Hondo

TM

MODEL 03207225

Assembly Instructions

Rev. 03-28-03

1

2

1

2

0

8

2

4

:

N

/

P

CAUTION ! This unit is heavy.

CARBON MONOXIDE HAZARD

Burning charcoal inside can kill you.

It gives off carbon monoxide, which

has no odor.

NEVER burn charcoal inside homes,

vehicles or tents.

G

N

I

N

R

A

W

!

Tools needed: 2 adjustable wrenches,

a flat screwdriver and hammer.

DO NOT assemble without a helper.

CAUTION!

Read and follow all Safety

! !

Statements, Warnings,

Assembly Instructions and

Use & Care directions before

attempting to assemble and cook.

CAUTION!

Some parts may contain

sharp edges. Wear

protective gloves as

necessary.

STOP!

Missing a part?

No Need To Go Back To

Call Our Help Line

The Store!

The store where you made your purchase

does not stock parts for this item.

If you need parts,

whether they are missing or damaged,

call the Customer Service

toll free Help Line.

Call us and we will gladly ship the

part you need

FREE OF CHARGE.

55700208 Smoke Chamber Kit 1

55700209 Firebox Kit 1

55700210 Wood handle Kit 2

55700211 Logo Plate Kit 1

55700212 Axle Kit 1

1-800-232-3398

55700213 Wheel Kit 2

55700214 Leg Brace Kit 2

55700215 Smokestack Kit 1

55700216 Short Leg Kit 2

55700217 Long Leg Kit 2

55700218 Knockout Cover Kit 1

55700219 Door Latch Kit 1

55700220 Butterfly Damper Kit 2

42000012 Hardware Bag 1

PARTS LIST

40002811 Fire Grate Set (3 ea) 1

40009916 SC Grate Set (2 ea) 1

40009925 FB Grate (1 ea) 1

46030090 Wood Rack 1

44830150 Grease Can Holder 1

42802812 Wire Front Shelf 1

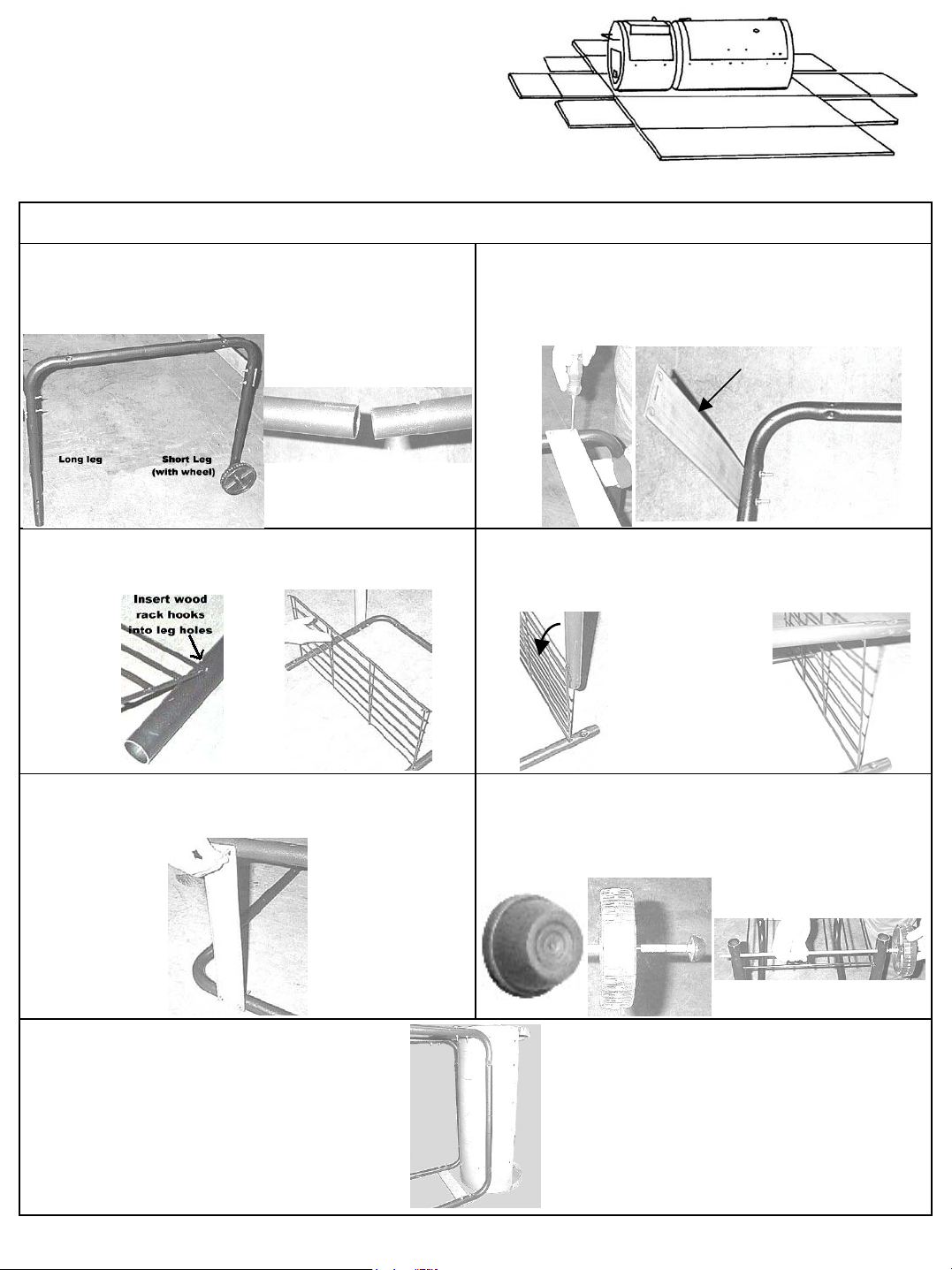

GET A HELPER ! This unit is heavy and may require a second

person for lifting and moving.

Pick a suitable location to work. Open the carton and slit the

corners to open like the illustration at the right. This will give you a

protective work surface upon which to start the assembly of your

new smoker.

Hardware parts list and descriptions are listed on next to last page.

For steps 1 through 8, do not tighten bolts until all parts are assembled and attached to smoke chamber.

STEP 1. Build two leg assemblies. Do this by sliding a

long leg and short leg together as shown.

