NEWLONG INDUSTRIAL CO., LTD.

ml----

SEWING

MACHINE

HEAD

MODEL

=~O=O®

=~[LO=O@

=~W

For Operator Safety

T ha nk you f or p u rch asing the NLI

Model DN- HS Bag Sewing Machine Head.

( ) DN- HS

• This

manual

using

sure

to

use the

•

Keep

reference.

when

company.

•

Plea.,e

is lost.

• The contents of

without prior notice

~Hazard

•

Be

careful,

the

the

2

contains the instructions

the

Model

DN-2HS

read

and

understand thls

machine

this

lending or transfe.ning

order this

sewing

machine

111BJ1Ual

Be

SUI'e

of

when

machine,

between

corTectly.

near the

manual.

this manual

Being

Bag

to

attach this

from

for

improvement

Caught in the

you

insert a

or your

the

e.nd

Sewing

Machine

manual

sewing

manual

it

to

the nearest

are

subject to change

bag

fingers

presser foot and

before

machine

to the

another person or

and safety

Ma~hine

to be closed into

may

precautions

Head,

use

for

easy

machine

NLI

office

pUJl)ose.

--

be

caught in

feed

dog.

and

if it

for

Be

::=.

.:2- - a

f:'~Jl:1,\J:fj\,\~t.:i!";ff

•

=.,(f)

:,;

ltitfJltlfJ.l.l'i DN-2HS ~--}J.l~y:,;(f))li.1,

~tMJ:(f)tt;l:•Jl~~te.e~n

;::'~ffl nrm:.:(f)JlillHl

t-+~L:(IEt.,<~U<~~i.,

•

=-(f)

llilamfJ.I

...

1to.t;,

DN-2HS

l'i.:(!)Jljdi~.fjfif~-·;::~t,.

•

,:(f))lii\ilfJ.l·~~~tl,ft.iN"!::..2-P1/!/I.

Cf*>½mli!H&;Jn:;::-t±:1e<te~1,

•

;::(f)

l;::~J! 1"

• ~~1/l=tll~li*A

f*1ft.,-c<-n:~1t\,

UtQffl~V1/dlAfit.,,

llilt&llfJ.I

?>~J::~~ibt>-:ti'

&-~~-------

l=ffi;r)~-~i6*M:lo-{:t1,;r){§.>'J'*i'

!II•

• 2

fJ.1-~~-

ill1MM(f)-t

•11••

!Pl

TQlltn-;1:,

fflUffl

~.?

~~1,Y~To

-c1,

'*To

i":tdll"-<

J:f

R:,

,.,

'o

,~

~~._,

~~IJ.m

"£ft•:tMS!1JJ.l.g.

-C(f.:~1,

,0

'o

J: 3;ftl-J::R½(f)ftll),

o

tt•L.ll\.'btH>#.:r.*

o

~

v:,;

,-Ji

'o

~#

1r

,fte

-1"$-f,I!

l.-

• A· Hazardous"

sewing,

£Hazard

• A

Needle

at high speed. A" Hazardeus"

machine.

e.nd

yourself

Thread Take-Up.

mark

is attached to the

be

sure not to touch

of

Being

Bar and

When

the

away

Needle

machine

from

Cauiht

machine.

on

the

machine.

in

the

Machine

Thread Take-Up are

mark

is attached to the

is operation, keep

the

Needle

Bar

and

When

---..

movmg

fingers

Needle

£-~~-------

•

Bt*-~J:.*3cfff'iilTUili"t'I/J'-'

~Y-1/l=l-;t~tt-~-?~M-:>

~Y1/tSJ!h1,

~"'1ltfJ!1,

,-c1,

'o!:~t.t,

'°t'<~~l,

'-C'-'

''*To

-c11

'*T.

ftf41.!::J:-*3c~l=ffi~f*

\0

&

-~'1:

WARNING

• The instruction manual and parts list is subject to change without prior notice.

• ~(f)Jlill\ftfJ.1./ ,'~-o/!JAH:tift1PJJ:(!)7't~7ifflUqJfJ!TQ~tt,Si)tJ3;T

0

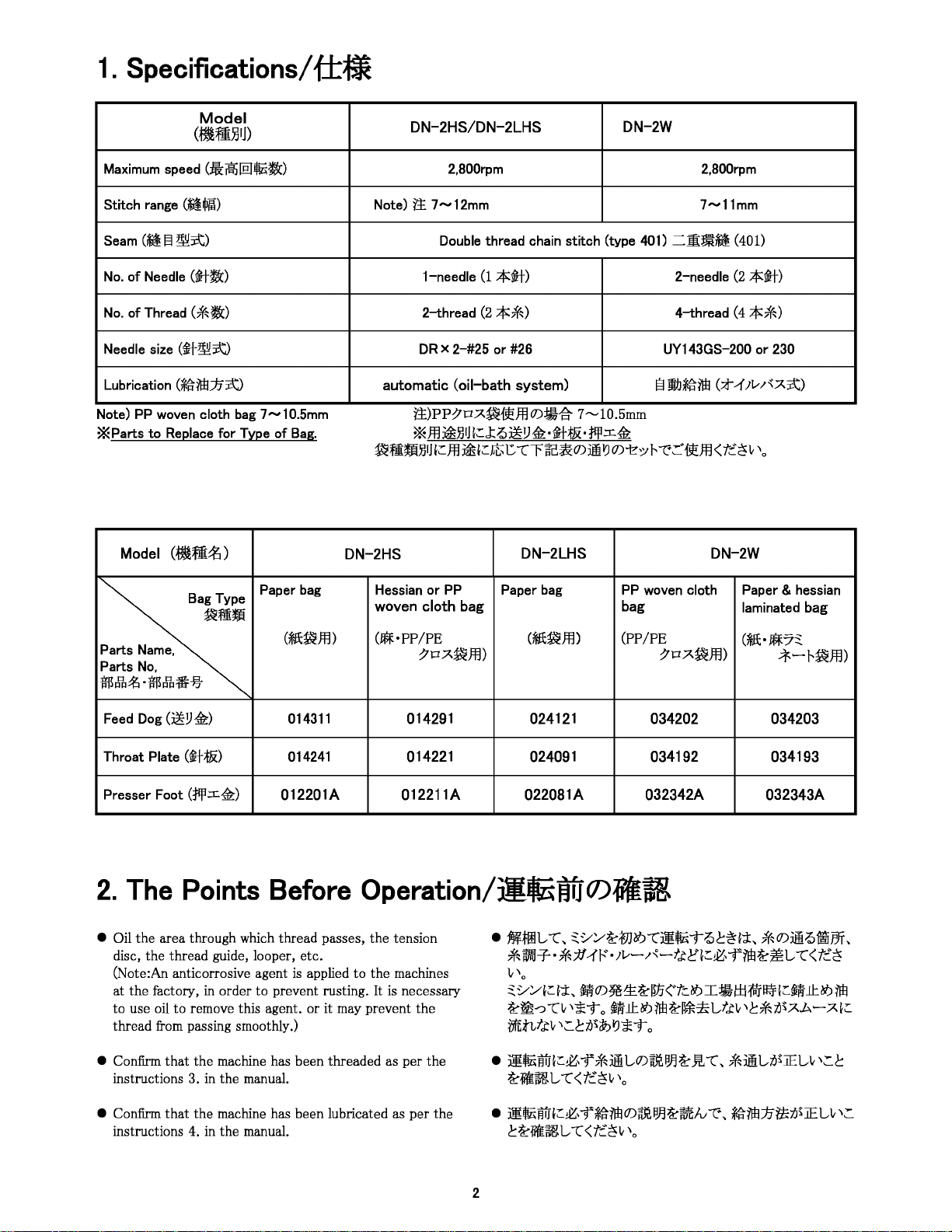

WARNING

PERSONAL

RESULT

SAFETY

NOT

OBSERVED.

1.

BE

SURE

THE

FREE

OF

ALL

OIL,

RUBBISH

INJURY.

2.

DO

NOT

OPERATE

OR

UNDER

THE

MACHINE

NOR

WATER-PROOF

3.

DO

NOT

OPERATE

INSTRUCTION

4.

DO

NOT

OPERATE

THAN

SPECIFIED

INJURY

IF

THE

PRECAUTIONS

AREA

SURROUNDING

HAZARDS

OR

WET

CONDITIONS.

IS

MANUAL.

SUCH

AS

ANYTHING

MACHINE

NOT

TYPE.

MACHINE

MACHINE

FOR

THAT

IN

AN

EXPLOSION-PROOF

BEFORE

ON

THE

MACHINE.

MAY

FOLLOWING

ARE

MACHINE

FIRE,

CAN

AN

EXPLOSIVE

READING

VOLTAGES

IS

WATER,

CAUSE

AREA

TYPE

OTHER

•

1.

UIUJ&O)Jilull::~i!&~®;:.-tmi~c!::t.J:~!k~,

:m,

iiJ~~t.J:c!::ti<t.J:1,

2.

ffl~O)~l!iO)

Ji±Ji"t:(;t{lffl

~"

R1Jiifli~

"t:(;tif.,

3.

:irx1&:ma_ijiJ:~~,-r~1v-r:ti,.;m**~ii:~~

I,

\0

,ti,m:ti,~-c<t-=~1,

if.>~Jl:tl

~f.J:I,

•

7J<iif!iti<@:till**l::tJ,tJ,~

\"(:(f,::~1,

LJ

*it

/v 0

\0

.::O)l!~(;t,

71<,

,0

Rn•

-c<t=~

5.

BE

SURE

MACHINE

ELECTRICAL

6.

BE

SURE

POWER

BEFORE

PARTS

7.

DO

COVERS

8.

DO

AND

OPERATION.

9.

BE

(LEVEL)

MAINTENANCE,

ADJUSTMENTS,

10.

BE

COMPLIES

11.

DO

"

PERFORMING

REPLACEMENT,

NOT

OPERATE

REMOVED.

NOT

TOUCH

MOVING

SURE

MACHINE

SURFACE

SURE

THE

WITH

NOT

USE

NLI"

GENUINE

IS

CONNECTED

SAFETY

PARTS

SPARE

GROUND

(AND

AIR

MACHINE

ADJUSTMENTS

MACHINE

KNIFE,

PARTS

CLEANING

MATERIAL

THE

NEEDLE,

WHEN

MACHINE

IS

PLACED

WHEN

PERFORMING

REPLACEMENT,

OR

TO

MACHINE

PARTS

PARTS.

TO

BUILDING

(EARTH).

SUPPLY)

WITH

BE

SPECIFICATIONS.

OTHER

IS

OFF

MAINTENANCE,

OR

CLEANING.

GUARDS

PULLEY,

ON A SMOOTH

STORAGE.

SEWN

AND

IS

IN

OR

CLOSED

THAN

BELT

6.

l!~O)giiffi·!B~:3ttt·ruUl·:Rl;tffl~O)fiil::~"(

ffi5Jffi(&'CtI7-ID~ijJ-::,"((f.::~l,\0

1.

ii~:n,

t.::~1,\0

8.

•**O)~~g:i(;t:n•.:.,11-,

fil!ilJ1,

9.

l!*'O)~iiffi· !B~:3tti· fflffl~-ffl~~ii~O)t:2"1::

1;t.!jli:,t.J:~r1r1::11:1,

10.

*li!S?t:"9

~t<t.::~1,\0

11.

"=-.:i..-CJ~~I:¥(*)"tal!:iE$~~*(;t{lffl~f.J:I,'

-r:<t.::~1,\0

{-ti<*nt.::~tm-r:r;t•*'~~~~t.J:I,

7'-

,0

1

)-,

~JL,l---fO)

,-r:<t.::~1,

,~ti,m:ti,

it,

,-c1,

,~mr1r1::r;t-¥~Mnt.J:1,

,-c<t-=~1,

~**1ti<l!**O)i±~(::'8"-::,-CI,

,-r:<

,0

Identifying and Ordering Parts

Cautions When Using the Machine

Maintenance

Where the construction permits, each part

all

with its part number. On

number, part name

Safety Rules

To prevent personal injury:

All

power sources to the machine must be turned off

•

before threading, oiling, adjusting or replacing parts.

All

cover and guards must be

•

machine.

