Page 1

Flashlink User Manual

ADC-SDI-CC

Multi standard NTSC, PAL, YPbPr,

RGB-Decoder/Converter

network-electronics.com

Component and Composite

Analogue Video Converter

Rev. 3

Page 2

ADC-SDI-CC Rev. 3

DATE: 23 July 2008

Revision history

The latest version is always available in pdf-format on our web-site:

http://www.network-electronics.com/

Current revision of this document is the uppermost in the table below.

Revision Replaces Date

Change Description

3 2 2008-07-14 Added Declaration of Conformity.

2 1 2007-10-23 New front page and removed old logo.

1 0 2007-10-09 Added Materials Declaration and EFUP

0 B 03.03.05

Specification update and changed ConQuer to flashlink®.

B A 02.09.04 First preliminary release

A 12.08.04

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

2

Page 3

ADC-SDI-CC Rev. 3

DATE: 23 July 2008

Index

Quick Start Guide for ADC-SDI-CC.........................................................................................................4

1. General......................................................................................................................................................5

2. Specifications............................................................................................................................................6

3. Connector module....................................................................................................................................7

3.1 Correspondence of connectors and signals.........................................................................................7

3.2 Mounting the connector module ..........................................................................................................7

4. Configuration and Setup.........................................................................................................................8

4.1 Setting the DIP switches ......................................................................................................................8

4.2 Reset...................................................................................................................................................10

5. Module status .........................................................................................................................................11

5.1 GPI ALARM – Module Status Outputs ..............................................................................................11

5.2 Front Panel - Status Monitoring .......................................................................................................12

6. Interface with GYDA and RS-422 command set ................................................................................13

6.1 ADC-SDI-CC Command table...........................................................................................................13

6.2 The “?” command .............................................................................................................................13

6.3 The “info” command .........................................................................................................................14

6.4 Video modes commands.....................................................................................................................14

6.5 Mark Field 1, Pedestal and Comb - commands. ...............................................................................15

6.6 get, set, eget and eset. ........................................................................................................................15

General environmental requirements for Network flashlink® equipment...........................................16

Product Warranty .....................................................................................................................................17

Materials declaration and recycling information ...................................................................................18

Materials declaration ................................................................................................................................18

Environmentally-friendly use period.......................................................................................................18

Recycling information ...............................................................................................................................19

EC Declaration of Conformity .................................................................................................................20

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

3

Page 4

ADC-SDI-CC Rev. 3

DATE: 23 July 2008

Quick Start Guide for ADC-SDI-CC

Without GYDA controller (This is the default setting upon shipping)

1. Set DIP-switch 1 on (towards backplane), switches 2 and 3 according to the input mode you want (see

Table 2 on page 9).

2. Insert ADC-SDI-CC into a slot in the sub-rack.

3. Attach Analogue input (CVBS, S-Video, RGB+sync or YPbPr) and SDI-output to the backplane

module (see Figure 2 on page 7).

4. Power on. After some seconds the ADC-SDI-CC will be running, and the input detected. All LED’s

will be green and the SDI output active. If this is not the case, please see section 5.2 Front Panel Status Monitoring on page 12.

With GYDA controller (firmware> 1.1)

Insert ADC-SDI-CC into a slot in the sub-rack.

Attach Analogue input (CVBS, S-Video, RGB+sync or YPbPr) and SDI-output to the backplane module (see Figure 2 on page 7).

Power on. After a few seconds the ADC-SDI-CC will be running, and the card detected by GYDA. Use

GYDA to set up which analogue video format to use, CVBS, S-Video, RGB+sync or YPbPr. All

LED’s will now be green and the SDI output active. The card settings are stored on the card which

means that the card will remember its configuration despite any eventual power loss.

