Page 1

TVG480

JPEG2000 Post Production Gateway

User’s Manual

Revision: 2.8.24 (4422)

2014-06-02

Valid for SW version 2.8.24 and newer

Page 2

Page 3

Contents

1 History 9

2 Introduction 11

2.1 Scope 11

2.2 Warnings, cautions and notes 11

2.3 Heed warnings 12

2.4 Contact information 12

3 Short Product Description 13

3.1 Software options 14

4 Getting Started 15

4.1 Configure the management Ethernet interface 15

4.2 Configure device name and time settings 16

4.3 Select the operational mode 16

4.4 Connect the signals 16

5 Installing the Equipment 19

5.1 Inspect the package content 19

5.2 Installation Environment 19

5.3 Equipment installation 20

5.4 Ventilation 20

5.5 Power supply 21

5.5.1 AC power supply 21

5.5.2 Dual AC power supplies 21

5.5.2.1 AC power cable 21

5.5.2.2 Protective Earth/technical Earth 22

5.5.2.3 Connecting to the AC power supply 22

5.5.3 DC power supply 23

5.5.3.1 DC power cable 23

5.5.4 Powering up/down 23

5.6 Connecting the TVG480 24

5.6.1 Physical description overview 24

5.6.2 SDI ports 24

5.6.3 Ethernet Ports 24

5.6.4 Power Supply 25

5.6.5 Technical Earth 25

5.6.6 Alarm/Reset 26

5.6.7 Serial USB interface 26

6 Operating the Equipment 27

Page 4

6.1 Accessing the graphical user interface 27

6.2 Password protection 27

6.2.1 Resetting the password list 28

6.3 Changing the IP address of the unit 28

6.3.1 Changing IP address via the Web GUI 28

6.3.2 Changing the management port IP address via the terminal interface 30

6.3.3 Configuring automatic IP address assignment 30

6.4 Stereoscopic 3D operation 31

6.4.1 Requirements 31

6.4.2 Configuration 32

6.5 Hitless switching 32

7 WEB Interface 35

7.1 Login 35

7.2 Status header 36

7.3 WEB pages overview 37

7.3.1 Status 37

7.3.2 Device info 37

7.3.3 Encoders 38

7.3.4 Decoders 38

7.3.5 SDI Ports 38

7.3.6 IP Status 39

7.4 Status 39

7.4.1 Current Status 39

7.4.2 Alarm log 41

7.5 Device Info 42

7.5.1 Product info 43

7.5.2 Alarms 45

7.5.2.1 Device alarms 46

7.5.2.2 Global configuration 46

7.5.2.3 Relays and LED 47

7.5.2.4 Alarm log settings 49

7.5.3 Time Settings 50

7.5.4 Reference Sync 53

7.5.4.1 IP RX Video RefSync 53

7.5.4.2 Alarms 54

7.5.5 Network 54

7.5.5.1 Interfaces 55

7.5.5.1.1 Main 55

7.5.5.1.2 Interface Settings 56

7.5.5.1.3 DHCP Settings 56

7.5.5.1.4 DHCP Status 57

7.5.5.1.5 Manual IP Settings 58

7.5.5.1.6 Interface Status 58

7.5.5.1.7 Detect Settings 59

7.5.5.1.8 Alarms 59

Page 5

7.5.5.1.9 Advanced 59

7.5.5.1.10 Status 60

7.5.5.1.11 VLAN 62

7.5.5.1.12 Main Settings 62

7.5.5.1.13 Manual IP Settings 63

7.5.5.1.14 Advanced Settings 63

7.5.5.1.15 DHCP settings and status 63

7.5.5.1.16 SFP 63

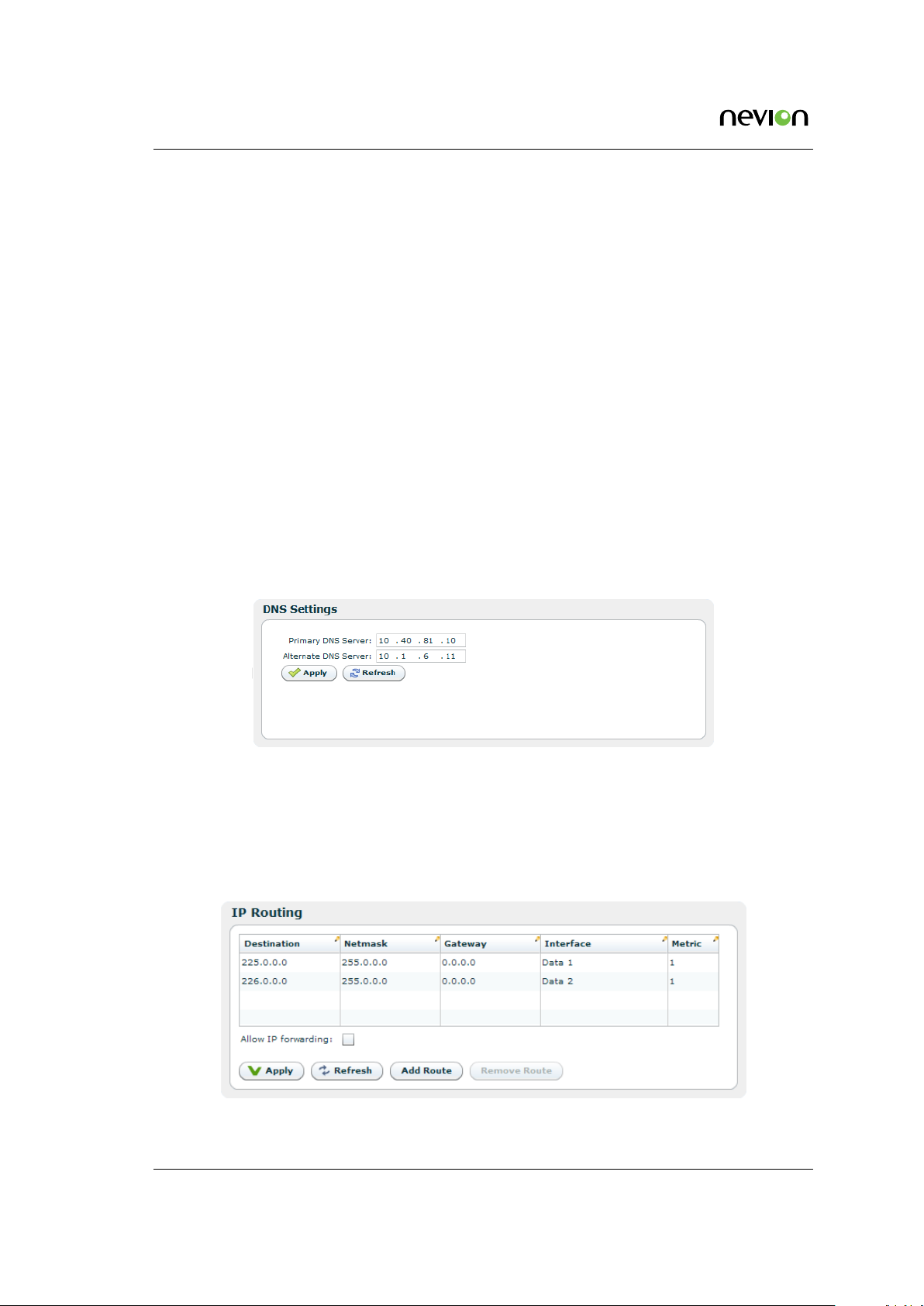

7.5.5.2 DNS Settings 72

7.5.5.3 IP Routing 72

7.5.5.4 TXP Settings 73

7.5.5.5 SNMP Settings 74

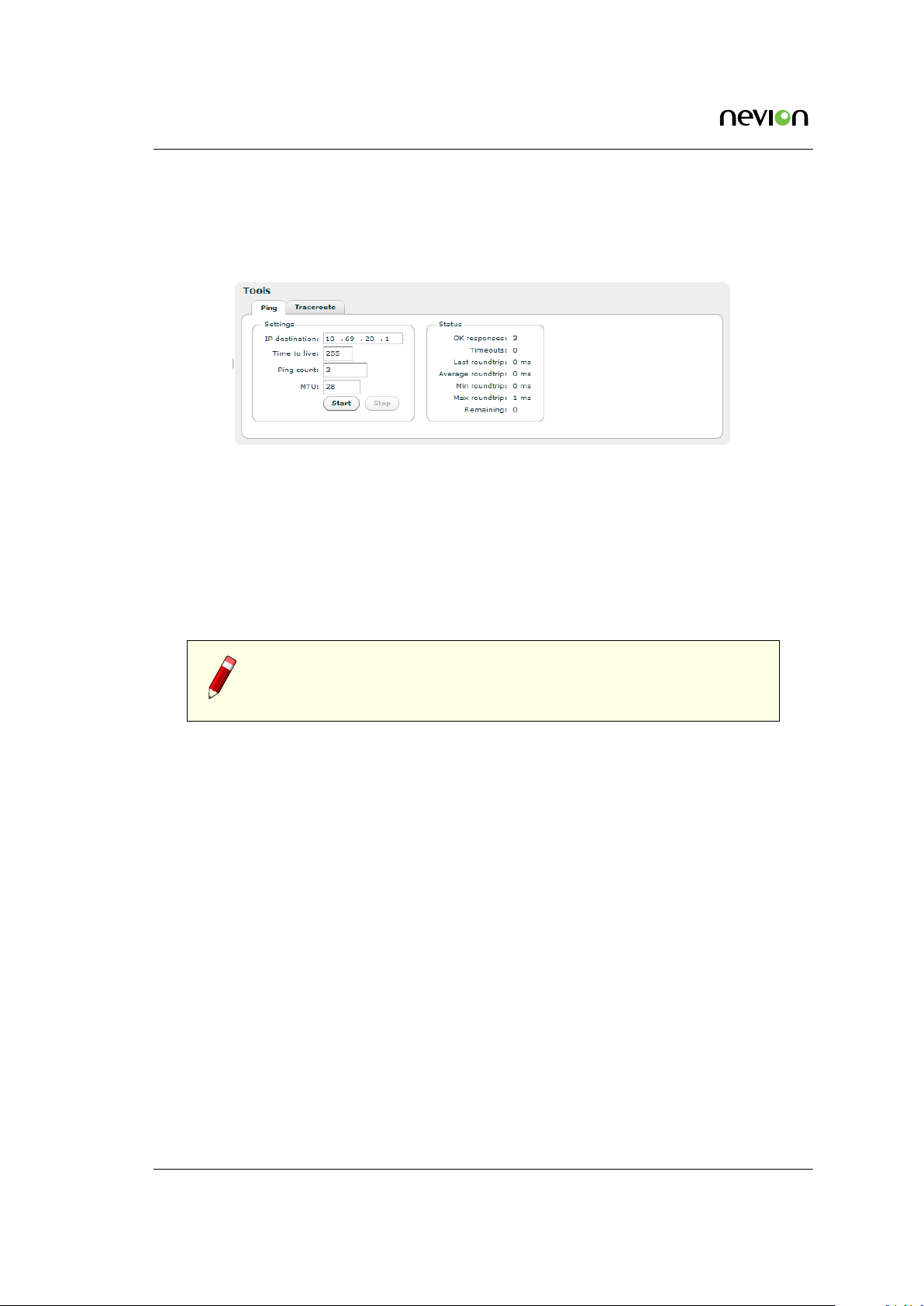

7.5.5.6 Tools 75

7.5.5.6.1 Ping 76

7.5.5.6.2 Traceroute 77

7.5.6 Save/Load Config 78

7.5.6.1 Save/Load Configs 79

7.5.6.1.1 Save Configuration 79

7.5.6.1.2 Load Configuration From file 80

7.5.6.1.3 Load Configuration from Remote Device 80

7.5.6.1.4 Load options 81

7.5.6.2 Boot Log 81

7.5.6.3 Stored Configs 82

7.5.6.4 Emergency Switch 83

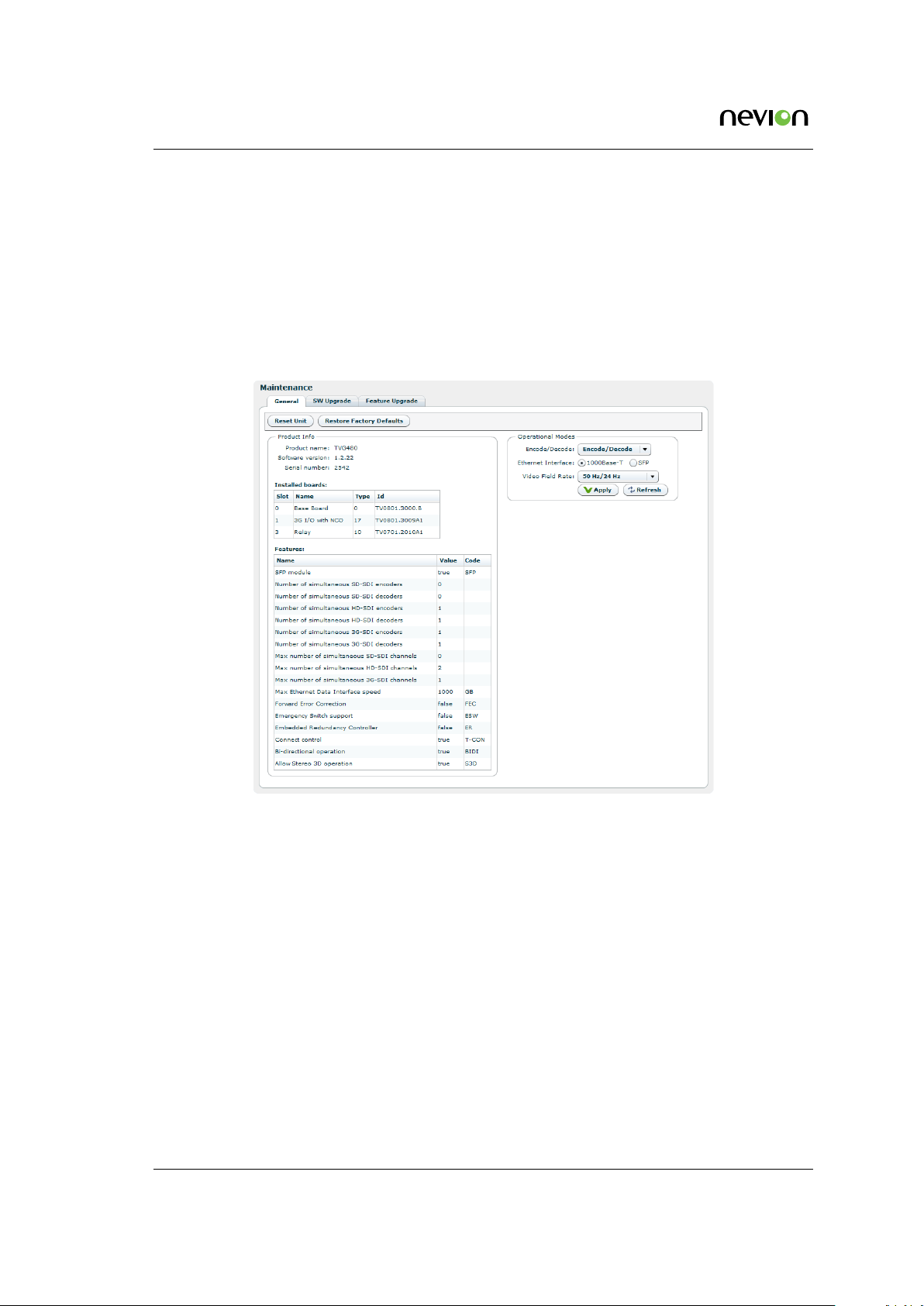

7.5.7 Maintenance 86

7.5.7.1 General 86

7.5.7.2 Software Upgrade 87

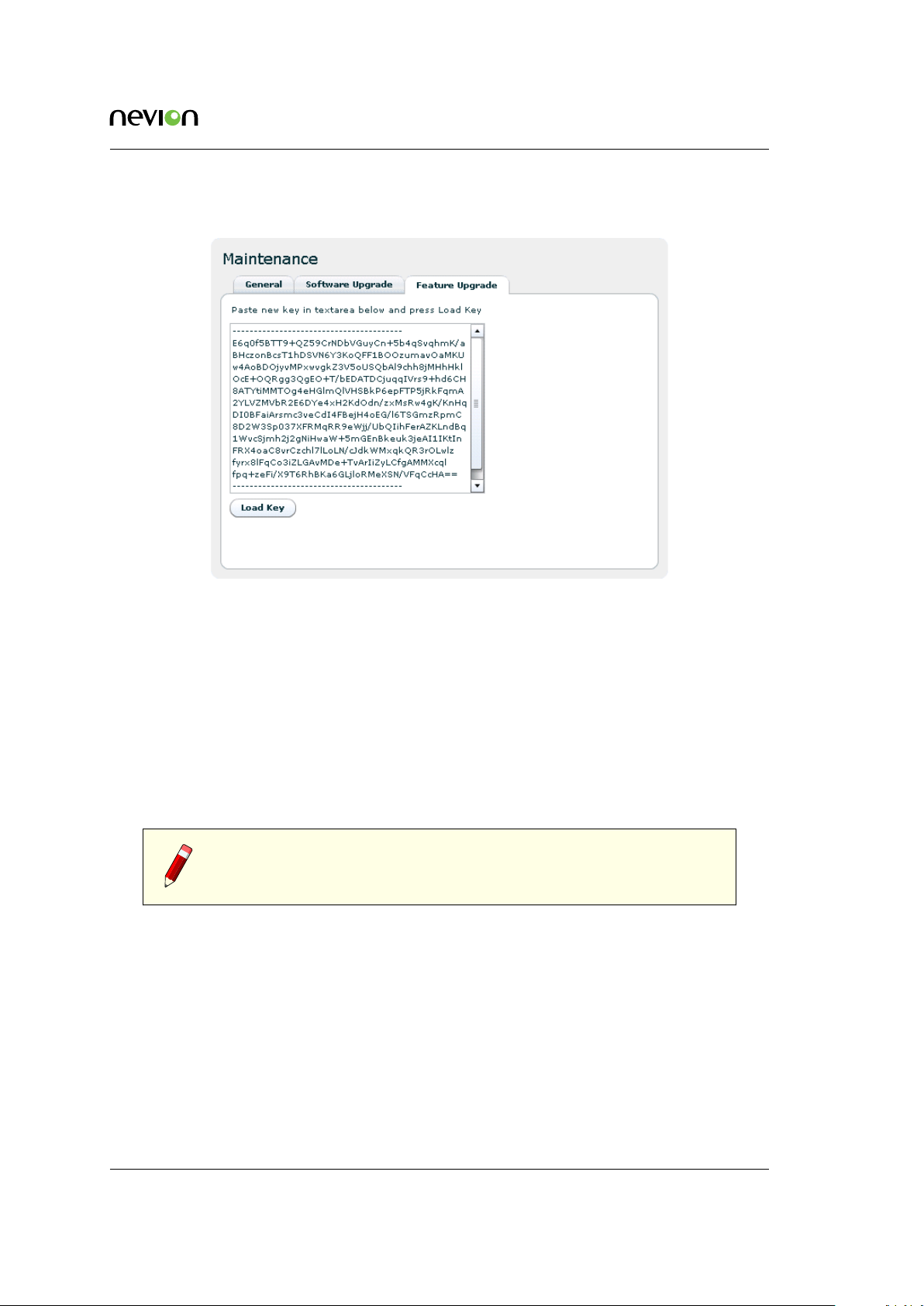

7.5.7.3 Feature Upgrade 89

7.5.8 Users 89

7.5.9 GUI Preferences 90

7.6 Encoders 91

7.6.1 Encoders overview 91

7.6.2 Encoder 92

7.6.2.1 Main 92

7.6.2.2 Alarms 95

7.6.2.3 JPEG2000 95

7.6.2.4 Audio 96

7.6.2.5 HD VBI 97

7.6.2.6 ANC 97

