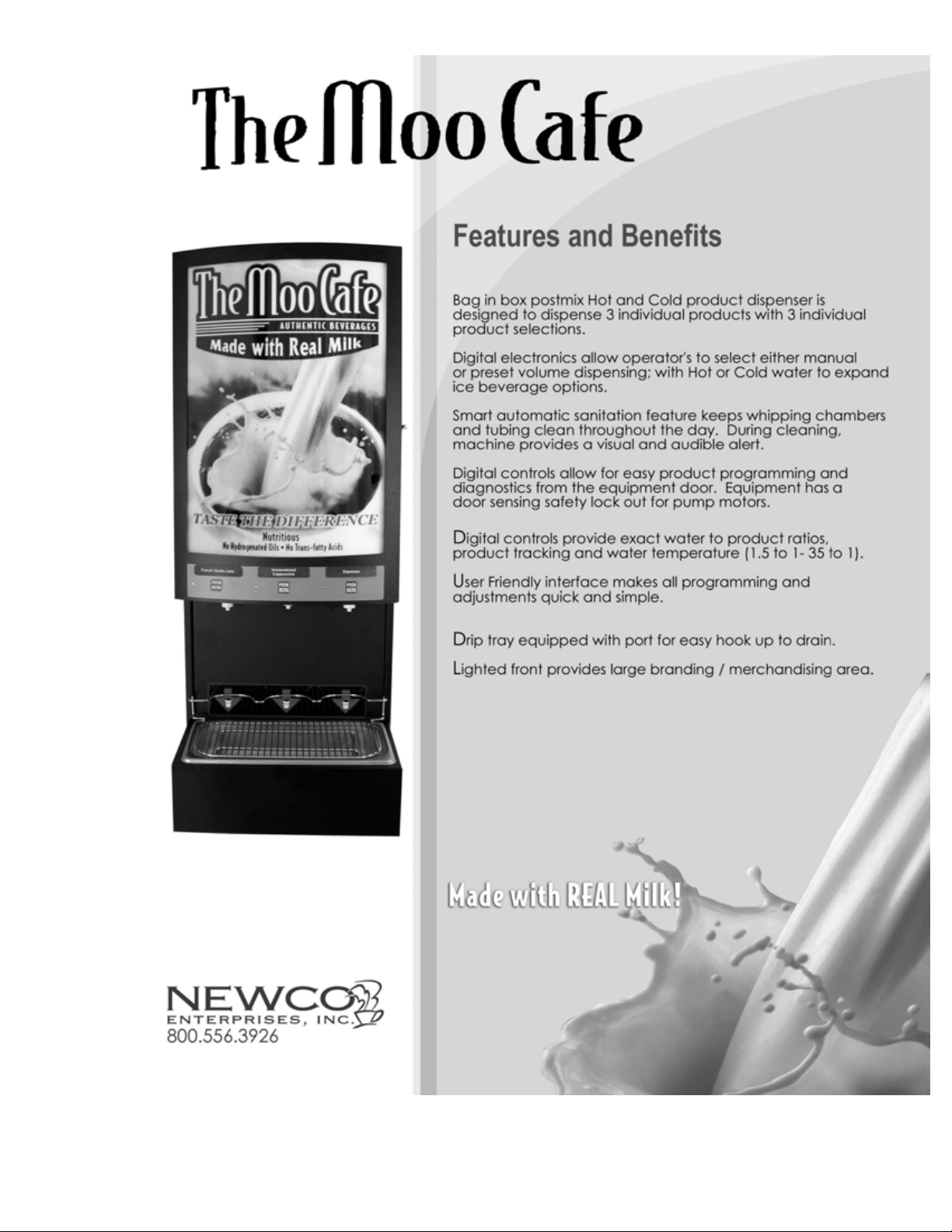

Page 1

1

Page 2

Contents

FEATURES/ SPECIFICATIONS...........................................................................4

NEWCO PRODUCT WARRANTY........................................................................4

ITEMS INCLUDED WITH MACHINE....................................................................5

EQUIPMENT START-UP PROCEDURE..............................................................7

EQUIPMENT CALIBRATION................................................................................7

SANITATION.......................................................................................................11

PROGRAMMABLE BUTTONS ...........................................................................13

PRODUCT RATIO...............................................................................................15

PORTION CONTROL .........................................................................................16

MANUAL DISPENSE..........................................................................................17

HOT / COLD WATER SELECTION ....................................................................18

WHIPPER MOTOR ENABLE/DISABLE..............................................................19

BAG TRACKING.................................................................................................20

BAG TRACKING RESET....................................................................................21

SERVICE – CALIBRATION AND TROUBLESHOOTING...................................22

TEMPERATURE ADJUSTMENT............................................................22

CABINET ACCESS.................................................................................23

HOT & COLD (AMBIENT) WATER CALIBRATION ................................25

TROUBLESHOOTING ............................................................................28

REPLACEMENT PARTS.........................................................................29

WATER TANK HEATING........................................................................31

WHIPPER & PUMP ASS’Y......................................................................32

WHIPPER & PUMP MOTORS................................................................33

DUMP VALVES.......................................................................................34

DISPLAY BOARD ERROR MESSAGES ................................................35

2

Page 3

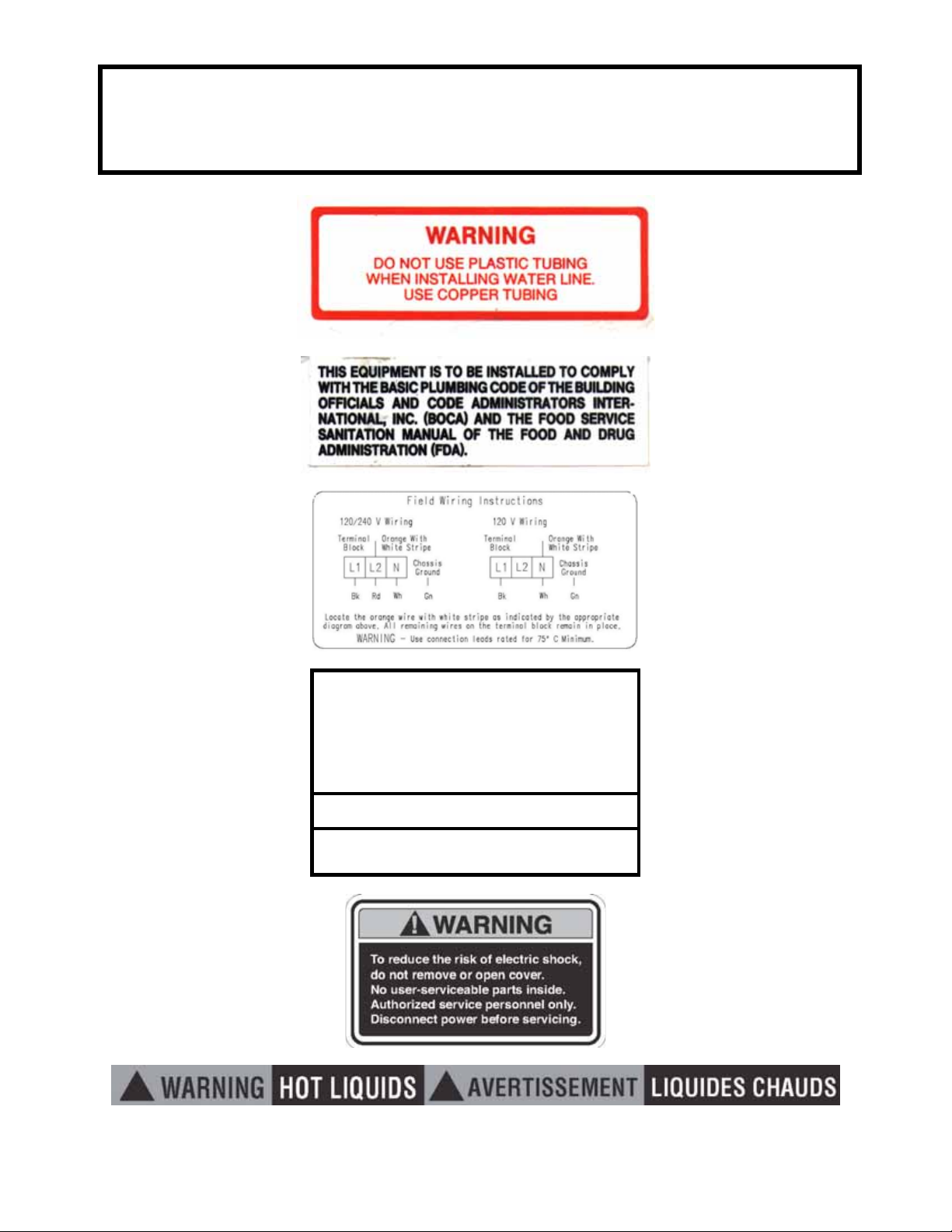

NOTICE: Read and follow all notices posted on this machine.

Do not damage or destroy these notices as they are for your

protection

! WARNING

DO NOT OVERLOAD CIRCUIT.

ALWAYS ELECTRICALLY GROUND THE

CHASSIS OR ADAPTOR PLUG.

DO NOT DEFORM PLUG OR CORD.

FOLLOW NATIONAL AND LOCAL ELECTRICAL

CODES.

KEEP COMBUSTIBLES AWAY.

FAILURE TO COMPLY RISKS EQUIPMENT

DAMAGE, FIRE OR SHOCK HAZARD.

READ THE ENTIRE OPERATING MANUALBEFORE

USING THIS PRODUCT

3

Page 4

MCM-3-COMBO

Features/ Specifications

• Product to Water Ratio Range: 1.5:1 to 35.0:1

• Cup Volume Range: 1.5 oz to 25.0 oz

• Hot Water Temperature Range: 160 to 190 deg F

• Concentrate Calibration Range: 2.5 oz to 10.0 oz

• Water Calibration Range (Hot or Cold) 13.0 oz to 25.5 oz

• Initial fill Timeout: 10 Minutes

• Fill Timeout: 40 Seconds

• Automatic Sanitation-Sanitation cycles at power up when water

temp reaches 160 degrees, 1 hour after last product dispensed,

and 24 hours after the last sanitation cycle

• Electrical Specifications-120V 1500W 1ph / 240V 6000W 1ph

Newco Product Warranty

Newco warrants equipment manufactured by it for 90 days labor- 1 year parts.

