Page 1

Manual PN 119985 Rev 02-06

20:1 Brewer Operation and Service Manual

Model Height Width Depth US 120 V Canada 120

240 V

V

NB-LD 17-7/8 8-1/2 19-1/4 14.6A 11.7A 14.6A

NB-TD 24-3/16 8-1/2 19-1/4 14.6A 11.7A 14.6A

1

Page 2

Manual PN 119985 Rev 02-06 Firmware Rev 4

20:1 INSTALLATION / SETUP INSTRUCTIONS

WARNING: - Read and follow installation / setup instructions before plugging or wiring in machine to electrical

circuit. Warranty will be void if machine is connected to any voltage other than that specified on the name plate.

Plumber's Installation Instructions

1) Plumb brewer in to water supply using 1/4 inch copper tubing. Flush water line before installing brewer to remove

sediment. Brewer should be connected to COLD WATER LINE for best operation.

2) Water pressure should be at least 20 lbs. For less than a 25 ft run, use 1/4" tubing and connect to 1/2" or larger

water line. The inlet water fitting on the back of the brewer is a 1/4" flare fitting.

3) If installed with saddle valve, the valve should have a minimum of 1/8" port hole for up to 25 ft run, and 5/16" port

hole for over 25 ft runs.

4) Check for leaks.

Initial Setup Instructions

Ensure power switch on right rear of unit is in the off position. Plug or wire brewer to the appropriate voltage circuit as

indicated on the serial tag. Turn power switch to the on position. Brewer tank will begin to fill. Once the tank is full

the brewer will begin to heat. Ready light will come on to indicate tank has finished heating.

CAUTION: The water faucet will dispense hot water anytime the handle is pulled.

Programming

The brewer has two program modes, service mode and user mode. The service mode is used to establish basic

operating parameters of the unit while the user mode allows the three buttons to be programmed for brewing into

various containers or for varying beverage volumes. Programming mode is initiated as outlined below. The following

will outline the various steps as displayed by the programming “screens”. The screens will loop continuously until

exiting the mode.

