Page 1

INSTALLATION AND OPERATION INSTRUCTIONS

LC-D SERIES COFFEE CONCENTRATE BREWER

WITH DIGITAL ELECTRONIC CONTROL CENTER

PLUMBER'S INSTALLATION INSTRUCTIONS

107353 1-00

CAUTION:

Water pipe connections and fixtures directly connected to a potable water supply shall be sized, installed and maintained

in accordance with Federal, State and Local codes.

1) Flush water line before installing brewer.

2) Water pressure should be at least 20 psi. For less than a 25 ft run, use 1/4" copper tubing and connect to 1/2" or

larger water line. For longer runs, use 3/8" copper tubing & connect to 1/2" or larger water line and provide an adapter

fitting for connection to the brewer.

3) If installed with saddle valve, the valve should have a minimum of 1/8" port hole for up to 25 ft run, and 5/16" port

hole for over 25 ft runs.

4) For applications without a filter. Connect the incoming water line to the fitting on back of brewer.

5) For applications with a filter. Flush the filter cartridge per the manufacturer recommendations. Attach the cartridge

replacement instructions to this manual for future reference. Attach the filter assembly to the rear of brewer using 8-32

screws and mounting holes provided. Use the copper tube provided to connect the filter to the solenoid inlet fitting which

protrudes from the rear of the unit. The fittings on the filter feature a simple push in connection.

6) For applications with a filter. Shutoff valve on filter should be in the off position. Connect the incoming water line to

the fitting extending from the shutoff valve. With power to brewer shutoff and water supply turned on slowly open shutoff

valve to allow system to fill with water. Depress the pressure relief button on the filter to release trapped air. Check for

leaks. Turn shutoff valve on filter to the off position for initial setup outlined below.

Power to brewer must be OFF before proceeding with plumbing installation.

INITIAL SETUP INSTRUCTIONS

WARNING:

void if machine is connected to any voltage other than that specified on the name plate. Initial setup should be done by

qualified personnel only.

SETUP SUMMARY

1) Plumb unit in (previous section). Water should be turned off.

2) Turn unit power switch off. Connect to electrical supply.

3) Load beverage concentrate.

4) Prime pumps. Set ratio and temperature.

5) Turn on water. Let tank fill.

6) Allow to heat. Ready!

