Page 1

INSTALLATION

INSTALLATION

PROCEDURE

PROCEDURE

September 2006

Page 2

Translucent

Door Graphic

Cabinet

Door

Programmable

Dispense Buttons

Unit Overview

Unit Overview

Door

Latch

Dispensing

Nozzles

Drip Tray and

Drain Assembly

Legs

(4)

Page 3

BIB

Installation

Instructions

Programming

Instructions

Unit Overview

Unit Overview

BIB

Cabinet

Pump

Display

Board

Assemblies

Whipper

Assemblies

Page 4

Unit Overview

Unit Overview

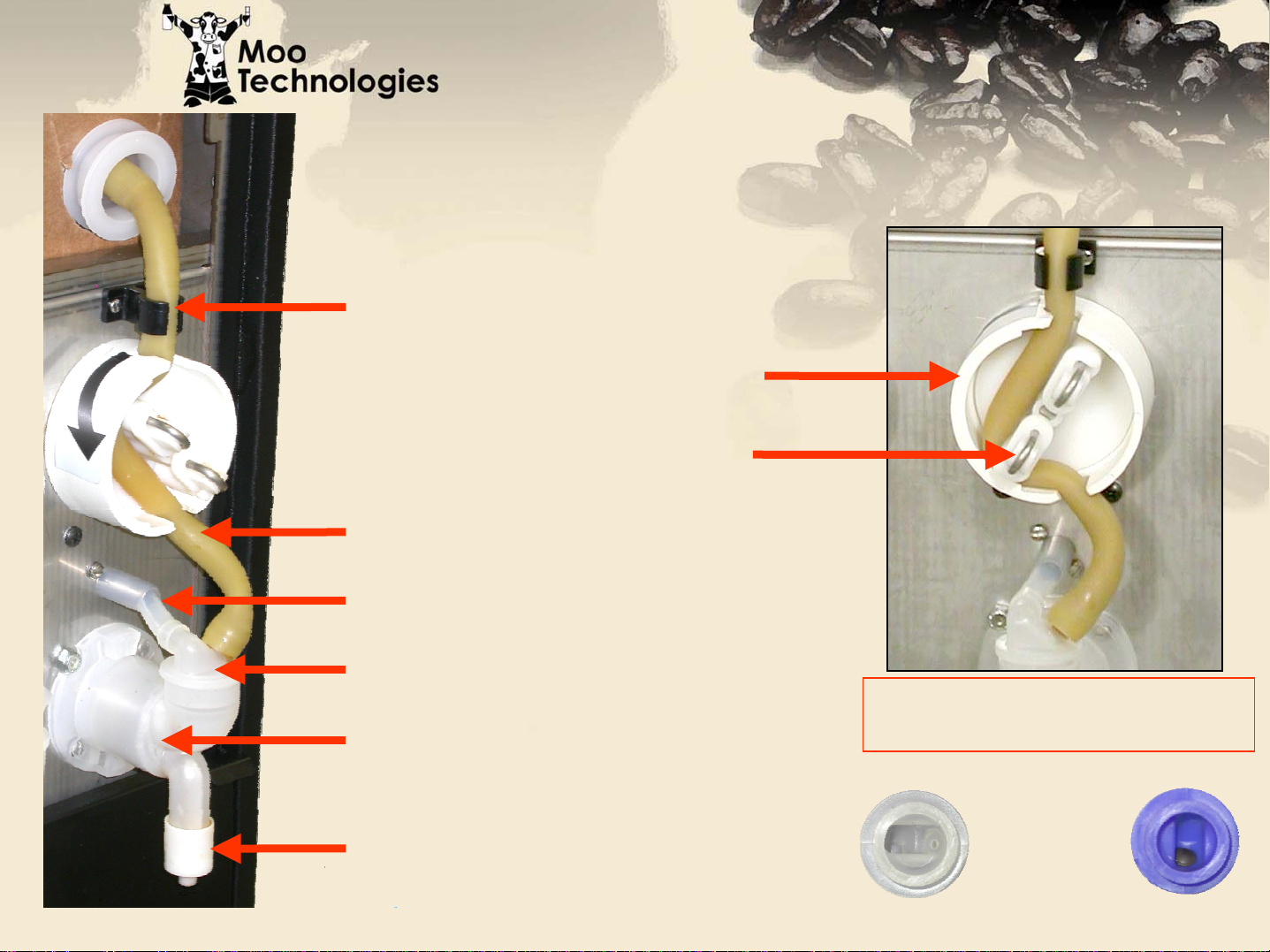

Plastic Tubing Holder

Pump Housing

Pump Rotor

BIB Product Tube

Water Supply Tube

Whipper Dosing Head

Whipper Chamber

Whipper Restrictor

Note: Pump Rotor should only

be rotated counter-clockwise

Dosing

Heads

Moo

Expresso

Page 5

Moo

Product

Product Overview

Product Overview

Expresso

Product

Check

Valve

No

Check

Valve

Moo Dosing Head Expresso Dosing Head

Expresso

Adapter Kit

Page 6

Shipping Carton Contents

Shipping Carton Contents

• MCM-Combo Unit

• Drip Tray Assembly (drain hose included)

• Water Filter (with shut-off & mounting hardware)

• Four Inch Plastic Legs (4)

• Fluorescent Tubes (2)

