Page 1

R

HANDLING INSTRUCTION

opticalCON Coupler

MAINTENANCE

|

www.neutrik.com

R

Page 2

R

optical CouplerCON

MAINTENANCE

I

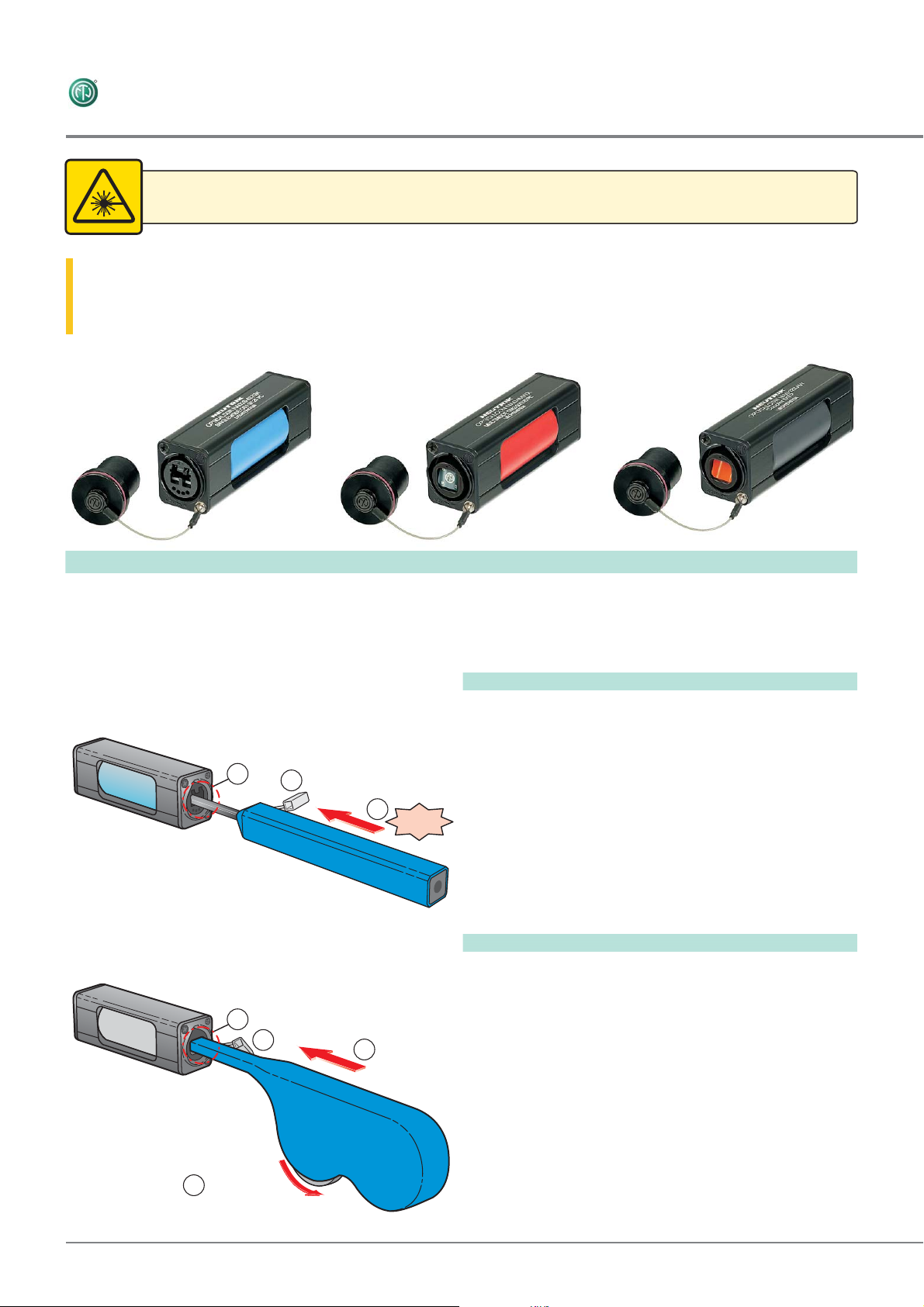

CAUTION: Laser radiation, do not stare into beam!

