Page 1

NHW-15 HOT WATER MACHINE

OPERATING MANUAL/

INSTALLATION

120/240 V 1650/6600 W US

120/240 V 1350/5500 W CAN

CONVERTIBLE

2 GA LLON

DRIP TRAY INCLUDED

ADVANCED TEMPERATURE

CONTROL

TVT TECHNOLOGY

NEWCO

ENTEPRISES

3650 NEW TOWN BLVD

ST. CHARLES

MISSOURI

63301

Phone: 636- 925-1202

800-325-7867

Fax: 636-925- 0029

WWW.NEWCOCOFFEE.COM

Page 2

SPECIFICATIONS

MODEL NW15 HOT WATER MACHINE

120/240 VOLTS 3 GAL/HR (120V) 6 GAL/HR (240V)1 PH

OPERATING TEMP RANGE: 170 DEG F- 208 DEG F

7"

24 1/8"

2 9/16"

1 3/8"

1 1/2"

8 1/2"

* UNIT CAN BE CONVERTED FROM 120 V 1PH TO 240V 1PH

(240V POWER CORD NOT SUPPLIED)

SEE 240 V SCHEMATIC

12 3/8"

6 1/4"

2

Page 3

MACHINE SETUP

PLUMBER'S INSTALLATION INSTRUCTIONS

CAUTION: Power to machine must be OFF before proceeding with plumbing installation.

1) Flush water line before installing machine. Machine should be connected to COLD WATE R

LINE for best operation.

2) Water pressure should be at least 20 psi. For less than a 25 ft run, use 1/4" copper tubing

and connect to 1/2" or larger water line. For longer runs, use 3/8" copper tubing & connect to

1/2" or larger water line and provide an adapter fitting for connection to the machine.

3) If installed with saddle valve, the valve should have a minimum of 1/8" port hole for up to 25 ft

run, and 5/16" port hole for over 25 ft runs.

4) Connect incoming water line to the flow control device on the back of the machine. A 1/4”

flare fitting is provided. Manufacturer recommends connecting to copper tubing .

ELECTRICAL HOOKUP

WARNING: - Read and follow installation instructions before plugging or wiring in machine to

electrical circuit. Warranty will be void if machine is connected to any voltage other than that

specified on the name plate.

The machine has a power cord attached for 120 volts. Machine should be connected to the

appropriate receptacle type. A wiring diagram at the rear of this manual illustrates the complete

machine wiring

INSTALLATION INSTRUCTIONS

WARNING: - Read and follow installation instructions before plugging or wiring in machine to

electrical circuit.

1) Make sure machine is level. Connect machine to water line as described in “PLUMBER’S

INSTALLATION INSTRUCTIONS”. Connect to suitable power supply as described in

“ELECTRICAL HOOKUP”. Tank will begin to fill when connected to power supply. The

display will inicate ‘fill’ when filling is in process. Time required to fill the tank is about 4-1/2

minutes.

2) Water level in the tank is controlled by a level probe which senses when water contact is

made. A maximum run time of six minutes is programmed into the machine for the initial fill

cycle to prevent flooding should an error occur.

3) Once the water level has reached the proper water level the tank heater will begin to heat the

water to the preset temperature. This prevents premature failure of the element by heating it

dry. This probe will also call for power to be shut off to the element should the probe not

detect water for 3 minutes. Heating time will be approximately 20 minutes. The heating circuit

has a maximum continuous run time of 45 minutes. Should the machine call for heat for a

time period in excess of 45 minutes the machine will shut down the heating circuit and display

an Er5 message. See the “ERROR MESSAGES” section for instructions on how to clear the

error and possible causes. The heating icon (thermometer) on the faceplate will indicate

heating status. As the preset temperature is approached the icon will begin pulsing as the

power to the element is cycled on and off.