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

4

Page 5

ADC-SDI-CC Rev. 3

DATE: 23 July 2008

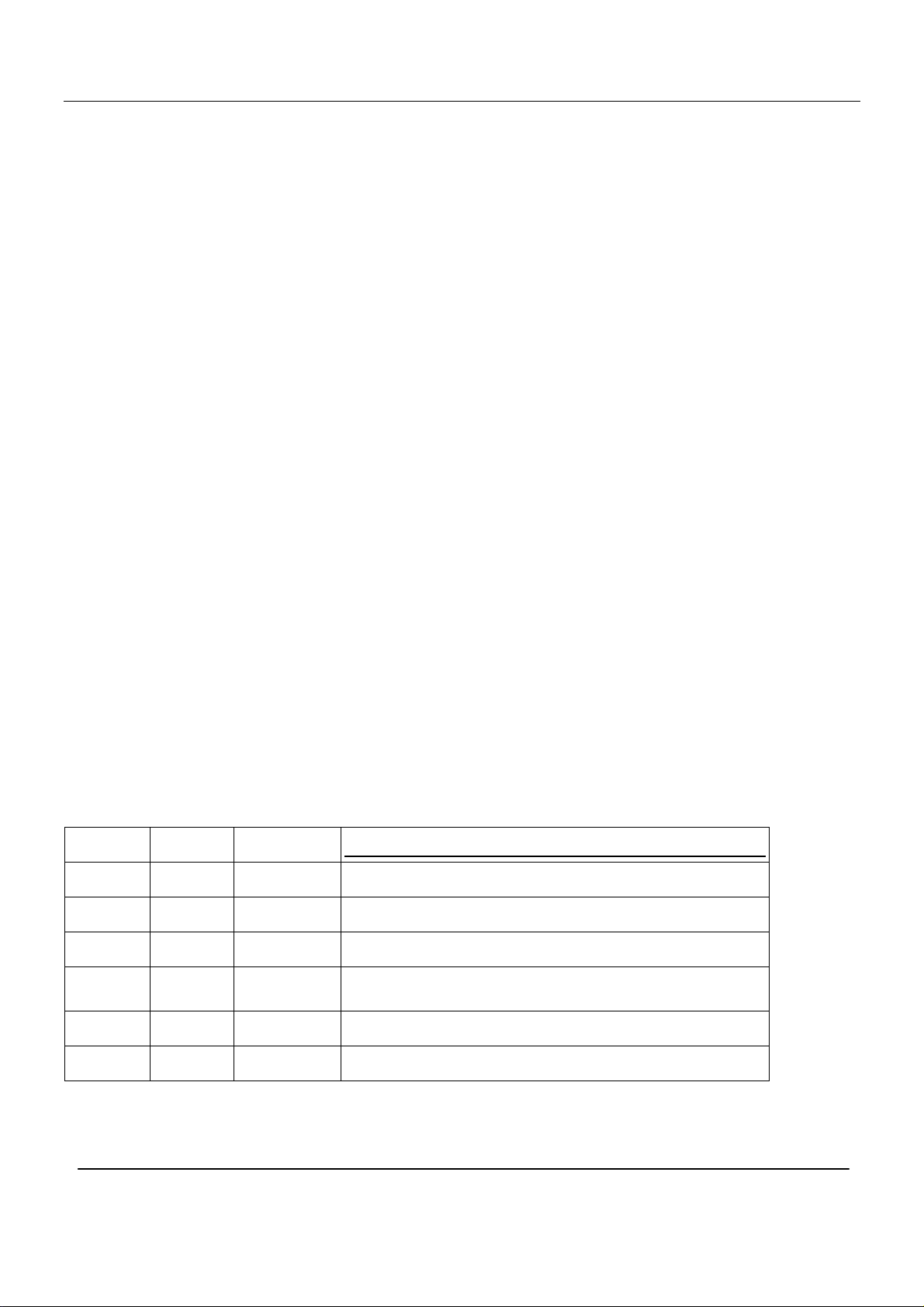

1. General

The flashlink ® ADC-SDI-CC is a high quality digital video decoder that digitises and decodes all

popular baseband video formats into SDI 4:2:2 digital component video. The ADC-SDI-CC supports the

analogue-to-digital conversion of component RGB and YPbPr signals, as well as the decoding of NTSC

and PAL composite and S-video into component digital video. This decoder features four 10-bit A/D

converters running with 2 x oversampling (27MHz), which are then digitally filtered and decimated to the

1 x pixel rate giving a higher signal-to-noise ratio for each input channel.

When used with the GYDA control system, gain adjustments may be made to each analogue input.

Composite video decoding utilises a 5-line adaptive comb filter for both the luma and chroma signal

paths to reduce cross-luma and cross-chroma artefacts. A alternative chroma trap filter is also available.

On composite and S-video inputs, the user can control video characteristics such as contrast, brightness,

saturation and hue via the GYDA control interface. The GYDA system controller is used with all

flashlink and flashlink modules providing a common control and monitoring platform.

