NEWLONG

MATPARTS

MODEL

NEWLONG

MACHINE

WORKS,

LTD.

(

MATPARTS

Identifying and

Where the constru~tion~permits, each part is stamped

with its

number, part name

part

number.

Ordering

On all

and

model name

Parts

orders, please include part

of

machine.

)

[

+f

-

E

x

LZ

88

if

5

bj

Fu~

&

*

)

(Safety

To prevent perdonal injury:

All power sources to the machine must be turned

threading, oiling, ajusting or replacing

All cover and guards must

machine.

Do not

is in operation.

Maintenance

Please keep in mind to handle the machine carefully

and

to msintenance the in good condition.

Thread fuzz or dust must be cleaned with air or brush after

the day's work.

tamper

Rules

parrs.

be

in position before operating

with

safety cover, guards, ctc., while machine

off

1

before

(H

s

~~~R%~~EE&IJ\S&%F~~~~X%~~~~TL\~T~

ZS;%

1

sa>{$%hf4$7~&

~~~~~d7~~~~~~~~~~~~~o

<

@

5

2

2

%

IZ%IZE{%IZI~!%\I~TT

Lf:(;.

%'k~f;13i.9.

2

Li0

Hi;

3.

MATPARTS

ADJUSTMENT

/

CONTENTS

...............................................

4

3-1) ADJUSTING THREAD TENSION

3-2)

SETTING NEEDLE AND ADJUSTING NEEDLE BAR HEIGHT

&tDiT!743I3ZBU$t&D&

3-3) TIMING SHUTTLE RACE BODY AND NEEDLE

@*EA+St

3-4) ADJUSTING PRESSER FOOT HEIGHT AND TIMING WITH NEEDLE

@~&a~st$t&aa%

3-5) ADJUSTING PRESSER FOOT PRESSURE

4.

REPLACING BOBBIN THREAD

5.

OPERATION

/

82

Dl%

................................................

2

/

@

-*-.--*

*

***

@I&EEcr)i@B

. .

-

.***-.-

....--.-m.""

**-**-u-""'

-uu"*

-**-".-

**

**

.

4

4

4

5

5

*

6

-7

PARTS LIST

/

...............................

.............