3

Page 4

NHW-15

OPERATING INSTRUCTIONS

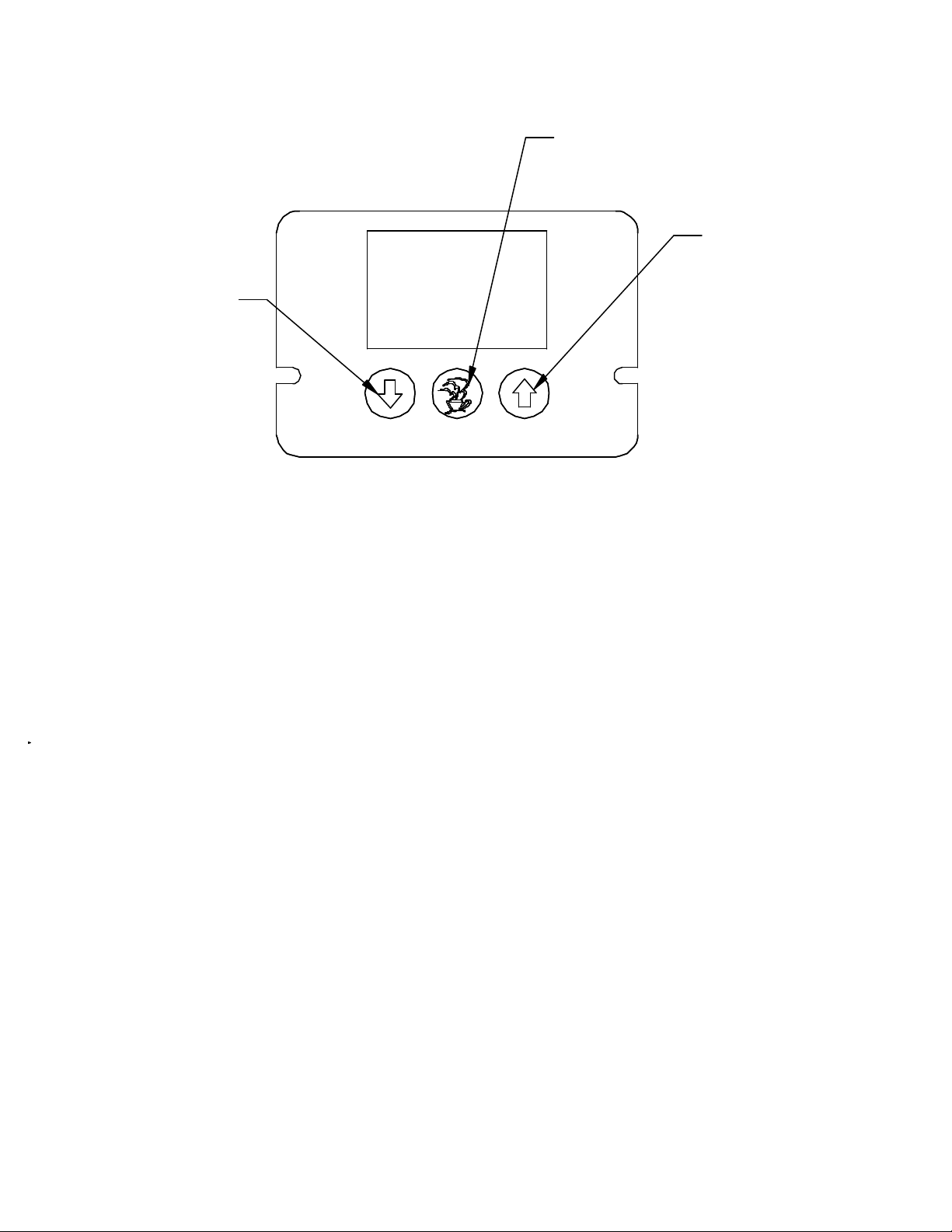

CENTER BUTTON

HOLD DOWN FOR 5

SECONDS TO ENTER

PROGRAM MODES

LEFT BUTTON:

TOGGLE TEMP DOWN

IN PROGRAMMING MODE

MONITOR UPPER TANK TEMP

IN NORMAL OPERATING MODE

FACTORY DEFAULT TEMPERATURE SETTING IS 200 DEGREES F

TO ADJUST TEMPERATURE SETTING:

1. DEPRESS AND HOLD CENTER BUTTON FOR 5 SECONDS UNTIL

'prog' APPEARS

2. TOGGLE TEMPERATURE SETTING UP OR DOWN WITH ARROWS

3. DEPRESS CENTER BUTTON, 'end' WILL APPEAR

4. DEPRESS LEFT OR RIGHT BUTTON TO EXIT PROGRAM MODE

TEMPERATURE SETTING WILL BE STORED

RIGHT BUTTON:

TOGGLE TEMP UP

IN PROGRAMMING MODE

MONITOR LOWER TANK TEMP

IN NORMAL OPERATING MODE

TO MONITOR UPPER AND LOWER WATER TEMPERATURE LEVELS:

1. DEPRESS LEFT ARROW TO MONITOR UPPER TANK TEMPERATURE

2. DEPRESS RIGHT ARROW TO MONITOR LOWER TANK TEMPERATURE

TO CHANGE FROM FAHRENHEIGHT TO CENTIGRADE TEMP DISPLAY:

1. UNPLUG POWER CORD

2. DEPRESS AND HOLD CENTER BUTTON, WHILE HOLDING BUTTON

PLUG POWER CORD BACK IN

3. WHEN 'prog' APPEARS TOGGLE F TO C WITH LEFT OR RIGHT BUTTONS

4. DEPRESS CENTER BUTTON TWICE UNTIL 'end' APPEARS

5. DEPRESS LEFT OR RIGHT BUTTON TO STORE SETTING AND EXIT PROGRAM MODE

NOTE: A THERMOMETER ICON IS DISPLAYED WHEN THE HEATER IS ENERGIZED

A "HAPPY FACE" ICON IS DISPLAYED WHEN TEMPERATURE SETPOINT IS REACHED

4

Page 5

PLUMBING AND ELECTRICAL

COMPONENTS

17

13

9

12

11

10

6

7

8

16

15

4

5

1

14

3

2

5

Page 6

PLUMBING AND ELECTRICAL COMPONENTS (CONT)