ADC-SDI-CC features:

• Multi-standard NTSC, PAL, YPbPr, RGB Decoder/Converter

• 10 bit 4:2:2 SDI video quality

• 5 line adaptive comb filter for NTSC/PAL decoding

• EDH generation and insertion

• 2 x oversampling of both composite and component video

• 10 bit component 8:8:8 oversampling with digital 4:2:2 decimation and down-conversion

• VBI data transparent

• 3 SDI outputs

Figure 1 – Simplified block diagram of the ADC-SDI-CC card

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

5

Page 6

ADC-SDI-CC Rev. 3

DATE: 23 July 2008

2. Specifications

Digital Serial Output Signal type: SMPTE 259M / ITU-R BT.601 Connector: BNC Impedance: 75 ohm Return loss: >15dB @ 270MHz Jitter: < 0.2UI Peak to peak signal level: 800mV ± 80mV

Composite and Y/C Input:

Signal type: Composite video, PAL 625/50Hz or NTSC 525/60Hz

Y / C (S-video)

Connector: BNC

Impedance: 75 ohm

Signal level: 1Vp-p

Return loss: >40dB

Component and RGB Input:

Signal rate: 625/50Hz or 525/60Hz

Signal type: RGB without setup, with separate sync.

SMPTE / EBU Y, Cr, Cb

Connector: BNC

Impedance: 75 ohm

Signal level: Y = 1Vp-p. Cb, Cr, R, G, B = 0.7Vp-p

Return loss: >40dB

Processing Performance:

Signal path: 10 bits

Sampling: 27MHz, 2 x oversampling

Luma/Chrome separation: selectable 5 line adaptive comb filter or chroma trap filter