• Translucent Door Graphic

Page 7

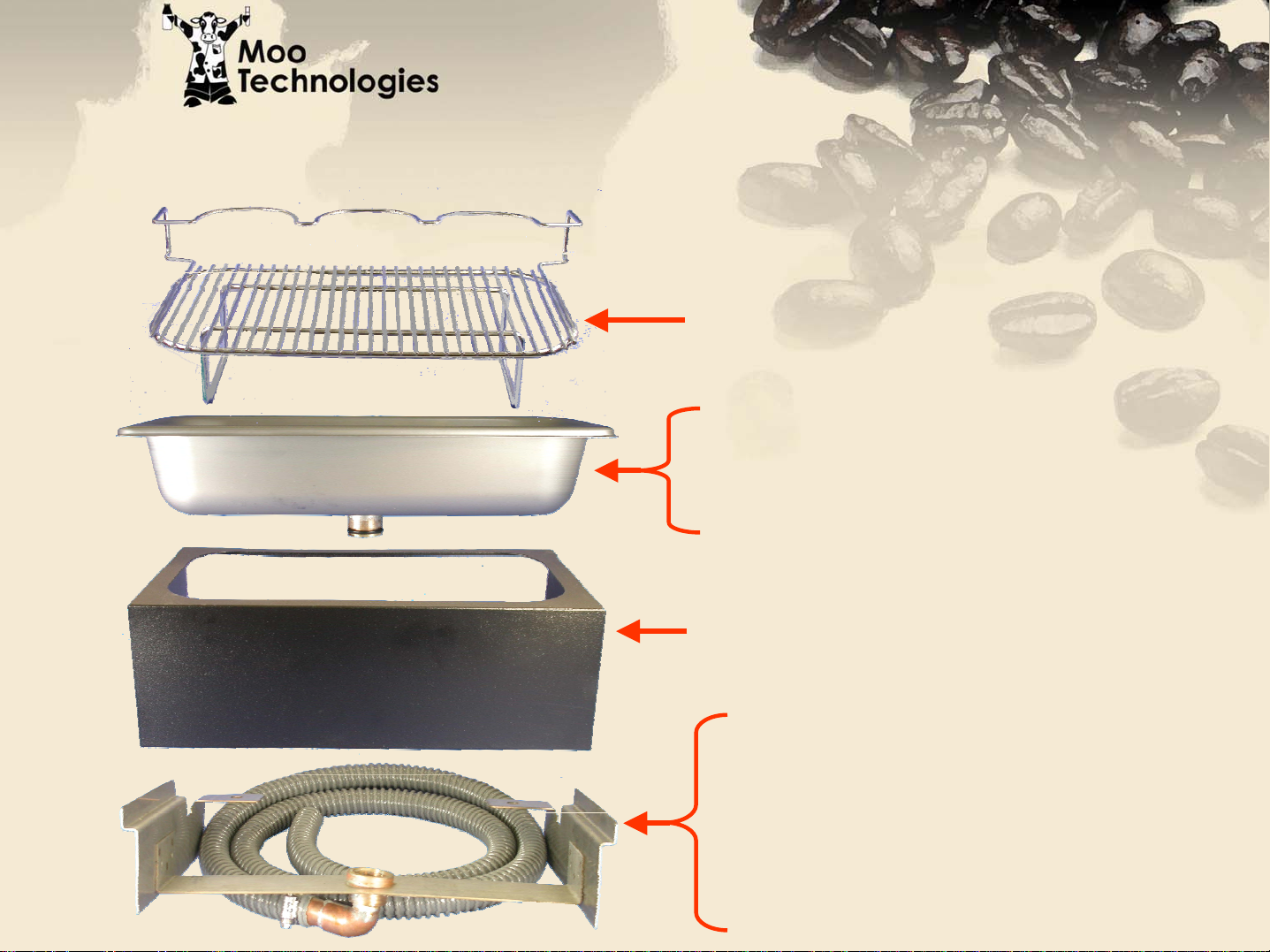

Drip Tray Assembly

Drip Tray Assembly

103426 Cup Rest

103415 Drain Pan

103425 Drain Pan Fitting

02-0158 O-Ring

103420-BPC Drip Tray Housing

103417 Drain Support Bracket

103424 Drain Receptacle

103455 Drain Hose

103452 Hose Clamp

Page 8

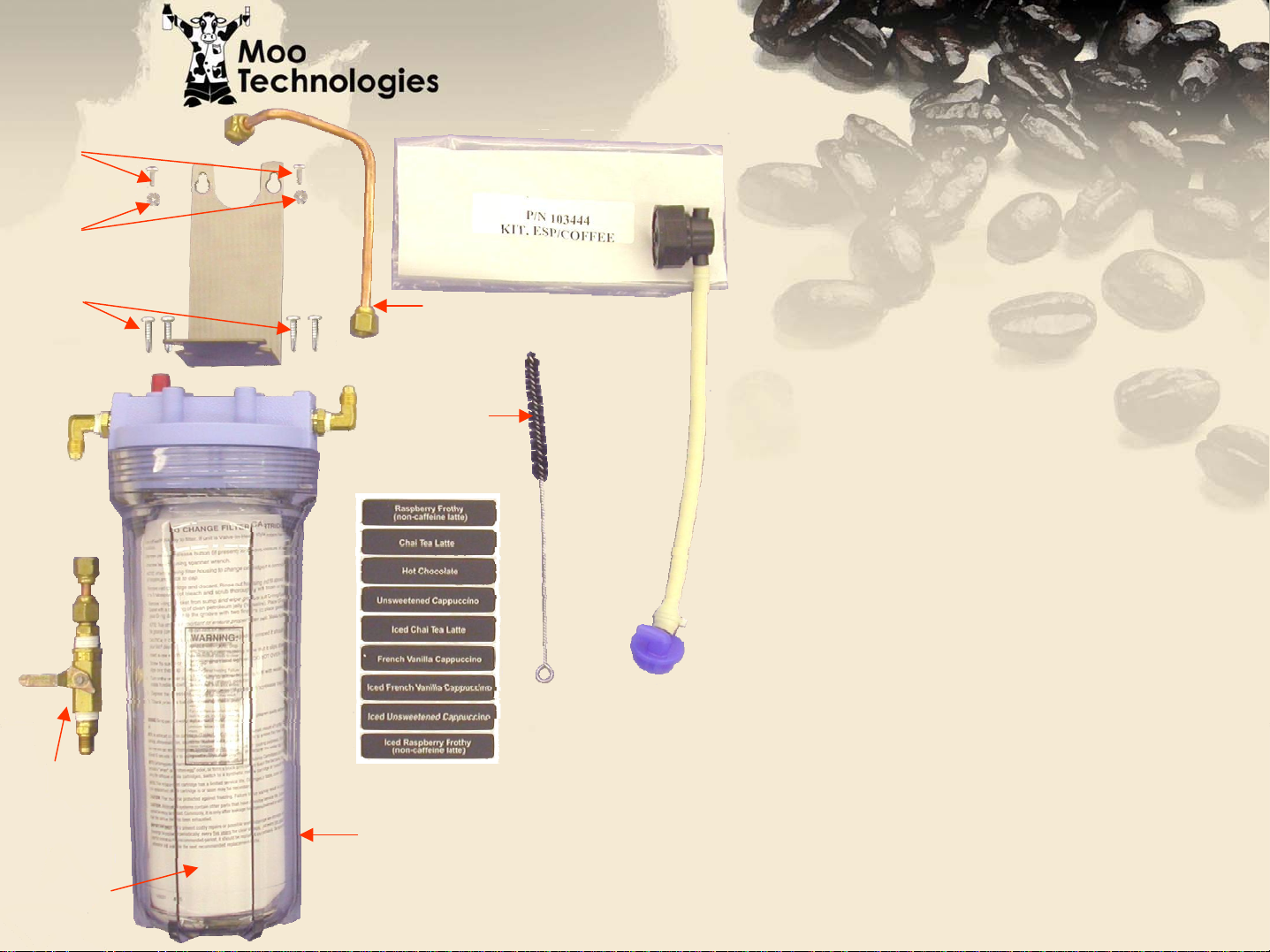

511027

100054

100754

103382

103457

111622

Water Filter

Water Filter

Accessories Bag

Accessories Bag

Product Labels

Nozzle Brush

Shut-off Assembly

Water Filter

Water Filter Bracket

Filter to Unit Water Line

103485

107018

Bracket (Unit) Mounting Screws (2)