LONG LEG

SHORT LEG

STEP 3. Place the wood rack hooks into the holes

provided in each end of leg assembly as shown. Now

swing wood rack up so it is perpendicular to the floor.

STEP 2. Attach 1 leg brace to the outside of each end

of one leg assembly using 10-24 x 1 3/4” screws and

10-24 flange nuts.

LEG BRACE

STEP 4. Now with the aid of a helper, take the second leg

assembly, making sure that the two short legs on each

assembly are on the same end, and hook the wood rack

holes on the legs onto the wood rack hooks.

Swing the leg

assembly over

so that it is

parallel to the

opposite leg

assembly.

STEP 5. Attach the loose end of the leg brace to the

corresponding leg. Turn the leg frame assembly upside

down in preparation for axle and wheel attachment.

STEP 7. Turn the leg frame assembly on end

with the wheels on the floor to attach the

smoker chamber. Slide the smoker chamber up

against the frame aligning the four holes in the

legs with the four holes in the bottom of the

body. The smoker chamber should be standing

up on the solid end cap.

STEP 6. Using a hammer, knock one plastic axle cap

onto one end of the axle. Slide one wheel onto axle.

Slide the axle through the holes in both of the short legs.

Slide on the other wheel and tap on a plastic wheel cap

to secure the axle.

STEP 8. Bolt chamber to leg assembly

using 4 1/4-20 x 2” Combo Truss Head

Screws and 4 flange nuts.

TIGHTEN ALL BOLTS AT THIS TIME.

STEP 9. Align the heat passage bolt pattern on the firebox with the heat passage bolt pattern on the smoker

chamber. The firebox should sit slightly offset from the smoker chamber. Bolt together using 6 1/4-20 x 3/4” hex

head bolts, 12 1/4” flat washers, and 6 1/4-20 flange nuts.

Washer

Body

Flange Nut

WITH THE AID OF YOUR HELPER, STAND THE UNIT ON IT’S LEGS AT THIS TIME.

STEP 10. Install butterfly damper on the backside of the barn door with the pin through the opening at the bottom

of the door. Secure by using a 1/4-20” x 3/4” hex bolt, a 1/4” flat washer and a 1/4” reversible lock nut on the inside

of the barn door. Tighten just enough to where the butterfly damper can be easily opened and closed.

