NEWLONG INDUSTRIAL CO., LTD.

BAG SEWING HEAD

MODEL

For Operator Safety

Thank you for purc h a s ing t he N LI

Model DKN-1 Bag Sewing Machine Head.

• This

manual

the

Model

sure

to

use the

•

Keep

Be

when lending

company.

• Please order this

is

lost.

•

The

contents

without prior notice for improvement and safety

purpose.

&Hazard

•

Be

careful, when you insert a bag

the

sewing

machine,

the

machine

•A•

Hazardous" mark

sewing,

be

sure not to touch on the

the

DKN-1

understand manual before

near the

sure

to

attach

or

transferring

manual

of

this manual are subject

of

Bein1 Cau1ht

or

between the presser foot and

iB

Sewing

sewing

manual

it

to

another person

from the nearest

in

the

to

ycur

fingers may

attached

to

the machine.

machine.

be closed into

Head.

for

to the

NLI

office

to

Machine

be

caught in

feed

Be

use

and

machine

or

if

change

dog.

When

:..:i.-P

:J:3Ji:i,

e

,:O)J&fJHllJHFl-;t

itffl

16tlill

:iE

•

;::O)J&flll

ltQJ:?,

DKN-1

,:O)J&fllllJI

it

e.:©J6tf1ia1J1•~~~~tt,tt;&½tt:.~-P~~I-

(m½m!i1Mi;il:.:::~ttX<tt:~1,

1/!/II@(.)

,J::lf\, ,'ft.te~°fl

DKN-1~1\ltl!ffl:::

J:

O)J':Ui*ll:6~ie«~n

l!JH!f

~~-

-f

:toff

L-<

~

itffl

<tt:~1,

'o

l!JH!fli~v~QJ-c

f*tfl.,

't"<tt:~"'·

~JU~ffl~~~~l.,l:f:IL,,

1'fa-1hU:.:::~t..,

DKN-1

~

M;

li-<

tt:~1;

J'!l:.:::,

R~ffl

~~1,

'*To

~~O)

,:-1,

''ti"

o

~

'o

l".1$~+~J.mff¥L-

1,

'--:>'1:t>~IJffl

'3:1tl~Jlill0);&€N-;S:

i:-<

tt:~t-

'.,

\,

• .:©16tii~M•1~lltm1AJJ:*1ttt~½©1t~,

l:~J!i"o.:>:.iJ~ib~'£To

&-~~-

• ~~~1r.aa-1'7'-to>:.~t.t~•L-'.t"'~tt~¥fl:c.~

1:.:::*i)i•~lb *M~tL:61~tJ*i" o

• ~v~lr.1-J:#ib~;i:-?-~~~-:> 't°ll

flii,S~v1/lr.i«-~tJ~ftl, '.l:?

'°£Ta

l:.:::ttB:L-

't°(~~ll

~

V1/~

16tlill

itffl

t.m:.:

7i!ftit..

,jj#;_}:.

©

,:-

1,

,tttt:

'o

~ Hazard

• A Needle Bar end Needle Thread Take-Up

moving

to

the

keep fingers and yourself away from the Needle Bar

and

Needle

of

Being Caught

at

high speed. A·

machine.

When

Thread Take-Up.

Hazardous"

