Page 1

KB-TCF KB-3F

Man. PN: 781224

Rev. 20170309

NEWCO ENTERPRISES

INSTALLATION, OPERATION, AND SERVICE MANUAL FOR

KB SERIES BOTTLED WATER BREWERS

KB-APF/LDF

KB-2F

Model Warmers Width Depth Height Weight Watts Amps

KB-1F 1 9 1/2" 18” 20 1/8” 34 1500 12.5

KB-2F 2 18” 9 1/2" 22 3/8” 39 1600 13.3

KB3-F 3 16 1/2" 18” 20 1/8” 43 1700 14.2

KB-TCF 0 9 1/2" 18” 20 1/8” 34 1400 11.7

KBAPF/LDF*

*We recommend up to 3 gallon bottles only due to stability, unless anchored to wall.

WARNING – Read and follow installation instructions before plugging or wiring in machine to electrical circuit. Warranty

1.) Place bottle on top of brewer with neck of bottle extending into receiving hole.

2.) Hold faucet open until water flows from it. Allow one minute for automatic leveling of water in tank. Plug or wire brewer to

appropriate voltage circuit as indicated on serial tag. Place decanter/carafe/airpot under brew basket and turn lower warmer

switch to the “ON” position. Depress brew start switch & check volume of water delivered into decanter/carafe/airpot. Adjust

timer to deliver desired amount of water. Turn timer dial clockwise to increase volume of water, and counter clockwise to

decrease volume.

3.) Allow 10 to 15 minutes for water in tank to heat to brewing temperature. Water has reached brewing temperature when

thermostat clicks off and heating noise stops. Green ready light will be lit on models so equipped. Empty vessels and

replace.

4.) Run one cycle to check for proper temperature setting with an accurate thermometer. Take the temperature of the water at a

point below the brew basket opening, at the start of the brew cycle, and when the vessel is half full. Recommended

temperature is approximately 195°F.

5.) In higher altitudes [5,000 feet above sea level] the thermostat may have to be adjusted to a lower temperature to prevent

boiling.

6.) CAUTION: On faucet models the water faucet will dispense hot water when the handle is depressed. The faucet may be

operated during brew cycle.

0 9 1/2" 18” 26 1/2" 42 1400 11.7

FILL BREWER TANK WITH WATER BEFORE CONNECTING TO POWER SUPPLY!

Vessels Not Included

INSTALLATION INSTRUCTIONS

Page | 1

Page 2

Tanks

Containers

Miscellaneous

Parts

Warming Plates

Brew Baskets and Rails

COFFEE PREPARATION PROCEDURES

• Place filter into brew basket.

• Put the proper amount of coffee into the filter.

• Slide the brew basket into holder.

• On warmer models, place empty decanter on warmer located directly under the brew basket and turn

corresponding warmer switch to “ON” position. On thermal models, place dispenser or airpot directly under

the brew basket.

• Press brew start switch. [Brew cycle may be canceled by turning the red rocker switch back to the “OFF”

position.]

• Hot water will be delivered through the spray head. This distributes the hot water evenly over the coffee

grounds within the brew basket. The coffee brew will drain from the brew basket into the decanter below.

• The resultant coffee brew should be crystal clear and have the desired properties attainable through excellent

extraction.

• TURN OFF WARMER WHEN NOT IN USE. [Illuminated red rocker switch indicates warmer is on.]

• To clean brew basket simply remove from the brew rails and dump coffee filter into waste basket. The

brewing process, as described above, can now be started again.

• On units with a “CHANGE BOTTLE” light, this indicator will come on at any time the bottle empties. The bottle

should be changed at this time. The brewing circuitry will be disabled until bottled water supply is replenished.

