Neutrik NAC3FX-W OPERATING & ASSEMBLY INSTRUCTION

R

OPERATING & A S S E M B LY I N S T R U C T I O N

NA C3F X -W power CON TRU E1

|

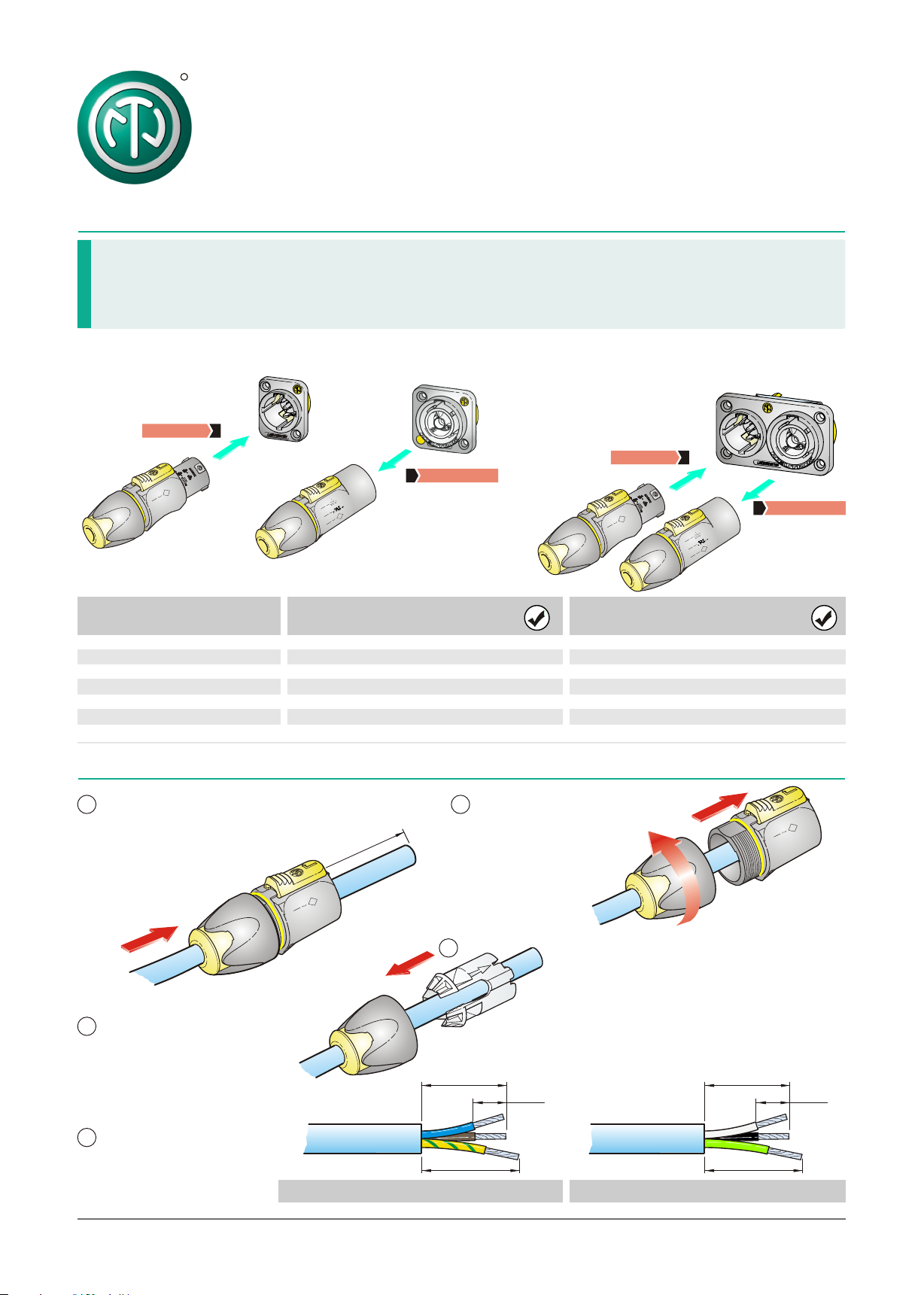

A. OPERATING INSTRUCTION

Ap plic ation:

The powerCON TRUE1 system is certified as connector with breaking capacity according IEC 60320,

VDE 0625. It is intended for use as appliance couplers and interconnection couplers. It serves to

supply power to an appliance and from an appliance to another equipment. To be installed by qualified

person only.

Connector Assignment:

APPLIAN CE INLET APPLIANCE OUTLET

NAC3MPX NAC3FPX

Powe r IN

ET

J

S

P

E

20

0

5

2

NAC3FX-W

(Connector)

W

MX

3

NAC

6

1

0

25

ET

J

0

2

S

P

0

5

2

E

0

2

0

25

NAC3MX-W

(Plug connector)

Powe r OUT

NAC3FPX-ST

INLET OUTLET

C OM BI NATION

NAC3PX

Powe r IN

NAC3FX-W

(Connector)

JET

S

P

E

20

0

5

2

APPLIAN CE

3MX-W

AC

N

16

0

5

2

T

E

J

20

S

P

0

25

E

0

2

250

NAC3MX-W

(Plug connector)

Powe r OUT

Approval based:

VDE

EN 60320-1/EN60320-2-2

Rating:

Cable Type :

Strain Relief:

Cable O.D.:

250 V ac / 16 A

H05VV-F3G 1.0 mm

H05VV-F3G 1.5 - 2.5 mm

H07RN-F3G 1.5 mm

White chuck

6.0 - 12.0 mm

B. ASSEMBLY INSTRUCTION

A

Insert cable into the

bushing and housing.