9

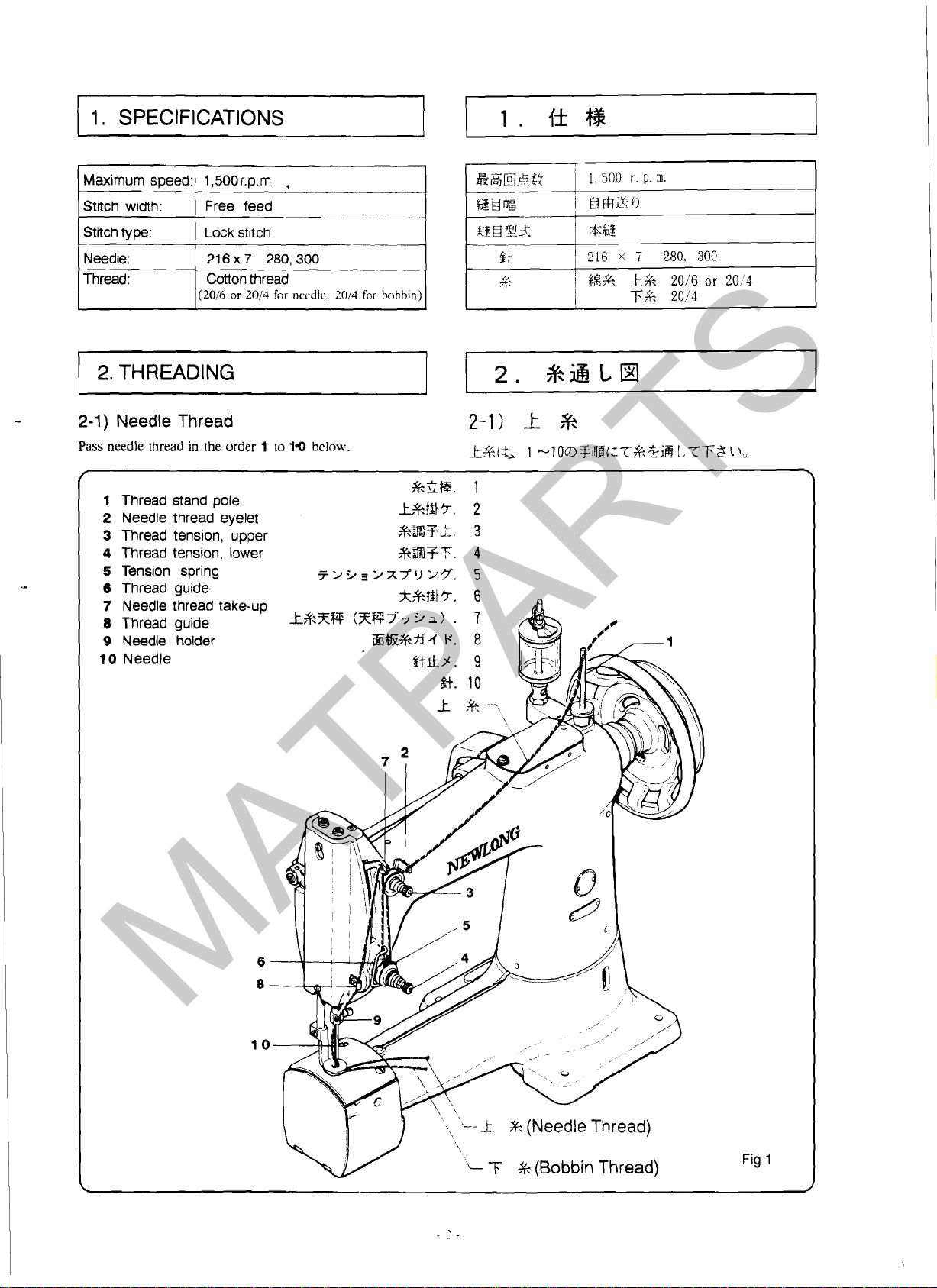

1.

MATPARTS

SPECIFICATIONS

Maximum speed:

Stitch width:

type:

Stitch

Needle:

Thread:

2.

THREADING

2-1)

Needle

Pass needle thread

1

Thread stand pole

2

Needle thread eyelet

3

Thread tension, upper

I

Thread tension, lower

Tension spring

Thread guide

Needle thread take-up

Thread guide

Needle holder

Needle

1,500

Free feed

Lock stitch

216x

Cotton thread

(2016

Thread

in

the order 1 to

r.p.m.

7

or

2014

,

280,300

for

necdle;

1.0

1%

---

-

-

-

2014

for

hohhin)

below.

A+337T.

7.

(3'

>

4

?

4

5

.

7

.

8

.

Fig

'"

7;

&

(Bobbin

Thread)

