Page 1

DB2A INSTALLATION

REV 3-29-2006

DUAL BREWER AUTOMATIC

DB2A

INSTALLATION, OPERATION, AND TROUBLESHOOTING MANUAL FOR

DB2A AUTOMATIC BREWER WITH WARMERS & POUR-OVER

Model DB2A

8-1/2 W x 18 D x 33 H

4700 Total Watts, 23.3 AMPS

120/208 V

Ship Wt approx. 54 LB’s

Decanters Not Included

Page 2

2

Page 3

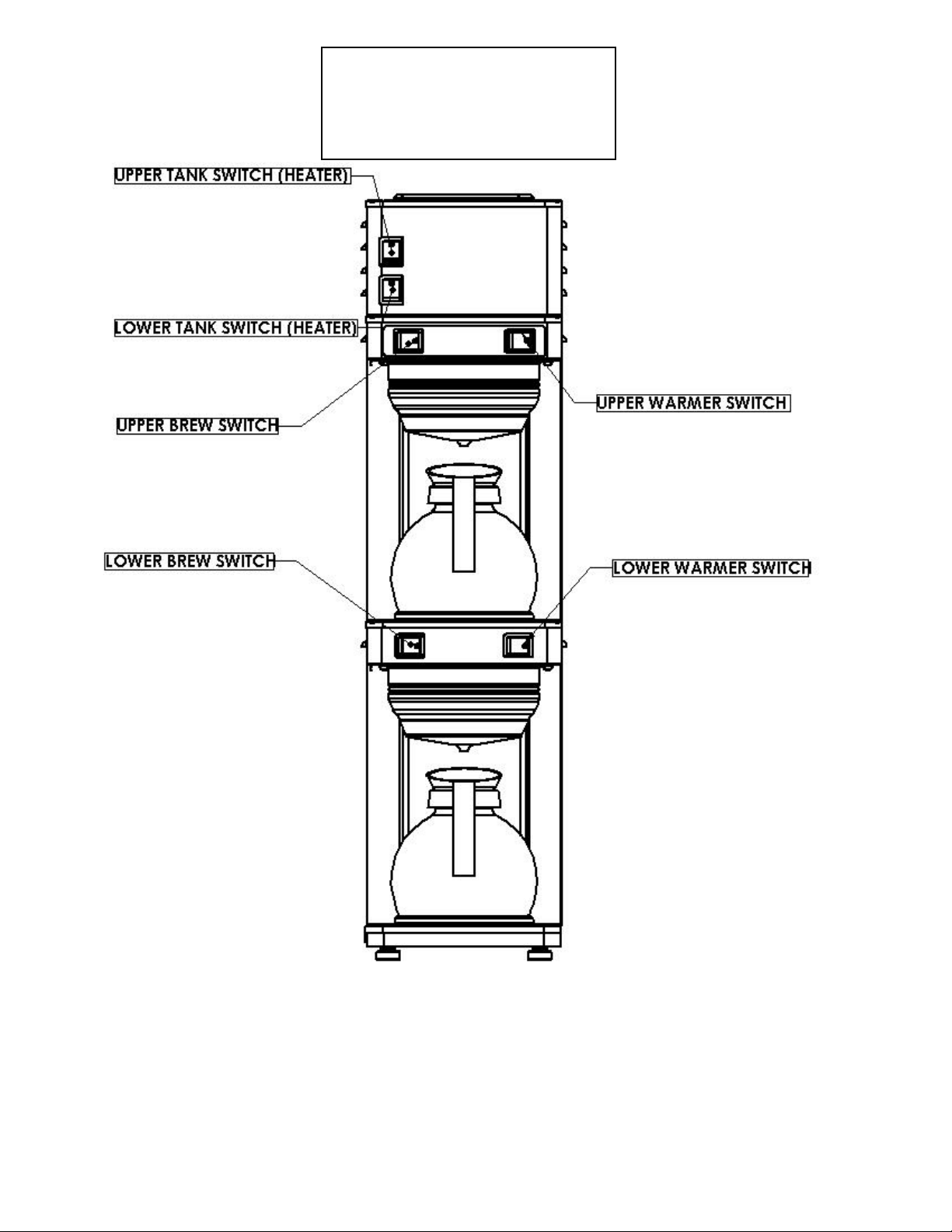

DB2A

CONTROL SWITCH

LOCATIONS

3

Page 4

PLUMBER'S INSTALLATION INSTRUCTIONS

CAUTION:Disconnect Power to brewer before proceeding with plumbing installation.

