing, be sure not

the

to

attach this manual

or

transferring

of

Being

or

to

touch on

instructions and precautions fbr

Head.

the

sewing machine for essy

to

the machine

it

to

another person

from

the nearest

Caught

your fingers

in

to

the

NLI

office if

to

the

Machine

be

closed into

may

be

caught

the machine. When

machine.

Be

or

it

change

in

==-~-P

;fo Jl

•

,:O)Jtit-.mM1H;t

2::fst!JflJ:0)&;1:•lJ{t,~Ja-~tL

O)JtitffUl"tH~~--ftdll."ij.<ft~1,

-oEt..<

•

,:O)Jlj{jJd~\'1

r-:lt-oJ::?,

DR-3A ~Hffl~VY~itlA:l:\t..,

.:

~~I~(,lt)

\,

\ J::lf\,

~

M

O)Jtitlim

DR-3

vft:r.:

~

-;ff

~

M ; =

DR-3A ~ffl~VYO)Jtitt&1,vjj~

<r-:~1,

'o

!FJ'1~VYO),t

{*/fl,

"t"<r-:~1,,0

M -~-~iU:ffl#t..

f"!l:,

A~Jfl

~\,

'~

-n, ,~-ro

'o

1,

'-?°"C:b~llJJfl

~

1/~~

To

~l!fflfill.:::..:

~~a-+~Ut..

'£'/t.t.J:llillO);!l-€/"f';l:

"C

<

ft~i,

'o

e;:O)Jlj{ti~M-~~~~ntt.•~t.1:~~-o~~I-

<•)~BH!IUfffil:~ltj:<t::~1,

•

.:

0)

l&t&~.11.I

•1:tllfE

IAI

l.:::.~J!-r-o.:!::~$~~'£To

e ~V~l:fi4tl61t:t.,.,.-?~J&"'..) 't"li

ffit,S~VYli:.ia!l~t,~t,ti, ,J::%:i±tt..

\D

J:

1:ttf:t~~O)ft.af.>,

'"~T.

7is't.t

"C

<t.::~v

'•

1,

,tt.

t....

~

• A Needle Bar and Needle Thread Take-Up are

Hazard

moving

to

the

keep fingers and yourself away

and Needle Thread Take-Up.

of

Being

at

high speed.

machine. When

Caught

A·

Hazardous"

the

machine is in operation,

in

the

Machine

mark

from

the Needle Bar

is attached

~

•

tt•tJ:IA

~~;!-

3i:.ff

l-;t

iij3(~1f:11,

t~:,..,l::fi~l6&;1:--7-?~JI&"'..>

~

v~t,ilf:Ji,

,lr~Jtf_t1,

,-ci,

'o.!:~•'itt•.!:J:IA

\~<'l!::~1,

\a

---~

~jA,tjl;

WARNING

''t"1t , 1:-r.

-c1,

'*T.

3i:.ff

l~ffi~-f*~

• The instruction

•

~O)•••it1•

manual

/ /

(-':J

and

parts

list

is

1

JAt-rcttltlta:l..1:0>t:~~-~L.f=JfJ!T

subject

to

change

without

prior

.f>~l!::b(~~~T

notice

.

O

WARNING

If

PERSONAL

FOLLOWING

OBSERVED.

1.

BE

SURE

FREE

OF

OIL,

RUBBISH

INJURY.

2.

DO

NOT

OPERATE

AREA

OR

THE

MACH I NE

TYPE

NOR

3.

DO

NOT

INSTRUCTION

4.

DO

NOT

OPERATE

THAN

SPECIFIED

5.

BE

SURE

ELECTRICAL

INJURY

SAFETY

THE

AREA

ALL

HAZARDS

MAY

PRECAUTIONS

SURROUNDING

SUCH

OR

ANYTHING

MACHINE

UNDER

OPERATE

WET

CONDITIONS.

IS

NOT

AN

WATER-PROOF

TYPE.

MACHINE

MANUAL.

MACHINE

FOR

MACHINE

IS

SAFETY

ON

THE

MACHINE.

CONNECTED

GROUND

RESULT

AS

THAT

IN

IF

THE

ARE

NOT

MACHINE

FIRE,

AN

WATER,

CAN

CAUSE

EXPLOSIVE

IS

EXPLOSION-PROOF

BEFORE

VOLTAGES

READING

OTHER

TO

BUILDING

(EARTH).

~~©~~~§~~~L~~~~~~

r::r~UJtdl:©~~

L <

t::

~

I,

\0

1.

•~O)

~

(f;:~(,\o

2.

•~

f.1,f.1,7a>Jl:tl--c:l;t{tffl

;::_

m1 m 1=$i!&

..

7.1<

..

1m

0)

m:

11.t

O)l!~l;t,.

..

iiJ~~tJ

0)

if.>

7a>

IJn!ti~

c.

t.;.1.J

*"t©~;i~

~

®;::

"t"

c!::t.ittJ

nu! .

7.l<rrti

L

~1,

'1:

•

IJnflti~--C:l;ti'-,

lvo

3.

mimm~•~~1"~1v--c:t.i,

-c

<

t::~

(,\0

4.

-~©tltijtiiff!~Hi-

~(,\o

5.

7-A*if.Jfti(Sc~*1,-Cl.'7a>$~.fit~ L

t:: ~ (,

\0

--c:

.;•*'~ii,ii

l;tiifii L

lffl

~

c!::

tJ

1,

,t.i,muJ,cY)

t.itil

tt

•~,

<

t::

~

l.

'o

LJ

tJ

l.'

--c:

L

7a>

*

-c

=

°tit

L

<

t::

-C

<

6.

BE

SURE

POWER

BEFORE

PARTS

PERFORM

REPLACEMENT,

CLEANING.

7.

DO

NOT

OPERATE

COVERS

8.

DO

AND

REMOVED.

NOT

TOUCH

MOVING

OPERATION.

9.

BE

SURE

MACHINE

(LEVEL)

MA

I

NTENANCE,

ADJUSTMENTS,

10.

BE

SURE

THE

COMPLIES

11.

DO

"

NL

WITH

NOT

USE

I"

GENUINE

(AND

AIR

I

NG

MACH I NE

MACHINE

KNIFE,

PARTS

SURFACE

NEEDLE,

WHEN

IS

PLACED

WHEN

PARTS

CLEANING

MATERIAL

THE

SPARE

TO

MACHINE

PARTS

PARTS.

SUPPLY)

IS

OFF

MA I NTENANCE,

ADJUSTMENTS

WITH

GUARDS

PULLEY,

MACHINE

OR

AND

BELT

IS

IN

ON A SMOOTH

PERFORMING

REPLACEMENT,

OR

STORAGE.

BE

SEWN

OR

CLOSED

SPECIFICATIONS.

OTHER

THAN

6.

l!~©fHffi · !B~3'ttl ·

ri11=~9~;Jj

t:: ~ (,

\0

7.

iif.>:h

fJ(,\""{:(

8.

·*'

~JL,

fJ(,\""{:(

9.

-~0)-iiffi

0)

10.

ifl;Js-3

7a,

11.

"=.:i.-Cl/?"I:¥(~)"

{tffl L

1{-t.it,i.nt=~fm--c:l;t·~~iifii

f;:~(,\o

0)

iifii

cjJ

l;t

1--

-f

©-ft!!II.I

f;:~(,\o

· !B~3'ttl ·

c!::

~

I=

l;t:if.; fJ:llrJil=~l.'

c!::"t"

7a>M*1t.it-~O)f±~l=~-::i

f.1,.fitf.1,cY)-C

tJ

<

l.' 1: <

rull~

(.&~I7-;JU

7.J

·.!I

1Z -,.

1,,

-c

1,,

7a>

flrli1= 1i-¥

IDI].

t:: ~ (,

\0

t::

~

l.

'o

• Xl;ttffi~©

~~-::,-C <

L

1

$-t,.

·

-C

$1!1E!B~W.,i.l;t

) -

-:J

-

,.

~Mn

tffl~f.>fi'if

<

t::

~

l.

'o

-C

1,,

Identifying and Ordering Parts

Cautions When Using the Machine

Maintenance

Where the construction permits, each part

its part number.

part name

Safety Rules

To prevent personal injury:

All

power sources

•

before threading, oiling, adjusting or replacing parts.

All

cover and guards must be

•

machine.

•

Do

not tamper with safety cover, guards, etc., while

machine

On

and

model name

is

in operation.

all

orders, please include part number,

of

machine.

to

the machine must be turned

in

position before operating

is

stamped with

Safety Precautions

1)

Always

adjusting the machine or replacing parts.

2)

Wear safety glasses.

turn power off before threading, oiling, and

e .:::..:i-01/::1'I~

~

0)

:::'tl:J'.CO)~l:t,

•

off

<t;:~1,,\0

~TI:

ff~

(-f*)

~OO'B~m-~~ml.:l:tDR-3A

£

:a::-m--Om

1..,

--c

:t3

/{-o/!J.7-J-.0)/'\-o/:j:i}c:~~-e:::-m*

•*fflL:::'~~~~&O*ffl~O)~-~~-~~,~

O)ft!!~-Omri~-emv:i

'!L,f;:.:::..:i

-o1/:1'I~(-f*)~OO'B~ffl·

h:.<1t\~~1:t, :t3Jn \Lf11t

<t;:~1,,\0

r,!ij~O)~,

:a::-:::·m*<tc~v

-f.l~'

\'!T

-~:I:%'

J:.5:t3ijJi1t

l)~M/'!vJ·*-g});n,O)b~·O)*®l,,

'l'f~

J'ri

3t~,

1,,

\0

2)

wlll~f-'p~O)

f*"r -~~f'F~O)M

c!:::'e:

1:t'tc~,,(ff *O)*ffl

vJ

'!To

~"S/1/lm$~'

\v

\f;:L,'!To

*0)3t~,

1.:~,

i"ffl7JJR:a::--g)J0--C

:a::-:t3TT~

\tc.tc'e:

~~ml.::::'~~

~-S.,-1/:j:i}

*iri'IE,

wl/J~,

<tc~

L,

'!To

3)

Make sure, before starting the machine, that

in

and shields are

4)

Do

not touch on the machine when it is run.

5)

Turn power off and make sure the

operate before you put your fingers under the

blades and the needles

6)

Do

not touch on the machine when it is run.

place and closed.

to

adjust.

cutter

all

covers

does not

cutter

in

mind

to

• Please keep

to

maintain the machine

• Thread fuzz or dust must be cleaned with air or brush on

in

throat plate,

after the day's work.

• Wipe the area easy

• Check the machine for loose screws and tighten them,

any, once a month.

Good

•

maintenance

the groove of feed dog or around looper

handle the machine carefully and

in

good condition.

to

rust with

will

oil

prolong

cloth.

the

machine

life.