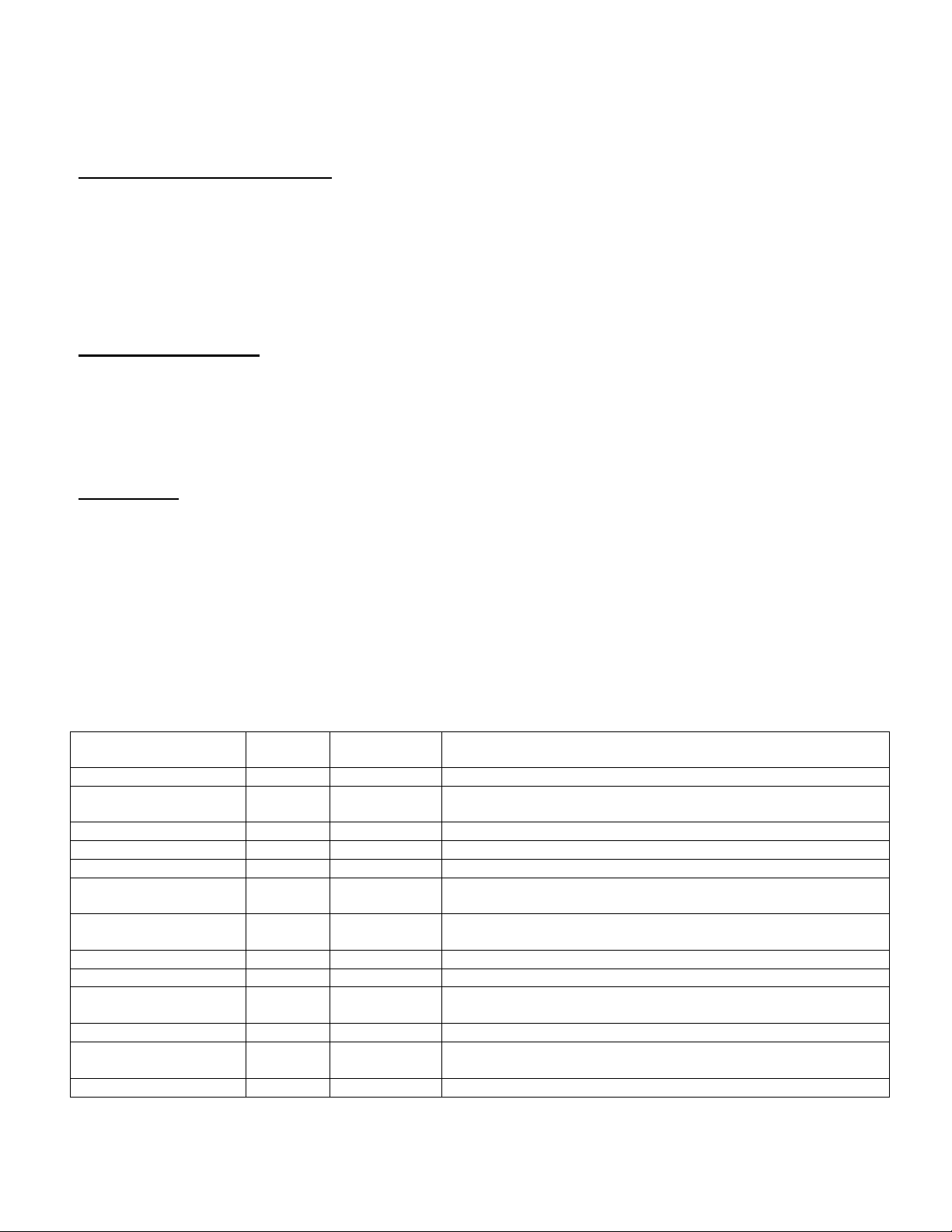

Service Mode is entered by holding any two of the buttons on the face of the machine while powering up the brewer.

The brewer firmware revision number is displayed for a couple of seconds when entering this mode. The table below

list the items that may be programmed along with available values or settings. Use the center brew button to advance

through the items and the left and right button to decrement or increment the values/selection respectively. These

items are programmed at the factory and will typically not need adjustment.

Item Selected Screen

Water Temperature 200 170-205 Degrees F

End of Cycle Beeper On On, OFF Used to audibly indicate brew cycle has completed with a

Brew Pump Speed b:05 1-10 Pump speed used for brewing

Not Used F:05 1-10 No effect. Unused feature.

Pump Calibration CAL N/A See instructions below. Must be done if pump speed modified.

Volume Delivered

During Calibration Step

Water Fill Flow Rate 0.30 Off, 0.20-1.40 Adjustable in increments of .05 GPM. Should match flow rate

Water Filter Capacity 100 Off, 500-2000 In tens of gallons. 50=500 gallons. Increments are 500 gallons.

Power Mode nor nor, SAV, dn Normal, Power Down, or Power Save.

Power Down/Save

Time

Brew Counter 0-999 N/A Shows number of brew cycles since last reset (up to 999).

Service Data Srv N/A

Exit End N/A Use left or right button when displayed to exit this mode.

Example

39.0 16.0-99.9 Ounces. Only displays if calibration cycle was run.

4:00 0:30-4:00 Hours:Minutes from last brew until brewer enters the selected

Values

Available

Comment

series of beeps.

through valve.

power mode. No effect if mode is “Off”.

Used to view temperature & probe data. See Service Data

below.

2

Page 3

Manual PN 119985 Rev 02-06 Firmware Rev 4

Pump calibration is necessary when the pump speed is changed or if the brewer is delivering substantially more or

less beverage than what it has been programmed for in the user mode. Pump speed may be adjusted up or down if

required to deliver water at a faster or slower rate to meet a specific beverage taste profile. Calibration tells the

brewer control how much hot water is delivered within a specific time frame so it can adjust the time required to run to

deliver the desired brew volumes.

Ensure the brew basket is in place. Place a suitably graduated container in place below the brew basket to capture

and measure the water delivered. To calibrate, enter the service mode as noted above and advance to the “CAL”

screen. Press either the left or right brew button and water delivery will begin. If the brewer has not reached

operating temperature, it will finish heating before automatically starting. The pump will cycle on and off for

approximately 2 minutes at which time the currently programmed volume is displayed. Use the left and right button to

decrement or increment the value to the measured value. For better accuracy, you may want to measure a couple of

cycles and average the measured values. Note that user mode will be entered automatically when exiting the service

mode if calibration values have been changed.