These warranty periods run from the date of installation Newco warrants that the

equipment manufactured by it will be commercially free of defects in material and

workmanship existing at the time of manufacture and appearing within the

applicable warranty period. This warranty does not apply to any equipment,

component or part that was not manufactured by Newco or that, in Newco’s

judgment, has been affected by misuse, neglect, alteration, improper installation

or operation, improper maintenance or repair, damage or casualty. This warranty

is conditioned on the Buyer 1) giving Newco prompt notice of any claim to be

made under this warranty by telephone at (800) 556-3926 or by writing to PO Box

852, Saint Charles, MO 63302; 2) if requested by Newco, shipping the defective

equipment prepaid to an authorized Newco service location; and 3) receiving

prior authorization from Newco that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER

WARRANTY, WRITTEN OR ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT

LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of

Newco are not authorized to make modifications to this warranty or to make

additional warranties that are binding on Newco. Accordingly, statements by

4

Page 5

such individuals, whether oral or written, do not constitute warranties and should

not be relied upon.

If Newco determines in its sole discretion that the equipment does not conform to

the warranty, Newco, at its exclusive option while the equipment is under

warranty, shall either 1) provide at no charge replacement parts and/or labor

(during the applicable parts and labor warranty periods specified above) to repair

the defective components, provided that this repair is done by a Newco

Authorized Service Representative; or 2) shall replace the equipment or refund

the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST NEWCO FOR THE BREACH OF ANY

OBLIGATION ARISING OUT OF THE SALE OF THIS EQUIPMENT, WHETHER

DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT NEWCO’S

SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall Newco be liable for any other damage or loss, including, but not

limited to, lost profits, lost sales, loss of use of equipment, claims of Buyer’s

customers, cost of capital, cost of down time, cost of substitute equipment,

facilities or services, or any other special, incidental or consequential damages.

Items Included with Machine

Drip tray Ass’y w/Drain Hose Qty 1

Water Filter w/Hardware & Shutoff Qty 1

Florescent Bulbs Qty 2

Durotrans Translucent Door Sign Qty 1

4” Plastic Legs Qty 4

5

Page 6

Machine Set-Up

NOTE: The MCM-Combo machine weighs approximately 100 LBS . Use more than

one person when unpacking and lifting machine. DO NOT LIFT BY THE DOOR.

See illustrated machine set-up guide supplied with equipment.

1. Remove the box containing the accessories listed above. Open and

remove the 4” plastic legs and the drain pan, drain pan housing (black),

and the drain pan support with hose. Once equipment is out of the box,

install the 4” plastic legs to the base of the machine. Note: The front legs

and drain support bracket must be installed at the same time. Align

bracket holes with the holes in the front of the machine base, and secure

by screwing the plastic legs tightly against bracket. The 4” legs are

designed to hold the drain support bracket to the base of the machine. The

drain bracket has an 6’ drain hose attached for hookup. Place equipment

at final location and plumb in the drain line. Note: The equipment must be

plumbed to a drain because of the Automatic Sanitation System Feature of

the machine.

