Page 1

Model LCD-2 (Hot Only)

PN: 120309

Model LCD-2 (Hot Only)

Stainless Front Door

3 Dispensing Handles

PN: 120496

Model LCD-2 Dual (Hot/Cold)

PN: 120441

Installation

And

Programming Guide

LCD-2 By NEWCO Enterprises

Page 2

Section 1 – Installation Instructions and Warranty Policy

Section 2 – Set-Up Programming Instructions

Section 3 – Service Level Programming Instructions

Section 1

Installation Instructions:

Place Machine on a Level Countertop Surface

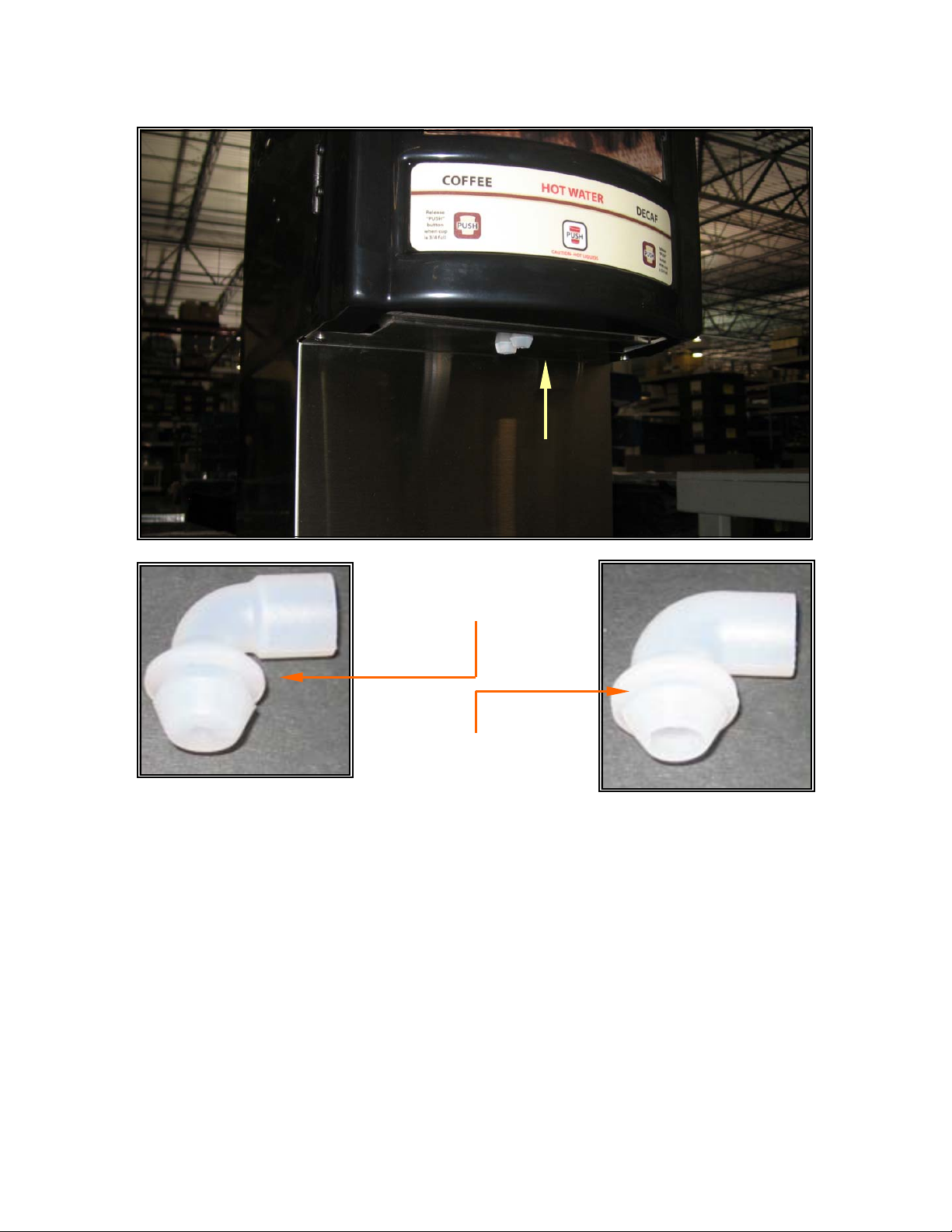

Connect ¼ Inch Flare water Supply to the Water Inlet located on lower Left Rear of the Machine.

(NEWCO recommends copper tubing for use as water supply to all of our brewing equipment)

Turn water Supply On

Plug or wire brewer to the appropriate voltage circuit as indicated on the serial tag.

Locate power switch on the upper right rear of the machine and turn machine power on.

Machine will begin to fill.

If machine has not filled to probe level within 6 minutes it will enter an error mode. Error code

E-4 will appear on the display screen. To reset the error and resume filling turn power switch

off and then on.

When water in tank reaches probe level, heating cycle will begin.

You are now ready to proceed to Set-Up Programming.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

2

Page 3

Section 1

NEWCO PRODUCT WARRANTY

NEWCO warrants equipment manufactured by it for 1-year parts and labor.

These warranty periods run from the date of purchase. NEWCO warrants that the equipment

manufactured by it will be commercially free of defects in material and workmanship existing at the

time of manufacture and appearing within the applicable warranty period. This warranty does not

apply to any equipment, component, or part that was not manufactured by NEWCO or that, in

NEWCO’S judgment, has been affected by misuse, neglect, alteration, improper installation or

operation, improper maintenance or repair, damage or casualty. This warranty is conditioned on the

Buyer: 1) Giving NEWCO prompt notice of any claim to be made under this warranty by telephone at

(800) 556-3926 or by writing to PO Box 852, Saint Charles, MO 63302 2) If requested by NEWCO,

shipping the defective equipment prepaid to an authorized NEWCO service location 3) Receiving

prior authorization, from NEWCO, that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY,

WRITTEN OR ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED

WARRANTY OF EITHER MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

The agents, dealers, or employees of NEWCO are not authorized to make modifications to this

warranty or to make additional warranties that are binding on NEWCO. Accordingly, statements by

such individuals, whether oral or written, do not constitute warranties and should not be relied upon.

If NEWCO determines in its sole discretion that the equipment does not conform to the warranty,

NEWCO, at its exclusive option while the equipment is under warranty, shall either: 1) Provide at no

charge replacement parts and/or labor (during the applicable parts and labor warranty periods

specified above) to repair the defective components, provided that this repair is done by a NEWCO

Authorized Service Representative or 2) Shall replace the equipment or refund the purchase price for

the equipment.

THE BUYER’S REMEDY AGAINST NEWCO FOR BREACH OF ANY OBLIGATION ARISING OUT

OF THE SALE OF THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR

OTHERWISE, SHALL BE LIMITED, AT NEWCO’S SOLE OPTION AS SPECIFIED HEREIN, TO

REPAIR, REPLACEMENT OR REFUND.