Service Data consist of the tank temperature as measured at two points in the tank and an indication as to which

probe(s) are making contact with the water. To view data, enter the service mode as noted above and advance to

the “Srv” screen. Use the left or right button to enter service data mode. Use the center button to advance through

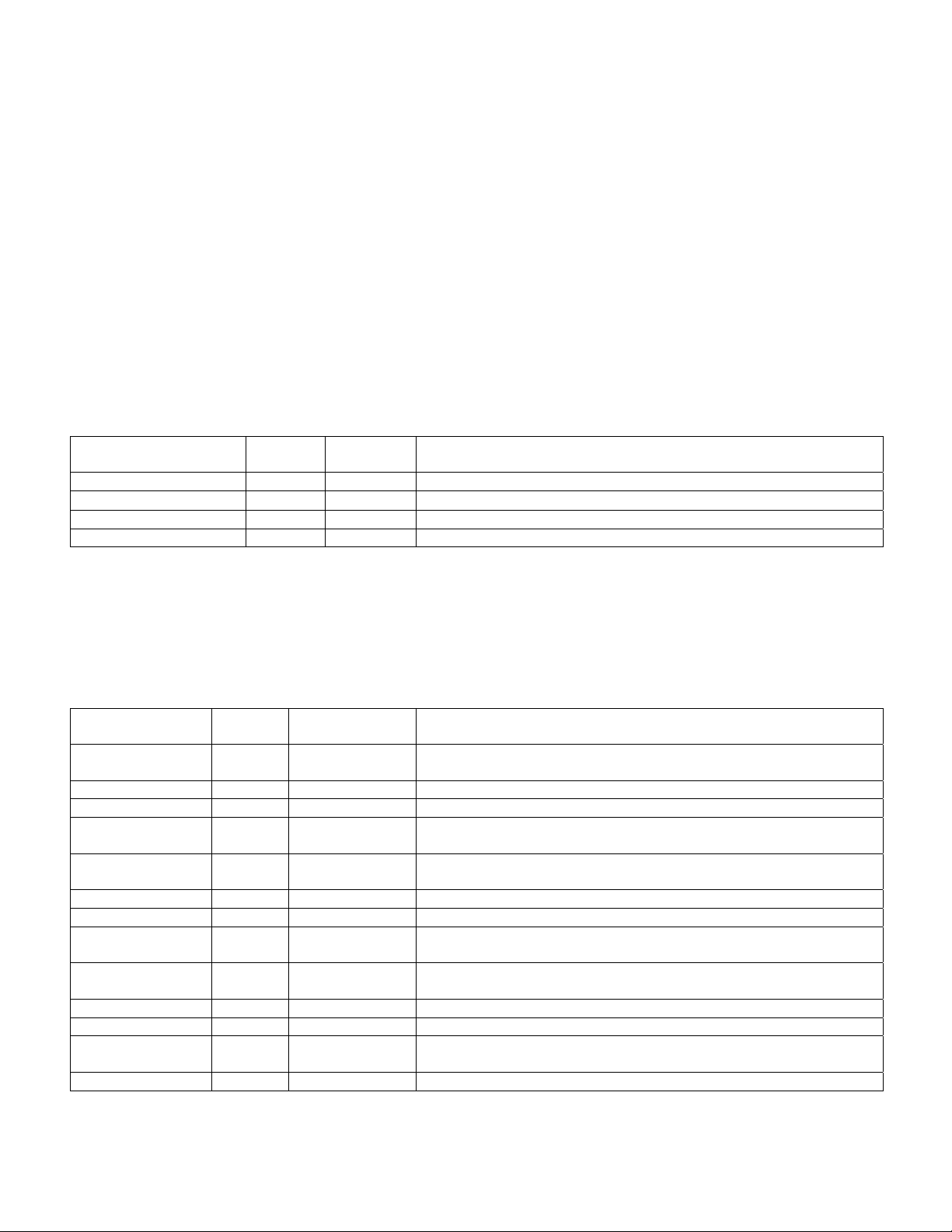

the data. The table below list the data that is displayed.

