Page 1

Operation & Installation Manual

MODEL RD-8 Remote

REFRIGERATED SHOWCASE

MODEL RD-3

REFRIGERATED SHOWCASE

Document Part #: 1160915

Rev: I

ECN: 55118

Rev. Date: 5-28-14

Page 2

The RD-8 and RD-3 refrigerated display showcase unit has been safety and performance-test approved by

various safety regulatory testing agencies. In the course of new installations or periodic inspections, reference to

agency approvals may be required. Following are the regulatory agency file numbers:

2

Page 3

CONTENTS

MAIN COMPONENTS AND DIMENSIONS………………………….4

SPECIFICATIONS………………………………………………….......5

INITIAL SET-UP

Cabinet Set-up………………………………………………….6-10

Remote condenser installation………………………………....11-15

Cabinet Electrical wiring…………………………………….....16

Shelf & Accessory Installation…………………………………16

START-UP & OPERATING INFORMATION

Start-up Information and Performance Evaluation…………….17

Operating Guidelines…………………………………………..17

COOLING AIRFLOW PATTERN………………………………......18

GENERAL MAINTENANCE

Cleaning the Honeycomb………………………………………19

Cleaning the Bottom of the Inner Box & the Drain. …………..19

Cleaning the Cabinet…………………………………………...19

Lighting ………………………………………………………..19

PRECAUTIONS

Storing the Cabinet…………………………………………......20

TROUBLESHOOTING………………………………………………...20

WIRING DIAGRAM……………………………………………….......21

WARRANTY ACTIVATION SHEET…………………………………23-24

3

Page 4

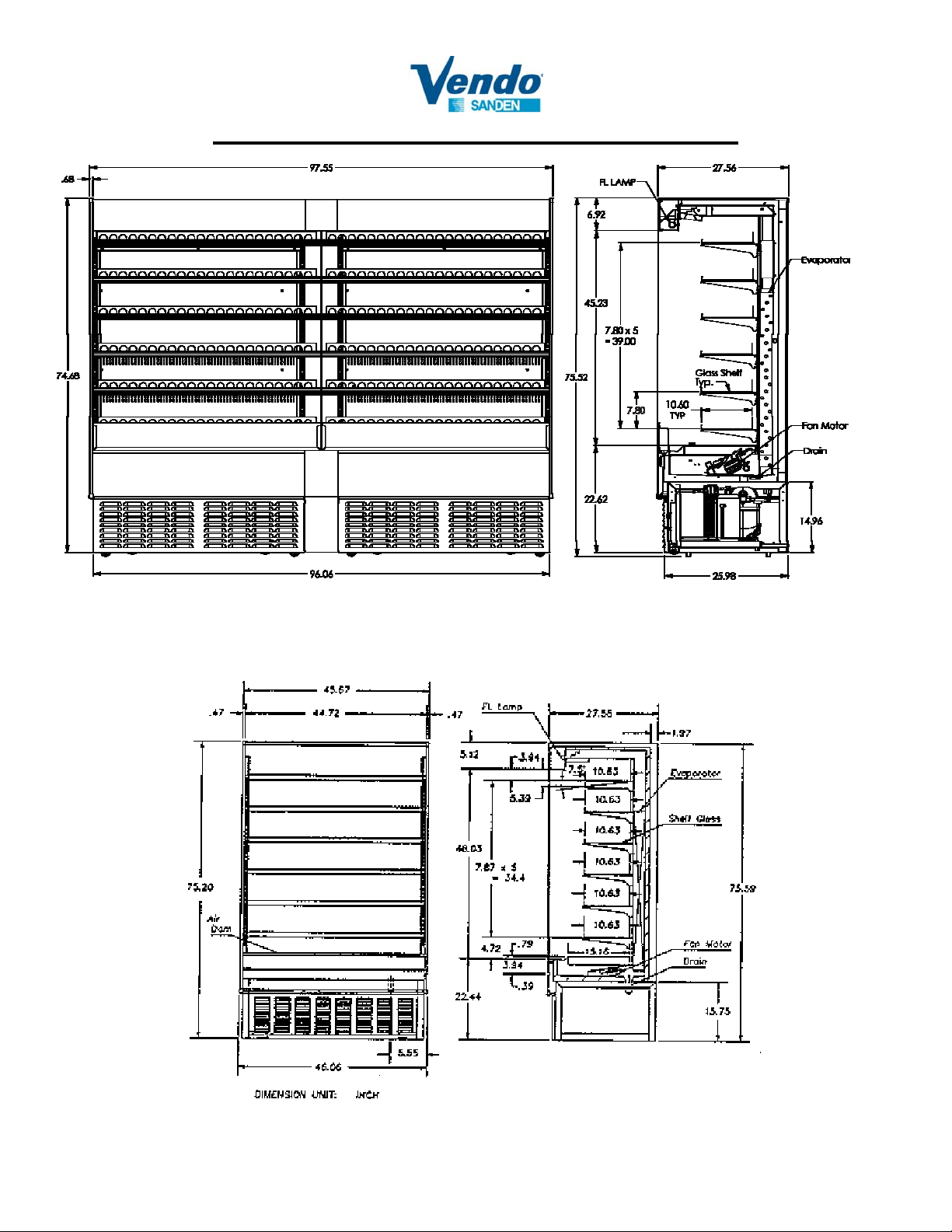

MAIN COMPONENTS AND DIMENSIONS

RD-8

RD-3

4

Page 5

SPECIFICATIONS

MODEL RD8 Remote

Product Temperature Below 40°F

Environmental Conditions Indoor 75°F, 55% relative humidity, Maximum air velocity =60 ft/min

External Dimensions Height 75.52”

Width 45.67” for RD-3 / 97.55” for RD-8

Depth 27.56"

Structure Outer Box Glass & baked acrylic resin finish on electrolytic zinc-coated steel.

Inner Box Baked acrylic resin finish on electrolytic zinc-coated steel.

Insulation Rigid polyurethane foam

Shelves (6 Total) Depth = 10.6”

Electrical Parts

115V 60Hz 1-Phase

Lighting 25 Watt, 0.39 Amp