Do

not tamper with safety cover, guards, etc.,

•

machine

is

and

in

operation.

orders, please include part

model name

in

position before operating

of

machine.

is

stamped

Safety Precautions

1)

Always

2)

Wear safety glasses.

turn power off before threading, oiling, and

adjusting the machine or replacing parts.

while

•

::=.:i

-

P::.,,

tf~J'b:a:-~@L,

•

:."tl:.JtO)~f';:l:,

::1'I~ ( *-*)

-C:}31'.Jj;To

~IILi!llJ~·ffl

/{-o/!};7.j-0)/{-o/:ffi:%,J::~fA;-C:."ffi;if-

<t-c.~lt'o

•

-fse:J=i=LJ:::'.::'~l=!Jclft,i/t&V-fse:Jtl

ftl!tlf-Omft,J::·-ctgfl'.)

tc.::=.:i

-

P:'./

~O)~,

~fl~,

:_"ffi;if-<t-c.~v

1)

~ti!fj;l'.J · *·WH1,0),l::~O)*;imt.,,

tf~J'b3'.tffi:,

v

'o

2)

Wlff

llf

f!o~O)

1;:<1t

::1'I~(*-*)~00i!U!m

~~:ffi:%, ~1/:'./)mtf~~'

,j;-t

J::5:t3!HJiv

{;~'tj',~~fp~O)JVJl;:~,-r~~:a:--WJ0t<t-c.~

,i::~

l'i~~,,i

g=rO)it(ll'f~~i:ft,~, ~ 0)

,tiJ..g-f';:l:,

:JJ'*

:t3Jh ,J::fflt

'v

,t;:.t.,j;-t"

*0)3'.tffi,,

0)-fse:ffl

/;:

l'i

D

N-2HS

1::."~~<

o

:a:-:t3-t"-t"

0)*4iJ:E

,t;:.t-c.~j;l.,

tt~

v

'o

r,!iJ

~1/:'./:ffi:%:a:-

~$,

Wl/ltlf,

ilO

t.,

j;-t" o

3)

Make sure, before starting the machine, that

in

and shields are

4)

Do

not touch on the machine when it is run.

5)

Turn power off and make sure the cutter does not

operate before you put your fingers under the cutter

blades and the needles

6)

Do

not touch on the machine when it is run.

place and closed.

to

adjust.

all

covers

• Please keep

to

maintain the machine

• Thread fuzz or dust must be cleaned with air or brush on

throat plate,

after the day's work.

• Wipe the area easy

• Check the machine

any, once a month.

Good

•

in

mind

in

the groove of feed dog or around looper

maintenance

to handle the machine carefully and

in

good condition.

to

rust with

for

loose screws and tighten them, if

will

oil

prolong

cloth.

the

machine

life.

3)

~tO)if

4)

.fJ/~-tt,1::·ntr,,Jj;0tv'Q::.,1:::a:-~~1., tn•G~!lizit.,

· .fJ/~-l'i~,i"~!l\ziMl:MilOt<t-c.~v'o

t<

tc~v'o

5)

iJ-O)rf:,¥:a:-Jd1,Q,l::~f';:l:,

{~;f:!Wl/lllfO),J::~f';:l:,

:a:-~~t.,

tn•Gft~:a:-ff0t<tc~v'o

~,-rm~:a:--WJl'.l~1/:'./i1!m/Ji3>ftv

~,-rm~:a:--WJ0t<tc~lt'o

,::_,i::

• ~1/:'./.li"l$l'i~~ft,J,~ft$J'1=1n•Gl±l*J::n!0t1t'j;To

ti:~~<

•

-~

q:r,

J&:¥&5

,i::,i::t

1: m-1:mvm

O)ft~n!~Tt.,j;L,fc.G,

1:,r,,m+t-c

if-fJiO)J::,

<tc~v

,0

~!J~O)f$\:O)

;v-r~-O)j;:bl'.Jl;:~j:0fdi::.1'.l~l'i~n1t'f:1&1'.l

~v't<tc~v'o

•

-¥

AnO)

~ UIIU'i~~O)~ifuf;:~9t.,j;-t"O)-C:."r.t~

<tc~v'o

ii

CONTENTS/

~

{X

1.Specifications/

{±~

2.The Points Before

3.Threading/

*iffiL,~

4.Lubrication /~tlE

5.Aqjustment/ji}Wf

1 Looper (1v~/~~O)IDl3~)

1-1 Check of Looper Travel Distance

1-2

Check of Dimension of Needle

(it~il~t:J,1,,~,,~~0);'cft#.l'i--c:O),frt)

1-3

Check of Height of Needle and Looper (if-0)

1-4

Clearance between Needle and Looper

2 Feed Mechanism

2-1 Positioning of Feed

2-2

Needle Guide and Loop Retainer

2-3

Feed

Dog

a) Adjustment

b)

Adjustment

c) Height Adjustment

----------------------2

Operation/~~OOO)im~

----------------------3

--------------------4

-------------------5

.............................................................................

(;v~,,~~O)~l/Jii)

Center

(*~

~f*O)IDl3~)

Lift

Eccentric Cam

(*!J~O)wl3~)

in

Crosswise Direction

in

Longitudinal Direction

.......................................................................

(J: r O)wl3~)

...............................................................

(jtjJ,1F,&rJ;i,~:fjJ,1j..:'O)~~)

(tc.~O)wl3~)

............................................................

-------------2

..................................

to

Looper Point

...................................................

rWJ

~)

..

..

..

..

..

..

..

..

..

..

..

..

..

..

(jtc!::;v~/~~O)~j~,~~)

(*!J

J:

r:b

.b.O){ftfft:f;R:66)

........................................

(trHfO)~~)

.....................................

...................

...................

................

5

5

6

..

..

..

..

..

.. 6

7

8

8

8

9

9

9

9

2-4

Change of Stitch Spacing

3

Presser

3-1 Positioning of

3-2

4 Needle Setting

5.

Throat Plate

6 Adjustment for Single Thread Sewing

6-1 Distance between Looper and Needle (if-c!::;v~/~~O)]Eg/U)

6-2

6-3

6-4

Foot

(1'.::r:~O)~~)

Presser

Pressure

Check Height of Needle Bar (if-.O)rWJ~)

Fixing

Check of Looper Travel Distance

Adjustment of

(if-O)!&{tlt:n)

(jtf)ltO)~~)

Throat Plate Thread Retainer (if-f)ltJRO)!&{tlt)

(*-i

§

~jO)~J!)

..................................................

.......................................................................

Bar Connection

Presser

..........................................................................

Foot Ass'y (1'.::r:~O) fEjJIDl3~)

.....................................................................

(1'.::r:.?7'':\=-0){ftffi:f;R:66)

(1*iffl*-i1t

(;i,~,,~~O)~l/Jii)

,O)~~)

..................................................

6.Troubleshooting/:3:"1/~0)1'7~;vO)J)j{~c!::::M;r&

Parts

Numerical index of

List

List/$

of

£;fl!t.

Screw, Nut &

....................................................................................

Parts/r~--o/*51

Washer/*:/

........................................................

...

To/

1'

...

......................................

..........................

..................................

..................................

---------14,

17o/"1/1"---~~

......................

....................

................. 36

10

11

11

11

12

12

13

13

13

13

13

1734,

..

15

35

37

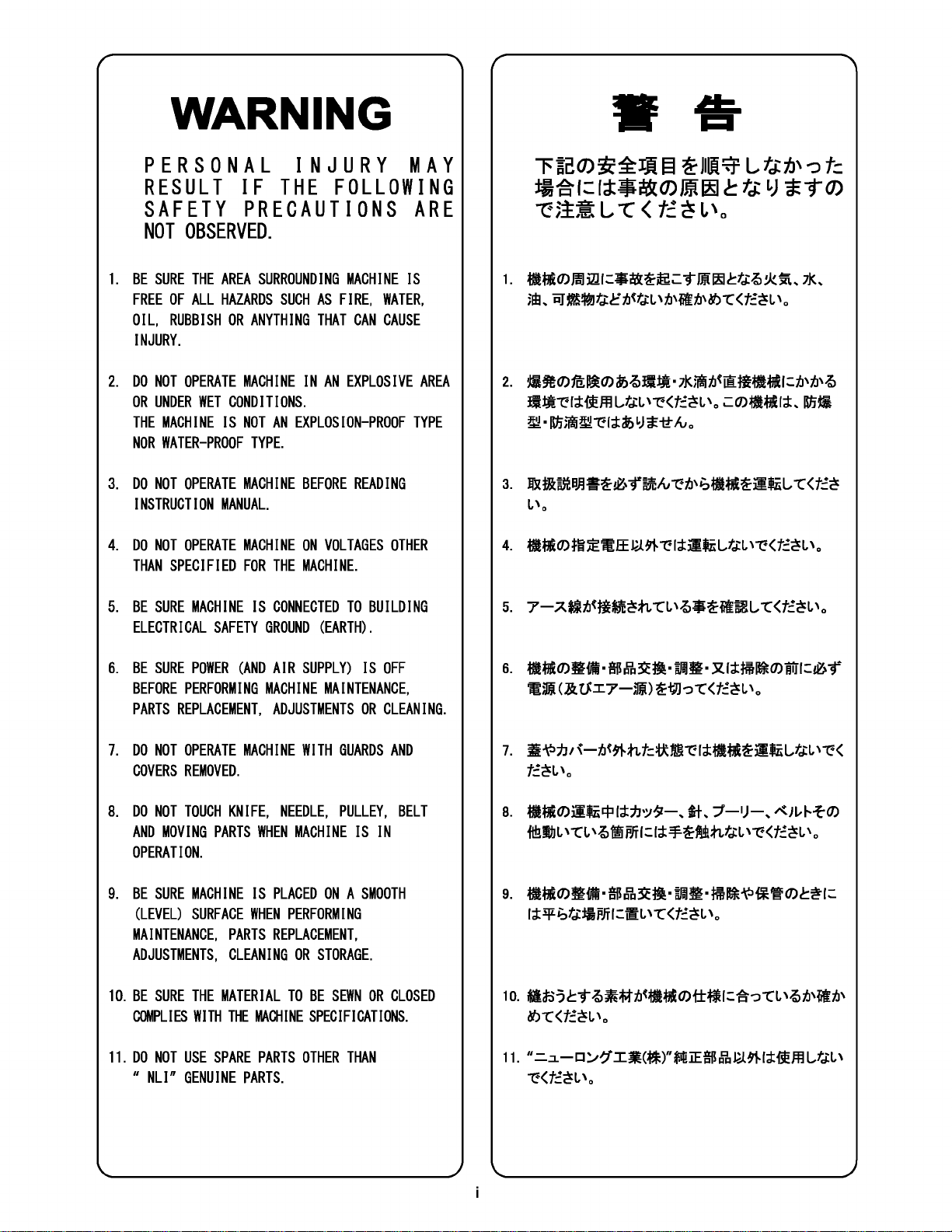

1.

Specifications/ ftm

Maximum

Stitch

range

Seam

(~

No.

of

Needle

No.

of

Thread(*~)

Needle

Lubrication

PP

Note)

:>!<:Parts

to

Model

speed

(~~i)

§

ru:i:t)

(it~)

size

(iJ-ru:rt)

C*irlliliJ:rt)

woven

Replace

(~fjq5)

Model

(~fl.81J)

(:i'ii@i@J~~)

cloth

bag 7 ......

for

Type

10.5mm

of

Bag.

DN-2HS/DN-2LHS

2,B00rpm 2,B00rpm

Note)

r_l

7.....,12mm

Double

1-needle ( 1

2-thread (2

DR

X 2-#25

automatic (oil-bath system)

r_l)PP::7PA~~ffl

*ffl~JJIH~J:7.JJ!!J~·itti ·tifl.:r.~

~fiirnu

,~m

~f~r,ti:::,--cflc*O)im

DN-2HS

thread

Jl;;:ij-)

**)

or

#26

DN-2W

chain

stitch (type 401) =m~~ (401)

UYl 43GS-200

§

O)~~

7

~

10.5mm

¥)

O)~o/

r--c::=

DN-2LHS

7

......

2-needle (2

4-thread (4

ib*irllil

(;:t,{;J.,/'{.A;i:t)

~ffl

<

DN-2W

llmm

Jl;;:ij-)

**)

or

tc.2!:v

'o

230

Paper

Bag

Type

bag

~flt~

Parts

Name,

Parts

No,

lflh1i~ ·

2.

• Oil the area through which thread passes, the tension

'lflh1i:#%

Feed

Dog

(J!!J~)

Throat Plate (ij-t\()

Presser

Foot

(tifl.:r.~)

The Points Before

disc, the thread guide, looper, etc.

(Note:An anticorrosive agent

in

at the factory,

to

use

oil

to remove this agent. or it

from

thread

order

passing smoothly.)

C*J£~ffl)

014311

014241

012201A

is

applied

to

prevent rusting. It

Hessian

woven cloth bag

(tllf•PP/PE

or

::7PA~ffl)

014291 024121

014221 024091

012211A 022081A

Operation/~~jWO)i{I~

to

the machines

is

necessary

may

prevent the

PP

Paper

(~~ffl)

•

fWffllt.,

ff.:

wlil--r

V

\o

~v:,,,f~IJ:,

~~--::i--Cv

mE:t1J

bag

PP

woven

bag

(PP/PE

cloth

Paper &

laminated

(~.1£-tllf7~

::7PA~ffl)

034202 034203

034192 034193

032342A 032343A

·c

~v:,,,~W~-tx-Cil~T7.Jb~IJ:,

•

:ff.::Jf-1F·

1v-/~-f.cc:'l~!.16,f'lm~~1.,

:ff.:O)im7.JliiBi\

~O)§e1'_~1i.15¢'tc~I~/±lfi/fl!ifl~~Jr.~lli!