Reversible lock nuts are identified

by a small rectangular indentation

on the side of the nut.

STEP 11. Install barn door latch using 1/4-20 x 3/4” hex

bolt, 1/4” flat washer, and a 1/4-20 reversible lock nut.

Tighten so the latch can move freely.

STEP 12. From inside the smoke chamber, slide the

smokestack up through the large hole at the right-rear of

smoke chamber. Align the bolt holes and secure using 2

1/4-20 x 3/4” hex bolts from outside the unit and 2 1/4-20

flange nuts from inside of unit.

STEP 13. Install smoke stack damper by sliding damper

over pin on smoke stack. Secure by tapping a 3/8” PAL

nut on top with a hammer.

STEP 15. Install grill support bolts in all four holes on the

back of the smoker chamber. Use 4 10-24 x 1” Combo

Truss Head screws and 4 10-24 flange nuts.

STEP 14. Attach a wood handle to smoke chamber door

using 2 1/4-20 x 3” bolts, 2 aluminum sleeves, and 2 1/420 flange nuts as shown below. Repeat steps for firebox

door handle.

STEP 16. Front Shelf Installation. Insert ends of wire

shelf into 4 aligning holes as shown. After inserting the

ends of the wire shelf into the holes, tilt the shelf fully

upright and push the ends all the way into holes and then

bring the wire shelf down to the horizontal position. Install

1/4” chrome plugs in second hole from each end of

smoke chamber.

STEP 17. Install 13/16” chrome plug in temperature

gauge hole in smoke chamber lid if you have not

purchased the optional Model 3000 temperature gauge

(12503000).(To order call 1-800-232-3398).

STEP 18. Install the grease can wire clip. From below

the unit push the wire clip up through the large hole and

then pull down so that the tip of the wire clip goes down

through the smaller hole.

A 12 oz. tin can (i.e. soup can or vegetable can) will fit

nicely into clip to collect grease.

STEP 19. Install die cast logo plate by inserting the pins

on logo plate through the two holes in the lower right

corner of smoke chamber door. Secure in place by

slipping the Tennerman clips over the protruding pins

and pushing them until they are snug against the inside

surface of door.

STEP 21. Diamond Fire TM plate (24810036) installation

(FOR UNITS WITHOUT DIAMOND FIRE ACCESSORY

(22504850)).

STEP 20. If you wish to grill in the smoke chamber,

insert BOTH wire fire grates into the smoke chamber

and place them on the bottom of the cooking chamber

to build your fire on. Insert the two porcelain cooking

grills into the smoke chamber and rest them on the

protruding grill support bolts.

Firebox fire grate installation for smoking: Insert a

wire fire grate into the firebox through the barn door

opening and rest it on the bottom of the firebox

chamber. When smoking food, do not put a cooking

Locate the 2 3/32” x 2 11/16” cover plate in the hardware

grate in the firebox.

box. At the bottom right end of the firebox are the holes

for the Diamond Fire Propane igniter accessory (not

included). Align the two holes in the cover plate with the

holes on each side of the large hole in the firebox.

Secure using 2 #8-32 x 1/2” combo pan head screws and

2 #8-32 keps nuts.

Firebox cooking grill If you wish to use the firebox to grill with, you will need to install 4 10-24 x 1” Combo truss

head screws and 4 #10-24 flange nuts into the 4 holes provided in the firebox. Use the smallest of the three

cooking grates in the firebox.

Firebox cooking grill installation Insert porcelain cooking grill into fire box as shown.

HONDO SMOKER HARDWARE (not to scale)

20 10-24 Flange Nut 16 1/4”-20 Flange Nut

2 11/64” Logo Plate Clip 1 13/16” dia. Chrome Button Plug

1 3/8” PAL Nut 10 1/4-20 x 3/4” Hex Head Machine Screw

4 1/4-20 x 3” Combo Truss Head Screw 2 1/4-20 Reversible Lock Nut

Small Indentation

on side of nut

8

10-24 x 1” Combo Truss Head Screw 4 1/4-20 x 2” Combo Truss Head Screw

2 8/32 x 1/2” Combo Pan Head Screw 2 8/32 Keps Nut

8 10-24 x 1 3/4” Combo Truss Head Screw 2 .281 Chrome Button Plug

14 1/4” Flat Washer 4 .400” dia x 1.125” Aluminum Spacer

2 Axle Cap 2 1 3/8” Leg Cap

Parts diagrams ARE NOT actual size.