In no event shall NEWCO be liable for any other damage or loss, including, but not limited to, lost profits, lost

sales, loss of use of equipment, claim’s of BUYER’S customers, cost of capital, cost of downtime, cost of

substitute equipment, facilities or services, or any other special, incidental, or consequential damage.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

3

Page 4

Section 2

Set-Up Programming Instructions:

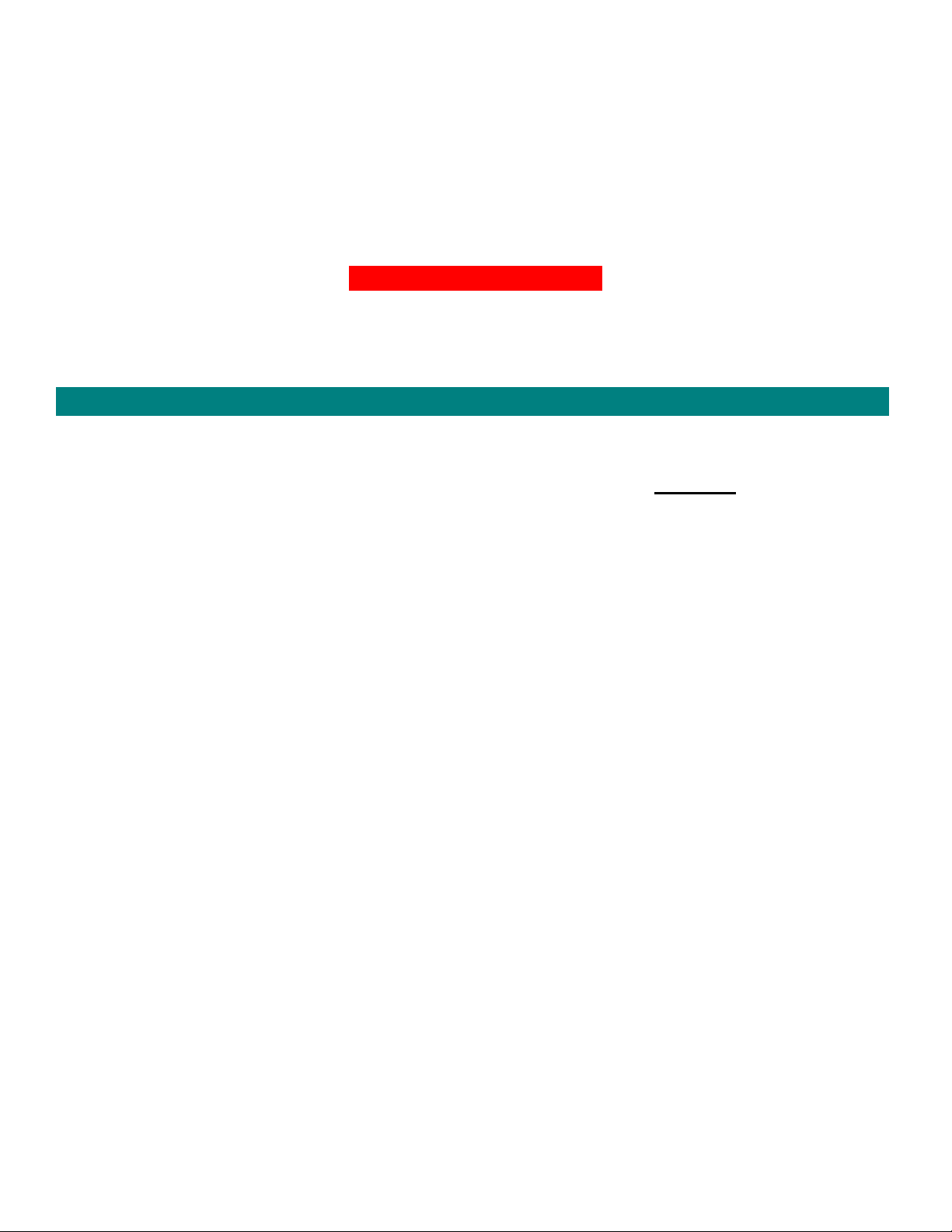

Open machine cabinet door and locate the 3-switch

control panel w/lighted display screen. The temperature

will show on the display screen. As shown in figure 1.