100626

Bracket (Filter) Mounting Screws (4)

107038

Espresso Product Packing Adapter

Page 9

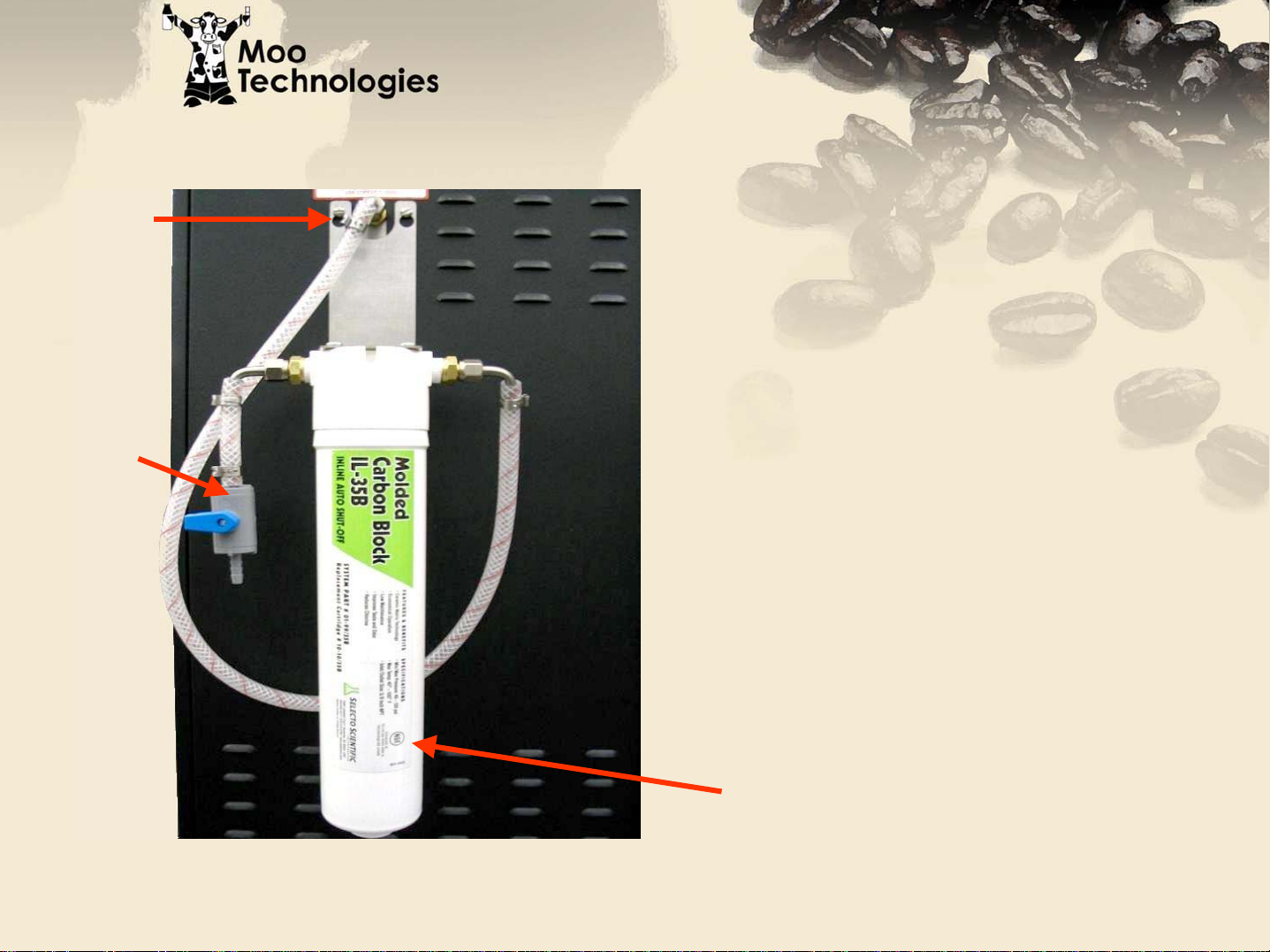

Bracket

New Water

New Water

Filter Assembly

Filter Assembly

New units will be shipped with

an upgraded water filter

Shut-off

assembly. The installation will

be exactly the same as the

previous filter assembly,

however some of the parts

(shutoff, filter, & bracket) may

look slightly different.