1) Attach water line to bottom PDS valve , rear of brewer .

2) Flush water line before installing brewer. Brewer should be connected to COLD WATER LINE for best operation.

3) Water pressure should be at least 40 lbs. For less than a 25 ft run, use 1/4" copper tubing and connect to 1/2" or larger water

line. For longer runs, use 3/8" copper tubing & connect to 1/2" or larger water line and provide an adapter fitting for

connection to the brewer. A dedicated water line is necessary for this machine.

4) If installed with saddle valve, the valve should have a minimum of 1/8" port hole for up to 25 ft run, and 5/16" port hole for

over 25 ft runs.

5) Manufacturer recommends connecting to copper tubing.

INSTALLATION INSTRUCTIONS

UPPER TANK SWITCH

WARNING: - Read and follow installation instructions before plugging or wiring in machine to electrical circuit. Warranty will be

dbvoid if machine is connected to any voltage other than that specified on the name plate.

FILL BREWER TANK WITH WATER BEFORE TURNING TANK THERMOSTATS OR HEATER SWITCHES ON !

1) Brewer is shipped with thermostat turned OFF, (full counter-clockwise position). Plug or wire in machine to appropriate

voltage as noted on the brewer serial tag. Serial tag is located on side of brewer.

2) Adjust timer to deliver desired amount of water (Timer is located behind front access panel). To brew into a regular 64 oz.

decanter little adjustment should be needed. Turn timer dial clockwise to increase volume of water, and counter clockwise to

decrease volume.

3) Place the decanters under brew baskets, turn on bottom two warmers, and using brew switches brew three brew cycles or

until water starts to drain into decanters.

4) Turn on tank heater switches. Allow 10 to 15 minutes for water in tank to heat to brewing temperature. (Additional water

may drip from brew baskets on initial expansion of water in the tanks). This will not occur thereafter.

5) After water has reached brewing temperature, thermostat will click off, heating noise will stop. Empty decanters and depress

brew start switches and run a cycle of water to remove expanded water from tanks. (Brew cycle may be canceled by turning

the warmer rocker switch back to the OFF position.)

6) Run one cycle for each tank to check for the proper temperature setting with an accurate thermometer. Take the temperature

of this water at a point below the brew basket opening, at the start of the brew cycle and when the decanter is half full.

Recommended temperature of the water is approximately 195 F. Adjust brew volume by adjusting the brew timer up or

down .

7) In higher altitude locations (5000 feet above sea level) the thermostat may have to be adjusted lower to prevent

boiling.

8) Water volume may need readjustment after brewing a decanter of coffee. (See next page)

4

Page 5

COFFEE PREPARATION PROCEDURES

1) Place filter into brew basket.

2) Put the proper amount of coffee into the filter.

3) Slide the brew basket into holder.

4) Place empty decanter on warmer located directly under the brew basket and turn corresponding warmer switch to ON

position.

5) Press “Brew” switch, switch will beep, and amber light will blink.

6) Hot water will be delivered through the sprayhead. This distributes the hot water evenly over the coffee bed within the brew

basket. The coffee brew will drain from the brew basket into the decanter below.

7) The resultant coffee brew should be crystal clear and have the desired properties attainable through excellent extraction.

8) TURN OFF WARMER WHEN NOT IN USE. (Red light indicates warmer is on.)

9) To clean brew basket simply remove from brew rails and dump filter into waste basket. The brewing process, as described

above, can now be started again.

DELIMING

To prevent liming problems in tank fittings remove sprayhead and insert deliming spring all the way into the tank. When

inserted into tank properly, no more than ten inches of the spring should be visible at the sprayhead fitting. Saw back and forth five or

six times. This will keep fittings open and clear of lime. In hard water areas this should be done everyday. This process takes

approximately one minute. In all areas the sprayhead should be cleaned at least once a week. Where bad liming has already occurred,

a new complete tank assembly may be installed. Deliming spring will not go in overflow orifice. (see diagram below)

Sprayhead

outlet

DELIMING SPRING PN 120127 (INCLUDED)

WARRANTY

Refer to Warranty Agreement between TDL Group, BBC Sales, and Newco Enterprises.

