Page 1

Mini Cappuccino

Instruction

Manual

Features

• Under 17”

Tall-Fits On

Counter

Under Cabinets

• Programmable Auto Dispense Feature

• Auto Rinse Feature

• Pump Technology for Precise Liquid Control

Date:

- -

03 29 2004

Page 2

Table of Contents

2

Specifications……………………………………Page 3

Unpacking and Start-up………………………..Page 4

Troubleshooting…………………………………Page 6

Product Loading…………………………………Page 7

Machine Operation………………………………Page 8

Cleaning and Sanitizing …………………………Page 10

Service Procedures & Diagrams...………………Page17

Wiring Diagram…………………………………..Page 24

Newco Enterprises, Inc.

3065 New Town Blvd

Saint Charles, MO 63301

Telephone 1-800-325-7867

Technical Support 1-800-556-3926

Fax 1-636-925-0029

Page 3

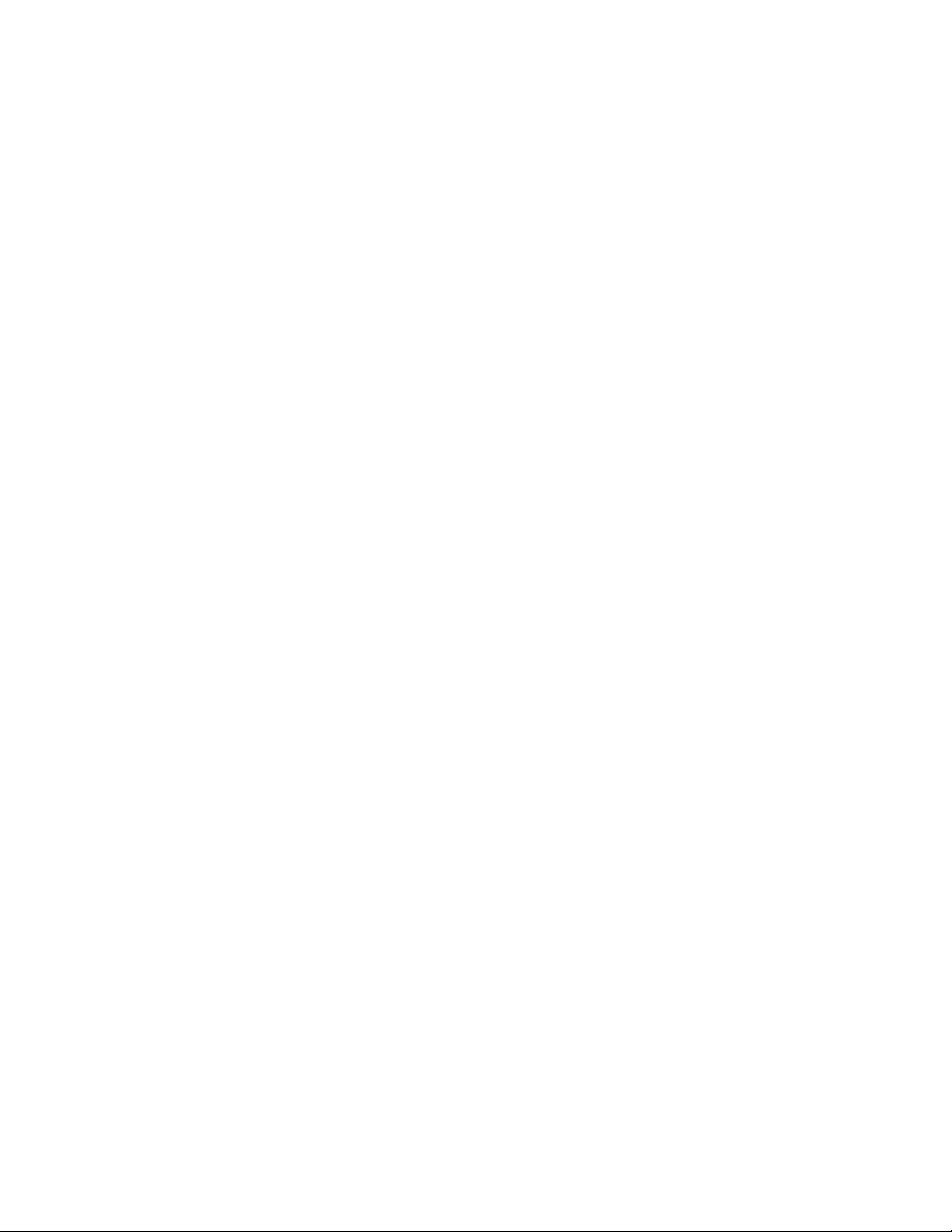

3 # Mach

20 1/8"

+ 4" Legs

24 1/8"

17 1/2"

10 3/4"

MODEL MINI CAP-3

# 771040 (2Lbs)

#781860 (3Lbs*)

SPECIFICATIONS:

Shipping Weight: 39 Lbs

Body Construction: 300 series Stainless

Electrical: 120 VAC 15 A

Heater: 1400 W

Tank Capacity: 1 US Gallon

Products: 3

Canister Size: 2 Lbs *

Dispense Mode: Portion or Manual

4 25/32"

20 1/4"

3

Page 4

ELECTRICAL SPECIFICATIONS

Model No. Mini Cap-3 (#771040)

Volts-120 Phase-single

Hz-60

Heater 1400 w

120V, 1.4 KW, 15A .