2. Install the two (2) florescent bulbs in the door face and rotate ¼ turn to seat

in socket. Unscrew and remove the three (3) brass screws in the inside top

of the door panel and remove door cap. Remove the translucent durotrans

sign from the protective cardboard sleeve, remove protective film from

both sides of sign, and install by sliding the sign panel from the top of the

door opening down following the slide guides until the sign is seated at the

bottom of the guides. Re-seat door cap and secure with the three (3) brass

screws.

3. This equipment is shipped with a water filter. Before installation unscrew

the blue top ass’y, remove the filter cartridge and remove the ‘plastic wrap’.

Re-assemble and follow the ass’y instructions provided with the filter.

Install the water filter bracket (use 2 #8 screws) on either side of water line

connection, upper rear center of machine, and install water filter &

connections to the to the water inlet outlet located in upper rear of

Machine. Note: Pre-flush filterand water lines before connecting to

equipment water inlet.

4. Connect free end of plain water lines to water supply. Note: This equipment

is to be installed to comply with the applicable Federal, State, or local

plumbing codes having jurisdiction. Flow requirements: Minimum flowing

pressure of 35 PSIG (2.46 kg/cm 2, 2.41 BAR) Maximum static pressure of

100 PSIG (7.02 kg/cm 2, 6.85 BAR) Provide enough extra coiled tubing (at

least 2x the depth of the unit) so that the machine can be moved for

cleaning underneath.

5. Turn on water supply and check for leaks.

6

Page 7

Equipment Start-Up Procedure

1. Plug machine into electrical supply [120V, 1.8 KW, 15A,] [240V, 3 poles, 4

wire grounding type Twist-Plug Receptacle. For 240V units, Use L6-20R or

L6-30R, 2 pole, 3 wire Twist-Plug Receptacle]. Hot water tank will start

filling.

2. Activate the Light switch (Toggle Up) located on the inside of the door.

3. The LCD window will display self-test message briefly, sanitation indicators

will light (will not sanitize until tank reaches 160 deg). (The sanitation cycle

can be cancelled by pushing the Rinse/Auto-Rinse button).

4. Allow approximately 6-8 minutes for the tank to fill. If the tank does not fill

up within the first 10 minutes an error message will appear in the LCD

window FIL. (See Definition of Screen and Troubleshooting Guide). The

machine is factory preset to dispense water at the rate of 20-25 oz. /30 sec.

For hot water & 30-32 OZ. /30 sec. for cold water.

5. Allow up to 50 minutes for the water to reach a temperature of 175°F. The

heat up time will depend on the water inlet temperature, the input voltage.

6. This unit is equipped with a pump safety interlock switch activated by

opening and closing the door. When door is open, concentrate pumps will

not operate.

7. Set-up and calibrate the Moo Products for each channel while the machine

is heating.

Equipment Calibration

Machine Hot & Cold water volumes have been pre-set at the factory. These

volumes have been programmed into the software. It is necessary however to

calibrate the Product Concentrate for each dispense channel in order for the

machine to allow digital calibration of correct Water to Product Ratio.

Moo Concentrate Milk Products will dispense 6-9 ounces of product within 30

seconds, depending on product flavor, as each product blend has slightly

different viscosities.