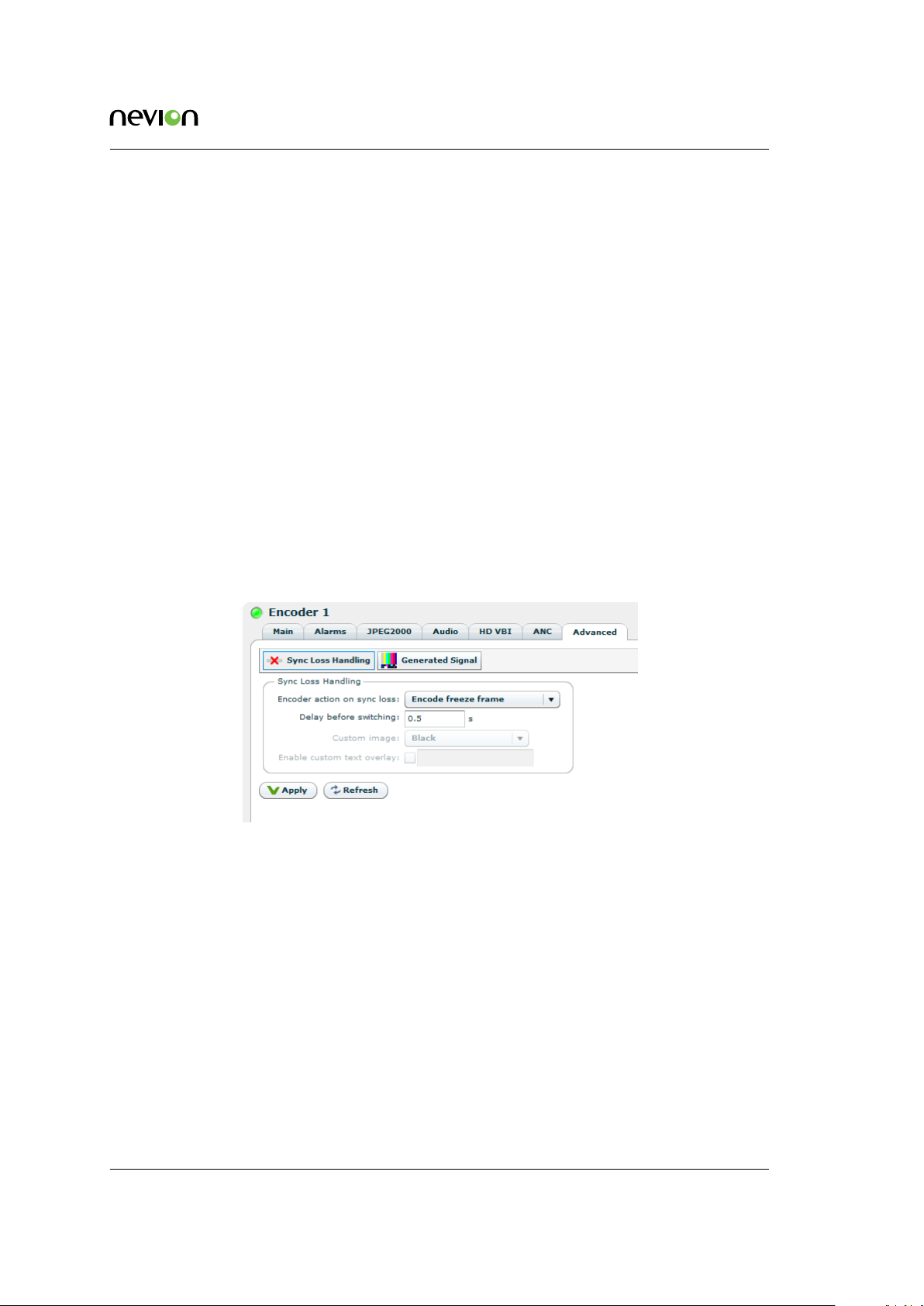

7.6.2.7 Advanced 98

7.6.3 Encoder, Source 99

7.6.3.1 Main 99

7.6.3.2 Alarms 100

7.6.4 Encoder, IP Destination 101

7.6.4.1 Main 101

7.6.4.2 FEC 103

7.6.4.3 Ping 104

Page 6

7.7 Decoders 105

7.7.1 Decoders overview 105

7.7.2 Decoder 106

7.7.2.1 Main 106

7.7.2.2 Alarms 108

7.7.2.3 JPEG2000 108

7.7.2.4 Audio 110

7.7.2.5 HD VBI 110

7.7.2.6 ANC 111

7.7.2.7 Advanced 111

7.7.3 Decoder, Source 113

7.7.3.1 Main 113

7.7.3.2 Alarms 114

7.7.3.3 FEC 115

7.7.3.4 Ping 115

7.7.3.5 Stat 115

7.7.4 Decoder, IP Diversity RX 115

7.7.5 Decoder, SDI Out 117

7.7.5.1 Main 117

7.7.5.2 Decoder SDI Out Alarms page 117

7.8 SDI Ports 117

7.8.1 Main 117

7.8.1.1 SDI-IN 118

7.8.1.2 SDI-OUT 119

7.8.1.3 Alarms 119

7.9 IP Status 120

8 SNMP 121

8.1 SNMP agent characteristics 121

8.2 MIB naming conventions 121

8.3 MIB overview 121

8.3.1 Supported standard MIBs 121

8.3.2 Custom MIBs 121

8.4 SNMP related configuration settings 123

8.4.1 Community strings 124

8.4.2 Trap destination table 124

8.4.3 Trap configuration 124

8.5 Alarm/status related SNMP TRAPs 125

8.5.1 The main trap messages 125

8.5.2 Severity indications 125

8.5.3 Alarm event fields 126

8.5.4 Matching of on/off traps 127

8.5.5 Legacy trap messages 127

8.6 Using net-snmp to access MIB information 128

8.6.1 Reading a parameter with snmpget 128

8.6.2 Writing a parameter with snmpset 128

Page 7

9 Preventive Maintenance and Fault-finding 131

9.1 Preventive maintenance 131

9.1.1 Routine inspection 131

9.1.2 Cleaning 131

9.1.3 Servicing 131

9.1.4 Warranty 132

9.2 Fault-finding 132

9.2.1 Preliminary checks 132

9.2.2 PSU LED not lit / power supply problem 133

9.2.3 Fan(s) not working / unit overheating 134

9.3 Disposing of this equipment 134

9.4 Returning the unit 134

A Glossary 135

B Technical Specification 141

B.1 Physical details 141

B.1.1 Half-width version 141

B.1.2 Full-width (dual power) version 141

B.2 Environmental conditions 141

B.3 Power 142

B.3.1 AC Mains supply 142

B.3.2 DC supply 142

B.4 Input/output ports 142

B.4.1 HD-SDI port 142

B.4.2 Ethernet ports 143

B.4.3 Serial USB interface 143

B.5 Alarm ports 143

B.5.1 Alarm relay/reset port specification 143

B.6 Compliance 144

B.6.1 Safety 144

B.6.2 Electromagnetic compatibility - EMC 144

B.6.3 CE marking 145

B.6.4 Interface to “public telecommunication system” 145

C Forward Error Correction in IP Networks 147

C.1 IP stream distortion 147

C.2 Standardisation 148

C.3 FEC matrix 148

C.4 Transmission aspects 151

C.5 Quality of service and packet loss in IP networks 152

C.6 Error improvement 153

C.7 Latency and overhead 154

Page 8

D Quality of Service, Setting Packet Priority 157

D.1 MPLS 157

D.2 Layer 3 routing 157

D.2.1 TVG480 configuration 158

D.3 Layer 2 priority 158

D.3.1 TVG480 configuration 158

E Alarms 159

F References 169

Page 9

1 History

Revision Date SW version Comments

2.8.24 June 2014 2.8.24 Updated for sw version 2.8.24

2.6.8 April 2013 2.6.8 Updated for sw version 2.6.8

2.4.4 March 2012 2.4.4 Updated for sw version 2.4.4

2.2.8 January 2012 2.2.8 Updated for sw version 2.2.8

2.0.20 August 2011 2.0.20 Updated for sw version 2.0.20

1.2.22 December 2010 1.2.22 Updated for sw version 1.2.22

1.0.0 October 2009 1.0.0 Initial release

History 9

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 10

10

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 11

Introduction 11

2 Introduction

2.1 Scope

This manual is written for operators and users of the TVG480 JPEG2000 Post Production Gateway and provides necessary information for installation, operation and day-to-day maintenance

