Page 1

AIR PURIFIERS

New!

™

TitanClean

A QUANTUM LEAP forward in Air Purification

New space age air purification technology now available

f rom Airpura Industries.

Titanium Dioxide Photocatalytic Oxidization

Airpura’s Titanium Dioxide Photo-Catalytic Oxidizer (PCO)

dramatically increases the range of dangerous airborne

chemicals that can be neutralized safely and effectively.

Nano-Technology Developed for the space Age

The Airpura TitanClean™uses the latest discoveries

in nano-technology,developed by space research laboratories,

to deliver a new and instantaneous airborne chemical

abatement process.

Safely Breaks Down Harmful Chemicals and Odors

TitanClean™’s titanium dioxide (T iO2) coating in conjunction

with the UV light, creates an oxidizing process tha t instantly breaks

molecular bonds and reduces airborne chemicals to smaller safer

compounds, until only carbon dioxide and water va por are left.

No ozone

Airpura strictly uses non-ozone generating UV lamps. When the UV

lamps irradiate the (TiO

are produced to oxidize Volatile Organic Compounds (VOCs)

and at the same time kill and decompose bio-aerosols.

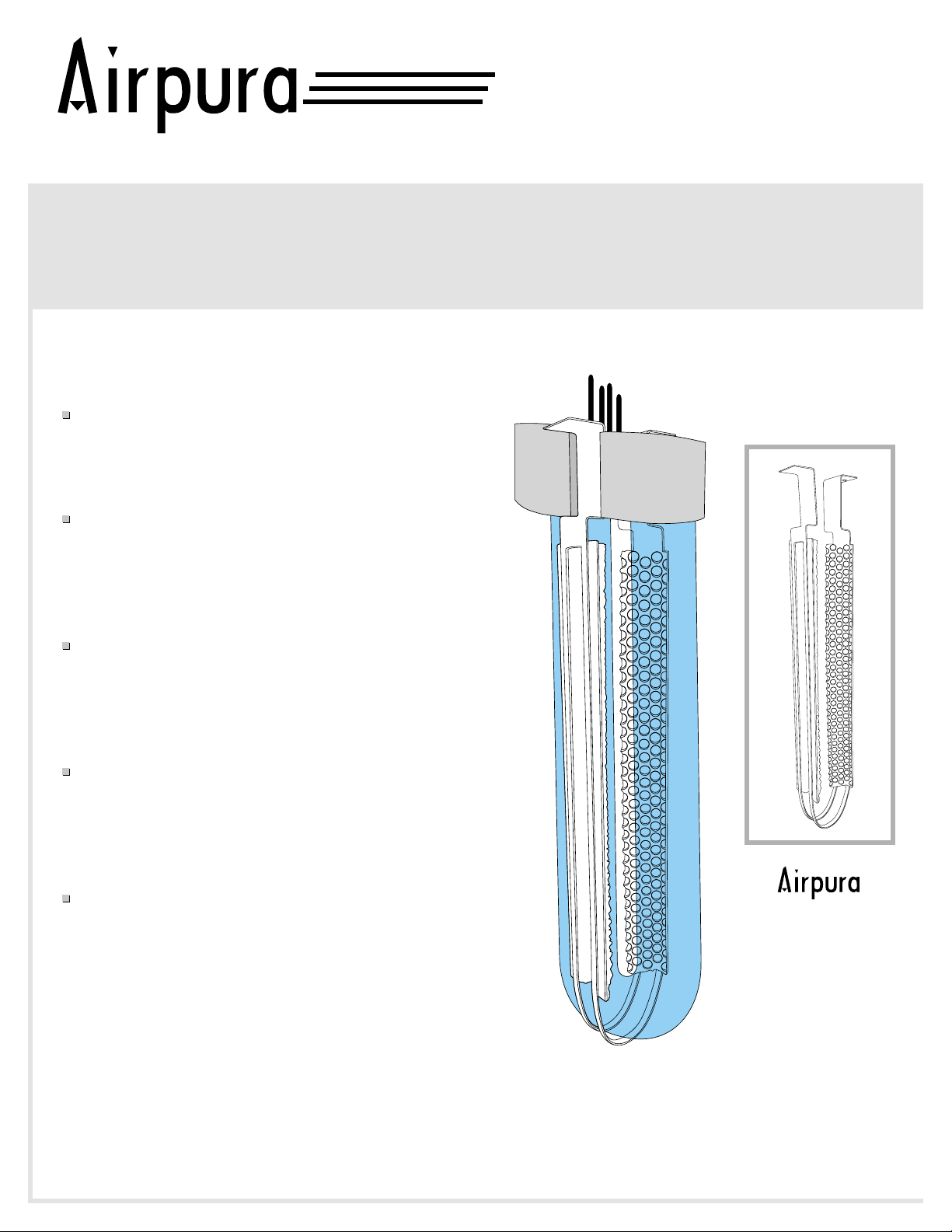

The Airpura TitanClean™reflector

The TitanClean™Reflector (patent pending) was created

following Airpura’s SPEC-A design principle:

Simple Powerful Effective Clean-Air

Airpura’s design team have produced a simple powerful

and effective design that maximizes the photocatalytic effect

of the UV light on the titanium dioxide coating while at the same

time allowing the full germicidal effect of the UV lamp.

), hydroxyl radicals and super-oxide ions,

2

TitanClean

Safely eliminates

harmful chemicals

and odors

™

Available in the new P 600 air puri f ier

or as a retrofit

Page 2

AIR PURIFIERS

A New For mula

for Clean Air…

TiO2+UV=PCO

Photocatalytic Oxidization (PCO)

Developed and used in space technology laboratories for both air and water purification,

the Photocatalytic Oxidation (PCO) process is simple and elegant.