Video bandwidth: 6MHz

Hue Accuracy 0.5° typical

Colour Saturation Accuracy 0.8% typical

Luminance Nonlinearity 0.6% typical

SNR (unified weighted): 66dB typical

Diff. gain: <1.0%

Diff. phase: <1.0°

Video processing delay 3 video lines

Power: +5V DC / 2.75W

-15V DC / 0.5W

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

6

Page 7

ADC-SDI-CC Rev. 3

DATE: 23 July 2008

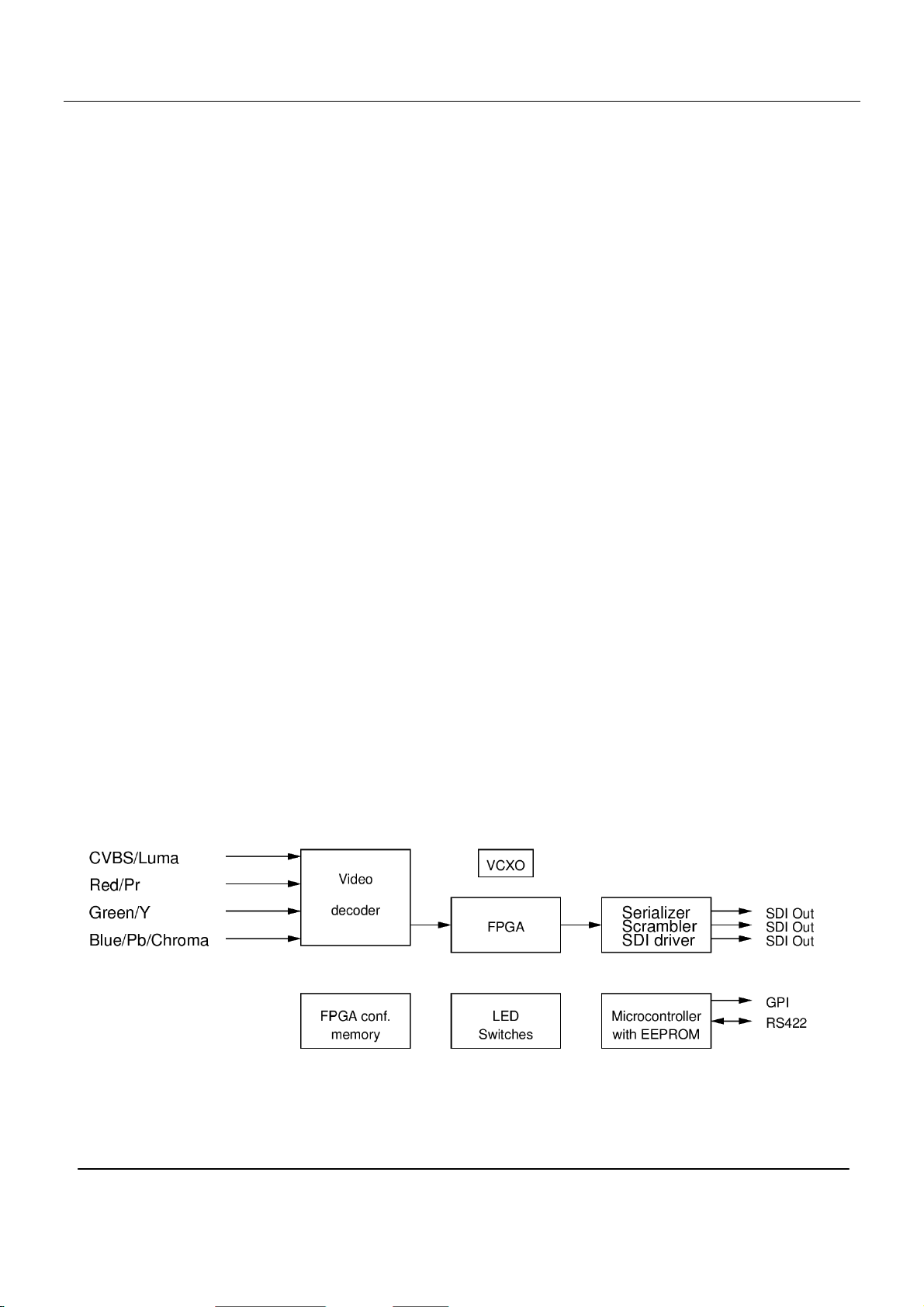

3. Connector module

The ADC-SDI-CC has a dedicated connector module: ADC-SDI-CC-C1. This module is mounted at the rear of the sub-rack. The module is shown in Figure 2 .

Figure 2 - ADC-SDI-CC-C1 connector module.

3.1 Correspondence of connectors and signals

The ADC-SDI-CC-C1 connector module has 7 BNC's: CVBS/Y Analogue input: CVBS, SYNC for RGB or S-Video Luma. R/Pr Analogue input: Red or component Pr. G/Y Analogue input: Green or component Y. B/Pb/C Analogue input: Blue, component Pb or S-Video Chroma. SDI-OUT Digital SDI output SDI-OUT Digital SDI output SDI-OUT Digital SDI output

SDI1, SDI2 and SDI3 are equivalent SDI outputs.

Note: The analogue inputs are internally terminated with 75Ω on the ADC-SDI-CC card.

3.2 Mounting the connector module

The details of how the connector module is mounted, is found in the user manual for the sub-rack frame FR-2RU-10-2.

This manual is also available from our web site: http://www.network-electronics.com/

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

7

Page 8

ADC-SDI-CC Rev. 3

DATE: 23 July 2008

4. Configuration and Setup

Figure 3 - ADC-SDI-CC simplified silkscreen.

4.1 Setting the DIP switches

The ADC-SDI-CC card has a Dual-Inline switch (DIP-switch) that has 10 individual On/Off switches.

The purpose of these switches is to provide an easy interface to some of the most used features of t

DC-SDI-CC card, without the need of a GYDA controller. The switches are numbered from '1' towards

A

the . A switc the tap is placed in direction of the front handle.

top of the card, see Figure 3 h is off when

he

Switch #

Function Comment

1 Manual mode on/off When on, enables switches 2, 3, 4, 5, 6 and 8. 2 Input Channel select 3 Input Channel select

According to Table 3.

4 Mark Field 1 enable on/off e Mark Field 1-feature enabled. When on, th 5 Comb filter/Trap filter When on, the comb filter is selected. When off, the trap filter

is selected.

6 Pedestal on/off ur analogue video,

If a setup level of 7,5 IRE is present on yo

t to on. When black level is 0 IRE, set to off. This setting

se

only applies to 525 lines video st

andard. 7 Reserved 8 Factory Reset on/off To reset the internal EEPROM. 9 Reserved

10 Run mode on/off For factory use only

Table 1: Summary of the DIP switches. Switch 7, 9 and 10 are mainly for factory use, while switches 1, 2,

3, 4, 5 and 6 will be used when no GYDA controller is available.

Switch 1 - Manual mode

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

8

Page 9

ADC-SDI-CC Rev. 3

DATE: 23 July 2008

Switch 1 is the manual mode switch. If on, the ADC-SDI-CC may be operated with the switches. If off,

the ADC-SDI-CC is to be used with a GY

DA controller.

Factory setting is s

witch 1 in on position

ith switch 1 off:

W

While in automatic

mode, switches 2, 3, 4, 5, 6 and 8 do not have any effect.

ith switch 1 on:

W

In manual mode, th

e functionality of switches 2, 3, 4, 5 , 6 and 8 is as follows:

witches 2 and 3

S

These two switches determine the input selec

tion. See Table 2.