of the unit. The manual covers the functionality of the software version 2.8.24 or later, and continues to be relevant to subsequent software versions where the functionality of the equipment

has not been changed. When a new software version changes the functionality of the product,

an updated version of this manual will be provided.

The manual covers the following topics:

• Getting started

• Equipment installation

• Operating instructions

• WEB interface description

• Preventive maintenance and fault finding

• Alarm listing

• Technical specifications

2.2 Warnings, cautions and notes

Throughout this manual warnings, cautions and notes are highlighted as shown below:

Warning: This is a warning. Warnings give information, which if strictly

observed, will prevent personal injury and death, or damage to personal

property or the environment.

Caution: This is a caution. Cautions give information, which if strictly

followed, will prevent damage to equipment or other goods.

Note: Notes provide supplementary information. They are highlighted for

emphasis, as in this example, and are placed immediately after the relevant

text.

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 12

12 Introduction

2.3 Heed warnings

• All warnings marked on the product and in this manual should be adhered to. The

manufacturer cannot be held responsible for injury or damage resulting from negligence of warnings and cautions given.

• All the safety and operating instructions should be read before this product is installed and operated.

• All operating and usage instructions should be followed.

• The safety and operating instructions should be retained for future reference.

2.4 Contact information

Our primary goal is to provide first class customer care tailored to your specific business and

operational requirements.

Please contact us at:

Telephone +47 22 88 97 50

Fax +47 22 88 97 51

E-mail support@t-vips.com

WEB www.t-vips.com

Mail and visiting address T-VIPS AS

Nils Hansens vei 2

NO-0667 Oslo

Norway

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 13

Short Product Description 13

3 Short Product Description

The TVG480 JPEG2000 Post Production Gateway represents the next generation solution for

transport of high definition TV over IP networks.

The TVG480 JPEG2000 Post Production Gateway is a member of the T-VIPS Video Gateway suite;

a line of compact, powerful and cost-effective products designed for real-time contribution and

distribution of broadcast quality video over IP networks.

The TVG480 JPEG2000 Post Production Gateway provides encoding or decoding of up to two

HD-SDI channels simultaneously.

TVG480 JPEG2000 Post Production Gateway takes advantage of the unmatched quality of JPEG2000

compression combined with the inherent flexibility of IP. JPEG2000 wavelet compression technology enables transmission of compressed 3G HD, HDTV and SD television over Gigabit Ethernet. Broadcasters are offered an efficient, affordable and scalable solution for studio quality,

high definition, video contribution.

TVG480 enables operators to utilize Ethernet technology to build cost effective SONET, IPMPLS or Metro Ethernet networks for video transport. Built in Quality of Service functionality

combined with Forward Error Correction and error concealment secures flawless operation from

end to end even in presence of IP impairments as packet loss or heavy jitter.

Salient features of the TVG480 are:

• Up to two JPEG2000 compressed simultaneous HD-SDI video channels, depending on

licensed features.