KB SERIES – PARTS LIST

781178 Tank Assy., KB1F,KB3F,KBAP/LD 100510 12 Cup Glass Decanter [Decaf]

781287 Tank Assy., KB1 & KB3 100550 12 Cup Glass Decanter [Regular]

781219 Tank Assy., KB2F 112005 Thermal Dispenser, 85 oz. [Short]

781287 Tank Assy., KB2 112006 Thermal Dispenser, 85 oz. [Tall]

781217 Receiving Tank/Bracket Assy. without Probe 120795 Airpot, 2.2L Diagonal Lever KK Series

781194 Receiving Tank/Bracket Assy. with Probe 120818 Airpot, 2.2L Stainless Steel Lever KK

102580 Main Element Assy., 1400W 120V 111445 Thermal Server, 1.9L Short Vaculator

111592 Manual Hi-Limit Thermostat, 221F 109115 Thermal Server, 1.9L S/S Coffee Butler

781181 Gasket, Receiving Tank

102770 Faucet with Red Handle

100008 Plate, Porcelain Black 152114 Deltrol Solenoid Valve

100010 Warming Plate Assy., 100W 120V Black 152130 Valve Repair Kit, Deltrol

100187 Warming Element, 100W 120V 100024 5-hole Spray Head, S/S

110985 Brew Basket Assy., Black Vac. 201173 Spray Head Nut

110987 Brew Basket Assy., Color Changing Vac. 101365 Timer Only, 25004-4

781030 Right-hand Brew Rail 781195 Liquid Level Board, KB Series

781031 Left-hand Brew Rail 781220 Harness, Tank-SW-Sol-Vio/Wh

781211 Timer Harness Only

100022 Power Cord Assy., 14/3 15Amp 120V

773300 Thermostat Assy., 4.78” Robertshaw

201985 Start Switch, Momentary Black

100085 Red Rocker Switch, Lighted

781212 Ready Light Assy., Green KB series

201189 Pilot Light with Terminals

100078 Bumper Foot with Screw

100025 Spray Head Gasket

Page | 2

Page 3

WARRANTY

Applies to all equipment manufactured after 2/1/2017. This warranty supersedes

all other previous warranties that are currently in manuals.

• Newco warrants equipment manufactured by it for 1 year parts and labor.

• Accessories and Dispensers 1 Year parts only.

• Electronic Circuit and Control Boards- 3 years parts, 1 year labor.

• Equipment manufactured by others and distributed by Newco- please see original equipment manufacturers

warranty, Newco will follow.

These warranty periods run from the date of sale Newco warrants that the equipment manufactured by it will be

commercially free of defects in material and workmanship existing at the time of manufacture and appearing within the

applicable warranty period. This warranty does not apply to any equipment, component or part that was not manufactured

by Newco or that, in Newcoʼs judgment, has been affected by misuse, neglect, alteration, improper installation or

operation, relocation or reinstallation, improper maintenance or repair, incorrect voltage applied to the unit at any time,

damage or casualty. This warranty does not apply to any equipment failures related to poor water quality, excessive lime

and chlorine and non-periodic cleaning and descaling. Warranty is null and void if muriatic or any other form of

hydrochloric acid is used for cleaning or deliming. In addition, this warranty does not apply to replacement of items

subject to normal use including but not limited to user replaceable parts such as faucet seat cups, sight gauge tubes,

washers, o-rings, tubing, seals and gaskets.

This warranty is conditioned on the Buyer 1) giving Newco prompt notice of any claim to be made under this warranty

by telephone at (800) 556-3926 or by writing to 3650 New Town Blvd, Saint Charles, MO 63301; 2) if requested by Newco,

shipping the defective equipment prepaid to an authorized Newco service location; and 3) receiving prior authorization

from Newco that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of Newco are not authorized to make

modifications to this warranty or to make additional warranties that are binding on Newco. Accordingly, statements by

such individuals, whether oral or written, do not constitute warranties and should not be relied upon.

If Newco determines in its sole discretion that the equipment does not conform to the warranty, Newco, at its exclusive

option while the equipment is under warranty, shall either 1) provide at no charge replacement parts and/or labor (during

the applicable parts and labor warranty periods specified above) to repair the defective components, provided that this

repair is done by a Newco Authorized Service Representative; or 2) shall replace the equipment or refund the purchase

price for the equipment.

THE BUYERʼS REMEDY AGAINST NEWCO FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF

THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT NEWCOʼS SOLE

OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall Newco be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss

of use of equipment, claims of Buyerʼs customers, cost of capital, cost of down time, cost of substitute equipment,

facilities or services, or any other special, incidental or consequential damages.