When machine is equipped with “Coffee Kit” liquid coffees will dispense in 3-5

oz/30 sec. ranges

7

Page 8

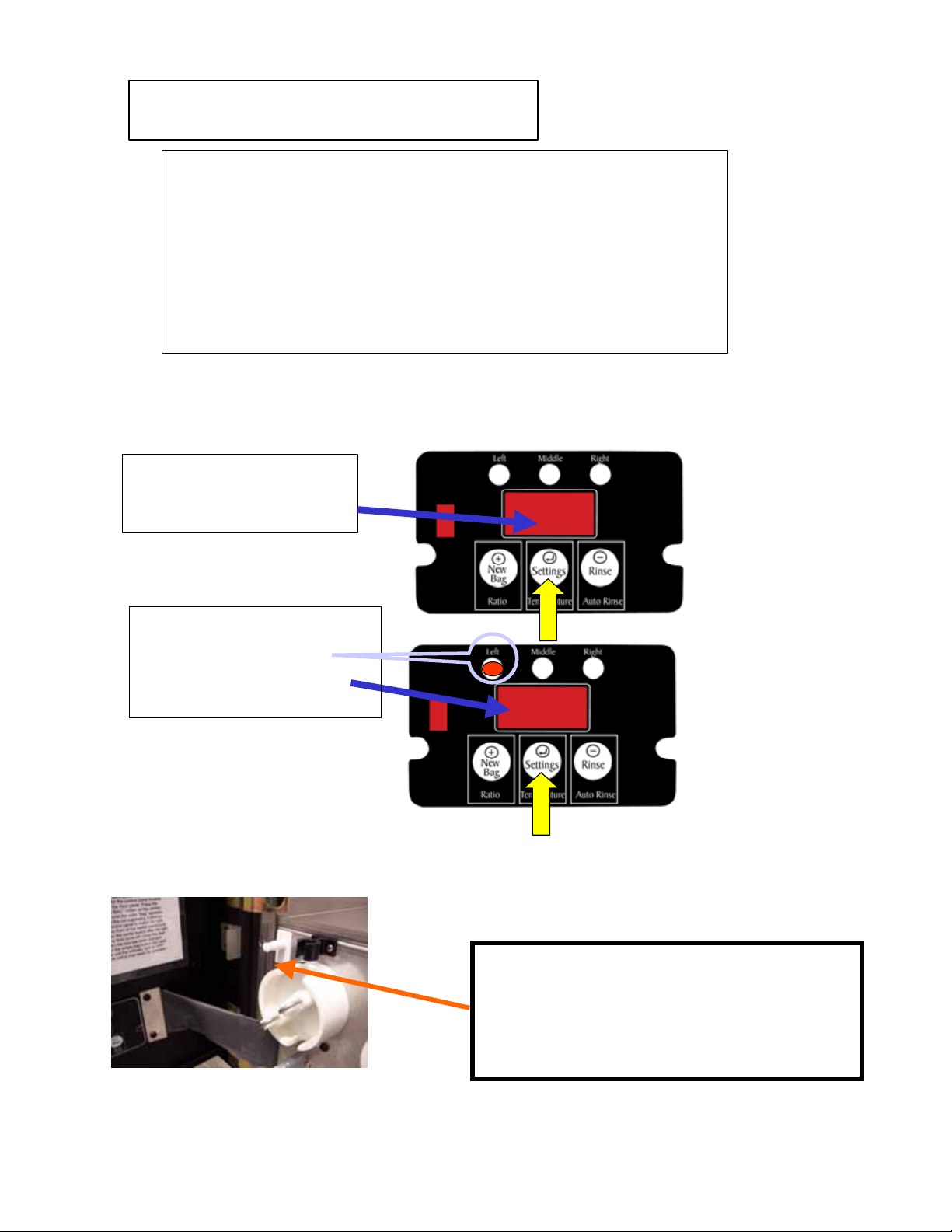

Product Calibration Instructions

Overview: Machine H2O settings are calibrated at the factory and

normally do not need adjustment. Concent rate calibration

should be performed at initial machine set-up, and each

time the product density (or viscosity) changes.

(If same product is used, I.e. just changing out an empty box

of the same product, channel does not need recalibration)

Should it become necessary to re-calibrate H2O settings,

see page 25

Step 1

Press & hold Button 2 “Setting s”

After approximately 5 seconds

Display will change to”- - -”

---

Step 2

Continue holding for approximately

8 more seconds until display

Changes to “Con” and “Left”

Channel indicator is displayed

Release Button 2

con

Note: Pull out safety switch on door during

product calibration cycle. If switch is not

pulled out to ”on” position the pumps will

not operate, and an error code will flash,

“P1, P2, or P3”

8

Page 9

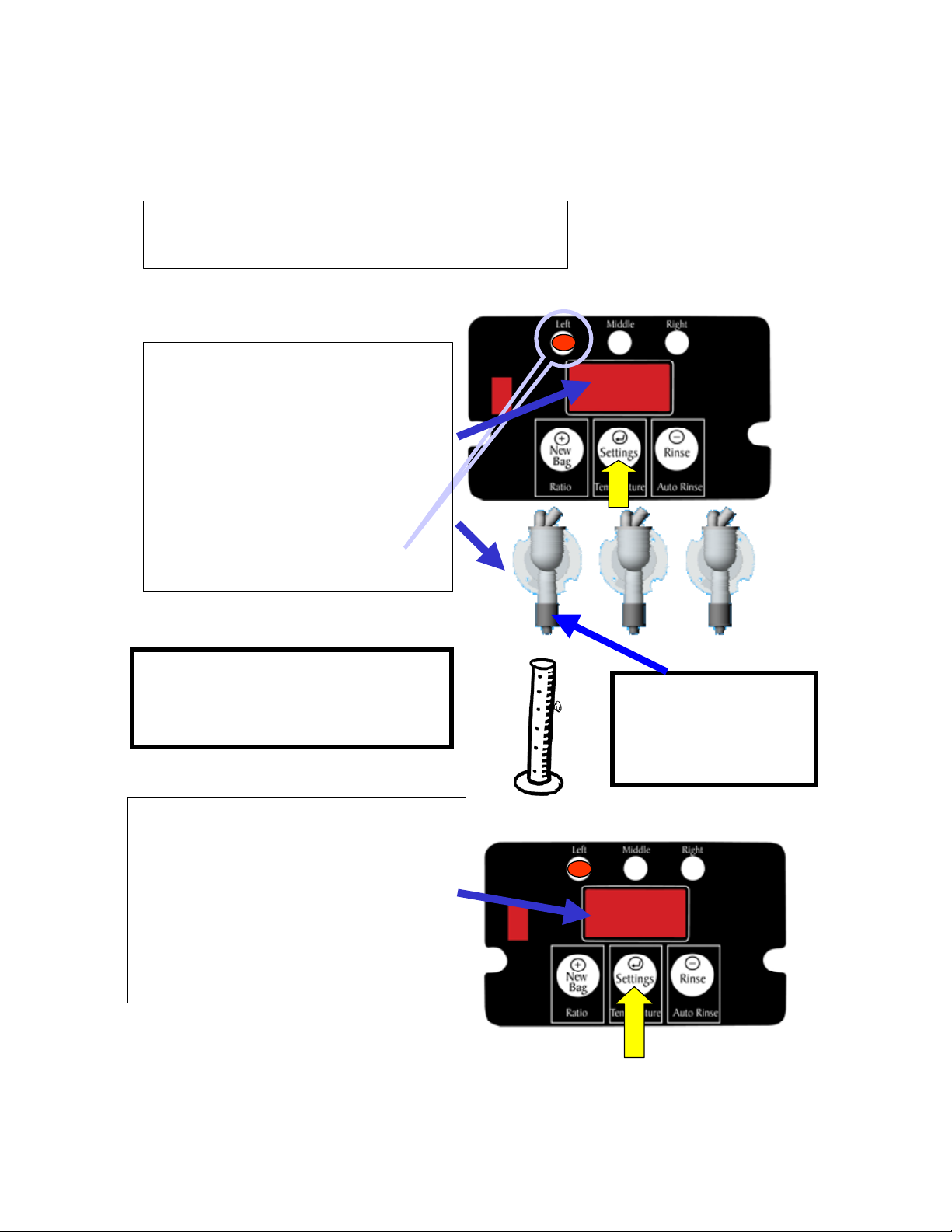

Product Calibration Instructions-Cont’d

Step 3

Depress button 2 (Settings)Display will change to” 0:30”

Place a measuring cup

(preferably a graduated cylinder)

under the dispensing head to be

Calibrated ( as indicated by

channel light)

0:30

If graduation is

in Millimeters, divide by 28.36

to convert to ounces

Step 4

Press button 2 agai n , machi n e will

pump concentrate into measuring cup for

30 seconds-When concentrate stops,

read concentrate volume (in ounces) from

cup.

Toggle buttons

Until measured value is displayed.

1(+) & 3(-)

Remove nozzle when

calibrating

concentrate. Replace

when finished.