3)

~--CO)it· ;tJ/{-l:t~,-f'~~Ml.:M~--c<tc~1t

4)

;tJ/{-ft~il~M'!0--C1t\0:.c::a::-~i'UN-L,

--c;o,t:,~~1..,

f;:~1,,\0

5)

it·

;bo/::$7-0)

<tc~1t

rl.:-¥:a::-Ah0c!:::'e:IJ:,

'o

it·

;tJo/?1-il~lbf1FL,ft1t

~,-f'ffl7JJR:a::--g)J0--C

,:.c::a::-1ft~1..,

~:a::-f-1'0--C<t;:~\.,\o

6)

~"S,/1/0)~~

• ~"S/1/lm$l:t~Wft1J,~ft'tf~£il>G/±H~Li1~0--C1t''!To

~

1.:1:t,

~"S/1/l.:f!knftv ''i:<tc~\t

tl:~~<J&t&5c:c:tl.:~1.:~-0ml.:,tA!Ht--c<tc~1t'o

• - a O)f-'p~;o~~TL,'!L,tcG, ittJitO)L,

~,

;t,,-/{-0)'!:bvJ 1.:~'!0tdI:.vJ~l:t'e:h1t

~1,,,--c<tc~v'o

if

•

-¥

AhO)

.l

UII

1..,1:t•~

<tc~v'o

O)~iff

1.:~W

L,

'!T

\0

--c<

--c;o,Gf1F

'o

~!)~0)$:0)

,1.:1&vJ

0)

-e

:::'

tl:~

ii

CONTENTS/

1.

Specifications/{±~

2.

Threading/*iffiL,~ 2

3.

Lubrication

4.

Adjustment/1.ffilff

4-1 Needle

4-2

Aqjusting

a) The distance between

b) The clearance between

4-3 Adjusting Spreader (7-71-

/~AA

Setting(~{l):Jt~)

of

Looper

--------------------2

---------------------------3

(Jv-r{-(J)w/3~)

the

Needle

and

Looper

(~c:1v-/{-(J)igli!l)

the

Needle and Looper (~c:;v-/{-(l)rl!jllJ!1!)

,/,:/-(J)w/311rf)

...........................................................................................................................................................

~

1X

.............................................................................................

3

3

4

4

4

5

a) The distance between

b) The clearance between

4-4 Adjusting Thread Retainer

4-5 Adjusting Feed Dog

a) Height Aqjustment

b) Adjustment

Adjusting

4-6

4-7 Adjusting Needle Guard (~jJ-F(J)wl/l!lrf)

4-8

Presser

a) Height Aqjustment

b) Aqjustment

4-9 Thread Tension

a)

(:ff.:w/3-=f)

b)

(J::ff.:wl/liilll)

Parts

List/$£~

Numerical

in

Stitch

Foot

(;f!Jl.:c.1l2(J)wl/l!lrf)

in

............................................................................................................................................................................................................................

.......................................................................................................................................................................................................................

index

of Parts/,r~-o/mi31

the

Needle

and

Spreader (~c:7..7vo/,:/-(J)ffili!l)

the

Needle and Looper (~c:7..7vo/,:/-(J)F,lj~)

(:ff.:;j£1jq:-(J)w/311rf)

(J~!J1l2(l)wl/J!lrf)

(1:

r(J)wl/l!lrf)-------------------------6

Crosswise Direction (ti:~(J)wl/l!lrf) 6

Spacing(~§

(J:r(l)wl/J!lrf)

Crosswise Direction (ti:~(J)wl/l!lrf)

(:ff.:wl/lr~1:*)--------------------------8

lj!j(l)~J!)-----------------------6

...................................................................................................................................................................................

........................................................................................................................................................

.....................................................................................................................................................................

.........................................................................................................................................................

-------------------------8

--------------------8

---------------------10-

List of Screw, Nut & Washer/ *"1/, To/

r-,

?o/1/~--~

.....................................................................................

.......................................................................................

~

5

5

5

5

7

9

a

9

22~

24

23

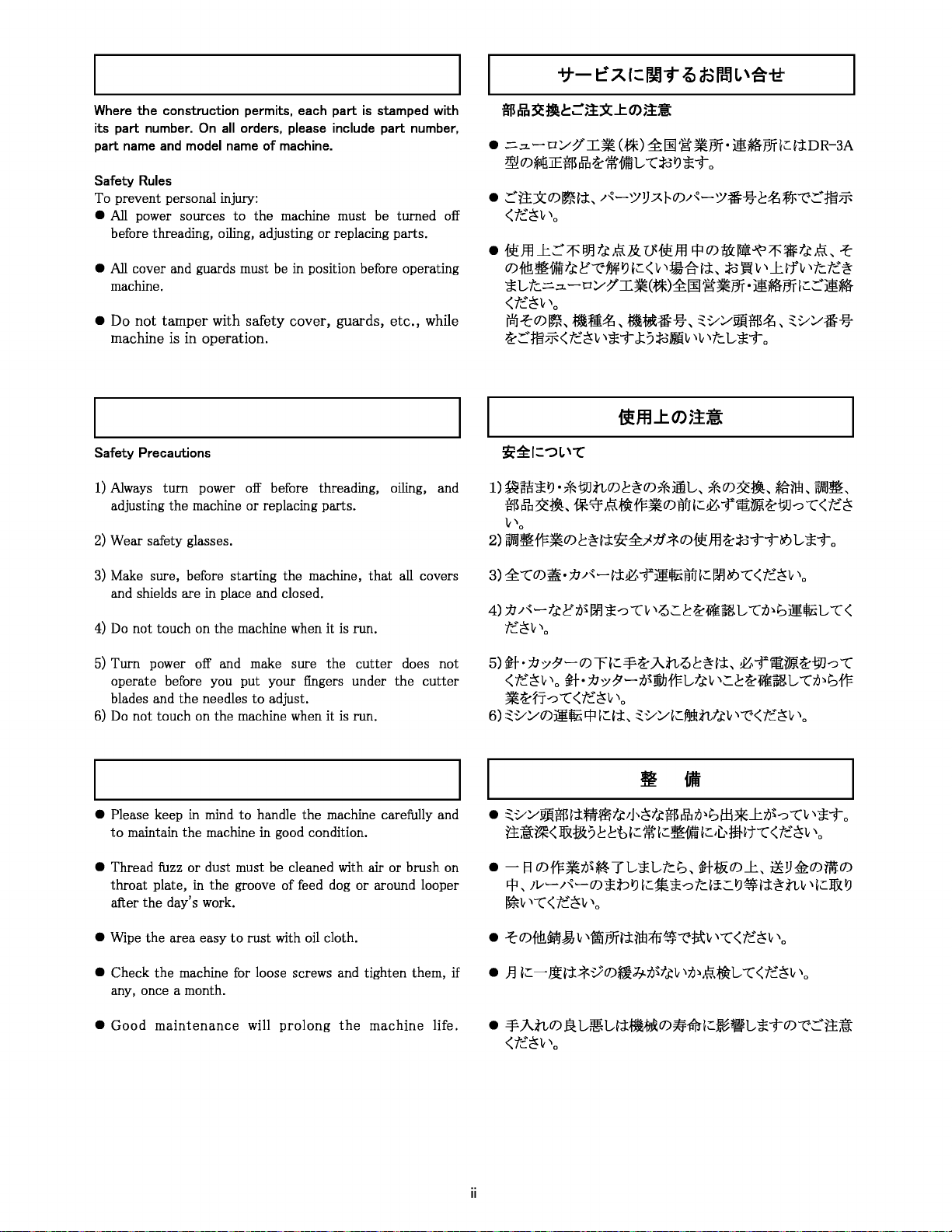

1. Specifications/

2. Threading/

Seam specification and

Stitch Range

Standard Sstting

Maximum thickness

Feed

Needle Type end size

Thread (Cotton

Working speed

Maximum

Motor

speed

Motor

pulley diameter

V-belt

type

DESCRIPTION

One-needle

APPUCA TION ilffl

Double-thread chain

such

esjute

or

speed

and size

two-threadjute

bags,

stitch

of

Range

of

material

jute)

bag sewing machine 1 *ti- 2 *Kt •&a1,,at,:.,

stitch

machine

PP container

type

bep,

81.'Bit

a1.,1iMI

•••l.'i•

-~-1,\jf:

••Jnit

tt

M*

..

**

fl=.li.fillt

aa1EJ&1t

~~-lifilt

~~-:f-lJ-

V,(JL,t-

for

thin

to

thick

etc.

fabrics

401-SSa-1

6.5mm-15mm

10mm

Plain Feed

U01975-280

Cotton, aynt:hatic and

1,850rpm

2,000rpm

2,800rpm

M41

.a

0)

15mm

maximum

•a•':J

(50Hz) /

(/,

105mm (50Hz) /

(50Hz) / M40 (60Hz)

:ll)ij

..

PP

=:J!l7-J--1

2 a1la1,,at,:.,

jute

Mkt

..

•Rt

..

itakt

3,400,pm

(/,

90mm (80Hz)

(60Hz)

<~?~eO>MIJiJ'iI,JJ:IJ~~O)•tJ

Naed

la

CD

=~ =®=©=@=@=

Looper

®=©=®=®=®=®

Thread

Thread

C

..l:.

C T

ff-

1it

)

J

Loo

(

T~)

er

(i)

Thread

Needle

Thread

CJ:.*

J

Looper

Thread

CF~)

2

.

(jjg[)

D

3. Lubrication/

4. Adjustment/

(1) Oil

the

machine before you

eccentric parts on

oil holes in

running

minutes

oiling point.

(2) Check

the

the

at a low

the

machine.

start

it. Oiling points are all

the

main shaft, needle bar, oil cups,

the

base cover, and bottle oilers. Before

machine for production, idle it for about

speed

to

allow

the

oil

to

reach each

oil

level

in

the

bottle oilers before starting

Refill

when necessary.

(1)

At±t::--c~1/::..,,:a:-fficl/JTQ-~1H;:??,ftGi"r±}ll3:a:-L-

1.,

, 0

rct:rlil

11

m

:;d--11v.iJ:;,-7"_

10

'7-l::i'tlll3L-

i)~Jfi)t(;:aj>~:bt~QJ:::jt;:f.il;jm""t:

tt~v'o

(2) if-l-1v:;d--1'7-0)lll3:i::a:-ifi~

WI/JL-

--c<tt~v'o

fj:

,

::t.

$m

0)

--t

.r:::.

--c

0)

.:r.

::\'-

--e::..,, ~ 1*

.r:::.-?..iJ/~-O)*fl'lll31C'l'.!'~,

--c<tt~v

'o

-t"

L-

--c*~WI/Jt::1'QMt::,

10 )tf.i./i'.~~~L,

.&

L-&ti1t:n1it1Uil'L-

--c<tt~

,

it~,

Vif-l-1v:;d--1

lll3

--c<

--C??>G

NOTE:

1.

Poor

oiling

will

Use pure mineral

viscosity.

Ex. Shell Tellus Oil ClO.

cause seizing

oil

of 8 to

and

other problems.

12cSt

at

40

°C

kinematic

}±~

1.

~5ElltJ<-f'~~-c:""t

c!:::mf-t~~O)

90)""{:~"(fif~-:>t<t::~l,

~ffl:;d--1

~fflL-

(

Jtl)

Jvl'J:,

1/Jfi!i./i'.ffii.,c

--c<tt~v'o

'1/'

.:c.Jv77

?.:;d-

-1

Jv

8-12cSt

C 10.

t-·:r::111,©mt~c!:::t~LJ

\0

(40°C)

0)*11!®t~rll3:a:-

*

4-1)

NEEDLE SETTING

(1) The needle should be installed

will

as it

(2) The needle must be installed with

toward

direction.

(3) Tighten

in position.