'~To

.c v \:

~lr.~lm~~~l.,f.cv

.

.1:'.

t,,

ih

¥J

~To

,.1:::ff.:iJ,AA-AI~

hessian

bag

-*-r~ffl)

--c<tc.2!:

ililiilfiH~!-16,f'*iml.,O)m~~J!--C,

• Confirm that the machine has been threaded as per the

3.

in

4.

in

the manual.

the manual.

instructions

• Confirm that the machine has been lubricated as per the

instructions

•

•

2

~lit~L-

ii~

.1:'.~1i'{l[~l.,

--c<tt.2!:v\

1W

f

~!-16,

f'~llil

0)

t<tc.2!:v'a

m

~

~w'Vv

:ff.:imL,iJ,JEU\: . ./:'.

--C,

*irllil

::1J7't?

t,,

lE U ,_:_

3.

Threading

/ -*ii L,

I DN-2HS

I

DN-2W

L.ooger

CF

,Y,

) .

Nt1eoleToiea~

Ll;,¼)

21

ihr~~

I DN-2LHS I

ll

4. Lubrication/**

All

oil

has been

shipment.

Fill

oil

in

removed

reservoir betbre starting

from

your

7EB

machine

machine.

betbre

DN-2HS

tJti.,

.ffJ~MIH'ltl!fflL,

,..,.,~~,:::ttNIL-

~ffl~v~-tt

'7't:lil!ll~l±l-.rL-

-ci..

-Ct/lb:i!15'L-

e lbMNl~~v1/'t"-ttJt,

-c1,

'"~-to

t}Jbl.>-CMGtt-?>~~,

,t,c1,

'~v1/dl1-t-?>t!J'1,

-c<~~i.,

'o

NI~

*1t

~--r*-<

•

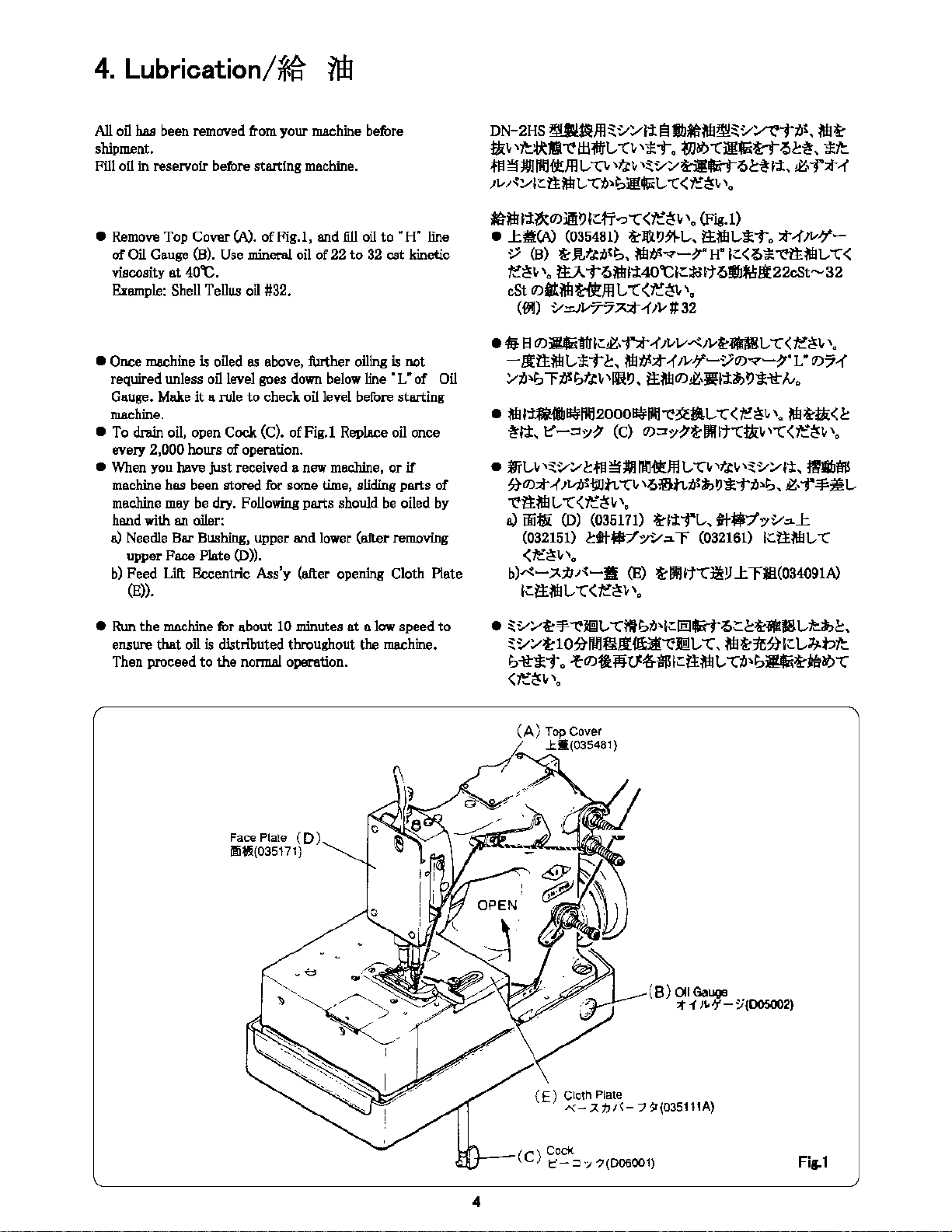

Remove

of

viscosity at

Example:

• Once

required unless

Gauge.

machine.

•

To

every 2,000 hours

•

When

machine

machine

hand

a)

b)

• Run the

en.sure

Then proceed

Top

Cover

(A).

Oil

Gauge

(B).

Use

mineral

40°C.

Shell

Tellu.s

oil

ma.chine

drain oil, open Cock (C). of Fig.I

you

with

Needle

upper Face Plate (D)).

Feed Llft Bccentric A$s'y (after

(E)).

is

oiled

as

oil

level

Make

it a role to check

of

operation.

have just received a

has

been

stored

may

be

dry.

Following

an oiler:

Bar

Bushing,

machine

that

oil

is distributed throughout the

to

upper and

tbr about

the

normal

of Fig.I, and fill

oil

of

22

#32.

above, further

goes

down

below

oil

level before starting

Replace

new

machine,

for

some

time,

parts should

lower

opening

10

minutes at a

operation.

oil

to

32

oiling

line • L"

sliding

(after

low

to

"H"

line

est kinetic

is not

of

oil

once

or

if

parts of

be

oiled

by

removing

Cloth Plate

speed

machine.

Oil

to

~NIJ-J:~O)Jffit)l.'.:.fi-?"(<~~1,\o

•

..1:itiW

V (B) t-JUttJlb,

~~\,

cSt O)a!N!~ffll,

(011)

•

4iJ

-lfttNIL-*"t~,

1/ti~;

(035481)

~J&t)~t.,,

Nlt/S"'7-~·

,.,

ft.A-t-?>Nlli40"Cl::::folt-?>lb~.!t22cSt-32

-C<l!~1,

v.:i:1v?°5~-1',v#32

a

O)•tt11:::~,ff-1'1vv~,1,,~-t.,

Nltl~*-1'1vJ/-V0)"'7-~·1•0)7-{

""FtJSbf.;!1,\lfit),

i:tN!O)~,

• Nll~~lll'l2000~111'1~3f-l,

~ft,

•

ffit.,i.,

~O),t-,<

t"-:3:Y~

'~v~

,~tWn

~.ffJ

(C)

O)::ro/~f:DIHt-CtJli.,

~M

111:l~ffl

-ci..

'-?>!inti~"t)*-tti~;, ~-i"-¥:~t.,

(Fig.l)

i:tNIL-j;-t.,

H"

l:::<-?>*~ttNIL-

'.

••

';t,,t)j;-tt/v.,

-c<,e~1,

t.,

-ci.,

,tl\t

*-<ivl/-

-c<~~1,,"

,.,

Nl~ta:<t

'"'C<~~i,

,~v::.,fi,

-C<

,,,

tllba!S

~ltNIL--C<~~1,,o

a)

iiiffi:

(D)

{035171)

co321so

(7'!~1,,0

~tttitl7':,,v.:i r

b)~-~1J.1{-11

l;:i:tN!L-

-c<~~1, , ..

~1'1i"L-,

CE>

t-lll•t-c~!J

tt•-f

o/V.::L..I:

co321so

l:::ttNIL-

J:

ra<os4091A)

-c

• ~v::.,~-¥~Jl!ll, -cmb1N;:leJl1-t-?>~t~ifKIIL,~,,t,

~v::.,f:lO~fll:l§fffU"(iJml,

h~*-t"

~O)•

flivt45-itm:1tN1

-C,

Nlt-~~l:::L--'J.btt

L-

-cti~b-~teab

-c

<~~\,'o

( E) Cloth Plate

,..._-~t,1<-""J

0

(C)

~

~:::i-;;?(006001)

4

1'(035111A)

Fig.1

5.

Aqjustment/f,il

!I!!!:

Your machine has been properly adjusted before shipment

at

our plant.

end due

obsruve instructions given below.

1 LOOPER

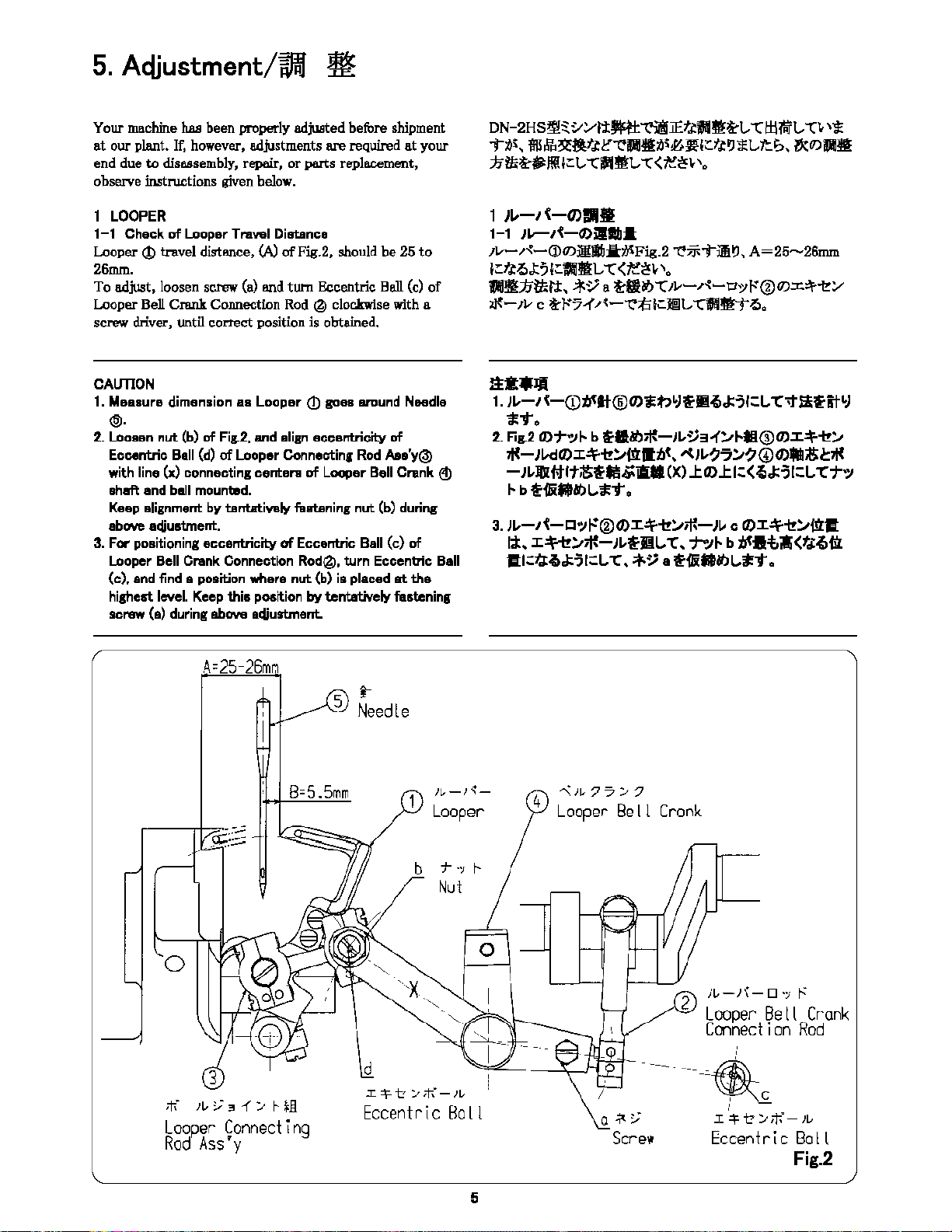

1-1 Check of Looper Travel Distance

Looper (!) travel distence, (A)

26mm.