Fig. 1

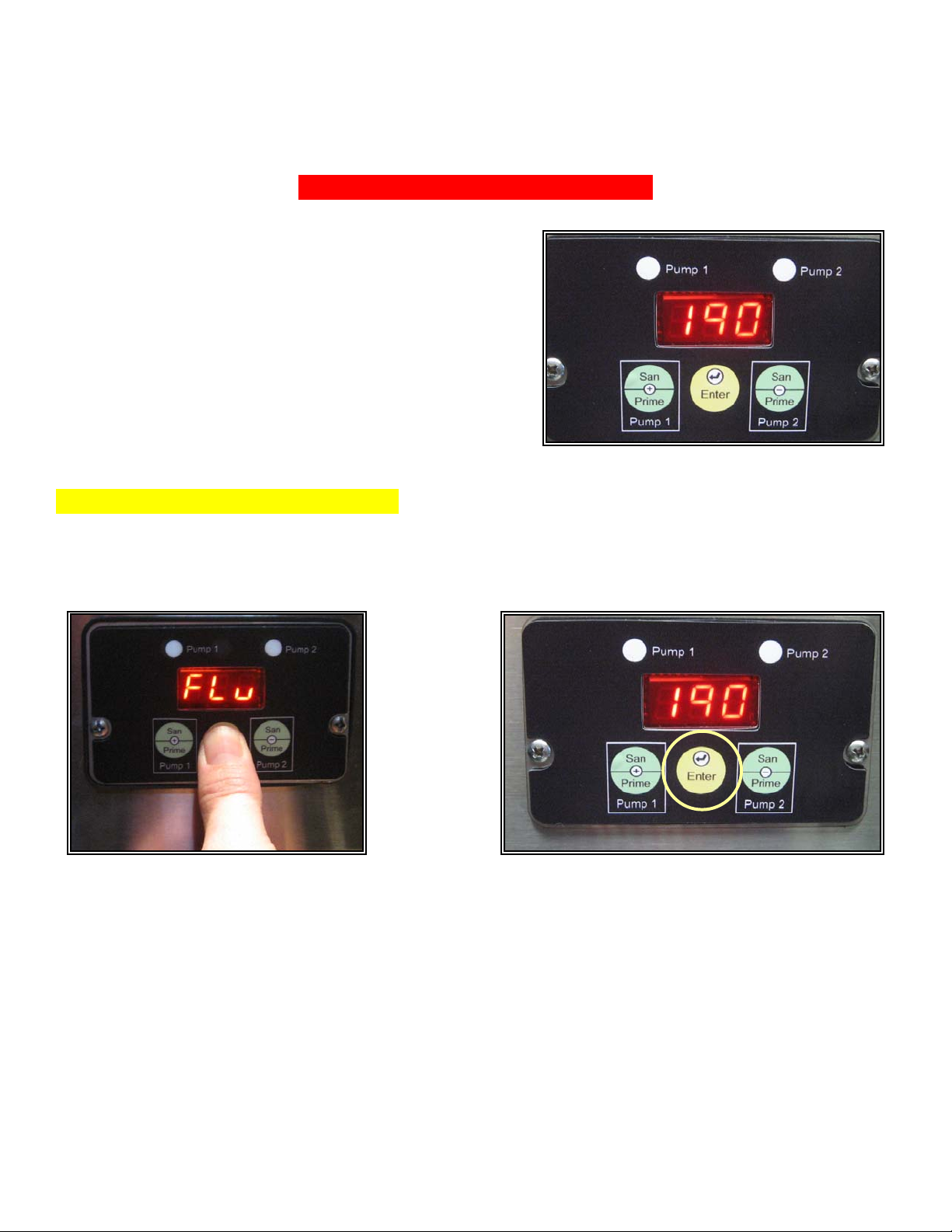

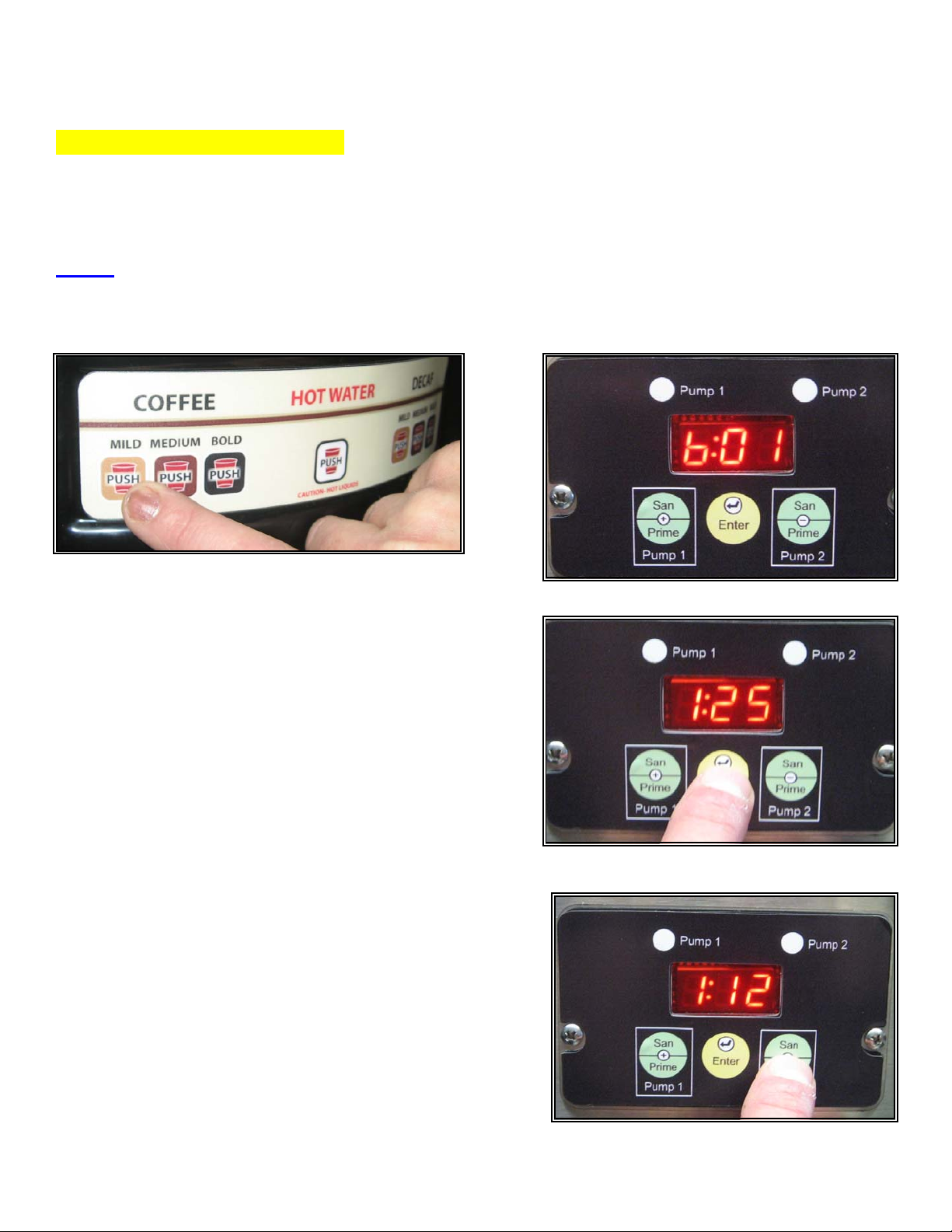

Step 1. Enter a Programming Mode

Press and hold the center switch labeled “Enter”. After five seconds, the display will flash “Flu”

approximately 13 times. Continue to hold in the switch and the temperature will appear. (Release the

switch when temp. appears on the display.) As shown in figures 2 & 2A.

Fig. 2A Fig. 2

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

4

Page 5

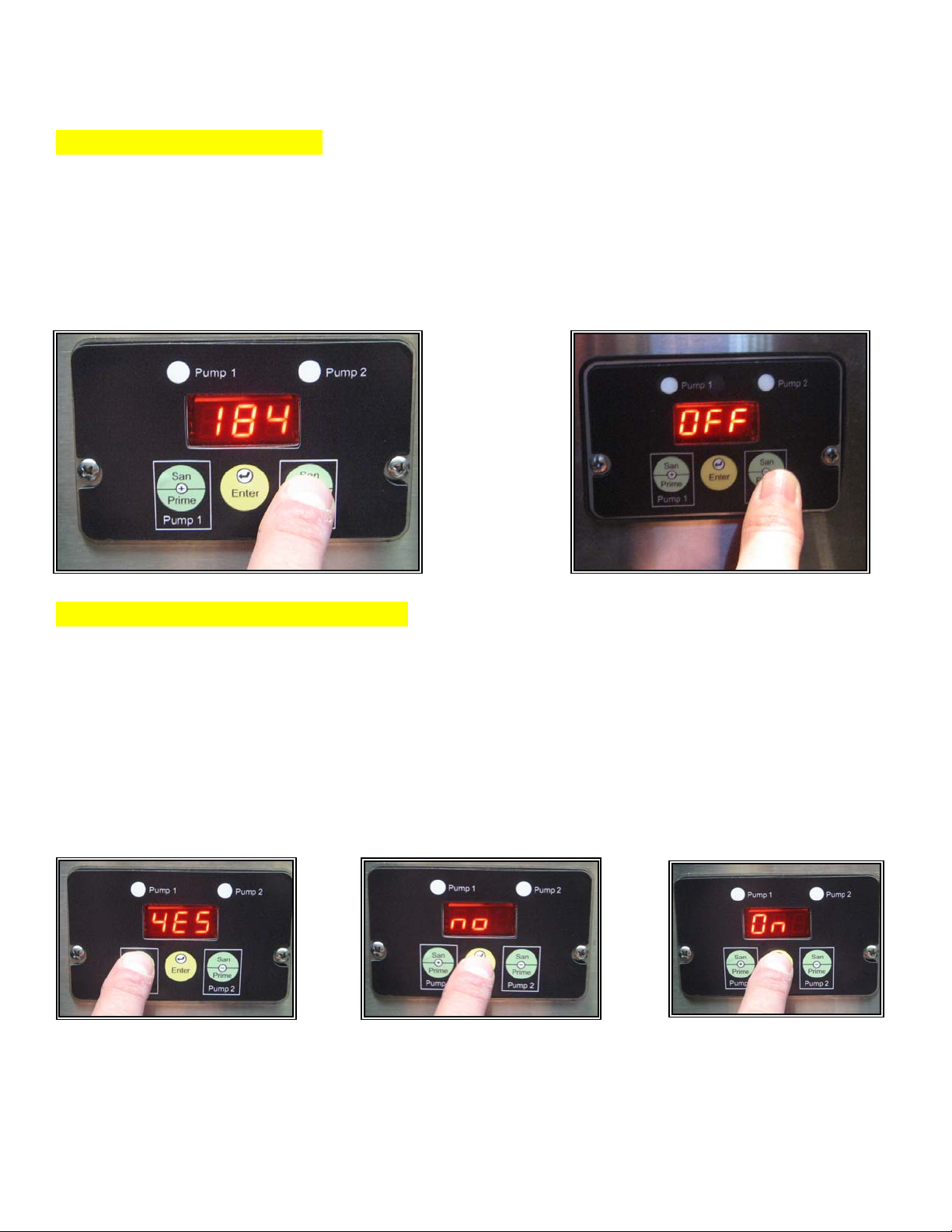

Step 2. Adjust Temperature

The machine features an adjustable temperature range of 100-200F. Use the + or – switch to scroll to

the desired temperature setting. (To turn off the heater press the + or - switch until “OFF” is

displayed.) As shown in figures 3 & 3A.