the

machine

in

the

Machine

mark

is attached

is in operation,

are

~

-~~-

• tt•J:J:*~ffJ":J:ii.il("t*lbv

~v~lr.t;t~~-~-~~M-:>-Clr

~~~»~11J1,

ili:-?,ttt1r \

,,:-1,

'o.!:::~1-J:tt*fi.!:::l:*~~1r.m~f*a-

"t*(

~~l,

'o

''t°"

'*i°o

'*i"

a

• The instruction manual

• =o.>lDlllll'-1•

/,

and

<--.:,•J

parts list

A H:t•1ua:i

is

subject

..1:

o.>t::~~trt~L.r=•J!T

to

change without prior notice.

.f>=~titt>

~

*1'"

D

WARNING

Wilt

P E R S O N A L I N J U R Y M A Y

RESULT

SAFETY

NOT

OBSERVED.

1.

BE

SURE

FREE

OF

OIL,

RUBBISH

INJURY.

2.

DO

NOT

CONDIT

3.

DO

NOT

INSTRUCTION

4.

DO

NOT

THAN

SPECIFIED

5.

BE

SURE

ELECTRICAL

6.

BE

SURE

BEFORE

PARTS

CLEANING.

IF

THE

PRECAUTIONS

THE

AREA

SURROUNDING

ALL

HAZARDS

OR

OPERATE

IONS.

OPERATE

MANUAL.

OPERATE

MACHINE

SAFETY

POWER

PERFORMING

REPLACEMENT,

SUCH

ANYTHING

MACHINE

MACH I NE

MACHINE

FOR

IS

ON

THE

CONNECTED

GROUND

(AND

AIR

MACHINE

FOLLOWING

MACHINE

AS

FIRE,

THAT

CAN

UNDER

MACHINE.

ADJUSTMENTS

WET

BEFORE

READ I NG

VOLTAGES

TO

BUILDING

(EARTH).

SUPPLY)

MAINTENANCE,

ARE

IS

WATER,

CAUSE

OTHER

IS

OFF

OR

~~©~~~§~~~L~~~~~e

l:::11$i!iS(©ffl\~

L < t=~

1.

It~

~--

(f::~l,\o

2.

1J<fr2i

l,\""(:(f::~l,\o

a

~mm~•~~~~~-c:~;•~~~tiL

-C

(

4. lt~O)}~>E'.ffll±J~Bi--c:l;t~fi

~l,\0

5.

7-AftfJfti*!c

t::

~

6.

-~O)Jf-filfi • $~3'.tf'l •

AAl::~~~:Ji

t::

~

0)

Jal

11<

..

tJf

i~Ji

f::~

I,

\0

I,

\0

(,\0

u1

im

..

i!Uli

l,\o

c.

~

1.J

"t"t©"t:5±~ L

I:: $

i!&

~

®

.:.

9

i:iJ:l!~tJ:ctJftJ:1,,tJ,.fiitJ,~-c

I::

fJ,

tJ,

7a>

II

:J:;t-c:

~*1,

-CI,

,7a>$~m~ L -C

~ff

C.&tFI7-:Ji)

mi

~

c.

f.J:

l;t

fl

ffl L

Lf.J:L'-C:

•

:Rl;;l:tffllf*O)

~~-:,-C(

7a>

!k

t.J:

<

t::

<

7.

DO

NOT

OPERATE

COVERS

8.

DO

AND

REMOVED.

NOT

TOUCH

MOVING

OPERATION.

9.

BE

SURE

MACHINE

(LEVEL)

MA

I

NTENANCE,

ADJUSTMENTS,

10.

BE

SURE

THE

COMPLIES

11.

DO

II

NLI,,

WITH

NOT

USE

GENUINE

MACHINE

KNIFE,

PARTS

SURFACE

NEEDLE,

WHEN

IS

PLACED

WHEN

PARTS

CLEANING

MATERIAL

THE

SPARE

TO

MACHINE

PARTS

PARTS.

WITH

GUARDS

PULLEY,

MACHINE

ON

AND

BELT

IS

IN

A

SMOOTH

PERFORMING

REPLACEMENT,

OR

STORAGE.

BE

SEWN

OR

CLOSED

SPECIFICATIONS.

OTHER

THAN

7.

ii~:ti

f.J:I,\""(:

~

-~O)~ti$~:ti~,-

~Jv

f.J:I,\""(:

9.

-~O)--filfi·!B~3'.tf'l·~--fffl~~~~O)

~[::[;t:ijI

10.

-~

7a>

11

11.

-tlffl L

1{-tJf~*1,f=~~-c:l;tlt~~~,ii

<

t::~

1,\0

.....

1--

-f

O)ft!ll1.J

<

t::~

;t.J::flj:iJr[::Thfl,\""(

-3

c.

"t"

tJ,mtJ,~ -c <

=.:i.-CJ~~I¥(+*)"

~I,'

1,'

-c

1,'

7a>

~

rJfl::

l,\0

<

7a>~~tJflt~O)i±~l::-€i"-:,

t::

~

1,

,0

~iE!B~~~[;t

1: <

t::

~

I,

'0

~-~-

l;t-¥

t::~

l,\0

L

..

~Mn

-C

1,,

Identifying and Ordering Parts

Cautions When Using the Machine

Maintenance

Where

stamped with its part number.

include part number, part name

machine.

•

•

•

the

construction permits, each part

On

all

and

model name

Safety Rules

To prevent personal injury:

All

power sources

before threading, oiling, adjusting or replacing parts.

All

cover and guards must be in position before

operating machine.

Do

not tamper with safety cover, guards, etc., while

machine

is

in operation.

to

the machine must be turned

is

orders, please

Safety Precautions

l)Always

adjusting

2)Wear safety glasses.

turn

power off before threading, oiling, and

the

machine or replacing parts.

of

•

:=.::i.

-01/:t'I:~

8'1=1:a:-'M-uml.,

• :::·r±xO)~l'i,

<tc~'v'o

off

(~)

~00i!l!if4tffl'l;:.fj: DKN-1

-C:t3VJ~To

/';-o/D7.J--O)/-/;-o/:ffi:%t1;~--c-:::·m~

•~fflJ::~~~~~&O~ffl~O)~-~~-~~,~

O)ft!tlf-vmttt·--c-mVJ

L,t~:=.::i.

r,!;j~O)~,

:a:-~m~<tc~v

-o1/:1'I~(~)~OOJ!i!if4tffl'l;:.;::'J!!!if4t< tc~v

~f.11;' ~~:ffi:%'

1>~~~VJ·*-wJnO)t'e:O)*ifill.,,

$8'1=13t~,

V

\o

f:Ji1:"r,¢.e~f'f~O)trJf;:.~,--r•n»::a:--wJ0-c<tt~

'~T

1;:.<1v

,~,g-1-;t,

J::5:td!ffiv

:t3J'lv

,J::Jf1v

~y1/JijHf~1;'

'v

,t~t.,~-t"a

*0)3t~,

2)W.Om{'f~O)t'e:l'i'tc~}jj-*O)~ffl:a:-:t3-t"-t"0'>L,~-t"o

O)KuliIEI~

,t~tt'e:~

~y1/:ffl:%

~rm,

wmm,

'a

that

3)Make sure, before starting the machine,

in

covers and shields are

4)Do not touch on the machine when it

5)Turn power off and make sure

operate before you put your fingers under the

blades and the needles

6)Do not touch on the machine when it

place and closed.

the

cutter

to

adjust.

is

is

run.

run.

all

does not

cutter

• Please keep in mind

and

to

maintain

• Thread fuzz or dust must be cleaned with air or

brush on throat plate, in the groove of feed dog or

around looper after

• Wipe

• Check the machine for loose screws and tighten

• Good maintenance

the

area easy

them, if any, once a month.

to

handle

the

machine in good condition.

the

day's work.

to

rust with oil cloth.

will

the

prolong

machine carefully

the

machine life.

4).iJ/'{-ftt·7i~M~0-Cv ,;s::.t:a:-$~L,

~V\o

5)iJ-O) r 1;:.-¥:a:-An-5t'e:l'i,

{~;E!l!w.ffmO)

:a:-$~L,

•

~y1/Jljf~l'i~-\tft1J,~ft$

r±Jt~<

t'e: l'i,

~,

-ci'i,Gf'F~:a:-n-0-c<tc~v

I&:lJk5

ttt

~,

--rtn»::a:--wJ0

--rm:n»::a:--wJ

8'1=1i'i'Gl±Hf~J::i'i~0

f;:. m 1;:.m,o;

-c7i,G3ffi'.~L,

VJ~y1/7i~IIJ7i,ftv

'a

f;:.,tAtHt-c

• - a O)f'f~i'i~~TL,~L,t~G, ittfO)J::,

~,

1v-/';-O)~:bVJ 1;:.~~0tdl::.VJ~l'i'e:nv

~1v,-c<tc~'v'o

•

-¥

AnO)

~

Ull

L,

l'i~~

0)

~~

f ;:.~9

L,

<tc~'v'o

-c

<tc~v

-Cv

'~Ta

< tc~v

'a

j!!J~0)7$\:0)

,1;:.I&VJ

~TO)

--c-

:::·

-c<tc

'a

,::.t

r±tt

ii

CONTENTS/

1.

Specifications/{±~ 2

2.

Threading/*iffil,

3.

Lubrication

4.

Adjustment/1.ffilff

4-1 Needle

4-2

Looper

a) Check

b)

Needle Height1*(J)?ili~

c) Space Adjustment between needle and

d)

Setting

4-3

Aqjustment of Feeding

a) Level Adjustment/

b)

Vertical

c) Longitudinal Aqjustment/jW'~(J)wl/1• 6

d)

Crosswise Adjustment/ti.ti(J)wl/1

e) Setting Upper Feed Dog/ J:~lJ:&(J)wl/1

/~AA

Setting/*(J):it~----------------------------4

Aqjustment/Jv-r{-(J)wl/1•

the

Loop

Aqjustment/Jk-'jZ-(l)wl/J•-------------------------6

distance between needle

--------------------2,3

center

and looper

............................................................................................................................................................................................

looper/*.l:::1v-/S:-(J)ri,i~

Guide/1v---;/'7J~p-

Function/~lJ:&(l)wl/J•---------------------6

J:T(l)wl/J!ifl:--------------------------6

.........................................................................................................................................................................

......................................................................................................................................................................

..........................................................................................................................................................

edge/*.l:::1v-/S:-(J)iel!ll----------4

~

1X

.................................................................................................

2,3

4

4

4

5

5

5

5

4-4

Chenge of Stitching Length/ffl!it,\

4-5

Needle Guard

4-6

Presser

a)

b)

c) Mounting Top Feed Lifter/ J:~1J:&1J7?"-(J)wl/J•

4-7

Thread

a) Setting Thread

b)

c)

5.

T

roubleshooting/3:

Parts

Foot

Presser

Presser

Tension/i(::wl/J-f-~1*--------------------------9

Setting Upper Thread Guide/ 1:

Castoff

List/$£~

Numerical

Aqjustment/*:Jf-]-'(J)wl/J•----------------------7

Adjustment/W.::r::&(J)wl/l!ifl:-----------------------8

Bar Height/iWi~wlll•

Foot Pressure/fljl.::r:fE(J)wl/1•

Tension/if::wl/J-f--------------------------9

Wire/

if::

"Ji;.

1...,

.................................................................................................................................................................................................. 9

"1/'~

-------------------------13-

index

of Parts//~---o/71{5[

!::l

ijljl'j(J)wl/J•----------------------7

.................................................................................................................................................................................

............................................................................................................................................................

-------------------8

.ff.:

ft

~F

...........................................................................................................................................................

1'

7"/

Jv(l)

)]j{

~

~M;r&

------------32,33

List of Screw, Nut & Washer/;.f'1/, To/1',

---------10,11

?o/"1/'-Y---~!i~

9

9

9

----34,35

1.

Specification/{±~

Maximum speed:

Stitch range :

Seam:

Lubrication system :

Application:

Maximum thickness

Thread:

Mode/·~~

Bag type

Seam

Needle

Feed

Dog,

upper

Feed

Dog,

lower

Throat Plate

Presser Foot

Looper

Throat Plate

Thread Retainer

of

material:

~fiffi

~§~;i:\;

it

1::*!J1i'l

*%k

itt.oc

}ljl::r..1]}:

1v~.1-{~

itt&Jl\

~

i@i@J

~~

~§~i

~§~;i:\;

*S-lm