F e sw f.

actory s tting is itch 2 and switch 3 of

#3 #2 nnel Select

Sw Sw Input Cha

0 0 CVBS

0 1 S-Video

1 0 YPbPr

1 1 RGBS

Table 2: Manual selection of video mode

Switch 4

Switch 4 turns on/off the Mark Field 1-feature. With switch 4 off the Mark Field 1-feature is disabled,

with switch 4 on the

. This features gives improved encoding quality when used with an encoder like the DAC-SDI which

1

Mark Field 1-feature is enabled and the card inserts a marker on line x of each field

can use this feature.

Factory se

tting is switch 4 in on position.

Switch 5

witch 5 selects which filter to use when separating Luma from Chroma in CVBS. With switch 5 on, the

S

5-line comb filter is selected, with switch 5

off, the chroma trap filter is selected.

Factory se

tting is switch 5 in on position.

Switch 6

Switch 6 selects whether pedestal is present on the analogue video. With switch 6

set to 7,5 IRE. With switch 6 off, the black level will be 0 IRE. This switch only affects 525 lines

be

video. Typically a black level of 7,5 IRE is

used in the USA and 0 IRE in Japan.

on, the black level will

Factory setting is switch 6 in on position.

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

9

Page 10

ADC-SDI-CC Rev. 3

DATE: 23 July 2008

Switches 7 and 9 - Reserved

These switches are reserved and should always be in the off position.

Factory setting are switch 7 and 9 in off position.

Switch 8 - Reset to factory default

ADC-SDI-CC contains an EEPROM which stores the configuration of the card. Switch 8 can be used to reset the EEPROM to the factory default. Follow the procedure described below.

Action Comment

1 Power down. 2 Turn switch 8 on. Switch 1 must also be turned on for this to have effect. 3 Power up. ADC-SDI-CC enters a special state where the EEPROM is restored to

factory default values. This is flagged by the Card State LED, which starts

to blink yellow.

4 Power down.

5 Turn switch 8 off. If you want the DIP switches to be placed in the factory default position,

this is the time to do so: Switch 10 should, as always, be turned to the on

position. Switch 1 may be turned on or off. 6 Power up. The card EEPROM is now reset to factory settings.

Table 3: Method to restore the ADC-SDI-CC card to factory settings. Remember to let some seconds pass

by each time you power down, to allow capacitors to be fully discharged.

Switch 10 - Run mode

Switch 10 is purely used for service upgrade of the ADC-SDI-CC card. It should always be in the on

position. If switch 10 is in the off position, the Card State LED will light up red, and the ADC-SDI-CC

card will enter programming mode. This causes no harm, but the card will not work in this mode.

Factory setting is switch 10 in on position.

4.2 Reset

The push-button just behind the front LEDs is a reset switch, see Figure 3 . It has the same effect as a power off – power on cycle.

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

10

Page 11

ADC-SDI-CC Rev. 3

N

DATE: 23 July 2008

5. Module status

The status of the module can be monitored in two ways.

1. GYDA System Controller (optional).

2. LED’s at the front of the sub-rack.

The LED’s are mounted on the module itself, whereas the GYDA System Controller is a separate module

which gives detailed information on the card status. The functions of the LED’s are described on the next

page. The GYDA controller is described in a separate user manual. This manual is available on our web

site: http://www.network-electronics.com/

5.1 GPI ALARM – Module Status Outputs

These outputs can be used for wiring up alarms for third party control systems. The GPI outputs are open collector outputs, sinking to ground when an alarm is triggered. The GPI connector is shown in Figure 4 .

Electrical Maximums for GPI outputs

Max current: 100mA

Max voltage: 30V

ADC-SDI-CC module GPI pinning:

Signal Name Pin # Mode

Status General error status for the module. Pin 1 Open Collector Input

o video input detected Pin 2 Open Collector VCXO Module not gen-locked to video input Pin 3 Open Collector SDI Output No SDI output present Pin 4 Open Collector Ground 0 volt pin Pin 8 0V.