Press the “Enter” switch to save and proceed to the next programming option. Either the word “YES”

or the word “NO” will appear on the display screen.

Fig. 3

Fig. 3A

Step 3. Enable/Disable BIB Tracking

This machine features the option to track the liquid output of a BIB and then alert the operator when

the BIB is empty. (Display will flash the pump number affected and buzzer will beep if enabled.)

To Enable BIB Tracking, use the + or – switch to scroll until the display reads YES. To disable BIB

Tracking, use the + or – switch to scroll until the display reads NO. As shown in figures 4 & 5. When

you have made your selection, press

“ Enter” to save and proceed to the next programming option. On or Off will appear on the display

screen. As shown in figure 6.

Fig 4 Fig 5

Fig 6

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

5

Page 6

Step 4. Enable/Disable Alarm

This machine features a buzzer alarm that will sound to notify the operator when one of the following

three things has occurred:

• BIB Tracking has detected an empty BIB (See step 4)

• A machine malfunction has been detected

• The machine has completed a sanitization cycle

This feature offers the option to disable the buzzer alarm.

To enable the alarm, use the + or – switch to scroll until the display reads ON.

To disable the alarm use the + or – switch to scroll until the display reads OFF. See figure 7. When

you have made your selection, press “Enter” to save and proceed to the next programming option.

SEL will appear on the display screen. See figure 8.

Fig. 7 Fig. 8

Step 5. Program Selector Switches

This machine features a 7-selector switch control panel. The center switch on the control panel is

reserved for Hot Water Dispense. The remaining 6 switches can be programmed to deliver a drink

from either of the product BIBs or can be programmed to create a drink by blending product from both

BIBs.

In order to proceed with switch programming, it is first necessary to familiarize you with pump

orientation.

Pump 1 is mounted on the left side of the mixing chamber. (When facing the machine from the front.)

Pump 1 supports the product BIB that is installed directly above it.

Pump 2 is mounted on the right side of the mixing chamber. Pump 2 supports the product BIB that is

installed directly above it.

To program a selector switch to create a drink using the product on the left, enter the pump speed

from Chart A below in to Pump 1 and set the speed of Pump 2 to :00

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

6

Page 7

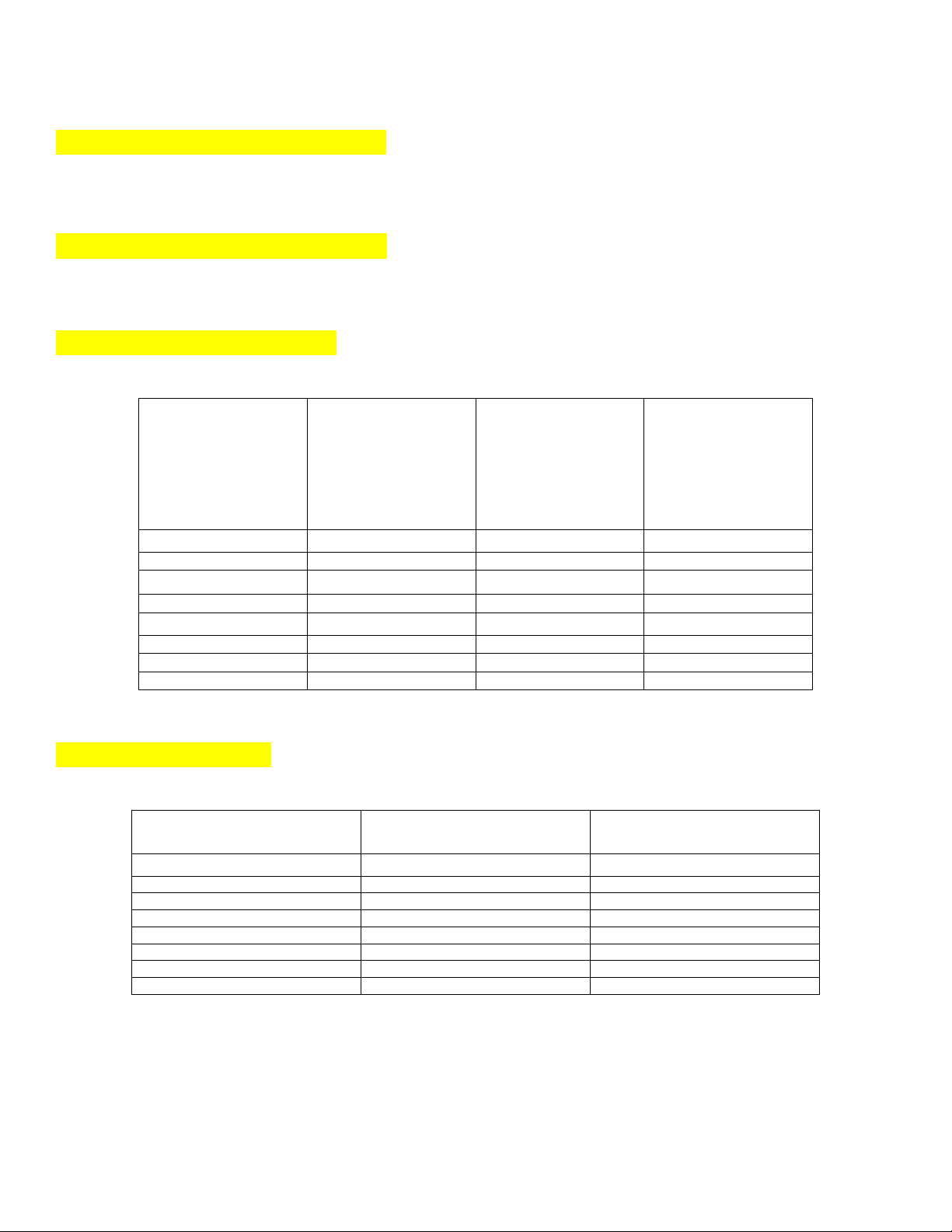

Program selection single product:

To program a selector switch to create a drink using the product on the right, enter the pump speed

from Chart A in to Pump 2 and set the speed of Pump 1 to 0:00.

Program selection blend products:

To program a selector switch to create a blend using both products, set the speeds of Pump 1 and Pump 2 using Chart B

as a guideline.

High Flow Rate Ratio Chart (Use this chart if the unit is a high flow unit.) See

page 8 for visual of the nozzle.

Chart A

Chart B

Chart C

Ratio

Pump Speed

Setting

Single

45:1 9 4/4 1/6

40:1 11 5/5 1/8

35:1 13 6/6 1/10

30:1 15 7/7 2/11

25:1 19 8/8 3/13

20:1 - 11/11 -

15:1 - 17/17 14:1 - 18/18 -

Pump Speed

Settings

(Blend 50/50)

Pump Speed

Settings

(Blend 25/75)

Low Flow Rate Chart (Use this chart if the unit is a low flow unit.) See page 8 for

visual of the nozzle.