Overflow

orifice

5

Page 6

TROUBLE SHOOTING GUIDE

SYMPTOM POSSIBLE

CAUSE

CAN'T START BREW CYCLE

NO HOT WATER

DRIPPING

STEAMING OR SPITTING

AROUND FUNNEL

WATER KEEPS RUNNING

1. No water.

2. No power.

3. Warmer switch not on

4. Brew start switch.

5. Timer or timer harness.

6. Solenoid valve.

1. Tank heater.

2. Hi-limit thermostat or main

thermostat.

1. Not siphoning properly.

2. Solenoid valve not seating

properly.

1. Main thermostat.

2. High altitude.

1. Solenoid valve.

2. Start switch.

3. Timer

WHAT TO

CHECK

1. Incoming water lines & water shut

off valve.

2. Fuse or circuit breaker.

Power cord and plug connections.

3. Switch is on and lighted red,

continuity

4. Switch continuity.

(Normally closed.)

5. Wire leads to solenoid and

white 3-pin connector.

6. (A) Voltage at solenoid valve

terminals. Start a brew cycle and

check for 120 volts AC.

(B) If voltage is present at

terminals, check for water at line

pressure on the inlet side of

solenoid valve.

1. Check the voltage at the tank

heater terminals. Voltage should be

as indicated on the serial tag (on

rear of brewer.)

2. Check the voltage between the

VIOLET/RED wire on the tank

element and the incoming terminal

(VIOLET/BLACK) on tthe hi-limit

thermostat, then the outgoing

terminal (VIOLET/BLACK) on the

hi-limit thermostat.

1. Water should flow freely from the

sprayhead.

2. Solenoid valve assembly .

1. Thermostat points stuc k or out of

calibration.

2. Located above 5,000 feet.

1. Refer to "DRIPPING", Step 1.

2. Remove wires from switch an d

check continuity.

3. Solid state timers are not

repairable. If timer will not shut

off, replace timer.

REMEDY

1. Be sure water shut off is open.

2. Replace or reset circuit protector

3. If warmer switch does not make and

break contact, replace warmer switch.

4. If brew start switch does not make and

break contact, replace brew start switch.

5. Make sure these connections are tight. If

so, and all else checks out OK, replace

timer.

6. (A) If voltage is not present at terminals,

refer to steps 2 through 5.

(B) If voltage is present at terminals and

water at line pressure is present on the

inlet side of the solenoid, but not present

on the outgoing side, replace solenoid.

1. (A) If correct voltage is present at the

tank heater terminals and water in tank is

not being heated, replace the tank heater.

(B) If voltage is not present at the tank

heater terminals refer, to step 2.

(C) If incorrect voltage is present at the

tank heater terminals, check voltage at

outlet.

2. (A) If voltage is present on the incoming

terminal of the hi-limit t hermostat, but

not on the outgoing terminal, replace the

hi-limit thermostat.

(B) Check voltage at the terminal blocks.

If voltage is not present check outlet or

circuit breaker.

(C) If voltage is not present on the

incoming terminal of the hi-l imit

thermostat, replace the main thermostat.

1. (A) Clean sprayhead holes.

(B) Check tightness of sprayhead tube.

(C) See "DELIMING" , Page 5.

2. Be sure spring is in place and any

particles are cleaned from valve seat. If

valve seat is worn or mutilated, replace

solenoid valve.

1. (A) Adjust thermostat.

(B) Thermostat should be calibrated or

replaced.

2. See "INSTALLATION

INSTRUCTIONS", Page 4..

1. Refer to "DRIPPING", Step 1.

2. If start switch does not m a ke and break

contact, switch should be replaced.

3. Replace timer.

6

Page 7

TROUBLE SHOOTING GUIDE

SYMPTOM POSSIBLE

CAUSE

IRREGULAR YIELD

DRY COFFEE REMAINING

IN BREW BASKET AFTER

BREWING

WEAK COFFEE

SOLENOID CHATTER OR

HOWLING

COLD WARMER STATION

1. Not siphoning properly.

2. Timer.

3. Fluctuating water pressure.

4. Solenoid valve.

5. PDS valve

1. Filters.

2. Not siphoning properly.

3. Improper loading of the brew

basket.

1. Filters.

2. Not siphoning properly.

3. Improper loading of brew basket.

1. Brewer connected to hot water

line.

2. Vibration.

3. High water pressure.

4. Water hammer.

5. 60 cycle vibration.

1. Warmer - defective.

2. Warmer ON/OFF Switch.

3. Bad harness.

WHAT TO

CHECK

1. Refer to "DRIPPING", Step 1.

2. Timer consistency. Time several

brew cycles.