Do not disassemble opticalCON couplers, if not required. Sealing shutter mechanism of the opticalCON

avoids contamination ofthe ferrule locked inside. Dust-proof design reduces maintenance intervals to a

minimum; if nevertheless necessary, follow the maintenance procedure below to avoid damages on

ferrules due to improper cleaning.

optical CouplerCON

DUO: NAO2* QUAD: NAO4* MTP : NAO12*

A. Dry Cleaning

Depending on opticalCON coupler,

use corresponding DRY-cleaner:

2.

IK

R

T

U

E

N

1.

3.

“pop”

DUO FOCD-DC125

QUAD FOCD-DC125

®

MTP FOCD-DCM

DUO & QUAD

1.

Remove dust cap. Insert the stick of the

cleaning device.

2.

Make sure that the insertion position is on the

bottom of the LC connector hole in order to hit

the sealing shutter release bar.

Push the outer shell to start cleaning the LC

3.

connector end face.

A “pop” sound indicates end of cleaning

process.

Remove cleaning device and put dust cap on

4.

the stick.

®

MTP

®

Remove dust cap and insert the tip of the dry

1.

cleaner.

2.

Guide the tip of the dry cleaner into the chassis

1.

IK

R

T

U

E

N

Plastic wheel

3.

2

2.

2.

housing.

Rotate the plastic wheel to start the cleaning

3.

procedure. An endless lint free tape removes

dust particle on the ferrule surface of the MTP

connector on the rear of the chassis.

After cleaning procedure, remove dry cleaner

4.

and cover the tip with the dust cap.

®

Page 3

R

MAINTENANCE

I opticalCON Coupler

B. General Overhaul

If increased attenuation cannot be reduced with dry cleaning (section A), a general overhaul is recommended.

The following cleaning procedure is carried out on the example of an opticalCON DUO coupler.

1.

Untighten screws on both opticalCON chassis

1.

NEUTRIK

with a screw driver.

3.

2.

2.

4.

2.

Remove top and bottom shelf of metal housing

to release the protection tube.

NEUTI

3.

Further slide colored protection tube towards

to one of the chassis.

4.

Carefully disconnect the LC (MTP - ferrule)

®

on the rear-side of the opticalCON chassis.

Attention:

Do not bend the fibers too much.

Enhanced risk of macrobending!

3

Page 4

R

MAINTENANCE

I opticalCON Coupler

cleaning fluid

5.

Fold lint free wipe into a square and fix it with

the magnet.

6.

Moisten one section of the wipe with one drop

of cleaning fluid. Be sure that a portion of the

wipe remains dry.

7.

Wipe slightly the ferrule tip in the

cleaning fluid

moistened portion of the wipe. Immediately

repeat this wiping action on the dry section as

the wipe to remove any residual alcohol.

8.

Dispose the wipe. .

9.

Repeat the process if required.

10.

After cleaning procedure plug in the LC

®

(MTP ferrule) on the rear side of the chassis.

NEVER REUSE A WIPE

Attach the housing and secure chassis by

tighten the screws.

NEUTRIK AG

NEUTRIK USA Inc.

NEUTRIK UK Ltd.

NEUTRIK

Draft. Nr.: BDA 358 Update: 01.02.2013/ 3102M2131

()

Vertriebs GmbH

LI

USA

UK

DE/NL/AT/DK

www.neutrik.comwww.neutrik.com

T: F:

+423 /237 24 24 +423 /232 53 93

T: F:

+1 704/ 972 3050 +1 704/ 438 9202

T: F:

+44 1983/ 811441 +44 1983/ 811439

T: F:

+49 8131/ 280 890 +49 8131/280830

II

Data subject to change without prior notice. 2013 NEUTRIK . ALLRIGHTS RESERVED. NEUTRIK are registered trademark.©

NEUTRIK France

NEUTRIK Tokyo Ltd.

NEUTRIK

-4-

FR

JP

Ltd. T: F:

HK

® ®

T: F:

+33 1 / 4131 6750 +33 1 / 4131 0511

T: F:

+81 3 / 3663 4733 +81 3 / 3663 4796

+852 / 2687 6055 +852 / 2687 6052Hong Kong

R

Loading...

Loading...