Ratios

45:1 5 1/1

40:1 6 2/2

35:1 7 2/2

30:1 9 3/3

25:1 11 4/4

20:1 15 6/6

15:1 24 9/9

Chart A Pump Speed

Setting

(Single) (Blend)

Chart B Pump Speed

Settings

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

7

Page 8

The front nozzle determines the flow rate.

The back nozzle is for hot water use only.

800203, Low Flow Nozzle

(Small Diameter Opening)

800204, High Flow Nozzle

(Large Diameter Opening)

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

8

Page 9

To Program a selector switch:

• On the 7-selector switch control panel, press the switch that you want to program. The display

will change to identify the switch that you have chosen. (b01 thru b06 are the switch

identifiers.) See figures 9 & 10.

NOTE: The optional liquid coffee dispensing unit with a stainless front door uses handles. These act

as buttons for programming. Pulling and holding down the handle acts in the same way as pressing a

button. The center handle is for hot water only and cannot be used for programming.

Fig 10Fig 9

• Press Enter. The number “1” and the current

speed for pump 1 will appear in the display. As

shown in figure 11.

• Using the + or – button to scroll, set Pump 1 speed

for the desired ratio using chart A above as a

guide. (If blending two products, use chart B as a

guide.) As shown in figure 12.

Fig 11

Fig 12

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

9

Page 10

• Press, “Enter” to save and proceed

to set Pump 2. The number “2” and

current pump speed setting for

Pump 2 will appear on the display.

Fig 13

As shown in figure 13.

• Using the + or – button to scroll, set Pump 2 speed for the desired ratio using chart A above as

a guide. (If blending two products, use chart B as a guide.) Refer to figure 12.

• NOTE: (FOR LCD-2 Dual Only) Press “Enter” to save. “HOt” or “CLd” will appear on the

display. This entry chooses whether the selected button will use ambient temperature water

(“CLd”) from the water supply line or hot water (“HOt”) from the tank for dispensing. Use the +

or – button toggle between “HOt” or “CLd.”

• Press “Enter” to save and proceed with the set-up

program. A time value (min: sec) will appear in the

display. If the switch that you are programming has

been set in a portion control mode, the value will

represent the current dispense time for the switch.

If the switch is in a continuous flow (push and hold)

Fig 14

mode, the time value will be 0:00 Shown in figure

14. To set portion control, in this mode, use the +

and – keys to enter the time of dispensing.

• Press “Enter” to save and proceed to the next setup programming option. SEL will appear on the

display.

• Continue with switch programming by repeating steps 1 thru 7.

• When switch programming is completed, continue to press and release the “Enter” button until

the display returns to 3 dashed lines. The machine will be in a normal operating mode.

Fig 14

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

10

Page 11

Procedure: Setting Portion Control In Normal Run Mode

To program a switch for portioned controls, while in run mode, dispense time must start at “0:00" (See

figure 14) to do this:

1.

Place the desired cup (or carafe) under the dispense head.

2.

Press and hold the “Enter” switch.

Press and hold the selector switch that you want to program.

3.

4.

After two seconds release the “Enter” switch.

5.

When the cup (or carafe) is filled to the desired level, release the selector switch.

6.

The switch is now programmed to automatically fill to that level.

Procedure: Return Switch to Continuous Flow Mode

1. Enter program mode by pressing and holding the “Enter” switch for five seconds.

2. Press and release the “Enter” switch until SEL appears on the display.

3. Press the selector switch that you want to return to continuous flow mode. (The switch

identifier will appear on the display.)

4. Press and release the settings button 3 times. (The selector switch timer will appear on the

display.)

5.

Using the + and – switches, scroll until the selector switch timer reads 0:00

6.

Press and release the “Enter” switch until 3 dashed lines appears on the display.

The switch is now in a continuous flow (push and hold) mode.

Procedure: Disable a Selector Switch

1.

Push and hold the “Enter” switch for 8 seconds to enter a programming mode. The current

temperature setting will appear on the display. (Refer to: Page 3 Programming Mode.)

2.

Press and release the “Enter” switch repeatedly until SEL appears in the display.

3.

Press the selector switch that you have chosen to disable.

4.

Press and release the “Enter” switch. Pump 1 speed will appear in the display.

5. Using the + or – button to scroll, set Pump 1 speed to 0.00

6. Press and release the “Enter” switch. Pump 2 speed will appear in the display.

7. Using the + or – button to scroll, set Pump 2 speed to 0.00

8.

Press and release the “Enter” switch until thee dashed lines appear in the display. The switch

is disabled.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

11

Page 12

Section 3

Service Level Programming Functions:

Sanitizing Instructions

Press the + switch to enter sanitize mode. SAN will

appear in the display. (As shown in figure 15)

Remove the product BIBs from the machine and

connect a BIB of sanitizing solution to the PUMP 1 BIB

connector. (The one on the left (as you face the

machine from the front.)

Place an empty decanter or other vessel under the dispense area of the machine.

Press the “Pump 1” (+) switch on the display panel to begin sanitizing.

When sanitizing cycle ends (2.5 minutes total: pump 45 sec., dwell 90 sec., & water 15 sec.), the

buzzer alarm will sound 3 times if enabled during the “Set-Up Programming”. The machine will

automatically advance to “Pump 2”. (Pump 2 will duplicate Pump 1’s process.)

Disconnect the BIB of sanitizing solution from the Pump 1 BIB connector and connect it to the Pump

2 connector.

Press the “Pump 2 (–) switch on the display panel to begin sanitizing.

When sanitizing cycle ends, remove the sanitizing solution and replace the products. The machine

will automatically advance to the Prime Pumps mode.

To Prime: Press and hold the “Pump 1” (+) switch until a steady stream of product flows from the

dispense area into the vessel.

Press the “Enter” switch to advance to Pump 2.

Press and hold the Pump 2 (-) switch until a steady stream of product flows into the vessel.

Press and release the “Enter Switch until 3 dashed lines appear in the display.

Discard the contents of the decanter or vessel.

Fig. 15

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

12

Page 13

Prime Pump Feature:

This feature allows you to enter directly into a Prime Pump mode without sanitizing.

Press the - switch to enter the Prime Pump mode.

Follow the same Prime Pump procedures from Sanitizing Instructions.

BIB Counter Auto-Reset Feature:

If enabled during the “Set-Up Programming” of the machine a buzzer alarm will sound once per

second to indicate that a product BIB is empty.

Entering into a Prime Pump mode turns off the alarm.

Only reset the pump shown on the display.

BIB tracking is automatically reset when the pump is primed.