1

1

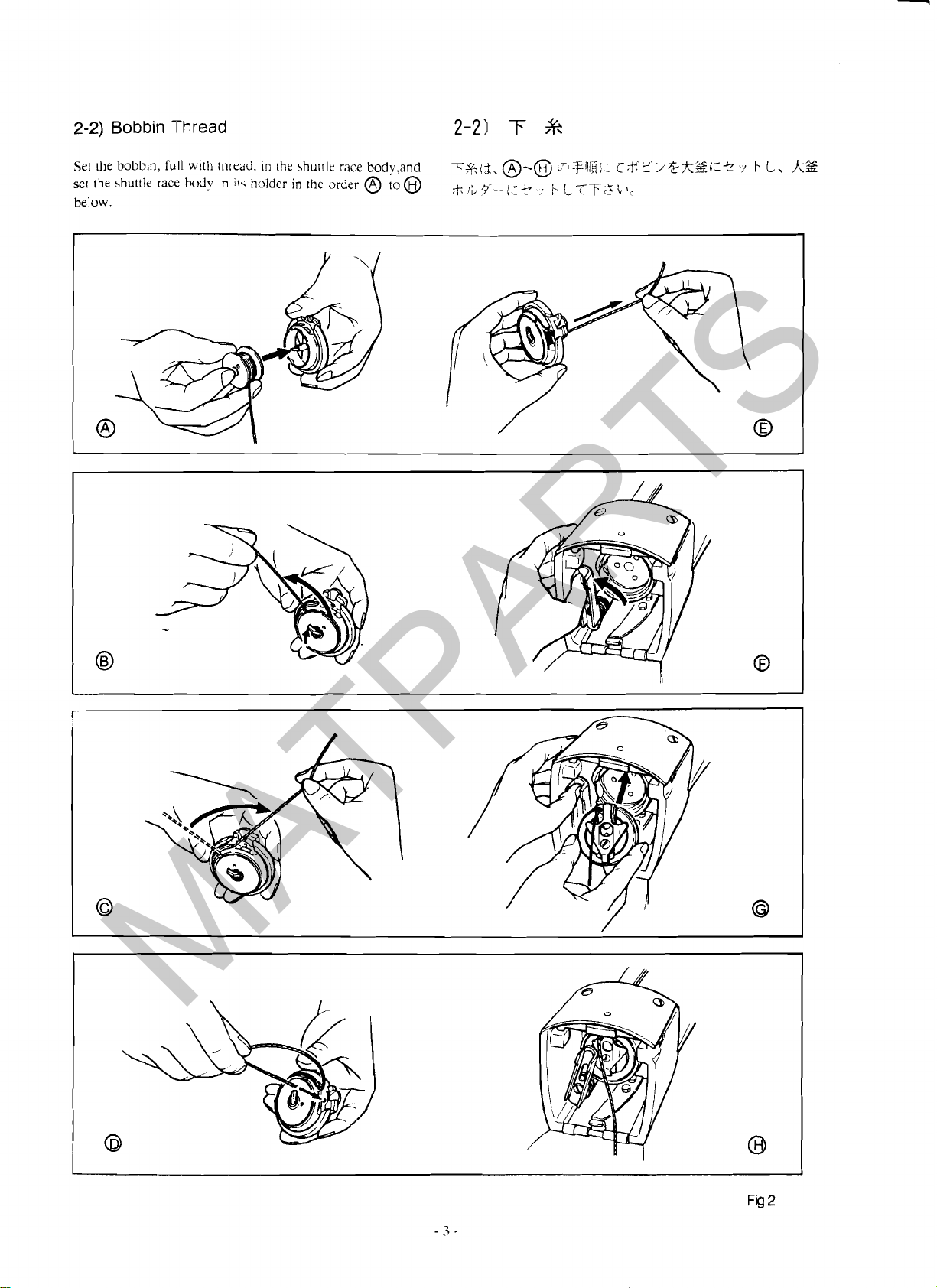

2-2)

MATPARTS

Bobbin

Thread

2-21

-F

3+

Set the bobbin, full

set the shuttle race

below.

with

body

thread.

in the shurtlc race body,and

in

holder in the

order @ to

(@

F%(t,

,;

g-

@--@

(=+.

,;

~-~illWi~?$

L

77;

t"i&fi;%CZ+z

g

,c

.Y

b

L.

Fig

2

3

-

3.

MATPARTS

ADJUSTMENT

3-1)

Adjusting

Check a sample seam to see the tightness

tight needle thread, loosen thread tension, upper

Tighten

adjust, turn thread tension nut.