UNPACKING INSTRUCTIONS

Carefully unpack the Mini Cap-3 Machine and inspect immediately for shipping damage. Your MC-3

Machine was shipped in a carton designed to give it maximum protection in normal handling. It was

thoroughly inspected before leaving the factory. In case of damage, contact Newco.

INSTALLATION INSTRUCTIONS

Water Inlet Connection:

This equipment is to be installed to comply with the applicable Federal, State, or local plumbing codes

having jurisdiction. In addition:

1. Install the quick disconnect water connection with washer (located in bag kit) to the water inlet outlet

located in upper rear of machine.

2. Install the shutoff/strainer between the water line and the machine insuring the connections do not leak.

Provide enough extra coiled tubing (at least 2x the depth of the unit) so that the machine can be moved

for cleaning underneath.

Level the machine (using the 4 Adjustable Leveling Legs, factory installed).

START-UP PROCEDURE

1. Connect the ¼" dia. copper waterline to the ¼" flare water inlet fitting of the valve, turn water on,

check for leaks.

2. Plug the power cord into a proper receptacle.

3. Activate the Power switch (Toggle Up) located on the left rear of the machine. The tank will start filling.

4. Allow approximately 3-5 minutes for the tank to fill.

If the tank does not fill up within the first 10 minutes an error message will display a blinking LED code.

See Definition of Codes and Troubleshooting Guide.

5. Allow up to 30 minutes for the water to reach a temperature of 180°F.

The heat up time will depend on the water inlet temperature, the input voltage.

While the tank is heating up, remove the 2 lb. product cassettes, load them with product and reposition

them back in the machine (see loading diagram page 7 ).

6. Adjust cup volume settings and water flow rate. (See Operating Instructions page 8)

SANITIZING INSTRUCTIONS:

Sanitizing: All food dispensing units should be sanitized weekly. All parts to be sanitized must be

cleaned first.

To prepare a sanitizing solution: ADD 2 TSP. OF LIQUID CLOROX BLEACH (5.25%

CONCENTRATION) TO 1 GALLON OF WATER AT

ROOM TEMPERATURE (70°- 90°F).

Note: Always start with an unopened bottle of Clorox Bleach since the solution from an opened

bottle has a short life span.

• Soak all parts for a minimum of 3 min. in the sanitizing solution.

• Let all sanitized parts drain and dry naturally. DO NOT WIPE THEM DRY.

• Before using the sanitized unit (or parts) with foodstuffs, rinse all parts thoroughly with water.

Water pipe connecting and fixtures directly connected to a potable water supply shall be sized, installed,

and maintained in accordance with

Federal, Sate, and Local codes (sec tion 7).

4

Page 5

Cleaning

1. Remove the drip tray with grill and empty the contents.

2. Wash and let dry the tray and grill (use a mild dishwasher detergent).

3. Wash and let dry the dispense area.

4. Turn the power switch to ON.

Flushing the Whipper Chambers (See Illustration of Membrane Switch Page 8 )

1. Push and hold any 2 dispense buttons for 3 seconds.

Whipper will run briefly to show this has been done.

2. Push and hold any dispense button to flush.

Flush will stay active as long as button is held.

3. Flush mo de will end after 3 seconds of inactivity.

Whipper will run briefly to show the mode has ended.