12Vac Transformer Controller 12VAC 16A 2HP 250VAC

Electrical Parts

230V 60Hz,

Input voltage

210-253V 1-Phase

Refrigerant HFC-404A ( pre-charged 3.0 lbs)

Evaporator Fin-tube type

Expansion Valve Internally Equalized Automatic Thermal-expansion Valve.

Solenoid Valve Hermetic Direct Acting Type Solenoid Valve for Refrigeration

Thermostat Electronic- Defrost on Demand (10 ~ 30 minutes, every 2 hours)

Drain-pipe Dimension 1.25” copper tube

Evaporator

Fan Motor

Compressor(s)

Condenser fans

6 Watt, 3 each

1.25 HP, 10 Amp Left side

10 Amp Right side

Buck and Boost Transformer required when voltage is below 210VAC

or above 253VAC

Internal Volume 26.4 ft3 for RD-3 / 53.3 ft3 for RD-8

Weight 560 lbs. for RD-3 / 900 lbs. for RD-8

Noise Less than 65 DB at 3.3 ft.

Agency Approvals UL, UL NSF

Top Shelf Tilt 7.5°

NOTE: The manufacturer reserves the right to make product improvements and change specifications without notice

5

Page 6

INITIAL SET-UP

The Model RD-8 and RD-3 Remote Refrigerated Showcase, when properly installed and maintained, is

designed to provide years of trouble-free operation. This Operation Manual contains information necessary for

proper installation, maintenance and cleaning of the unit.

It is the responsibility of the installer to ensure the unit is installed and working properly. The following

instructions provide step-by-step set-up, piping, condensate drain connections, wiring, start-up, performance

and maintenance guidelines.

Following installation, please review, fill out and sign form for activation of warranty within 5 days of

installation. FAX: 1800-561-5684 or email: customerservice@vendoco.com

Additional reference manuals can be obtain at www.vendoco.com

CABINET SET-UP

Step 1: Choose a location for your new refrigerated display case. Avoid placing the cabinet near equipment that

releases heat. Avoid direct sunlight. To protect all electrical parts, do not place the cabinet where it

will be subjected to rain, splashed liquid, or excessive humidity.