Figure 4 - GPI Outlet

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

11

Page 12

ADC-SDI-CC Rev. 3

p

N

N

N

DATE: 23 July 2008

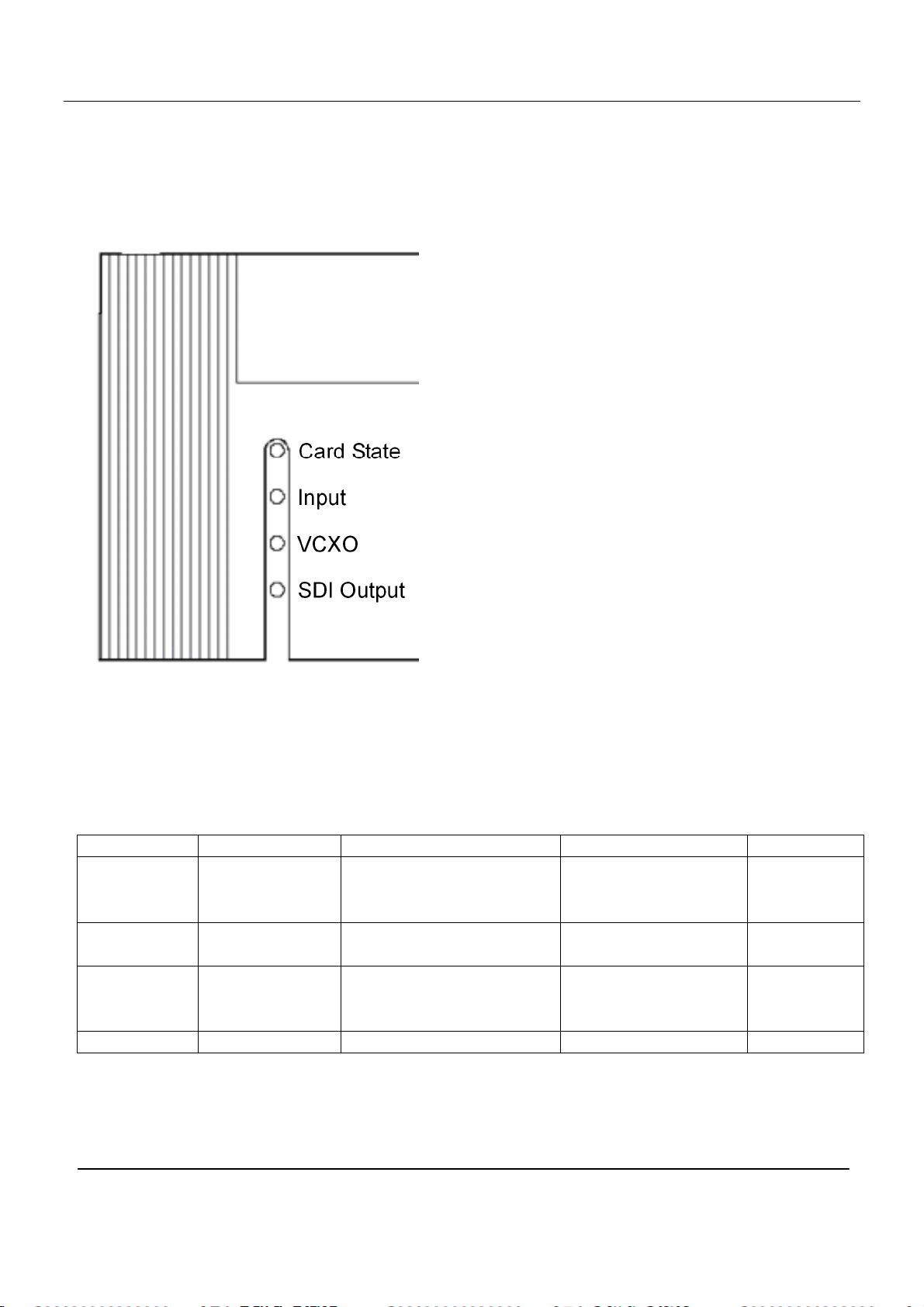

5.2 Front Panel - Status Monitoring

The status of the module can be easily monitored visually by the LED’s at the front of the module. The LED’s are visible through the front panel as shown in Figure 5 below.

(Text not printed on the front panel).

Figure 5 - Front panel indicator for ADC-SDI-CC

The ADC-SDI-CC has 4 LED’s each showing status information. The position of the different LED’s is shown in Figure 5 .

Diode \ state Red LED Yellow LED Green LED No light

Card State Module is faulty Start-up-sequence is running Module is OK

Module power is OK

Module has no

ower or

memory fault

Input

o video input

Video input detected

detected

VCXO

o input detected Input signal is detected.

Video not yet locked or input

Input signal is detected, and properly locked

comes from a VCR

SDI Output

o SDI output Correct SDI output

Table 4 - Front panel LED indicator overview

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

12

Page 13

ADC-SDI-CC Rev. 3

DATE: 23 July 2008

6. Interface with GYDA and RS-422 command set

All commands follow the flashlink® protocol and can be used for direct control access to the module.

The control system can either be a GYDA or a third-party control system with integrated flashlink®

protocol. The module can also be manually controlled with a VT100 compatible terminal program.