Data displayed Screen

Example

Lower Temperature 198 N/A Degrees F

Upper Temperature

20

.

0

Values

Comment

Available

N/A Degrees F

Probes 1:UL U,L,UL Displays probes in contact with the water; Upper, Lower or Both.

Exit End N/A Use left or right button when displayed to exit this mode.

User Mode is entered by holding any of the buttons on the face of the machine while powering up the brewer. Note

that the user mode is also automatically entered whenever the calibration volume setting is changed. The beverage

volume, brew time, and visa-brew time can be programmed for each of the three buttons on the face of the brewer.

The brewer will determine the minimum brew time possible based on pump speed and calibration values as outlined

previously. This time is set as the default whenever calibration values are changed. The brew time can be extended

to lengthen the water delivery time to meet a specific beverage taste profile. The table below list the data displayed

and values available.

Data displayed Screen

Example

Values

Available

Comment

Brew 1 Settings b1 N/A Displays briefly to indicate that the parameters are for brew

button 1 (left)

Brew 1 Volume 64 Off, 30-128 Ounces. Button can be turned off and will serve as cancel only.

Brew 1 Time 3:30 Min-9:59 Calculated minimum to 9 minutes and 59 seconds.

Visa-brew 1 Time 0:30 0:00-4:00 Set to allow for beverage to finish dripping from basket after

water delivery time has been completed.

Brew 2 Settings b2 N/A Displays briefly to indicate that the parameters are for brew

button 2 (center)

Brew 2 Volume 64 Off, 30-128 Ounces. Button can be turned off and will serve as cancel only.

Brew 2 Time 3:30 Min-9:59 Calculated minimum to 9 minutes and 59 seconds.

Visa-brew 2 Time 0:30 0:00-4:00 Set to allow for beverage to finish dripping from basket after

water delivery time has been completed.

Brew 3 Settings b1 N/A Displays briefly to indicate that the parameters are for brew

button 3 (right)

Brew 3 Volume 64 Off, 30-128 Ounces. Button can be turned off and will serve as cancel only.

Brew 3 Time 3:30 Min-9:59 Calculated minimum to 9 minutes and 59 seconds.

Visa-brew 3 Time 0:30 0:00-4:00 Set to allow for beverage to finish dripping from basket after

water delivery time has been completed.

Exit End N/A Use left or right button when displayed to exit this mode.

3

Page 4

Manual PN 119985 Rev 02-06 Firmware Rev 4

OPERATION INSTRUCTIONS

Coffee Preparation Procedures

1) Place filter into brew basket.

2) Put the proper amount of coffee into the filter.

3) Slide the brew basket into holder.

4) Place the appropriate empty decanter into position below the brew basket. For airpots first open lid and remove

pump stem unless of a brew through design. For other dispensers remove the lid unless it is a brew through

design.

5) Press the appropriate brew start switch. Note: a brew cycle may be initiated even if the heating light is on. The

brewer features an autoarm circuit which will flash the heating light indicating that the brewer is heating and will

begin to brew immediately after the heating cycle is complete. To over ride autoarm, hold in brew button until

cycle starts (5 seconds).

6) Do not remove decanter. Brew cycle may be canceled by depressing any brew button or the cancel switch on

the front control panel.

7) Hot water will be delivered through the sprayhead. This distributes the hot water evenly over the coffee bed

within the brew basket. The coffee brew will drain from the brew basket into the decanter below.

8) The Brewing light should continue to flash until all the liquid has finished flowing from the brew basket. Do not

remove decanter until the brewing process has stopped and all liquid has stopped flowing from the brewbasket.

9) The resultant coffee brew should be crystal clear and have the desired properties attainable through excellent

extraction.

10) To clean brew basket simply remove from brew rails and dump filter into waste basket. The brewing process, as

described above, can now be started again.

Error Messages

This brewer incorporates a number of self diagnostic test that are routinely run. If a fault condition should occur the

unit will display an error number as outlined below. All errors may be reset by powering unit off and then back on.

