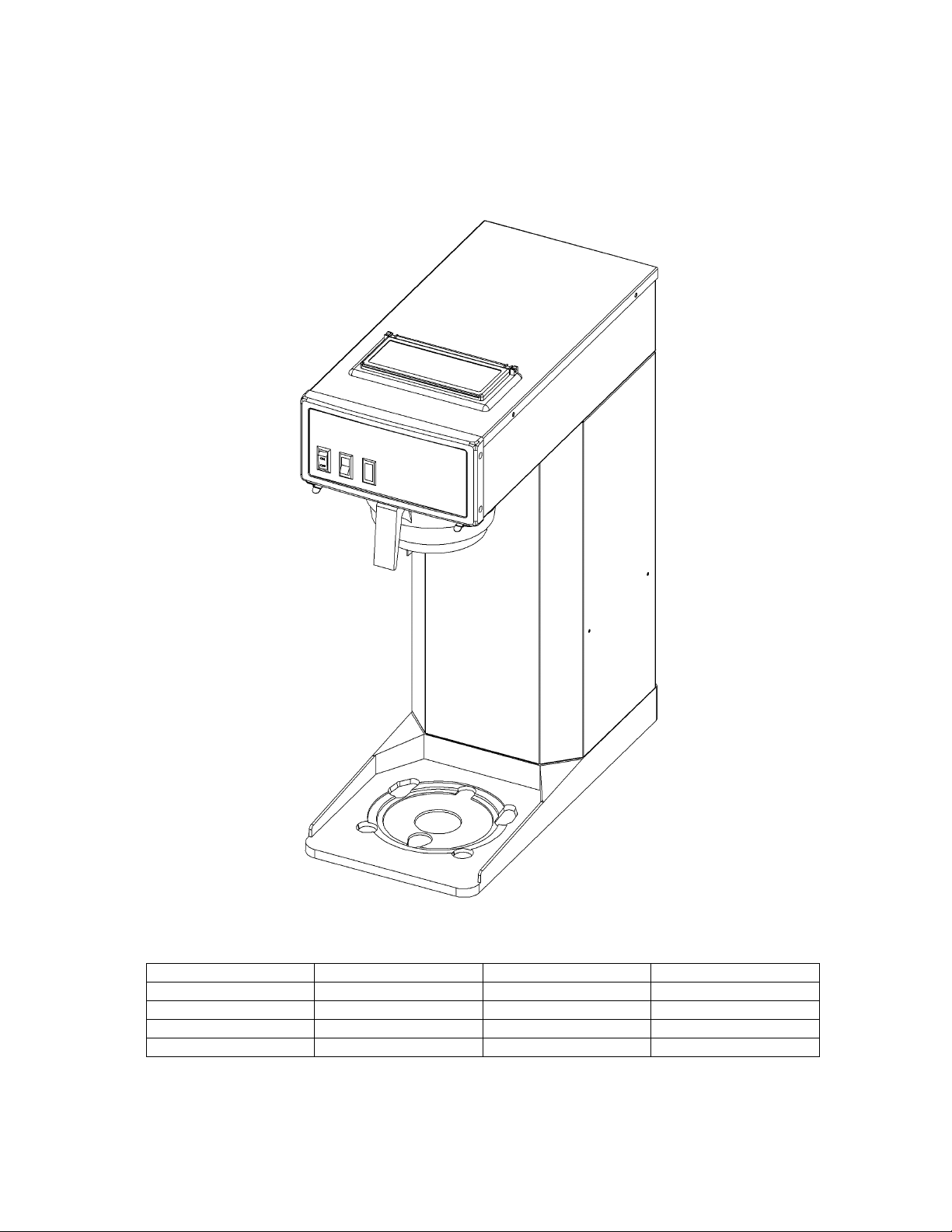

Newco AKH-AP-A Installation Manual

Prelim E Series pn 120725 iss 20091211

N E W C O E N T E R P R I S E S

INSTALLATION and OPERATION MANUAL

For AKH Autofill E - SERIES BREWERS

BREWER SPECIFICATIONS

Model Width Length Height

AKH-TC-A 8-1/2 17-11/16 17-1/2

AKH-LD-A 8-1/2 17-11/16 21-1/16

AKH-AP-A 8-1/2 17-11/16 23-5/16

AKH-D-A 8-1/2 17-11/16 27-3/16

Water Connection Note:

All models have ¼” flare plumbing connection unless specified otherwise.

Electrical Connection Note:

All units are intended to operate on a 15 A, 120 V ac circuit unless specified otherwise. Check units serial tag.

E SERIES SYSTEM ADVANTAGES

The E Series/AKH Line offers several advantages over a traditional commercial brewer with a hot water reservoir.

Since the water that is poured in, is the water used to brew, a fresher brewed product is produced.

No energy is wasted maintaining a tank of water at a near boiling temperature. Water is heated on demand, as it is

poured in. The energy savings will vary as a percentage based on the number of brews per day but the AKH can save

$85 or more per year just based on the brewer standby (or idle time). .15 per kWH assumed.

A hotter brew temperature is maintained throughout the brew cycle resulting in superior extraction.

PLUMBER'S INSTALLATION INSTRUCTIONS

CAUTION: Power to brewer must be OFF before proceeding with plumbing installation.

1) Flush water line before installing brewer. Brewer should be connected to COLD WATER LINE only.

2) Water pressure should be at least 20 lbs. For less than a 25 ft run, use 1/4" copper tubing and connect to 1/2"

or larger water line. For longer runs, use 3/8" copper tubing & connect to 1/2" or larger water line and provide

an adapter fitting for connection to the brewer.

3) If installed with saddle valve, the valve should have a minimum of 1/8" port hole for up to 25 ft run, and 5/16"

port hole for over 25 ft runs.

4) Connect incoming water line to the flow control fitting extending from the elbow on the back of the brewer. Flow

control/strainer must be in place. Manufacturer recommends connecting to copper tubing.

5) Ensure that tank heater switch on the rear of brewer is in the off position. Connect brewer to appropriate

electrical supply as indicated on serial tag.

INSTALLATION INSTRUCTIONS

WARNING: - Read and follow installation instructions before plugging or wiring in machine to electrical circuit.

Warranty will be void if machine is connected to any voltage other than that specified on the name plate/serial tag.

1) Plug or wire brewer to appropriate voltage circuit as indicated on serial tag. Turn the power switch on front of

brewer to the On position.

2) (AKH warmer model), make sure warmer switches are in the OFF position. Place one of the empty decanters

on the warmer located below the brew basket. For (AKH thermo model) pump style airpots, remove the pump

stem. Place the empty dispenser into position below the brewbasket.

3) Press the brew start button or raise the top evaporation cover and pour ONE decanter (on AKH warmer model)

or pitcher (on AKH thermo model) of water through the pour-in grid into basin.

4) NOTE: Float assembly will prevent heat pump from activating if water is not present in the basin. This first pot

will be a few ounces short due to some water retention in the system.

5) Optional Step: Empty decanter and place back in position. Depress the brew start switch and run a brew cycle

to check for proper volume. Adjust the timer located behind plate on left side of brewer to increase or decrease

volume as required. Use small adjustments and verify results.

6) Machine is now ready to use and will yield a full pot on following brew cycles.

OPERATION NOTE

This brewer is equipped with an automatic fill system. The brewer also incorporates a backup manual fill option for

brewing in case there is a problem with the water supply. To utilize the manual pour over fill option, simply raise the top

evaporation cover and pour the appropriate amount of water in to brewer for the vessel being brewed into. Do not

exceed the max fill level noted on the pour in grid.

2

Loading...

Loading...