~~~

~~P=J[

3,500rpm

4-8.5mm

Double thread chain stitch (type 401) 2 :m]\lt~ (401)

Fully automatic

For PP woven cloth bags and PP Paper bags PP

6ply gusseted kraft paper sack or equivalent

Vinylon Synthetic or cotton,

*

DKN-1

PP

Paper Bag

~~

Double Thread Double Thread

2

mffl~

DN-1 #25

51126N

51105N

51124E

51120N

51108E

-

Woven

Cloth Bag Cloth Bag

pp

::7t:1A~

2mffl~

UY143GS

754031 51126N

754021 51105N 6605L

754011 51124M 6624L

752011A 51120N

51108E 51108K 51108E

-

13

1b*S'7ll3

200

20/6

or

20/9

Paper Bag

*.El;~

Single Thread

.lj:f.ffl~

DN-1 #25

AV

::7t:1A~·*.E!;~

*.E!;~~JJ

DKN-1BP

PP

PP::7t:IA~

Double Thread

2

UY143GS

75-1827F

6

/ii:::::$f

Woven

mffl~

-

-

fst=\'-

200

2.

Threading/*

3.

Lubrication/mM

Oil

is

completely drained out of the machine

when delivery.

before starting the machine. The

procedure.

• Open the

with

oil

line. (Fig.l) Use mineral

40°C.

• A brand

certain period should be

a)

Upper needle bar bushing (51154C) and lower

needle bar bushing (51154D)

b)

Feed bar (51134X) and upper feed bar (51134L)

c) Feed crank stud (51136E)

d)

Feed lift eccentric ass'y (29476DY) and looper avoid

eccentric ass'y (294760S)

• After

necessary to

line. Check

• To drain oil, take out the plug screw © beneath the

pulley. (Fig.

• Change

Be

sure

oil

cap @ mounted on shoulder lid, and

till the

oil

Example: Shell Tellus

new

machine or a machine out of service for a

oil

bathed once as mentioned above, it

fill

oil

oil

level every time when operating machine.

l)

to

new

oil

iffi

L-

in

our plant

to

fill

with

oil

in

the

oil

reservoir

followings

level of the gauge ® comes

oil

of

22

to

oil

#32.

well

oiled as

unless

oil

level indicates below lower

after every 2,000 hours operation.