Page | 3

Page 4

TROUBLE SHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE WHAT TO CHECK REMEDY

CAN’T START BREW CYCLE 1. No Water

2. No Power

3. On/Off Switch

4. Brew Start Switch

5. Timer/Timer Harness

Timer/Probe & Harness

6. Solenoid Valve

NO HOT WATER 1. Tank heater

2. Hi-limit thermostat or main

thermostat

STEAMING/SPITTING

AROUND FUNNEL

FAUCET WATER TOO SLOW 1. No Water 1. (A) Water bottle (B) Faucet

DRIPPING 1. Not siphoning properly 1. Water should flow freely

DRY COFFEE REMAINING IN

BREW BASKET AFTER

BREWING

1. Main Thermostat

2. High Altitude

1. Filter

2. Not siphoning properly

3. Improper loading of brew

basket

1. Water bottle is empty?

2. Fuse or circuit breaker,

power cord & plug

connections

3. Switch continuity [normally

closed 1 & 2]

4. Switch continuity [normally

open]

5. Leads to solenoid, switches,

& level sensor probe.

6. (A) Voltage at solenoid

valve terminals, start a brew

cycle & check for 120V AC

(B) If voltage is present at

terminals, check water on

the inlet side of solenoid

valve

1. Check voltage at the tank

terminals, voltage should be

as indicted on the serial tag

2. Check voltage between the

white wire on the tank &

incoming terminal [blue

wire] on the hi-limit

thermostat, then the

outgoing terminal [black

wire] on the hi-limit

thermostat

1. Thermostat points stuck or

out calibration

2. Located above 5,000 feet

clogging

from the spray head

1. Correct filters being used?

2. Refer to “Dripping” step 1

3. Filter & coffee in brew

basket

1. Replace empty bottle with

new one

2. Replace or reset circuit

protector as required, unit

should be plugged in

securely

3. If On/Off switch does not

make and break contact

replace it

4. If brew start switch does not

make & break contact,

replace it

5. Make sure these

connections are tight, if all

checks out ok replace timer

6. (A) If voltage is not present

at terminals, refer to steps 2

thru 5 (B)If voltage is

present at terminals, water

is present at the inlet side

but not at the outlet side of

the solenoid valve replace it

1. (A) If correct voltage is

present at the tank heater

terminals & water not

heated, replace the tank’s

heating element (B) If

voltage is not present at the

tank heater terminals refer

to step 2 (c) if incorrect

voltage is present at the

tank heater terminals, check

voltage at outlet

2. (A) If voltage is present on

the incoming terminal of the

hi-limit thermostat, but not

on the outgoing terminal,

replace the hi-limit

thermostat (B) Check the

voltage between the black &

white wire on the

receptacle, if voltage is not

present check outlet or

circuit breaker (C) If voltage

is not present on the

incoming terminal of the hilimit thermostat replace the

main the main thermostat

1. (A) Adjust thermostat (B)

Thermostat should be

calibrated or replace

2. See installation instructions

1. (A) Replace empty bottle

with new one (B) Clean or

rebuild faucet

1. (A) Clean spray head holes

(B) Check tightness of spray

head tube

1. Insert proper filter

2. Refer to “Dripping” step 1

3. Filter centered, coffee bed

level

Page | 4

Page 5

TROUBLE SHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE WHAT TO CHECK REMEDY

WEAK COFFEE 1. Filters

2. Not siphoning properly

3. Improper loading of brew

basket

COLD WARMER STATION 1. Warmer – defective

2. Warmer ON/OFF switch

3. Bad harness

CONDENSATION ON THE

INSIDE OF CABINET

WATER KEEPS RUNNING 1. 1.Solenoid Valve

1. Tank lid gasket

2. Spray head tube assy.

3. Thermostat grommet

4. Receiving pan nut

5. Main thermostat set above

201°F

2. Start Switch

3. Timer

1. Are the correct filters being

used?