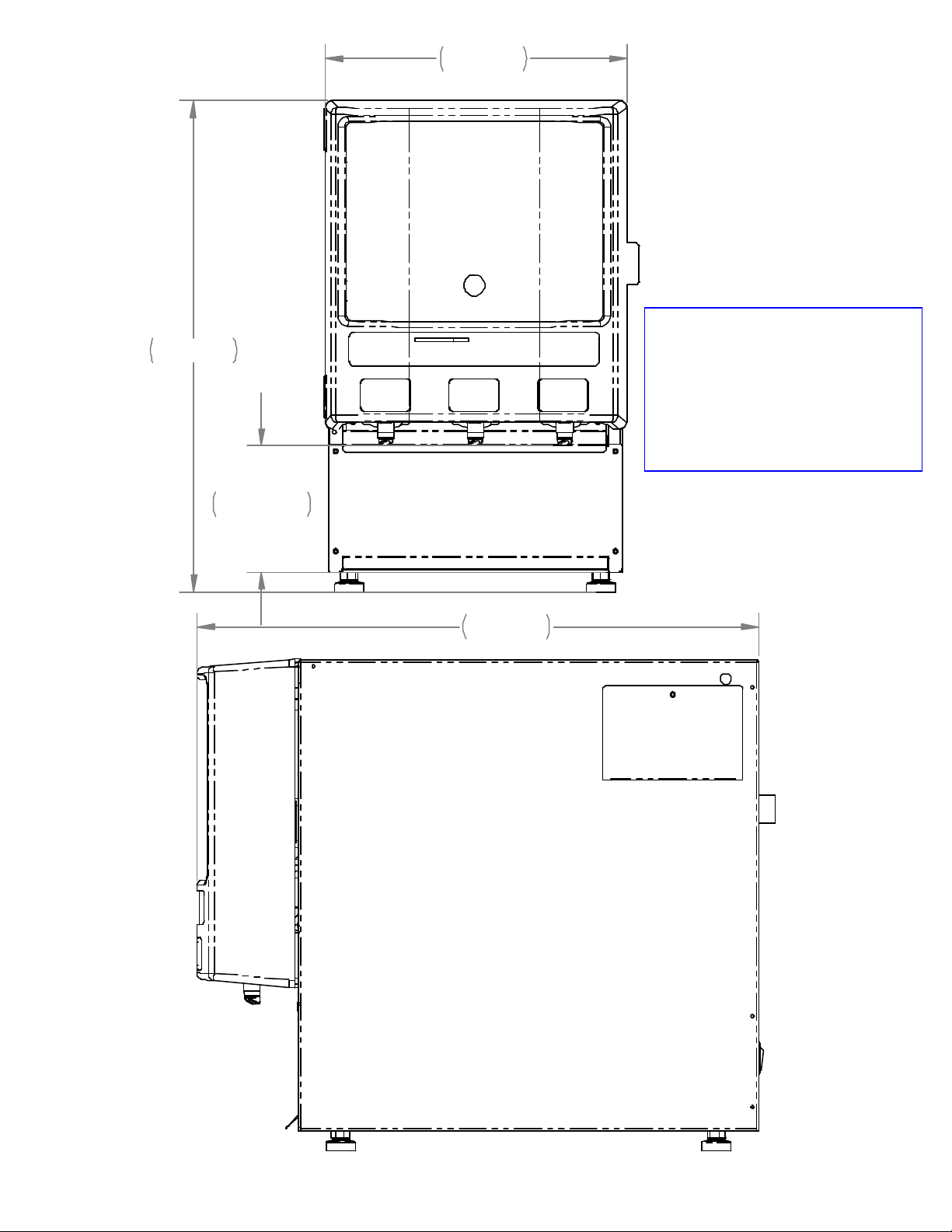

Removing and Cleaning the Whipper Chambers (See Illustration Below and on Page 12)

1. Remove the steam cap by turning while on whipper bowl, then remove cap by pulling it

upward.

2. Remove the whipper bowl by lifting upward to free from mixing chamber, then away from

machine to disengage bowl stem from water outlet.

3. Turn the mixing chamber clockwise to disengage from whipper base and remove.

It is important that these two keyways are lined up when re-assembling the components.

5

Page 6

TROUBLESHOOTING GUIDE

WARNING: To reduce the risk of electrical shock unplug the dispenser power cord before

repairing or replacing any internal components of the unit. Before any attempt to replace a

component be sure to check all electrical connections for proper contact

Error Codes:

1 blink = water fill run-on (8 minute initial time, 20 seconds thereafter)

2 blinks = heater rise error (temperature increase within 4 minutes)

3 blinks = thermistor shorted or reading out of range (over 215*F)

4 blinks = thermistor open or reading out of range (under 32*F)

Temperature range on this machine is adjustable from 150 – 195 degrees F.