32 cSt

follows;

are the best

in

viscosity at

to

upper

is

not

fill

DKN-1

tc:l*~'t"/±lfi/JL

flii~fflL

G~~L-c<tc~1t'o

• l::iH::.-01t ,-ci., '0::?J--11v=\'--y::.,7"@(39582L)~lllHt,

•

•

e

• 7ll31±~1/J~OO 2000

ru~~J:ll~~<1/f'i

-Cv

-Cv'ftv'~1/1/~~~T6c1:::~I±,

7ll3L,

-C::?J--1

;v,1/~1/®(50-648)~

""-JvO)

J::0)7..{1/I;::.

40°

T671Bl'i

~ffll.,-C<tc~v'o

C f;::.:t3ft01b*i!iil'.

(f1tl)1/.:r.Jv77A::?J-..{

~u,~1/1/bfl:l

5t0)::?J-..{

't"r=l:7ll3L,-C<tc~1t'o

a)

b)

c)

d) * !J

e) itf*v.1~~!)::..,,::7(54)

1v;o;-\Wn

it-$7:;.,1/.::z.l::·T(51154C, 51154D)

*!J

±il'(51134X),1::*!J

*!Jwl31{fi$fb(51136E)

1::

r

7J

A

(294760S)

~1/1/~-'¥-c:}!g(L

~1/1/~

.:r.1vH;::.L,.7j.:bfcGit'*To -i-O)~{l}V~t~1;::.r=t7ll3L,

G~~~~a.lfJ-c<tc~v'o

4if:

-/i'.r=l:7ll3L,'*""t

Gftv

l'i,

-c<tc~v

7ll3;o;~1t'*""to

10

000ffl/i'.f.!f5*-c:}!g[L

f::l

O)~~irrJt;::.~,f::?)-..{ JvV""-Jv~l/i~l.,-C<tc~v'

'~ilJ,

r=l:7ll30)~,~l±iblJ'*itlvo

7"~

!J

~O)

T t;::.;b6

\0

~1/1/~:t'~!J~fjf)Jt;::. Tl-f-C{~IOt6c1:::M

131/J~Mru~1/1/l'Ti0;71B~~1t'

"*To

W.lfJ-c~~T6c1:::~,

~71Bl'i~O)im1Jh:.f-]'-:i-C<tc~1t'o

~/t;o;G,

<6

'*'t"r=l:71BL

-C

<tc~v 'o (Fig. l)r=l:A

22cSt-32

'*fdl:l

~,fr=l:ML

M;o;::?J--11vv

cSt O)jt7ll3~

Jv#32

~~rJ.l~fflL

-Cv

'0~:h,;o;iblJ'*""t;o>G,

*1J.

(294

-CrltG;o,1;::.@J~T0.:.c1:::~$~L,fcibc1:::,

-c1t,ft1t

±il'(51134L)

76DY)

,

Jv ~ .1-{

-c,

,~1/1/l'i,

~,f

~

~j

L,

7ll3~7E01;::.::?J-..{

c1:::7ll3;o;::?J--11vv""-1v0) T 0)7..{::..,,;o,G

~00-c:3'.t~L

7"'7~'©(Fig.1)(22571A)~l'ifL,

-c<tc~v'o

7ll3~~<c1:::~

m'lb®

.c¥~L

7J

~~

-C;o>

r=t

A

*..ll

1v7

-C;o>

0

T;o;

.lj:f.l;::.

2

AU.

MAIN

Oil

*

Cap

,'(

)l,~-r:,:1

1

Needle

(J:.Kt)

2

Thread

Looper

("'FKt)

Mltaf'

C

+

......

~

Thread

Plug Screw

*~

CAUTION!

ALL

OIL

BEFORE

MACHINE

BEFORE

RESERVOIR

STARTING.

HAS

BEEN

SHIPPING.

tta!

-~~:.,~m&1"

l&"rttMIL:C<t:~I.

• ,::~:0,0).il Ip l.t~..,

-~-1.

illlff:

\"((f:~I.

DRAINED

'•

'o

~-~

~~ Oil

ef

- -

KEEP

BETWEEN

·

OIL

LEVEL

LINES

Gauge

*"'

)1,J/~.)

3

4.

Acijustment/wi.Jm

The machine

before shipment. However, in case

yau

to

or

replacement

manner.

4-1

Needle

Insert a

The concave part

stitching direction. Then, tighten

to

avoid loosening of needle. (Fig.2)®

• Confirm if

to

move needle up-and-down.(4-1)

• For your

distance between upper

lowest point

goes up

4-2

Looper

a) Check

edge.

When the looper is reaching farthest right position,

adjust

edge

direction, on

twn

* Pay attention

b) Needle Height (Fig.2)

Adjust the height of needle bar so

can accord with looper hole when

is passing

done

the

hu

been adequately adjusted

that

adjust in the field according to disassembly, mending

of

parts,

follow

Setting

new

reference,

to

Acijuatment

the

{Fig.3)

the distance between needle center and looper

to

be

unclockwise direction.

by

moving needle

screw A

(Fig.2)

needle into needle bar as deep as

of

needle should

or

not the needle face is

it

is the easiest manner to adjust the

surface

of

needle hole

the

highest point. {Fig.2)©

distance between needle center and looper

3.9±0.lmm,

the

to

the

.rear

side

of

needle bar holder. (Fig.2)@

turn the joint rod(C) clockwise

contrary, if more than 3.9 ± 0.1mm,

nut A

of

needle. The adjustment is

bar

the

be

the

of

to

be

as

it

is left-threaded.

the

up-and-down after loosening

at

our factory

it

is

necessary for

below mentioned

it

faced

to

rear

needle bar nut iinnly

set

correctly, trying

throat plate and

19.5mm

that

when needle

the

needle hole

left edge

of

will go.

side of

the

looper

to

be

DKN-1

t)l,

~t-#

4-1

!f!tv~l~!i*tl::-r!il:iEt.ttlll!lfEt-L,

tns&i

~-fl~"t'IMJlt>S~,Jf •~flt.I*

lfff

VC111!£L,

"C

< fe~i,

'o

tf-0~-

"Cl:f::\Jil,

L,ft;'

"(\,'*T

1k

0)1/l'iJJljj

tl-OJJ&#lt (Fig.2)

ttt-fflt#lt

a)

fJ-0)

l;:1fiHt-Cfflt#•t-c<t.:~1,

b)

tt•l~tt~•t.,;.M:rl::~,

,bA,

-o~~l-.tll•ti~l::?l~=

.it.