A metal surface coated with a metal oxide is irradiated with UV light

to produce hydroxyl radicals and super-oxide ions.

The hydroxyl radicals and super-oxide ions break the molecular bonds of chemicals

they come into contact with and slice them into smaller compounds, that are further broken

down until only carbon dioxide and water vapor are left.

The specific type of metal oxide coating used is critical. Titanium dioxide (TiO

has proven to be the most effective, efficiently breaking down a wide range

of chemicals without producing harmful byproducts (such as ozone).

For maximum efficiency, the process requires a sufficient surface area of reflective

metal coated with a metal oxide to be positioned at a critical distance from the UV lamp

while still allowing a good flow of air to bring the airborne chemicals into contact

with the resulting hydroxyl radicals and super-oxide ions.

2

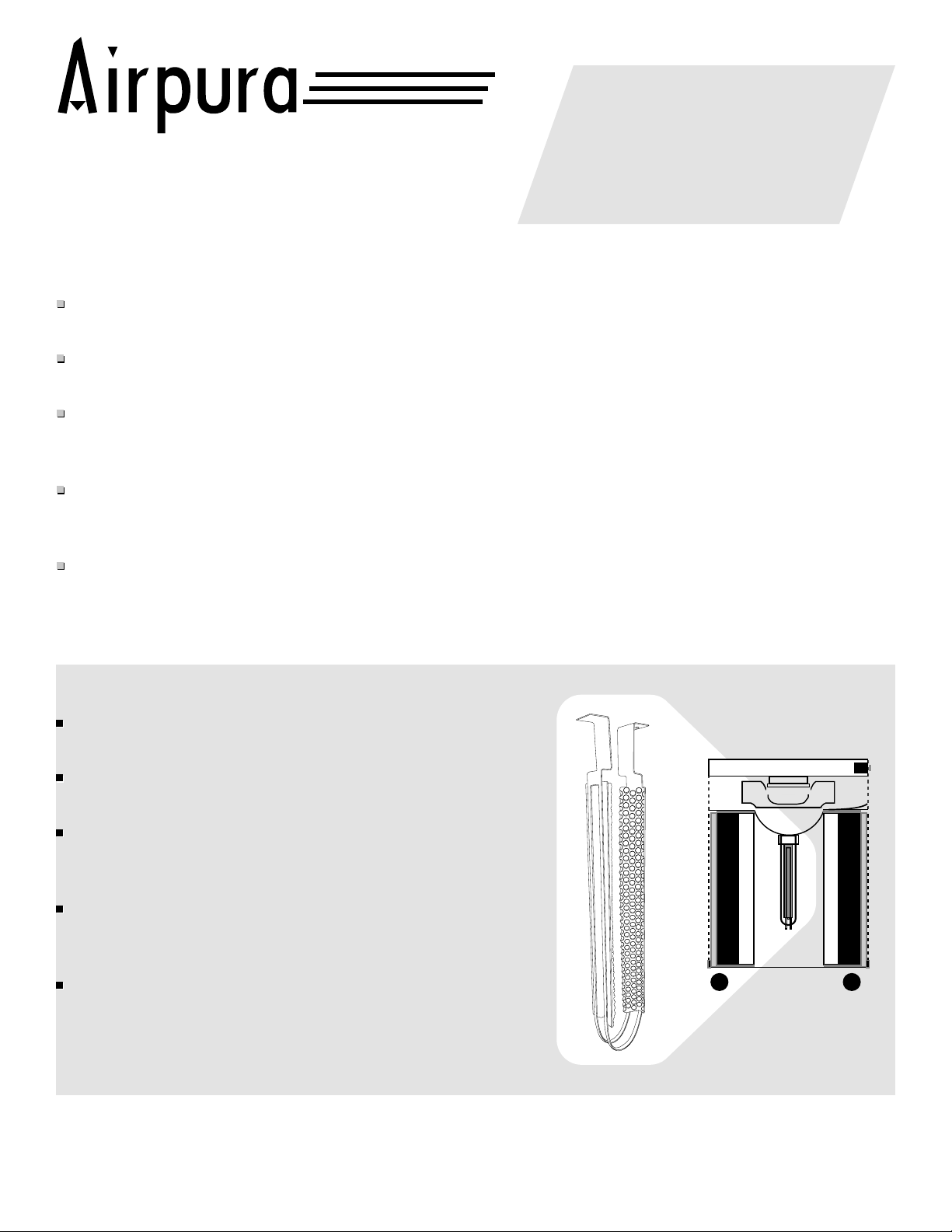

The Airpura TitanClean™ Reflector

The TitanClean™Reflector provides a premium amount of TiO

coated surface area (115% of the width of the UV lamp).

The angled reflector design maximizes the range of

photo-catalytic oxidation within the filter chamber.

The UV germicidal lamp maintains 98% of its antigen

and pathogen destruction effect due to the interior

position of the TitanClean

The location of the TitanClean

in the center of the filter chamber allows them

to work in concert with the HEPA filter.

™

reflector.

™

reflector and the UV light

2

)

Particulate pollution is stopped by the HEPA filter before reaching

the reflector. This keeps the coated surface cleaner and more effective.

Contact time of airborne chemicals is increased as they slow down

passing through the HEPA. The diffusion of the germicidal dosage

from the UV lamp is enhanced in the confined chamber.

Available in the new Airpura P 600 model or retrof i tted to an existing UV unit

The TitanClean™reflector is offered as an integral part of the new P600 range of High Efficiency Air Purifiers

from Airpura featuring a choice of HEPA and Carbon filtra tion or as an add on to your existing UV600 model.

G0995R00_Airpura P600

Loading...

Loading...