OVERVIEW

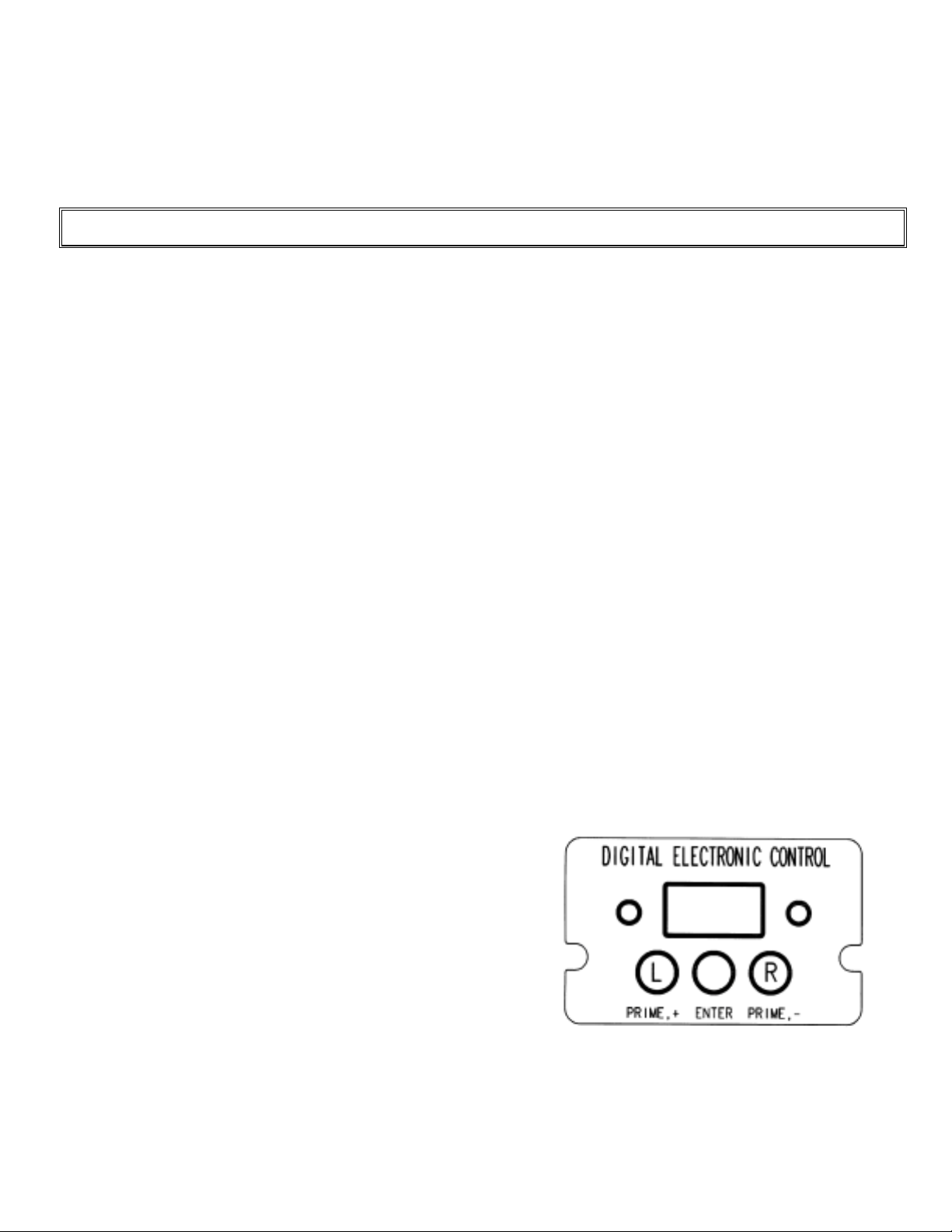

Located behind the front access door is a digital electronic control panel that controls all dispensing unit functions.

This includes tank water level and fill valve operation, regulation of water tank temperature, pump operation, and

monitoring of pressure switches during normal operation.

- Read and follow instructions before plugging or wiring in machine to electrical circuit. Warranty will be

1

Page 2

The control panel will allow the user to set the appropriate product ratio by simply entering in the number which represents the

water portion of the water to product ratio. The user will also be able to digitally set the desired tank temperature. A factory

calibration will be performed on the dispensing unit prior to shipment to ensure that the ratio entered coincides with the ratio

delivered. Feedback from the pump motors will allow the control to compensate for variations in operating conditions to maintain

the proper ratio.

INITIAL SETUP

1) Brewer should be connected to water supply as outlined in PLUMBERS INSTALLATION INSTRUCTIONS above.

Water should be turned off. Turn the on/off switch on back of unit to the off position. Plug or wire unit to the appropriate

voltage circuit as indicated on the serial tag. Remove the front access door from the unit by lifting up, tilting bottom

forward, and then lowering the door to clear drip angle. Place the concentrated product in place in the appropriate

compartment. The lower product compartment and pump supply the right side faucet. The upper product compartment

and pump supply the left side faucet. Remove the protective cap from the product spout. Attach the connector from the

lower pump to the lower product, and the connector from the upper pump to the upper product. The pumps must now be

primed. Skip ahead to the section titled SETUP MODE for instructions on how to prime pumps.

2) If you would like to check the “calibration ratio” do so before proceeding to the next step. The calibration ratio is set

at the factory but should you wish to check or change the setting, skip ahead to the CALIBRATION MODE section.

3) Turn on water supply. Make sure that the on/off switch on back of unit is in the on position. The hot water tank will

begin to fill. The tank system incorporates a multipurpose water level probe. The probe signals the control board when

the water in the tank has reached the appropriate level. This probe also acts as a heater safety probe telling the control

board when the tank has filled so the board will supply power to the tank element. The probe also signals the control

board to cut power to the element should the water fall below it for more than one minute. Power is restored when the

water level again reaches the probe. Actuate all the faucets on the machine to remove air from the lines and to ensure

that the pumps actuate when the water and concentrate make contact internally in the faucet. Allow approximately 10

minutes for the water in the tank to heat to preset temperature. This will be evident by the cessation of the heating noise

from the tank. You may then check the temperature of the water by drawing water from the hot water faucet. The tank

incorporates an electronic temperature control system which may be adjusted to the desired temperature. Skip ahead to

the section titled SETUP MODE on page 4 for instructions on how to adjust tank temperature and the product ratio.