<"tJ~(ft~lli:<

~<

,e~i,

O)D!J/v~1,

'o

-tUJib~tt;lt-r7t-(56):(:l,-:>tJ:.tJ.ao-0

-0ibt.1"£i'"

o

'-oi6~~)~0)jlfjjjraJ

'o

(Fig.2) @

tttii-0:ti:.;to*~-~,;:-1..,

•t-c<t.:~11,.

tto.>

..t.

"'F

• tt~J:"'fL,ftl::~l~tj:, ftO)raJ~l=tttL, "C<t=~i,,.

•

ttiMi'l>J:iJ~"'.:>/t.utlR"t',

~~

19.5mm

i'". (Fig.2) ©

ru

ttOJraJ~~lflJil*--ol::,

lr.tJ:tJ

,~ibt.>-ltol::Jv-.1{-0)PJJIO)l::~11.illi"t'

"£To

tttii

dlr

ttUttJ:.'!,ft~OJ"'fffii"£~OJ-t

1v-.1{-~tfl~ibtttJ,

tittJ.

*it.ttlr.

{It,~~~

-ob~Wtt.,

*Wtt.

IHll'Cltii~~~r*i"• ~1..,1,,ftl::~-1..,-c<te~i,,.

4-2

)l,-1(-0)9.I.

a) tt.!::1v-.r~-UJffi!ff (Fig.3)

,1,,-.,.{-titttJAL,

MM.!::tf-UJtp

le~

A(269), B(18}~lJaD-CPo/r C(43242N)~JIL,

<t=~i,,.

tf-l::lv-

"C,

ru

-r,;,f-(269)1'1~-*V~i'". Jli'":ntal

,C.,*~UJitiM1'1

1,,.

1v-.1{-Vs

.r~-0) Ill

iQ!l::k~i, ,.-ft-1:tliMl:Bt.,

"C:ll'l>tiill!l

,(

l!lti~,J,.;1,

l~~tt.!::~.

3.9mm±0.lmm

~l-

P,;,

r(43242N)

,;!l½tj:, Po/

"C<t=~i,

l:~,lt,

1v-.1{-0)~

l::.1'!£L,

UJ

-r-:1

"C1'flEL,

r~~M

'•

l~JWL,

"C<t.:~

1,,.

b)

tf-O)jl!fj~

1t--rt-t)!:nfjjll,

i"-o~~' ,1,,-.,.{-0)~,!::tf-~tJ(-§ci"-oJ:;

~~--L,

Rf£1'1tf-*-1@&~(51254H)OJ-*

(51117)~

"C<t.:~11,.

J:

-C,

Jt,-.1{-0)~i\'ltlltf-O):fl,!,~lffiil

{Fig.2) @

"'f~-lt"(ftffjl,

V(22562A)~llao,

"C<t.:~1,

,.

l=tt•O)jl!fj

ti-*'

-c<

f-

"(

Concave

;r.!f!}f6

Needle

tth:.\'-

A Screw (22562A)

-*V

Bar

Conneotion

(51254H)

Part~

.

JJ

/A\

'-&

==

..,

Ball

Joint

~-,trh,{:Yf-

(52841.A)

~

LF--

Clamp

Nut

(56)

tt•-ro/l-

0,

4-_

®

Looper Rocker

Jv-.1<-,c±'tt

4

1

111

3.9±

0

·

1mm

j

~

Frame

(51244)

ANut (269) (43242N)

'To/I-

!

Looper

/t,-;'{-±it

Rocker

Rod

(753071)

P,;,r

1---Dscrew

C

looper

(225~

*~

Connect.ing Rod

~

,1,,-.,..i:-Vs--f~I-Po/t:'

(29192)

Fig.3

C)

Space

Ac:tiustment

Adjust

the

space between concave

to

looper

and pa.sses

-0.05mm,

frame shown on

d)

Setting

Set the loop guide so

side

be A=0-0.05mm when the looper goes forward

rear

first loosen the screw D

Loop

Guide

of

needle when

Looper

,1,,-.1~-

o--o.osmm

between

side

of

needle.

Fig.3 and

(Fi1.5)

that

the

looper moves forward.

(51108E)

needle

and

looper

part

To

obtain

the

of

then

incline looper rocker.

it

will

slightly contact the front

(Fig.4)

of

needle and

figure

A=O

looper rocker

C)

tt

~Ji,-,

Jv-/~-fflllfJ"-A(51244B)O)..:t-~(22519H)a~-Clv

-.1~-±-ti'(29192)~·10t-Clll~L, -C(t.:~1,

,t--.1~-il;tfr~L

SU.!:::1t--.,.~-.!:::O)IIIJl!f'H'i

1t

'o

d)

Jl,-:1:fl..(t: (Fig.5)

1t---:/P-1'r(75308l)J'11t--.1{-0JIIJ~l::.

<

.!:::~,

lt',,

~-o.>IUI

1111

-Ctf-0.)tl?l~ilillli"'o.!:::~,

{Fig.4)

fJ-0.)ifJ"t-~~Tillf

o-o.osmm

::.W!bi"'

8

Throat

Plate

tt-*l(51124E)

l::.tHliL--C<t.:~

oJ:;

l::.Jtit

A

Feed

~!J~51105N)

'o

(Fig.3)

tf-0.);t

.:t""'.J

-Cii:

~

M lt-c < te

Dog

@

<'~

l::.IIJ

~

Needle

tt

Loop

1v--:/P-1'r

Guide (753081)

Looper (51108E)

Screw (73)

*~

Fig.4

Feed Dog

i!!J.