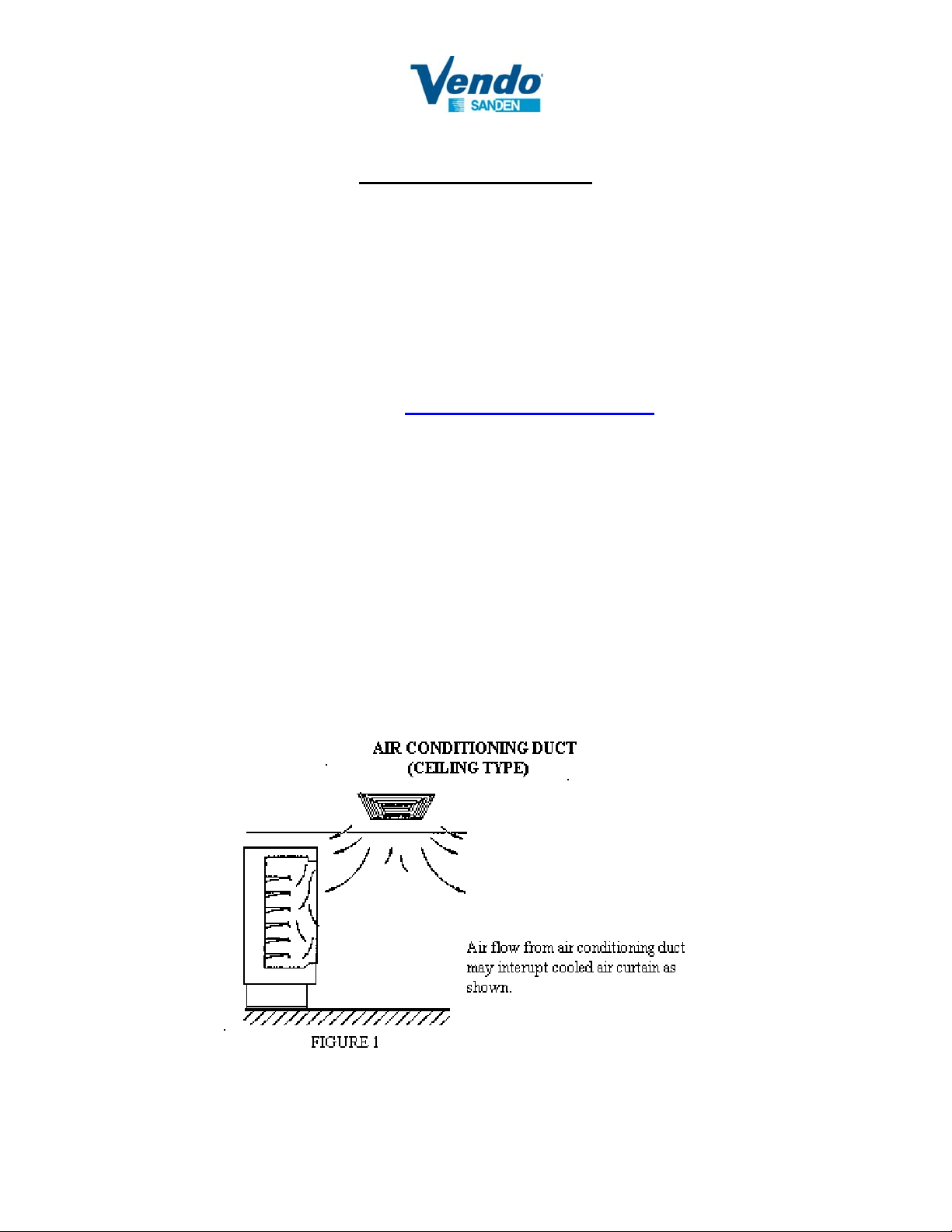

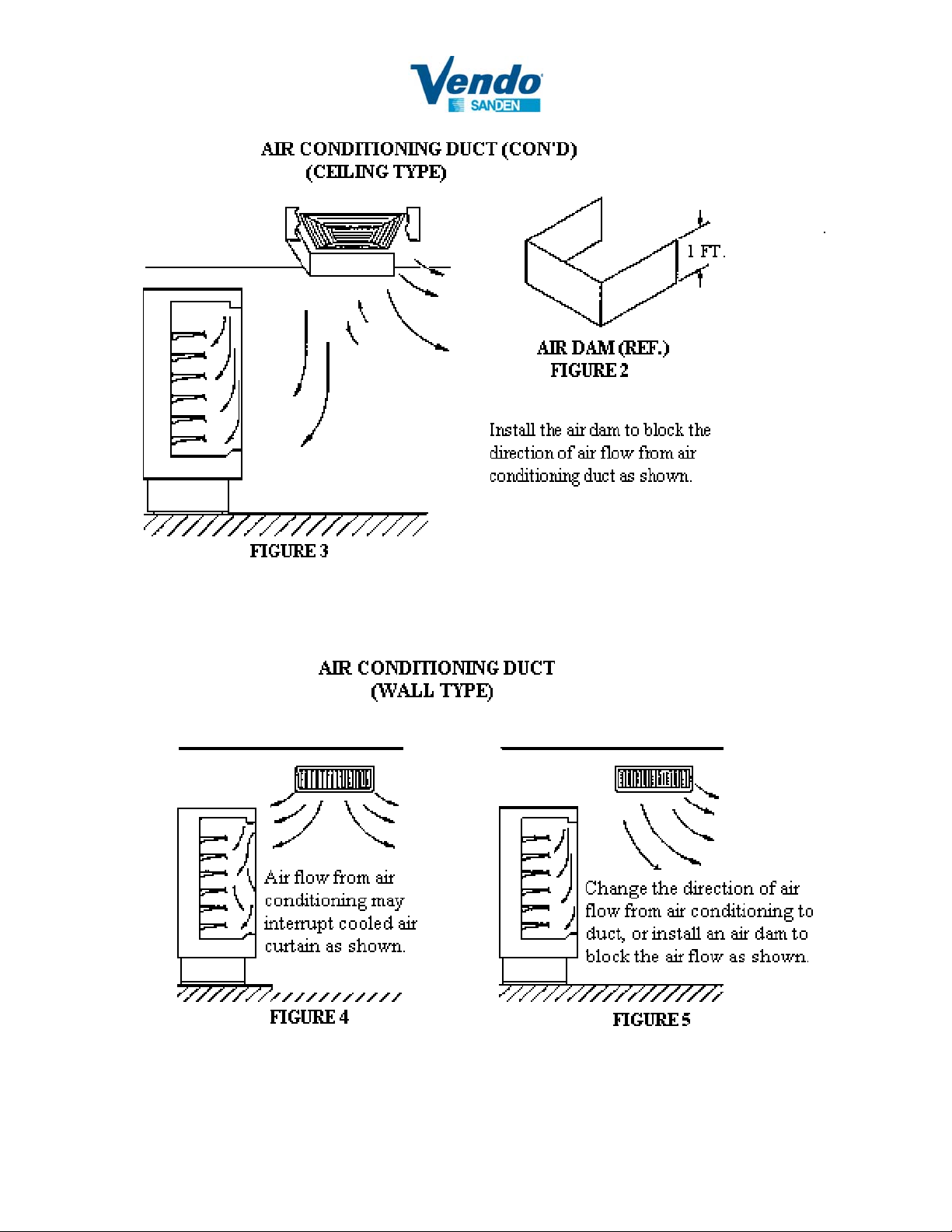

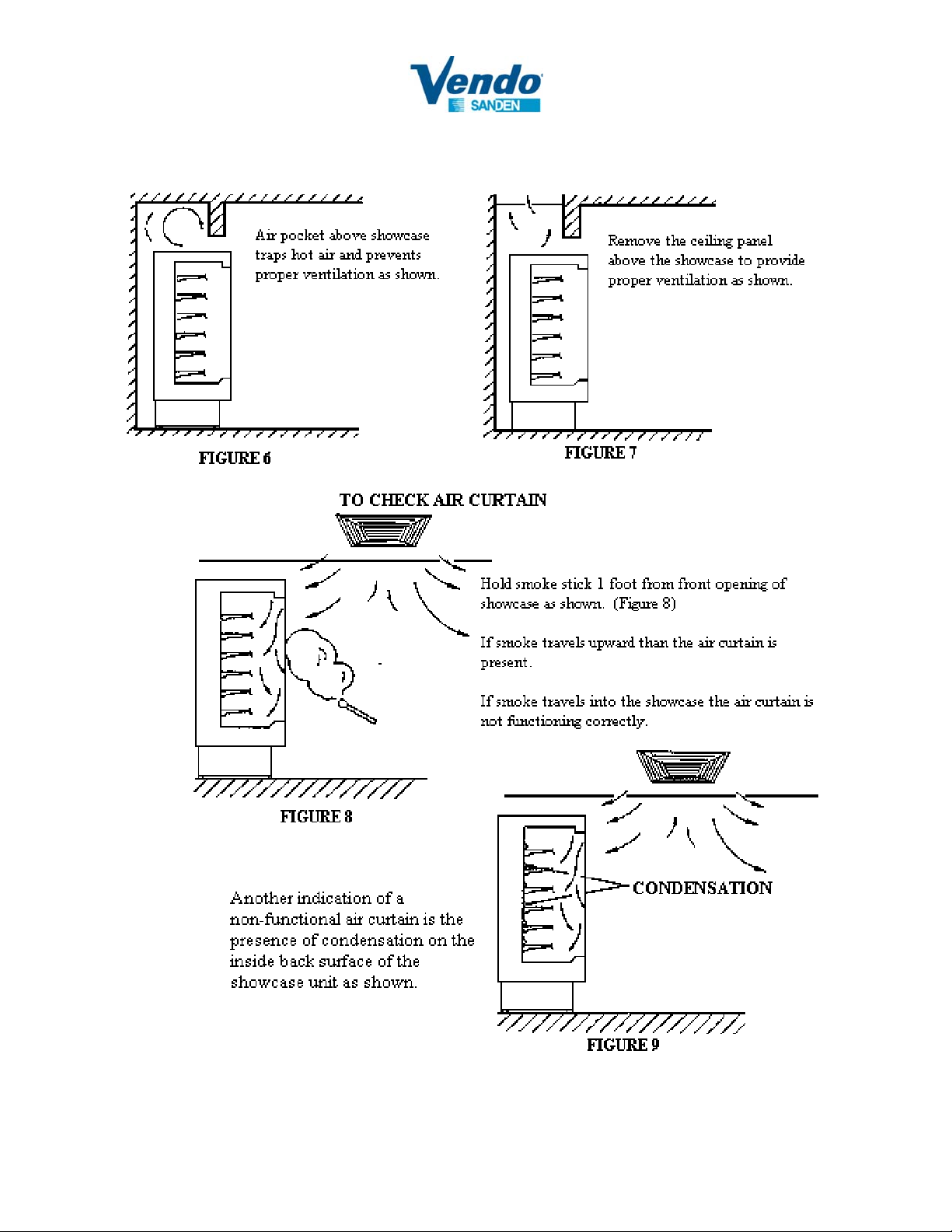

Step 2: Check the airflow around the cabinet, since strong airflow may displace the cooled air in the display

case. Place the cabinet where the airflow speed is less than 60 ft/min. Also, avoid areas subject to

strong winds (see figures 1-9).

6

Page 7

7

Page 8

8

Page 9

CONDENSATE DRAIN CONNECTION (PREFERRED METHOD)

Install the appropriate condensate drain line between the 1 ¼” copper tube outlet to a floor sink, a drain line or

other, allowing a code required air gap.

9

Page 10

CONDENSATE REMOVAL METHODS (ALTERNATE)

HEATED CONDENSATE PAN

Heated condensate pan, when used, is

recommended to be placed behind the

unit and not inside the compressor

compartment.

CONDENSATE PUMP

Condensate pumps, when used, can be

placed inside the compressor

compartment or behind the unit with the

outlet connected to the nearest drain.

SVA Part Number: 1231359

10

Page 11

REMOTE CONDENSER INSTALLATION

For proper operation of the RD-8 and RD-3 showcase the following installation guideline must be followed.

Failure to do so may result in loss of refrigeration capacity, premature part failure, and may void all warranty.

Installation Guideline

1. Refrigeration pipe sizing: Remote condenser discharge 1/2”, fitting: 3/8” Flare.