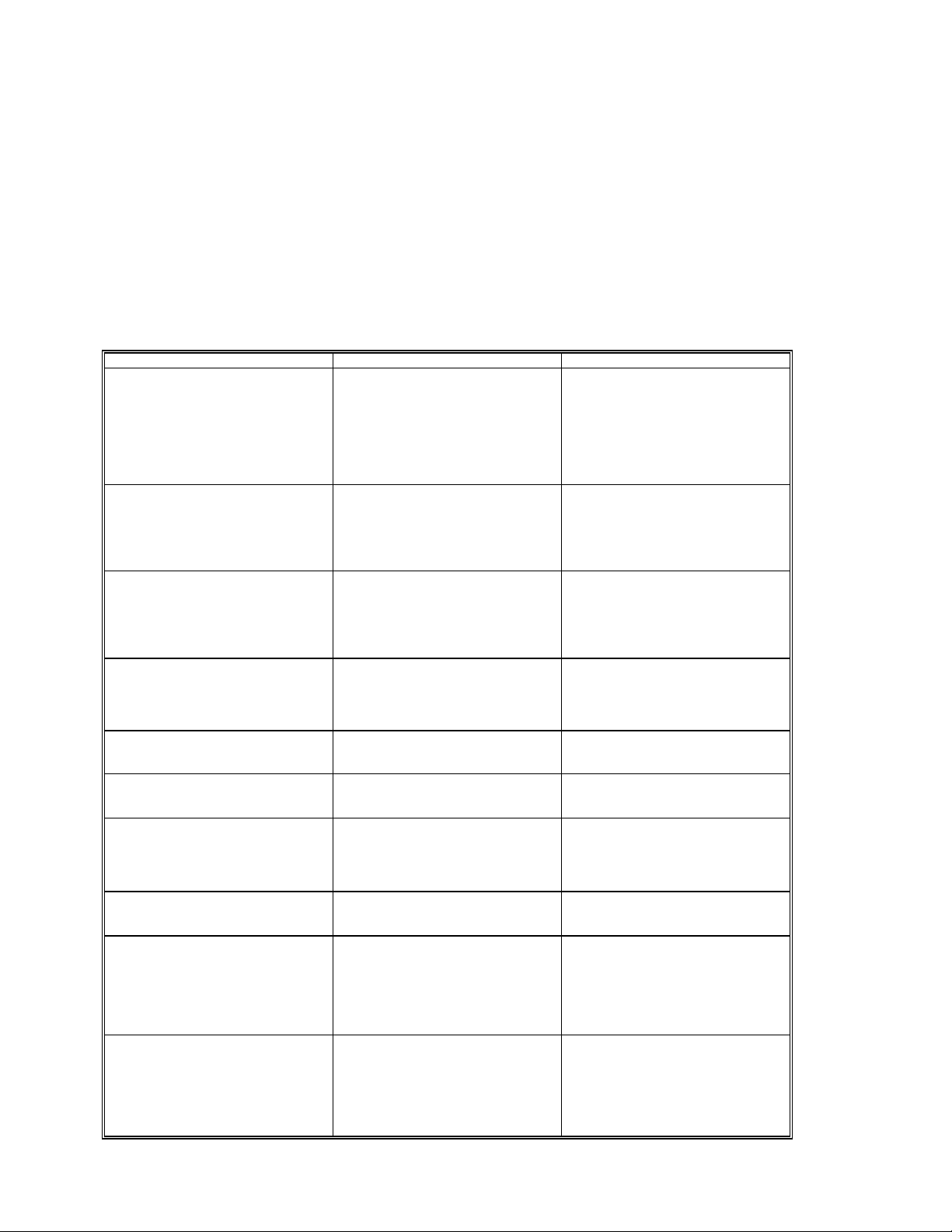

PROBLEM PROBABLE CAUSE REMEDY

1. No water a)

Water turned off

b)

Water line not connected

c)

Faulty water inlet valve

a)

Turn water on –open shutoff

valve

b)

Ensure water line is

connected

c)

Check valve and

connections-replace if

necessary

2. No water one channel only a)

3. Water not hot a)

4. Water does not shut off a)

5. Drink too strong a) Water pump adjustment

6. Drink too weak a) Water pump adjustment

7. Drink not whipped a)

8. Exhaust fan does not turn a)

9. Noise coming from whipper a)

Loose connection @ water

pump

b)

Loose connector on main

board

c)

Faulty dispense pump

Temperature setting too low

b)

Heater overload tripped

c)

Defective heater element

Liquid level probe

malfunction

b)

Faulty water inlet valve

settings incorrect

settings incorrect

No whipper blade

b)

Whipper motor connection

c)

Whipper motor bad

Fan motor connection

b)

Fan motor bad

Whipper chamber not

seated

b)

Slinger washer pushed on

motor shaft too far.

c)

No whipper blade

a)

Check connectors @ water

pump (see page 21 & 22 )

b)

Make sure harness is

seated and locked

c)

Replace water pump (PN

781690)

a)

Adjust temperature setting

(see instructions page 9)

b)

Reset hi-limit thermostat

(Call Newco )

c)

Replace heater element

(Call Newco)

a)

Check probe connections

(see page 21)

b)

Check valve and

connections-replace if

necessary

a) Adjust water pump (see

page 9)

a) Adjust water pump (see

page 9)

a)

Install whipper blade

b)

Inspect whipper motor

connections @ motor and

@ board plug-in

c)

Replace whipper motor

a)

Inspect fan motor

connections @ motor

b)

Replace fan motor

a)

Reseat whipper chambersee whipper cleaning

instructions

b)

Check gap at slinger

washer (see page 12)

c)

Install whipper blade

10. Membrane Switch does not work a)

b)

c)

No power to machine

Power switch turned off

Machine is in error mode

6

a)

Make sure machine is

plugged in and control

board has power

b)

Turn switch on

c)