Fig.5

5

Fig.7

4-3

Acljustment

of

Feeding Funation

4-3 i1

1

J•0••

Feed dog

a)

b)

c)

d)

e)

Adjustment

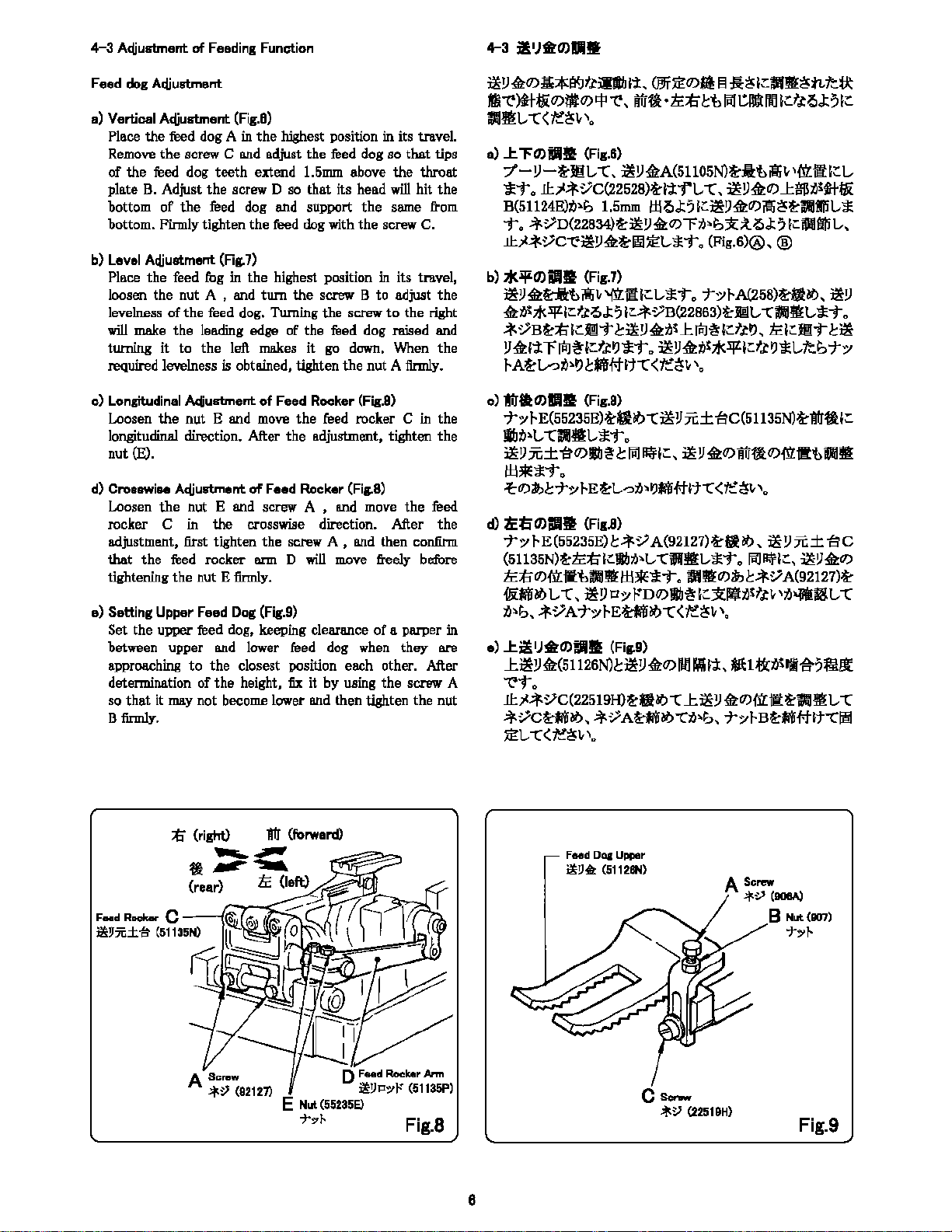

Vertical

Place

Remove

of

plate B. Adjust

bottom

bottom.

Level

Place

loosen

levelness

will make

tuming

.required levelness is obtained, tighten

Longitudinal

Loosen

longitudinal direction. After

nut

Crosswise Acliustment

Loosen

rocker C in

adjustment, first tighten

that

tightening

Setting

Set

between upper and lower feed dog when

approaching

determination

so

B firmly.

A<fiuatment

the

feed dog A in

the

screw C and adjust

the

feed dog

of

the

Firmly tighten

Ac:Uuatment

the

feed fog in

the

nut A , and

of

the

the

it

to

A<tiustment

the

nut

(E).

the

the

feed rocker arm D

the

Upper

the

upper feed dog, keeping clearance

that

it

may

(Fig.8)

the

highest position

teeth

extend 1.5mm above

the

screw D

feed dog and support

(Flg.7)

feed dog. Turning

leading edge

the

left makes

E and move

nut E and screw A , and move

the

nut

E

firmly.

Feed

Dog

to

the

closest position each other. After

of

the

not become lower and then tighten the nut

so

the

feed dog with

the

highest position in

tum

the

of

of

Feed

the

the

of

Feed

crosswise direction. After

the

screw A , and then confirm

(Fig.9)

height. fix it by using

the

feed dog

that

its

screw B

the

screw

the

feed dog raised and

it

go

the

Rocker

feed rocker C in

adjustment, tighten

Rocker (Fig.8)

will

move freely before

head

the

the

down,

nut

(Fig.8)

of

in

its

travel.

so

that

the

will

hit

same from

screw

its

travel,

to

adjust

to

the right

When

A finn]y.

the

a parper

they

the

screw A

tips

throat

the

C.

the

the

the

the

feed

the

in

are

~!J1tl(J)&*$9t.c•lblj:,

S"'('')tt*J:i(J)$(J)tp"-e,

<PJr~(J)l,il

nut&•

ii:::t"

~

:ll:~l::Nl'E~n~t\::

ct>

PllCR!Jtflfl

lO~o~?