CAUTION:

Incorrect needle setting, bent needle, or

point or

other

go.

the

the

hole

problems.

rear

side as viewed in

needle bar nut

results

in

thread

in

the

(HA56)

skipping

needle bar as deep

the

to

secure

curved relief

the

bag feeding

the

worn

or

snapping,

needle

needle

or

4-1)

tf-O)JD{i-;tlt

(1) iJ-fj:iJ-~f;:

(2)

iJ-0)

fj!Jj

[;:

(3)

it~To/

[}i~~lj]

tttJ<:iE ~ (::lDH-t

"'"'.)i)>X.Q

fPJ~t'J:,

<QJ::?

r;:J&{-tlt--C

HHA56)""t:,

'i""t::mU:,/v""t:<fc~l.,

if-O).:r.:7''!J

'l'.f~??~~O)ji§fi.1J

<tt~v

it:a:".{srtt--C

It

i:,*1,

-Cl,

\fJ:fJ,-:>t.::

'o

$t0)$'fj~tJ<j;[.<f~-:,f.::LJtf-7'(::fitJ<-:>(,

Rt~v.

-c<t::~1,

3

!!Hll"Ct~©

,o

t-:r:i

Jt,©fflt~c!:::t~LJ*""t©-c:}t~L-

<tt~v

LJ'

tttJ<al:I

\-Cl,

\

0

fPJ

t::M L---c,

'o

tJ<-:>t.::

\f.::LJ

l-*9

~

LJ'

c!:::,

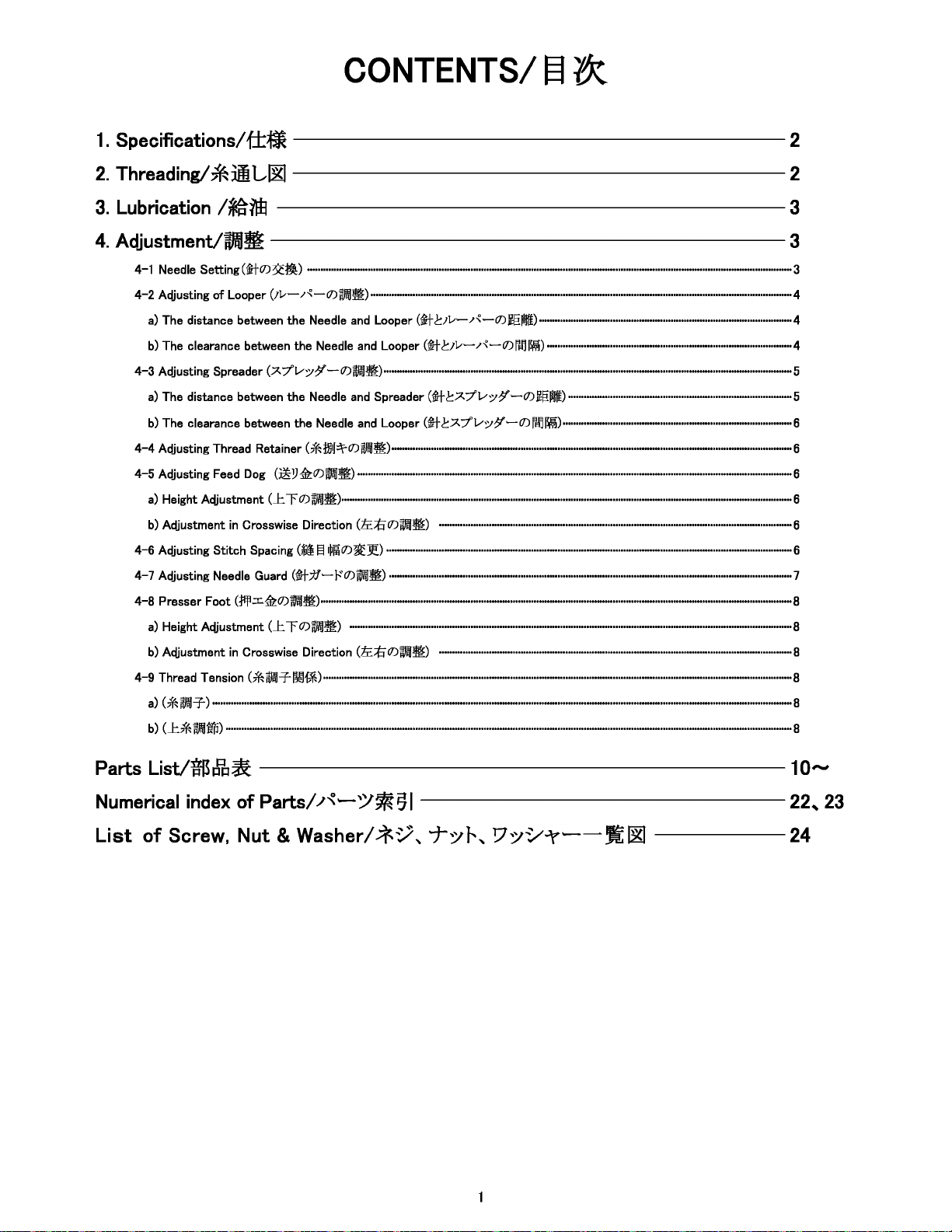

4-2)

LOOPER

For

the

convenience

throat plate, and feed

so

(80233)

needle,

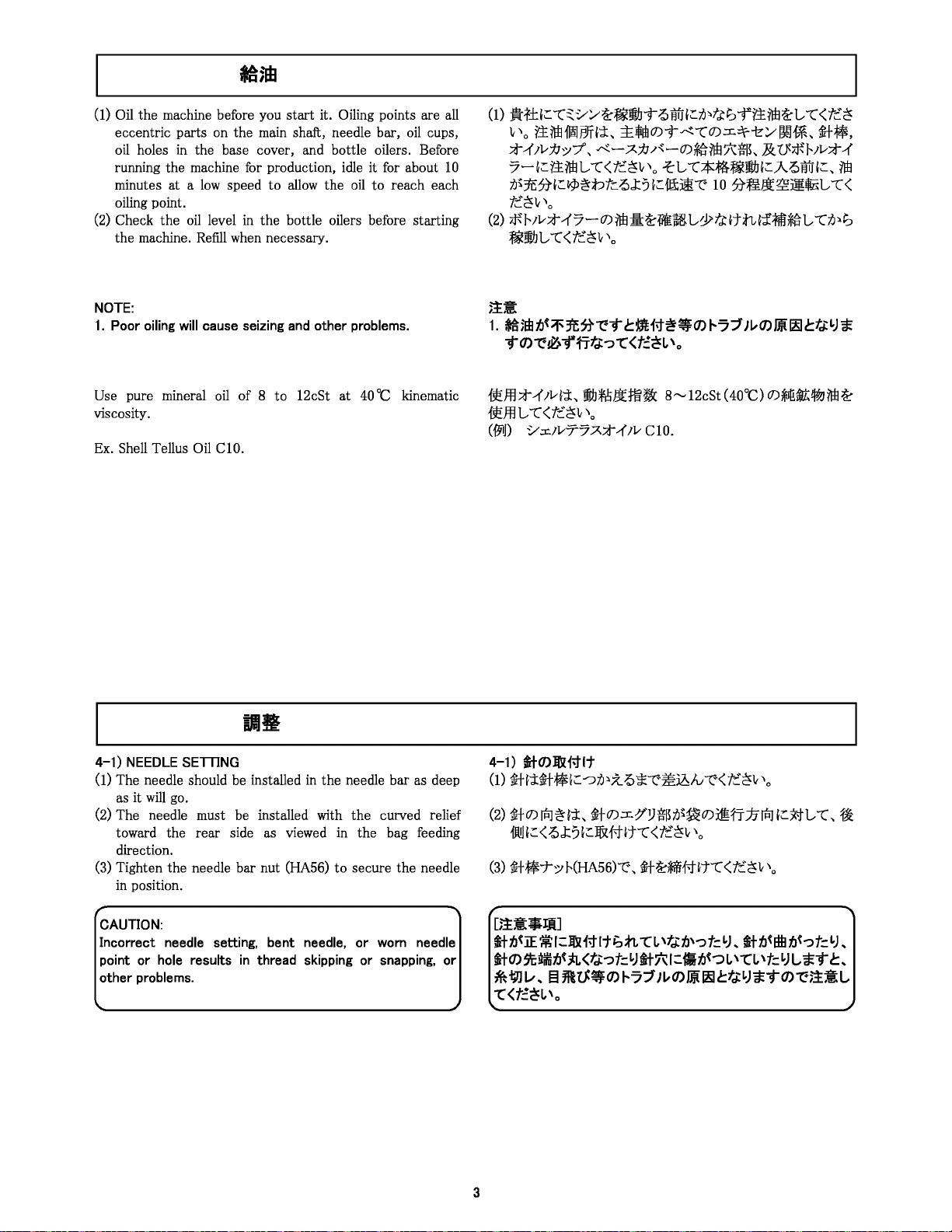

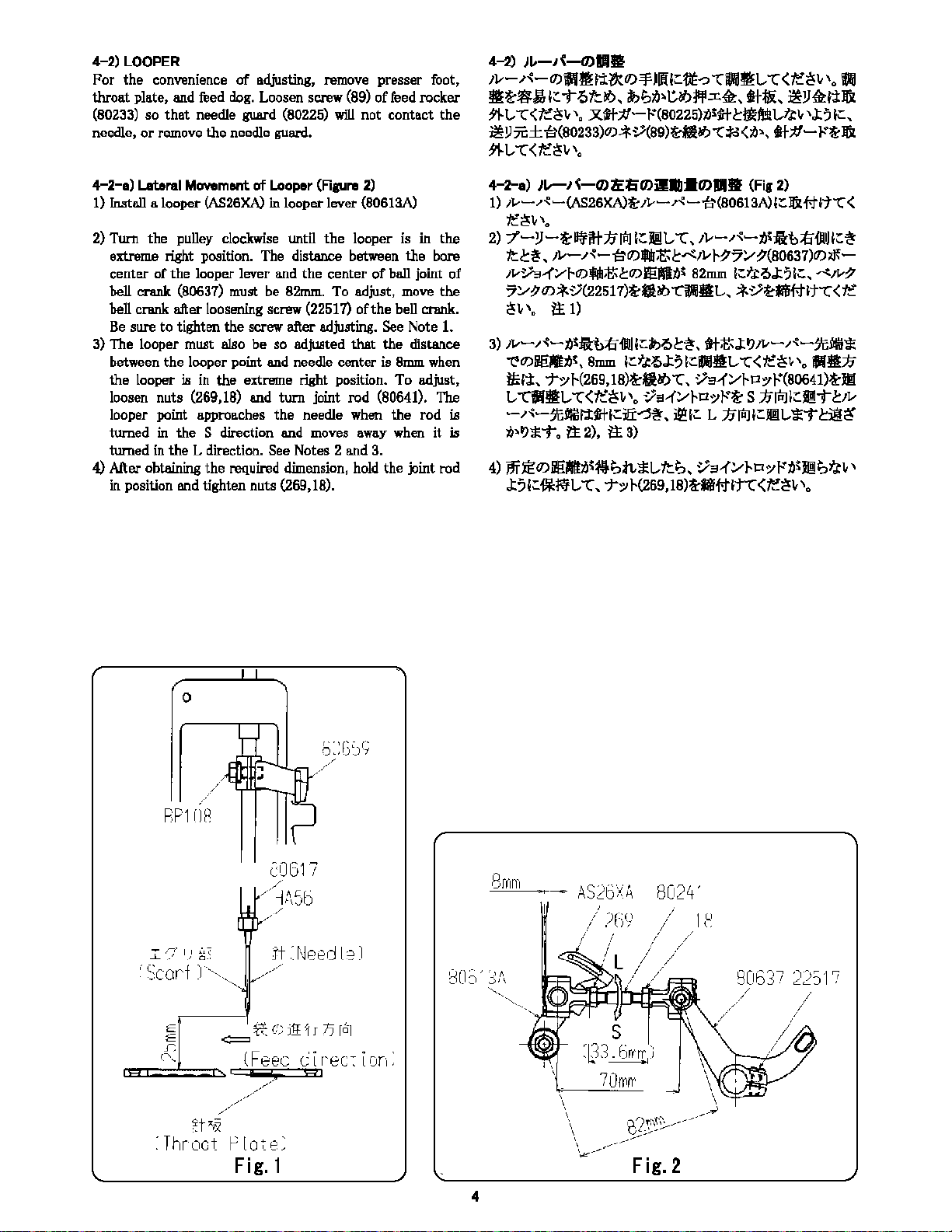

4-2-a)

1) Install a looper

2) Turn the pulley clockwise until the looper

extreme right position. The distance between

center

bell crank

bell crank after loosening screw (22517) of the bell crank.

