Page 1

Brewer

Brewer

OPERATOR’S HANDBOOK

Page 2

This handbook contains instructions for the GEVALIA Brewer .

Please read the handbook before using the machine.

OPERATOR’S HANDBOOK

Keep this fold out page open while reading the Operator’s Handbook.

Page 3

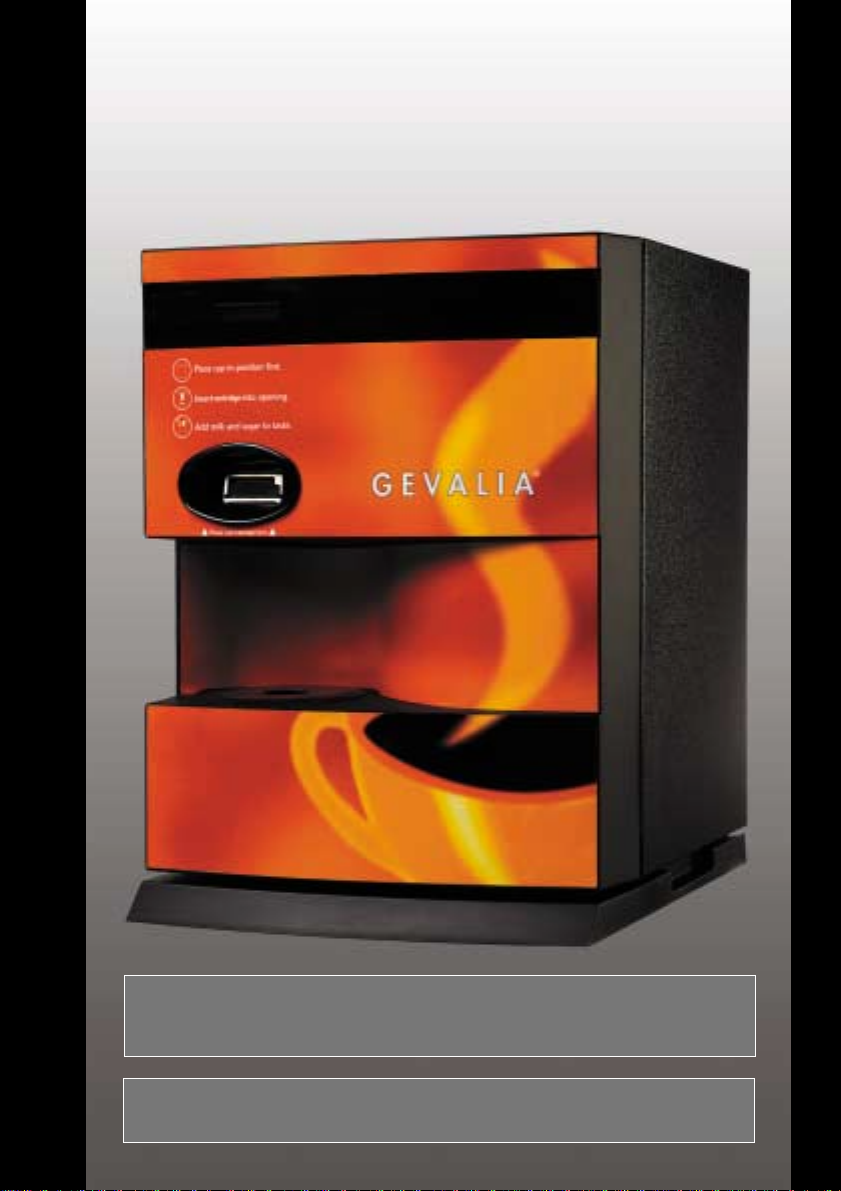

Machine Layout

Display

Capsule

Entry Slot

External Features

Power Cord

Cup Fill

Position

Door

Program

Button

Reset Button

Brew Mechanism

Release Catch (see

page 8 for detail)

W ater Inlet

Fitting

Internal Features With Door Open

Over-Temperature

Reset Button

Filling Funnel

Capsule Entry Flap

Tank Drain T ube

Capsule Bin

Spill Sensor

(Behind Capsule Bin)