Remote condenser liquid line 3/8”, fitting: 3/8“Flare.

2. Outdoor ambient operating temperature: -20°F (-28°C) to 110°F (43°C)

3. Indoor operating requirements: 75°F, less than 55%RH.

4. Maximum refrigerant line length: 45 ft. (13.7 m) including fittings.

be used to minimize adding length to the line set.

90° long radius elbow fittings should

5. Maximum vertical rise without oil trap in discharge line: 15 ft. (4.6 m)

6. Minimum condenser height: Remote condenser for RD-8 and RD-3 must not be installed more than 6 ft.

(1.83 m) below the refrigerant line connections at rear of showcase unit. No part of refrigerant lines,

between machine and condenser, should fall below this point.

7. Insulate 3/8” liquid line, to limit heat exchange between lines. Liquid lines should be sloped 1/8 inch per

foot (10.4 mm/m) in the direction of refrigerant flow and insulated. Trapping is unnecessary.

8. Isolate all lines when passing through walls and room from abrasion. Support all refrigerant lines at

minimum intervals with suitable hangers and brackets.

9. Leak check with nitrogen and evacuate remote line set (This will require installation of “Schrader Tee”

in the remote air cooled condenser line set). Vacuum to a minimum of 200microns prior to opening

service valves.

10. Discharge lines carry both refrigerant vapor and oil. Since refrigerant may condense during the off