7.5

9

Page 10

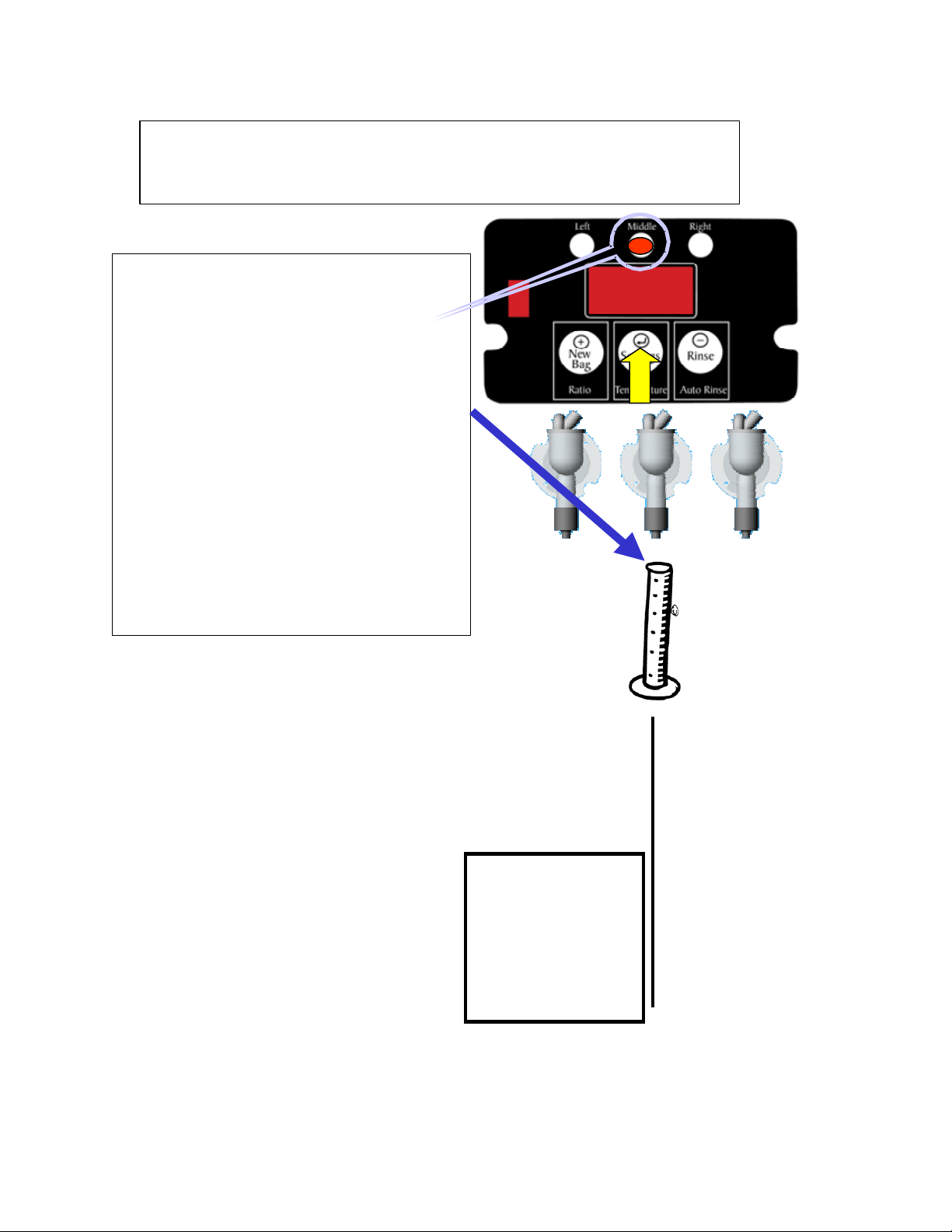

Product Concentrate Calibration Instructions

-

Cont’d

Step 5

Press center button to store settings,

Display will change to 0:30 and

Indicator light will move to Middle

button on display

Move the graduated cylinder (at

least 8 fl oz) under the Middle

Dispensing head, repeat steps 3 - 5

For Middle and Right Dispense

Heads

When Right dispense info is

Stored, display turns blank &

returns to operating mode

0:30

A graduated

cylinder or

Brixing cup will

assure accurate

calibration of

product

concentrate

10

Page 11

Sanitation

Automatic Sanitation Cycle:

Sanitation cycle waits for water temp to reach 160 deg F. min.

Sanitation cycles are performed at power up, 1 hr after the

Last product dispense, and 24 Hrs after the last sanitation cycle.

Once a 24 Hr sanitation cycle has been performed, no more

sanitation cycles will take place until initiated by a dispense or

another power-up.

Sanitation cycle lasts for approx 6 seconds, all three hot water

dispense valves open and the whipper motors run. Sanitation

cycle may be cancelled by pressing any button on the display

board.

Sanitation cycle can be manually initiated by pressing the right

button on the display board. Cleaning cycle will initiate as above.

Cleaning & Sanitizing Instructions:

TSanitizingTT: All food dispensing units should be sanitized periodically. All parts

to be sanitized must be cleaned first.

To prepare a sanitizing solution: ADD 2 TSP. OF LIQUID CLOROX BLEACH (5.25%

CONCENTRATION) TO 1 GALLON OF WATER AT

ROOM TEMPERATURE (70°- 90°F).

Note: Always start with an unopened bottle of Clorox Bleach since the solution

from an opened bottle has a short life span.

• Soak all parts for a minimum of 3 min. in the sanitizing solution.

• Let all sanitized parts drain and dry naturally. DO NOT WIPE THEM DRY.

• Before using the sanitized unit (or parts) with foodstuffs, rinse all parts

thoroughly with water.

Water pipe connecting and fixtures directly connected to a potable water supply

shall be sized, installed, and maintained in accordance with

Federal, Sate, and Local codes (section 7).

11

Page 12

Cleaning & Sanitizing Instructions-cont’d

Cleaning

1. Remove the drip tray with grill and empty the contents.

2. Wash and let dry the tray and grill (use a mild dishwasher detergent).

3. Wash and let dry the dispense area.

4. Turn the power switch to ON.

Manually Flushing the Whipper Chambers

1. Open the cabinet door.

2. Place a container under each dispense nozzle and push the Auto Rinse button.

Removing and Cleaning the Whipper Chambers

1. Remove the dispense cap by pulling it upward.

2. Grab and twist the whipping chamber clockwise and pull it off the

mounting plate.

3. Pull the whipper blade off the motor shaft. Notice the flat keyway on the

shaft and the matching keyway inside the whipper blade shaft. It is

important that these two keyways are lined up when re-assembling the

components.

4. Slip off the slinger washer from the whipper chamber mounting plate.

Clean slinger washer, whipper blade, motor shaft, whipper housing and

dispense cap.

5. Reinstall making sure slinger washer is within 1/32” of whipper seat, but

not touching whipper seat. (See illustration below and on page

25HHH32)

12

Page 13

Programmable Buttons

(3 per channel)

TTA. Manual DispenseTT-“Push & Hold” center button for manual dispensing

Example: Program the center button to manually dispense once drink per channel.