The protocol can be found on our web page; http://www.network-electronics.com

6.1 ADC-SDI-CC Command table

Command Response Comment ? Yes The “Hello” command. info Yes Gives back the card state. CVBS “OK” Set video format to CVBS. Svideo “OK” Set video format to S-Video. RGB “OK” Set video format to component RGB + sync. YPbPR “OK” Set video format to component YPbPr. MarkF1 on “OK” Turn on the Mark Field 1-feature. MarkF1 off “OK” Turn off the Mark Field 1-feature. Comb on “OK” Set chroma luma separation filter to 5-line comb filter. Comb off “OK” Set chroma luma separation filter to chroma trap filter. Pedestal on “OK” Pedestal is present. Pedestal off “OK” Pedestal is not present. Calibrate “OK” Calibrates RGB gain. Must be in RGB and input must be 75%

colour bar. eget [0xHH] Yes Get a value from a numbered eeprom register. eset [0xHH] [0xHH] “OK” Set a value to a numbered eeprom register. get [0xHH] Yes Get a value from a numbered register. set [0xHH] [0xHH] “OK” Set a value to a numbered register.

Table 5 - All commands available to the user

6.2 The “?” command

According to the flashlink®, no card can use the RS422-bus before it has been activated with the “?” (hello) command. The response from ADC-SDI-CC will be:

xxxxADC-SDI-CC\

PIC sw rev X.X.X\

FPGA sw rev X\

Protocol ver X.X

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

13

Page 14

ADC-SDI-CC Rev. 3

d

d

d

N

N

N

N

DATE: 23 July 2008

Here xxxx denotes the source and destination rack and slot coordinates, while X represents a version number. As of primo July 2004, these revisions would be:

xxxxADC-SDI-CC\

PIC sw rev 1.0.2\

FPGA sw rev 6\

Protocol ver 1.0

6.3 The “info” command

This command report the entire state of the card. An example:

xxxxCVBS\

Locked 50Hz\

Field 1 mark on\

Comb on\

Pedestal on

Status of Status string Comment Input Select

CVBS CVBS is selecte Svideo Svideo is selecte YpbPr YPbPr is selecte RGB RGB is selected

Analogue input.

Locked 50Hz Locked to 625 lines 50 Hz. Locked 60Hz Locked to 525 lines 60 Hz.

ot locked 50Hz

ot locked 60Hz

ot locked, previously locked to 50Hz.

ot locked, previously locked to 60Hz. Field 1 marking on The Mark Field 1-feature is turned on.Field 1 marking Field 1 marking off The Mark Field 1-feature is turned off. Comb on Comb filter selected.Chroma filter Comb off Chroma trap filter is selected. Pedestal on Pedestal present is selected. Pedestal Pedestal off Pedestal not present is selected.

The “info” command is composed by many minor lines, fully specified in table 6. In general, when a condition is normal, it is not reported. For instance, pedestal is reported when locked to 50Hz, even tough the setting has no effect on the video.

6.4 Video modes commands.

The CVBS, RGB, Svideo and YPbPr commands sets the video input mode. Remember that RGB -mode needs separate sync on the CVBS/Luma channel. This sync may be a synchronous CVBS-signal.

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

Table 6: The info command broken up in components.

14

Page 15

ADC-SDI-CC Rev. 3

DATE: 23 July 2008

6.5 Mark Field 1, Pedestal and Comb - commands.

Commands to turn on/off the Mark Field 1-feature, Pedestal and the Comb filter commands are straightforward text, see Table 5 .

6.6 get, set, eget and eset.

These commands are for internal factory use. The end-user should avoid these commands.

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

15

Page 16

ADC-SDI-CC Rev. 3

DATE: 23 July 2008

General environmental requirements for Network flashlink® equipment

1. The equipment will meet the guaranteed performance specification under the following environmental

conditions:

• Operating room temperature range 0°C to 40°C

• Operating relative humidity range up to 90% (non-condensing)

2. The equipment will operate without damage under the following environmental conditions:

• Temperature range -10°C to 50°C

• Relative humidity range up to 95% (non-condensing)

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

16

Page 17

ADC-SDI-CC Rev. 3

DATE: 23 July 2008

Product Warranty

The warranty terms and conditions for the product(s) covered by this manual follow the General Sales Conditions by Network Electronics AS. These conditions are available on the company web site of Network Electronics AS:

www.network-electronics.com

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

17

Page 18

ADC-SDI-CC Rev. 3

DATE: 23 July 2008

Materials declaration and recycling information

Materials declaration

For product sold into China after 1st March 2007, we comply with the “Administrative Measure on the

Control of Pollution by Electronic Information Products”. In the first stage of this legislation, content of

six hazardous materials has to be declared. The table below shows the required information.