Be

3) The looper must

between the looper point and needle center is

the looper

loosen nuts (269,18) and turn joint rod (80641).

looper point approaches

turned

turned in

4) After obtaining the required dimension, hold the joint rod

in position and tighten nuts (269,18).

that

or

remove the needle

Lateral

sure

Movement

of

the looper lever and

(80637)

to

tighten the screw after adjusting. See Note

is in

in

the

the

of

adjusting, remove presser foot,

dog.

Loosen screw

needle guard (80225) will not contact

gUard.

of

Looper

(AS26XA)

also

the

S direction and moves

L direction. See Notes 2 and 3.

in looper lever (80613A)

must

be

82mm.

be

so adjusted that the distance

extreme right position. To adjust,

the

(89)

(Fiaure

2)

the

center

To adjust, move

needle when

away

of feed rocker

is

in the

the

of

ball joint of

8mm

the

when

the

bore

the

1.

when

The

rod is

it

is

4-2)

)l,-1

<-0••

iv-

.1,( -

0)11911

J'1

~

O)~

)lfH;::::.fJt·:>

!llt-5a,:-r-ottao,

~L,

"t:'<tt~i.,

~95c±-S(80233)0)*~(89)t-a~"t:':Jo<tJlo,

~L,

"t:'<fe~\,

4-2-a)

1)

1v-.1'1!-(AS26XA)t-1v-.1'1:-,S(80613A),;:::J8tftlt"t:'<

'•

'o

Jl,-1

(-0)1£g0)1111J·O)··

~;tJlot,~,ii.:r.~,

Xff-P-~(80225)7)tft~~ftit.-t.t\.

"t:'Jill!L,

tt&t,

(Fig

"t:'

< te ~"'

~9ftfi18t

,~;,~,

tt;tJ-ft-18t

2)

te~v'o

2)

7"-1J-t-~lt.1i"IPI

ft}:_~, 1v-.1{-e0)$df~.!::~1vf-?7:,.,?(80637)0),f--

/vV:f.-(:,.,f-O)fdl~.!::O)ffiliU1

7;:..,?0)-*VC22517)t-atao"CRfflt..,,

~v'o

tt

1)

3)

1v-..1{-~l:libti-OOU::i>-o.!::!,

"('O)ffiMtJS,

th1:t, ro/H2s9,1s>t-ll~"t:', ~:1.-f:,.,t-Po/r(soo41)t-J11

L,

"'Cllf!RL-

-.1{-~tliU:tttl::ili:"'1~,

i,l~*To

4)

af~O)ffi87}1ffl,e,t1,*L,1t~,

~;1::i*~L,

-c<~~l,

t£

2).

"(,

l:JQlL,

"t:',

1v-.1'l:-1}~itttiiJl~I:~

82mm

l::tJ!oJ:;l;:::,

-*~~lffi#lt-C<~

tt~J:tJ1v-..1{-~tJW~

8mm

l:fJ:-oJ::H-:PJmL,

'o

~9.-(:,.,}-cz7~t-S

iQ!l:: L 1ilfiJl::illL,~-r~~

tt

3)

7::,l-(269,lS)d#lt"t:'<te~\.

-c<~~v'o

Va.-f:,.,}-tro/f:1)~Jm!~tJ:1,,

jj("ti,U.'.:@!T

'o

'o

Ml

~,v?

••11

}:.Iv

0

BP108

. ~

r----=

~<--

CT

hroot Plot e:

it

,.//

*&

_

,,,,.

/

,,.,·

""'

(]0617

/'

_,,,

-lA5b

//

8mm

-

-~-+

A

S26:<A

/

/•{

I ; I /

80S'3A

~

(J)

11E

h

15

(ci

1

(fuec

/,.,/

Fig.

qjr

.,,,,,,,

,

ec-:Ion:

1 Fig.2

802

)C)()

/ /

; L / /

I / /

I

I

4'

I

Q

1

t,

4

NOTES:

1.

Be sure no

the

bell

2. The

3. The

the

ball

are

70mm

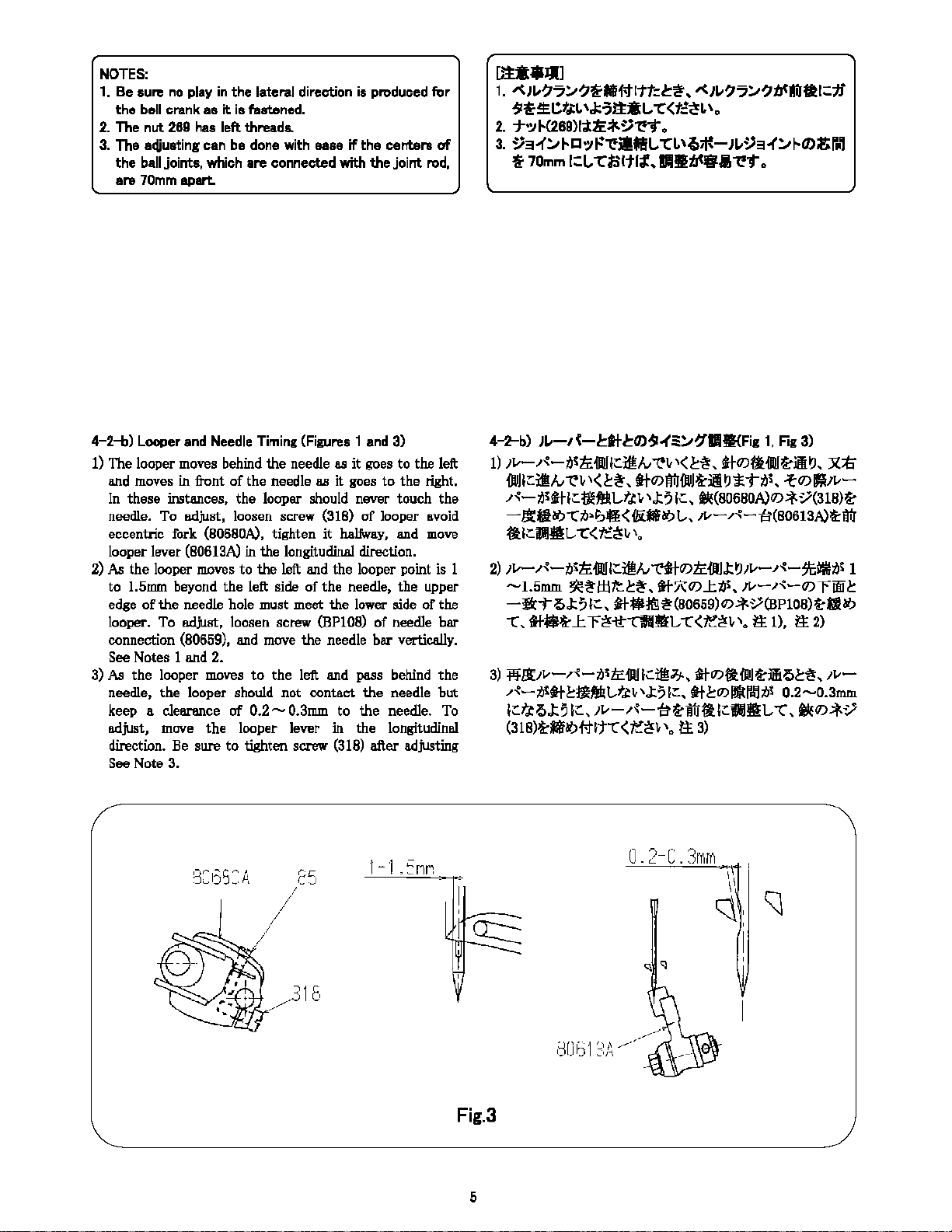

4-2--b)

Looper

1) The looper moves behind

and moves in front

In

these

needle. To adjust, loosen screw (318)

eccentric fork

looper lever

2)

As

the looper moves

to

1.5mm

edge

looper. To adjust, loosen screw (BP108)

connection (80659), and move

See Notes 1 and 2.

3)

As

the

needle,

keep a clearance

adjust, move

direction. Be

See Note 3.

play

in

the lateral direction is produced

crank as

nut

269

actjusting

joints,

instances,

beyond the left side

of

the

looper moves

the

it

is

fastened.

has left

apart.

and

(80613A) in the longitudinal direction.

needle hole must meet

looper should not contact the needle but

sure

threads.

can

be

done

with

ease

which

are

connected

Needle

Timing

(Figures 1

the

needle as

of

the needle as

the

looper should never touch

(80680A), tighten

to

the

to

the left and pass behind

of

0.2,...,

the

looper lever in the longitudinal

to

tighten screw

it

left and the looper point is 1

of

the

the

0.3mm

for

if the centers

with

the joint

and

it

goes

it

goes

to

of

looper avoid

halfway, and move

needle, the upper

the

lower side

of

needle bar vertically.

to

the

needle. To

(318)

after adjusting

of

rod,

3)

to

the left

the right,

the

of

the

needle bar

the

~-JI]