Disable outer buttons on each channel.

26H HHSEE PAGE 17

Indicates buttons that have been disabled

Buttons Enabled

13

Page 14

Programmable Buttons Cont’d

TTB. Portion ControlTT-Ability to set a volume dispense (in ounces) for any button

Example: Program the 1PP

the center button for a large cup dispense, and the 3PP

st

PP

button for each dispense for a small cup dispense,

rd

PP

button for a

manual dispense HH27HSEE PAGE 16

All Buttons Enabled

C. Hot/Cold Water Dispense-Ability to have hot or cold (ambient)

dipsense choice per button

Example: Pr ogram t he 1

st

& 3rdbutton s on each chan nel “Hot” & “I ced”

Center Buttons Disabled

HH28HSEE PAGE 18

14

Page 15

Product Ratio

Multi Level Programming

Step 1

Press and hold until display

changes to

Step 2

Press and hold until display

changes to

rAt

Step 3

Press Button to be

Programmed-Display will

change to a Ratio Value

Water:Product RATIO

Step 4

Toggle Ratio Value + or –

When desired ratio value is

obtained press center button

3.0

Ratio valu e is now locked in for

button-Display changes to

rAt

Repeat step 3&4 for remaining

buttons

15

Page 16

Portion Control

Multi Level Programming

Step 1

Press and hold until display

changes to

Step 2

Press and hold until display

changes to

Por

Step 3

Press Button to be

Pr o g r am med-D i s play wil l

change to a Ounce Volume

Value

Portion Control

Step 4

Toggle Volume Value + or –

When desired Volume (ounce)

value is obtained press cen ter

button.

Portio n Control is now locked in

3.0

for button-Display changes to

Por

Repeat s tep 3&4 for rem aining

buttons

16

Page 17

Step 1

Press and hold until display

changes to

Step 2

Press and hold until display

changes to

Manual Dispense

Multi Level Programming

Button-Manual Dispense

Enable/Disable

Step 4

Toggle Ounce Volume Value (–)

Por

Step 3

Press Button to be

Programmed-Display will

change to an Ounce Volume

Value

3.0

until display

Reads “on” or “off”(+)

on

If “off” is selected button is disabled

If “on” is selected button is set for

Manual Dispense

Press center button to store settings for

selected button

Repeat step 3&4 for remaining buttons

off

17

Page 18

Hot / Cold Water Selection

Multi Level Programming

Step 1

Press and hold until display

changes to

Step 2

Press and hold until display

changes to

o

F

Step 3

Press Button to be

Programmed-Display will

change to Temp Option

Hot/Cold Water Selection

Step 4

Press either button

to toggle “hot” or “cold (ambient)” water

temperature

Hot

Press center button to store button selection

Cl d

Hot

Temp choice is now locked in for button-Display changes

to

o

F

Repeat step 3&4 for remaining buttons

18

Page 19

Whipper Motor Enable/Disable

Step 1

Press and hold until display

changes to

Step 2

Press and hold until display

changes to

Multi Level Programming

Whipper Motor

Enable/Disable

Step 4

bln

Step 3

Press Button to be

Programmed-Display will

change to “on” or “off”

on

Toggle “on” “off” + or –

Center Button stores last value

displayed

Repeat step 3&4 for remaining

buttons

19

Page 20

Bag Tracking

Multi Level Programming

Bag Tracking Enable/Disable

Step 1

Press and hold until display

changes to

bag

Step 4

Step 2

Continue holding until

display changes to

btr

Step 3

Pressing Left or Right

buttons toggles channel

indictator to select channel

To Enable/Disable

Pressing middle button

changes display to

on

Step 5

Pressing Left or Right buttons toggles

display“on” or “off”

Pressing Middle Button

Stores “on” or “off” setting for

indicated channel

Repeat step 3-5 for other channels

Note: Bag Tracking

cannot be used when

more than (1) ratio is

programmed in the

same channel

20

Page 21

Bag Tracking Reset

Bag Tracking Reset

Step 1

Press and hold for 1 second-

display changes to

bag

Step 2

Pressing Left , Middle or

Right buttons will reset the

bag count to full for

corresponding channel

Left Middle Right

Note: When indicator

light remains

steady, buttons are

disabled until

Channel is reset

21

Page 22

Service – Calibration and Troubleshooting

Temperature Adjustment

Temperature Adjustmen t

Step 1

Press and hold until displa y

changes to

Step 2

Release and repress Middle

Button-display changes to

180

Hot Water Tank

Step 3

Toggle Te mperature Value + or –

When desired Temperature value

is obtained press center button to

store

Note: Middle Indicator Light will

turn on if Tank is Heating

22

Page 23

Service – Calibration and Troubleshooting

Cabinet Access

POWER PANEL & VALVE ACCESS

Lift up &

Remove LH side panel

23

Page 24

Service – Calibration and Troubleshooting

Cabinet Access Cont’d

Machine Panel Removal

Component Access

2. LIFT & REMOVE

BACK PANEL

3. LIFT AND REMOVE SIDE PANEL

1. REMOVE

BRASS

THUMBNUTS

(4) PL

FROM INSIDE

MACHINE

LIFT & REMOVE

TOP PANEL

24

Page 25

Service – Calibration and Troubleshooting

OW

Hot & Cold (Ambient) Water Calibration

H2O Calibration Instructions

H2O Calibration applies to the following :

A. Hot Water flow rate

B. Cold Water (ambient) flo w rate

Calibratio n routine-Note: H2O Calibratio n is a factory

setting & should not need re-calibration unless

A dispensing valve is replaced o r t h e mea sured

dispense volume does not match the displayed set ting

NOTE: MACHINE MUST BE AT OPERATING TEMPERATURE PRIOR

TO CALIBRATING HOT WATER FL

Step 1

Press & hol d Bu t ton 2 “Settings”

After approximately 5 seconds

Display will change to”- - -”

Step 2

Continue holdi ng for approximately

8 more seconds until display

Changes to “con”. Do not release

button, after approx 8 more seconds

Display will ch an g e to “H2 o ”

RATE.

---

H2o

25

Page 26

Service – Calibration and Troubleshooting

Hot & Cold (Ambient) Water Calibration Cont’d

H2O Calibration Instructions-Cont’d

Calibration routine-Hot Water

Step 3

(See hot water calibration

note on previous page)

Depress button 2 (Settings)Display will change to” 0:30”

Place a measuring cup (at least

32 fl oz) under the left dispensing

head (and as shown by indicator

light)

0:30

Step 4

Press button 2 ag ain, mach ine will

Dispense water into measuring cup for

30 seconds-When water stops, read

water volume (in ounces) from cup.