FIGURE # QTY. PART # DESCRIPTION

1 1 104113 FAUCET-HI HEAT

2 1 104114 NUT-HI HEAT FAUCET

3 1 800236 FITTING, TEA FAUCET

4 1 104118 FITTING -EXTENSION,

FAUCET

5 1 800244 GASKET-NYLON

.671*.937*.062

6 1 104111 VALVE ASSY-HOT

WATER

7 1 100155 CONNECTOR-MALE ¼ C X

1/8 NPT WITH NUT

8 1 104135 TUBE-COPPER INLET

9 1 511053 BLOCK-TERMINAL

120/240V

10 1 104117 TUBE ASSY-OVERFLOW

11 1 120256 BOARD-LIQUID LEVEL

12 1 111684 TRIAC-40 AMP, 600V

13 1 121659 HEATSINK

14 1 104109 TANK-HOT WATER

15 1 705002 LIMIT,66TM DPSTC 40A

16 1 120275 BOARD-LIQ CRYSTAL,

HOT WATER

6

Page 7

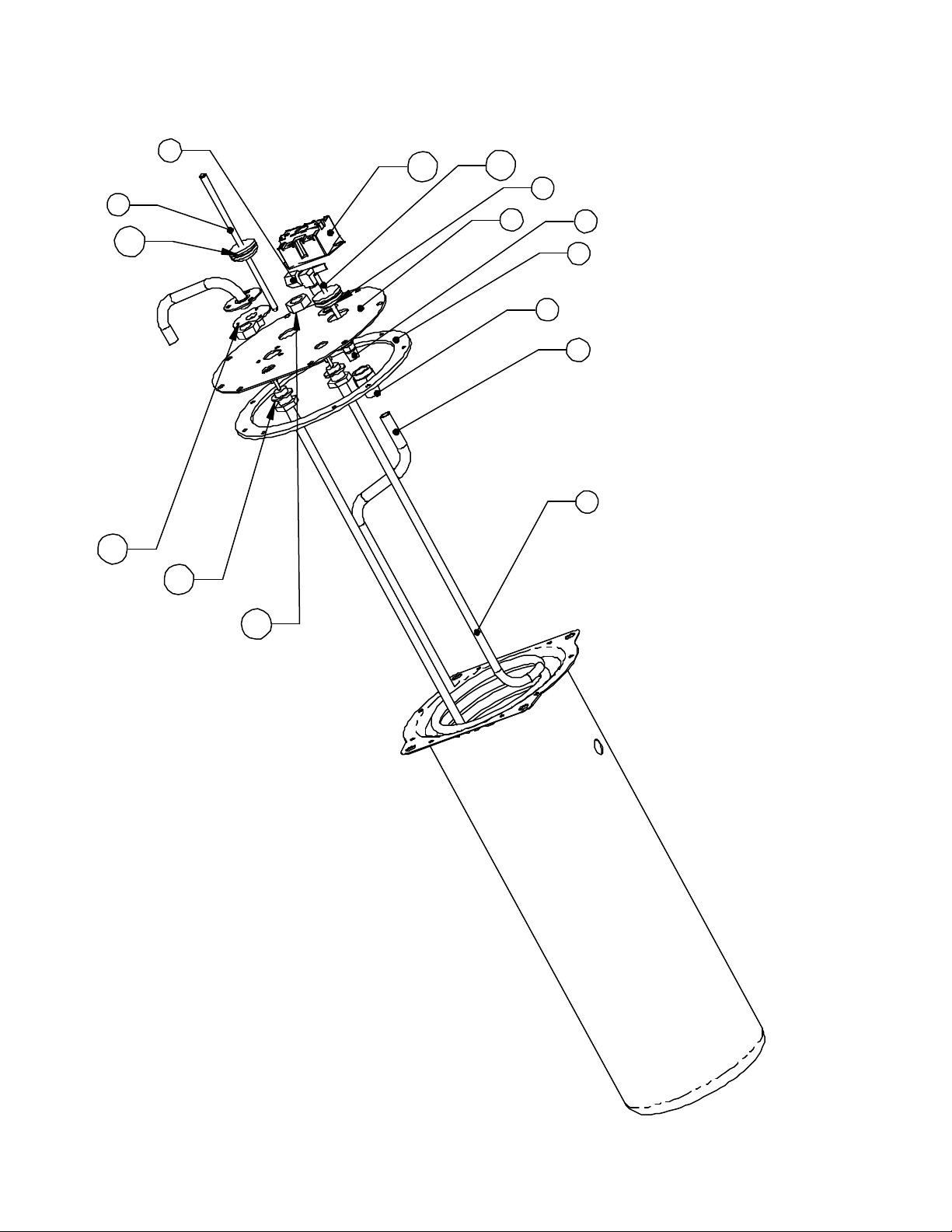

WATER TANK

3

10

14

9

13

12

15

ASSEMBLY

7

1

8

2

6

4

5

11

7

Page 8

WATER TANK ASSY (CONT)

FIGURE # QTY. PART # DESCRIPTION

1 1 104108 LID-SPOTWELD

HOT WATER

2 1 704221 GASKET-TANK SILICONE

3 1 151677 PROBE-DUAL

THERMISTOR

4 1 102019 TUBE-WATER INLET

5 1 701286-10 ELEMENT, DUAL

VOLTAGE 1350W/5500W

6 1 100431 NUT-BRASS 9/16-24

7 2 100030 GASKET-BRASS .566 ID

8 1 101720 CONNECT FM 3/C X 1/8

NPT

9 1 100149 ELBOW -1/4C 90 DEG W

NUT

10 1 704222 GASKET-SILICON 3 HOLE

11 2 100190 NUT-1/2-20 JAM, BRASS

12 1 705002 LIMIT, HI, 40 AMP

13 2 100409 GASKET-BRASS .520 ID

14 2 102836 GROMMET-SILICON

15 1 705071 PROBE-2”

8

Page 9

FLOAT SWITCH

ASSY-HI TEMP

PN 110890

FLOAT SWITCH ASSEMBLY

DRIP TRAY

BRACKET-FLOAT

SWITCH

PN 151761

DRIP TRAY

GRATE

PN 104134

DRIP TRAY

PN 1041339

9

Page 10

Service Notes

1) Should water overflow the tank into the float switch, the water fill valve

(solenoid) circuit is interrupted. This is a safety feature to prevent as spill from

occurring should the water level-probe system malfunction (ER6). To empty the

overflow cup, unplug the power cord and loosen screw on the sheet metal cup

holder bracket. (see illustration on page 9) and empty cup.

2) The heater element is protected by a hi-limit manual reset thermostat (ER5).

Error Modes - To reset an error condition simply power the machine off and

back on. If the error continues, check the condition of all sensors,

hardware & wiring.

ER1 – Top thermistor shorted

ER2 – Top thermistor open

ER3 – Bottom thermistor shorted

ER4 – Bottom thermistor open

ER5 – Heater has run for more than 45 minutes continuously

ER6 – Fill time has run for more than 6 minutes

Newco Enterprises, Inc. * 1735 South River Rd. * P.O. Box 852 * St. Charles, MO 63302

10

Page 11

RD/WH

OPTIONAL

BK

BK

WH/RD

11

WH/RD

BK

BK

Loading...

Loading...