cycle, the piping should be designed to avoid liquid refrigerant and oil from flowing back into the

compressor. Discharge lines should be pitched 1/8 inch per foot (10.4 mm/m) in the direction of

refrigerant flow towards the condenser

11. Addition of refrigerant is .7oz per feet of refrigerant line added. View sight glass for minimal vapor

bubbles. Properly charged unit will have head pressure 30°F above the ambient conditions

12. If environment is subject to cold weather, use a Head Master valve. Recommend LAC-4-210

13. Check compressor superheat at compressor suction line 15-25°F, Subcooling 4-6°F

11

Page 12

p

REMOTE LINE SET INSTRUCTIONS

1. Refrigeration pipe sizing: Remote condenser discharge 1/2”, fitting: 3/8” Flare.

Remote condenser liquid line 3/8”, fitting: 3/8“Flare.

2. Maximum refrigerant line length: 45 ft. (13.7 m) including fittings.

3. Maximum vertical rise without oil trap in discharge line: 15 ft. (4.6 m)

4. Minimum condenser height: Remote condenser must not be installed more than 6 ft. below the

refrigerant line connections at rear of showcase unit.

5. Insulate 3/8” liquid line, to limit heat exchange between lines.

6. Add 0.7oz of refrigerant per feet of refrigerant line added. View sight glass for minimal vapor bubbles.

Properly charged unit will have head pressure 30°F above the ambient conditions.