4) Replace all covers previously removed. Brewer is now ready to operate.

CALIBRATION MODE

During the calibration process the control dispenses concentrate from the faucet for a set amount of time. The

amount of concentrate delivered is then compared to the volume of water normally dispensed within the same time

period and the resulting "calibration ratio" is entered in. This provides the control the information it needs to ensure that

the "product ratios" entered in during subsequent programming will be accurate. This process will be performed at the

factory and will generally not be necessary for the customer.

During the calibration process the fill solenoid and the heater relay will be inactive. If the dispensing unit has been

run previously this will allow you to drain the tank below the faucet lines which is necessary for the calibration process.

The following procedure will outline the calibration procedure. The steps are first given in an abbreviated "quick start"

format and are followed by detailed steps and ratio calculation procedure.

!

Quick Start Directions:

1. Turn on/off switch on back of dispenser unit off. Hold the control board enter button in while turning power switch

back on. Control enters calibration mode.

2. Drain tank below faucet lines. Drain faucet lines by opening faucet.

3. Select side to calibrate by pressing L or R button. Press Enter. Indicator light flashes.

4. Lock product faucets open. Hold a small graduated container below appropriate faucet and push enter.

5. Calculate ratio (See "Calculate Calibration Ratio" on next page) and enter using L and R buttons. Display "End" and

press enter to exit.

6. If calibration ratio was changed the product ratio must be set as described in SETUP MODE.

2

Page 3

!

Detailed Directions:

To enter the calibration mode turn on/off switch on the back of the unit off (On units rated other than 120V this

switch powers control board only). While pressing the enter button on the control board return the switch to the on

position. Continue to hold the enter button and after approximately three seconds the unit will enter the calibrate mode.

In the calibration mode the fill solenoid and the tank heater relay will be inactive. This will allow you to drain the tank

below the faucet lines which is necessary for the calibration process. After draining leave the coffee faucets for the

side(s) to be calibrated in the locked open position.

This is the main screen and is displayed upon entering the calibrate mode. Both the left and right side

L - r

indicator lights will also be lit when at this screen as a prompt to select a side for calibration. You may exit

calibration mode by pressing the enter button again.

L

r

been chosen for calibration and the chosen sides indicator light will be lit. You may toggle between the left and

right sides if the wrong side is inadvertently chosen. At left are the two possible displays

When the desired side has been chosen press enter again to confirm the selection. The digital display

Select the side to be calibrated by depressing the L or R button. The digital display will indicate which side has

L

r

remains unchanged but the indicator light for the chosen side begins to flash. Hold a small graduated

container below the faucet to catch the concentrate which will be dispensed in the next step. A container

graduated in milliliters is preferable for accurate measurement of the small volume which will be dispensed.

Note: The faucet should be in the locked open position and the tank drained.

Press enter and the machine will dispense concentrate for 5 seconds 6 times in a row. During the

0 5 4

dispensing process the indicator light for the chosen side will flash. After the process is complete the current

calibration value ratio will be displayed. Calculate the new ratio as described in the "Calculate Calibration ratio"

section below and use the L and R buttons to change the display to the desired value. Press enter to set value

and return to the main screen.

L - r

You are now back at the main screen. The process may be repeated for the other side if desired. When

calibration is complete close the faucets and press enter to exit calibration mode. After a 5 second delay the

fill valve and the tank heater relay will be active again.

!

Calculate Calibration Ratio:

The calibration ratio is determined by dividing the amount of water normally dispensed in 30 seconds by the amount

of concentrate dispensed during the calibration procedure outlined in the preceding section. Note that you must use the

same units of measurement for both the water volume and the concentrate volume to obtain the correct ratio. In other

words ounces or milliliters must be used for both numbers. The information in the table below and the provided

conversion factors will assist you in determining the ratio.