Filter cartridge

Page 10

Plastic Legs, Fluorescent Tubes and

Plastic Legs, Fluorescent Tubes and

Translucent Door Graphic

103377

100542

102062

Page 11

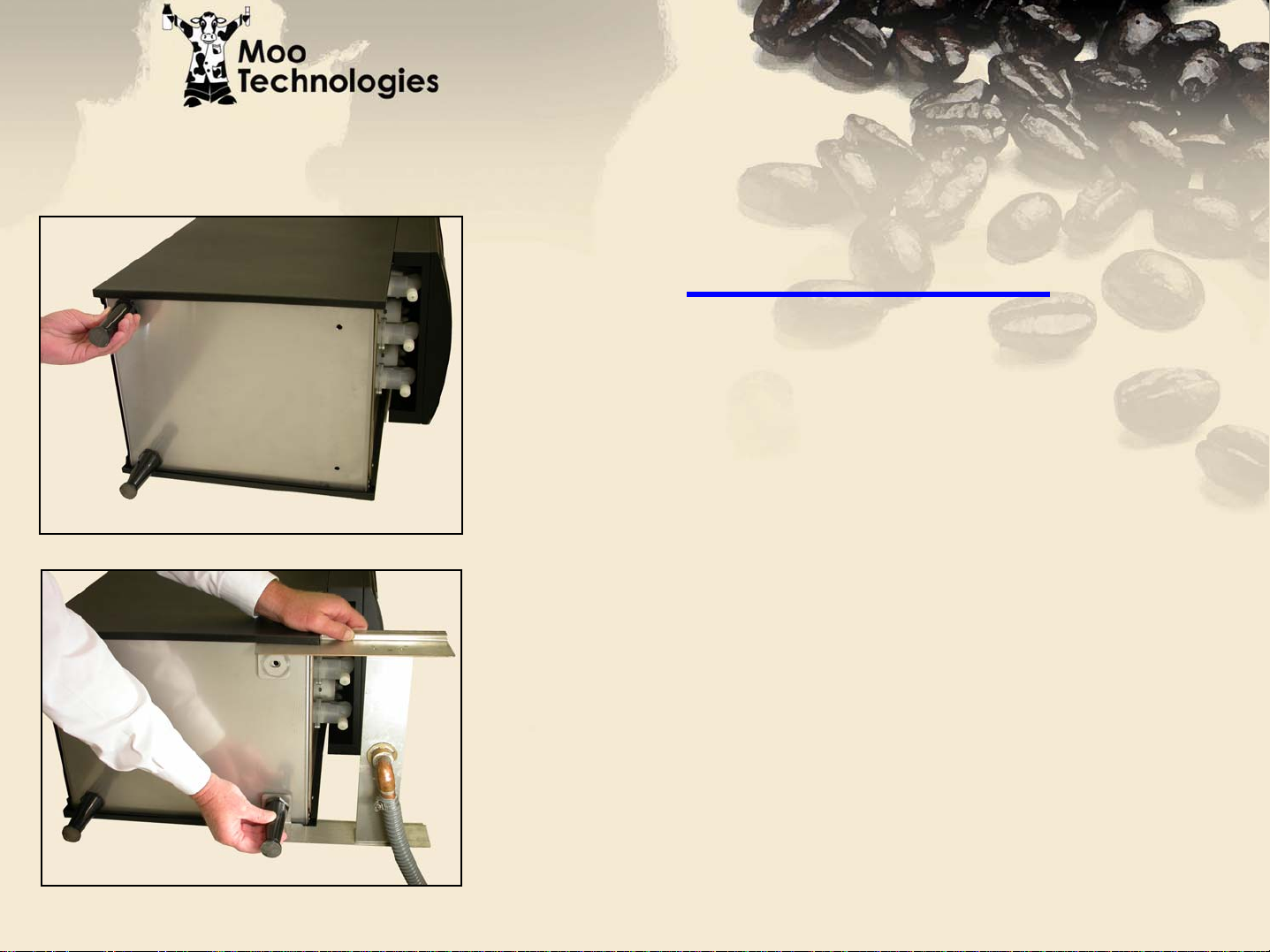

Machine Setup

Machine Setup

1. Install two rear unit legs.

2. Align Drain Support Bracket holes

Leg Installation

with those in bottom front of unit and

install front legs.

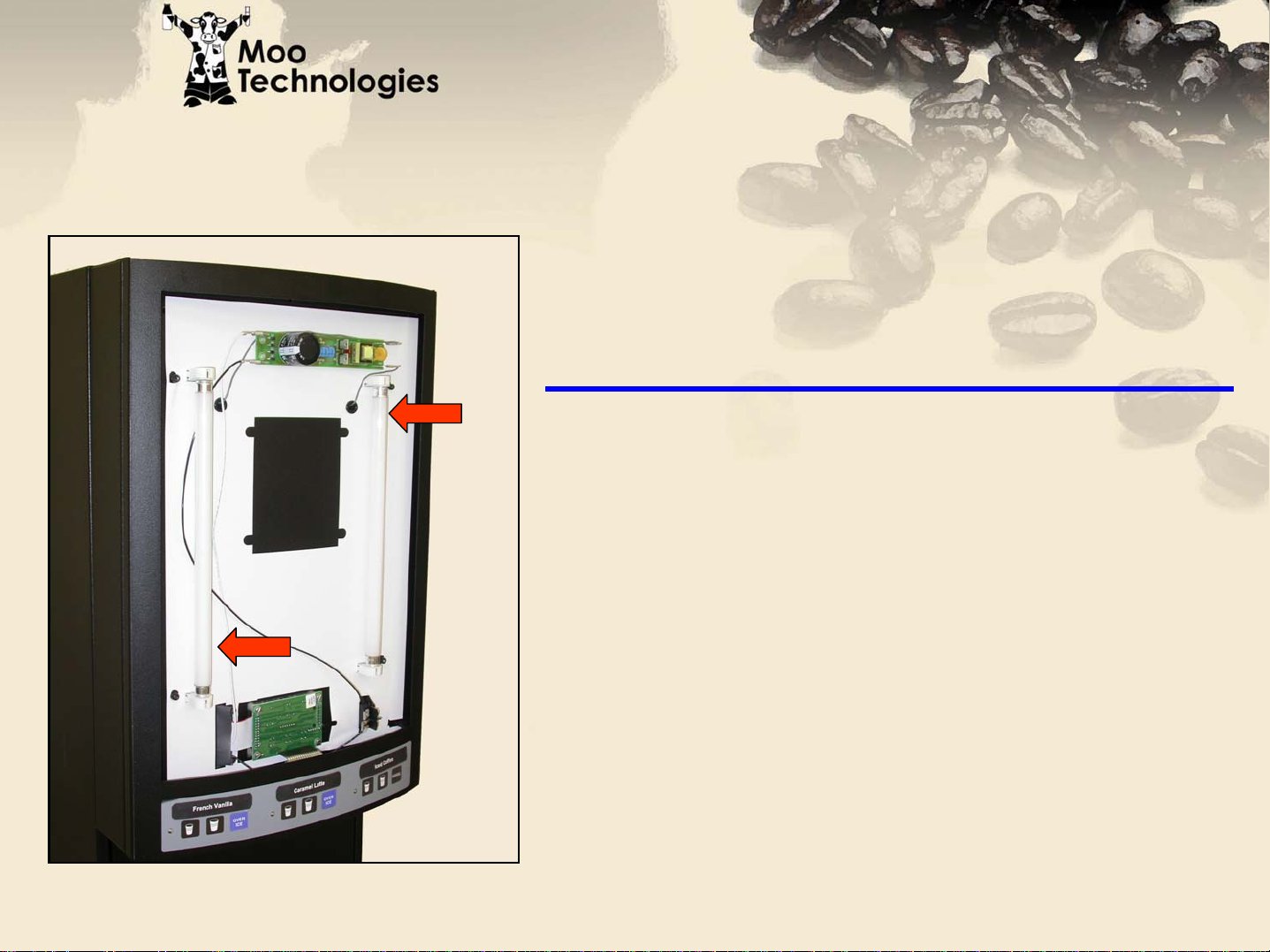

Page 12

Machine Setup

Machine Setup

Fluorescent Tube Installation

Install two (2) fluorescent tubes in

door face and rotate ¼ turn to lock in

holder.