1. ~Jl,?"5!-l?~M#lttd::f'

~~~c~1.

2.

t--:.,1--(289)1-ttf*~l!'t

3. ~3..f:.,t-c~t:-cSIML.

~

70mm

4-2-b)

1)

1v-.r~-1),~fflf:,i5A.,~i.,,<)::~, tl-O)flffla-lffi~,

-flllU:::ilA,--ei,

,.1;-;:taL.

r=L.

-C'31tlt

Jl,-1<-tttl::O>~..(~!,,~-lf(Fig

'<i!::!,

ftO)fiJ,fAIJa-lil~*t"t>i,

/{-1)lfH::.•mt1.,t,t1,

-~aao-ct>:.1::>fi<<&•ao1.,,

fll;::.PJilL, -c<~~"'·

2)

1v-/{-i)t~-1Jf;::.JIA,-c.'ft<1)~-0IJJ::~,i,-/{-1c•ill t

-t.5mm

-!t--t

-c,

3)

:i!Jal:1v-/{-i)i~-1PJJl.:.il~-

/{-i)Sft,!::.ML,t,ti.,

l:l.toJ::?

oJ::;

tt•t-

~~l±lfti!::!,

l:.,

tt•~

..1:

r~-tt--c11!fit..

l.:.,

Jv-/{-it~nutll;::.IIJ!IIL,-C'

(318)~-abt-t1t-c<te~1,,o

..

~J1,?"5!-l?.b<1iffil=fl

-c<t:~1.

-Cl.

..

••ti<••~1"

,D

0

,.f>;tt-,1,~3..(:.,t,.0.&rr.1

0

1,

Fig

3)

.."f:0)51v-

,J::;

f;::.,

l'E(80680A)O)*

,v-/{-,a(so6t3A)~fil

ftJ'cO)J:t)~,

~cso659)<7)*

-c<te~i..

/y-/{-O)rimi!::

,.

~CBP1os>~•ao

~(318)~

a o, a

ftO)tiffilJa-lffioi!::~,

,J::;

1-=.,

ttc!~O)lf.ftr.rit1s

o.2--o.3mm.

t#EO)*~

i:t

3)

2>

X::6'

Jv-

8C68:A

85

1-1 . 5r.ir,

I

Fig.3

5

0. 2-0.

3rnm

c:1

11

I

1

1

I

I

~

NOTES:

1. Check

2.

3.

the

orientation

needle bar height. (See

For

the

convenience

throat plate and needle point should

needle in

Be

direction

eccentric

screw (85)

the

sure

the

as you tighten

fork.

of

highest position.

loopel"

Any play

looper avoid eccentric fork.

of

the

4-

1.)

of

adjusting,

has no play

the

must

needle

be removed

as

the

distance between

be

25mm

in

the

screw

of

you adjust

when

longitudinal

looper avoid

by

tightening

the

the

~-ll]

1.

~.,_,ilri~~lllilffiL:ft~~'

(4-1

-JftO

2.

il'.>~iJ'."C.af)tf-t,1Jctil'.>ti~-:,1t~~

~OJitiMa-

3. ~O)*~a-li'li#•tttt~1v~/{-'IJ~Kirfi1::.n~'IJ$f1,1,,'I)

t-•HL-

25mm

l::.L-·cto'IJ:.tf,

-c<n:~1,,.

(85)a-*f#•t"C"ll!llt..

~0)11iJ~l::.t±tL-

..

tl-Ut1:iiiJ::tJtt.$'c.ffll"t

111!11':ttfJ&~T.

t

L-n?'tJS!£C1ttl-8-t.1:,

"C"

<~~\,

'•

"C"<r.:~1,,.

~O)*~

...

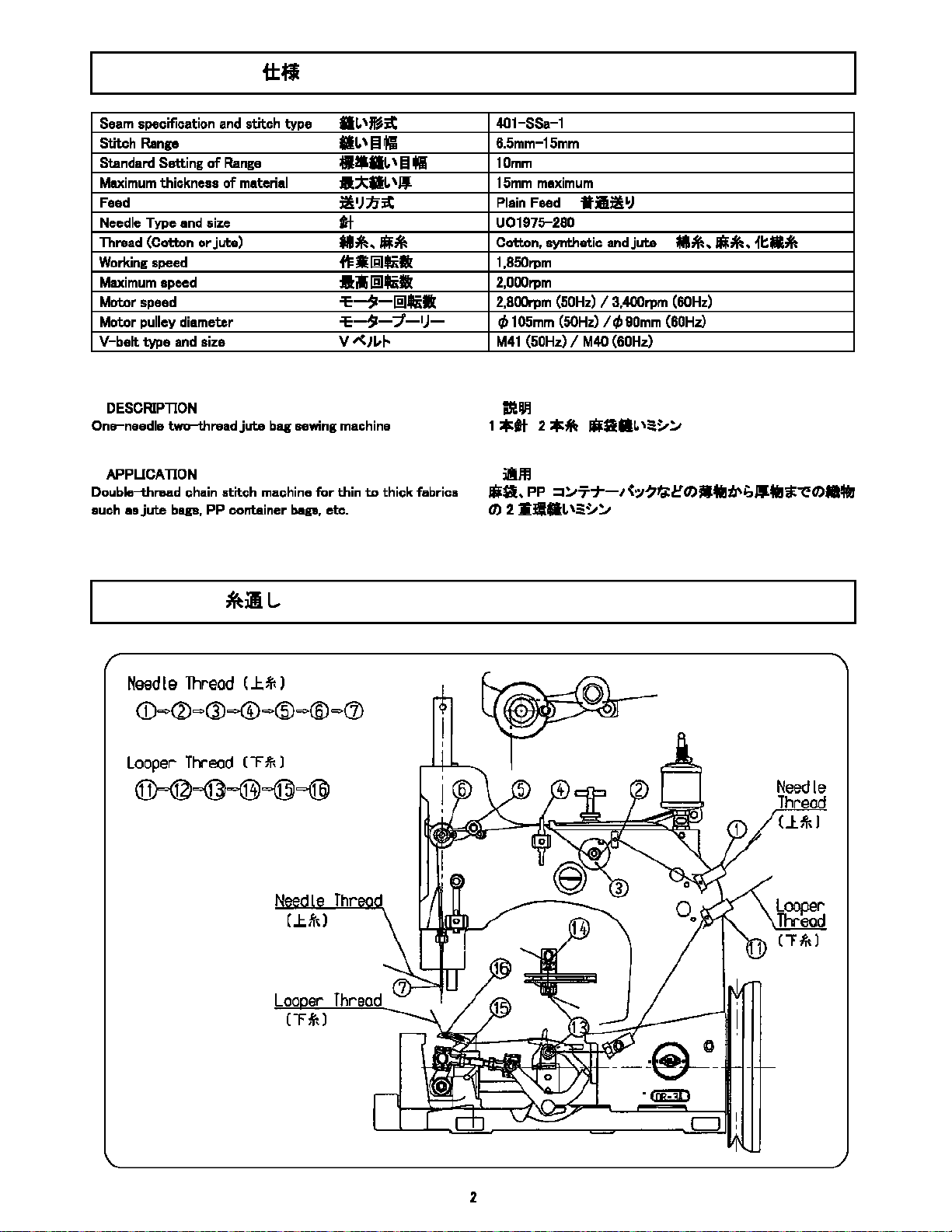

4-3)

FEED

DOG

(1)

Feed

dog

(80205)

(80224). Loosen screw

plate

required, move

as

halfway.

(2) Height

should be Imm above

is

adjust

and mount

the

of

feed dog :

in

the

highest position. To adjust, remove feed dog,

the

height with screw (97X)

the

screw.

(Figure

4)

should

the

the

feed dog so

not

touch

the

grooves

(89)

of

feed rocker (80233)

feed rocker, and tighten

The

last

teeth

on

the

throat plate when

of

that

it

rests

the

feed bar (802348),

on

the

80234B

in

throat

the

screw

feed dog

feed dog

head of

4-3)

(1)

(2)

1

m.

Jfl0il9

(Fig

4)

~!}~(80205)'1JStJ-U{(80224)0)fflOJiPJJiiil::..Mt..t1.1,

;1::.;!!}jc±'S'(80233)0)*~<89)a-*lab"C"i!!J5c±-aa-

l/J;o:i.l,

"C"

-*~a-Oaf;

~!}~O)jflj~t.l:.

iUSftffi:1:iiiJ::rJ

~!J~a-Jlk?f.

llHlt...,

l,~!}

~!J~tJ~~O)-*~Ml.:~ttoJ::;l::.t...

llk#lt"C"<~~"

80205

t,

-c

<~~i, '•

~!J~tJ~M'.tl:tJ~-:,ft,otlil~'

1mm

1::.t.toJ::,l::.t..*T·

±~(802348)0)*~(97X)

--jj'~t;t

-c,

\0

80224

M'.fitflSOJ

~•~t-

~!J~a-

,J::

89

b _ ~·-

I

I

97X

8~233

Fig.4

6

4-4)

STITCH

(Figures 5 and

WIDTH

6)

AND

NEEDLE

GUARD

Stitch width is adjustable in the 6.5

machine

(1) Tum

(2)

has been

the

advanced position.

Loosen

(80696),

eccentric connection

(3) You can vary

regulating stud in

Stitches become larger

finer stitches

adjusting, tighten

(4) After adjusting

(80225)

(5)

Tum

the

and needle. The clearance between them should be O

0.05mm

Adjust with needle guard. See Notes 1 and 2.

NOTES:

1.

The

needle

have

changed

2.

if

the

clearance

actiusted,

set

to

10mm

pulley until

the

nut (HAlSA) of stitch regulating stud

which connects feed rocker and feed rocker

the

(80651),

the

stitch width

the

fan-shape slot

by

are

available by moving

the

nut.

the

stitch width, install needle guard

on

the

feed

bar.

pulley and check

as

they

approach each other most closely.

guard

muat

always

the

stitch

width.

of

needle

guard

the

needle

may

break

to

15mm

at

the factory.

feed dog is in

and tighten

by

moving

of

the

moving

the

timing

be

to

or

thread

the

stud down, and

of

actiuated

needle

range. Your

it

just lightly.

feed rocker.

it

needle guard

is

not

skip.

the

most

the

stitch

up. After

to

when

you

property

3il

B

ili•';l:.

6.5-15mm

lltf'i

lOmm

lr.1'J!lt.,-c

(1)

7'-9-t-Jet.,

(2)

~!J5c±ii'~~!Jtto/f-:'(8065l)~il'6Vn,,?>~!Jllll'ifdl

C8o696)0)-r:;,

(3)

i!!Jll'dtlli$i~i!!J5c±ii'O) &~:11:ill~~?-C J::Ji'"'Ftf

T-5.l::~tJa B ill~$fftJ*i"o

l'.J.

l9!l~J:•i'-?>~*8:6~<tll'.J;:T.,

*l,1t~-r:Yl-d#lt-C

(4)

till

B •t:,)tt'(:*r.l*t.,1t~. tt.tl-r(80225)f:~!J

f.tl't-C<~~i.,

(5)

7'-!J-f:ffll,

i..

,D

ttn-r

nus

o--0.05mm

'-''o

i±

1),

*~l'lllliiJ18~To

1±1•vctol'.J*T

-ftO)I.l±li\ir

D

-C~!J~~i-t>lfiJilt.,tt-otlRl~t.,*i""o

t-<HA1sA>aao,

G<-iliMtao

"'Fli'-?>~a

t.,;:r

B

m~0)5i B

•fi:wt<t.i::

1

•1h

1S~i:,tt,

<f!:~1, , ..

±ii'l~l«

'o

-Ctf-;fJ-t:'ktl-OJ?'-{~:,,~f: Jt -C<t!:~

ttttis~•;Jf"1i..

,a.t-?>~%:tt;tJ-f-:'f:iRllL,

i±

2)

,~--

tt.tJ-r

~ftO)!I

..

-C<t!:~

806

911

(ITJ( I

,

,.,,./

HA18A

1

8065

Fig.5

7

93A 80225

\ I

~

80225

Fig.6

4-5)

THREAD

Adjust the rolling needle thread guide assembly (80665D)

that

the

(Figure 7),

4-6)

INSTALLING

PRESSER

The presser bars must move freely,

(80887

A)

(482C),

GUIDE

(Aaure

needle thread is raised

when

the

needle is

PRESSER

FOOT

PRESSURE

and determine

as

follows

the

7)

by 2 to

low.

BAR

position

AND

(Flgure

Remove

3mm,

as

ADJUSTING

8)

the face cover

of

the

set

shown

collar

4-5)

ktlllliO>IIHI

so

th'J~r1)t,;,ft.~f1C1J.!::~, Fig 7

in

Mi:>J:.~61H:::.J:.*iRffi*8.(80665D)~I/J:bi.L,

4-6)

#I..O)Jllf.J"lt~M1.::c:1iJ±0>alf

tfp.:r.*fltJ:ffl~tJ::.1;::J:.

(80887A)~*M-L--e::,J,.jJ7-(482C)C1J«t:R~~ao*t"o

{Fie

7)

~~t"

J:;l:::...l::*7>~

~l,t.tJttLl:ff.t~r~it

(Fig

lvo

2-3mm

--C

<t.::c!i.,

8)

J:.ffijJ

'o

/'(-

(1) Adjust and

the clearance between

and

{Figure 8).

(2) Make the clearance between the presser bar holder

the

and

(3) Make the clearance between the

·s·

(4) Place the

busrung, upper, and the presser bar holder.

(5) There must

presser foot (in

nut (in the lowest position). Adjust the

that

time when

(80648).

(6)

Now

been determined, and they are properly set, adjust

spring pressure properly

plate spring adjusting screw

cover (80688).

After

using

set

the presser

the

presser lifter pin (22870) is 1mm,

set

collar •

A"

7mm

set

collar •

be

a sufficient clearance between

the

highest position) and the needle bar

the

presser foot will

the

presser foot

that the position

the

adjustment, firmly lock the adjusting screw

the

lock nut (35733B),

bar

holder (80632) so that

the

presser lifter lever (80648)

1.5mm.

set

collars •

C"

in the

middle

of

set

not

hit needle bar nut

is

lifted by the lifter lever