To adjust, loosen screw (a) end

Looper Bell Crank Connection

screw driver, until correct position is obtained.

CAUTION

1.

Measure

@.

2.

Loosen

Eccentric Ball (d)

with line (x) connecting

shaft and ball mounted.

Keep alignment by tentatively fastening nut (b) during

above a~ustment.

3.

For positioning eccentricity

Looper Bell Crank Connection

(c).

highest level.

screw (a) during above a~ustment.

If,

however, adjustments

to

disusembly, repair, or parts replacement,

dimension

nut

(b) of

and

find a position where

as

Looper

Fig.2,

and

of

Looper Connectin1 Rod Aaa'y@

centers

Keep

this position

are

required

of

Fig.2, should

tum

Eccentric Ball (c)

Rod © cloclcwi.se

(D

goes around Needle

align

eccentricity of

of Looper

of

Eccentric Ball (c) of

Rod<Z.),

turn Eccenbic Ball

nut

(b) is placed

by

tentatively fastenin1

be

Bell

at

your

25

to

with a

Crank

Ill

the

of

@)

DN-2HS'I!!;: c,:.,-t;t\llqj:,?iffl[iEtl\il!l!t'.l-

-r,<,

!lil

,II,

31:ll'l 1'1?lllll•',11Jl!ICfl~ >lel-ttt,, !XUJlllll

:J,!Jit'.$/i!ICL, 1:Ji!i!L,

,

}~-,

(-OJ!llllf

1-1 11,-11-0>ll!IIJA

,v-,-{-(DQ)Jl:ltJ:A:~Fig.2 't'ff..Til~, A=25--26mm

ICfloJ:?ICllJ!i!L,

Pilffl.1i~ti,

,t--,,

*~

c t'.1':,-1',<-1?;/';lcllilL-U!i!T'->.

1:(;\'"'1

1:(;\'"'1

a til~-c"!J,,-.,.{-o-::;.,f,:'@(7).::r::.~i!1/

'•

'•

1:

t!lllif

L-

1:1

'lie

ll&•J!I

1.

,.-,

(-(D

>l'tl®

O>**>'J

~ll!~J:?l=L.

,::,t

!!~

it')

*"t·

2.

Fig.2

OJt""Jj.. b :f&dJif'-JL,~31':.,H!l@O)Z~-tC,.,

1/l-

Jl,dO):i:~-1!!/fl'liRb<,

-

1•1111

t-llt;!';~li!;-0:ilill

~

b ~ililill!IJL-*"t.

3.

}L,-J'(-CJ"Ji-!°@O)I.~-t!:.,,K-JL, C

la:, :i:'\'--l!:,;!l-1•~BL-,::, 1--,~ b

11:1=t,.~,1:-;1=t.

"C,

*~

-<1•1'5!/1

(X)

.t

O>

© 0>.;!';1:1/l

.t

I=<

oJ:?

O)I.~-t!:.,m:c

>l':IH,lli<t,.~fl',:

a ~ililill!IJL-*"t.

l=L.

"Ct"-:,

A•25-26mn

0

;tf

'"

Looper

Rod

Ass'y

~

;'I

1

:,

r-

rn

Connec1ing

l:-

----"5v Needle

8•5.5mm

I*t

Eccentric

)l,-)'\-

Looper

b

T·,

Nut

:.,;j;"-JI,

Bal

1

I--

0

I

'\11,?5/?

Looper

a ~ ;.:

Bel

Sere..-

Cronk

l

----·~

JI,-/~-

Looper

Corinect i on

.I

'=1=-

t?

:.,

D

Be

;r,·

..

Eccentric

;

r-:

11

Cr·ank

Rod

-

Jl,

Boll

Fig.2

•

5.

Aqjustment/wlff

1-2

Check

of

Dimension

point

Distance between Needle

Fig.2,

is

5.5mm,

To

obtain this dimension, loosen nut (b), and

Ball

(d)

of

dimension (B)

when

it

is

After adjustment, check looper travel distance W and

confirm

Eccentric

again

and Looper

it

while

when

Looper Connecting

is

smaller than

larger than

is

in

specified

Ball

(c)

of

checking dimension between Needle @ center

(D

point, until both dimension.

center

Looper

5.5mm.

range

Looper

of

Needle Center to Looper

(D

Rod

5.5mm,

of

Bell

!i!f

and Looper point, (B)

is

in

the extreme right.

tum

Eccentric

AE.s'y

@ clockwise

and counterclockwise

25

to

26mm.

Ifnot

adjust

Crank Connection

Rod

of

when

®

,v-

r~-(D

il~:Al:tli"ill!I

,t/-@<DZJ:~

ii~

5.5mm

,,f,-1vdt,;/;ICJil!l,,

Ba5.5mm

.t

t),J,~l,

I::

~ft.!:~,

,v-

,-{-(D

lcft'.,J:;ilc, T7rbt-lil!O'> B

'.!:~l:t,

.f--

JV';.'9--(:.,,J-.ffi@OJ:L.;:\'-"'e':.,,

J2'1C*~-'~I±,

/clCJil!l,

OJ;'c;MNti~.

-tlk

"C11fiJI!!

vc<t-'~•',

-{'l,

-C:jij!lJi,-,-{-O)~llJ:il

Otil7".::i::.7P°l,

il!l!t•' 25-26mm

JV-

,1{-

-C(ft"~V

'•

C/lill!l!IIIC),-c,

Po/}.'"@ O).:L.;:\'-"'e':.,,,N-/VC~ffi[l, -Cill!J::l;~7" :r.

,,;,i,, 'let, -Cilt@<D;t;,~,v-,<-(D<DltiJ!!!1t1'<D-t/k

tt.::i::.o/P-L

,<-JtiJ!!!1t1'<D-t/k

t:~l-

\,

-c.

,i,-,-{-(DOJil:l!I-AW&.tnt-~.ttJ,v-

(B)

A i)S, 25-26mm l.:f,t-:,-CV'

-C,

,t,,

,1111N1,

l'!'!t,

;lffiij<.J-!l,lcft'.,J:;i IClilll!'l,

-C

<

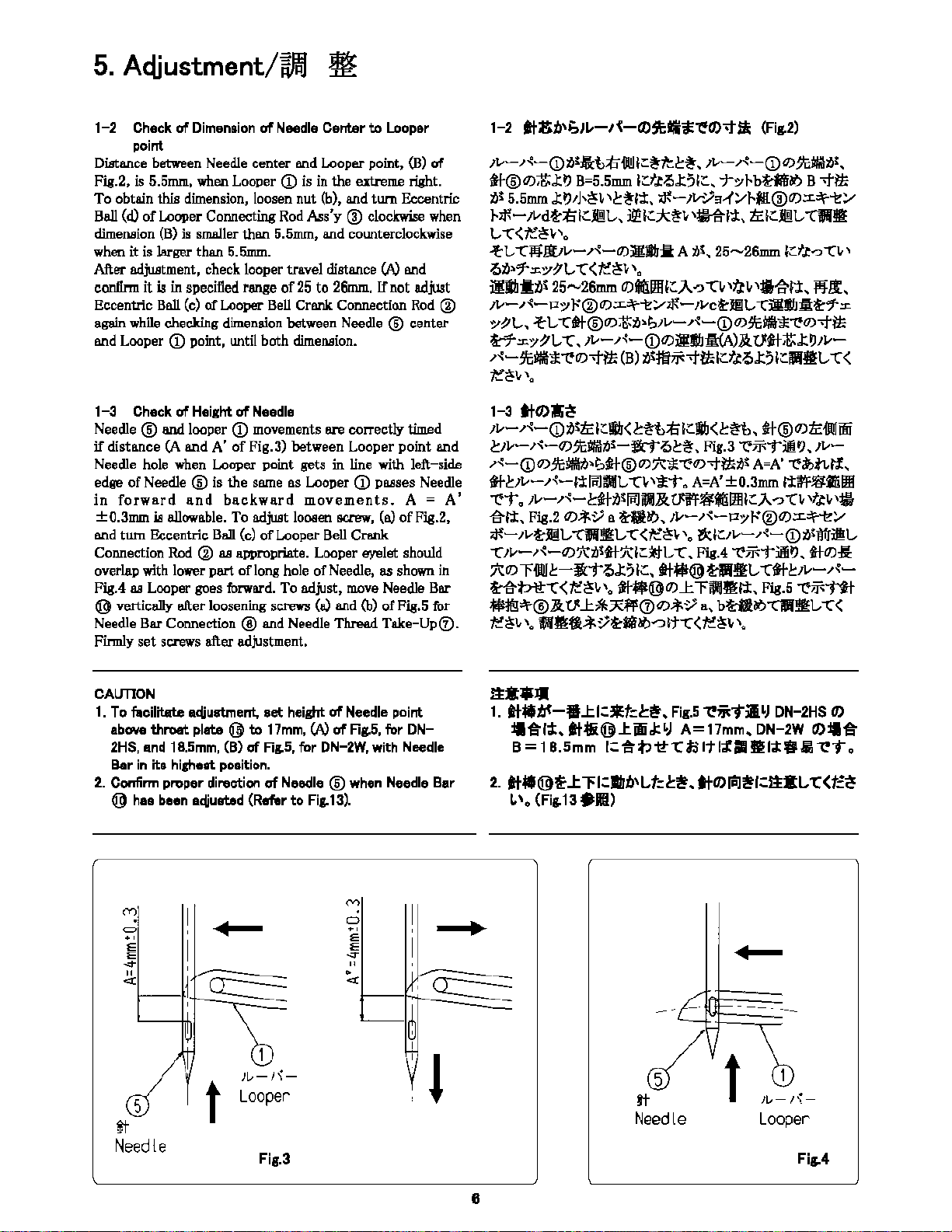

1-3 Check

Needle ® and looper

if

distance (A and A' of Fig.3) between Looper point and

Needle hole when Looper point gets in line with left-side

of

edge

in

forward

±0.3mm

and

tum

Connection Rod

overlap with lower

Fig.4

@ vertically after loosening screws (a) and (b) of Fig.5 for

Needle Bar Connection

Firmly

CAUTION

1.

To facilitate aqjustment,

above

2HS, and

Bar

2.

Confirm

@ has been aqjusted (Refer

of

Height

of

Needle

(D

movements are correctly timed

Needle ® is

iB

allowable. To adjust loosen screw, (a)

¢ric

as

Looper goes forward. To adjust, move Needle Bar

set

screws after adjustment.

throat

18.5mm, (B)

in

its highest position.

proper direction

the

same as Looper

and

backward

Ball (c)

®

part

plate @ to 17mm, W

of

Looper Bell Crank

as

appropriate. Looper eyelet should

of

long hole

@ and Needle Thread

set

height

of

Rg.5,

for

of

Needle @ when Needle Bar

to

(D

passes Needle

movements.

of

Needle,

of

Needle point

of

Flg.5,

DN-2W,

Fig.13).

with Needle

A =

ofFig.2,

as

shown in

Take-Up(v.

for

DN-

A'

1-3

tlO>;i!;~

1v-,<-CD•'lclc!l!<l:1!b;/;lc!l!<l:1!b,

.!:1t.--,1{-QJ;'c;MNti~-ttC.!:!. Fig.3 -e,jf-;--tiilJ,

,1{-(D

1*.!:1t.--,-{-l:tlmi'ffl,

~l:t.

,N-,1V.f:'.m!VCll!!lf:l, -C<f-:~i,,. ~l.:11,,-,1{-(Dti~lfiiil;l,

-~@Ji.V__c!l,;R1'l'CT)<Di<;!'

OJ;'c;~ill~lJ-@

"'e'T

JV-

O

Fig.2

,1{-cif-i)S

OJ..t-~

OJ

.1'::*-'e'OJ-t'*il~

-Cl-

'*-i'.

lmffll&.

a

&tf!i;,

-c,i,-,1{-0J'.Ail~tt'.Al::j:j-L

.'/\:OJ

r-111!1.!::-!i:TQ.t;1.:,

Hl-t>-lt-c<t-'~• '•

t-'~-

'· i(iJl!!ji,t,;!'t,!*O'>--:>lt-C<f-'~-

tt-fff@t-ll§L

,t/-lll<@<DJcl'~iJl!!tl:,

A==A'

at'F~«llffl Ii:}..-:,

Jt.,-,1{-i:zo/J-.'"@OJ.:L.~:.,,

-c.

Fis.4

a,

il@<D/ciJQJi!ii

A==A'

'e3';>tL,t!,

±0.3mm

'"t'"jf-;-TiiltJ.