7. If environment is subject to cold weather, use a Head Master valve. Recommend LAC-4-210.

8. Minimum allowable voltage is 210V. For lower voltages use buck and boost model number SQUARE

D 500SV43B.

Condenser above the unit

IMPORTANT: Inverted 1/2

x 1/2 copper P-Trap to

prevent liquid draining from

condenser to compressor.

IMPORTANT: In cold

weather conditions, use

Headmaster valve LAC-4-

210. See manual for

additional instructions.

Correctly installed roof top

discharge line P-Trap and insulated

liquid line.

Max. two 20”

s

loo

12

Do not install more than two 20”

loops.

Page 13

p

p

p

When installing the condenser above the machine. When installing the condenser below the machine.

DO Slope refrigerant lines downward toward compressor. DO Slope refrigerant lines downward toward condenser.

Slope discharge

line towards

condenser.

Max. two 20”

s

loo

Slope liquid line

towards

ressor.

com

Max. two 20”

s

loo

DO NOT Install any part of the refrigerant lines below the DO NOT Install the condenser lower than 6 ft. (1.83m) below

connection fittings at rear of machine. the connection fittings at rear of machine.

DO NOT Create oil trap in refrigerant lines by sloping lines

down ward than rising upward.

Condenser sizing and placement

The condenser should be designed for proper capacity for RD-8 or RD-3. (9850BTU per side)

The location of the remote condenser should be such that the ambient air temperature does not exceed 110°F

(43°C). If ambient temperature exceeds 110°F (43°C) cabinet performance might suffer.

13

Page 14

The condenser coil and fan blades must be kept clean. The condenser can be cleaned with compressed air or by

using a brush. If a brush is used, brush in the direction of the fins taking care not to be bend the fins.

If condenser fins are bent this will also restrict air flow through the condenser and the fins will need to be

straightened with a fin comb.

If the air flow is restricted or the condenser is dirty the head pressure will be excessively high, no heat exchange

will result and the compressor will overheat and eventually become damaged. Problems related to dirty

condenser or poor air flow will not be covered under warranty.

Head Pressure Control Valve

When the temperature at the condenser is above 70°F (21°C), the refrigerant flow from the compressor is

directed by the head pressure control valve through the condenser and into the receiver. When the temperature

at the condenser drops below 70°F (21°C), the pressure in the bellows of the head pressure control valve

becomes greater than the pressure of the liquid refrigerant coming from the condenser. This change allows the

valve to partially restrict the flow of liquid refrigerant leaving the condenser. This allows discharge gas to bypass the condenser and flow directly into the receiver, mixing with the liquid refrigerant from the condenser.

The amount of discharge gas that by-passes the condenser increases as the ambient temperature at the

condenser decreases. This action of head pressure valve allows the head pressure to be maintained at

approximately 240 p.s.i. (16.5 bar) on RD-8 unit during low ambient conditions. The remote system depends on

an adequate refrigerant charge in order for the system to remain balanced during ambient temperature changes.

If the refrigeration system is undercharged and the ambient temperature is below 70°F (21°C) the head pressure

control valve will not work properly. The head pressure control valve will allow too much refrigerant to bypass

the condenser.

Problem Possible Cause Remedy

1. Head pressure low / liquid line

between valve and receiver cold.

Ambient condenser temp. below 70°F

(21°C)

2. Head pressure low / liquid line

between valve and receiver hot.

3. Head pressure high/ liquid line

returning from condenser is cool.

Ambient condenser temp. above 70°F

(21°C).

a. Valve defective, not allowing

discharge gas into receiver

a. System low charged.

b. Valve defective, not allowing enough

sub-cooled liquid into receiver.

a. Valve defective, not allowing

refrigerant to circulate through

condenser.

14

a. Replace valve.

a. Find and repair leak if present.

Recover refrigerant and weigh in proper

charge.

b. Replace valve.

a. Replace valve.

Page 15

Pump Down System

A pump-down system consists of a normally closed solenoid valve installed in the liquid line and a lowpressure control that senses suction pressure.

The system operation is as follows: A thermostat is wired to the liquid line solenoid valve. On a call for cooling,

the thermostat contacts close. This causes the solenoid coil to be energized, opening the valve. Liquid

refrigerant flows into the evaporator and the suction pressure rises above the low-pressure control setpoint. The

contacts on the low-pressure control close and the compressor begins to run.

When the thermostat is satisfied, its contacts open, causing the solenoid valve to close. This stops refrigerant

flow into the evaporator. As the compressor continues to run, refrigerant is pumped out of the evaporator coil

and suction pressure falls. When the suction pressure reaches the cut-out setting on the low-pressure control, its

contacts open, stopping the compressor. This removes most of the refrigerant from the low side of the system

and prevents liquid migrating to the compressor crankcase during the off-cycle and the ensuing possibility of

liquid slugging at compressor startup

.