• High Quality Video

− Programmable JPEG2000 compression

− 10 bit video resolution

− Frame-by-frame encoding

• Robust transmission of HD-SDI signals

− Flexible Forward Error Correction (option)

− Error concealment

− Ethernet interfaces, electrical or SFP

− Smallcast

− Hitless switching (using RTP/IP diversity reception (option))

• Very Low Delay

− Aggregate encoding and decoding delay less than 60 ms (mode dependent)

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 14

14 Short Product Description

• MXF encapsulation

− Suitable for file-based workflow

• Ancillary data support

− Transparent transfer of embedded audio and vertical interval data

• Compact, flexible cost-effective solutions

− Half-width 19 inch 1 RU version, sideways stackable

− Full-width 19 inch 1 RU version with dual power.

• User-friendly configuration and control

− WEB/XML based remote control

− SNMP agent for easy integration with network management systems (NMS)

− Can be integrated with T-VIPS Connect

3.1 Software options

The TVG480 JPEG2000 Post Production Gateway functionality depends on software modules

that may be individually enabled through a software licensing scheme. Software licences may

be purchased from T-VIPS and installed by the user.

The following table describes features available as software options. Please refer to

for more information about how to enable new software features.

Table 3.1 Functionality enabled through software licences

Functionality Function

Connect Control Supervision of the unit through the Connect software. This must be enabled in order to

allow remote supervision.

Forward Error Correction Pro-MPEG Forward Error Correction.

Encoding Enables encoding functionality.

Decoding Enables decoding functionality.

SFP Module Enables use of the SFP module.

Allow Stereo 3D operation Enables encoding/decoding of stereoscopic 3D signals.

RTP/IP Diversity Reception Enables hitless switching between two identical IP input streams

The feature list for the TVG480 JPEG2000 Post Production Gateway will show more features

than listed here. For available upgrade options, please contact sales@t-vips.com.

Chapter 7

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 15

Getting Started 15

4 Getting Started

This section provides a short description of the minimum steps that must be taken in order to

start operating the TVG480.

If you are an experienced user of T-VIPS equipment or similar types of encoding/decoding

equipment the following description should enable you to quickly install the TVG480 JPEG2000

Post Production Gateway and start operation. If this is your first time to install such equipment

you are strongly adviced to read the full installation procedure. To gain full benefit of the

product functionality and capabilities refer to the user interface description.

The procedures outlined below are based on the assumption that the unit is in the factory

default state.

4.1 Configure the management Ethernet interface

Since the primary interface for controlling the TVG480 is Web based, the first step is to set up

the IP address for the management interface.

Changing the default IP address using the Web interface requires that your management computer may be configured with a static IP address. If a static IP address cannot be configured on

your computer the IP address may be configured via the terminal interface. The procedure is

described in the user manual.

Note: Avoid connecting through a network at this stage, as this may give

unpredictable results due to possible IP address conflict.

1. Connect an Ethernet cable directly between the PC and the Ethernet 1 port of the

TVG480. The default IP address of the TVG480 is 10.0.0.10/255.255.255.0. Configure the

PC to be on the same subnet as the TVG480.

2. Open your Web browser and type http://10.0.0.10 in the address field of the browser.

Log into the GUI with username admin and password salvador.

3. Browse to Device Info > Network > Ethernet 1 in the GUI, and set the IP address

settings required for your network. Click Apply to activate the new parameters.

4. The connection with your management PC will now be lost. To re-connect to the

TVG480 connect both the Ethernet 1 port of the unit and the management PC to the

network. The IP settings of the management PC must now be set to agree with the

network used.

5. Again, open your Web browser and type http: (New-IP-Address) in the address field of

the browser. Log into the GUI with username admin and password salvador.

An alternative to using the WEB browser to configure the IP address is to set up the address

using a local USB cable. This procedure is explained in Section 6.3.2.

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 16

16 Getting Started

4.2 Configure device name and time settings

1. Assign a name for the device in order to more easily identify the unit in the network.

Browse to Device Info > Product Info and enter a Name and Inventory ID. Click Apply

to activate.

2. Set date and time of the real time clock to ensure correct time stamping of the alarm

log entries. Browse to Device Info > Time Settings. The internal clock may be used to

time stamp alarm log entries, in which case a manual Date and Time adjust is all that

is needed. Click Apply to activate.

You may enable an external time source to provide a common reference for alarm logs

of all units of a system. Refer to the user manual for details.

4.3 Select the operational mode

Before starting to use the TVG480, it is essential to understand the fundamental operational

modes of the unit.

Note: Changing the operational mode requires reboot of the unit.

For the TVG480, there are three fundamental operational modes that need to be configured.

These are listed in the following table.

The operational modes are configured on the Device Info > Maintenance subpage as shown in

Figure 4.1.

To change an operational mode, select the new mode from the drop down lists/radio buttons.

When pressing the Apply button, you are asked to confirm reboot of the device. By accepting

the request, the unit will reboot and the device will start up in the new configured mode.

4.4 Connect the signals

After configuring the IP address and operational mode, the product is ready to do encoding or

decoding of video signals. To configure parameters needed for encoding, see Section 7.6. To

configure parameters needed for decoding, see Section 7.7.

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 17

Getting Started 17

Operational mode Description Values

Encode/Decode This mode selects whether the device shall operate as

a pure encoder, a pure decoder or a combined

encoder/decoder (“bidirectional mode”).

Ethernet Interface The TVG480 in standard configuration has three

network ports, but only two of them can be used

simultaneously. Depending on the operational mode,

it can operate with either two electrical Gigabit

Ethernet ports, or one SFP and one electrical Gigabit

Ethernet.

As a HW-option, the TVG480 can be delivered with

two additional network ports, one electrical and one

SFP. Except for Ethernet port 1 (electrical Gigabit),

which is always available, only ports of the same type,

electrical or SFP, can be used simultaneously.

Depending on the operational mode, it can thus

operate with either three electrical Gigabit Ethernet

ports, or one electrical Gigabit Ethernet port and two

SFP ports.

Video Field Rate Selects the fundamental video field rate of the unit.

It must be set to match the video formats that will

be used during operation.

Encode, Decode or Encode/Decode

SFP, 1000Base-T

50Hz/24Hz, 59.94Hz/23.98Hz and 60Hz

Figure 4.1 Operational modes for the TVG480

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 18

18

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 19

Installing the Equipment 19

5 Installing the Equipment

Caution: The TVG480 must be handled carefully to prevent safety hazards

and equipment damage. Ensure that the personnel designated to install

the unit have the required skill and knowledge. Follow the instructions

for installation and use only installation accessories recommended by the

manufacturers.

5.1 Inspect the package content

• Inspect the shipping container for damage. Keep the shipping container and cushioning

material until you have inspected the contents of the shipment for completeness and

have checked that the TVG480 is mechanically and electrically in order.

• Verify that you received the following items:

− TVG480 with correct power supply option

− Power cord(s)

− CD-ROM containing documentation and Flash Player installation files

− Any optional accessories you have ordered

Note: 48 VDC versions do not ship with a power cord; instead a Power

D-SUB male connector for soldering to the supply leads is supplied.

5.2 Installation Environment

As with any electronic device, the TVG480 should be placed where it will not be subjected to

extreme temperatures, humidity, or electromagnetic interference. Specifically, the selected site

should meet the following requirements:

• The ambient temperature should be between 0 and 50◦C (32 and 122◦F).

• The relative humidity should be less than 95 %, non-condensing. Do not install the

unit in areas of high humidity or where there is danger of water ingress.

• Surrounding electric devices should comply with the electromagnetic field (EMC) standard IEC 801-3, Level 2 (less than 3 V/m field strength).

• The AC power outlet (when applicable) should be within 1.8 meters (6 feet) of the

TVG480.

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 20

20 Installing the Equipment

• Where appropriate, ensure that this product has an adequate level of lightning protection. Alternatively, during a lightning storm or if it is left unused and unattended for

long periods of time, unplug it from the power supply and disconnect signal cables.

This prevents damage to the product due to lightning and power-line surges.

Warning: If the TVG480 has been subject to a lightning strike or a power

surge which has stopped it working, disconnect the power immediately.

Do not re-apply power until it has been checked for safety. If in doubt

contact T-VIPS.

5.3 Equipment installation

The TVG480 is designed for stationary use in a standard 19" rack. When installing please observe

the following points:

• Route cables safely to avoid them being pinched, crushed or otherwise interfered with.

Do not run AC power cables and signal cables in the same duct or conduit.

• The TVG480 has all connectors at the rear. When mounting the unit, ensure that the

installation allows easy access to the rear of the unit.

• The fans contained in this unit are not fitted with dust/insect filters. Pay particular

attention to this when considering the environment in which it shall be used.

• Make sure that the equipment is adequately ventilated. Do not block the ventilation

holes on each side of the TVG480.

5.4 Ventilation

Openings in the cabinet are provided for ventilation to protect it from overheating and ensure

reliable operation. The openings must not be blocked or covered. Allow at least 50 mm free

air-space each side of the unit.

Warning: Never insert objects of any kind into this equipment through

openings as they may touch dangerous voltage points or create shorts that

could result in a fire or electric shock. Never spill liquid of any kind on or

into the product.

• This product should never be placed near or over a radiator or heat register. Do not

place in a built-in installation (e.g. a rack) unless proper ventilation is provided in

accordance with the device airflow design as depicted in Figure 5.1.

• The TVG480 may be vertically stacked in 19" racks without intermediate ventilation

panels. In systems with stacked units forced-air cooling may be required to reduce the

operating ambient temperature.

Figure 5.1 shows the air path through the unit, where cool air is taken from the left

hand side, seen from the front.

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 21

Installing the Equipment 21

CP541

Cool

Air In

Warm

Air Out

Figure 5.1 Air path through the unit

5.5 Power supply

The TVG480 may be delivered rated for AC or DC operation, respectively.

Warning: This product should be operated only from the type of power

source indicated on the marking label. Please consult a qualified electrical

engineer or your local power company if you are not sure of the power

supplied at your premises.

5.5.1 AC power supply

The TVG480 has a wide-range power supply accepting the voltage range 100-240 VAC, 50/60

Hz. Please refer to Appendix B for a detailed specification of the AC power supply.

5.5.2 Dual AC power supplies

Alternatively, the TVG480 may be fitted with dual internal wide-range AC power supplies. If so,

the size of the cabinet is full-width 19" rack, 1RU. The power supplies cover the voltage range

100-240 VAC, 50/60 Hz.

During normal operation, load-sharing is used between the internal supplies. In case of a single

power supply failure alarms will be raised and the unit will continue operating off the second

power supply. To guard against failure in the external power circuitry it is imperative to connect

each power supply to separate AC mains circuits.