Tank Overflow Tube

Page 4

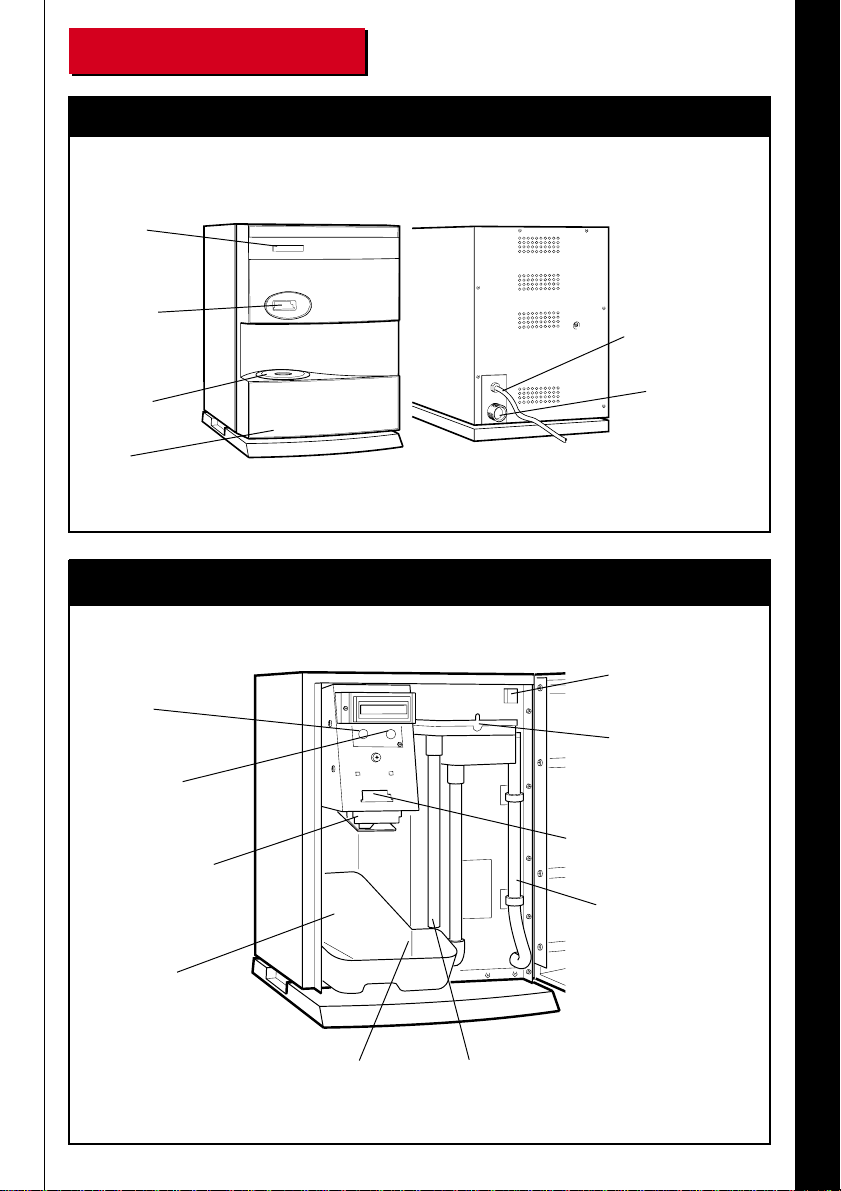

Technical Details

18.3in / 465mm

1.9in / 50mm

16.9in / 430mm

Dimensions

13.8in / 350mm

ELECTRICAL POWER SUPPL Y

The machine operates from a 120 V 50-60 Hz

single phase A.C. power supply.

POWER RA TING

The machine is rated at 1.3 kW for Canada and

either 1.3 kW or 1.6 kW for US only. Current

drawn is approximately 10.8 and 13.3 A

respectively.

W A TER SUPPLY OPTIONS

PLUMBED

1) Flush water line prior to brewer installation.

Connect to a cold water line.

2) W ater pressure should be at least 20 psi. For

less than 25' run, use 1/4" copper tubing and

connect to 1/2" or larger water line. For longer

runs, use 3/8" copper tubing and connect to

1/2" or larger water line and provide an

adaptor fitting for connection to the brewer.

3) If installed with a saddle valve the port should

have a minimum of 1/8" port hole for up to

25' run and 5/16" port hole for over 25' run.

4) Connect water line to plumbing fitting

extending from the rear of the brewer.