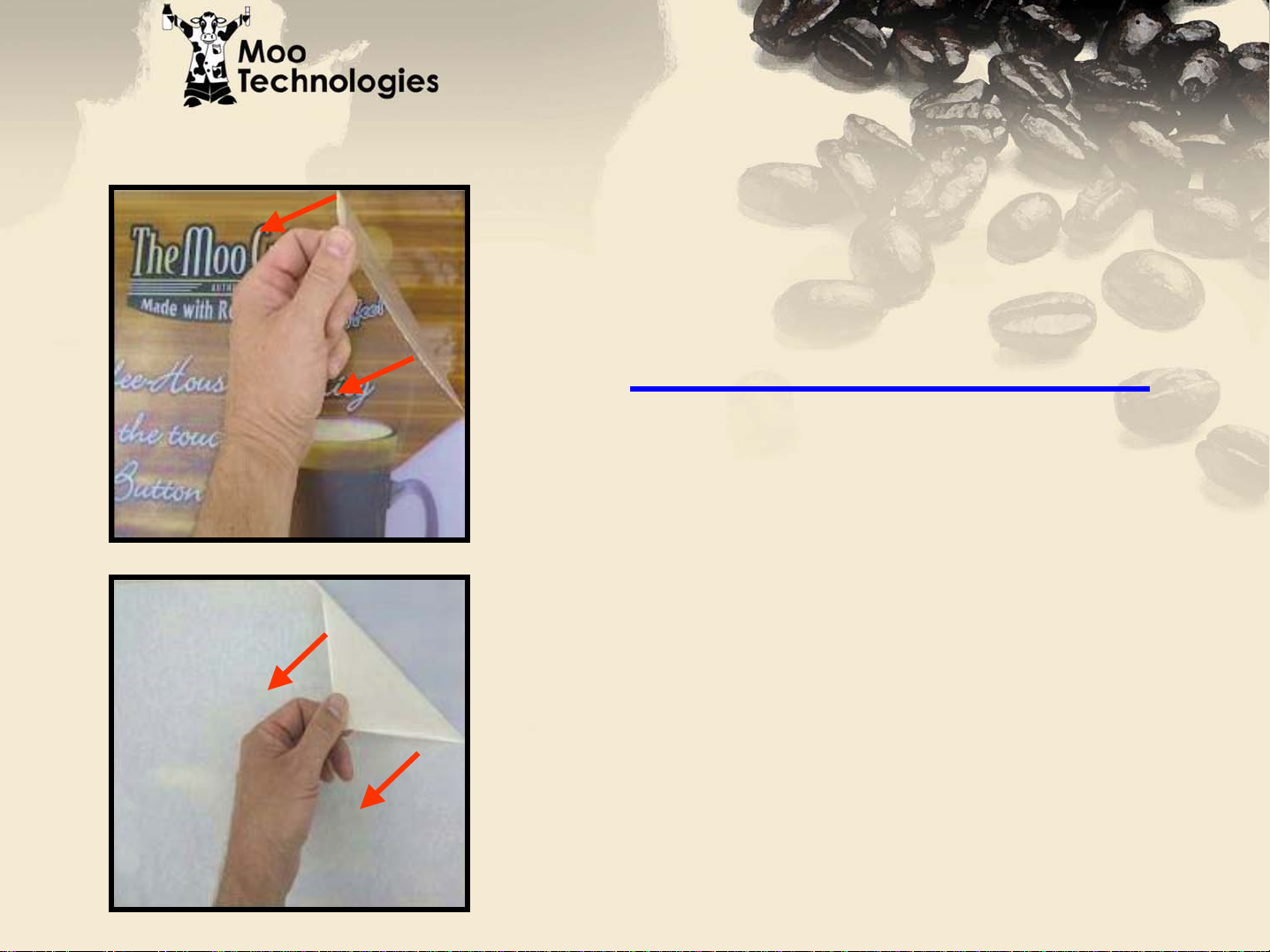

Page 13

Machine Setup

Machine Setup

Preparing the Graphic

Both the translucent graphic and

the clear plastic cover shield are

shipped with a protective film.

Translucent Graphic

Clear Plastic Cover

Start at a corner, and carefully pull

the protective film diagonally to

remove.

Page 14

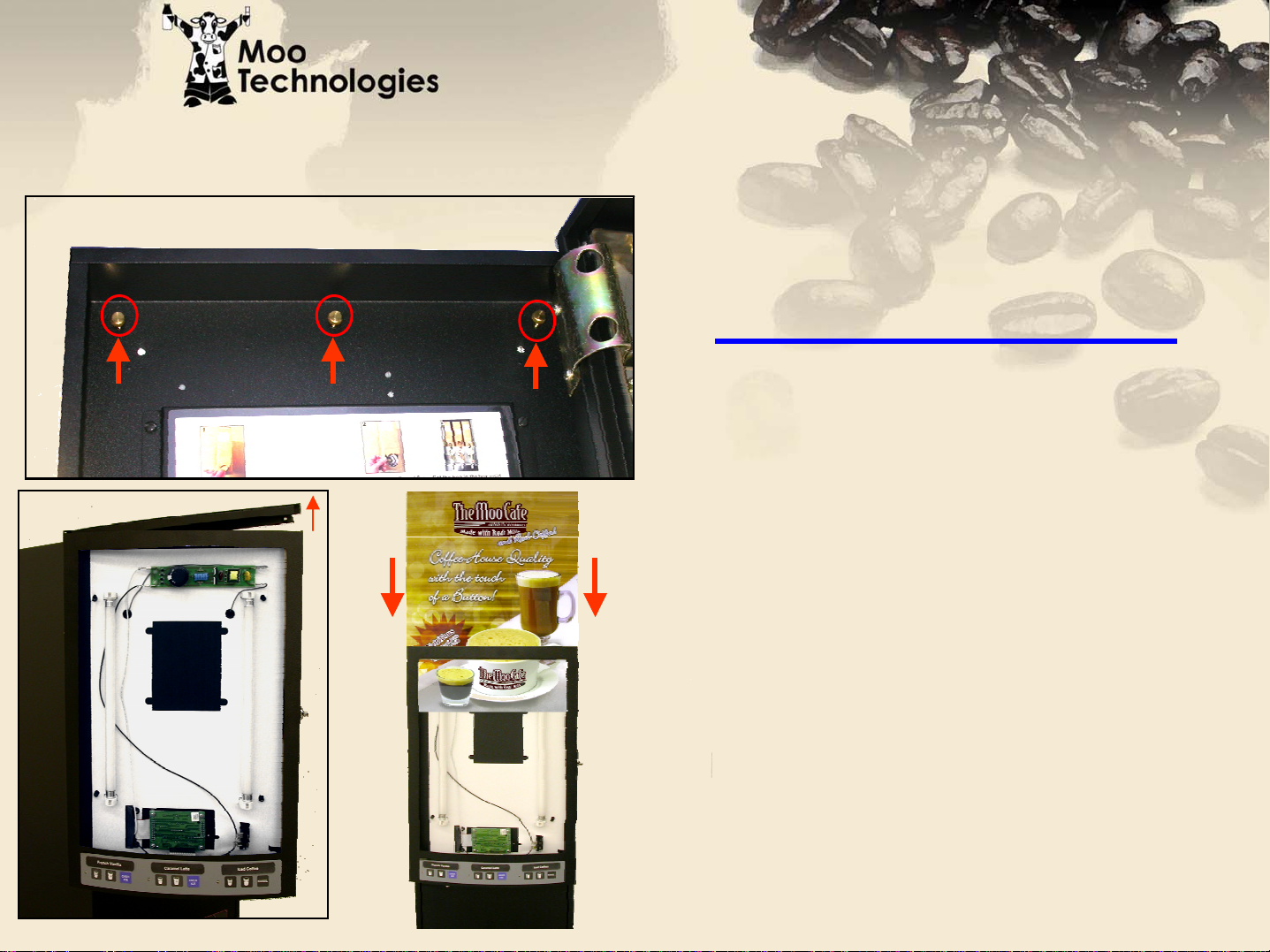

Machine Setup

Machine Setup

Graphic Installation

Unscrew and remove three (3)