Check for error signal,

correct and repower

machine

Page 7

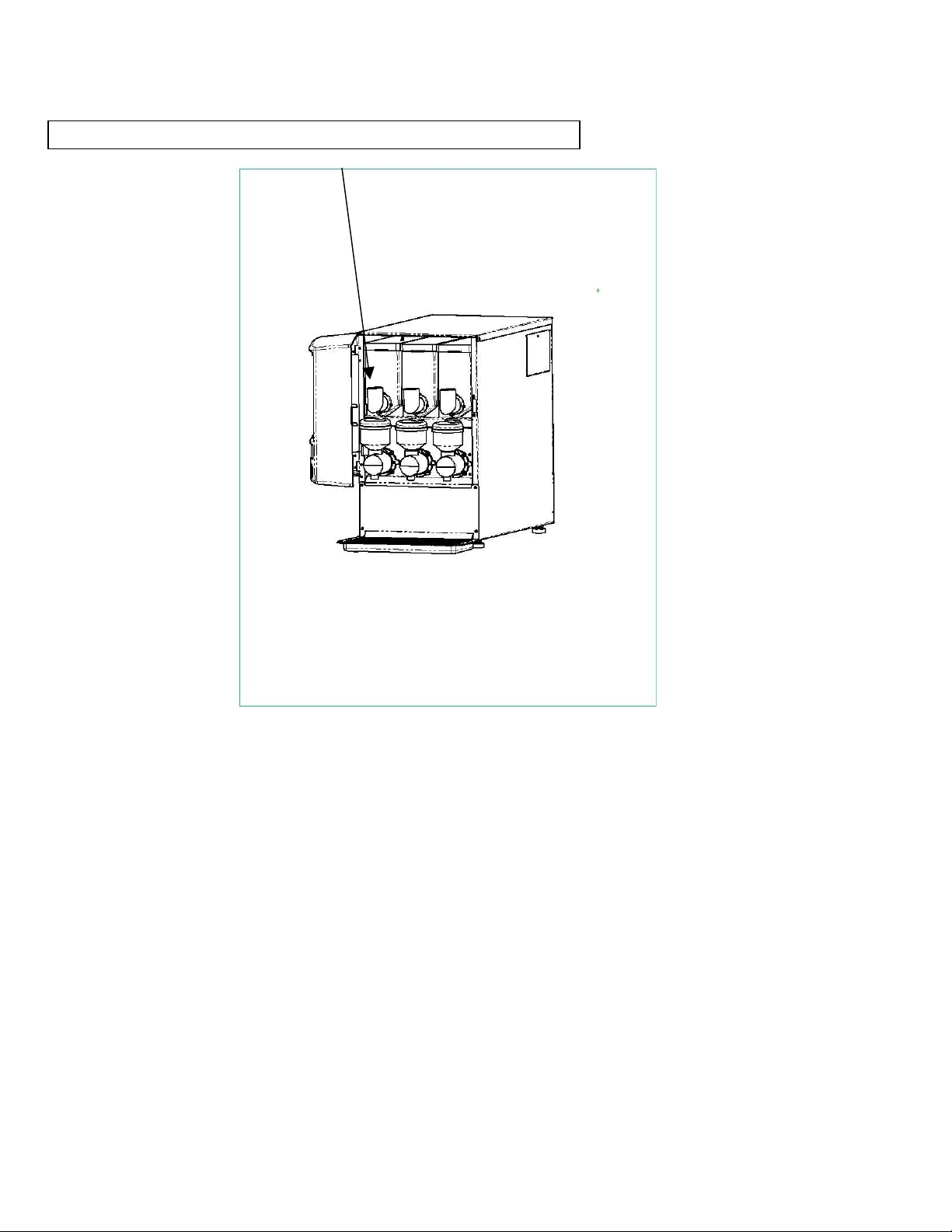

Product Loading Instructions

Turn Nozzles Up Prior to Removing Product Hoppers

2 Lb Hopper Drip Tray #781691

3 Lb Hopper Drip Tray # 781861

Product Hopper Removal:

1. Turn Nozzle UP as illustrated above

2. Grasp Hopper at Nozzle and lift slightly to disengage locating pin

3. Pull Hopper assembly forward and remove from machine

The Hoppers hold approximately two pounds of Product. Do not overfill or pack product in canisters.

Pour Product into Hoppers in a back and forth motion to evenly distribute the powder, to avoid spilling.