of

the

set

collars

by

means

of

the presser foot

(64Y)

located on

to

prevent it' s loosening.

the presser

·A•

as

shown

collar •

to • D"

the

A"

D"

at

in

and

bar

the

so

the

has

the

top

(1) tfll.:r.l\~t"~(22870)C1JIUIIJ:b~

-5J::;

l:::.tfll.:r.~*(80632)tt::,

tfll.:r.M*l:1?::,J,.jJ7-A

(2)

(3)

1?::,J,.jJ7-A

(4) 1?::,

J-::,jJ7-C

l:::.<QJ:?l;::-f!::, J,.t°Qo

(5) :&ili&fRl;::J:.])t--:,jttfll.:r.{tl::&it&JRl;::""ft,1-:,)'ttf-.

'To/

J,.C1J

tfll.:r.il~v

{t;b1tJ-f14i-r::,H;::

lfllJL,

"t"(fe~t,,o

(6) W,..l::C1JiffitJ-t!::,J,.jJ7-A-D

*L-1t~J:.1'(80688)1;::~Qtfll.::C.{t~/'(*••*~(64Y)

~ A 7

(35733B)~RJl-*

l:1?::,J,.jJ7-B l:17),tfl)~

l';J:tfll.:r.-~

fllH;::

+~t.t•lffl

/<-(80648)~tfll.:r.1t~Mi:>J::l1t.:.!::~,

~

tt.~f.tt,

!J

~

!f

JE

~ifiE

~~-°*t.,:1,

FigS

J,.

t"-5o

l:'7)1!tfl0~

o/'l

~..1:..1::tfll.:r.M *(1.)

:bV.tlttitf f.t

,J::;

l;::-t!::,

C1J/lLW])t~"ttJ,

I;::

ll!fl

l,,

Ill

,J:,tt::,?l-

-e~-tlffitJ

1.5mm

7mm

tJ

*it

Iv.,

l-7J7i-"

!flit

tJ:

Po/?

-r<t.::~1,

1mm

l;::t,t

l:t"6D

l;::l:,5.,

cp

J:-:i

--C,

tfll.:r.

D"

~-

-t!::,J,.~~

'To/

,.,

00

1-

0

,

,

0

/

22870

y

\

I

8GE650

Fig.7

80348

8

64Y

C

8

A

Fig.8

=====

ORDERING

PARTS

ORDERING

1.

Description of each part and its stamp number

adjacent

2. The parts which have no

3. A

4. The last figure on the parts stamp number advances on each improvement of

*The parts list

1.

;::'7'.tJ'.cO)~fj:,

2.

{!!L,~:ffi:

\,,\0

3.

*-.ll'!f~J'bf:i.:CO)q:iO):±,,~~o/O)t1J1::p:ffl:%-c:*~1..,

4.

tLl

<f;:~l,,\

to

the

set

of assembled parts

(Ref.No.)

l::P:ffi:%f:i,

.:CO)lf~J'b

0

relevant parts. When ordering parts, describe clearly stamp number with its name of part.

Ref.

Number can not be delivered independently; always order it as an assembly.

is

represented by

is

subject

to

change without prior notice.

J'fBJ'ri:ffl:%,

J'.l%fb~

O)llcA7i!ftlt

~,

ffl~~l3Jlllc<f;:~1,,

'lf~J'rif:i,

1*i1*J:l&?'c-C:~~it

7)t~_&~t16;ffi3J.i'.t;:,

is

described

the

stamp number of its main parts.

--Cilf-JIJ~To

;l&~O)~*;,it1

PARTS

in

\

0

/vO)-C:,

:ffi:i"-0*11J

this parts list. Screws and nuts for parts are shown

.:Cnt;:~~T6%-vffi'!f~J'b

J::7i!IJ,

the

AA-U

parts.

(*-.ll'!f~J'b)

,t1J

l::P:ffi:-§-t;:7),:blJ~TO)-C::::·yif<

~:::-rtJt<tt~

CONTENTS

01. BUSHING, OILER AND COVER PARTS

-fo/1/=1.-,

02. MISCELLANEOUS THREAD GUIDE

*

Wffl-=f,

03. NEEDLE LEVER, PULLEY AND CRANK SHAFT PARTS

:77/':71/~71',

04. PRESSER FOOT LIFTER AND PRESSER FOOT PARTS

¥13::r..f!-1/'

05. LOOPER DRIVE PARTS

;t-,{7-,

*

:iJ-1

F ~flf-

*~~1*

1'fl::r..~~1*

jJ/-{-~{lf-

END

......................................................................

/

~

7X

...................................................

THREAD TENSION PARTS

Jv-/~-~ilf-

06.

FEED

LIFT AND

FEED

DRIVING PARTS

..................................................

*Y~flf-

NUMERICAL INDEX OF PARTS

.............................................................

/~-o/*51

LIST OF

.:t~;\

SCREW,

To/1',

NUT AND WASHER

17o/1/~--~~

.....................................................

...............

...............................

..............................

10

12

14

16

18

20

22,23

24

9

01

BUSHING,

7'

o/~

;2..,

OILER

;d-

.{7-,

AND

jJ

,r~

COVER

~

~~

PARTS

7

~ 10

9

/,J

6

.;

44

For

Throat Plate 80

ttflH80224,A7008Mll

~9

45

224,A7008

) I

11

14

I

I

10

01

BUSHING, OILER AND COVER PARTS

7 o/1/

~·

Ref.No.

1

2 80437A Axle

3

4 81239 Guide

5 80438

6 80440 Screw

7 22574 Screw for 785021A

8

9 22514 Screw for 785041

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

::i.,

;t--17--,

!fl3

J'ri

ffi:

% t~Jb~~

Part

No.

785021A

89

785041

15/64W20101 Washer

785011A

785011

666-79

22562 Screw for 785011

80291

22513 Screw for 80291

80293A Oil Distributing Member ;;t

95

96A

80688

80246

89

80644

88

80689A

80673C Guard for Needle Bar

80273

80262

80273A

80262A

80887A

376

80690A

22539F

80284 Shield for Looper Drive

94 Screw for 80284

80694 Bushing for Main Shaft

22539 Plug Screw

80640D Bushing for Transverse Shaft

80292 Bushing for

80239C

80239D

80280A Base Plate

21681B

78-80201

AS24A

Cloth

Screw for 80437 A

Spring

Fabric Edge Guide

Cloth

Cloth Plate, Oil Reservoir

Sight

Oil Tube Clamp

Screw for 80293A

Screw for 80293A

Top Cover

Bushing for Needle Lever Shaft

Screw for 80246

Plug Screw

Screw

Oil Cup (

Bushing for Needle Bar,

Bushing for

Bushing for Needle Bar, lower

Bushing for

Face

Screw for 80887 A

Oil Cup

Plug Screw

Bushing for Looper Shaft, left

Bushing for Looper Shaft, right

"T" bolt T #1v}-

Cloth

Fabric Edge Guide

7'J

Plate

Plate,

Feed

c/J

Cover

Plate

Ass'

Oiler

3/16)

Presser

Presser

Feed

Ass'

/~

--

~-f*

Description

y

~-.A:h/~-*-'l

-"-7'7J/"-1:::·:.,,

*1/

Po/71:::

7-7°~:.,,~

o/"¥~

*1/

JE'.m

*1/

J*1i't:

Oil

Reservoir

Ass'

y

;EbffiM.

ritJtf

#!--1v;;t

*1/

r{,{7°;j:lfl.::r:.

*1/

-1'

7-'.3t

*1/

*1/

J:~

ttf*v/"-$1il7°o/1/;:t.

*1/

*1/

*1/

;;t

,{

Jv7Jo/7°

itf*;fJ'-F

upper

Bar, upper

ttf*::t'o/1/;:t.J:

;j:lfl.::r:.f*::t'o/1/;:t.J:

ttf*:t-o/1/;:t. r

Bar, lower

W.::r:.f*:1'

J:

jm;f:j

*1/

;.;d-,{

Jv7Jo/7°

7°7~

r*-::tJ/"-

*1/

±

$11J:1'

7°'7!f

iv-

/-::-t.Hb$1il7°

Rocker Shaft

y ~-.A:h/~-*-'l

*

~

jj:; ± ii'

1v-/-::-1/-y7!--7o/1/;:t.(1r.)

1v-/-::-1/-y7J--7

~1/1/-"-

)Em

0

1/

.,('J-

o/1/

7

o/1/;:t.

;:t.

7°

o/1/

.A

r

o/1/

;:t.

o/1/;:t.(::;t")

;:t.

-fflll~

Q'ty

1

1

2

1

1

1

3

1

2

2

1

1

2

2

1

1

1

1

1

1

2

2

2

2

3

1

1

2

1

2

1

2

2

1

1

2

2

1

2

2

1

1

1

2

(1)

(1)

-~

Remarks

(H)

(12,13)

(2--6)

11

02

MISCELLANEOUS

THREAD

GUIDE

AND

THREAD

TENSION

PARTS

*ii.Jr,

*

ff

-11''00-f*

5 1

I

56:1

~ ·~1

54~

28

55

,f

<::&

/'f

1·1

2 4 2 !

~

6

·

~

T

3

51

~

I

50

54

52

12

02

MISCELLANEOUS

*

wffl-r'

*jf-{1"~1*

THREAD

GUIDE

AND

THREAD

TENSION

PARTS

~:ffi:

Ref.No.

1

81256A

2

AS137

81256 Thread Sleeve

3

28C Screw for 81256

4

AS137A

5

6

HA103B

7 225608

8

108

9

107

10

110--2

11

HA1349

12

80676A Tension Disc

13

HA1348

14

HS106

15

110--4

16

80667

17

Glll

18

95

19

80665D

20

HS538

21

22560 Screw

22

HA1286B

23

12964C

24

81086G

25

80668

26

80665

27

88

29774D

28

29

80659

BP108

30

31

91

32

80655

22743

33

HS52B

34

22560 Screw

35

HA1286B

36

12964C Ball

37

38

81086C

39

81093

40

88

41

HSlO0D

42

80669

43

80676 Tension Disc

44

HA58C

45

HA58F

46

80046 Tension Post

47

HA58D

48

21111

49

88

50

80653A

51

80604 Thread Hook

52

AS22D

53

80653

54

HA102A

55

22743

56

22839C Screw for 80653

{f~Jb:ffi:%

Part

No.

Thread

Support

Thread

Thread Eyelet

Screw for 81256A, AS137A

Tension Regulating Nut

Tension Spring Ferrule

Tension Spring

Tension Sleeve

Tension Post Ferrule