3-2)

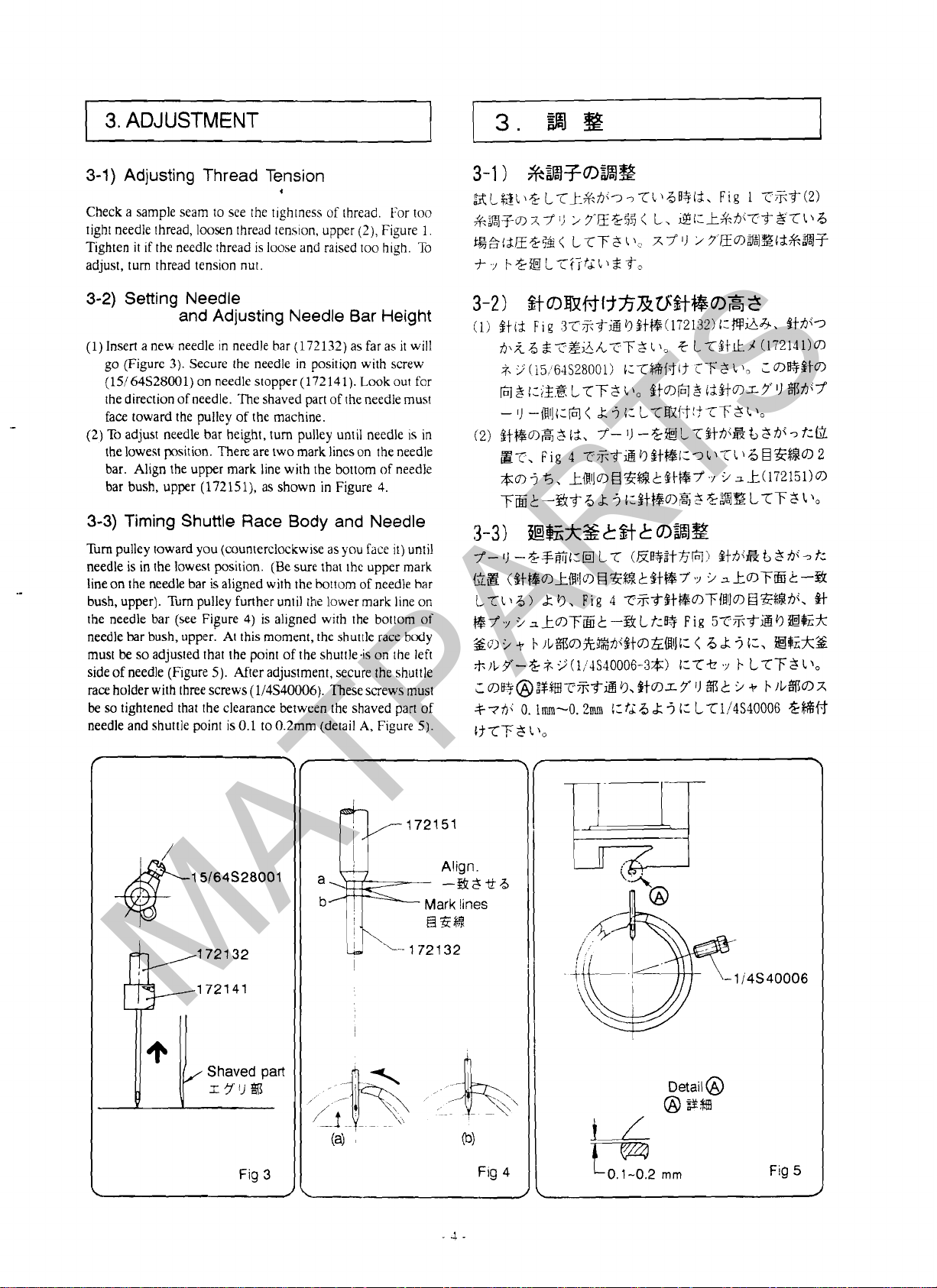

(1) Insert a new needle in needle bar (172132) as far as

-

(2) To adjust needle bar height, turn pulley until needle

3-3)

Turn pulley toward you (counterclockwise as you face

needle is in the lowest position.

line on the needle bar is aligned with the bottom of needle

bush, upper). Turn pulley further until the lower mark line on

the needle bar (see Figure

needle bar bush,

must

side of needle (Figure

race holder with three screws

be

needle and shuttle point

it

-

if the needle thread is loose and raised too high. To

Setting

go (Figure

(15164S28001) on needle stopper (172141). Look out tbr

the direction of needle. The shaved part

face toward the pulley of the machine.

the lowest

bar.