7

Page 8

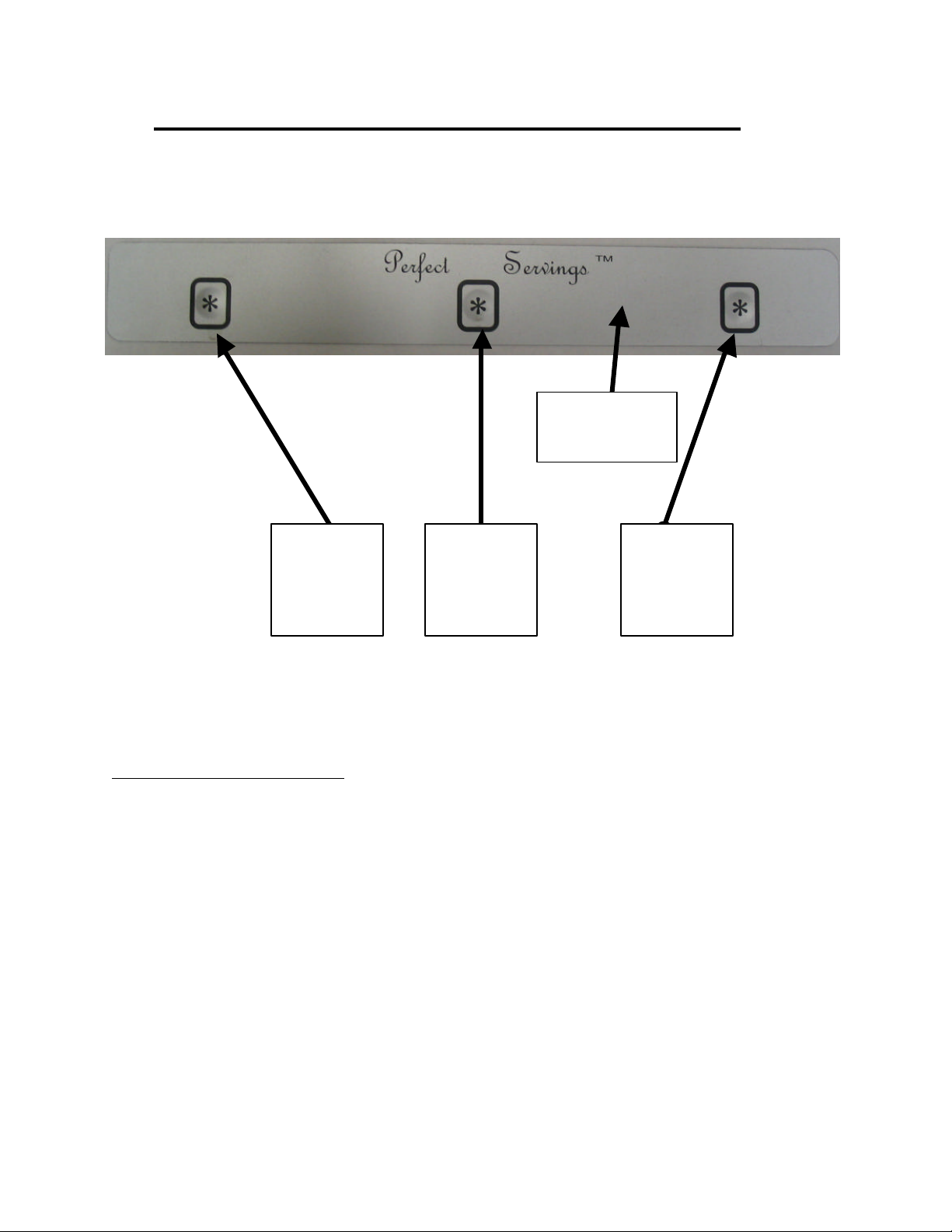

Machine operation and calibration settings

Dispense

Dispense

Dispense

Hidden

Dispense Membrane Switch

PN 781596

Button*

Button

One

(Left)

*Note: The Hidden Button has a slight depression in the face of the membrane switch and

is centered between Dispense Buttons Two and Three below the 'TM'

Portion Control Mode:

To initialize the portion control mode perform the following steps:

1. Select cup size and position under desired dispense nozzle

2. Push and hold Hidden Button

3. While holding in Hidden Button also push and hold Dispense

Button which corresponds with dispense nozzle in step 1

4. After a 1-second pause the drink will start to dispense

5. Release the Hidden Button and continue holding the Dispense

Button until the cup is about 2/3 full . (Hold <3 sec's resets to manual)

6. Portion size is now in memory, if incorrect repeat until desired

dispense is achieved. Repeat steps for the other selections

7. Dispense can be cancelled by pressing any button a second

time .

Button

Two

(Center)

Button

Three

(Right)

8

Page 9

Manual Dispense Mode (Momentary)

Error

Water

Heater

To cancel Portion Control Mode and return to Manual Mode, follow the

Portion Control Instructions-release Hidden Button in step 5 after product

dispense starts in less than 5 seconds.

When using Manual Mode release the hidden button when cup is approximately 2/3

full or less.

Heater and Pump Control Interface

The Interface is located behind the access panel on the right upper rear

side of the machine (see illustration page )

Support Pins

PN 102844

Indicator

Light

Volume

Controls

Temperature

Adjustment

Drink Strength Adjustment

Dry Product Delivery from Canister Canisters is not adjustable. The Water

Volume Controls are used to fine-tune Drink Strength

9

Page 10

Heater Adjustment

The Heater is adjustable from a range of 150 F-195F (see illustration

page 9) Note: Temperature at dispense point will be slightly lower.

Flushing the Mixing Chambers

The Mixing Chambers should be sanitized at least once per day. To

initialize Sanitation Mode perform the following steps:

1. Push and hold any 2 dispense buttons for 3 seconds.

Whipper will run briefly to show this has been done.

2. Push and hold any selector button to flush mixing chamber.

Flush will stay active as long as button is held.

3. Flush mode will end after 3 seconds of inactivity.

Whipper will run briefly to show the mode has ended.