Tension Post

Tension Spring

Tension Disc Stop Pin

Thread Guide

Screw for

Rolling

Rolling

Spring

Spring Ball

Rolling Thread Guide Axle

Thread Guide Roller

Thread Roller Support

Screw for HS53B

Needle

Needle Bar Connection

Screw for 80659

Screw

Thread Guide Pin

Screw for 80655

Rolling

Spring

Rolling Thread Guide Axle

Guide Roller

Screw for HS52B

Pin Screw

Tension Post Ferrule

Thread Tension Ferrule

Tension Spring

Thread Tension Ferrule

Collar

Screw for 21111

Looper

Screw for 80604

Holder for Thread

Thread Eyelet

Screw for HA102A

Sleeve

Eyelet

Glll,

Thread

Thread

Bar

Connection

Thread

Thread

Ass'

y

with

Support

80665D, 81256A

Guide

Ass'

Guide

Ass'

Guide

Axle

Cast off

Ass'

Cast-off

$J'ri~ft-

Description

Ass'

y

y

y

Ass'

y

y

13

ii~

Q'ty

*:fl-<

i-:M

:J(,df,{}:'jl.::r..

*;!J

,{}:'

*1/

*fl-<i-:M.

*;!J,{}:' 1

*1/

il\!H·-ro/

*

*

wl/J-f-

*ffl-f-A:t'!J:-,,Y

A

7"!)

*ffl-f*ffl-f-A!J-:1'

*ffl-f-;Jt$

*wl/J-f-A7!J1/Y

*

wl/J-f-

*ff-<F

A

1/

~-:Jt

_[fil

_[filJ!:;,(

1--

7"!)

1/ Y

-7

:lt-7

*1/

.t*~lffffl

*:fi-<i-:0-7-

*1/

A7!}1/~-

;f--1v

J:

*

wl/J

flri

P-7-

J:*J(~P-7J:*fflflri

$dJ

*1/

i:f-~1f::f-M.

it$?7'::\'-

*1/

*1/

*ff-<F

*1/

*:fi-<i-:o-'5-M.

*1/

A:1'!):-,,~·

;f--,i,

J:*J(ffi:z-7-$11J

*;!J

,{}:'i:z-7-

*1/

*

wl/J-f-

_[filJ!:;,(~':-,,

*ffl-f-A!J-:f

*ffl-f-

_[fil

*ffl-f-A:t'!J:-,,Y:Jt-7

*wffl-f-A7!J1/Y

*

wl/J-f-

;it$

*wffl-f-A:t'!J:-,,Y:Jt-7

wl/J-f-

;it$

jJ

*

7-

*1/

*fl-<i-:M.

r*J(~B

*1/

*ff-<F±il'

*ff-<F

*1/

*1/

11i~

Remarks

(2-4)

3

4

3

4

(2,4,6)

1

3

2

2

1

2

4

2

2

1

2

1

3

(20,

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

2

1

2

2

1

25-27)

(21-24)

(29-41)

(35-38)

(51-56)

03

NEEDLE

LEVER,

PULLEY

AND

CRANK

SHAFT

PARTS

?7~?~~71',

it-IV]~

34

!

31~~

I

36

I

I

I

I

I

37

I

I

I

I

I

r38

39

32

26

22

~

23

19~

21

I

~20

i

tt

24

18

~

10

9

2

1

12

14

03 NEEDEL LEVER, PULLEY AND CRANK SHAFT PARTS

~7~~V.Y71',

~:ffi:

Ref.No.

1 80621H Pulley

2

3

4

5

6 80694A

7 22539

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34 22565C Screw for 51134V

35

36

37

38

39

{f~Jb:ffi:%

Part

No.

80

80621A Pulley Hub

80674 Lock Washer

80685

HA81

HA95

80681

22891

HA66K

29782

80222 Main Shaft

80652

22587 Screw

80630D

80630

765011

80630C

29066L

80650

80656 Ball Stud

80636A Guide

22729 Screw for 80636A

80615 Needle Lever

BP108

80643 Needle Lever Shaft

81

95

HA54A

51134V

666-149 Oil Wick

91

80659

80617

HA56

815001

tt•OO-f*

Screw for 80621H

Crank

Shaft

Bearing

Plug Screw

Screw for 80685

Screw for 80685

Collar

Screw for 80681

Woodruff Key

Main

Shaft

Ass'

Bearing

Nut, right

Needle Lever Connecting Rod

Felt

Nut, left

Needle

Bearing

Screw for 29066L

Screw for 80643

Screw for 80643

Needle Bar Connecting Link

Pin

Screw for 51134V

Needle Bar Connection

Needle Bar

Clamp Nut

Needle

for

Crank

thread

thread

Lever

Fork

Ass'

y

(001975-250)

Bearing

y

Shaft

Bearing

Housing

Ass'

y

$J'ri~ft-

Description

ii~

Q'ty

7"-1)-

*1/

7"-1)-r,:f

7"-lJ-tf!l.:r:&~ 1

:±.fer:1

·.:,~

.i/\

'7

-y:..,?"

:tlij:lo/1/.:i~

@ii

-*1/

-*1/

3::lijjJ'7-

-*1/

=\'--

?"5:..,?~°"71--M

771/71/-Y7l-

.lf.[J•.:,t:""F

-*1/

To/l-

li

u

o/

F it~f.!jl. 1

~71il*1n

To/ Htc.:t

.!l.

[J

.ll.

[J

it•v

;f--1v:Jf-1F

•.:,

t:

..t

M

•.:,

i:

..t

/~-;f--1v

1/)

*1/

it•v/~-

*1/

it•v/~-'1b

*1/

*1/

it.1J1/7

7-1<-1:::..,

~71il*1n

*1/

*1/

it.*2=\'-

it.

it•To/l-

it

11i~

Remarks

1

4

1

(6)

1

1

1

1

1

1

2

1

(14,15)

1

1

(16)

1

4

1

1

1

(22-25)

1

(16)

1

1

1

1

1

1

1

1

1

1

(33)

2

2

1

1

1

1

1

1

15

04

PRESSER

¥Pxmif, ¥Px~~-1*

FOOT

LIFTER

AND

PRESSER

FOOT

PARTS

6

36

For

Container

~•t•fflC.>taJ

22

34

I

21)

Bog

24

19

14

22

7

I 2

! 21)

16

19

18

I

14

04 PRESSER FOOT LIFTER AND PRESSER FOOT PARTS

~.:i:fl,3/,

~~

Ref.No.

1

2 80664

3

4

5

6

7

8 482C Collar

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36 80220

37

®JI1~%

Part

80663

80667

64Y

35733B

80661

80660

98

80632

95

258

22870

80220A

80620E

22570

80220D

HA65L

782021A

782021

80220C

22570

HA65E

22525C Screw

907

910 Screw

11639H Screw

80631

376

80267

80649

420

80648

782011A

782011

80220B

~.:i:~~f*

No.

Presser

Presser

Pin

Screw

Lock Nut

Presser

Presser

Screw for 482C

Guide for

Screw for 80632

Nut

Screw

Presser

Presser

Screw for 80220A

Presser

Screw

Presser

Presser

Presser

Screw for 782021A

Screw

Nut

Guide Plate

Screw for 80631

Presser

Spring

Screw

Presser

Presser

Presser

Presser

Presser

Foot Spring, upper 1':r.f./i(/~-* (J:)

Foot

Spring, lower

Bar, right

Bar, left

Presser

Foot

Ass'

Foot

Shank

Foot

Bottom

Foot

Ass'

Foot

Bottom

Foot

Shank

Foot Lifter Hand Lever 1':r.ffi,1/ 1

Foot Lifter Lever

Foot

Ass'

Foot

Foot

Ass'

Foot

Bottom

Bar

y,

left

y,

right

y

y right

tf~Jb45~

Description

1'1fi/~-*

1::°1/

1'

.:i::.

wl/J

1'

.:i::.

wl/1

1':r.~

1':r.~

jJ=j-

Cf)

fn-* 1/

fn-r o/ "

(ti)

(tc)

-t-:J

1':r.~;j§:\'-

-t-:J

-:r

o/ "

1':r.ffi,1/

tlJl:r:~M

1':r.1i2J:

~o

C~)

(ti)

1/

-t-:J

1':r.1i2

-t-:J

Ml:r:~M

(ti)

1':r.~

1':r.~J:

(ti)

-t-:J

-t-:J

-t-:J

-:r

o/ "

-t-:J

1'

.:i::.

m

3/$11!-t-

:J

jj,,(

1-°fi

-t-:J

1':r.ffi,1/ v

/~-

;(.

1':r.ffi,1/ v /~-$lb

1':r.ffi,1/ v

tlJl:r:~M,

/~-

1':r.1i2

Ml:r:~M,(ti)

1':r.1i2

7

-11~

Q'ty

2

2

1

1

1

1

1

4

8

1

2

1

1

1

1

2

1

1

1

1

1

2

1

1

1

(1)

1

2

4

!}

1/

!f

1

1

1

(1)

(1)

(1)

(1)

-~

Remarks

(15-18)

(20-26)

(21-26, 35)

(21-25, 37)

17

05

LOOPER

iv-/~-oo~

DRIVE

PARTS

43~

441

41

40

42

28

~48

46

~

ep_

47

4

1h

3

2

7 8

~--------.

~

r~

26

I

25

22

'

)

,_______,__,

,

~

214

3J

~~

23

I ·-"'.

22

///

,/

~~

~ 1

,_

__

17

19

20

_,

'P

38

12

11

18

05 LOOPER DRIVE PARTS

iv--,1{--M~

~~

Ref.No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

$J'1=1~%

Part

No.

29442N

80236

88F Screw for 80236

80642

22894L

22894C

80636A

22515A

80645

80691

80638A

136

96

80640

80637

22517

80623

J79J

6039K

97A

HS36K

18

80641

269

80657A

97A

12538

AS26XA

73

G29479

15745B

80613A

15465F

88

12987A

1280

80639

482C

98

80680

80680A

80680B

94

85

318

80680C

AS38B

81

Eccentric

Connecting

Eccentric

Screw for 80642

Screw for 80642

Guide Fork

Screw for 80636A

Ball

Conical Nut

Drive Lever

Screw for 80638A

Screw for 80640

Looper Drive Lever Rocker Shaft

Drive Lever for Looper

Screw for 80637

Looper Thread Take-Up

Screw for 80623

Ball

Screw for 15442L, 6038K, 6039K

Washer

Nut

Connecting

Nut, left thread

Ball

Screw

Nut

Looper

Screw for

Looper

Looper Rocker Cone Stud

Looper Rocker

Rocker Cone

Screw for 15465F

Nut

Nut

Looper Drive Shaft

Collar

Screw for 482C