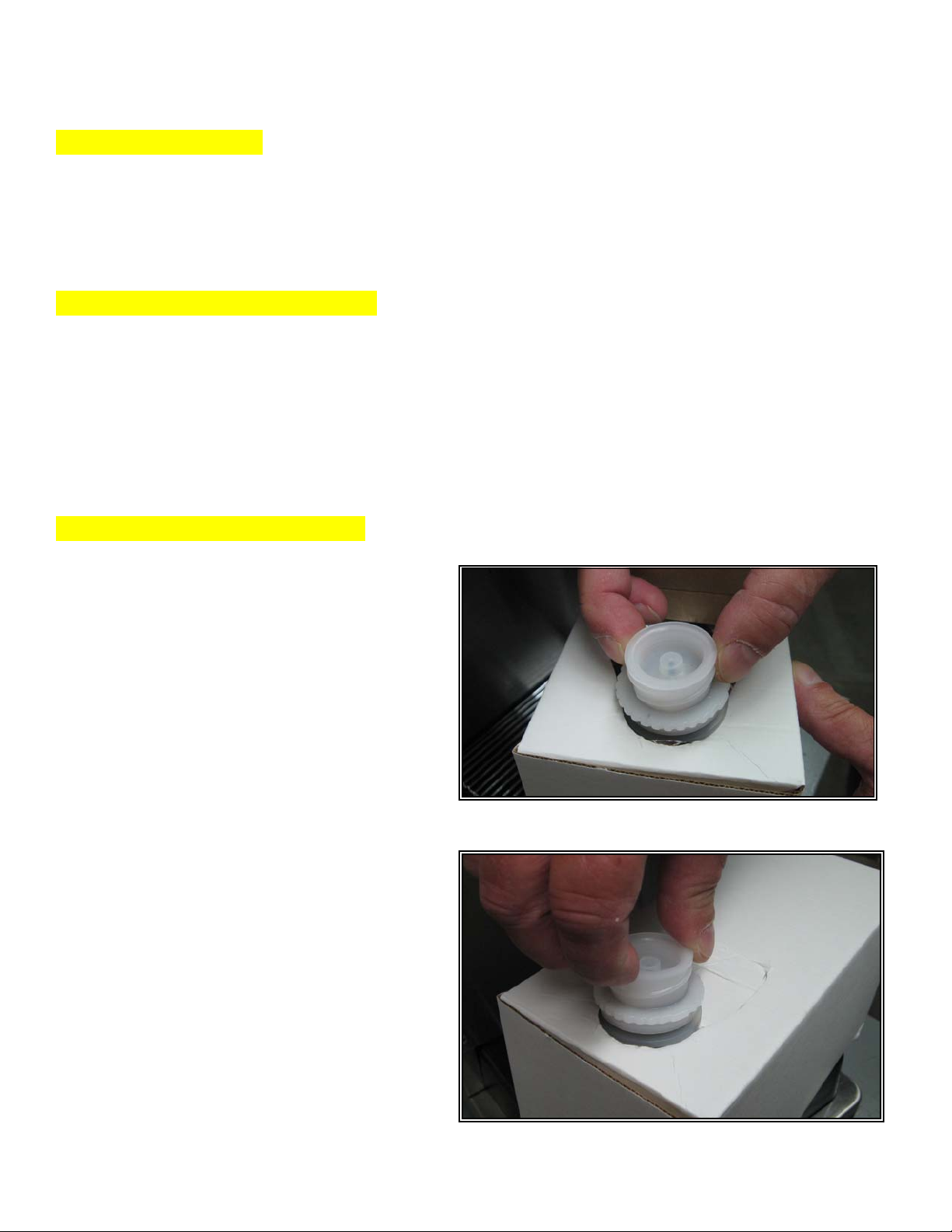

Product Installation Procedures:

• Open the cutout on the product box

and position the BIB fitment into the

slotted area as shown in figure 1.

Remove the plastic insert from the BIB fitment

as shown in figure 2.

Fig. 1

Fig. 2

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

13

Page 14

Using finger and thumb only to prevent over-tightening,

thread the BIB connector on to the BIB fitment until

Fig. 3

seated as shown in figure 3.

Place the product in the storage compartment as shown in figure

4.

Position the tubing as shown in figure 5

Fig. 4

Fig. 5

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

14

Page 15

Cleaning & Sanitizing Instructions:

Remove product from storage area and disconnect BIB connectors as shown in figures 1 & 2.

Fig. 1

Place an empty container in the dispense area of the machine as shown

in figure 3.

Connect the sanitizing solution to the BIB connector for Pump 1 (the

connector on the left as you face the machine from the front) and place

sanitizing BIB on the product shelf as shown in figures 4 & 5

Fig. 4 Fig. 5

Fig. 2

Fig. 3

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

15

Page 16

Press the Pump 1 button to enter sanitizing mode as

Fig. 6

shown in figure 6.

Press the Pump 1 button again to begin sanitizing. Sanitization cycle will run for

2-1/2 minutes. Buzzer alarm will sound 3 beeps when cycle is complete.

Fig. 7 Fig. 8

Disconnect sanitizing solution from Pump 1 and connect to the BIB connector for PUMP 2 as shown

figures 7 & 8.

Press Pump 2 button to begin sanitizing Pump as shown

in figure 9.

Fig. 9

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

16

Page 17

When cycle is finished remove sanitizing solution and reinstall

products as shown in figure 10.

Press and hold Pump 1 button until product flows from dispense head

to prime pump 1 as shown in figure 11.

Press enter to proceed to Pump 2 as shown in figure 12.

Press and hold Pump 2 button until product flows from dispense head

to prime Pump 2 as shown in figure 13.

Fig. 10

Fig. 11

Fig. 12

Fig. 13

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

17

Page 18

Press enter to return to the normal operating mode as

shown in figure 14.

Fig. 14

Flushing Instructions:

Flush the mixing chamber by pressing and holding the “Enter” button for 5 seconds until “FLU”

appears on the display. Release the “Enter” button. Press and hold either the + or – button to flush

the mixing chamber with water. (Refer to: Page 3 Figure No. 2.)

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

18

Page 19

Error Messages:

Error

Number

tHU/ tHL Thermistor warning –

Er3 Heater Run Error Water did not heat within timeout

Er4 Tank Fill Error Water did not reach probe in

Er5 Comm Error Serial communication error

Er7 Open Motor Circuit - The motor

Description Cause What to Check

Resistance extremely high from

immediately upon detection the

machine will beep twice and

show the warning message for

a minute as well as turn on the

right most upper dot on the

display. This dot will stay on to

signify there is a thermistor out.

Also upon power up the

machine will beep twice and

show the warning message for

a short period of time and turn

on the high dot if the warning

conditions are present

errors (Er7 and Er8) do not

cause a system error and will

not shut down the machine.

Immediately upon detection the

machine will beep twice and

show the error message. Every

time the key is pressed to

activate a dispense motor it

clears the error and allow

another attempt to be made. If

this error occurs the dump

valve still will release water.

upper or lower thermistor will

cause or the resistance extremely

low from upper or lower

thermistor will cause a tHU or tHL

warning for the thermistor that

sees the condition and causes

the control board to switch from

watching the lower to the upper

thermistor. If both the upper and

lower resisters fail then we flag a

thermistor ErC error

period. Timeout period is 240

seconds which is reloaded

whenever the heater is off or the

fill valve is on

timeout period of 6 minutes for

initial fill and 1 minute during

normal operation. The 6 minute fill

time is reloaded if no key is

pressed within 24 hours

to/from non-volatile memory

(EEPROM).

Open motor circuit. Pump 0 or

pump 1.

This warns you that 1

thermistor has failed. Nothing

is required at this time as the

upper thermistor has taken

over but ordering a

replacement thermistor is

advisable

Check element for short and

proper resistance. Replace if

bad.

Check valve function and flow

rate. Replace valve or

increase flow rate. Check

probes for excess scale.

Hold down the enter key to

enter Machine Set up mode

pressing the enter key to

cycle through all options then

exit mode. This resets all the

defaults. If the error still

occurs then replace main

board.

Retry pump if the error still

occurs then check

harness/motor continuity.

Replace if defective.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

19

Page 20

Error Messages Cont’d:

Er8 Bad (Open) Motor Driver - The

motor errors (Er7 and Er8) do

not cause a system error and

will not shut down the machine.