Example:

Assume that the volume of concentrate delivered was 19 milliliters and the faucet flow rate is approximately 45

ounces in 30 seconds. First convert the water volume from ounces to milliliters. 45 x 29.57 = 1331ml. Next divide water

volume by concentrate volume to get ratio. 1331 / 19 = 70. This indicates that 70 parts of water would be delivered for

each part of concentrate. The calibration ratio is 70:1 and 70 would be the value entered into the control.

Conversion Formulas and Table:

Multiply ounces by 29.57 to obtain milliliters.

Divide milliliters by 29.57 to obtain ounces.

Typical Values And Ratios For Calibration Procedure

Normal Water Flow Rate In 30

Seconds From Coffee Faucet

Concentrate Volume Delivered

During the 6-5 Second Intervals

Calibration Ratio =

Water/Concentrate

45 ounces .643 ounces 70

1331 milliliters 19 milliliters 70

3

Page 4

SETUP MODE

To enter setup mode, ensure that dispensing unit is connected to power supply and that on/off switch is turned on.

Press and hold the enter button for 3 seconds. The board will respond by displaying the first choice from the main menu.

When the board is in setup mode the L and R buttons are used to scroll through menu choices and to increment and

decrement the displayed value respectively. Pressing the L button will step through the menu choices in the order shown

below. The menu choices are as follows:

!

Menu Choices:

P r

Prime - Used to remove air from the concentrate lines and bag in box and to prime faucets with concentrate at

appropriate times such as when replacing or changing product. Faucets must be opened during the priming

process. Pressure switches are not active during priming and will not shut down pumps if line pressure builds

up.

1 : - -

- - °F

E n d

!

P r

1 : - -

L - r

1: 54

- - °F

Product Ratio - Used to set the ratio of water to product concentrate, such as 54:1.

Tank Temperature - Used to set the tank temperature of water in the dispensing units hot water holding tank.

This is the water which will be mixed with the concentrate to "brew" coffee.

Exit - This option is used for exiting the setup mode.

Setup Mode Procedure:

When entering the setup mode the first menu item is displayed. Note that when in the main menu screen

neither left nor right indicator light is lit. The first menu choice is the prime mode. To select the prime mode

press enter. The left and right side indicator lights will blink prompting you to select a side to prime. Faucet(s)

should be open for priming. Press and hold either L or R to prime the left or right faucets respectively. Press

enter to exit the prime mode and return to the main menu.

Press the L button to access the next menu choice, product ratio. Press enter to select this option.

The display will show L - r and both the left and right side indicator lights will be lit as a prompt to select a side

to set the ratio for. Use the L or R button to select a side.

The current ratio for the selected side is displayed and the indicator light for the selected side is also lit. Use

the L and R button to increment or decrement the displayed value to the appropriate ratio for the product being

dispensed. When the desired value is displayed press enter. This returns you to the previous screen and the

other side may be selected and the ratio set. Press enter at this screen to return to the main menu.

Press the L button to access the next menu choice, tank temperature. Press enter to select this option.

185°F

L - r

The current temperature setting is displayed. Use the L and R button to increment or decrement the displayed

value to the desired tank temperature setting. When the desired value is displayed press enter. This returns

you to the main menu.

Press the L button to access the next menu choice, exit. Close the faucets if open and press enter to exit

setup mode. After a 5 second delay the fill valve and the tank heater relay will be active again.

ERROR MESSAGES

The digital control monitors key elements of operation and shuts unit down if an error condition occurs. The table below

list the different error codes produced, the possible cause and what to check. Error code may be cleared by shutting

power switch off then on or by holding enter on the control board for approximately 3 seconds.

Error Code: Problem Area: Cause: Check:

Er1 Temperature Probe Thermistor is open. Replace Thermistor.

Er2 Temperature Probe Thermistor shorted. Replace Thermistor.

Er3 Water Fill System detects that fill valve has run for 5 min.

without making contact with probe.

Er4 Tank Heater Tank heating system has run for 2 minutes

without increase in tank temperature.

4

Water supply to brewer, water filters &

water probe to see if limed up.

Tank heater relay, tank heater,

limit thermostat.