1:t~.$:ili'ilffl

·n

,flV

t+OJ:!:

-ctt-c!::,v-,-{-

Fig.51'ii<-ttl

bti!IO'>"Cll'lll!l,

'·

,v-

,;11-

,<

ttt:•lll

1.

tt•lft-'l!.tl=*t=I:~,

'l!Jl:f;I;,

B = 1 B .Smm

2.

tt•@l!'.t

l,\., (Fig.13:t=lffl.)

tlti@.ti!ii.l:•J

,l=IIJn,t,tcl:i!t. tlO)P'Ji!tl=ttt:t,

I=

jl: V -tt-C

Flg.5

~;;i"j";!<J DN-2HS

A=17mm,

tl

It

f;f

111

!I!

DN-2W

I.I:

111

0)

O>'l!Jl;

ii,

~T

•

-c<t=~

=

. '

~

~

«

"

1--lf'+----------=

~

~,,b

I

Jl,-1'\-

5

tt

Need

le

Looper

t

Fig.3

'l

•

Needle

Jl,-/\-

Looper

Fig..4

5.

Aqjustment/w,'/J :If

1-4

Clearance between Needle

Cleanmce between Needle ®

0.05mm

travel, as shown in Fig.6.

Needle. To adjust, loosen screw (a) of Looper Rocker Shaft

as

Looper passes far side

and

Looper

lllld

Looper

In

no case, Looper should

(D

is

of

Needle in its forward

O(zero)

to

hit

Crank@.

Clearance between Needle and Looper

this side of Needle

0.05

to 0.5mm Looper

adjustment.

Looper

and decreased

Avoid

in its backward movement should be

Avoid

Eccentric Cam ® is used for

SlBnt

of Looper can be increased by turrring

Eccentric Cam @

by

turning it in direction

in

direction

as

Looper passes

of'

X'

of'

Y'

.

(Fig. 7),

1--4

tt1:,•-,<-0>llllr,,iilllt

it.!::1v-,.-i:-QJ;J:l'ffli'i:

Js~•'tl@<Dl,l~;g;iilli"'->b!.

0.05mm

-C<:fe~i.,,o

JllffiJj:JJ.,-,.-.:-±i:r@OJ-*~a

l;:::ft.J!>J:;

i,,1c,,-,<-,<Jiltiltril!n.,

,,.::-

(l)ffl:kl'ffltJS:11:1:,ftE.!IL,

lcfl'->J:

L,

i"

5

lcljfllJIH.,

--C

<

il:/!o

'•

Fig.

l:1v-,<-<D~!IIJ:l:i,J:;Jc,!<t,~, ~ ICY:/,

Fig.6

1;::

L,

-C,

j-f-(l)flt-'3il!tJ~tti.-

--C:/,lc!IIJ,

""C'Mff-.!::(l)

--C < /,'~;

7't'jji-j" A~

'•

""{'i'~i"

J:;

tll:<D!li(IIM'

~~

-CJllHIL-

,--c,

l!lll'ffltJS

ljfllJl!i,J:t/<j!

tl<i!

3i

s,s,

l!<t.i:~>lei".

f;::.,

11,,-,.-<:-(D

A=0-

,J:;

l;::Jllffi:L,

'C (

~~\,

'<b!.

tll:Jv-

B=0.05--0.5mm

3i

'le'le@

@f:Jct;

'"1

ICl!li"

'"1

(l)

'o

't'llfll!

ICil!

l:1J,

CAUTION

To

facilitate

Eccentric

45\

as

Cam

shown

adjustment,

in Fig. 7,

highest position.

tt"' !@S'

Needle Bar

Connectioo

® ao

6

that

first

ita

when

adjust

aet

screw (a)

nut

(b)

ID

a

Looper

ia

of

Fig.2, is in

tiff

Needle

*;;

Screw

~;.;

Screw

Avoid

located

Bar

1ta•J11

M1!3i'E'E@l;tilr,;;t,,tlb

aa

t:il'LSO>I:~

its

t,t-45

Q)f;ljl!Jc<{>.l:';lcl.,

Fog. 7 'l!;;iT

Fo~2

0)1'-:,f- b ti'IU,;;;<t~-,

.l:';icM1!3i'E'EO>-t?-:,f-*;; a

--Ct.lltlfill!lti'l!P.1,

-0.

'l!T.

mm

7

.l

~,"'ff

t-laedle

Thread

Toke-Up

tt!li

Throat

0 0

Plate~

-

"

<

0

~

.

..

co

•

-

"'

"

D

"'

Fig.5

7

tt

Neoole

......._

5

a~;;

/t,-)~-

Looper

Screw

Fig.6

5.

Aqjustment/wlff

2

FEED

MECHANISM

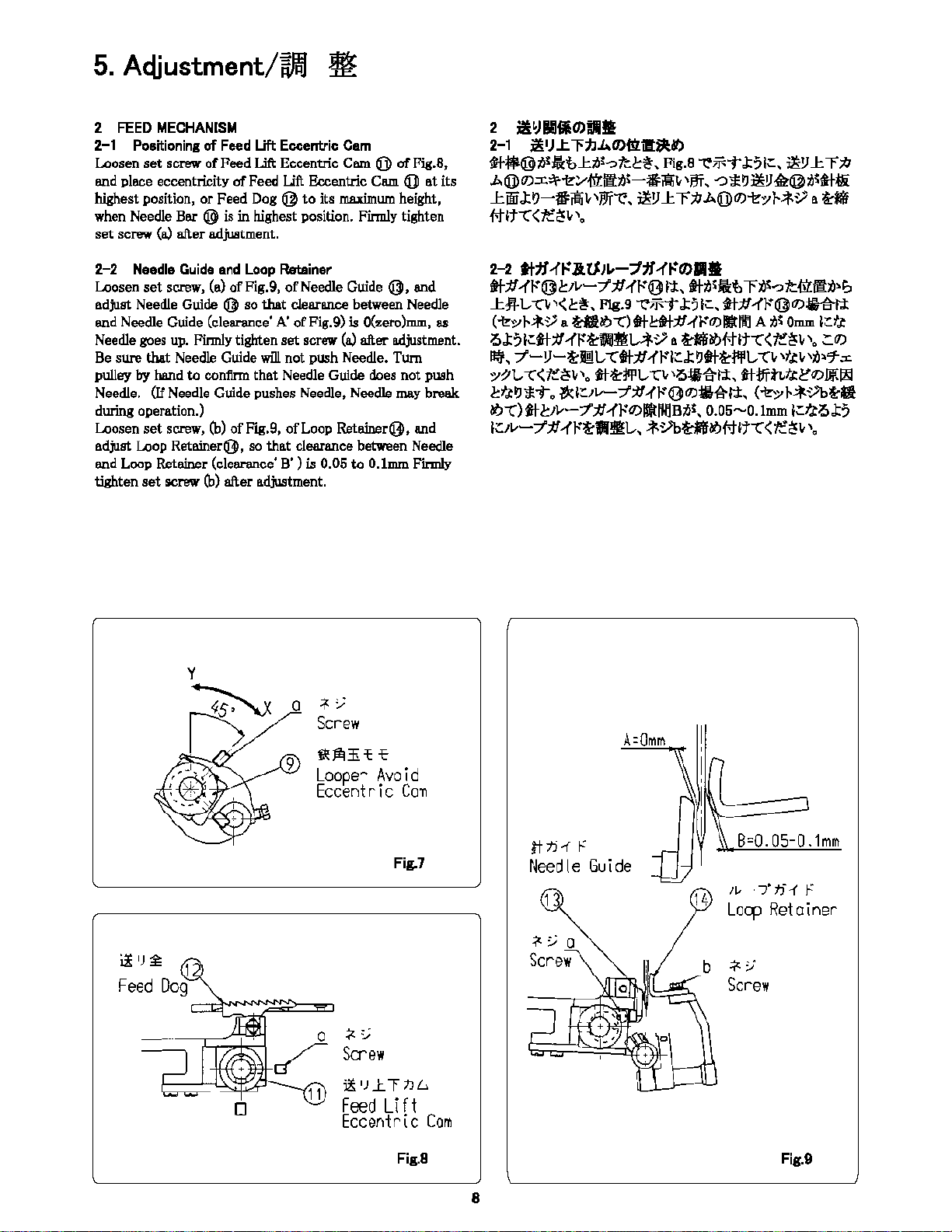

2-1 Positioning

Loosen

and place eccentricity

highest position,

when

set

set

Needle Bar @

screw (a) after adjuatment.

of

Feed Uft Eccentric Cam

screw ofFeed Llft Eccentric

of

or

Feed Dog @

is

in highest position. Finnly tighten

!i!f

Cam@

Feed Llft Eccentric Cam @

to

its

maxim.um.

ofFig.8,

height,

at

its

2

il!•JlllfiOliilli!ll

2-1

il!•J..tl'/J.L.Oli!i11!!il!Nl

ti-$@>l'Jiil,..t>l<-o/tc!.

A@<DXa\'i<:.--ill'.Jlill-Ji,;,,;;

Fig.a

~ii<T J:51c. i!Ylcl';IJ

'ITT.

,:,

,.~

i!Y

<il:@illtf-,l!t

JciliiJ:~-#i!O;,jjj~. i!Ylcl';/JA@<Di<o,J-i',,o;,

#ltt<t,'~;,.

Hf

2-2 Needle

Loosen

adjust Needle Guide

and Needle Guide (clearance' A' ofFig.9)

Needle

Be

sure that Needle Guide will not push Needle.

pulley

Needle. (If Needle Guide pushes Needle, Needle

during operation.)

Loosen set screw,

adjust Loop

and

Loop

tighten

Guide

and

set

screw, (a) ofFig.9,

@ so

goes

up.

Finnly tighten set screw

by

hand

to

confirm

(b)

Retainer'3,

Ret6lller (clearance'

set

screw

(b)

after adjustment.

Loop Retainer

of

that

clearance between Needle

that

Needle Guide does not push

ofFi.g.9, of

so

that

B')

a

Needle

Guide@,

is O(zero)mm, as

(a)

after adjustment.

Loop

Ret6lller(Bl, and

clearance between Needle

is 0.05

to

0.1mm

;:j(:

:_;

Screw

9

"' "'

'E " "

Loope~

Avoid

Eccentric

and

Tum

may

Fkmly

Ca11

break

2-2

ttfl

-ft'.lltli•-::1:lf

-ft'Olll•

ttff-fl'@c1v-7';!/,(t'@l:t.

Flg.9

1c;i.1.,-,:;,<t!.

(i<o,)-t,,o; o

till>'>"<:)

~ii<T J:?lc.

tllctl;!/,(l'<D~llll A

0J:?1ctt;!l-ft''!cllllll!A"',

Bi';,

7-!J-t-l!!L-

,-;,1.,

-c<t,'~;

cft~>sT.

1/J"'()

t-t-~,v-7;1!-1'1"'

IUv-7';!/

ttt.:t'-1'1--"lr.J:~tt~f!JIL,

,.

tt'!cl<l'L,

-c,

li(IC1v-7';!/,(t'l3<Djjl-1ttl:,

O)lffltll,ljB;6;,

,(t'f:il!f'ilf!:l.,,

i'-"'1>Hf

A=Omm

ttil<JiU, l'>l'-oltO:,Jl,i,~

,tt;!l,(t'@<D~tl:

1)!

O=

Hf>'>#ltt<t,'~;

"'CV

'oiJl-1tti:.

ttJ/int,l'"'W.ill

(i<oy

0.05-0. lmm

>'>#lt-C <

-~

,.

,t.tv

vlJl'T.cr.

i-i'-"'1>'!:li

lr.1.tOJ:?

t,'~;

'•

IC

""'

ft

ttti-f

jz

IJ

Feed

~

Dog

Fig.7

I

+

,;

Needle

~

::;

Screw

Screw

i.l;_IJJ:."ftJL:,.

Feed

Lift

Eccentrlc

Cam

Fig.8

8

f

a

Guide

~,Bc0.05-0.1mm

/1,

14

·7'tf1

Locp

Retainer

Fig.9

f

5.

Aqjustment/i,llB m

2-3

Feed D01

Clea.re.nee

Throat Plate @ must be uniform both in crosswise and

longitudinal

@ is

'""""·

Feed

Throat

Feed

adjustments

a) Actiuatment

Loosen nut, (d) ofFig,11,

position

Tighten nut (d)

smoothly.

b)

Aqjustment in

Adjust Feed Drive Eccentric Cam @ with its adjust screw,

(a) offlg,11, so

To adjust, loosen screw, (b) ofFig.11,

Eccentric Cam, @

counterclockwise

decrease it.

Clearance

Plate @ when

should be equal

Dog is in extremely

adjustmant, loosen screw (c) of

screw (e) as appropriate,

between

set

to

Dog @ teeth

Plate@

Dog is

of

Feed Rocker @ so that A=A' is obtflin.ed.