Toxic or hazardous substances and elements

組成名稱

Part Name

ADC-SDI-CC X O O O O O

O: Indicates that this toxic or hazardous substance contained in all of the homogeneous materials for this part is below the limit requirement in SJ/T11363-2006.

X: Indicates that this toxic or hazardous substance contained in at least one of the homogeneous materials used for this part is above the limit requirement in SJ/T11363-2006.

鉛

Lead

(Pb)

汞

Mercury

(Hg)

镉

Cadmium

(Cd)

六价铬

Hexavalent

Chromium

(Cr(VI))

多溴联苯

Polybrominated

biphenyls

(PBB)

多溴二苯醚

Polybrominated

diphenyl ethers

(PBDE)

Environmentally-friendly use period

The manual must include a statement of the “environmentally friendly use period”. This is defined as the

period of normal use before any hazardous material is released to the environment. The guidance on how

the EFUP is to be calculated is not finalised at the time of writing. See

http://www.aeanet.org/GovernmentAffairs/qfLeOpAaZXaMxqGjSFbEidSdPNtpT.pdf for an unofficial

translation of the draft guidance. For our own products, Network Electronics has chosen to use the 50

year figure recommended in this draft regulation.

Network Electronics suggests the following statement on An “Environmentally Friendly Use Period” (EFUP) setting out normal use:

EFUP is the time the product can be used in normal service life without leaking the hazardous materials. We expect the normal

use environment to be in an equipment room at controlled temperature range (0ºC - 40ºC) with moderate humidity (< 90%, noncondensing) and clean air, not subject to vibration or shock.

Further, a statement on any hazardous material content, for instance, for a product that uses some tin/lead solders:

Where a product contains potentially hazardous materials, this is indicated on the product by the appropriate symbol containing

the EFUP. The hazardous material content is limited to lead (Pb) in some solders. This is extremely stable in normal use and the

EFUP is taken as 50 years, by comparison with the EFUP given for Digital Exchange/Switching Platform in equipment in

Appendix A of “General Rule of Environment-Friendly Use Period of Electronic Information Products”. This is indicated by the

product marking:

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

18

Page 19

ADC-SDI-CC Rev. 3

DATE: 23 July 2008

50

It is assumed that while the product is in normal use, any batteries associated with real-time clocks or battery-backed RAM will be replaced at the regular intervals.

The EFUP relates only to the environmental impact of the product in normal use, it does not imply that the product will

continue to be supported for 50 years.

Recycling information

Network Electronics provides assistance to customers and recyclers through our web site

http://www.network-electronics.com. Please contact Network Electronics’ Customer Support for

assistance with recycling if this site does not show the information you require.

Where it is not possible to return the product to Network Electronics or its agents for recycling, the following general information may be of assistance:

Before attempting disassembly, ensure the product is completely disconnected from power and signal

connections.

All major parts are marked or labelled to show their material content.

Depending on the date of manufacture, this product may contain lead in solder.

Some circuit boards may contain battery-backed memory devices.

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

19

Page 20

ADC-SDI-CC Rev. 3

DATE: 23 July 2008

EC Declaration of Conformity

MANUFACTURER

AUTHORISED REPRESENTATIVE

(Established within the EEA)

MODEL NUMBER(S)

DESCRIPTION

DIRECTIVES this equipment complies with

HARMONISED STANDARDS applied in order to verify compliance with Directive(s)

TEST REPORTS ISSUED BY Notified/Competent Body Report no:

TECHNICAL CONSTRUCTION FILE NO

YEAR WHICH THE CE-MARK WAS AFFIXED

TEST AUTHORIZED SIGNATORY

MANUFACTURER AUTHORISED REPRESENTATIVE

2008-07-14

Network Electronics AS

P.B. 1020, N-3204 SANDEFJORD, Norway

Not applicable

ADC-SDI-CC

Component and Composite Analogue Video Converter

LVD 73/23/EEC

EMC 2004/108/EEC

EN 55103-1:1996

EN 55103-2:1996

Nemko E07379.00

Not applicable

2008

(Established within EEA)

Not applicable Sandefjord, Norway

Date of Issue

Place of Issue

Name

Position

Thomas Øhrbom

Quality Manager

(authorised signature)

Network Electronics AS, P.O.Box 1020, N-3204 Sandefjord, Norway. Tel.: +47 33 48 99 99 – Fax: +47 33 48 99 98

E-mail: support@network-electronics.com – Web: http://www.network-electronics.com/

Technical specifications are subject to be changed without notice.

20

Loading...

Loading...