3. Water pressure.

4. Refer to "DRIPPING", Step 2.

5. Possible defective flow

control.

1. Are correct filters being used.

2. Refer to "DRIPPING", Step 1.

3. Filter and coffee in brew basket.

1. Are correct filters being used.

2. Refer to "DRIPPING", Step 1.

3. Filter and coffee in brew basket.

1. Incoming water line.

2. If brewer is on a metal stand or

counter, neither the bottom pan

nor copper tubing to the brewer

should touch the counter.

3. Water pressure on incoming line.

4. Incoming plumbing.

5. Nut on top of solenoid.

1. Voltage at warmer terminals

should be 120 volts AC.

2. If voltage is not present on warmer

terminals, check continuity of

switch.

3. Check connections betwe e n

harness and switch, and betw een

switch and warmer.

REMEDY

1. Refer to "DRIPPING", Step 1.

2. If times are irregular, replace timer.

3. If pressure fluctuates 10-20 PSI d uring

operation of brew cycle, add a pressure

regulator to inlet side of brewer , set to

lowest pressure level registered. Adjust

timer to yield correct water level.

4. Refer to "DRIPPING", Step 2.

5. Replace PDS valve

.

1. Insert correct filter.

2. Refer to "DRIPPING", Step 1.

3. Filter should be centered in the brew

basket and coffee bed should be le vel.

1. Insert correct filter.

2. Refer to "DRIPPING", Step 1.

3. Filter should be centered in brew basket

and coffee bed should be level.

1. Brewer should be connected to cold

water line.

2. Adjust as necessary.

3. If water pressure is over 90 PSI install a

pressure regulator and adjust to 50 PSI.

4. This is not the fault of the brewer an d can

usually be corrected by rearranging some

plumbing or adding an air chamber to

the incoming water line.

5. Nut should be tight. Tighten as required.

1. If voltage is present on terminals, but

warmer will not heat, replace w a rmer.

2. If switch does not make and brea k

continuity when turned off, replace

switch.

3. All connections should be tight.

7

Page 8

DB2A

ACCESS

PANEL

COMPONENTS

8

Page 9

REPLACEMENT

PART DIAGRAM

FRONT VIEW

9

Page 10

REPLACEMENT

PART DIAGRAM

REAR VIEW

55

34

4

54

47

33

1

32

3

10

Page 11

REPLACEMENT

PART DIAGRAM

WATER TANKS

5

120079

UPPER TANK ASS'Y

74

27

22

41

120069

LOWER TANK ASS'Y

36

42

23

39

58

11

Page 12

PARTS LISTING

* NOT SHOWN IN DIAGRAMS

PART

ITEM #

# DESCRIPTION ITEM # PART # DESCRIPTION

1 100250 VALVE,SOLENOID (SKINNER) 38 100043 KNOB,THERMOSTAT (102299)