(B)

end

of

Feed

Dog @ e.nd

directions,

a specified stitch length within its adjustable

in

its hlghest position. Detail ofrequired

iB

II.I!

in

e.nd

that

between Feed Dog @ and grooves

Feed

e.s

shown

in

Fig,10,

on

trailing edge should protrude above

by

2,0mm (dimension'

follows:

Croaawiae Direction

of

Peed

conlinn

Longitudinal

e.nd

to

to

clearance

adVBIJ.ced

that

Direction

feed amount

tum

adjust screw

increase feed amount, and clockwise

Dog is in extreme

(B')

position,

C'

Dog@,

Feed

Rocker @ moves

of

Peed

of

backwtin:l.

between them when Feed

For

Feed

Rocker@,

grooves

when

Feed

ofFig,10),

e.nd

adjust

Dog@

Peed Drive

(a)

thiB

is

ofThroat

position

clearance

and

of

Dog

when

10mm.

to

tum

2-3

.t•Jlfl:O)!llll

.t9111:@11,

®"'fflillitffll*"''":>tt.:c

(A=A'

t,~lle-!!:h,.

x,

ll!Y

1:iliiJ:~

) , llfrfj!

Jo-~

(B=B"

Jii:;!<ic-1<,,r;!<tttt.t~;1;11rc>,

) tl,filll:.ll!!lll!lcft'!>J:'ilcl..ttltt,,l:f

111:@tJ:;.;,1:,,0

C=2.0mm

t!j,:,,ttltttl:ftl~lle-\th,,

Fig.lo

ttill:11t1:.tY111:"'ii.111,•ttll<@

11J<<l)tt,a~t--t.

a)

ti;=!;O)DJ!l

~!Ji?trJ)ti:.;ti"(l)ll'f:IH;t, Fig.11 rJ) d

±-1>@~:lr.=!;ic!IIJa,t.. t A=A"

,,.

-tl..

tTo/r d HIJ#ltt,

!IIJ(,j<~l'il!ISL.

b)

fJ!l!O)iJl!ll

;!911,:@<l)Jl!~

<l)il'!'ilf!)!<l-'a"t'il'!l!!:l..

ii<Tll!9 ,c,\'--.c:.,;b

;Is

ICJl!IT

1'T.

!<1Cll!9111:@a'>i:l>f&l!!;

<l)llli!lli!Bt,

<l)llli(lli!ff

,)c;>.~Jlo!l..

t(t,:;!<,,.

!I.•'

10mm

t(!,:;!<, '•

A@<l),)cl-'!,H\l111;

ti!~

!1:11:/c\!;-(t,~:t,

i!9111:a<fil,

al'!)\\' lcfl'!>J:'i

t1lll!!:L.

t(!,:;!<,

1ct,'!>J:?1cilllll!L.

.t9:ii;±-l>@•'"'-"-Xlc

lcfl'!>J::ilc.t9,c,\'--.c:.,;b

Jl!~:!!:<l)!llllf!:11Fig.11

IClllT ti!~!l:11,J,;!<(tt~

l..ttb~<l)ftlJi$tll!9111:t

il1Jl!!;L.ttb!·<l)J!9

iCJl!9

,c±-/>@

'·

till<

1.'ii<T J::ilc,

:lr.:t,

;:t,,(,<l)JllGll!

(1)7-::,l-~lt/lJ-C~!Jjc

t(1':;!<

A@

tt;>!',JllGll!,)cl-',~

±-I>

tflff

.-fl' t

<l),)c

lJcH\l111;

1:

t

c)Heitht Actiustment

Adjust height

teeth

on trailing edge are to 2.0mm high above Throat Plate

@

('

C' ofFig.10) when

Firmly

Feed

When

Feed

Dog a bit higher.

<

•

<

set

Feed Dog

of

Dog

screvr, (a)

make11

of

Fig, 10, so

Feed

Dog is

at

its highest position.

in

position by tightening scrow (b).

scratches on

the

that

Feed

crepe tape,

Dog @

set

c)

1:"FO)!llll!

Jl!9111:@"';!li;!<i1,

0tt,\l:li!'.1.',

Fig.10

"t'il<T J:'ilc, Jl!Y~•;.;,_1:;,

Jl!911,:<l)!;lllJ•'ftll<l:iliiJ:~

J:'ilC, ,)cl}a(/)";'<~llffllf!:l.. t(i,:;'<, '•

blCcllli#ltt(k'.;'<, '•

Pv-:f'T-:f

9<il:~

1:IJ'la\'ilelCL.

~lil0

0 +~

Screw

ti!911i:<I)

iJ

I 0

tlli#ltt(k'.;!<,

s·

,,l!"ffi•'-0(

b ~;:;

Screw

C=Z.Omm

{cl,

til£911,:~,)cl}

'•

il

Feed

Fig.10

lcfl'!>

U!1S-11Jl!

'Jtti:

Dog

9

5. Adjustment/wl/)

2-4

Change

Standard setting of

(when paper bags were specified) for DN-2HS, and 8mm for

DN-2W. When

end,

observe following procedures:

Loosen screw, (b)

@,

and

spBcing, and clockwise

stitch

( b ) tentatively, and

confirm

screw (b) flrmly.

of

Stitch Spacing

stitch

spacing

changing standard

of

Fig.11

of

tum

adjust screw (a) counterclockwise

.M.lil

several pieces of material

that

you get required

stitch

~

of

your machlne

stitch

spacing

Feed Drive Eccentric Cam

to

reduce it. Tighten screw

spacing. Fine.lly, fasten

is

at

to

to

10mm

your

enlarge

test

2·4

IIL'!l!li!O>illllll!

DN-2HS

10mm

l!ltl:lll•' ~ 118mm

l!l!!!J!!/llsY0/11,

l;:il!JIH.,, PP'.7P.A)tlQ);!i--$-ti

(F;g.11)

ICilll!llA!HII/L:n

lit•,~ !i'ac!icll!-t>.;l:!tl:,

il!9

~"'i,:,;b

lll,>sT,

i!lc;/;lcl!!-t /:Ill>'~ (itJ:,J,~<tt~>sT,

to

-*~M:{&$1~1..,

~

'ac

)!.

-C,

-c

<

1"~,

:fe~l_.\o

A@

(7),j<yl,t-,11..,,, llllli<sJa'acl!!l,

llllli<sJa'aclclCll!ITI:, lit•'~ 1111:*:!<tt~,

"(7";(!-fiV''kl,

(ll';'<!C7)1il0' ~ (ilcft-o-CC '01l•1'')1l•)

'•

llU!l>l'

t!JJIE":lel,;',:~,j<,-,1,.,l,-o

IJl!!!/ll

C7)jj-@-,

8mm

Ill•'~

I::.,

"i.1t

,£-t,

l!l{C7)11Jll"i'-ellffllt,

-C(:fe~V'o

,<1"~•

TA/'~QJfti.,,

··~lll#lt-C <

Ii

DN-2W

,,

-ci\l'I

Ql,

i,!

IJ

ic±

Ej

Rocker

~~

C

Sere•)

16

0

reed

*::

Screw

-1-

S::rew

+

·:,,

Nut

~·

)--

e

d

"

~

IJ O -~

Feed

t-:°

Conrecting

Rod

10

i3:IJI4'-t'YtJ6

F99d

Driv9

Eccentric

Com

Fig.11

5.

Adjustment/wl/J

3

PRESSER

3-1 Positioning

Clearance between Presser Foot

Plate@,

2W), when

Presser

(a) and adjust Presser Bar Connection

Firmly

that

Needle Clamp Nut @ (DN-2HS)

(DN-2W)

Needle Bar @ is lowered

3-2

Pressure

Pres8UI'8

materials are

adjust, loosen nut,

adjust screw (c) clockwise

counterclockwise

ce.use

thread

threads

length.

Repeat

pressure for your material. Firmly tighten nut

adjustment.

FOOT

of

Presser Bar Connection

(A)

ofFig.12,

Presser

Foot

tighten

will clear Presser

of

chaming

tests

Foot

Lifter Lever

set

screw

Acfiustment

Presser Foot

fed

at

a constant and unilbnn speed, To

(b)

to

break,

etc,

at

ends

o.nd

adjustments until you

is 8mm (DN-2HS)

&s'y

@,

To

(a) u.fter

Foot

to

its lowest position.

of

Presser Foat

&s'y

ofFig.12 and turn Presser Bar spring

to

increase pressure,

decrease it. Too large pressure will

and

too

of

materials

!/1:

&s'y

@ and Throat

or

@ is raised

adjwrt, loosen

@.

adjustment.

or

Needle Holder

Ass'y

@ even when

Ass'y

@ is so adjusted

small pressure, failure

or

nonunil'onn seem

get

appropriate

5mm (DN-

by

means

set

screw

Now con:finn

that

o.nd

(b)

u.fter

of

your

of

3

l'i'Illl,0)!11!1

3-1

l'i'IM!lf,,.O)f;iill!il.!tl

jll,o-,,_@l:t,

f/iiC"(,

F",g.12

~"e'l1J.f-it.

ti

5mm

lcflo.l;';IC,

li:lii!Mltt<1':"''',

r

l)l-o

ltill:11!-etl-lll>-t",:,

-)

:jql;r.~@1;:~"':1-n·

3-2

jl!Illl,O)EE:llill!I

jll,o!i!!f@ICJ;~jll,o>'l,@/i:Jciflt:1/t

~jf--j";j!~flj!(@JciJiiJ;~j!!,o>'l,@O)riJii

A

tis

DN-2HS

11)~~1:l

8mm, DN-2W

j!!,o_,,_@li:lllll!'l,

~L

t.C0):1/t~O)/:~,

c@lll (DN-2W

,t,ti.-

'*~-l,

0)4!,g-J;tftlls1J.-?"

-c<tt:~i.-

11)~

-C-1',:,,;l'-Sla

fllll>@ll'>i:»

'o

11,g-1>J,i•-•1c~~1':"'MJ;';Jcjll,o>'l,@O)!EJJ/i:lllll!

\.,

t<1':a'<,,,

!',, jll,o$;s:;l'V:.,?11JIJl!;l'-Sl C li:,;/'i!Cl!!i"

ft~lc

l,IJ'il!ti,

ICJ!!i"

l:jll,o[Et;toli< >\:~£T, !EJJ

Fig.12

~il<i";ii~-t",:,c b

l:jll,o[EJ:t'l!II<

Jll'l!lli"l!"

li:lil!"'-Cll>

o

I:*

<']tl,$1'0)1Ji(l!jlctt~£i"L, 5Jli,,1:'l!illll~t,<tt-o/t~il

~

Jll"f'j!ii;,1ct,~£TO)~,

,,

iiili!ll'l<U,~£Llt!',-t",:,c b li:liiMlt-c<te"',

,

'J';s,a,,li:L

-Cl,IJ'il!L

t<1':"<

,.

•

C

t!¥'.I~fil'.i

Presser Spring

Regulator

b

t-

_,,.-

Nut

jfI!fl1]+

Presser

·:,

~::,;

_,,@)

1,:i:11'i

Presser

!---

0

~ifter

..

----;

_-.?

Foot

Lever

It~

Bar

i---xl;;oO

Needle

Bar

Conecction

,.

..

,

a

•

0

Screw

~

I

"'

" "

'

D D

E E

E E

CX)

en

"

~

' z z

ltl!i

Throat

~

•

Prate

•

0

tt~-t--~

!---

Needle

Clamp

flj!.I~

Presser

Nut

Fool

11

Fig.12

5. Adjustment/wl/)

4

Needle

1)

Needle

Size

Available needle size includes

me.chine

Your

you have changed the needle size, positional adjustment

of looper must be carried out.

bent

2) A

skipping stitches,

new one in

to

figures

by hand until

Tum

the

spanner included

the

needle from

must be observed when you install a new needle.

a)

The shaved

cfuection of the machine (Fig.13).

b)

Push

the

c) When you have installed

clamp

nut

d)

For DN-2W install needles

secure them with screws.

is

provided with

or

damaged

the

13

needle clamp nut in

needle

Jinnly.

needle reaults in thread break,

l!lld

other troubles. Replace it with a

steps below. Install a new needle referring

and

14.

To

remove

the

needle bar reaches its hlghest position.

in

the

accessory. You can

the

needle bar.

part

of

the

needle must face

in

the

needle

the

in

~

DRX2

#25,

DNX

DRX2

#25

needle.

the

needle,

the

arrow mark using

Two

important points

the

b8l'

88

deep

needle, tighten

the

needle holder, and

tum

now

leading

88

it will

the

11125,

remove

needle

etc.

When

pulley

the

go,

4

ttO>ll:11

1)

DN-2HS ll!sl/1/U)litU)QICl:l:

#

25)

ftl'll'a,~1leT.

1

~t-tltil,llll!t!H!fl-

!tif

1;:,v-,'{-o:>i'ftl&-L-

2)

lilll'ilhll'~- >sttlltlcfllll'"<'~'!><sl/:,"'*lllln,

Vll<ilil::~1leT.