MANUAL FILL

Jug Fill - the machine may be filled manually

by opening the front cover to expose the filling

funnel. The tank has an average working

capacity of 30 cups between refills.

CAPSULE BIN CAP ACITY

The capsule bin will hold up to thirty capsules.

Capacity can be increased by mounting the

machine on a base cabinet with built in trash

bin.

WEIGHT

Filled with water: 53 lbs / 24kg.

Empty: 40 lbs / 18kg.

CAUTION: This machine should not be

used with artificially softened water.

Page 5

Do Not Print

Do Not Print

This

This

Page

Page

OPERATOR’S HANDBOOK

Page 6

Contents

Machine Layout Inside Front Cover

Technical Details Inside Front Cover

Important Safeguards 3

Setting Up 4

How to Get a Drink 6

Daily Maintenance 7

Weekly Maintenance 8

Adjusting Drinks Volume 10

Drinks Counter 1 0

What T o Do If Things Go Wrong 11

Display Messages 1 2

Customer Service 1 6

OPERATOR’S HANDBOOK

1

Page 7

OPERATOR’S HANDBOOK

2

Part No. 792440/1

Page 8

Important Safeguards

When using your Brewer, always follow these basic safety precautions:

1. Read all instructions before using the machine, and ensure that anyone who will

be involved with the cleaning or refilling of the machine also reads the

instructions.

2. This machine may contain up to 1-1/3 gallons of very hot water (up to 205° F).

Therefore, supervision should always be available when the machine is being

used near young children, the aged, or the infirm.

3. The machine should be situated on a strong horizontal surface, at a convenient

height, in a position where it is not likely to be knocked off.

4. The Power Cord should never trail from the machine, and should always be kept

away from hot surfaces and sharp edges.

5. Do not operate the machine if any part is damaged, e.g. Power Cord, until it has

been checked by a qualified Technical Service Representative.

6. Allow the machine to cool before handling or moving.

7. Never immerse the machine in water, or any other liquid, and never clean with a

water jet.

8. If the machine should accidentally freeze up, call a Technical Service

Representative to check it before switching on.

AL W A YS DISCONNECT THE MACHINE FROM THE ELECTRICAL POWER

SUPPL Y BEFORE CLEANING AND SER VICING.

OPERATOR’S HANDBOOK

3

Page 9

Setting Up

Plumbed In Fill Option

Ensure water connection is made and

water is turned on.

Press and hold the Program button, and at

the same time, plug the power cord into

the wall socket.

Machine will display

Release Program button and press Reset

button to scroll through options (which

alternate between Plumbed and Manual)

until the display reads

Press and release Program button to return

to normal operation. Water will fill into

machine until display reads

After a delay of approximately 15-20

minutes, the display will show 'Ready' and

the machine can be used.

OPERATOR’S HANDBOOK

4

or

Page 10

Manual Fill Option

Press and hold Program button and, at the

same time, plug the power cord into the

wall socket.

Machine will display

Release Program button and press Reset

button to scroll through options (which

alternate between Plumbed and Manual)

until the display reads

(i.e. filled by hand into the fill funnel)

Press and release the Program button to

return to normal operation.

When display shows

Pour water into funnel, as shown, until

water is level with the 'full' mark on the

side of the fill funnel.

Display will then show

After a delay of approximately 15-20

minutes, the display will show 'Ready' and

the machine can be used.

or

OPERATOR’S HANDBOOK

5

Page 11

How To Get A Drink

1. Place a cup in the correct

position on the cup grille.

2. Hold capsule as shown, label side

up.

3. Insert capsule, pointed end first,

fully into the slot above the cup

station.

The capsule will be automatically

drawn into the machine, and will

commence brewing.

4. The drink will now be delivered

into the cup. The capsule will

be disposed of automatically.

Add milk and sugar as required.

OPERATOR’S HANDBOOK

6

Page 12

Daily Maintenance

Emptying The Capsule Bin

The capsule bin holds thirty capsules, and should, therefore, be emptied and cleaned daily. If the

bin becomes full, the machine's display will read:

The capsule bin is full. Open the front door, remove the bin (fig i), and dispose of the contents.

Replace bin, after washing in warm water. If 'Check Bin' message persists, switch off the machine

and check underneath the brew mechanism to ensure a capsule is not still trapped. Remove the

offending capsule, close the front door, switch on

the machine and it will reset automatically.