brass thumbscrews from inside top

of door panel, then lift and remove

door cap. Peel clear plastic on

front, and white paper on rear of

Graphic. Slip Graphic into slide

guides and lower until sign is

seated at bottom of guides.

Reinstall door cap and secure with

the three (3) brass thumbscrews.

Page 15

Machine Setup

Machine Setup

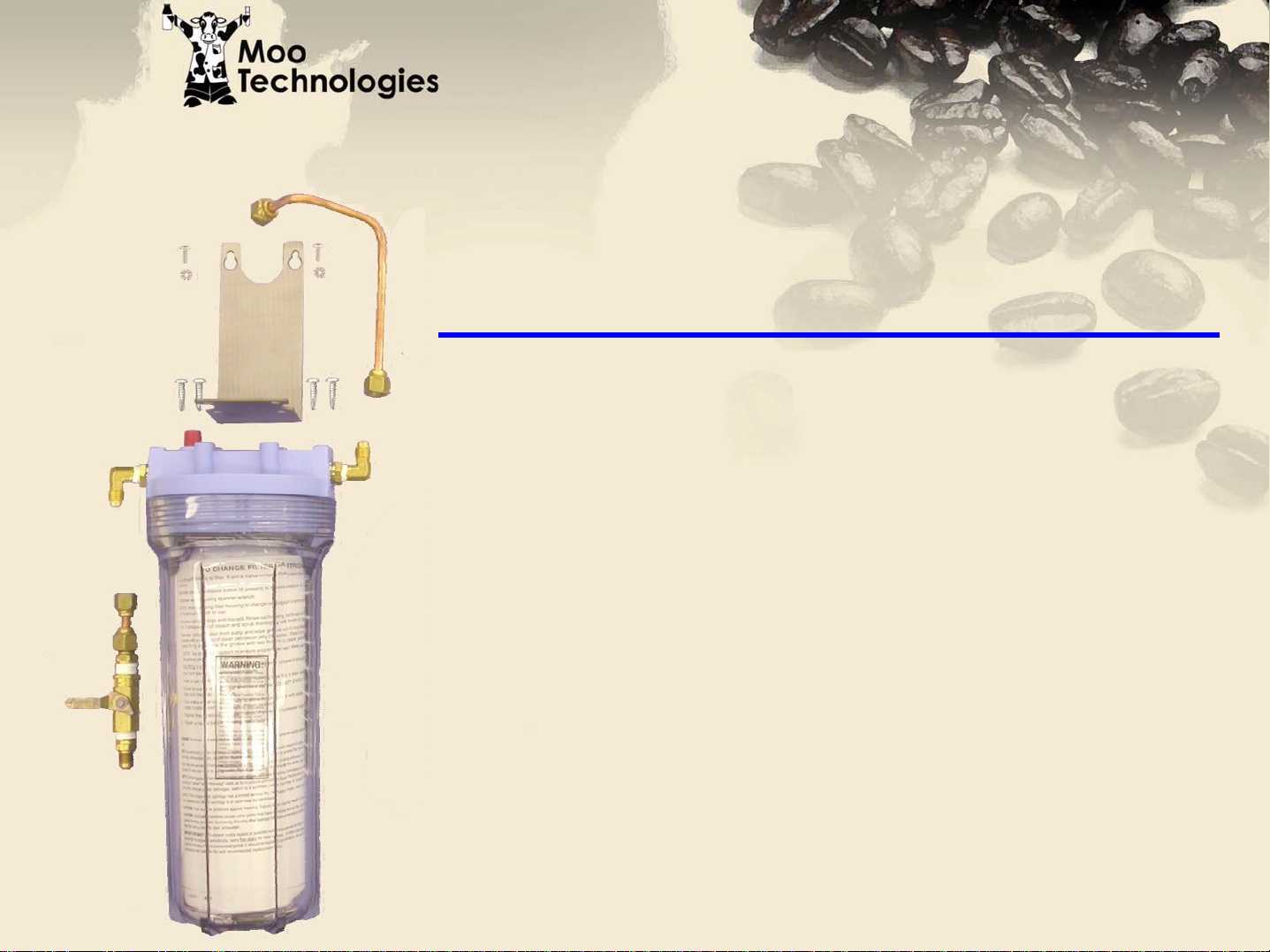

Water Filter Installation Overview

The water filter will require some assembly and

preparation prior to installing. The filter bracket

will need to be mounted to the top of the filter,

the cartridge will need to be removed from the

protective bag and the filter installation

instructions must be removed from the canister.

Page 16

Machine Setup

Machine Setup

Mounting

Screws

Water Filter Bracket

Mount water filter bracket to filter

with four (4) screws provided in

accessories bag. Assure that “outlet”

is on the right of bracket so the preformed tubing (installed in future

step) will reach unit water inlet.

Mounting

Screws

Outlet

Fitting

Page 17

Machine Setup

Machine Setup

Mounting Water Filter Bracket

Locate water inlet at upper rear of

unit. Install filter bracket using two

(2) #8 screws and star washers

provided in accessories bag.

Page 18

Machine Setup

Machine Setup

To Unit Inlet

Fitting

Tubing & Shutoff Connections

Run pre-formed water supply line

between water filter outlet and unit

water inlet.

Page 19

Machine Setup

Machine Setup

Run water supply line between water

source and shutoff inlet. It is highly

recommended to leave enough extra tubing

length to allow for serving unit. Equipment

should be installed to comply with all

federal, state and local plumbing codes.

Flow requirements are a minimum of 35psi

Water Supply Connection

To water supply

flowing pressure and a maximum of 100psi

static pressure.

Page 20

Machine Setup

Machine Setup

Drip Tray Housing

Installation

Align Drip Tray Housing guides with

Drain Support Bracket arms and

slide toward rear of unit.