L,

t<1"~,

a,11'1<T.

91-~>sT.

'•

7'-V-~"'"('ffi!L,

fl$To/

fl~

Iii<

-1:l:~'I'"'

·n

'1<T. lil"'<t,<;<~,i,;t'!,b~l:tl"I

-C

(Fig.13,

~#It

14)

,~t-t

illl"'"-''-r"t1l!O')'!>l:fl~ll<

'!><~l:tll!lft.1:::,,i<=

<

t.:~v

~il'li!L-

(DR

X 2 ii 25),

(DR

X 2 #

'a

tffit.,;

ttt~Jil:t

•ttc3l:lf!

;11;,

--.,;,~,s

T.

o)

*"'

;l

<'~~

leliClelltt!l<~t-lltt<1"~,,.

(tt7':,!i'<"' l!']A,

b)

tt$1ctt~,:tt.,il,t,c~,

ii,A,

"('<le'~

c) -fcl7)a,ctt$-ro/ ,~L--oll•~M.,,t<le'~, ,.

d)

DN-2W lli!U)jjl1l-i:J:ttttl*1v;f-fc.,L,il,]j., lc-"'f

P.

~Mfbtl"?lt-C<~<'!V '

""'

(Fig.

ttll<--.,,i,;t

0

'-'5$1>}~)

13)

'!>

>s"<'-jif'lcl:tL-

ll!O)Jl!;ff

(DN

X

25)

~Iii<

~JR

•irrl!tlC

~

::I,

p r

L 7

')

g~

0

0

0

u

il!

rj

"' "'

-

Directlon

bog

Caution:

Thread may break

inst.alled

correctly. To check

it

5 Throat Plate

The throat plate is constantly subject

presser foot, and may

the

resulting in a machine trouble. To replace, loosen

setscrews.

or

on a flat

throat plate

or

it

is

bent

if

surface

such

iB

bent, it may be hit

skip

if

the

needle is

or

damaged. Install a new needle

the

needle is

as a pane

be

bent in due course

bent

of glass.

of

travel

not

correctly

or

not, simply

to

pressure given by

of

operation. If

by

feed dog teeth,

Fig.13

roll

r

tf-;t,;1,9"-

Needle

Clam

jj-

[ltt]

tlO>ll:l!Ucl;UJi

~,

t-

Nut

·J

r

~

It

l,

L

'ti

~il/ll

VC

(

Fig.14

t:

.!<

L

#'

'•

ilb

ti<-,

tt~~~O>-Ml-tttt~illlll-*T<~~~a,*~

;,., ll

illtFO>liiil!il

5

tt~O>ll:l!I

ttttil:J:Jli',cil,iCJ:

J;l,

•11!1

lcliltti"'

il,U)!lllca,tt

1"~, '• 'll'lf!ICl:tttl/a-"i<,' 2 a<~ll!O')ttttti~<~,

t <

ffiL-,otttti~ll<~t-t1t1lei'.

bfJ-C<~<'!V'

lct.J:

-0

tilt

'P

,ell<

~oJ<:'4'11)

0

Ji{I!,

'J

1<1".

IC..l:ll•lo/E;/Jlllll•ll•-o

ilb

ll<-o

t~1leT.

1ct,~1<T.

ttttill'

ffit.,;

•ttttic

""'"'1c-"i<,'~voll•~,M

-c,

'1'T.

ilb

ll''!><il!V

3l'!!ll-

t:

12

5.

Aqjustment/w,'/J :If

6 ADJUSTMENT FOR SINGLE THREAD

6-1 Distance between Looper and Needle

Distance between Needle center and Looper point is 5

when

Looper

To

obtain this dimension, loosen nut (A).

Looper travel distance should

loosening screw (B). (Fig.15)

6-2

Check Height

Adjust the height

between Looper point and Needle

gets in line with left-side edge ofNeedle in forward and

backward movements. (Fig.16)

is

in the extreme right.

be

of

Needle Bar

of

Needle Bar

5n,n

~t

,.,.-··

,..

t -

---------

adjusted

to

have distance of

Hole

SEWING

Rt

24mm

by

2mm

when

Looper point

ltlli</11

Thread RetoinGr

Ploi:e

mm,

6

*llllL

6-1

JV-

5mm

1V-,.{-l])i'fllJ::l:tJ~

i!il!l/!L-

::UJ\lll!ll!i1!11~>i<L-,.

jj,;.f-~1-::f.tQJ:;t.:L, t<tt:~v

6-2

,s-,<-UJJ\sil/,la<ttUJtc-Olli!iilc~tti:~.

1<UJ

~'1:llff!l/!L,

'O)Di!I

tll::J,--11-0)IUI

.r{-:@.Jib1&-i.!!L,1t.,!:~, ;t,,-,1~-0J;'c;i:rlNtl~ft;H;J::.

lcfJ:'.>l:?To/l- A

t<1"~•'•

a1il!~iff!ll!L-

24mm

(Fig.

15)

,,-

t<1"~,

l.:t.tQJ::?I.:,

'•

..:f~

,<-UJJ\sil/,lJellill::l!!!lll:l:a'lli

'o

tt•O)-~

[mjll~l:tltt

Jc!lilJ:~;o-,<-Q)jsil/,la!

,<1"~''·

(Fig.

16)

2mm

lcfJ:'.>J:?ICtll!IIUJi!l;

B

I)

~/l)t

6-3

Rxing Throat

Fix

Thread Retalller at Throat Plate, keeping it having

1.1mm

clearance

into the loop, Loope

succe,11sful

6-4

When

needle board nail, Loosen screw B not

looper, end please decide a

stitchlng. (Fig.17)

Check of Looper Travel Distance

a escape ditch

f>late

Thread Retainer

from

Needle point. When Needle

Guide

helps to spread the

of

a looper goes along a bottom

momentum

come

into contact a

of a looper.

~

~·

(9.6mm)

I.

11

I.

Imm

Fig.15

is

loop

sinking

for

of

a

6-3

tll!iJT\O)!lllt-llt

tllliJl\i,l:, tl1r-J:~

~i.,,o

tllliJl\i,l:,

J:? ICJ>-::t'l://;;lj''.>tiJ~t:L-llei".

6-4

,v-,1'\-0J.::::.~tlii~,

~ttGt,.,J;,ic,j;;,

-C<tt:'~i.,,o

tta<,s-::tlcl/ibiblv1'fi<~~-

i•-1

<-O);JHIJI

1.1mm

lcfJ:'.>J:?

ittiJT\OJ"f~O~~,

B

-Hi~,,

-

Fig.16

ICtlll,lc->c,,J-L-

(Flg.17)

t<1"

~

•'llll:ft,.,

,v-,1.::-ti~,

,s-,<-UJl!!!IIJ:l:'l:!lc~

ft!/i/11

Throat

Thread

Plat~

Re\atner

13

Fig.17

6.

Troubleshooting

When trouble occurs while operating

Trouble

Needle thread breaks

Looper thread breaks

No chaining on

edges

work

Damaged looper Replace looper.

1.

Needle thread

2.

3.

Worn

Thread twisting

4.

stand and needle

Improper needle setting;

5.

needle

6.

Needle thread

Looper thread

1.

2.

Damaged looper Replace looper.

Thread

3.

stand and looper

Incorrect

1.

Looper thread

2.

Improper timing

3.

4.

Presser

the

machine, refer

to

the

following table for selecting suitable measures:

Cause

too

tight

out

feed dog causing fine

or

entangling between thread Secure

too

loose Increase tension.

too

tight

or

twisting

or

entangling between thread Check

threading Thread machine correctly.

too

tight

of

needle and looper

foot

screw loosened

Bent

too

stitches

or

damaged

loose

Reduce tension.

Replace feed dog.

correct

Set

needle properly; Replace needle.

Adjust

tension.

for

correct

Reduce tension.

Adjust

timing

the

Tighten

screw.

Cure

threading.

threading.

of

needle and looper.

Thread skips

Needle

No uniform

seam

or

looper breaks

not

straight.

stitch

length;

Needle setting

1.

Bent

or

2.

Needle thread regulator

Needle thread sticking on needle due

3.

4.

Needle bar

Needle thread pinched

5.

collapsing loop

6.

Looper thread

triangle

Improper timing

1.

Bent

2.

1.

2.

3.

needle Replace needle.

Weak pressure

Bent

needle

Worn

out

not

damaged Replace needle.

feed dog Replace feed dog.

correct;

set

too

loose,

of

needle and looper

of

presser

set

too

by

needle guard, Lower needle guard slightly.

not

foot

Set

needle correctly.

low. Raise regulator.

to

heat Use lubricant

Lower needle bar.

making a good Increase looper thread tension.

Adjust

Increase pressure.

Replace needle.

timing

on

thread.

of

needle and looper.

14

J::*

~7:1

il'--w:J

Jl.,P-J~

hi5

~

mi

1.

Jv-/{-t::~iJ,;bi5o

2.

J::,%

W!i!-=f

0)

T

:,.,,:,,3:,.,,

iJ,

!Ji

T ~

i5

o

3.

~~~iJ,.$GL.,

4.

,%:ftti,Git~--c."O)rl!J--c.",%ti,t--:Jti,tcl?,

--C~

§l

tis~iJ,<fJ:0

0

Ti5o

5.

itti'-IE 'itt::I&l'J#ftGn

--Cv

\0o

6.

J::,%

Mil-=f

0)

7"

:,.,,:,,3:,.,,

--Cv

\ftv

ti'-ffiii1//,H

::!J!J T ~-

\o

iJ,i:J~-?tcl'J

Ji!lti,-?tcl?ffl~L-

i5

o

~

~

1v-/{-a-~~T00

7:,.,,:,,3:,.,,a-!J!J<T.:So

~~~a-~~Ti5o

,%ti,t--:Jntcl'J, iJ,G~ftv \J::5,%ifilU::tt

;i:i"".:So

if-O)J&

I?

~u

#ftJJti,IE -itti,~l:JiJ,fi~ T

\if-t::~~

Ti5o

.:So

7:,.,,:,,3:,.,,Bt<T.:So

T *il'--w:lh0

@:~iJ,t±\ftv\

§~V

it

iO'

1ff

hi5

1v-/{-iJ,1ffh0

1.

r

,%0)7:,.,,:,,3:,.,,ti'-%ii""~tcl?,

2.

Jv-/{-t::~ti,;bi5o

3.

* ftiJ,G1v-/{-~--c."O)rllJ--c.",%iJ,ti,i:J~-?tcl'J,

ntcl?Ti5o

1.

,%0)ifill.,1Jti,~t;,ti,-?--Cv

2.

r

*wm-=f-0)7:,.,,:,,3:,.,,ti'-!lt-r~.:so

3.

it-bv-/{-0)?1-1~:,.,,~-ii'-f'r-?--Cv

4.

1'Jl.::i:.~O)

1.

itti'-IE-itt::I&l?#ftGn

if-ti,

2.

J::,%

3.

j!P.\O)f;:bl'.),%tisif-(;::<-?--:J<o

4.

it~ti,~<--eo/t-~tL--Cv

5.

J::,%ti,if-;tf-1F--c."¥Jl~x.--:JftGn--c1v-:1ti,5~<--c."

~--c1.,

6.

r ,%ti,~-r~---c

(ti,x_l?

1.

if-~1v-/{-0)?1,1~:,.,,~-ti,~v

2.

if-ti,

11:;,t*

::Jti,*llv--c."v

Jill

ti,-? tc

I?

ffl

~L,

wm:tmti,fil;<--eo/ t-L-

\ttv

\0

J::1.,

\-=-fti~a---:J<Gttv

\0o

Jill

§l

ti,-?

~V)

--Cv

--Cv

i""~'--c1.,

ffil'r#i!t::*ii""~.:So

\0o

\;so

--c1.,

\ttv

\0

\0o

\00

\0o

\0

\ftv

\0

\0

t--:J

*

ID!ff-=f

0)7

:,.,,:,,3:,.,,

a-Wlillfllf T .:So

1v-/{-a-~~T00

* ti,t--:Jntcl'J, iJ,G~ftv \J::5,%ifilU::tt

;i:i"".:So

IEL-<,%a-ifilTo

r

*wm-=f0)7:,.,,:,,3:,.,,a-!J5.l<-r.:so

itbv-/{-0)?7-1~:,.,,::1'a-WlillfllfTi5o

¥Jl.::i:.~l1:;,!;;t.::PHilbl'.:li5o

if-O)J&

fstftJJti,IE '/tiJ,fiim

~u

\if-t::~~

J::,%

amJ:Wa-J::ff

*

t::7l!la--fie:ffiTi5o

Ti5o

00

Ti5o

it~a-rff.:So

if-;tf-1Fa-rffi5o

r

,%0)7:,.,,:,,3:,.,,a-%i<T00

it-~1v-/{-0)?1-1~:,.,,

~-a-wli!lfllfT

.:So

ita-~~Ti5o

~

§ ~j;o,~;Jil., \

~§ii'-JilliJ,-?--Cv\0

1.