NOTE: This automatic warning feature will not

normally work on the optional base cabinet with

the bin inside the cabinet; this must be checked

daily by the key operator.

fig. i

Pull

Cleaning The Cup Station

Remove the cup stand and drip tray (fig. ii), and wash in warm, soapy water before replacing.

Ensure it is correctly located.

fig. ii

Cup Stand

Drip tray

OPERATOR’S HANDBOOK

7

Page 13

Weekly Maintenance

Cleaning The Clamp Assembly

WARNING: ALWAYS DISCONNECT THE MACHINE FROM THE ELECTRICAL

SUPPLY BEFORE CARRYING OUT THIS OPERATION.

For weekly cleaning, or in the unlikely event of a capsule jamming, switch off the machine, open

the door and remove the capsule bin, and lower the clamp assembly as follows:-

Place your thumb on the front cover of the

brew mechanism and your forefinger behind

the plastic latch. Unclip the latch by closing

your thumb and forefinger. Gently lower the

clamp plate assembly (fig. i).

CAUTION!! When the clamp plate

assembly is lowered, or removed, sharp

cutting teeth are exposed - handle with

care!

fig. i

With the clamp plate assembly lowered,

if you are clearing a jammed capsule,

you will now see whether a capsule is

2 - SLIDE FORWARDS

1 - LIFT

fig. ii

CAUTION!!

Sharp Edges

jammed inside. Carefully remove any

jammed capsules with your fingers - do

not use sharp instruments or tools in the

mechanism!

To unhook the clamp plate assembly,

firmly grasp it by the sides (fig. ii),

taking care not to touch the cutting

edges. Swing the clamp plate towards

you, to an angle of approximately 45°,

then lift and slide it towards you,

keeping it at the same angle.

OPERATOR’S HANDBOOK

8

Page 14

With the clamp plate assembly removed, the

clamp plate should be thoroughly cleaned,

paying particular attention to ensure that the

cutting teeth are clean.

A

fig. iii

If necessary the lower clamp plate can be split

to allow more thorough cleaning; simply push

in the two plastic lugs (fig. iii A) and the clamp

plate should unclip.

To re-assemble, push in the two plastic lugs

and snap the clamp plate back into position.

Whilst the clamp plate assembly is removed from the machine, look underneath the brewing

mechanism on the machine, and clean the underside of the brewing mechanism.

A

A

To replace the clamp plate assembly after

cleaning, look underneath the machine to

locate the hinge grooves (fig. iv A) either side

of the brewing mechanism. Holding the clamp

plate assembly in the palm of your hand, at

an angle of 45°, align the clamp plate hinges

(fig. iv B) with the hinge grooves and slide

the assembly backwards, whilst still holding

the clamp plate assembly at 45°, until it drops

on the hooks (fig. iv C). The clamp assembly

will swing freely if it is correctly located.

C

fig. iv

fig. v

B

Close the mechanism by placing your forefinger

behind the tab on the clamp plate assembly and

raising it upwards, towards you. With the clamp

plate in the 'up' position, place your thumb on the

latch and, whilst keeping your forefinger behind

the tab on the clamp plate assembly, snap the latch

shut (fig. v). Close the door and switch on the

machine.

OPERATOR’S HANDBOOK

9

Page 15

Adjusting Drinks Volume

If, for any reason, you wish to adjust the drinks

level, open the front door to gain access to the

program button:

Press and hold the program button for five

seconds.

Release the program button and the display will

show:

Press the reset button to increase the drinks level.

On reaching maximum, the levels will

automatically decrease in stages back to

minimum. Select the desired level, then press

the program button to return to operating mode.

!

W ater T emperature

Up T o 205°F / 96°C

Drinks Counter

Press the program and reset buttons together.

The display will remain for as long as you press

both buttons.

Release both buttons to return to normal

operation.

Note: The counter cannot be reset.

OPERATOR’S HANDBOOK

10

Page 16

What To Do If Things Go Wrong

In the unlikely event of a problem occurring, your machine will attempt to diagnose the fault and

display the appropriate message.

Try to identify the fault shown on the display with one of those illustrated on the following pages,

and follow the remedial course of action. Most of these problems can be solved by clearing the

cause of the fault, and pressing the reset button, or unplugging the machine from the electrical

outlet and then back in again after five seconds delay.