Errors E1 and E2 are auto-resttable and will clear themselves if the condition that caused them goes away. You may

still brew, but call for service. E3 will disable heater but will allow brewing to take place. E4 and E-A must have power

to unit cycled to clear them. E5 will force brewer to use its default settings for brewing. E7 and E8 will clear when a

brew cycle is started. E9 will disable input from dsplay board. If error repeats, correct the cause of the error.

Error

Number

E1 Open

E2 Shorted

E3 Heater Run

E4 Tank Fill Error Water did not reach probe in timeout

E5 Comm Error Serial communication error to/from

E7 Open Motor

E8 Bad (Open)

E9 SPI Comm Error Serial communication error to/from

E-A Possible Leak

Full Filter Full Water filter has reached capacity. Replace filter.

Description Cause What to Check

Thermistor

Thermistor

Error

Circuit

Motor Driver

Detected

Resistance extremely high from

upper or lower thermistor

Resistance extremely low from upper

or lower thermistor

Water did not heat within timeout

period

period

non-volatile memory (EEPROM).

Open motor circuit. Pump 0 or

pump 1.

Bad/open motor driver. Pump 0 or

pump 1.

display board.

Water system may have a leak. Check all plumbing system components for

Check/replace thermistor.

Check/replace thermistor.

Check element for short and proper

resistance. Replace if bad.

Check valve function and flow rate.

Replace valve or increase flow rate. Check

probes for excess scale.

Replace main board.

Check harness/motor continuity. Replace

if defective.

Replace main board.

Verify good connection in proper port. Try

new display board. Try new main board.

possible leak. Look for water on counter.