Cleaning and Sanitizing Instructions

Daily Cleaning

1. Rinse the Mixing Chambers

2. Empty the Drip Pan if needed and wash with mild detergent, rinse

clean with warm water

3. Check the Canister Nozzles, clean and dry thoroughly

4. Check and clean the Sheet Metal Panels in the dispense area

10

Page 11

Weekly Cleaning

Whipper and Mixing Chamber Disassembly and Cleaning

(see Illustration page 5 & 12 )

1. Remove the Steam Caps by Turning Clockwise to free

2. Remove the Mixing Bowl by lifting the front edge of the

bowl until it is free of the Whipper Chamber and pull

forward to free the Mixing Bowl water inlet stem free of

the Bulkhead Fitting.

3. Rotate the Whipper Chamber Clockwise and pull forward

to remove

4. Remove Flow Restrictor by pulling free from Whipper

Chamber

5. Soak these parts in warm water, clean with mild

detergent, rinse and sanitize (see sanitization page 4 )

Whipper and Mixing Chamber Reassembly

1. Replace the Flow Restrictor

2. Replace the Whipper Chamber, push and twist

counterclockwise until the posts on the Whipper

Chamber engage and seat

3. Reseat the Mixing bowl by locating the Water stem

on the Mixing Bowl into the Bulkhead Fitting, tilting

the bowl up. Push forward engaging the O-ring

seal on the Wa ter stem through the bulkhead

fitting, then continue to push forward until the lip

of the Mixing Bowl slips into the Whipper

Chamber. Push down to firmly seat the Mixing

Bowl

4. Replace the Steam cap by seating inner lip of the

Steam Cap with the upper edge of the Mixing

Bowl, with the steam opening away from the sheet

metal panel. When Steam Cap is seated rotate the

steam opening into the slot in the sheet metal

Steam Chamber opening

11

Page 12

Mixing/Whipper Chambers

Disassembly

Steam Cap

PN 781568

(3)

Mixing Bowl

PN 781571

(3)

Bulkhead Fitting

PN 781040

(3)

Whipper Chamber

PN 781558

(3)

Flow Restrictor

PN 781562

(3)

Slinger Washer

PN 781717

(3)

Whipper Motor

PN 781563

(3)

Whipper Base

PN 781557

(3)

Shaft Seal

PN 781566

(3)

Whipper Blade

PN 781564

(3)

12

Page 13

Product Canister Disassembly and Cleaning

(see illustration page 15)

1. With door open turn the Dispense Nozzles facing

up (see page 7)

2. Remove the Product Canister and dispenser nozzle.

3. Rotate the front Threaded Retaining wheel

counterclockwise and remove

4. Remove the Nozzle Bushing

5. Turn the Canister around and remove the rear

Threaded Retaining ring

6. Pull and remove the Drive Link Assembly and

Auger Spring

7. Wash all components with mild detergent and

warm water, rinse clean and sanitize. When

washing Product Cansiter, rotate Auger Gear

Wheel to access gear teeth and Mixing Springs

8. Let all components air dry thoroughly before reassembly

Product Canister Reassembly

1. Ensure all Canister components are completely

dry

2. Slip Drive Link Assembly and Auger Spring

through the Canister and into the front opening of

the Canister (Note the shape of the Canister-the

Drive Link Assembly feeds in from the curved, or

overhanging side and the auger tip feeds through

the hole in the flat face of the Canister)

3. Ensure the locating tabs on the seat of the Drive

Link Assembly drop into the recesses of the hole

in the Canister

4. Screw the read Threaded Retaining ring

clockwise locking down the Drive Link Assembly

and Auger Spring

13

Page 14

Product Canister Reassembly (continued)

5. Insert the Nozzle Bushing “facing up” as shown in

the diagram

6. Ensure the locating tabs on the seat of the Nozzle

Bushing drop into the recesses of the hole in the

Canister

7. Screw the read Threaded Retaining ring

clockwise locking down the Drive Link Assembly

and Auger Spring

8. Replace the Dispense Nozzle -seat the “short” end

onto the Nozzle Bushing with the dispense

opening “facing up”

9. Refill Canister with product and reinstall in the

machine-ensure the Drive Link Assembly engages

the Auger Drive pinion gear, and the locating pin

in the Canister Base drops through the locator

hole in the sheet metal Canister Tray. Rotate

Nozzle down into Steam Cap

14

Page 15

Product Canister Disassembly

PN 781857

A. Canister Body -PN 781855 H. Back Motor Drive-PN 781840

B. Elbow-Dispense-PN 781833 I. Hopper Lid-PN 781583

C. Nozzle-PN 781584 J. Mixing Gear-PN 781828

D. Auger Spring -PN 781835 K. Mixing Spring Screw-PN 781830 (2)

E. Front Motor Drive-PN 781836 L. Mixing Spring-PN 781830 (2)

F. Bushing-PN 781838 M. Mixing Spring Nut-PN 781832 (2)

G. Nut-PN 781839 (2) N. Canister Base-PN 781841

Note - 3 lb Cannister Ass'y is PN 781864 . 3 lb Cannister body is PN 781582

15

Page 16

Steam Tray

PN 781649

Steam Tray Removal

Door Ass'y

PN 781776

Cleaning Brush is PN 111622, Brushholder bracket is PN 104023

16

Page 17

Service Procedures

Note: Servicing this unit should be done by

authorized personel only. Before Servicing unit:

1. Turn Power Switch to Off Position

2. Unplug Power Cord from outlet

3. Disconnect water line (ensure water supply to

machine is turned OFF!