Looper

Looper Avoid Eccentric Fork

Guide Plate

Screw for 80680B

Screw

Screw for 80680

Oil Felt

Looper Avoid Eccentric

Screw for

Screw

Joint

Joint

Rocker

Fork

Ass'y

Bearing

Ass'y

Rod

Ass'y,

AS26XA

Ass'y

AS38B

right

left

Ass'y

ti:~£~~

Description

J1.,-,<-i:i•;,j,:ffl

)1.,-J

<-i:i•;,t.:'

*1/

;v-/-:-mj!JjJA

*1/

*1/

~

-

1v-Jf

-1F

*1/

1v-/-:-oo/F~-1v

To/I-iv-/-:-'81*1::\'-

*1/

*1/

Jv-/{-v/~-,m

;v-/-:-v/~-

*1/

r*xff-A

*1/

i"F-JL,~3,(~l--(ti)

*1/

!*4=

To/I--

1/34:1/J--Oo/F

To/I--

i"F-JL,~3,(~l--(li::)

*1/

To/I-iv-/-:-

*1/

J1.,-,<-~*-!l.

Jv-/-:-mj/]'91

iv-/-:-..g-

P3

..

jJ7-

*1/

To/I-To/I--

1v-/-:-'S/-y7J--

jJ7-

*1/

~*-!!.

~

~ti

*1/

*1/

*1/

~71E~

;v-/-:--f¥!J'S/:iJA

*1/

ii~

Q'ty

1

1

4

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

2

1

2

1

1

1

2

1

1

2

1

1

1

1

2

1

1

1

1

2

1

1

2

2

1

1

1

1

1

*°~

Remarks

(2,

4-9)

(3)

(20,

21)

(27)

(31-35)

(41-45)

19

06

FEED

~11~-f*

LIFT

AND

FEED

DRIVING

PARTS

For

Container

~ML

,

me

Bogs

.1,trJ

26

25

15

~

tp

14

20

06 FEED LIFT AND FEED DRIVING PARTS

J!!J00-1*

~*

Ref.No.

1 29099V

2

3 22587 Screw

4 HS15A Feed Rocker Eccentric

5

6 80654

7 80696

8 HA20A Washer

9 HA18A Nut

10 80233 Feed Rocker

11

12

13

14 482C Collar

15

16

17 80234B Feed Bar

18

19 HA23 Feed Bar Shoe

20 93A Screw for HA23,

21

22 HA43X Feed Lift Eccentric

23 22894D Screw for HA43X

24 80225 Needle Guard

25 AS70A Holder for Felt

26 HS70A Oil Felt

27

28 20 Washer

29 18 Nut

30 784021

31

32

33

34 22526 Screw for 784011

35

36 80205 Throat Plate

37 A7008A Throat Plate

38 A7009A

'l'f~Jbffi:%

Part

No.

Feed Drive Eccentric Ass'y

80651

81

T26 Screw

8A Feed Rocker Shaft

89 Screw for 80233

98 Screw for 482C

11

88

HAlO Feed Bar Prong

765032

93 Screw for 784021

97X Screw

784011 Throat Plate

80224

Feed Rocker Eccentric Connection

Screw for HS15A

Bushing

Stitch Regulating Stud

Feed Bar Shaft

Screw for 80234B

Oil Felt

Feed Dog

Feed Dog

Feed Dog

HAl0,

80225

'l'f~J'riq5ft

Description

i!•JCJ·.:,~M,

i!•JCJ·.:,~

*1/

*!}

.:r.,t-~.:..,-.iJ

A

*1/

*!Jfflffli$11JA!J-:1'

*!Jw.JW!lilll

~1i'z

7"o/

I-

*!J5c±il'

*1/

*!J 5c±il':-r-t71-

*1/

jJ=j-

*1/

*!l±in:·.:..,*!J±il'

*1/

*!J±il'~til:

*1/

*!l±il'~tir

*!Jl:r.iJA

*1/

itff-r

*~iltl

*1il

:x

.:r.

*~iltl*1il

*~iltl*1il

~1i'z

7"o/l-

*!J1i'z

*1/

*1/

it*&

*1/

it*&

*!J1i'z

it*&

*!J1i'z

ii~

Q'ty

1

1

2

1

1

1

1

1

1

1

2

1

2

2

4

1

1

2

1

4

1

1

1

1

1

1

1

1

1

1

1

1

1

2

(1)

(1)

(1)

(1)

;Jfflj~

Remarks

(2,4,6)

(3)

21

PART

NO.

PAGE

NUMERICAL INDEX OF PARTS

.r~

---

PART

NO.

o/ *

PAGE

PART

51

NO.

PAGE

PART

NO.

PAGE

8A

HAlO

11

HS15A

HA23

AS24A

AS26XA

AS38B

HA43X

HS

52B

HS53B

HA54A

HA56

HA58C

HA58D

HA58F

64Y

HA66K

AS70A

HS70A

HSl00D

HA102A

HA103B

HS106

107

21-12

21-21

21-16

21-4

21-19

11-46

19-28

19-47

21-22

13-34

13-20

15-31

15-28

13-44

13-47

13-45

17-4

15-12

21-25

21-26

13-41

13-54

13-6

13-14

13-9

21111

216818

29066L

29099V

29442N

G29479

29774D

29782

35733B

51134V

80046

80205

80220

80220A

80220B

80220C

80220D

80222

80224

80225

80233

80234B

80236

80239C

80239D

13-48

11-44

15-21

21-1

19-1

19-30

13-28

15-13

17-5

15-32

15-20

21-36

17-36

17-14

17-37

17-21

17-17

15-14

21-35

21-24

21-10

21-17

19-2

11-41

11-42

80621H

80623

80630

80631

80632

80637

80636A

80638A

80639

80640

80640D

80641

80642

80643

80644

80645

80648

80649

80650

80651

80652

80653

80653A

80654

80655

15-1

19-17

15-18

17-28

17-10

19-15

15-24, 19-7

19-11

19-37

19-14

11-39

19-23

19-4

15-28

11-23

19-9

17-33

17-31

15-22

21-2

15-15

13-53

13-50

21-6

13-31

80681

80685

80688

80689A

80690A

80694

80694A

80696

80887A

81086C

81086G

81093

81239

81256

81256A

765011

765032

782011

78201

lA

782021

782021A

784011

784021

785011

78501

lA

15-10

15-5

11-20

11-25

11-33

11-37

15-7

21-7

11-31

13-37, 14-12

13-24

13-39

11-4

13-3

13-1

15-19

21-27

17-35

17-34

17-20

17-19

21-33

21-30

11-12

11-11

108

110-2 13-10

110-4 13-15

Glll

AS137

AS137A

420

482C

666-79 11-13

HA1286B

HA1348

HA1349

6039K

A7008A

A7009A

11639H

12964C

15465F

15745B

13-8

13-17

13-2

13-5

17-32

17-8, 19-38

21-14

13-22, 13-36

13-13

13-11

19-19

21-37

21-38

17-27

13-23, 13-37

19-33

19-31

80246

80262

80262A

80267

80273

80273A

80280A

80284

80291

80292

80293A

80437A

80438

80440

80604

80613A

80615

80617

80620E

80621A

11-21

11-28

11-30

17-30

11-27

11-29

11-43

11-35

11-15

11-40

11-17

11-2

11-5

11-6

13-51

19-32

15-26

15-37

17-15

15-3

80656

80657A

80659

80660

80661

80663

80664

80665

80665D

80667

80668

80669

80673C

80674

80676

80676A

80680

80680A

80680B

80680C

15-23

19-25

13-29, 15-36

17-7

17-6

17-1

17-2

13-26

13-19

13-16, 17-3

13-25

13-42

11-26

15-4

13-43

13-12

19-40

19-41

19-42

19-46

785021A

785041

78-80201 11-45

11-1

11-8

22

NUMERICAL INDEX OF PARTS

/~--o/*51

PART NO. PAGE

SCREW

AS22D

T26

28C

HA65E

HA65L

73

J79J

80

81

HA81

85

88

88

88F

89

(*--y)

13-52

21-11

13-4

17-23

17-18

19-29

19-18

15-2

15-29,19-48

21-5

15-8

19-44

11-24, 13-27

13-40,13-49

19-34,21-18

19-3

11-3 ,11-22

21-13

PART NO. PAGE PART NO. PAGE

NUT

22539F

22560

22560B

22562

22565C

22570

22574

22587

22729

22743

22839C

22870

22891

22894C

22894D

22894L

11-34

13-21,13-35

13-7

11-14

15-34

17-16, 17-22

11-7

15-17,21-3

15-25

13-33,13-55

13-50

17-13

15-11

19-6

21-23

19-5 WASHER('J '.!I-Y-'7-)

18

HA18A

258

269

907

1280

12538

12987A

80630C

80630D

80691

20

HA20A

HS36K

(-j-•.:.,t-)

19-22,21-29

21-9

17-12

19-24

17-25

19-36

19-27

19-35

15-20

15-17

19-10

21-28

21-8

19-21

PART NO. PAGE

91

910

93

93A

94

95

95

HA95

96

96A

97A

97X

98

BP108

136

318

376

22513

22514

22515A

22517

22525C

22526

22539

13-31,15-35

17-26

21-31

21-20

11-36,19-43

11-18,13-18

15-30,

17-11

15-9

19-13

11-19

19-20,19-26

21-32

17-9,

19-39

21-15

13-30, 15-27

19-12

19-45

11-32, 17-29

11-16

11-9

19-8

19-16

17-24

21-34

11-38,15-7

15/64W20101

OTHER(-f

B15001

O)ftg)

11-10

15-39

23

DR-3A

T26

88

88

95

95

136

136

28C

88F

88F

HA95

HA95

376

376

ij

HA65E

i)

89

i

96

22513

22513

ij

HA65L

91

91

I

96A

22514

225

14

73

80

J79J

J79J

80

81

81

91D

i

910

97A

97A

22515A

22515A

93

93

97X

97X

22517

22517

93A

98

98

;

22525C

85

318

22539

22539F

22560

22891

22729

HA18A

HA18A

80691

80691

22743

258

258

22891

269

269

22560B

ii

22894C

907

907

20

20

22562

I

22565C

22570

22570

22587

22894L

228940

22894D

1280

1280

HA20A

22894L

12987A

12987A

HS36K

@

12538

15/64W20101

22870

80630C

24

Loading...

Loading...