4

Page 5

LID ASSEMBLY 119972

1

2

Manual PN 119985 Rev 02-06 Firmware Rev 4

3 4

17

16

15

18

19

5

6

7 8 9

11

12

13

10

14

Item #

Part #

Description Qty

1 100190 NUT, 1/ 2 –20 JAM, BRASS 2

2 119997 CONNECT, FM 3/8C x 1/8P, MOD 1

3 119991 FITTING, 1/8 PIPE x 1/4 BARB 1

4 100030 GASKET, BRS, .566 ID, TIN/PLTD 2

5 100149 ELBOW, MALE, 1/4 COMP x 1/8 1

5 Alternate 100177 ELBOW, MALE, ¼ FLARE X 1/8 NPT 1

6 100445 TUBING, TEFLON, 3/16 ID

6 Alternate 119836 COPPER T UBE ASSEMBLY 1

7 202044 INSERT TUBING, 3/16 1

8 110946 NUT, 1/ 4 SELF ALIGN 1

9 110944 SLEEVE, 1/4 SELF ALIGN 1

10 101720 CONNECT, FM 3/8C x 1/8P, TNPL 1

11 102836 GROMMET, SIL, NO SLIT 3

12 119891 PROBE SPTWLD 2

13 119973 LID, TANK, PUNCHED, NB 1

14 152207 PLUG, TANK CVR NATURAL SIL 1

15 151677 PROBE, TEMP, DUAL, 7.312, THERM 1

16 152198 14GA, VIO/BLK, 4 TEF, 1S-1S 1

17 100269 BRACKET, HIGH LIMIT THERMO 1

18 111593 THERMO, MAN/RESET 1

19 202025 ELEMENT, TANK, 1750W, 120V 1

5

Page 6

LID ASSEMBLY 119972, CONTINUED

1

2

Manual PN 119985 Rev 02-06 Firmware Rev 4

3

Item # Part # Description Qty

1 100409 GASKET, BRASS, .520ID, TN/PLT 2

2 151677 PROBE, TEMP, DUAL, 7,312 THERM 1

3 202025 ELEMENT, TANK, 1750W, 120V 1

6

Page 7

TANK

Manual PN 119985 Rev 02-06 Firmware Rev 4

1

2

3

4

6

5

Item # Part # Description Qty

1 704221 GASKET 1

2 119971 TANK, PUNCHED 1

3 111635 CLAMP, HOSE .574 ID 2

4 152213 TUBING, SIL, 3/8 ID x 5/8 OD

5 102835 BULKHEAD, FAUCET 2

6 781772 PUMP, ASSY, WATER 1

7

Page 8

BREW PLATE / DISPLAY BOARD

Manual PN 119985 Rev 02-06 Firmware Rev 4

2 3 4

1

5

7

6

Item # Part # Description Qty

1 100731 DISPLAY BOARD & HARNESS 1

2 120025 SPACER, 6-32, 3/8 HEX x 7/16L 3

3 120046 SCREW, 6-32 x 1/4, PPHMS, POLY 3

4 110941 WASHER, NYL, .151 x .345 x .031 3

5 119970 BREW PLATE SPTWLD 1

6 152218 TUBING, SIL, 1/4 ID x 3/8 OD

7 152213 TUBING, SIL, 3/8 ID x 5/8 OD

8 111635 CLAMP, HOSE, .574 ID 2

9 111597 TUBE, SPRAYHEAD 1

8

9

8

Page 9

14

13

Manual PN 119985 Rev 02-06 Firmware Rev 4

COMPONENT, PANEL ASSY - 119994

1

2 3 4

5

11

12

Item # Part # Description Qty

1 100255 KIP VALVE, SOLENOID 1

2 110944 SLEEVE, 1/4 SELF ALIGN 1

3 110946 NUT 1/4 SELF ALIGN 1

4 202044 INSERT TUBING, 3/16 1

10

9

8

7

5 101527 REPLACEMENT KIT, KIP VALVE 1

6 105115 TRANSFORMER 1

7 100022 CORD, POWER 1

8 101035 GROMMET, STRN RELIEF 1

9 101898 CORD PLATE 1

10 110626 SWITCH, DP/ST, RECT, ROCKER 1

11 121659 HEATSINK 1

12 110367-10 RELAY, 50 AMP, SOLID STATE 1

13 100729 MAIN BOARD 1

14 102844 SUPPORT, CIRCUIT BOARD 3/8 4

9

6

Page 10

20:1 Wiring Diagram

SWITCH/DISPLAY BOARD

Manual PN 119985 Rev 02-06 Firmware Rev 4

100731-2

TANK ASSEMBLY

VL/BK

RIBBON CABLE

OPTIONAL 240V WIRING

HEATER

RELAY

VL/BK

TANK

HEATER

ELEMENT

VL/WH

VL/BK

VL/BK

VL/BK

HI-LIMIT

THER-

MOSTAT

HEATER

RELAY

TANK

HEATER

ELEMENT

VL/WH

PANEL ASSEMBLY

-

+

VL/WH

BK

WH

PROG

SWITCH

RD

RD

BK

COMPONENT

BK

RD

RIBBON CABLE

YL

STANDARD

PROBE

THERMISTOR

ASSEMBLY

MAIN

CONTROL

BOARD

GY

BK

RO

PROBE

100729-2

2

1

CN5

ON

BK\

WH

ON

BK

BN

PROBE

SIGNAL IN

6 1

7 2

8 3

9 4

10 5

CN2

4 1

5 2

6 3

CN3

3 1

4 2

DP-A

DP-B

CN1

RD

BL

BK

RD

RD

BN

2 1

2 1

BK\

WH

BN

YL

RD

BK

BK

RD

WH

POWER

CORD

BK

POWER

CORD

GN

BK\WHBK\

BN

BK

WH

WH

TRANSFORMER

GY

FILL

VALVE

WH

PROG

SWITCH

VL\BK

L1

WH

BK

WH

TERMINAL

BLOCK.

L2N

OPTIONAL

FOR 120 V

WARRANTY

Newco coffee brewers are warranted against defects in workmanship or materials, under normal use, for 90

days from the date of purchase. Brewer parts are warranted against defect for 12 months from date of purchase.

Liability in all events is limited to the purchase price paid and liability under the aforesaid warranty is limited to

replacing or repairing any part or parts which are defective in material or workmanship, and returned to our factory,

shipping cost prepaid. No warranty expressed or implied, other than the aforesaid is made or authorized by Newco

Enterprises, I nc.

Prompt disposition will be made if item proves to be defective, within warranty. Before returning any item,

write or call Newco, or the dealer from whom the product was purchased, giving model number, serial number, and

date of purchase, and describe nature of the defect. If damage was incurred during transit to you, file claim with the

carrier.

10

Loading...

Loading...