Please refer to

Appendix B for a detailed specification of the AC power supply.

5.5.2.1 AC power cable

Ensure that the AC power cable is suitable for the country in which the unit is to be operated.

Caution: Power supply cords should be routed so that they are not likely

to be trod on or pinched by items placed upon or against them. Pay

particular attention to cords at plugs and convenience receptacles.

The unit is supplied with a two meter detachable mains supply cable equipped with a moulded

plug suitable for Europe, UK or USA, as appropriate. The wires in the mains cable are coloured

in accordance with the wire colour code shown in Table 5.1.

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 22

22 Installing the Equipment

Table 5.1 Supply cable wiring colours

Wire UK (BS 1363) EUROPE (CEE 7/7) USA (NEMA 5-15P)

Earth Green-and yellow Green-and yellow Green

Neutral Blue Blue White

Live Brown Brown Black

5.5.2.2 Protective Earth/technical Earth

To achieve protection against earth faults in the installation introduced by connecting signal

cables etc., the equipment should always be connected to protective earth. If the mains supply

cable is disconnected while signal cables are connected to the equipment, an earth connection

should be ensured using the Technical Earth connection terminal on the rear panel of the unit.

Warning: This unit must be correctly earthed through the moulded plug

supplied. If the local mains supply does not provide an earth connection

do not connect the unit.

Caution: Consult the supply requirements in Appendix B prior to connecting the unit to the supply.

The unit has a Technical Earth terminal located in the rear panel. Its use is recommended. This

is not a protective earth for electrical shock protection; the terminal is provided in order to:

1. Ensure that all equipment chassis fixed in the rack are at the same technical earth

potential. To achieve this, connect a wire between the Technical Earth terminal and a

suitable point in the rack. To be effective all interconnected units should be earthed

this way.

2. Eliminate the migration of stray charges when interconnecting equipment.

Warning: If the terminal screw has to be replaced, use an M4x12mm long

pozidrive pan head. Using a longer screw may imply a safety hazard.

5.5.2.3 Connecting to the AC power supply

Warning: Do not overload wall outlets and extension cords as this can

result in fire hazard or electrical shock. The unit is not equipped with an

on/off switch. Ensure that the outlet socket is installed near the equipment

so that it is easily accessible. Failure to isolate the equipment properly may

cause a safety hazard.

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 23

Installing the Equipment 23

To connect the unit to the local AC power supply, connect the AC power lead to the TVG480

mains input connector(s) and then to the local mains supply.

5.5.3 DC power supply

The TVG480 can be delivered with a 48 VDC power supply for use in environments where this

is required. The DC power supply accepts an input voltage range of 36-72 VDC. Please refer to

Appendix B for detailed specification of the power supply.

5.5.3.1 DC power cable

Units delivered with DC power supply have a 3-pin male D-SUB power connector instead of

the standard mains power connector. Also a female 3-pin D-SUB connector is supplied. The

pin assignment is shown in Table 5.2. The power cable itself is not supplied.

Table 5.2 DC power connector pin

assignment

Pin Placement Specification

1 top + (positive terminal)

2 middle - (negative terminal)

3 bottom Chassis Ground

To connect the unit to the local DC power supply:

1. Use an electronics soldering iron or a hot air workstation to attach the supplied female

D-SUB power connector to suitable power leads.

2. Connect the power leads to your local power supply.

3. Connect the DC power connector, with attached power leads, to the TVG480 power

input connector.

5.5.4 Powering up/down

Before powering-up the unit, please ensure that:

• The unit is installed in a suitable location

• The unit has been connected to external equipment as required

Power up the unit by inserting the power cable connected to the power source. When the unit

has finished the start-up procedure, the fans will run at normal speed. Please check that all

cooling fans are rotating. If they are not, power down the unit immediately.

Power down the unit by removing the power supply connector at the rear of the unit.

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 24

24 Installing the Equipment

5.6 Connecting the TVG480

5.6.1 Physical description overview

The front panel provides two LEDs per TVG480. The meaning of each LED indicator is shown

in Table 5.3.

Table 5.3 Front panel LED descriptions

Indicator Colour Description

PSU Green

Alarm Red This LED is lit when a failure is detected by the unit

These LEDs are also replicated on the rear panel, shown in Figure 5.2.

Normal operation

Unlit

During system boot

Figure 5.2 Rear panel

Disconnect mains supply before moving or installing the equipment. Ensure ESD precautions

are observed while interconnecting equipment.

5.6.2 SDI ports

The TVG480 has 2 HD-SDI input ports and 4 HD-SDI output ports. The ports are physically

capable of both HD-SDI and 3G-SDI.

Note: Input ports 3 and 4 are not used for the TVG480.

5.6.3 Ethernet Ports

The TVG480 in standard configuration provides three Ethernet ports, of which two can be used

simultaneously. Ethernet 1 is always active, together with either Ethernet 2 or SFP (Small FormFactor Pluggable). (Switching between the modes is done by changing the operational mode

parameter described in Section 4.3).

The default interface speed mode for the electrical Ethernet ports is 1000Base-T. In this mode

the port can auto sense between 10, 100 and 1000 Mbit/s. The operator is able to force the

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 25

Installing the Equipment 25

interface speed to various fixed speeds. This is normally not necessary, but may be useful for

minimizing the synchronisation time when reconnecting signal cables.

For flexibility, the TVG480 provides a Small Form-Factor Pluggable (SFP) slot to carry a copper or

optical SFP, allowing customers to use different SFPs for special distance, cost, existing infrastructure, and future expansion requirements. The TVG480 is prepared for electrical (1000Base-T) or

optical 1000BASE-SX and 1000BASE-LX SFP transceivers.

The LEDs for the electrical Ethernet ports are used as follows:

Table 5.4 Electrical

Ethernet port LEDs

LED indicator Location Description Colour

Activity Left 10 Mbit/s

100 Mbit/s

1000 Mbit/s

Link Right Lit=Link Green

In an extended configuration, two additional Ethernet ports are provided, one electrical (Ethernet

3) and one SFP (SFP 2). These have the same specifications as the standard Ethernet ports, and

their usage is restricted so that each one is only active together with the ports Ethernet 2 or SFP,

respectively.

Green

Yellow

Orange

The rear panel when configured with these additional Ethernet ports is shown in Figure 5.3.

Figure 5.3 Rear panel in extended configuration

5.6.4 Power Supply

Section 5.5 provides details of the power supply, protective earth and security. Read all these

instructions prior to connecting the unit’s power cable.

5.6.5 Technical Earth

Connect the Technical Earth to a suitable earth point.

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 26

26 Installing the Equipment

5.6.6 Alarm/Reset

The unit is equipped with a 9-pin male DSub connector to provide alarm information. The

connector is labelled Alarm on the back panel.

Two programmable relays are provided. The first relay is always activated on a critical alarm or

when the unit is not powered. Please refer to

the relays.

The pin out of the connector is shown in Table 5.5.

Table 5.5 Alarm/Reset

connector pin out

Pin Function

1. Relay 2 - Closed on alarm (NC)

2. Relay 2 Common

3. Relay 2 - Open on alarm (NO)

4. Prepared for +5V Output

5. Ground

6. Relay 1 - Closed on alarm (NC)

7. Relay 1 Common

8. Relay 1 - Open on alarm (NO)

9. Optional Reset Input / GPI

Section 7.5.2.3 for a description how to program

When there is a critical (level 6) alarm in the unit, if the unit has no power or any other

programmed condition for relay 1 is satisfied, there will be a connection between pin 6 and pin

7. Otherwise, there will be a connection between pin 7 and pin 8.

The optional (additional) relay will follow the same behaviour, except that it can also be programmed not to be activated for a critical (level 6) alarm.

A connection between pins 9 and 5 (or a TTL low on pin 9) will hold the unit reset, provided

this function has been enabled. The connection must be held for more than 0.5 seconds in order

to activate the reset. This can be used to force a hard reset of the unit from an external control

system. This pin can also be used as a general purpose input (GPI).

For more details regarding the alarm relay, please refer to Technical Specifications,

Appendix

B.

5.6.7 Serial USB interface

The TVG480 is also provided with a USB interface to communicate with the administrator PC.

USB 1.1 is supported and the physical interface is a mini USB connector.

The USB interface requires a special COM port driver in the PC that shall communicate with the

device. This driver is provided on the product CD shipped with the device. The USB interface

is intended for initial IP address setup.

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 27

Operating the Equipment 27

6 Operating the Equipment

The TVG480 is configured and controlled locally and remotely through a Flash-based Web

interface. The only application required on the computer to use this interface is a Web browser

and the Adobe Flash Player.

Note: Adobe Flash Player 9.0 or newer is required to use the Web interface

of the TVG480. As a general rule it is recommended to always use the

latest official release of Flash Player (version 10 or newer). If the Flash

Player is not installed on the adminstrator PC, a copy is provided on the CD delivered

with the device. Alternatively, the latest Adobe Flash Player can be downloaded

free of charge from

Note: When using Microsoft Internet Explorer, version 6.0 or higher is

required. It is however recommended to upgrade to version 8.0 or newer

for best performance.

http://www.adobe.com.

6.1 Accessing the graphical user interface

The default IP address of the TVG480 will most probably not be suitable for the network where

the unit will operate. Initially therefore, the user should change the IP address of the management interface so that access may be gained from the network.

The TVG480 offers two options to alter the user interface IP address; through an Ethernet

connection or using a USB terminal interface. If your management computer allows setting a

fixed IP address, change the IP address using the Ethernet option described in Section 6.3.1.

If a static address cannot be configured on your management computer, Section 6.3.2 gives the

procedure to initially configure device network parameters (IP, netmask, etc...) using the USB

terminal interface.

Configuring the device functionality according to operational needs is done using the Web

interface, see Chapter 7.

6.2 Password protection

Remote access to the device is controlled by password protection. If you access the TVG480

using the USB terminal interface a password is not required.

There are 3 user levels providing different user privileges, each with a separate default password:

Username Default password Privileges

admin salvador Full access to device

operator natal Configure setting, cannot alter passwords

guest guest View configuration and alarm logs

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 28

28 Operating the Equipment

The passwords can later be changed, either from the Web GUI or via the terminal.

6.2.1 Resetting the password list

If a password is lost, the password list can be reset to factory defaults via the local USB terminal

interface. To reset the password list, type the following command in the terminal interface:

userdb factory_defaults

Note: The factory_defaults option on the userdb command is avail-

able without administrator previledges only when accessing the terminal

via the local USB interface. In remote terminal sessions with a Telnet

client, administrator privileges are required to run the same command.