Page 21

Machine Setup

Machine Setup

Drip Tray Installation

Align Drip Tray drain with Drain

Support Bracket drain receiver

and push down until seated.

Route Drain Support Bracket

hose into location drain

assuring a downward pitch to

allow for proper drainage.

Equipment should be installed

to comply with all federal, state

Note: Assure rubber gasket of drip tray is

properly seated in drain to avoid leakage.

and local plumbing codes.

Page 22

Machine Setup

Machine Setup

Drip Tray Wireform

Installation

Lower Drip Tray Wireform

into Drip Tray

Page 23

Machine Start up

Machine Start up

1. Turn on water to unit and check for leaks

2. Plug unit into electrical supply (120V,3 pole, 4 wire grounding type receptacle).

Hot water will begin filling.

3. Activate the Light Switch (toggle up) located on the inside of the door panel.

4. The LCD window will display self test message briefly, then sanitation indicators will

light. However, unit will not begin sanitizing until tank temperature reaches 160

degrees F. The sanitizing cycle may be canceled by pressing Rinse/Auto Rinse

button.

5. Allow approximately 6-8 minutes for the tank to fill. If tank does not fill within 10

minutes, a “FIL” error message will appear on LCD screen.

6. Allow up to 50 minutes for the water to reach 175 degrees. The heat up time will

depend upon the location’s water temperature and available voltage.

7. Open product door, hook up Moo products, then close door. Note that unit is

equipped with a safety lock device that will not allow product pumps to run while door

is open.

8. Set-up and calibrate the Moo Product for each channel while unit is heating up.

Page 24

Moo BIB Installation Instructions

Moo BIB Installation Instructions

Rear BIB Alignment Guide

Flap

Front BIB Guide

Round

Closure

Lay BIB on back and remove round

perforated cardboard closure

Front BIB Guide

Tubing Holders

Set BIB on product shelf just behind

front BIB guide. Align BIB tubing with

plastic tubing holder, then clamp

tubing inside holder

Lift up front cardboard flap and

remove BIB tubing, then re-close flap

Route tubing through top pump housing

cutout, then around left side of rotor and out

bottom cutout. Turn rotor assembly

counter-clockwise if necessary.

Assure front and rear BIB alignment guides

are in place before installing packaging

Turn rotor assembly counter-clockwise to

assure tubing is pinched at top and bot

Then remove red plug from tubing and install

tube over dosing head port.

tom.

Page 25

Expresso

Expresso

BIB Installation Instructions

BIB Installation Instructions

Rear BIB Alignment Guide

Expresso

Flap

Product

Adapter

Round

Closure

Lay BIB on back and remove round

perforated cardboard closure.

Remove Moo product dosing head

from Whipper Chamber and water

supply tube. Install Expresso Product

Adapter dosing head into water supply

tube and snap on Whipper Chamber.

Shipping

Cap

Lift up front cardboard flap, remove BIB

connector, then re-close flap. Remove Expresso

Product Adapter from unit accessory bag.

Route Expresso Product Adapter tubing through

bottom pump housing cutout, then around left side

of rotor and out top housing cutout .

assembly counter-clockwise if necessary. Place

tubing in plastic clip.

Turn rotor

Front BIB Guide

Assure that front and rear BIB alignment

guides are in place.

Holding Expresso BIB with connection

upwards, remove shipping cap and install

Product Adapter Connector. Set BIB on

product shelf just behind front BIB guide

Page 26

Machine Calibration Instructions

Machine Calibration Instructions

Overview:

Machine H2O settings are calibrated at the factory and normally do not need

adjustment unless a dispensing valve is replaced or the measured dispense volume

does not match the displayed setting.

Concentrate settings should be performed at initial set-up and each time the product

density (or viscosity) changes. If same product is used (i.e. just changing out an

empty box of the same product), channel does not need recalibration.

Calibration applies to the following :

A. Hot Water flow rate

B. Concentrate flow from pumps (liquid BIB)

C. Cold Water (ambient) flow rate

Note: Pull door safety switch out to place unit in “Service

Mode” during product calibration process. Pumps will not

operate and P1, P2 or P3 error codes will display if not

calibrating in “Service Mode”.

Page 27

Machine Calibration Instructions

Machine Calibration Instructions

Concentrate Calibration

Concentrate Calibration

Step 1

---

Press & hold “Settings” (middle) button

After approximately 5 seconds,

display will change to “---”

Step 2

Continue holding button until display

changes to “Con” and “Left”

Channel indicator light is displayed

(takes approximately 8 seconds),

then release “Settings” button.

---

Con

Page 28

Machine Calibration Instructions

Machine Calibration Instructions

Concentrate Calibration

Concentrate Calibration

0.30

Con

Step 3

Press “Settings” (middle) button.

Display will change to “0:30” (30 seconds).

Place measuring cup (preferably at

least a 12 fl oz graduated cup) under

the dispensing head to be calibrated

as indicated by channel light.

Page 29

Machine Calibration Instructions

Machine Calibration Instructions

Concentrate Calibration

Concentrate Calibration

0.30

Step 4

Press “Settings” button again,

machine will pump concentrate into

measuring cup for 30 seconds.

Page 30

Machine Calibration Instructions

Machine Calibration Instructions

Concentrate Calibration

Concentrate Calibration

Step 4 (continued)

When concentrate stops, read

concentrate volume (in ounces) from cup.

Enter measured value into display

Toggle left button

New Bag (+)

to increase value

Toggle right button

Rinse (-)

to decrease value

9.0 ounces

9.00

0.30

Page 31

Machine Calibration Instructions

Machine Calibration Instructions

Concentrate Calibration

Concentrate Calibration

Step 5

0.30

9.00

Press “Settings” to store settings. Display

will change to 0:30, and “Middle” Channel

Indicator light (middle dispensing head)

will illuminate.

Empty and move the measuring cup under

the middle dispensing head. Repeat steps

1-4 for the middle and right dispense head.

When Right dispense settings are stored,

display changes to “Con”.

Page 32

Machine Calibration Instructions

Machine Calibration Instructions

Water Calibration (if necessary)

Water Calibration (if necessary)

Step 1

---

Press & hold “Settings” button,

after approximately 5 seconds

Display will change to”- - -”

Step 2

Continue holding button for

approximately 8 more seconds, (display

---

H2O

Con

changes to “Con” and “Left”

Channel indicator light is displayed.

Without releasing button, continue

holding button for an additional 8

seconds, display will change to H2O.

Page 33

Machine Calibration Instructions

Machine Calibration Instructions

Water Calibration (if necessary)

Water Calibration (if necessary)

H2O Ambient Calibration is a factory. Settings should not need re-calibration unless the measured dispense volume

does not match the displayed setting.

Note:

Continuing to step #3 begins the calibration

the unit for Hot Water settings. If you would

Cld

like to skip hot water settings and proceed

directly to Cold Water settings, perform the

following step.