Immediately upon detection the

machine will beep twice and

show the error message. Every

time the key is pressed to

activate a dispense motor it

clears the error and allow

another attempt to be made. If

this error occurs the dump

valve still will release water.

Erb Dry Firing Tank – the tank is

empty but the heater is on.

ErC Thermistor Error Resistance extremely high from

Bad/open motor driver. Pump 0 or

pump 1.

The control board has either seen

a rise in temperature of 1 degree

a second, for 5 seconds or has

seen the temperature rise to

215°F or above

upper or lower thermistor will

cause or the resistance extremely

low from upper or lower

thermistor will cause a tHU or tHL

warning for the thermistor that

sees the condition and causes

the control board to switch from

watching the lower to the upper

thermistor. If both the upper and

lower resisters fail then we flag a

thermistor error

Retry pump if the error still

occurs then replace main

board.

The unit has been in the

intent to brew timeout for an

extended period of time,

allowing the tank to evaporate

to the point where there is

little water in the tank

Check/replace thermistor.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

20

Page 21

Dimensions & Electrical Specifications:

LCD-2 LIQUID COFFEE DISPENSER

**Electrical Specs**

PN: 120309, LCD-2

120V 1750W

15 Amps

PN: 120354, LCD-2

120V/240V 3500W

15 Amps

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

21

Page 22

Electrical Schematics:

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

22

Page 23

Electrical Schematics:

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

23

Page 24

Electrical Schematics:

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

24

Page 25

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Base Assembly & Door Assembly

120313

100054

100061

100104

105048

Base Assembly, LCD-2

Washer, #8 External Lock SS 1 EA.

1 EA.

Nut, 8-32 Hex SS 1 EA.

Washer, 3/8” External Lock Zinc 1 EA.

Screw, 8-32 x 3/8” With Washer PPHMS SS 1 EA.

111322

Trim, GX Radius Base 3/4" 1 EA.

111377

Foot, Appliance 3/8-16 x 1” 1 EA.

111667

Nut, 3/8-16 Jam ZPS 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

25

Page 26

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Base Assembly & Door Assembly - Continued

120334

100055

100191

100212

100243

Door Assembly, LCD-2 Hot

1 EA.

Screw, 4-40 x 3/8” PPHMS SS 1 EA.

Nut, 6-32 Hex SS 1 EA.

Washer, #6 External Lock SS 1 EA.

Nut, 4-40 Hex SS 1 EA.

102065

Magnet, Door 1 EA.

102333

Screw, 6-32 x 3/8” Combo Head Self Tapping 1 EA.

105043

Screw, 6-32 x 3/8” With Washer PPHMS SS 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

26

Page 27

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Base Assembly & Door Assembly - Continued

110766

120335

120336

120350

120351

Washer, #4 Internal Lock 1 EA.

Door, Vacuformed Plastic LCD-2 1 EA.

Panel, Inner Door LCD-2 1 EA.

Membrane Switch, 7 Button LCD 1 EA.

Label, Switch: Coffee – Hot Water – Decaf LCD 1 EA.

120352

Label, Hot Coffee Backlit LCD 1 EA.

120353

Clear Panel, Label LCD 1 EA.

120501

Label, Cleaning Instructions 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

27

Page 28

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Base Assembly & Door Assembly - Continued

121403

120421

781259

511050

Display Board Assembly, LCD-2 1 EA.

Light Assembly, LED Strip 1 EA.

Female, Hinge 1 EA.

Bushing, Snap Split 3/4" 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

28

Page 29

Spare Parts:

ITEM # IMAGE

DESCRIPTION

UM

Tube Assemblies, BIB & Others

120422

120383

107117

120683

120864

Tube Assembly, BIB 12.00”

Silicone Tubing, Grey 1/4 x 1/2 x 12.00” [111240] 1 EA.

Connector, Scholle 1910L 1 EA.

Clamp, SNP6-10C2 Black [Small] 1 EA.

1 EA.

Clamp, SNP8-10C2 Black [Large] 1 EA.

205189

Elbow, 1/4 x 1/4 Trimmed 1 EA.

120387

Silicone Tubing, 1/8” x 1/4" x 16.00” [773186] 1 EA.

120680

Silicone Tubing, 1/4” x 1/2" x 13.00” [781871] 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

29

Page 30

Spare Parts:

ITEM # IMAGE

Tube Assemblies, BIB & Others - Continued

DESCRIPTION

UM

120681

121315

701038

701702

767345

Silicone Tubing, 1/8” x 1/4" x 12.00” [773186] 1 EA.

Tubing, SS .312 x .020 x 1.00” [100966] 1 EA.

Silicone Tubing, 3/8” x 5/8" x 4 3/4” [152213] 1 EA.

Silicone Tubing, 3/8” x 5/8" x 32.00” [152213] 1 EA.

Teflon Tubing, 3/16” x 1/4" x 12.00” [100445] 1 EA.

781496

Silicone Tubing, 3/8” x 5/8" x 3.00” [152213] 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

30

Page 31

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Tank Assembly

120553

100030

100149

100166

100170

Tank Assembly, 1750W LCD-2

Gasket, Brass .566 ID 1 EA.

Elbow, Male 1/4C x 1/8NPT 1 EA.

Sleeve, 3/8” Compression Brass 1 EA.

Nut, 3/8” Compression Brass 1 EA.

1 EA.

100431

Nut, 9/16-24 x 11/16H Brass 1 EA.

101720

Connector, Female 3/8C x 1/8NPT Brass 1 EA.

102333

Screw, 6-32 x 3/8” Combo Head Self Tapping 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

31

Page 32

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Tank Assembly - Continued

102835

110944

110946

119879

119882

Bulkhead, Faucet Outlet 1 EA.

Sleeve, 1/4" Self Aligning Compression Brass 1 EA.

Nut, 1/4" Self Aligning Compression Brass 1 EA.

Nut, Faucet 3/8-18 Chrome Plated 1 EA.

Gasket, Tank 1 EA.

120332

Lid Assembly, 1750W LCD-2

1 EA.

100190

Nut, Jam 1/2-20 Jam Brass 1 EA.

100269

Bracket, Hi Limit Thermostat 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

32

Page 33

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Tank Assembly - Continued

100409

500396

111593

120333

151677

Gasket, .520 ID Brass 1 EA.

Probe Assembly, 1.537” With Bushing 1 EA.

Hi Limit Thermostat, Vertical Tabs 221F 25A 1 EA.

Lid Only, LCD-2 Tank 1 EA.

Temperature Probe, Dual 7.312” 1 EA.

152207

Plug, Tank Cover Silicone Natural 1 EA.

202025-10

Element Tank, 1750W 120V 1 EA.

500038

Silicone Grommet, No Slit .060 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

33

Page 34

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Tank Assembly - Continued

800297

120388

120549

202044

781468

Tube, Vent 6.5” 1 EA.

Fill Tube, LCD-2 1 EA.

Tank Only, LCD-2 1 EA.

Insert, Tubing 3/16” 1 EA.

Fitting, Tea Modified [800236] 1 EA.

800244

121446

Nylon Gasket, .671 x .937 x .062 1 EA.