6.3 Changing the IP address of the unit

The default IP configuration on the Ethernet ports is described in Table 6.1.

Table 6.1 Default

IP configuration

Interface IP address Subnet mask

Ethernet 1 10.0.0.10 255.255.255.0

Ethernet 2 169.254.1.11 255.255.255.0

SFP 169.254.2.12 255.255.255.0

Ethernet 3 169.254.3.13 255.255.255.0

SFP 2 169.254.4.14 255.255.255.0

Note that the ports Ethernet 3 and SFP 2 are only available as a HW option.

6.3.1 Changing IP address via the Web GUI

Figure 6.1 Configuring network

settings via the Web GUI

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 29

Operating the Equipment 29

1. Connect an Ethernet cable directly between the PC and the Ethernet port of choice on

the TVG480. Configure the PC to be on the same subnet as the TVG480. See Figure

6.2.

2. Open your Web browser and type the default ip address of the chosen interface in the

address field of the browser (for instance http://10.0.0.10 for Ethernet 1). Log into the

GUI with username admin and password salvador.

3. Browse to Device Info -> Network -> Ethernet 1 (resp. Ethernet 2) in the GUI, and set

the correct IP address settings. Click Apply to activate the new parameters. Figure 6.1

shows this GUI screen.

Note: Contact with the unit’s GUI will now be lost. Please type

http://<your new IP address> in your browser to reconnect to the unit.

Windows XP example

The screen-shot in Figure 6.2 shows how to configure the network interface in Windows

XP to communicate with the TVG480 via Ethernet 1 with factory default settings. The

IP address/netmask is set to 10.0.0.11/255.255.255.0 which is on the same subnet as the

TVG480, and does not conflict with the IP address of the device.

Figure 6.2 Setting static IP address 10.0.0.11 in Windows XP

Note: If several new devices are accessed one after the other, the ARP

cache of the computer from which the devices are being accessed may

have to be flushed between each new device access, since the same IP

address will be used for different MAC addresses. On Windows XP this is done on

the command line typing the command ’arp -d *’

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 30

30 Operating the Equipment

6.3.2 Changing the management port IP address via the terminal interface

If a static IP address cannot be configured on your computer, follow the procedure below to

configure the IP address via the terminal interface.

1. Install the USB driver from the product CD (setup_ftdi_usb_drivers.exe). (This step may

be omitted if the driver has already been installed.)

2. Connect your computer to the TVG480 via a USB cable to the USB port.

3. Access the terminal interface using a suitable terminal program, emulating an ANSI

terminal, on your PC (e.g. HyperTerminal). The USB will appear as a virtual COM

port on your PC. No specific serial port settings are required. Assure scroll lock is not

on. Type <enter> and see that you have a prompt (app>).

4. In the terminal, type the following command and press <Enter>:

net ipconfig --ip <ip address> --mask <subnet mask> --gw <default gateway> --if <interface

number>

Example:

app>net ipconfig --ip 10.40.80.100 --mask 255.255.255.0 --gw 10.40.80.1 --if 0

This will result in the IP address 10.40.80.100 being set on interface 0 (Ethernet 1). The subnet

mask is set to 255.255.255.0 and the default gateway to 10.40.80.1.

Note: The product CD shipped with the TVG480 contains a USB driver

to use for serial communication with the device on the USB port. The

MS Windows driver installation script is configured to give a one-to-one

relationship between the physical USB port number on the PC and the COM port

number to use on the PC. Drivers retrieved from http://www.ftdichip.com will also

work, but these may not have the same COM port number mapping.

6.3.3 Configuring automatic IP address assignment

The TVG480 can be configured to obtain an IP address automatically from a DHCP server on the

network. See section 6.3.1 for how to connect, and section 7.5.5.1.1.1 for how to configure this

from the GUI. Alternatively, configure it in the terminal by connecting as in 6.3.2 and issuing

the following command:

ipconfig --dhcp 1 --hostname <your_device_name> --if <interface-number>

Example:

ipconfig --dhcp 1 --hostname bonemachine-100 --if 0

Replace <your_device_name> with the name to register in the DNS system for your device.

After this, it should be possible to contact the unit in a browser using the URL:

http://<your_device_name>

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 31

Operating the Equipment 31

To disable automatic IP assignment, use the command

ipconfig --dhcp 0 --if <interface-number>

Note: Hostname registration is only done via the DHCP server, so if

DHCP is not enabled the hostname is not registered. The default hostname

used is on the format TVG480-<serial-no>-<interface-no>

Note: If automatic IP address assignment is configured and the interface

is connected to a network that does not support DHCP, the interface will

not receive an address and will fall back to a link local address after about 1

minute, using the first available address in the range 169.254.1.0 - 169.254.254.255.

If you have a unit that has been configured with DHCP, but current network does

not support it, you should be able to connect to the device for reconfiguration on a

local network connection using the address 169.254.1.0. If more devices are using

link local addresses, try 169.254.1.1, 169.254.1.2, etc.

6.4 Stereoscopic 3D operation

The TVG480 is capable of transporting high definition stereoscopic 3D TV over IP networks.

Figure 6.3 Encoding a stereoscopic 3D signal.

6.4.1 Requirements

To set up the TVG480 to transport stereoscopic 3D requires an Allow Stereo 3D operationlicence. Furthermore, at least two channels and encoders, resp. decoders, must be licensed, as

transmission of stereoscopic 3D signals requires two channels for encoding, resp. decoding.

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 32

32 Operating the Equipment

6.4.2 Configuration

The TVG480 must operate as a pure encoder, resp. pure decoder, to enable stereoscopic 3D

operation. The channels 1 and 2 (i.e. SDI-input port 1 and SDI-input port 2, Encoder 1 and

Encoder 2, etc) are used for the processing of stereoscopic 3D signals. Channel 1 will operate

as a master and channel 2 as a slave for the processing of 3D signals.

To set up the TVG480 for encoding of 3D signals do the following:

1. On the encoding unit, connect the (synchronized) stereoscopic SDI-signal to the SDI

input ports 1 and 2.

2. On the main tab for Encoder 1, enable the desired video format and enable the Stereo-

scopic 3D checkbox. This will turn Encoder 1 into the master and Encoder 2 into the

slave for 3D operation. All necessary IP connection parameters will be controlled via

Encoder 1. To maintain full flexibility, audio channels and other ancillary data can be

configured for each channel individually.

3. Set the IP destination address and port for Encoder 1. Encoder 2 will automatically send

to the same IP address, and a suitable destination port will automatically be chosen for

Encoder 2.

4. Finally, set the maximal available bitrate for 3D operation, i.e. for Encoder 1 and Encoder

2 combined.

On the decoding unit, select the desired video mode and stereo 3D operation on Decoder

1. Set the IP source address and port, and the remaining connection parameters will be set

automatically, with Decoder 2 being controlled by Decoder 1.

6.5 Hitless switching

The TVG480 enables hitless switching by combining smallcast on the transmitter side with

RTP/IP diversity reception on the receiver sider. Hitless switching provides redundancy by

protecting the stream against errors in IP transmission, but in a different manner compared to

Forward Error Correction (FEC). FEC is designed to protect the stream against single or short

burst packet losses, whereas hitless switching provides protection against loss of complete data

input, for example, due to link or equipment failure.

The main idea of hitless switching is to transmit two identical copies of the data stream over

separate network paths. At the receiver side, the data from the two incoming streams are

combined at packet level to form one data stream. This way, if one of the network paths

experiences severe packet loss or complete link failure, data from the other network path can

be used to output an error free stream.

At the transmitter side, the TVG480 allows sending identical copies of the data stream to a user

defined list of destinations by enabling smallcast. During smallcast transmission all identical

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 33

Operating the Equipment 33

streams are tagged with the same, randomly generated Synchronization Source ID (SSRC). For

each destination, the network interface (or a VLAN on any the interfaces) and separate unicast

or multicast destinations are selected so that the two data streams used for diversity reception

are routed to their respective network paths directly at the TVG480 or at the first sebsequent

network node.

At the receiver side, the IP source parameters are first configured as the master and slave sources

(i.e. first and second IP source). When the data streams have identical SSRCs, they are assumed

to be identical streams and used for diversity reception. Diversity reception operates on the RTP

packet level. The two incoming data streams are combined to form one error free stream as long

as there is one correctly received packet from either input stream. There will be packet loss at

the combined stream only when the packet is received on neither of the two IP sources. The

data stream resulting from combining the two incoming data streams will then be processed as

one RTP packet stream. RTP/IP diversity reception is a licensed feature and is required at the

receiver side. No licence is required for smallcast transmission.

Note: If the same data streams are received at both sources, the sources

will act as equal providers of data. If received streams at the sources are

not identical, the data from the master IP source will be used and data

from the slave IP source will be discarded.

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 34

34

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 35

WEB Interface 35

7 WEB Interface

The TVG480 is primarily controlled through a WEB interface using a Flash application.

7.1 Login

Access the TVG480 by entering its IP address in the address field of your favourite browser.

When accessing the TVG480 the first time, the progress bar (Figure 7.1) should appear while

the Flash application is loading from the device.

Figure 7.1 Flash application loading

When the loading of the Flash application is finished, the login window (see Figure 7.2) is displayed. Type the username and password to enter the GUI application. The default passwords

are listed in

The login dialogue has an option “Save password”, which makes the browser store the username

and password in a cookie and use them as default values at next login.

Section 6.2.