111mt...-c<te~1,,o

a)

..l:."'FO)illf

-f-!J-t-Jff

*i"'

0

B(51124E):IJ:.b

To

-*

1.1:Jt-*VC-e~!J:ftt-lil~L-*T.,

b)

*3110>11.

~!J

{tdt

1ttt.ii,l(.ljll::f.toJ:5

VB'k::t"

*

(Fig.6)

t...-C,

~!J1tlA(SllOSN)t-M'.tiiit-

J.b1.:f

VC(22528)t-l-j:--rt...

1.5mm

l±lo~5lr.~!}{tt1)jl!fj~a-Jllltlit...*

VD(22834)a-~!J~(J)

(Fig.7)

J6i,

'fil:W

l:.

t,*i"' o 'To/

l:.-*VB(22863)t-i!lt...

l-:tm-t

<!:~!1

•tii

-C,

~!){ttl)

"f

ti:.b;l(;;t.,5~;

(Fig.6)@,.

J.

A(258)dao,

J:.

!Pl~

l.:f.ttJ, ii:

'OllRl-:t...

J:.tffl;blft~

J::l\lf

@

-Cllill'EL-*T

l:.ffl-t

JJ{t1tr1P1~1::t.ttJ*i"' D ~!J{t;>)I,Klll•=t.ctJ*t...~~r,,

f.At-l/.>iJl>t).!::*f#•t-c

c)

1irft0>•t1

'To/

f..E(55235E)t-.ab-C~!J jc±'f:?C(51135N)t-tfJttl::.

lb:b~t...

~!J

JC±

(Fi1.8)

~--L-*"t

'E?(J)IJ ~ .!::

0

lffl

<tt:~i, ',.

ll~H::,

~

!J

{t(J)

nufl

(J)-fitR'b

l±l**To

-ctl)il>J:1"'!1

d) tfti0allll (Fic.8)

'To/

r

(51135N)t-ti::::t"l::I/Jti:.L,

f..E'k

E(55235E)

L,~tl:.tJMM-.t-C

.!::-*

V A{92127)t-ll

-Cft!IIL,*"t o fiiJ~l::,

<tt.

~"

ab

'o

..

~

!1

jc±-f:r C

~!]·'1)

ii:::t"tl)utfRtlll'El±l**Ta lll'Et1)i,.!::*VA(92127)t-

-OiM~

t,

-c,

~!Joo/ ro(J)I/J~ l::xl!iJ»tt.ti, '>NiiiSt,

tJ:.b, *VA'T:YrEt-Mao-c<f!~i,,.

1

e)

J:.m

)'.0)illf

J:.~!J•Cs1126N)c~!J1tl(J)flOMU-.t,

(Fig.9)

~1~:b11i-A-:>&Ul

~To

.I.I:;(*

VC(22519H)a-a~~ J:.~!J •(J)fltiRa-R!IIL,

*Vet-Mao,

~L,

-c<f!~l,

-*VA'a:Mab-Cti:.;, To/rB'kM#lt-Cfflif

,0

1-:

ffljl,,

~!J

o

J:~

11§1

-c

-C

::t"

FMdRoeker C

ia!J;u±-t;t

(51135N)

(right}

....__,,.

-.r~

(rear} ii: (left)

A

Screw

*~

(82127)

tfr

(forward)

E

Nut

7'71-

D

(55235E)

Feed

Rocker

i!!Ji:r::,J:

Feed

i!!J.

Ann

(51135P)

Fig.8

6

Doa

Upper

(51128N)

C Scntw

*V

A Screw

C22St9H)

*~

(908A)

8 Nut(807)

-t-::,J-

Fig.9

4-4

Change

The

7mm

change

mentioned.

• Loosen

{Pay attention

•

The

stamp number

(The figures mean

• Confirm

stitch length

tightening

nut

of

Stitching

machine

in

A firmly.

is

our

plant

the stitch

the

nut A of

indicated plate C should be corresponded with

if

or

not

the

Length

(Fig.10)

properly

as

of

nut A • After

actiusted

before

delivery.

length,

by

follow

feed crank stud.

it

is left-threaded.)

the

stitch regulator end cap.

the

number

the machine has obtamed

trial operations after tentative]y

by

Should

the

procedures

of

stitch

the

confirmation, tighten

the

stitch

you

per

length

require

as

an inch.)

the

required

of

to

below

the

the

4-4

al!!l.0>i1Hf (Fig.10)

DKN-1 m!Uffl~v;:.,f-;tai

*To

fl

El

ffi'k~J!"t-ol:~li,

•

~9111Jif11117)7o/J--

tt)1--,t-A

• ~9111'i

tt~i,

l;Uf*~~T

8(51185D)~DL-

'•

~!)'9flj

1Xl7)Jll.ff~llmL-

A(269)f:ll~--C

B f::~J/vielt*t.t.{:.-f,,~!'JO)it

tt~-r.

e °To/r A

TAt-fi©jli

tr~).{l(IRLL.-?:bi.~ftr-t•t"'C

~abl.-

El

f.-.Jl

"'C<~~lt'o

"'C7Arfl1, '~l.---C(fe~\,

--C,

(-*~©al

1*fM.tJ1ffB~'*L-~~'To/r

<te~v

El

(17mm 1:llmL-

(te~1,

o

•-t:1:Hti)l::tta1.,

--C

W:ilfi'L-

--c

<te~1,

\,

-C(t::~l.'o

"'CO;!aj::~li~&H:::-Etb1t--C

'o

El

(ll:::t.t-:,"'(1,,-?,tJl.!!:>

A(269)a-

'o

--c1,'

'o

<

811)

<Attention>

In

case

that

the

stitch

length

is

changed,

the

needle

guard

as

well.