2. Refer to “Dripping” step 1

3. Filter & coffee in brew

basket

1. Voltage at warmer terminals

should be 120V AC

2. If voltage is not present on

warmer terminals check

continuity of switch

3. Check connections between

harness & switch, and

between switch & warmer

1. Nicks or cuts in the gasket

2. Tightness of assembly to lid

3. Tight fit, nicks, or cuts

4. Receiving pan nut loose

5. Check thermostat

calibration

1. Refer to “DRIPPING” step 1

2. Remove wires from switch

& check continuity

3. Solid state timers are not

repairable, if timer will not

shut off, replace timer

1. Insert correct filter

2. Refer to “DRIPPING” step 1

3. Filter centered, coffee bed

level

1. If voltage is present on

terminals, but warmer will

not heat, replace warmer

2. If switch does not make &

break continuity when

turned off, replace switch

3. All connections should be

tight

1. Replace gasket

2. Tighten spray head tube

assy. to tank lid

3. Adjust or replace grommet

4. Tighten nut

5. Calibrate or replace

thermostat

1. Refer to “DRIPPING” step 1

2. If start switch does not

make or break contact,

switch should be replaced

3. Replace timer

Page | 5

Page 6

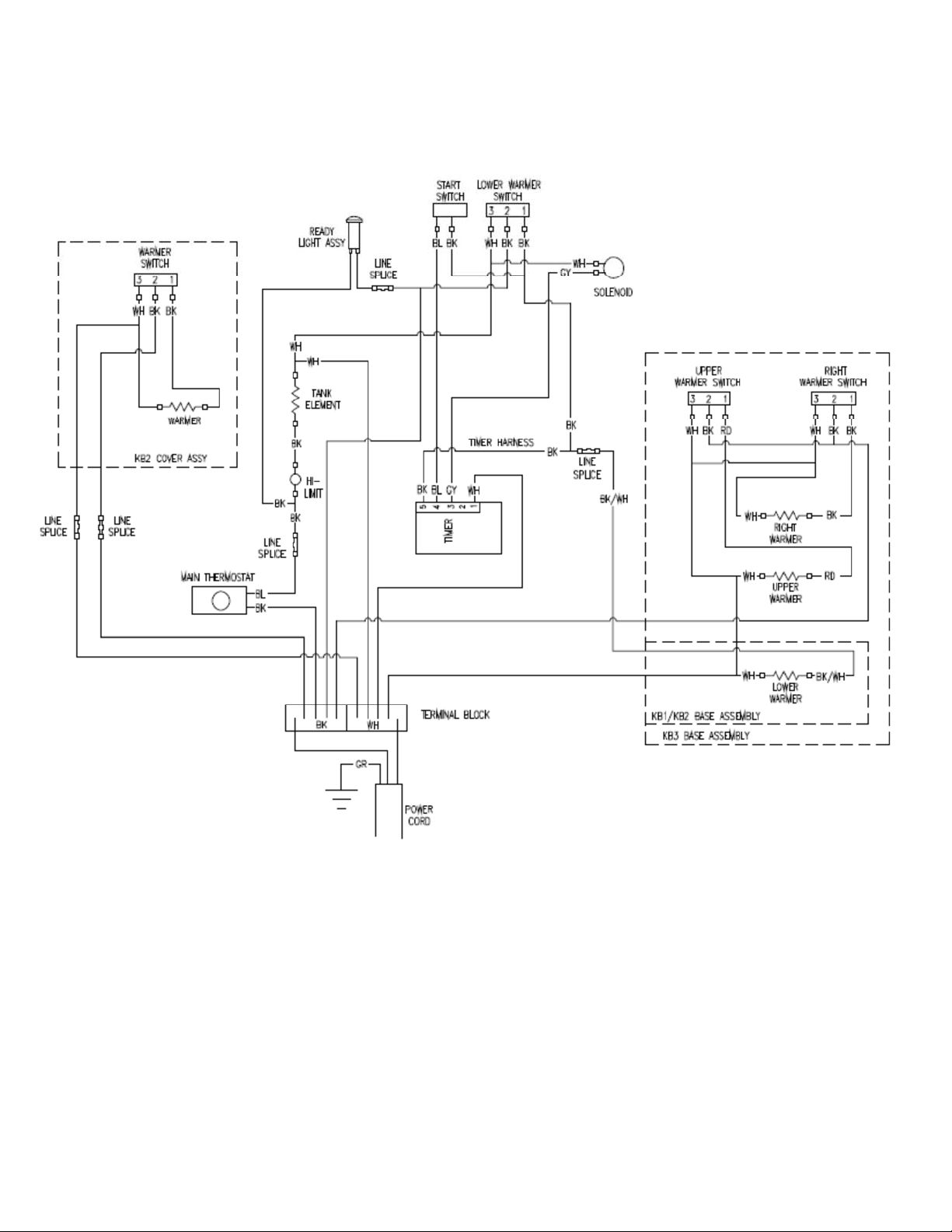

WIRING DIAGRAM

Page | 6

Page 7

NOTES

Page | 7

Page 8

NOTES

Page | 8

Loading...

Loading...