Toggle buttons

Until measured val u e is displ ayed .

1(+) & 3(-)

24.5

26

Page 27

Service – Calibration and Troubleshooting

Hot & Cold (Ambient) Water Calibration Cont’d

H20 Calibration Instructions-Cont’d

Calibration routine-Hot Water

Step 5

Press center button to store settings,

Display will change to 0:30 and indicator

Light will move to Middle button on

display

Move the measuring cup (at least

32 fl oz) under the Middle

Dispensing head, repeat steps 3-5

For Middle and Right Dispense

Heads

0:30

When Right dispense info is

Stored Display changes to “cld”,

see step 6

H2OCalibration routine-Cold (Ambient) Water

Step 6

H2O Calibration is Bypassed

(by toggling “Right” button until

“cld” appears in di sp lay)

cld

Repeat Steps 3-5 for cold (ambient)

values

27

Page 28

Service – Calibration and Troubleshooting

Troubleshooting

PROBLEM PROBABLE CAUSE REMEDY

1. No water a) Water turned off

b) Water line not connected

c) Faulty water inlet valve

2. No water one channel only a) Loose connection @ dispense

valve

b) Loose connector on main board

c) Faulty dispense valve

3. Water not hot a) Temperature setting too low

b) Heater overload tripped

c) Defective heater element

d) Check Triac

4. Water does not shut off a) Liquid level probe malfunction

b) Faulty water inlet valve

5. Drink too strong a) Concentrate calibration settings

incorrect

b) Water to concentrate ratio

incorrect

6. Drink too weak a) Concentrate calibration settings

incorrect

b) Water to concentrate ratio

incorrect

7. Drink not whipped a) No whipper blade

b) Whipper motor connection

c) Whipper motor bad

8. Pump does not turn a) Pump motor connection

b) Pump motor bad

9. Noise coming from whipper a) Whipper chamber not seated

b) Slinger washer pushed on motor

shaft too far.

c) No whipper blade

10. Door light does not light a) No power to machine

b) Faulty lamp bulb

c) Lamp ballast

11. Buttons are flashing a) Machine error

b) Bag empty

12. Buttons do not operate a) Check for Error message

b) Button may be disabled

a) Turn water on –open shutoff

b) Ensure water line is connected

c) Check valve and connections-

a) Check connectors @ dispense

b) Make sure harness is seated

c) Replace dispense valve (PN

a) Adjust temperature setting

b) Reset hi-limit thermostat (see

c) Replace heater element (see

d) Replace Triac (Fig Page

a) Check probe connections (see

b) Check valve and connections-

a) Recalibrate concentrate

b) Adjust ratio (see page

a) Recalibrate concentrate

b) Adjust ratio (see page

a) Install whipper blade

b) Inspect whipper motor

c) Replace whipper motor (Page

a) Inspect pump motor

b) Replace pump motor (Page

a) Reseat whipper chamber-see

b) Check gap at slinger washer

c) Install whipper blade (see

a) Make sure machine is plugged

b) Replace lamp bulb (PN

c) Replace ballast (PN 102064)

a) Check door Display for error

b) Reset bag track(see page

a) Check door Display for error

b) See Button enable section

valve

replace if necessary

valve (see page

29H HH34 )

and locked

102068)

(see operating instructions)

page

30HHH31)

page

page

HH31H31)

33HHH31)

32H HH31 )

replace if necessary

settings (see page

settings (see page

34HHH 8)

HH15)

35H 8 )

HH15 )

connections @ motor and @

board plug-in

HH36H33)

connections @ motor and @

board pug-in

)

whipper cleaning instructions

Page

HH12 )

(see page

page

38H HH12H )

HH39H12 )

in and control board has

power

102062) (page

(page

HH30)

messages- (see page

messages- (see page

page

HH43H17H)

40HHH30 )

41HHH35)

HH21)

HH42H35)

37H HH33H

28

Page 29

Service – Calibration and Troubleshooting

Replacement Parts

Temperature probe 151128

Thermostat-Man reset 111593

Tank Element 705439-10

Triac 111684

Relay-Backup 110908

Cooling Fan 205057

Whipper Motor 102474

Peristaltic Pump Motor 102042

Whipper Blade 102057

Whipper Seal 102049

Slinger Washer 102048

Whipper Base 102047

Whipper Dosing Head 102046

Whipper Chamber 102045

Whipper Restrictor 102044

Pump Housing 102054

Pump Rotor Ass’y 103396

Fill/Ambient Valve 103423

Repair Kit 101527

Dump Valve 102068

Filter Ass’y 103385

Filter Cartridge Replacement 107018

Heating System

Motors / Fan

Plastic Parts

Water System

Drip Tray

Cup Rest 103426

Tubing

Coffee/Espresso Kit 103422

Labels & Lights

Switch Labels 103384

Product Labels 100626

Durotrans Signage 103377

Bulb-Florescent 102062

Electrical Controls

Ballast Board 103378

Display Board 102026

Transformer-Ballast 105115

Transformer-16 Pump 105115-16v

Main board w/whipper 102027

Pump Board 103373

Encoder Board 103374

Switch-Door Safety 103416

Switch-Membrane 102066

29

Page 30

Service – Calibration and Troubleshooting

Replacement Parts Cont’d

Solenoid Manifold

PN 103423

Ballast Board

PN 103378

Bulb-Flourescent, 8W

Dump Valve

PN 102068

(3)

A

Display Board

PN 102026

PN 102062

(2)

Drain Pan w/fitting

PN 103426

Drain Tray Wireform

PN 103426

24 V Transformer

PN 105115

Pump Board

PN 103373

Main Board/Whipper Board

PN 102027

Safety Relay

PN 110908

120/240 Terminal

Block

PN 511053

Line Filter

PN 127178

Drain Tray Housing

PN 103420-BPC

16 V Transformer

PN 105115-16V

DETAIL A

30

Page 31

Service – Calibration and Troubleshooting

Water Tank Heating

Water Tank Ass e mbly

PN 102432- Acccess and Replacement

Parts

Tank Gasket

PN 102221

Cooling Fan

PN 205148

Hi-limit Manual

Reset Thermostat

PN 111593

Heating Element

PN 705439-10

Water Level

Probe

PN 108022

Thermistor

Probe

PN 151128

Remove Brass

Thumbscrews

in Compartment

Upper Rear

Lift and Remove

Back Panel

Remove Nuts

& Bracket to

Remove Tank

Page 88

Welded Tank

with Studs

PN 103322

Triac

PN 111684

31

Page 32

Whipper Ass'y

102063

Service – Calibration and Troubleshooting

Whipper & Pump Ass’y

Rotor Ass'y

3396

PN 10

Whipper Chamber

PN 102045

Whipper Dosing Head

PN 102046

Whipper Restrictor

PN 102044

Pump Housing

PN 102054

Whipper Blade

PN 102051

Whipper Seal

Slinge r Washer

PN 102048

PN 1020 49

Whipper Base

PN 1020 47

32

Page 33

Service – Calibration and Troubleshooting

Whipper & Pump Motors

Pump Motor Spacer

PN 102043

(4)