15

Page 16

CABINET ELECTRICAL WIRING

Step 1: Ensure proper voltage input, minimum 210VAC 60Hz maximum 253VAC 60Hz.

If voltage is below the 210VAC or above 253VAC, a BUCK and BOOST transformer is required.

Step 2: Remove the lower-rear and left-side compressor access panel.

Step 3: Remove the left-side junction-box panel and locate the electrical wiring diagram on

the inside of the panel.

Step 4: Install permanently connected field wiring to the 230V/ 60Hz/ 1 Phase (4-wire) compressor circuit.

The pigtail wires are provided. See the circuit amperage ratings located on the unit nameplate.

SHELF & ACCESSORY INSTALLATION

16

Page 17

START-UP & OPERATING INFORMATION

START-UP INFORMATION AND PERFORMANCE EVALUATION

Step 1: Open the front panel and flip the toggle switch to the “ON” position for both left and right side unit.

Both the condensing unit, and the evaporator fans should operate, and the fluorescent lighting should

turn on.

Step 2: While the condensing unit and evaporator fans are running, verify that there is a flow of cold air from

the honeycomb, at the top of the cabinet for each left and right side unit.

Step 3: Observing the controller in the upper-left corner, monitor the cabinet temperature, and verify that both

left and right side unit cools to 40°F within 20-30 minutes.

Step 4: Continue to monitor temperature performance through the complete run cycle, until the system enters

the defrost cycle. The defrost cycle (condensing unit shutdown) is programmed to run for 10 ~ 30

minutes every two hours.

Step 5: Verify that all unit access-cover panels have been replaced, and the cabinet is ready to be loaded by

store personnel.

OPERATING GUIDELINES

1. For best results, pre-cool all products before stocking the display case.

2. Stock products only after the cabinet has cooled.

3. When loading the cabinet, do not place merchandise outside of the shaded area.

4. Allow at least 1” between the upper surface of the displayed product and the shelf directly above it.

5. Do not overload product. Improper loading of merchandise may result in refrigeration inefficiency.

6. Do not remove the glass side panels during operation.

7. Do not stock the shelves with all bottles or cans. Heavy merchandise should not be loaded on the glass

shelves.

17

Page 18

COOLING AIRFLOW PATTERN

18

Page 19

GENERAL MAINTENANCE

CLEANING THE HONEYCOMB

In order to maintain peak operating performance, remove the honeycomb (as shown below) and rinse it with

clean water to remove dust. Under normal conditions, inspect and clean every 30 days.

CLEANING THE BOTTOM OF THE INNER BOX & DRAIN

Lift the fan duct, as shown below, and clean the bottom of the inner box with a mild detergent and a soft, damp

cloth. Check the drain hole for proper water flow and remove any blockage. Rinse with clean water.

CLEANING THE CABINET

To clean the cabinet and shelves, use a mild detergent and a soft, damp cloth. Rinse with clean water. Do not

use paint thinner, laundry detergent, or harsh chemicals.

LIGHTING

Power must be turned OFF prior to servicing fluorescent bulbs. Failure to switch power OFF will

damage the ballast.

Replace inoperable fluorescent lights.

19

Page 20

PRECAUTIONS

CAUTION: Do not operate the unit with the access panels removed.

STORING THE CABINET

Step 1: Disconnect the unit from its power source.

Step 1: Wipe the interior of the cabinet with a damp cloth.

Step 1: Polish the interior of the cabinet with a dry cloth.

Step 1: Store the unit in a clean, dry place. Do not choose a location where the unit will be exposed to direct

sunlight, high temperature, or high humidity.

TROUBLE SHOOTING

Before calling your serviceman, please make these simple checks:

If the unit is not operating:

1. Is the cabinet plugged in?

2. Is there a main-power failure?

3. Is there a blown fuse?

4. Has the refrigeration unit cycled off, because it is at the designated operating temperature?

If the fluorescent light is off:

1. Is the fluorescent-light tube properly connected to the socket?

2. Does the fluorescent light need to be changed?

If the cabinet temperature is too warm:

1. Is the thermostat set correctly?

2. Is the cabinet located in direct sunlight?

3. Is the cabinet located in a strong air-flow path?

4. Is the distance between the upper surface of the displayed merchandise and the shelf directly above it at

least 1”?

5. Is the air temperature around the cabinet above 75°F?

Reasons for high pressure trips:

1. Overcharge or Non-condensable.

2. Dirty condenser.

3. TXV sensor bulb loose or power head defective.

4. TXV sensor bulb poorly insulated.

REFER TO THE ENVIRONMENTAL CONSIDERATIONS, ON PAGES 5 THROUGH 9,

THAT WILL AFFECT COOLING PERFORMANCE.