2 110190 BREW TIMER 39 120071 SPHD TUBE ASY,LOWER,DB3A

3 110304 PDS VALVE, LOWER TANK 40 120075 TUBE ASSY,VENT,DB3A

4 110305 PDS VALVE, UPPER TANK 41

5 120048 PAN,REC,PUNCHED,DB3A 42 120106 SPHD TUBE ASY,UPPER,DB3A

6 120049 BASE ASSY,DB3A 43 120109 TERMINAL BLOCK SCREW/TAB

7 100010 PLATE,WARM ASSY BLK 44 120089 TUBE ASSY, FILL

8 111377 FOOT,APPLIANCE,3/8-16 X 1 45 120153 BASKET, SS, SMALL, FRENCH LBL

9 111667 NUT,3/8-16 JAM,ZPS 46 120088 TUBE ASSY,SOLENOID,DB3A

10 120050 BASE BOTTOM,DB3A 47 120090 TUBE ASSY,PDS TO PDS,DB3A

11 120051 BASE TOP,DB3A 48 120092 HARN,UPPER WARMER,DB3A *

12 120052 COLUMN,LOWER,DB3A 49 120093 HARN,POWER,LOWER,DB3A *

13 120053 PLATE,ACCESS,DB3A 50 120094 HARN,POWER,UPPER,DB3A *

14 120109 BLOCK,TERMINAL SCREW TAB 51 120095 HARN,MAIN,UPPER,DB3A *

15 120055 PLATE,BREW,SPTWLD,DB3A 52 120096 HARN,MAIN,LOWER,DB3A *

16 120057 RAIL,BREW,LH,DB3A 53 120097 BRACKET,SOLENOID,DB3A

17 120058 RAIL,BREW,RH,DB3A 54 120098 BRACKET,LOWER,INLET,DB3A

18 120059 WRAPPER,SPTWLD,DB3A 55 120099 BRACKET,UPPER,INLET,DB3A

19 120091 HARN,WARM&TIMER SWI,DB3A 56 151590 CORD ASY,240V,30A,CM BAR *

20 781431

21 781870 SWITCH. TANK POWER, GREEN

22 704221 GASKET,TANK SILICONE 59

23 704119 TANK,ONLY,K-STYLE 60

24 120061 BASE/COVER,TOP,DB3A 61

25 120062 COLUMN,MIDDLE,DB3A 62

26 120114 COLUMN,UPPER,DB2A 63

27 111593 THERMO,MAN,RESET,R/AG/TAB 64

28 100015 DISH, POUR-IN ASSY S/S 65 781432 SWITCH, WARMER, RED

29 100019 PLATE, POUR-IN S/S 66

30

100180-1

31 120065 COVER,DB3A 68

32 120066 PANEL,LOWER BACK,DB3A 69

33 120067 PANEL,MIDDLE BACK 70

34 120068 PANEL,UPPER BACK,DB3A 71

35 120085 BRACKET,COMPONENT,DB3A 72

36 100025 GASKET,SPRAYHEAD 73

37 107134

SWITCH,BREWER START- AMBER

58

COVER,ASSY W/CHAIN BLK 67

THERMOSTAT,SUN ASY ,201

74 1

120126-10

57 201128 VALVE, SHUTOFF 1/4 FLARE

120075 TUBE, ASS’Y, VENT, LOWER TANK

201991

120127

100187

100008

120079

120069

101429

100065

100160

110666

100055

100613

511027

781544

20146

ELEMENT MAIN 3000/2250W 240/208V

SOLENOID VALVE REPAIR KIT*

DELIMING SPRING (WITH BALL)*

WARMER ELEMENT*

WARMER PLATE*

UPPER TANK ASS'Y

LOWER TANK ASS'Y

#6 COMBO HD SCREW-COVERS*

#6-32 SCREW-BREW RAILS.*

SCREW, 4-40 X 5/8- WARMER PLATE*

SCREW, 6-32, THERMOSTAT MTG*

SCREW, 4-40 X 3/8, POUR-IN CVR*

10-32 SCREW, SOLENOID MTG.*

SCREW, 8-32 X 3/8, BODY & BRKT*

SCREW, 8-32 X 1/2, TERM BLK MTG*

OVERFLOW TUBE ASS’Y

12

Page 13

DBA2 WIRING DIAGRAM

UPPER ELEMENT

1

1

2

2

3

3

WH

LOWER ELEMENT

1

WH

2

3

BK

4

4

5

5

6

6

BK

4

5

6

BK

VI O

BK

BK

VI O

BK

UPPER TANK

ELEM

LOWER TANK

ELEM

VIO

BK

VIO

BK

VI O

RD

HI-LIMIT

REGULATING

THERMOSTAT

VI O

RD

HI-LIMIT

REGULATING

THERMOSTAT

VIO

BK

VI O

RD

VI O

RD

VI O

BK

MIDDLE WARMER

LOWER WARMER

BK

WH

1

2

3

1

2

3

WH

VI O

BK

WH

VI O

BK

BL

4

5

6

BK

4

5

6

WH

K

WHB

MIDDLE

WARMER

BK

VI O

RD

L1 L2 N E-L1

VI O

RD

WH

WH

BK

LOWER

WARMER

BK

VI O

RD

WH

RD

BK

UPPER BREW

1

2

3

YEL

BK

WH

RD

BK

LOWER BREW

1

2

3

YEL

BK

4

5

6

4

5

6

WH

RD

BK

WH

RD

BK

GREY

WH

VI O

BK

BK

GREY

WH

VI O

BK

VI O

BK

5

4

3

TIMER

2

1

1

2

3

4

5

6

BK

YEL

BK

FILL SOLENOID

BK

VI O

5

4

3

2

1

TIMER

1

2

3

4

5

6

BK

YEL

BK

FILL SOLENOID

GND

L1 L2 N E-L1

BK

GREEN

13

RED

LINE

BK

WH

Loading...

Loading...