Use ruler to determine correct size

1/16”

1/8”

1/4”

1/2”

1”

1” 2” 3”

Preparing and using your SMOKER / GRILL

Before cooking with your unit, the following steps should be closely followed to both cure the finish and season the interior

steel. Failure to properly follow these steps may damage the finish and/or impart metallic flavors to your first foods.

1. Brush all interior surfaces including grills and grates with vegetable cooking oil.

2. Build a small fire on the fire grate, being sure not to lay coals against the walls.

3. Close lid. (Position butterfly and smokestack damper approximately at one quarter opening.) This burn should be

sustained for at least two hours, the longer the better. Then, begin increasing temperature by opening the butterfly and

smokestack damper half-way and adding more charcoal. Your smoker is now ready for use.

Rust can appear on the inside of your smoker / grill. Maintaining a light coat of vegetable oil on interior surfaces will aid in

the protection of your unit. Exterior surfaces of unit may need occasional touch up. We recommend the use of a

commercially available black high temperature spray paint. NEVER PAINT THE INTERIOR OF THE UNIT !

GRILLING

Wood is recommended, however charcoal or a combination of both may be used as the fuel source for grilling, with the

fuel source placed and ignited on the fire grate. Do not build too large a fire. We recommend starting a fire with no more

than 4 pounds of charcoal and adding more as needed during cooking. After allowing the fire to burn down, place the

cooking grill in the unit. Failure to read and follow instructions for lighting charcoal may result in serious personal injury

and/or property damage.

GRILL MAINTENANCE

Frequency of cleanup is determined by how much the unit is used. Make sure coals are completely extinguished before

cleaning inside of unit. Inside surfaces may be cleaned with a strong solution of detergent and water applied with a scrub

brush. Thoroughly rinse with water and allow to air dry before using again.

SMOKING AND SLOW COOKING

If using unit as a smoker or slow cooker, build your fire on top of the fire grate in the firebox. Either charcoal or wood may

be used, but wood is the recommended fuel for it’s rate of burn and the flavor it imparts to the food being cooked. Most

seasoned hardwoods are good for smoking such as hickory, mesquite, pecan, oak, and many other fruit woods. The

firebox will accommodate most split fireplace size logs (16”). Bark should be avoided or burned off first as it contains a

high acid content and imparts an acidic flavor.

After allowing the fire to burn down, close the doors and control the temperature and smoke with the dampers located on

the firebox and atop the smokestack. Smoke is contained within these chambers which will reduce burn while imparting

more smoke flavor. Do not operate the unit with temperatures exceeding 450 degrees in the smoke chamber. Place the

food in the smoke chamber and monitor the temperature. Cooking and smoking are taking place using indirect heat.

There is no need to worry about a grease fire flare-up ruining the food. Do not place food within 6” of the opening from the

firebox into the smoke chamber. A general rule of thumb for cooking is about 1 hour per pound for smoking large cuts of

meat. Refer to a cook book for specific cuts of meats. A maintained temperature of between 225 degrees and 275

degrees will provide the best results for most cuts of meat. Limit the number of times you open the smoke chamber door

as this will allow heat to escape and extend the cooking time.

LIMITED WARRANTY

New Braunfels Smoker Company warrants the Smoker/Grill for replacement or repair of parts and or workmanship for a period of 3 months. New

Braunfels Smoker Company warrants to the original Smoker/Grill owner repair or replacement of the cooking chamber only,should “burn-out” or

“rust-through” occur for a period of 1 year. Paint is not warranted and will require touch-up.

These limited warranties are made exclusively to the original customer presenting proof of purchase. These warranties are limited to noncommercial usage. Any returned goods must be clearly marked with a New Braunfels Smoker Company Return Authorization Number and

shipped prepaid. These limited warranties do not cover normal wear and tear, damages resulting from abuse or mis-use. This warranty excludes

incidental or consequential cost due to damage or losses to persons or property of any nature.

NOTICE: Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an implied

warranty lasts, so the above limitations or exclusions may not apply to you. This warranty gives you specific legal rights and you may also have

other legal rights which may vary from state to state.

TOLL FREE 1.800.232.3398

Visit our web site at www.nbsmoker.com

Loading...

Loading...