(Refer

4-3-3)

4-5

Needle

Guard

Actjustment

the

Set

come

concave

by

position

between needle and needle guard. Simultaneously adjust

needle guard

needle hole shall

needle guard so

in contact with needle when looper is passing

part

of

needle.

the

screw A when

to

the

the

needle, keep

by

the

screw B

be

corresponded with

(Fig.11)

that

the

To

mount

the

needle guard comes

the

clearance

so

that

absolutely

edge

of

looper may not

needle guard properly

to

the

of

o-0.05mm

the

lowest point of

the

•

x·

level.

adjust

closest

the

the

tt>

am

•~•E-t-i>4!:~rt.

~l,

"C(tl~I.

4-5

tt:fl-t:O>ilHI (Fig.11)

'·

1>-rtt:n-i:cs122s>0>111m

tttJ-t:'(51225)f'i, Jv-~<-:bttf-11);.l <"~iU©ll~iltr.!::

~,

,i.,-~~-0),9ct1/ibltftl~$-?tJ\~ti1,

tf-~jJ-~17)111Jlat.t,

(Fig.11)@

*~

A(2258B)dab--Ctl-1J-~f.-l/Jt)\l.-

B(22834)

(Fig.

nm:b~~-:ittt:,,

l,

'•

f.-

ll)@X

JI

l.-

7-{1/a--,C~-lt*"t'.

M'.biff--:,1,

"'C

,

tt

A'.

11)

r iii

*~

A<22ss5s>a-L-....:i:b\!'J.!::*l-t-t•t"'C<r-:~

,ttl:~

l:

tt

,J::;

l:::PilflL-*"t

o-o.osmm

"'CPIJIL-,

jJ

*1t*~

-

1-.9

11)

..I:

o

~To

iii

11)

C Indicetor

ffljf-~ (51186E)

Stitch

B

Re1111ator

~!JIiii

End

<msso>

Cap

A Nut(289)

'To/I-

(Left-t:hread)

Fig.10

7

®

s-w

*~

(22585B)

~

®

B Screw

*~

Fig.11

(22834)

4-6

Presser

a)

Presser

Press

check

the lowest position and the presser foot can be

disassembled, it means that the presser bar is correctly

mounted. The adjustment of presser bar height shall be

done by

Foot

Adiustment

Bar

Height

(Fig.12)@

down

the lifter lever installed

the

height

of

needle bar. When

following

manner.

(Fig.12)

at

the rear side and

the

needle bar is

at

H ~I.fl0>:111

a)

-~--

(Fig.12)

(Fig.12)@

l1f!.:r.fl.ifv /<-(51183B)~:1'-!J-(1.)Ji!P]

.:r.*1t~.H1,

t.>J'±-fL-tis1:1:1*otitmti~i11E"t'-t

tt~AltJ:J11tuttal::L-tt.~'!,

o

&:.-~l1JIL,

l1fl.:r.~o:>l&

-Cl1JI

• Set the presser bar connection by

the clearance between upper surface of throat plate and

lower surface

up the presser

b)

Presser

Adjust the pressure

be

sewn

adjuster

and

will cause thread break, and too

result in mis-chaining

c)

Tum

upper feed dog comes in contact

not, it is

0.3mm

upper feed dog

position.

B in clockwise direction

unclockwise

Mounting

the

between

of

presser foot will be

foot

by the lifter lever.

Foot

Pressure

of

presser foot, so that

is

fed

uniformly.

direction to decrease. Too

Top

Feed

pulley for a rotation by hand

fixed

in

the

the

hook

at

where

Tum

of

stitch.

Lifter (Rg.12)@

exact manner. Then, set the clearance

of

top feed lifter and

the

upper feed

the

screw W so that

5.5mm

when

the

material to

the

presser bar spring

to

increase the pressure,

much

pressure

weak

pressure

to

check if

with

the top feed lifter. If

dog

will

or

the

is the lowest

not

edge of

lifting

often

the

•

l1f!.:r.fl~~l1PL-,

IW~

5.5mm.

~.:r.n~o:>-*~

l-it!IL-

b)

~I.EEO>D.111

-c

a11<-,r1:a

w.:r.~~

~o

(F'ig.12)@

A(531)~,

<tt:~1,

'o

1:.1

tli ~n.r,J:-;1:~I.flO)~I.EE~amL;~

J:Jftt~$,

~.:r.*flt@~(51257M)o:>«!W

tt*1iitW.:r.~o:>ri11

To

l1Jl~A:1'!J::.,-~pjli

t.ttJ,

ftl::D-r~ff(t.t~*i"., ¥Px$tJ~!li'~obf.~Wno:>

JJj(t!in:.tl~t*i" 0 *ttfii"~oc~a11

c) J:m•J••J:,,-0)

J:i*!J.!J7~-(51105G)CT>ot•f~.

B(51256N)l-~J:.tm-t~l1Jl.:r.J:EtJ~n<

,tis1±1tl<t.t~*i"

••

(Fig.12)@

:1'-!J-~

1

IID«i~-tt

tt~~, J:~!J.»s97~-l;:~vt;,tiltntfil1E"t'"to

J:;l!J:&tJSJit "ftJS~t.:c~,

Iii~

0.3mm

"t'i'. (Fig.12)@

.:f~

C(95)~aiii>-Cl\'l~L,,

1,\,

!J7~-o:>_1eWi1~J:j;&!)~o:>ni,

97~-o:>«£-~iiBL,

-C(ie~

0

Foot

Lifter

jlp~Ln<-

s-wA

*v

Screw

*v

Lowr

(531)

C

C95)

(51]83B)

-;::,---<

,,,<-

11/

{(

I:

I

'

i

B Pre,ter

.

:·

--r---u.J

Spring

jlp~:;l'!J~?'iilffi

Regulator

(51258N)

5.5mm

I

@

Serew

*~

(95)

Fig.12

8

Loading...

Loading...