Page 5

CLEANING OF EXTERIOR PARTS

Using a daily routine of cleaning all external surfaces and product compartments should maintain the brewer’s new

appearance.

IMPORTANT – Do not use cleansers, bleach liquids, powders or other substances that contain chlorine. These products

promote corrosion and will pit the stainless steel.

1. Use a soft cloth to wipe off any spills, dust or debris from exterior surfaces including upper and lower product

compartments.

2. Clean the outside of brewer with stainless steel polish where stainless steel shows. Use mild soap and water on

plastic parts. Coarser agents, scratch pads, steel wool etc. may scratch the brewer.

CLEANING PRODUCT FAUCETS

Using a daily routine of cleaning the plastic product faucets is recommended.

CAUTION:

1.

proceeding with next step.

2. Place a suitable container below coffee faucets and open faucets to drain water below inlet fittings.

3. Remove the entire upper bonnet assembly of faucet by unscrewing the plastic bonnet cap. At this point, the bonnet

assembly may be submerged in hot soapy water and then rinsed with clean hot water. Inspect the silicone seat cup for

wear or abrasions and replace if necessary. The bonnet assembly may then be submerged in a sanitizing solution of one

tablespoon of household bleach in a gallon of water for one minute, rinse with clean water.

Turn off electrical power (switch is located on back of brewer) and shut-off water supply before

4.

Reassemble the upper bonnet assembly to faucet body by

electricity and water on and restart system. After cleaning, priming the pumps may be necessary to get the concentrate

flowing.

Hand tightening only

until all play is out. Turn

IN PLACE CLEANING AND SANITIZING OF INTERNAL CONCENTRATE LINE SURFACES

Using a weekly routine of cleaning and sanitizing all internal surfaces in contact with the concentrate is recommended in

order to keep the system bacteria free. This brewer is designed so that cleaning and sanitizing solutions can be

circulated throughout the concentrate system without having to remove or disassemble those parts.

Recommended Sequence of Events:

1. Clean with hot soapy water made from Ivory Liquid.

2. Rinse with clean hot water.

3. Sanitize with a solution made from one tablespoon of household bleach in a gallon of water.

4. Rinse with clean water.

Procedure: (

1. Make sure electrical power is on and water in brew tank is at normal operating temperature.

CAUTION:

2.

USE CAUTION WHEN WORKING WITH VERY HOT WATER)

Shut off the water supply before proceeding with next step.

3. Remove any existing concentrate containers from the upper and lower product compartments by disconnecting at

the product line connector. Reconnect this connector to a mating connector, which will insure that the check valve in the

product line connector will be held open.

5

Page 6

4. Submerge connector in a container of cleaning solution. Each concentrate system must be cleaned and sanitized

separately. Position a container under the appropriate product faucet to catch the cleaning solution that will be pumped

through the concentrate system.

5. Place the appropriate product faucet in the locked open position. The concentrate pump may begin running until

sufficient water is drained from the line at which time the pump will stop running. At this point, go to SETUP MODE and

depress the appropriate prime button. Continue depressing the prime button while allowing the cleaning solution to be

circulated through the product lines and out through the faucet and into the receiving container.

6. Remove the entire upper bonnet assembly of faucet by unscrewing the plastic bonnet cap. At this point, the bonnet

assembly may be submerged and scrubbed in hot soapy water and then rinsed with clean hot water. Inspect the silicone

seat cup for wear or abrasions and replace if necessary. The bonnet assembly should then be submerged in a sanitizing

solution for five minutes and then rinsed with clean water. Scrub the upper inside cavity and thread area of the faucet

body with hot soapy water and then rinse with clean hot water. This area should then be scrubbed thoroughly with

sanitizing solution, left stand for five minutes and then rinsed with clean water.

7. Reassemble the upper bonnet assembly to faucet body by

8. Repeat step 5 continuing to circulate the hot soapy water for another 30 seconds.

9. Repeat steps 4 and 5 with clean hot water to rinse.

10. Repeat steps 4 and 5 with sanitizing solution. Allow the solution to be in contact with surfaces for at least five

minutes by running pump for one minute, letting stand for three minutes and running pump again for one minute.

IMPORTANT - Do not allow sanitizing solution to come in contact with stainless steel surfaces. Wipe up spills

immediately.