Al~gn the upper mark line with the bottom

bar bush, upper

Timing

be

so adjusted that the point of the shuttleis

so tightened that the clearance between the shaved part of

Thread Tension

e

of

thread. For too

(I),

Figure

-

Needle

and

Adjusting Needle Bar Height

3).

Secure the needle in position with screw

of

the needle must

position.

There are two mark lines on the needle

of

(172151), as shown in Figure

Shuttle

upper: At this moment, the shut~le race body

Race

5).

After adjustment, secure the shuttle

is

0.1 to 0.2mm (detail

Body and

(Be

sure that the upper mark

4)

is aligned with the bottom of

(114S40006). These screws must

4.

Needle

on

the left

A,

Figure

it)

1

it

will

1s

in

needle

until

bar

5).

3-1)

~it$~i~+~14_%h~~~11~6031d.

&flF~xy

&gr$Eg<&

t-.Y

3-21

(1) $+id

(2, $Jr~Dis,$

3-3)

7-

G,23

L?l)b)

+$$Y

Sol

;t;)LY-?&;i. 9 (li:+IS40006-3$)

c

%77Y

if7-F$

832lFU3aZ

1;

)

Y'J3555

{

L?7;$

i.fC-@L?ii~il)zE$,

l

<

L,

$i:k%h<T$$Tl\6

xll)

i

$tDRXktV3BCJ%t#~S2

Fig

3?;T;$;g

7S\L6

~~E;SA.TT'~

;i.

9

(i5:6+1~28001)

m3i:iB3

-

I)