Figure 7.2 GUI login window

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 36

36 WEB Interface

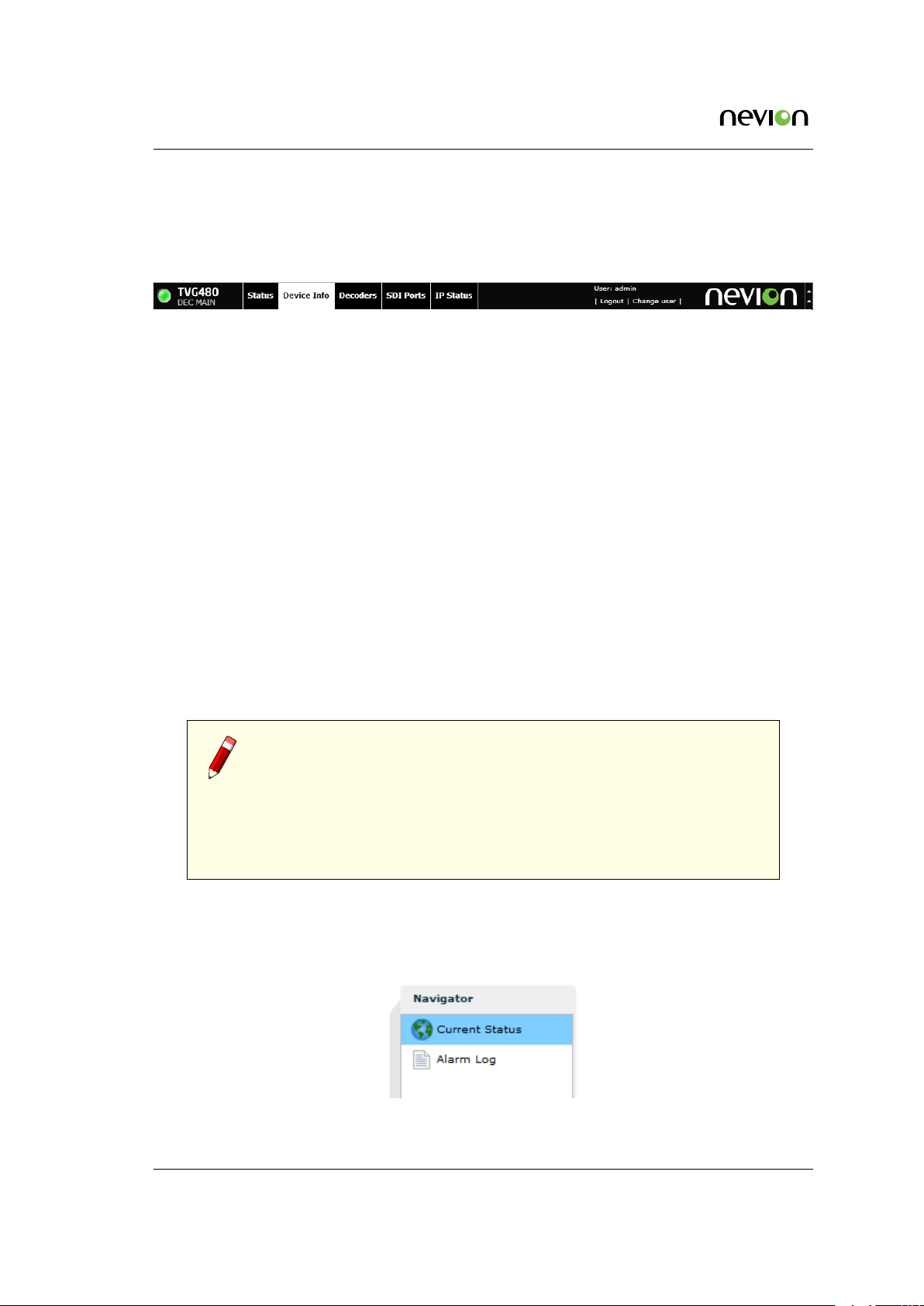

7.2 Status header

After successful login the start page is shown. The top part of the page (shown in Figure 7.3)

is called the status header.

Figure 7.3 The status header

In the status header the product name is shown on the left hand side, along with the T-VIPS

logo. Beside the logo is also shown the current operational mode of the unit.

The status bar displays an indicator showing the overall alarm status of the device. The colour

of the indicator shows the highest level alarm currently active in the unit. It is green if no alarm

is active. Other possible colours are described in Appendix E.

Several items are presented in the right corner/section of the header. Starting from the left:

• The user defined device name, if entered.

• A button to log out from the GUI.

• A button to switch current user level.

• A text showing the current user name.

• The local device time.

• A button for minimising the header. Using this hides a lot of the header information

and gives more space for the rest of the page.

• An activity indicator.

Note: The activity indicator shows one box for each request being

processed by the unit. Each box may change from green to red if ex-

cessive time elapses during the processing. During normal operation, no

squares should turn red. If squares start turning red there might be a problem with

the communication between the device and the computer, or the device may be

busy. If the device has not responded to a request within 20 seconds, the indicator

turns yellow. If no response has been received after 40 seconds, it turns red.

A tab bar is located beneath the status header. The exact number of tabs and tab labelling

depends on the units operational mode and licences. Clicking a tab will open the corresponding

page with a navigation pane to the left as shown in Figure 7.4. This pane is used to navigate

between sub-pages of the tab.

Figure 7.4 Status navigator

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 37

WEB Interface 37

Note: The navigator can be collapsed to economise on screen space. Click

the vertical grey line with two small arrows to the left of the navigator.

7.3 WEB pages overview

The following lists the hierarchy of WEB pages and sub-pages that may be accessed by clicking

on the tabs shown in the status header. These are described later in more detail.

7.3.1 Status

Current Status

Displays the current status of the unit, including status of all ports and any current alarms.

Alarm Log

Displays the Alarm Log on the unit. It allows download and clearing of the log.

7.3.2 Device info

Product Info

Displays general system information and allows setting the device label. The unit may be

physically identified by flashing the front panel power LED.

Alarms

Displays the status of all System alarms and allows the user to program the severity of

these alarms. Global alarm configuration is performed on this page, as well as alarm relay

configuration and alarm log configuration.

Time Settings

On this page the device clock synchronisation source can be selected and the UTC time

offset can be configured. The internal clock can also be adjusted manually.

Reference Sync

On this page an input reference synchronising signal may be enabled and configured.

Network

Displays status information for the Ethernet interfaces.

Ethernet 1 / Ethernet 2 / Ethernet 3 / SFP / SFP 2

Provides access to network settings for each IP interface of the unit. The number of

IP interfaces actually presented will vary depending on the operational mode and the

HW configuration.

IP Routing

Configures IP routing rules for the unit. The rules tell the unit which interface to use

for different destination IP addresses.

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 38

38 WEB Interface

TXP Settings

Settings for the TXP protocol, used for remote control/monitoring of the unit by

external systems.

SNMP Settings

Configures SNMP related settings such as destination IP addresses of trap receivers

and community string. Also displays a log of the latest traps sent by the unit.

Tools

Provides network related tools.

Save/Load Config

Provides file management interfaces for configuration profiles. Tasks available from this

page include importing or exporting configuration snapshots as XML files, and management of profile snapshots stored on the device itself.

Maintenance

Centralises hardware configuration as well as software licence information. The information presented contains the unit hardware configuration as well as the unit’s software

licence options. The maintenance page also provides services for performing software

upgrades and entering new licence keys to alter the licensed feature set of the unit.

From the maintenance page, it is possible to reset/reboot the device or restore the system

configuration to factory default settings.

Users

User administration interface for configuring passwords for users associated with each

security level. Auto-login options are also provided here.

GUI Preferences

Provides settings for altering the behaviour of the GUI.

7.3.3 Encoders

This page provides control of the video encoders of the unit.

7.3.4 Decoders

This page provides control of the video decoders of the unit.

7.3.5 SDI Ports

Provides configuration and status of the video data interfaces.

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 39

WEB Interface 39

7.3.6 IP Status

Provides status information of IP interfaces. Also gives access to enabling and disabling video

IP traffic.

7.4 Status

The status page presents an overview of the device operational status as well as a log of alarm

events.

There are two sub-pages within the status page.

Current Status

Indicates the running status of the device.

Alarm Log

Presents the device alarm log and provides operations for clearing the log or exporting it

as a comma separated value file (.CSV).

7.4.1 Current Status

Figure 7.5 Current status

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 40

40 WEB Interface

This page displays the current status of the device. It consists of a block diagram illustrating the

device with its input and output ports, an overview of the currently active network interfaces

and a list of currently active alarms.

Block Diagram

The block diagram provides a compact view of the unit status. It shows:

• The name of the functional units of the device.

• The name and alarm status of each input/output port.

• The status of non-I/O port related alarms.

The alarm status is shown with colours indicating the severity of the alarm. The various

severities and colours used are described in

Access to additional information pertaining to the various ports of the block diagram is

provided by hovering the mouse pointer over the port within the diagram. The port

representations in the diagram also act as shortcuts to the corresponding configuration

page for the port. The shortcut is activated by clicking on the port in the diagram.

Right-clicking the status block diagram top bar offers a shortcut to clear device statistics

parameters. Selecting Reset device statistics brings up a dialogue where you can select which

information to clear.

Appendix E.

Current Alarms

The bottom part of the page shows the currently active alarms. Some alarms may contain

several sub-entries that are displayed by clicking on the arrow in front of the entry’s

description. The severity of each alarm is represented by an error indicator (visually

similar to a LED). The colour of the indicator represents the severity level configured for

the specified alarm. The various severities and colours used are described in Appendix

E.

The Current Alarms table contains six columns:

Description

Description of the alarm condition.

For sub-entries, the extended index is shown in brackets. To the left is an indicator visualising the severity of the alarm. The indicator has a tool-tip providing a textual description

of the alarm severity.

On Time

The time when the alarm was raised.

Alarm type

Category of the alarm, i.e. Port, System, Switch etc.

Source

This identifies the source of the alarm. For port alarms, this is a reference to the specific

port raising the alarm. This field has a tool-tip showing the subid1 and subid2 values for

the alarm.

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 41

WEB Interface 41

Subid1

Reserved for future use in multi-slot chassis and is always set to 1 in the TVG480.

Subid2

The device or port to which the alarm relates. The value is zero for alarms that are

related to the device rather than to a specific port. Values of 1 and up reference

specific ports.

Alarm ID

Each alarm condition has an associated numerical alarm ID.

Details

An optional string to provide more alarm information in human readable form. The format

of this string depends on the alarm type. Hovering the mouse over this field produces a

tool-tip displaying the full text.

A detailed overview of alarm conditions is given in

Appendix E.

7.4.2 Alarm log

Figure 7.6 Alarm log

The alarm log shows every alarm that has been triggered since the last time the alarm log was

cleared.

The table consists of the same columns as the Current Alarms table, but does not show details

by default. You can change which columns to show, including the details column, in Section

7.5.2.4. Additionally a column named Off Time shows the time the alarm condition was cleared.

Rows will not have the Off Time set if the alarm is still active.

Each row provides additional information via a tool-tip shown when hovering the cursor over

the row. The tool-tip entries are:

Sequence #

A number identifying this specific alarm instance. This number is incremented each time

an alarm condition is raised.

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 42

42 WEB Interface

SubID 1

The primary numerical index of the alarm instance. This index is reserved for future use

and is always set to 1 in the TVG480.

SubID 2

The secondary numerical index of the alarm instance. When the alarm is of type Port

alarm this index contains the port number for which the alarm was raised. Other types of

alarms may use this index to identify a sub module, but normally it is set to 0.