4. Water in tank is HOT! Drain tank contents and let

tank cool before servicing unit (see Illustration

page 18 )

5. Loosen sheet metal screws as indicated in

Illustration page 19 . Slide Cover towards rear of

machine and remove. Remove water line and

slide back panel up and away from cabinet

)

17

Page 18

Front Access Panel Removal

Board Access Panel

PN 108014

Front Access Panel

PN 781576

18

Heater Leads

Heater

Indicator Light

PN 100667

Drain Hose Access

Area

Page 19

Sheet Metal Panel Removal

Access Screws

2 LB Cover PN 781597

3 LB Cover PN 781851

Back Panel PN 781676

2 LB Legs PN 111377

3 lb 4" Legs PN 100542

Loosen Screws:

Note: It is not necessary to

completely remove these

six screws to remove cover

and back panels

19

Page 20

Tank

Release

Screws

Front

PN 100425

20

Page 21

Tank Disconnects

1 1 1 2 34 5 6 7 8 Disconnect:

Prior to

Removal

1. Pump Tubes (3)

2. Main Power Connector

3. Float Switch Connector

4. Thermistor

5. Relay Connector

6. Pump Connector

7. Probe Connector

8. Water Line

21

Page 22

Float Switch

PN 781694

Tank Assembly

PN 781673

Tank Lid Punched

Tank

Gasket

PN 781181

PN 781770

Temperature Thermistor

PN 151800

Grommet #102836

Heater Relay

12 vdc

PN 110958

Barbed Fitting

PN 107329

Water Pump W/Elbow

PN 781772

(3)

Punched Tank

PN 781672

22

Heater Element

1400 w

PN 110792

Element Protector PN 110762

Element Gasket PN 110752

Page 23

Auger Drive Motor

(3)

PN 781587

Control Board

PN 103401

Inlet Solenoid

Valve

PN 781782

Water

Inlet

Components

Top and Rear Access

Transformer

110VAC

12-24 VAC

PN 105115

Steam Vent

Blower Motor

PN 781647

Liquid Level

Probe

PN 107077

Grommet #102836

Power Switch

PN 100500

23

Page 24

FLOAT

SWITCH

NC

VENT

FAN

120V AC

WATER

LEVEL

PROBE

THERMISTOR

PROBE

TANK

GROUND

DC MOTOR

NOTES

NOTE: ALL

MOTORS ARE

DC. DOT BY

MOTOR TERMINAL

INDICATES POSITIVE

THE AUGER DRIVE

*

MOTORS MUST HAVE

NEGATIVE WIRE ON

POSITIVE TERMINALS

AND POSITIVE WIRE

ON NEGATIVE

TERMINALS

WHITE MOTOR WIRES

ARE NEGATIVE

VOLTAGE,

COLORED MOTOR

WIRES ARE POSITIVE

VOLTAGE

VOLTAGE

CIRCUIT

RED

RED

LOW

YELLOW

BROWN

YELLOW

AUGER

DRIVE

1 (LEFT)

WHIPPER

1 (LEFT)

YELLOW

CN6

RIBBON

CABLE

(MEMBRANE

SWITCH)

CN2

3

1

4

2

CN5

12

11

10

7

8

9

5 1

2

34

6

DC

BLUE

AUGER

DRIVE

3 (RIGHT)

WHIPPER

3 (RIGHT)

-

+

24V

DC

*

WHITE

- -

+

24V

DC

ORANGE

AUGER

DRIVE

2 (CTR)

*

WHIPPER

2 (CTR)

-

+

24V

-

+

24V

DC

24V

DC

*

CN3

2

CN4

4

5

6

-

WHITE

110V AC

1

1

2

3

BL/WH

FILL

SOLENEOID

24V

AC

BROWN

BL/WH

AC TRANSFORMER

24V

AC

(CENTER TAP)

HEATER

RELAY

12V

AC

RED

BLACK

BLACK

WHITE

WHITE

BLACK

WHITE

12V

DC

+

12V

+

HEATER

INDICATOR

DC

-

LIGHT

VIOLET/BLACK

+

24V

DC

LINE

SWITCH

24

WHITE

HEATER

ORANGE

WHITE

BLUE

ELEMENT

120V

AC

YELLOW

WIRING DIAGRAM

MINI CAPPUCCINO MACHINE

PUMP

1(LEFT)

-

12V

DC

ORANGE

+

+

2 (CTR)

-

PUMP

12V

DC

+

BLUE

WHITE

PUMP

3 (RIGHT)

12V

DC

WHITE

Loading...

Loading...