Solenoid Valve, Dump 12V INVNSYS GS56

[Hot Water Faucet]

1 EA.

120386

Valve, Dump With Vent 120V LCD 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

34

Page 35

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Panel Assembly

120658

120545-BPC

100191

100212

100409

103277

Front Panel Assembly, LCD-2 [SS Model]

Front Panel Assembly, LCD-2 [BPC Model]

1 EA.

Nut, 6-32 Hex SS 1 EA.

Washer, #6 External Lock SS 1 EA.

Gasket, .520 ID Brass 1 EA.

Retainer, Tubing 1 EA.

104155

104204

Pump Head Assembly, LCD-2 1 EA.

Tubing, Neoprene .117 x .197 x 12.25” 1 EA.

107151

Tube/Hose, Barb 1/4 x 3/16 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

35

Page 36

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Panel Assembly - Continued

120391

120428

500024

104161

105043

Tube/Hose, 1/4 x 3/16 Modified 1 EA.

Mounting Bracket, Pump LCD-2 1 EA.

Screw, 2.6 mm x 5.0 mm FHMS SS 1 EA.

Chamber, Mix Double Stem

1 EA.

Screw With Washer, 6-32 x 3/8” PPHMS SS 1 EA.

111634

111635

Hose Clamp, .459ID 1 EA.

Hose Clamp, .574ID 1 EA.

120487

Bracket, Mix Chamber Retainer Elbow 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

36

Page 37

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Panel Assembly – Continued

205083

411039

700021

800203

800204

Bulkhead Union, 1/4 Tube 1 EA.

Hose Clamp, .510ID 1 EA.

Knurled Nut, 8-32 Brass 1 EA.

Elbow, Spray BF [Small Diameter Opening] 1 EA.

Elbow, Outlet BF [Large Diameter Opening] 1 EA.

120493 NA Kit, Pump Head Assembly LCD-2 1 EA.

120509

120513

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

Connector – Tubing Cleaning Kit [BevClean] 1 EA.

BevClean, 1 Gallon 1 EA.

37

Page 38

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Valve Assembly

781782

100161

100177

101377

102383

Valve Assembly, Mini Capp

Tube Assembly, Copper 1/4" x .030 x .88 1 EA.

Elbow, Male 1/4F x 1/8P 1 EA.

Fitting, Solenoid 1/8P 1 EA.

Valve, Solenoid TP 3/4 x 1/4 1 EA.

1 EA.

202105

100291

110114

Flow Assembly, Flare To Flare .50 GPM

Flow Washer, .50 GPM Light Blue 1 EA.

Flow Control Screen, PDS 1 EA.

1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

38

Page 39

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Valve Assembly – Continued

202103

790019

121431

121436

Strainer/Flow Control Body With Caps, Only

Nylon Gasket, Flow Control 1 EA.

1 EA.

Drip Tray Assembly

Molded Cup Guide, LCD-2 1 EA.

Label Set, “Place Cup Here”

“Caution Hot Liquids”

1 EA.

773214

773213

Drip Tray Grid, Only 1 EA.

Drip Tray Only, With Indicator 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

39

Page 40

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Miscellaneous Components

100054

100061

100408

101035

104015

Lock Washer, #8 SS

1 EA.

Nut, 8-32 Hex SS 1 EA.

Plug, Barbed Tubing PP 1 EA.

Grommet, Strain Relief 14/3 1 EA.

Bezel, Adaptor Black Plastic 1 EA.

104137

104151

105048

Washer, Star Lock .690 ID 1 EA.

Check Valve, Duck .301 x 0.656 1 EA.

Screw, 8-32 x 3/8” Washer PPHMS SS 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

40

Page 41

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Miscellaneous Components - Continued

105115

110626

110958

111634

111635

Transformer, 120VP 24VCT 40VA 2 EA.

On – Off Switch, Power 1 EA.

Relay, 12V DC 1 EA.

Hose Clamp, .459ID 1 EA.

Hose Clamp, .574ID 1 EA.

111668

120436

781843

Acorn Nut Locking 6-32, SS 1 EA.

Spring Retainer Clip, Mix Chamber 1 EA.

Power Cord, 14/3 With Shrink 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

41

Page 42

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Miscellaneous Components - Continued

120567

201222

511027

700021

701646

Control Board Assembly, LCD-2 1 EA.

Frame, Switch 1 EA.

Screw, 8-32 x 3/8” SPHMS SS 1 EA.

Nut, Knurled 8-32 Brass 1 EA.

Hose Clamp, Plastic 1 EA.

781258

781697

Hinge, Male Cappuccino 1 EA.

Clamp, Adhesive 1 EA.

500354

Probe, 1.537” Passivated

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

42

Page 43

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Miscellaneous Components - Continued

500350

500351

500382

781539

103600

NA

Grommet, Probe Bushing 5/16” 1 EA.

Bushing, Probe Insulator 1 EA.

Probe Assembly Kit, 1.537”

[Consists of: 1 ea. 500350, Probe Assy., & Instruction]

Screw, 8-32 X 1 3/8” PPHMS SS

[Used on Fan Assembly]

Fan Assembly 1 EA.

1 EA.

1 EA.

123092

100669

131133

Fan Harness, With Rectifier & Capacitor 1 EA.

Bridge Rectifier 1 EA.

Grommet, Solenoid Valve [Dump] 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

43

Page 44

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Door Assembly: Metal Door Model

120546-BPC

100055

100191

100212

100243

Door Assembly, LCD-2 Hot Metal Door

1 EA.

Screw, 4-40 x 3/8” PPHMS SS 1 EA.

Nut, 6-32 Hex SS 1 EA.

Washer, #6 External Lock SS 1 EA.

Nut, 4-40 Hex SS 1 EA.

102065

Magnet, Door 1 EA.

102333

Screw, 6-32 x 3/8” Combo Head Self Tapping 1 EA.

105043

Screw, 6-32 x 3/8” With Washer PPHMS SS 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

44

Page 45

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Door Assembly: Metal Door Model - Continued

110766

121403

120448

120452

120453

Washer, #4 Internal Lock 1 EA.

Display Board Assembly, LCD-2 1 EA.

Spring, Nudger Faucet 1 EA.

Cam Lock 50 Series 1 EA.

Striker Plate, Lock 50 series 1 EA.

120480

Label, LCD-2 Metal Door R/HW/D 3 Faucet 1 EA.

120481

Bracket Assembly, Micro Switch [Metal Door] 1 EA.

120558

Lock, Cam Sealed Black 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

45

Page 46

Spare Parts:

ITEM # IMAGE DESCRIPTION UM

Door Assembly: Metal Door Model - Continued

120568

120569

120570

120571

120573

Handle, Decaf LCD [Metal Door] 1 EA.

Handle, Hot Water LCD [Metal Door] 1 EA.

Handle, Coffee LCD [Metal Door] 1 EA.

Pin, Handle Faucet LCD 1 EA.

Stem, Faucet LCD 1 EA.

120594

Bonnet With Holes 1 EA.

511050

Bushing, Snap Split 3/4" 1 EA.

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

46

Page 47

Additional LCD-2 Models PN

LCD-2, 240V, Hot 120354

LCD-2, 120V, Hot With Fan 120532

LCD-2, 240V, Hot, Metal Door 120502

LCD-2, 240V, Hot, Metal Door With Fan 120559

LCD-2, 240V, Hot/Ambient (Dual Temp.) 120449

LCD-2, 120V, Hot/Ambient With Fan (Dual Temp.) 120520

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

47

Page 48

13-May-13 Phone: 1.800.325.7867 Fax: 1.636.925.0029 www.newcocoffee.com

48

Loading...

Loading...