a?.,

*D5!5,

L-crTS

-iRlli~6l<

It,

Fig

4

~~~~~~~%lc?$t~7~~ >xk(l72151)D

TEk--%f

4

Qtg(172132)

l)"

C

L7Stk.A

c:-crHc$if

L)o

k

3

4:

L7%!t4'!57T3

7'-

'9

--%BL?$tA<i%t

TZ$&t3$t@i:'l,l\?l~BRZ$$~2

6

h

3

c:PtWIS3%3E

rT'$

$tom$

i2HDI-7'lJ

~&~S&$+kIn%@

1)

-~+K~:IEI

($tt&OlkiFlilc?l €IZfSk$t%7'~.:,

dr

.i,_tDT&t:-!&LL:Q

.i

-P

+

1L%a%2%hX$ta&UltJi:

~B-+@;$~IT%-oB

0. lrrun-O.2mm

l\o

13,

LT

(EB+Zt36!)

Fig

4

~,?;t$t@o>T;lflll~HEK:~hi,

Fig

<

t:T+

5.

$tar

7

11

%f3

!:ti

b

5

C:

LT114S40006

Fig 1

T%$(2)

TBOE%l2kk&~~

l~#&?+.

i

$thX~

(172141)a

)7

L

o@Sta

%7YY'

l)o

3ni

-3

?:KL

LTT:!

gti~q~h

.i

x_tOlf;%t:-%

1~

si~q-t:

@f

57

iifiTiBfiC1Ek

6

.k

3

i:,

?@%A%

.r

i-

LTTf

L

.i

1),

+

111/%c~x

%$%$f

3-4)

MATPARTS

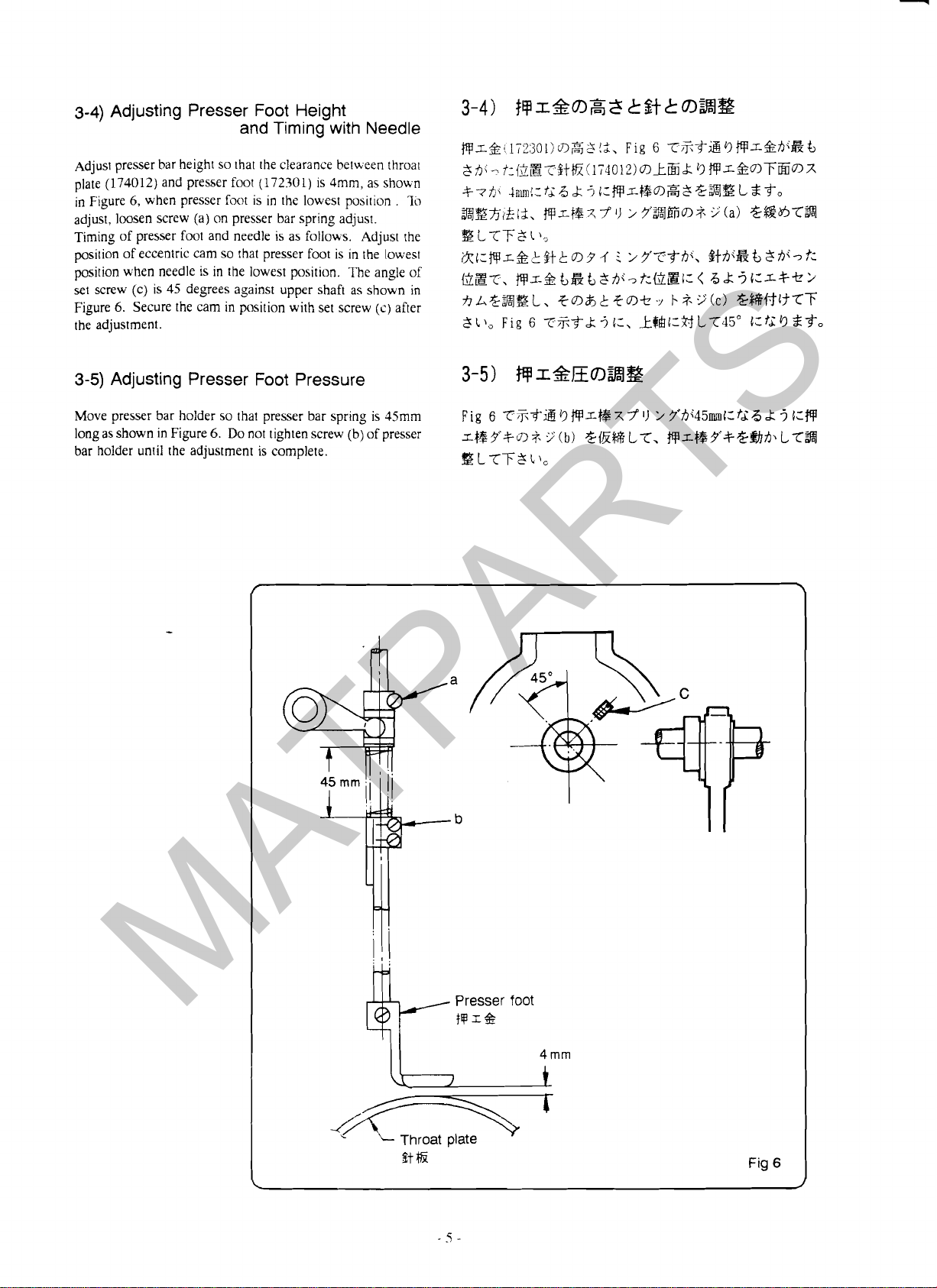

Adjusting Presser Foot Height

and Timing with Needle

Adjust presser bar height so that the clearance between throat

plate (174012) and presser foot (172301) is

in Figure

adjust, loosen screw (a) on presser bar spring adjust.

Timing of presser foot and needle is as follows. Adjust the

position of eccentric cam so that presser foot is in the lowest

position when needle

set

Figure

the adjustment.

3-5)

Move presser bar holder so that presser bar spring is 45mm

long as shown in Figure

bar holder until the adjustment is complete.

6,

when presser foot is in the lowest position . lo

is

in the lowest position. The angle of

screw (c) is 45 degrees against upper shaft as shown in

6.

Secure the cam in position with set screw (c) after

Adjusting Presser

Foot

6.

Do not tighten screw

4mm,

Pressure

(b)

as shown

of presser

/

\

Throat

\

NC

plate

Fig

6

1

Loading...

Loading...