Pump Motor

PN 102042

Whipper Motor

Whipper Motor

PN 102060

PN 102060

Whipper Motor Spacer

PN 102060

(2)

33

Page 34

Service – Calibration and Troubleshooting

Dump Valves

H2O (Hot) Flow Control Valves

A

Flow Rate Adjustments:

Clockwise-Decreases Flow

Counter Clockwise- Increases Flow

34

Page 35

Service – Calibration and Troubleshooting

Display Board Error Messages

Note: Unplug, re-plug machine, if error does not go away see cause or fix column

Message Meaning

d1.O Dump 1 open circuit Main board / No fix

d2.O Dump 2 open circuit Main board/ No fix

d3.O Dump 3 open circuit Main board/ No fix

b1.O Whipper 1 open circuit Fuse/Whipper board

b2.O Whipper 2 open circuit Fuse/Whipper board

b3.O Whipper 3 open circuit Fuse/Whipper board

P1.O Pump 1 open circuit 16V supply/Pump board/Door

Switch

P2.O Pump 2 open circuit 16V supply/Pump board/Door

Switch

P3.O Pump 3 open circuit 16V supply/Pump board/Door

Switch

F.O Fill Solenoid open circuit Fuse/Pump board

AL.O Ambient Left Solenoid 1 open circuit Pump board/ No fix

AC.O Ambient Ctr Solenoid 2 open circuit Pump board/ No fix

Ar.O Ambient Right Solenoid 3 open circuit Pump board/ No fix

d1.S Dump 1 shorted circuit Main board / No fix

d2.S Dump 2 shorted circuit Main board / No fix

d3.S Dump 3 shorted circuit Main board / No fix

b1.S Whipper 1 shorted circuit Fuse/Whipper board

b2.S Whipper 2 shorted circuit Fuse/Whipper board

b3.S Whipper 3 shorted circuit Fuse/Whipper board

P1.S Pump 1 shorted circuit 16V supply/Pump board

P2.S Pump 2 shorted circuit 16V supply/Pump board

P3.S Pump 3 shorted circuit 16V supply/Pump board

F.S Fill Solenoid shorted circuit Fuse/Pump board

AL.S Ambient Left Solenoid 1 shorted circuit Pump board/ No fix

AC.S Ambient Center Solenoid 2 shorted circuit Pump board/ No fix

Ar.S Ambient Right Solenoid 3 shorted circuit Pump board/ No fix

373 General Error 103373-x pump board Pump Board/Ribbon cable

unplugged

Th.U Thermistor Under value Bad Thermistor/Connection

Th.O Thermistor Over value Bad Thermistor/Tank temp too

high (Boiling)

H.O Heater Open Triac /Relay/Wiring/Main board

H.S Heater Short Triac /Relay/Wiring/Main board

Heater Error Temp. Not rising /Thermistor

/Heater element/Wiring

Fil Fill Solenoid Safety Timeout Fill Valve/Water not turned on

Err General feedback error main board Power-up error/ Wiring/Main

board

bAC Backup driver failure main board Main board/no fix

but Input failure Bad membrane switch/Switch

cable

195 General feedback error main board Main board / No fix

Cause or Fix

35

Page 36

LEFT

+

New

Bag

RATIO

THERMISTER 1

OUT

CN7

MAIN BOARD E2-2521 6

(NEWCO 102027)

WH

BK

1

FUSE

BL

BL

MIDDLE

Setti ngs

RATIO

RD

RD

21

43

GY

OR

BK

OUT

RIGHT

-

Rinse

AUTO

RINSE

OUT

BN

5

109483726

WH

CN1

CN3

DISPLAY BOARD

E2- 25218

NEWCO 102026

CN8

CN4

1 2

WIPPER BOARD

E2- 25201

NEWCO 102028

BK

BK

BK

654

CN1

DUMP VALVE

RIGHT 3

321

SELECTION MEMBRANE SWITCH

WH

GR

BK

CN2

PUMP

MOTOR

RIGHT

654

321

CN1

COLD WATER

SOLENOID

RIGHT

COLD WATER

SOLENOID

CENTER

COLD WATER

SOLENOID

LEFT

SOLENOID

3

CN3

FILL

VAL VE

RED

DOT

BK

WH

OUT

PUMP MOTORS

0-13VDC

PUMP MOTOR BOARD

103374-1

3 PL

YL

WATER

LEVEL

PROBE

TANK

GROUND

CN7

654

CN6

654

CN5

654

PUMP

MOTOR

LEFT

1

654

321

CN3

CN2

CN1

RED

DOT

16VAC XFMR

RIGHT

321

CENTER

321

LEFT

321

PUMP BOARD

103373-2

CN4

21

CN2

PUMP

MOTOR

MIDDLE

654

321

CN1

2

CN3

RED

DOT

CN4

OR

BR

RD

654

SOLENOIDS

321

CN1

GN

THERMISOR

PROBE

TANK

ELEMENT

HI

LIMIT

DUMP VALVE

MIDDLE 2

DUMP VALVE

LEFT 1

WH

BKBKWHBKWH

WHIPPER WHIPPER WHIPPER

GN

MOTOR

MOTOR

1

LEFT MIDDLE RIGHT

N(WH)

N(WH)

MOTOR

2

OR/WH

DOOR

PUMP

CUT/OFF

3

MAIN TERMI NAL BLOCK

SWITCH

BK

L1(BK)

N(WH)

WH

BK

BK

BK

BK

16VAC

TRANSFORMER

PRIMARY

WH

120VAC

BK

LINE

LOAD

BK

SWITCH

WH

FILTER

WH

24VAC

BALLAST

T5 LAMPS

BK

WH

24 VAC

TRANSFORMER

PRIMARY

WH

BK

120VAC

FAN

120VAC

COM

BL

COIL

NO

HEATER BACKUP

RELAY 120VAC

BK/

OR

WH

36

RED

BL

RELAY DRIVER 120 VAC

HOT

SOLIDSTATE

CHASSIS GND

POWER

Loading...

Loading...