SubID 3

The tertiary numerical index of the alarm instance. The use of SubID 3 depends on the

type of alarm. Some of the Port type alarms use this index to signal the PID value or

Service ID for which the alarm was raised. For example, if the CC Error of a PID is raised

then the PID value is given by SubID 3.

Details

An optional string providing more information about the alarm in human readable form.

The content and format of this string depends on the alarm type.

Beneath the alarm table is a caption showing the total count of alarms currently stored in the

alarm log.

To the right of the table are three buttons and a check box.

Clear Alarm Log

Clears all alarms from the alarm log.

Export to File

Saves the alarm log to a comma-separated value (.CSV) file. The button opens a file

dialogue where the user can choose the destination to save the file on the computer.

Export to Browser

Opens the complete log in a new browser window, showing the alarm log as a commaseparated value list. The format of this list is a text file (not HTML or XML).

Enable updates

This check box can be unchecked to stop the log from scrolling if new alarms are triggered

while watching the log.

The alarm log is stored in non-volatile memory, so the content is kept even if the unit is rebooted.

The log is circular. Events occurring after the maximum number of entries has been reached

overwrite the oldest entries in the log. The maximum number of stored entries is 10000.

7.5 Device Info

The device info page contains all the information and settings that are not related to a single

input or output port. It is divided into multiple sub pages accessed via the navigation list to

the left. In the list of physical interfaces in the navigation list, the currently active interface is

shown in bold. See Figure 7.7.

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 43

WEB Interface 43

Figure 7.7 Device

Info navigator

The exact layout of the navigator depends on the resources and features currently available in

the device.

7.5.1 Product info

The product info page contains general device information.

Figure 7.8 Product Information

Name

Configures the current user defined name of the unit. This parameter, together with the

management network parameters are used as device identifiers and remain untouched if

the unit configuration is changed by loading a different configuration file. See

7.5.6. The device name is shown in the web GUI status header (see Section 7.4.1), and in

the web browser title bar to facilitate identification of each device.

Section

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 44

44 WEB Interface

Inventory ID

Configures the current user defined inventory ID of the unit. This parameter, together with

the management network parameters are used as device identifiers and remain untouched

if the unit configuration is modified. It is only intended as a label/tag and will not affect

the operation of the unit.

Configuration ID

Configure a user defined name for the current configuration of the unit. This name will, if

given, be diplayed in brackets after the unit name in the status header as shown in Figure

7.3. The Configuration ID does not, as opposed to the Name and Inventory ID fields, remain

untouched when loading a new unit configuration. Loading a new unit configuration will

change the Configuration ID. See Section 7.5.6 on how to load a new configuration.

Product name

Displays the name of the product as designated by T-VIPS.

Serial number

The serial number of the device.

Software version

The version of the software currently installed on the device. The software version is given

by the following syntax:

<major_version>.<minor_version>.<patch_version>

The convention for the SW version numbering is as follows:

major_version

Incremented for significant SW changes.

minor_version

Incremented for minor changes. The minor version number is even for official retail

releases and odd for beta releases.

patch_version

If minor_version is even, patch_version gives the patch level of that version. A patch

level of zero means the SW is built on the latest code base, an even patch_version

means this is a released SW patch on a previous release. An odd patch_version means

that this is a test version. If minor is odd, this is a beta version, and the patch_version

simply gives the build number.

Software build time

Reports the time of which the current release image was built.

Device up time

The amount of time that has passed since the device was last reset.

Internal temperature

This shows the current internal temperature of the unit in degrees Celsius and Fahrenheit.

Fan speed

This bar chart shows the current speed of the device fans relative to full speed.

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 45

WEB Interface 45

Flash Power LED button

The Flash Power LED button activates flashing the green power LED on the device in

question. This is useful for identifying which device is currently being configured. Each

click of the button extends the blinking period by five seconds up to a maximum of about

30 seconds of blinking.

7.5.2 Alarms

The Alarms page is shown in Figure 7.9:

Figure 7.9 Alarm configuration

This page displays the status of all system alarms and allows the user to program the severity

of these alarms. Global alarm configuration is performed on this page, as well as alarm relay

configuration and alarm log configuration.

It gives access to the following sub pages:

• Device Alarms

• Global configuration

• Relay and LED configuration

• Alarm Log Settings

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 46

46 WEB Interface

7.5.2.1 Device alarms

The page shown in Figure 7.9 provides the administrator with an interface to view the status

and configure the behaviour of all alarms related to the system. At the top the Reset Alarm

Counters button allows resetting all alarm counters simultaneously.

The page is divided into two parts. On the left is a tree that shows all the alarms. The colour

of the folder icon and the specific indicator represents the current status of the alarm. The text

to the right of the tree shows the currently configured severity of the alarm.

The right hand side of the page displays the Alarm Details field when an alarm is selected:

Alarm ID

The internal numerical ID of the selected alarm.

Alarm

Title of the alarm.

Description

Brief description of the condition of the alarm.

Severity

A configurable option defining the severity of the alarm. Options in the pull-down box

range between Filtered (meaning ignored) to Critical. The text in brackets represents the

default setting.

Alarm turned on

The number of times the alarm has transitioned from off to on since last reset of the alarm

counter.

Error count

Not used.

’Reset Counters’ button

When clicked, clears the alarm counters for the current alarm.

The right-click context menu of the device alarm page provides an option to reset the counters

of all the alarms in the Device Info tree.

7.5.2.2 Global configuration

This page provides an interface to configure globally the behaviour of all alarms. By default

ports use the global configuration settings but each port alarm can be configured individually

to override these settings.

For each alarm a custom severity level can be configured. In addition the alarms can be omitted

from the alarm log and trap transmission.

Edited rows are highlighted until changes have been applied.

Tip: For the Log and Send Trap columns, you can quickly select/deselect

all items by right-clicking on the header fields in the columns.

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 47

WEB Interface 47

Figure 7.10 Global alarm configuration

7.5.2.3 Relays and LED

This page lets the user configure the alarm severity level that shall turn the relay and alarm LED

on. Note that the Alarm relay and the Alarm LED will always be enabled for alarm severity

level Critical, as indicated by the disabled check boxes in the Relay and LED level triggers field.

The current state of the relay and LED is indicated inside the associated brackets.

Figure 7.11 Relays and LED configuration

For further details on the physical relays refer to Section B.5.1.

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 48

48 WEB Interface

The Virtual Relays field shown in Figure 7.11 also includes settings for the so-called virtual

relays. These are programmable status indicators that can be set to react to any specific alarm

condition. In the simplest case you may want to enable a relay in case a specific alarm ID turns

up. In another case you may want to enable a relay if a specific alarm turns up on a given port.

Each relay status are exported on SNMP. Activation of a virtual relay also generates a specific

alarm, named "Virtual alarm relay activated" (ID=169).

The key element in the settings of the virtual relays is the Expression value. The expression is

very close to SQL in syntax and specifies when the relay should be activated. The behaviour is

as follows for each virtual relay:

1. Each active alarm event is evaluated against the Expression for the virtual relay (if

enabled).

2. If the expression evaluates to true, the Count value is increased by 1. You can at any

time see the current count value. The Count value simply tells you how many of the

current (active) alarm events in the unit that matches the expression.

3. If the count value is larger than or equal (>=) to the Count Thresh. value the relay is

activated.

The expressions are validated before they are accepted by the unit.

Table 7.1 shows the field

values you may enter in an expression.

Table 7.1 Legal field values to use in expressions

Field name Extracts from event: Type Sample expression

id Alarm ID Number id = 169

text Alarm text Text text = ’Defective fan’

type_num Type number Number type_num = 13

type_text Type text Text type_text = ’port’

sev Severity (number 2-6) Number sev = 6

details Alarm details (text) Text details = ’PID 113’

subid1 Alarm subid1 value Number subid1 = 1

subid2 Alarm subid2 value Number subid2 = 2

subid3 Alarm subid3 value Number subid3 = 1190

port Synonym for subid2 Number port = 2

service Synonym for subid3 Number service = 102

pid Synonym for subid3 Number pid = 2000

In the expressions you may enter parentheses to group sub-expressions together. Together with

the supported list of operators this gives great flexibility in constructing advanced “match”

patterns.

Table 7.2 summarises the operator types you are allowed to use. Please note that the examples

below are used for illustration purposes only. For example, the plus and minus operators may

not be very useful in practise, but they are included in this table for completeness.

TVG480 User’s Manual Rev. 2.8.24 (4422) ID: um_jpeg2000postproductiongateway

Page 49

WEB Interface 49

Table 7.2 Legal operators to use in expressions

Operator Description Sample

= Equal id = 169

!= Not equal id != 169

AND Logical AND id = 169 AND port = 2

OR Logical OR id = 169 OR id = 200

IN Set operator. Returns true if left-hand part is included in set to the right. id IN (169,200,201)

+ Addition id + 9 = 169

- Subtraction id - 8 = 160

* Multiply id * 10 = 100

/ Divide id / 20 = 8

> Greater than id > 100

< Less than id < 90

>= Greater than or equal id >= 100

<= Less than or equal id <= 100

Some examples are given in Table 7.3.

Table 7.3 Expression examples

Task Expression Count threshold value

To generate an alarm when any alarm with

ID = 200 turns up (independent on source)

To generate an alarm when alarm with ID =

200 turns up on port with ID = 1 (subid2 =

1)

To generate an alarm when alarm with ID =

200 turns up on both port 1 AND port 2

id = 200 1

(id = 200) AND (port = 1) 1

(id = 200) AND ((port = 1) OR (port

= 2))

2

Note the last example in the table: Here the count threshold value must be set to 2 to get the

expected behaviour. This is because the expression entered matches two different alarm events

(port=1 or port=2), and in order to match them both two matches are required in the global

alarm list.

7.5.2.4 Alarm log settings

This page is used to set alarm log properties.

Log delimiter

This parameter is used when exporting the alarm log. It specifies the column separator

character. The default value for the delimiter is ;. The character used may affect autoimporting of the exported file into your favourite tool used to inspect the file content.

ID: um_jpeg2000postproductiongateway TVG480 User’s Manual Rev. 2.8.24 (4422)

Page 50

50 WEB Interface

Figure 7.12 Configuring the alarm log

Columns

Each of the columns in the alarm log table has a checkbox. Columns that are selected are

shown on the alarm log page.

7.5.3 Time Settings

Figure 7.13 Time Settings

The time settings page lets the user configure time zone, the source for synchronising the internal

device time clock and set the internal clock in case of failure of all external sources of clock

synchronisation. The main use of the device time is stamping the entries of the alarm log.