20

Page 21

Wiring Diagram RD Remote

IMPORTANT: When using a Heatcraft Flexpack, connect the condenser fan motor wires shown above

to the relay dedicated for the RD refrigerated showcase.

21

Page 22

Wiring Diagram (buck and boost model number Square D 500SV43B)

Measure line voltage; if line voltage is less than 210V, use buck and boost per instructions below.

1. Connect line voltage supply (LV) side to H1 and H4/X1 terminal.

2. Measure output voltage between terminals H1 and X4. Do not connect to unit if voltage exceeds

253V.

3. Connect load side or unit side to H1 and X4 terminals.

22

Page 23

Warranty Activation

Form No.: QF-PE-0047-C

Date Issued: 4/20/2010

PART NUMBER: 1189633A

Document Name:

To activate the warranty for this machine the following information must be returned to

SandenVendo's Customer Service Department within 5 days of Installation

<Contact Information> FAX : 1-800-561-5684 or e-mail : customerservice@vendoco.com

Customer Store Addres s :

Store No. & Store Name

Date of Installation : Installer's Name

RD8 Warranty Activation and Checklist

Model Name :

Serial No. : Cabinet : Remote Condenser :

Asset Management No. : Cabinet : Remote Condenser :

ShockWatch State (Color) at Rear :

RD2 RD-8 (Self Contain) RD3 RD-8 REMOTE

at Front :

Installation: Manuals can be obtained at www.vendoco.com (http://www.vendoco.com/Documents.aspx?ID=8)

Check Items

Inspect for damages on cabinet.

1

When you joined the two halves together, did you follow the

2 Yes No

"RD8 Instructions" (document #1142811) ?

Refrigeration piping Size (Outer Diameter)

3

- Remote Condenser Dischar ge Line (actual) : 1/2"

- Remote Condenser Liquid Line (ac tual) : 3/8"

Refrigerant Line Length (actua l ) Max. Length is 45 ft.

4 ft.

Refrigerant Line Vertical Rise Max. Vertical Rise is 15 ft.

5 ft.

Was the Oil Return considered in Refrigerant Line set ?

6 Yes No

Pressurized line set with nitrogen prior to opening service

7

valve, leak test and evacuate.

Vacuum remote line set to 20 0micron.

8

How much additional refrigerant R404a was added (Remote)

9

If Remote Air-coole d Conde ns e r was installed higher than 15

ft. above the Cabinet, is the Discharge Pipe higher than

10 Yes No

Remote Condenser ? Inverted "P trap"

When you installed "Remote Condenser, did you follow

"REMOTE CONDENSER INSTALLATION" written in the

11 Yes No

Operation Manual 1160915?

Notes :

Result Note

in.

in.

If the result is NG, please write down the detail in the Note column. Date :

It is preferable that there is a photo of NG part.

Signature :

23

Page 24

Cabinet and Remote Condenser

Check Items

Input Voltage to Case 208-253VAC 60Hz

1

Left side case input voltage:

Right side case input voltage:

If Voltage is below 208VAC, is a Buck Boost Transformer

installed, what is voltage input with transformer:

Environment Condition

2

- Outside Ambient Temperature of Store :

- Inside Ambient Temperature of Store :

Temeprature inside Cabinet after pull down

3

Temperature in the Cabinet : Left sid e

Temperature in the Cabinet : Right side

What is the compressor superheat ; range 15-25F

4 °F

Is a Head master valve added for cold weather environment?

5

LAC-4-210

Number of Shelves excluded bottom plate :

6 Shelves

Lighting

7

- Lighting of FL Lamp :

- No Flickering of FL Lamp :

No Abnormal Noise

8

- Cabinet :

- Remote Condenser :

No Abnormal Vibration

9

- Cabinet :

- Remote Condenser :

- Refrigerant Line :

No Water Leakage

10

- Cabinet :

- Drain Line :

No Scratch, No Dent & No Deformation on the appe a r a nce

11

- Cabinet :

- Remote Condenser :

When you set-up, did you follow "CABINET SET-UP" and

"CONDENSATE DRAIN CONNECTION" written in the Operation

12 Yes No

Manual 1160915 ?

Notes :

Result Note

V

V

Yes No

V

OK NG

OK NG

OK NG

OK NG

OK NG

OK NG

OK NG

OK NG

OK NG

OK NG

OK NG

°F

°F

°F

°F

If the result is NG, please write down the detail in the Note column. Date :

It is preferable that there is a photo of NG part. Signature :

24

Loading...

Loading...