1'Jl.::i:.~J±ti,!J5.Jl.,\o

2.

if-ti,

Jill

ti,-?

--c1.,

3.

~%}:ti,.$G L---Cv

\;so

\0o

15

1'Jl.::i:.~J±a-%i<T.:So

ita-3'.t~T.:So

~%}:a-~~

Ti5o

ORDERING

1.

Description of each part and its stamp number

to the relevant parts. When ordering parts, describe clearly stamp number with its name of part.

2.

The parts which have

3.

A set of assembled parts

4.

The last figure on the parts stamp number advances on each improvement of the parts.

5.

Parts

No.

described

• The parts list

1.

S:::'r_tj(O)~l'i,

2.

{!::!.L,(~:ffi:Ref.

3.

*lltl'~£1'i-tO)q:iO):±/"~o/O)~iJFP:ffi:%--c.>*ff-L,

4.

~IJFP:ffi:%1'i,

<f;:~l,,

5.

ffi~ffilJq:iO)[

•

-*'lm~~(;l:ij!Ol©t::clf.>~is-fJ(~Jl!"t

-tO)tf~J1oi".J!afcJlt~n01'BJi'.I;:,

\o

Ji*Jl'ilS/"~o/:ffl:%--c.>To

no

Ref.

Number can not be delivered independently;

is

represented by the stamp number of its

in

[]

of Remarks means old parts

is

subject to change without prior notice.

$J1o:ffi:%,

No.)O)~"cA7'.l~fJ:v

$J1o~~'

,JmJlr:i

11~~1Jnc<t;:~l,,\o

l'i,

is

described

No.

l\if*Jl&n--c.>~'*it

tibVJ'*'"to

:i:ff0)~*7'.l~ 1

~.:.c!::ti<if>

LJ*"t

PARTS

in

this parts list. Screws and nuts for parts are shown adjacent

always

oder it as an assembly.

main

parts.

NO)--c_\

o

-tnl;:~ ~ T0~1im$J1r:i(*Jl.tf~J1r:i)~

:ffi:f'--::i~VJJ::7'.l~VJ,

frU,~iJFP:ffi:%1;:7'.J,:bVJ'*TO)--c.>:.·Tff(

S:::'ttx<t;:~1,,

'o

CONTENTS§~

r

01.

Bushing

Parts · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

,m~~f*

02.

Oiling

Parts · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

~ntl~flf-

03. Miscellaneous Cover Parts · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

7J/{~~f*

04. Thread Tension Parts· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

*

Wi\1-f-

~1*

05. Crank Shaft

~7:1/~1/-\"71--,

06. Needle Bar

irW,

07. Looper Rocker

,i,~

/~~~jb

08. Feed Mechanism Driving Parts · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

5~PJIM'¥f

Numerical Index of Parts · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

/~~o/mi31

List of Screw, Nut & Washer · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 36,

.;tV\

and

Arm Rocker Shaft Parts · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

J:llim~flf-

and

Presser Foot Parts · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

¥f!::r::.1i2~1*

and

Connecting Parts· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

~1*

~1*

-t-:>+,

17o/1/-\"~-1;!£Q

18

20

22

24

26

28

30

32

34

37

17

01.

BUSHING

~~~1*

PARTS

16

I

For

ON-2LHS

DN-2LHSm

,<O

18

01.

BUSHING

$dr~OO~

PARTS

l@:j:

Ref.

1 004003

2

3 3/16S28017

4

5

6

7

8

9

9-1

10

11

11-1

12

13

13-1

14

15

15-1

16

17

18

19

20

21

22

23

No.

031082

1A01004

031111

1A01002

031091

3/16S28014

031073

041033

15/64S28513

031063

041043

15/64S28516

032081

042031

032071

032061

042021

15/64S28516

032151

15/64S28501

032201

032161

032211

15/64S28516

092062

'tfBJ'piff:%

Part

No.

Oil

Seal

Crank

Shaft

Screw

fbr

Ball

Bearing

Collar

A

Ball

Bearing

Bearing

Screw

fbr

Crank

Shaft

Crank

Shaft

Screw

fbr

Crank

Shaft

Crank

Shaft

Screw

fbr

Arm

Rocker

Arm

Rocker

Arm

Rocker

Arm

Rocker

Arm

Rocker

Screw

for

032061,042021

Needle

Screw

fbr

Presser

Needle

Presser

Screw

fbr

Needle

(SC224211)

Bushing

Housing

031082

(6202ZZ)

(6302ZZ)

Holder

031091

Bushing,

Bushing,

031073,041033

Bushing,

Bushing,

031063,041043

Shaft

Shaft

Shaft

Shaft

Shaft

032081,042031,032071

Bar

Bushing,

032151

Bar

Bushing,

Bar

Bushing,

Bar

Bushing,

032161,032201,092062

Bar

Bushing,

middle

middle

front

front

Bushing,

Bushing,

Bushing,

Bushing,

Bushing,

upper

upper

lower

lower

lower

'tfBJ'p~f*

Description

rear

rear

middle

front

front

;t

-1

Iv-/~

Iv

~71/Y-:fJr~

;;(.

-*:/

*~;v~7!)Y~

jfJ~A

*~107!}:/~

~7!JY~~.:i:.

-*:/

-p:p:t'-::.,"1/.::r..

-p:p:t'-::.,"1/.::r..

-*:/

r~tr:::l-::;"1/.::r..

rM":7-::;"1/

.::r..

-*:/

J::*7-::.,"1/.::r..

J::*:1'-::.,"1/.::r..

J::

q:t:1'-::.,"1/.::r..

J::

~tr::f-::.,"1/

J::

~tr::f-::.,"1/

.::r..

.::r..

-*:/

*$:1'-::.,"1/.::r..J::

-*:/

~.:i::.$:1'-::.,"1/.::r..J::

*$:1·-::;"1/.::r..

~.:i::.$:1·-::;"1/.::r..

r

r

-*:/

*$:1'-::.,"1/.::r..T

ffl~Q'ty

DN-2HS DN-2LHS DN-2W

1 1 1

1 1 1

3 3 3

1 1 1

1 1 1

1 1 1

1 1 1

3 3 3

-

1

-

1 1 1

1

-

1 1

1

-

1 1 1

1

-

3 3 3

1 1 1

1 1 1

1 1 1

1 1

1 1 1

2 2 2

- -

1

-

1

-

1

-

1

1

-

1

-

1

1

-

1

-

-

1

trio~

Remarks

19

02

OILING PARTS

-~AA~~

26

Fer

°"-21..HS

ON-a.HS~

,Y--,~

@

20

,,_,o

For

OSM,'7N,6N

OSM,

'7N,

6Nlft

02. OILING PARTS

~M~-f*

Ref.

$8'riffi:%

No.

~·

1

1-1

2 W3/8Sl6001

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

32-1

33

34

35

36

37

38

39

40

Part

035251

045071

035302

035741

D05002

035282

035291

3/16S32023

015151

D06001

2Wl0

015141

015142

035381

15/64528516

1/2S24501

035721

035921

182271

11/64540072

035931

035651

035271

11/64540010

ll/64N40201

035321A

3/32S56006

035312

035321

D07006

D07008

035631

045161

035661

ll/64W15103

11/64540009

0354343

11/64540005

035821

065401

255351

No.

OilPan

OilPan

Screw

fur

035251,045071

Dust

Cover

Rubber

Pad

Oil

Gauge

(HL

Oil

Filter Cover

Oil

Filter

Screw

fur

035281

Oil

Pipe

Cock

(PFl/8)

Washer

fur

Oil

Pan

Fixing

Oil

Pan

Fixing

Oil

Pipe

Screw

fur

035381

Screw

Felt

Oil

Pipe

Collar

Screw

fur

035921

Felt

Felt

Holder

Screw

fur

035271

Nut

fur

035271

Coupling

Screw

Oil

Coupling

Compression

Compression

Oiler

Oiler

Cover

Washer

Screw

Cover

Screw

Fence

Rubber

Rubber

fur

Pipe

and

035321A,

Bush

Bush

VA--01)

015141,015142

Screw

Screw

Oil

Pipe

035321

Bushing

(M6252--6)

Sleeve

(M6254--6)

$&~~

Description

{l~Q'ty

;;t-,{Jv/~:,.,

;;t-,{

Jv

/~:,.,

*1/

~Mtlit

https://manualmachine.com/~:,+

;;t-

-1'

Jv3/-1/

7.:cJv

1-1'.::r::.

;;t-,{

Jv7

-1

Jv~-

*1/

;;t-,{

Jv~q'-/~,{7"

eo-::zo/::7

17o/:/-Y-

;;t-

-1'

Jv

/~:,.,J&fi-7-*1/

;;r,{

Jv/~:,.,J&{i-7*1/

;;t-,{

Jv

/~,{7"

*1/

*1/

~71E~

;;t-,{

Jv

/~,{7"

jfJ-

*1/

~71E~

~71E~

~71E~1'.::r::.

*1/

To/I-

i",{JL,1~,{-::f.:1..-=#~

*1/

;;t-,{

Jv

/~,{7"

.:L=#~

DN-2HS DN-2LHS

1

-

3 3 3

1 1 1

1 1 1

1 1 1

2 2 2

1 1 1

2 2 2

1 1 1

1 1 1

1 1 1

1

(1)

1 1 1

1

1 1 1

1 1 1

1 1 1

1 1 1

1 1 1

1 1 1

1 1 1

1 1 1

1 1 1

1 1

1 1 1

4 4 4

1 1 1

1 1 1

DN-2W

-

1

-

1

1

7o/://'-!/ 1 1 1

;(.!]-7''

*it71E:tm.@;/J~:,.,

::7

*it11E:tm.@;/J~:,.,::7

*ii-11E:tm.@;/J~:,.,::7jJ/~17o/:/-Y-

*1/

~/~-

*1/

7:r../'A

=i.'.b,q'--yo/7"

=i.'.b,q'--yo/7"

1 1 1

-

1

-

1

1 1 1

1 1 1

1 1 1

1 1 1

2 2 2

1 1 1

1 1 1

2 2 2

1

-

1

-

1

1

1

-

-~

Remarks

for DSM, 7N,6N

(27)

(27)

21

03. MISCELLANEOUS COVER PARTS

jJ

/ '\

--

~

ffi

For

1J,1-2LHS

1J,1-2LHS.f:l:I

22

03. MISCELLANEOUS COVER PARTS

j]/~--~~

im

J'1=1

ffi:

~ffi:

Ref.

No.

1

03511

1-1

045051A

2

035141

3 15/64528516

4

035131

5

9/64S40003

6

11/64540008

7

7/32S32007

8

015081

9

015091

10

3/32S56008

11

035151

12

15/64528018

13

15/64528017

14

3/16S32028

15

015111

15-1

025031

16

3/16S32004

17

035232

18

035222

19

11/64540006

20

035491

21

035481

21-1

035481L

22

9/64S40005

23

065401

24

035211

25

035191

26

035201

27

9/64S40035

28

035941

29

11/64540005

30

035911

30--1

045191

31

9/64S40004

32

035181

33

035171

34

9/64S40005

35

035241

35-1

035241L

36

5/16W05201

37

15/64528017

38

035261

38-1

045081

39

3/16S32024

9/64S40502

40

41

035952

41-1

045122

42

035691

43

15/64528511

44

9/64S40005

45

035642A

46

035831

47

EOlO0l

48

lNWl/4

49

035642

Part

lA

%

No.

Cloth

Plate

Cloth

Plate

Pin

Screw

for

035141

Cloth

Plate

Screw

for

035131

Screw

for

035131

Screw

for

035111A,045051A

Cloth

Plate

Spring

Screw

fur

015091

Stopper

Spring

Screw

Screw

Screw

Guide

Guide

Screw

fur

015111

Gasket

Rear

Cover

Screw

fur

035222

Gasket

Top

Cover

Top

Cover

Screw

fur

035481

Rubber

Bushing

Gasket

Side

Cover

Side

Cover

Retainer

Screw

fur

035201

Needle

Bar

Cover

Screw

fur

035342,035941

Cover

Cover

Screw

fur

035911,045191

Gasket

Face

Plate

Screw

fur

035171,035952,045122

Side

Cover

Side

Cover

Washer

fur

035241

Screw

fur

035241

Oil

Filter

Cover

Oil

Filter

Cover

Screw

fur

035261,045081

Screw

fur

035261,045081

Face

Plate

Face

Plate

Holder

Screw

fur

035691

Screw

fur

035691

Needle

Cooler

Base

Holder

U-Bolt (Wl/

Nut

Nozzle

Ass'y

Ass'y

Extension

Slide

Ass'y

4)