Press “Rinse” (right) button three times.

H2O

Channel indicator light will move to middle

position with first press, right position with

second press and display will change to

“Cld” (Cold) after third.

Continue with step #3 for either Hot or Cold water calibration.

Page 34

Machine Calibration Instructions

Machine Calibration Instructions

Water Calibration

Water Calibration

Step 3

Press “Settings” (middle) button.

Display will change to “0:30” (30 seconds).

Place measuring cup (preferably at least a

32 fl oz graduated cup) under the

dispensing head to be calibrated as

indicated by channel light.

0.30

Con

Page 35

Machine Calibration Instructions

Machine Calibration Instructions

Water Calibration

Water Calibration

0.30

Step 4

Press “Settings” button again,

machine will pump water into

measuring cup for 30 seconds.

Page 36

Machine Calibration Instructions

Machine Calibration Instructions

Water Calibration

Water Calibration

Step 4 (continued)

When concentrate stops, read

water volume (in ounces) from cup.

Enter measured value into display

Toggle left button

New Bag (+)

to increase value

Toggle right button

Rinse (-)

to decrease value

24.0 ounces

24.0

0.30

Page 37

Machine Calibration Instructions

Machine Calibration Instructions

Water Calibration

Water Calibration

Step 5

0.30

9.00

Press “Settings” to store settings. Display

will change to 0:30, and “Middle” Channel

Indicator light (middle dispensing head)

will illuminate.

Empty and move the measuring cup

under the middle dispensing head.

Repeat steps 3-5 for the middle and right

dispense heads.

Page 38

Machine Calibration Instructions

Machine Calibration Instructions

Step 7

Cld

In Hot water calibration mode, when right

dispense settings are stored, display

changes to “Cld” prompting you to repeat

steps 3-5 for Cold Water calibration of each

9.00

dispensing head.

In Cold water calibration mode, when right

dispense settings are stored, display

changes to “Pro” (program).

With “Pro” displayed, Press “Settings” twice

to enter settings as default and exit program

mode. (Note: En4 is a factory setting and

should not be changed). Display will go

blank once settings are entered.

After Hot water

programming

Pro

9.00

After Cold water

programming

Page 39

Programmable Buttons

Programmable Buttons

(3 per channel)

(3 per channel)

Each button on the door switch is programmable for the following:

A. Button Enable - Enables or disables each individual button.

Example: Enable center button only for a manual dispense, hot or cold

product.

PUSH

HERE

French Vanilla Latte

PUSH

HERE

Left Channel &

Dispensing Valve

Indicates buttons that have been enabled

Indicates buttons that have been disabled

Middle Channel &

Dispensing Valve

Unsweetened

Cappuccino

PUSH

HERE

Sweetened

Cappuccino

PUSH

HERE

Right Channel &

Dispensing Valve

Page 40

Programmable Buttons

Programmable Buttons

B. Portion Control Allows for the ability to set a volume dispense

( in ounces) for any button.

Example: Program the 1stbutton for each dispense for a

small cup dispense, the center button for a large

cup dispense, and the 3rdbutton for a manual dispense

French Vanilla Latte

Small

Large

MANUAL

Manual

Unsweetened

Cappuccino

MANUAL

Sweetened

Cappuccino

MANUAL

Page 41

Programmable Buttons

Programmable Buttons

C. Hot/Cold Water Dispense Allows customer choice of hot or cold

(ambient) dispense per button

Example: Program the 1st& 3rdbuttons on each channel

“Hot” & “Iced” (ambient).

French Vanilla Latte

Iced Iced IcedHot Hot Hot

Indicates buttons that have been disabled

Unsweetened

Cappuccino

Sweetened

Cappuccino

Page 42

Multi Level

Multi Level

Programming

Programming

Instructions

Instructions

Page 43

Product Ratio Instructions

Product Ratio Instructions

Step 1

Press and hold Settings

button until display

changes to

Step 2

Press and hold New Bag

button until display

changes to

Step 3

Press desired button on

front screen to program.

Display will change to a

Ratio Value

rAt

3.0

Toggle Ratio Value with:

New Bag (+) to increase

Rinse (-) to decrease

When desired ratio value is

obtained, press Set-up button

Step 4

to lock-in setting

Ratio value is now locked in.

Display changes to

Repeat step 3 & 4 for

remaining flavor buttons

rAt

Page 44

Portion Control

Portion Control

Step 1

Press and hold Settings

button until display

changes to

Step 2

Press and hold New Bag

button until display

changes to

Step 3

Press desired button on

front screen to program.

Display will change to a

Ounce Volume Value

Por

3.0

Step 4

Toggle Ratio Value with:

New Bag (+) to increase

Rinse (-) to decrease

When desired volume value is

obtained, press Set-up button

to lock-in setting

Portion Control value is now

locked in. Display changes to

Por

Repeat step 3 & 4 for

remaining flavor buttons

Page 45

Button--

Button

Step 1

Press and hold Settings

button until display

changes to

Manual Dispense ––

Manual Dispense

Enable/Disable

Enable/Disable

Step 4

Toggle Ratio Value with

Step 2

Press and hold New Bag

button until display

changes to

Step 3

Press desired button on

front screen to program.

Display will change to a

Ounce Volume Value

Por

3.0

New Bag (+) or Rinse (-)

buttons until display reads

on

If “off” is selected, button is disabled.

If “on” is selected, button is set for

Manual Dispense.

Press center button to store selection

Repeat step 3 & 4 for remaining flavor

or

buttons

off

Page 46

Hot/Cold Water Selection

Hot/Cold Water Selection

Step 1

Press and hold Settings

button until display

changes to

Step 2

Press and hold New Bag

button until display

changes to

Step 3

Press desired button on

front screen to program.

Display will change to a

Temp Option

o F

Hot

Step 4

Press New Bag (+) or Rinse (-)

buttons until display reads

“hot” or “cold (ambient)” water

temperature

Hot

Press Settings button to store selection

Temp choice is now locked in for button.

or

Cl d

Display changes to

Repeat step 3 & 4 for remaining flavor

buttons

o

F

Page 47

Whipper

Whipper

Step 1

Press and hold Settings

button until display

changes to

Step 2

Press and hold New Bag

button until display

changes to

Step 3

Press desired button on

front screen to program.

Display will change to

“On” or “Off”

Motor ––

Motor

bin

on

Enable/Disable

Enable/Disable

Step 4

Press New Bag (+) or Rinse (-)

buttons until display reads

on

If “off” is selected, Whipper is disabled.

If “on” is selected, Whipper enabled.

Press center button to store selection

or

off

Repeat step 3 & 4 for remaining flavor

buttons

Loading...

Loading...