11. Repeat step 9 for at least one minute. Remove connector from rinse water and continue to run pump until water

from faucet has stopped.

12. Repeat above procedure for other coffee faucet.

13. This step is to flush any remaining cleaning solution from faucet and lines prior to filling tank. Place available empty

container below each coffee faucet. Lock both faucets open. Turn water supply back on. As water tank begins to fill,

water will run from faucets. Allow flow to continue for 1 minute.

CAUTION: WATER IN TANK MAY STILL BE VERY HOT.

14. Close all faucets and allow tank to finish filling and be brought up to normal operating temperature. Operate each

faucet to ensure normal water flow by drawing off approximately one cup of water. After installing fresh concentrate you

may have to prime the pumps to get the concentrate flowing.

Hand tightening only

until all play is out.

WARRANTY

Newco coffee brewers are warranted against defects in workmanship or materials, under normal use, for 90 days from

the date of purchase. Brewer parts are warranted against defect for 12 months from date of purchase.

Liability in all events is limited to the purchase price paid and liability under the aforesaid warranty is limited to replacing

or repairing any part or parts which are defective in material or workmanship, and returned to our factory, shipping cost

prepaid. No warranty expressed or implied, other than the aforesaid is made or authorized by Newco Enterprises, Inc.

Prompt disposition will be made if item proves to be defective, within warranty. Before returning any item, write or call

Newco, or the dealer, from whom the product was purchased, giving model number, serial number, and date of

purchase, and describe the nature of the defect. If damage was incurred during transit to you, file claim with the carrier

6

Page 7

REPLACEMENT PARTS LIST

Part No Description Part No Description

107365 Tank Assy, 120V/1750W 790019 Gasket, Flow Control, Nylon

107375 Tank Assy, 240V/3500W 107063 Barb/Tube Fitting, 1/2 TU – 1/4 NPT

100660-1 Tank Cover 107151 Tube/Hose Barb, 1/4 X 3/16

100071-10 Tank Element, 120V/1750W 107355 Tube/Hose Barb, Trimmed

102850-10 Tank Element, 240V/3500W 702087 Tube/Hose Barb, 1/4 X 1/4

100633 Thermostat, Hi-Limit, 120V 205080 Union Elbow, 1/4 Tube

110578 Thermostat, Hi-Limit, 240V 205086 Male Connector, 1/4 NPT X 1/4 Tube

107073 Tubing, Silicone, 3/8 ID X 8.75 L 205104 Union Tee, 1/4 Tube

107074 Tubing, Silicone, 3/8 ID X 6.875 L 107123 Union Connector, 1/4 Tube

107075 Tubing, Silicone, 3/8 ID X 7.875 L 107076 Tubing, Superthane, 1/4 ID X 12.0 L

107299 Tube Assy, Teflon, 3/16 ID X 3.5 L 107182 Tubing, Teflon, 3/16 ID X 9.0 L

110029 Grommet, Tank, S ilic one 107183 Tubing, Teflon, 3/16 ID X 2.5 L

152184 Thermister Assy 107184 Tubing, Teflon, 3/16 ID X 6.625 L

152397 Washer, Therm i ster 107244 Tubing, Teflon, 3/16 ID X 5.5 L

102770 Faucet W/Red Handle 107246 Tubing, Teflon, 3/16 ID X 6.5 L

107061 Faucet Assy, Product Li ne 100500 Switch, On/Off Black Rocker

107062 Faucet Nut 107385 Switch, Pressure

107117 Product Valve, Schollee 107255 Switch Kit, Pressure

107118 Pump Assy, Peristaltic SR10/30 102841 Microswitch

107165 Filter Assy, Cold Water 152290 Pilot Light, Green

107038 Filter Housing, Cold Water 105057 Relay

107285 Drip Tray Assy 107357 Control Board Assy, Digital Electroni c

100250 Valve, Solenoid 110387 Control Board, Digital Electronic

705570 Flow Control Assembly 105115 Transformer

800001 Washer, Flow Control

WIRING DIAGRAM

Newco Enterprises, Inc. * 1735 South River Rd. * P.O. Box 852 * St. Charles, MO 63303

7

Loading...

Loading...