If, however, you require the assistance of a T echnical Service Representative, please help us to

help you by noting the cause of the problem and the circumstances under which it occurred. This

will help our Service Representative assess the situation more clearly.

OPERATOR’S HANDBOOK

11

Page 17

12

OPERATOR’S HANDBOOK

or

Display Messages

The machine is heating or filling the

water tank. This should take no more

than 15-20 minutes.

(manual fill machine only)

The capsule entry flap has locked

due to lack of water in the tank.

Refill the tank with water and the

machine will operate normally after

heating up the water.

The capsule bin is full.

NOTE: This automatic warning

feature will not work on machines

mounted on the optional base

cabinet. The bin inside the cabinet

must be checked daily by the key

operator.

Open the door, remove the capsule

bin, dispose of the contents, and

replace capsule bin.

If ‘CHECK BIN’ message persists,

switch off the machine and check

underneath the brew mechanism to

ensure a capsule is not still trapped

(see 'Cleaning the Clamp Assembly'

on page 8). Remove the offending

capsule, switch on the machine and

it will reset automatically .

Page 18

or

W ater or cof fee has leaked into the base

tray of the machine, either from the

capsule bin area or from the workings of

the machine itself.

Switch off the machine.

Open the door and remove the capsule

bin. Thoroughly dry the base tray using

absorbent paper towels. Pay particular

attention to the spill sensor, and dry it

thoroughly. Switch the machine on and it

will reset automatically.

If the fault recurs, and fresh clear water

is seen in the base tray area, disconnect

the machine from the power supply and

close the water tap.

Call a T echnical Service Representative.

There is a capsule in the entry flap

of the brew mechanism, or the

capsule entry flap is stuck open.

Remove the capsule from the entry

flap, or if the capsule entry flap is

stuck open, switch off the machine,

open the front door, and remove the

clamp assembly (see 'Cleaning the

Clamp Assembly' on page 8). Clear

away any obstacle holding the

capsule entry flap open and pull the

entry flap forward until it is in the

closed position. Reassemble the

clamp and close the door.

Switch on the machine to revert to

normal operation.

* may be any number from 1 - 9.

Switch off the machine, remove the

clamp, clear any jammed capsules

and replace the clamp.

Switch on the machine.

If the problem persists, call a

T echnical Service Representative.

13

OPERATOR’S HANDBOOK

Page 19

14

OPERATOR’S HANDBOOK

or or

Display Messages (cont.)

The lower plate of the brew mechanism

has been lowered or removed.

Switch off the machine.

Open the door, replace and close the

lower clamp plate.

Take care when handling the lower

plate as it has sharp cutting edges!

Switch on the machine.

An internal error has occurred.

Switch off the machine. After a delay of

5 seconds switch on again, this should

reset the machine.

If the problem recurs, call a Technical

Service Representative.

The machine has been trying to heat the

water for 20 minutes without success.

This suggests that the over-temperature

reset button has tripped, or the element

has failed.

Press the RED over-temperature reset

button situated on the top right hand side

panel, inside the main front door.

PRESS THE RESET BUTTON.

If the problem recurs after a further 20

minutes, SWITCH OFF THE

MACHINE, and call a Technical

Service Representative.

Page 20

or

or

(plumbed in machine only)

Ensure water supply is turned on.

Press the RESET button to return

machine to normal mode.

Pressure built up within the capsule while

brewing, the brewing cycle was stopped

and the capsule was ejected into the bin.

The customer may have received either

a short measure or possibly no drink at

all.

Switch off the machine and, after

following the instructions for ‘Cleaning the

Clamp Assembly’ (on page 8), close the

main door and switch on the machine.

If the fault recurs, call a Technical Service

Representative.

15

OPERATOR’S HANDBOOK

Page 21

Customer Service

Fault Rectification

Should you require the assistance of a Technical Service Representative, after

checking the ‘Display Messages’ (see Contents page), please contact the Newco

customer serice department at:

Telephone 800-325-7867

Fax 636-925-0029

Outside normal business hours, a telephone answering service is available.

If you wish to write to us, the address is:

Newco Enterprises, Inc.

1735 S. River Rd.

St. Charles, MO 63303 USA

OPERATOR’S HANDBOOK

16

Page 22

OPERATOR’S HANDBOOK

Page 23

OPERATOR’S HANDBOOK

Loading...

Loading...