Note: “Apply cable

pulling lubricant to

cable jacket.”

C

Place chuck over the

cable.

4

T

E

J

S

P

E

0

2

0

5

2

UL

UL 498 / CSA C22.2 No. 182.3

2

, Length max. 2 m

2

2

B

Separate the

housing from the

mm

0

5

-

0

bushing (cable

remain in bushing)

250 V ac / 20 A

SJTOW, SJOOW 3 x 12 AWG

White chuck

6.0 - 12.0 mm

JET

S

P

E

0

2

0

5

2

C

D

Prepare cable as

shown.

20 mm

[0.78 7”]

PE 23 mm

[0.9” ]

8 mm

[0.32 "]

20 mm

[0.78 7”]

PE 23 mm

[0.9” ]

8 mm

[0.32 "]

VDE (EN 60320-1/EN60320-2-2) UL (UL 498 / CSA C22.2 No. 182.3)

Page 1BDA 378

R

ASSEMBLY INSTRUCTION powerCON TRUE1

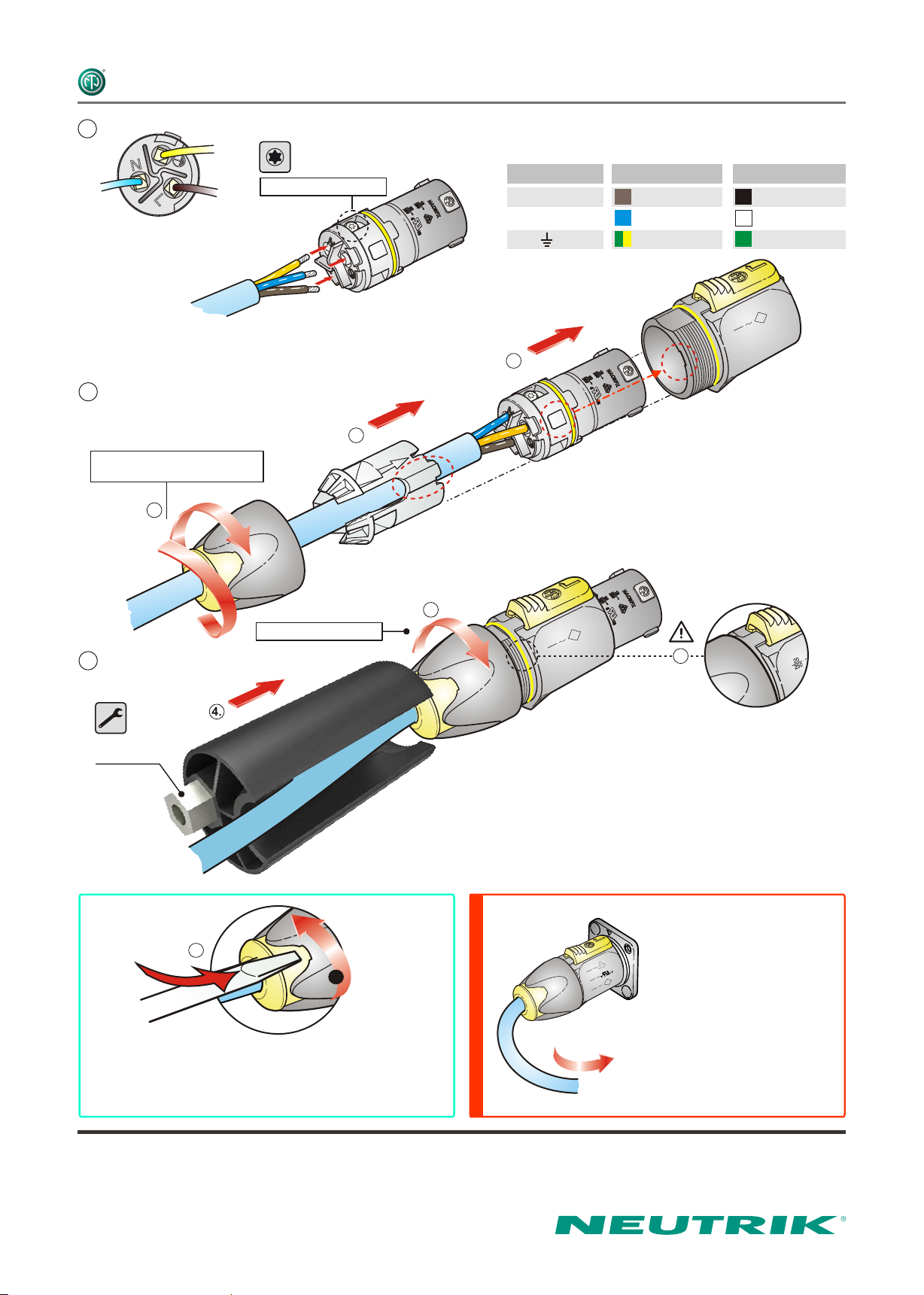

I

E

F

Important:

Push and turn simultaneously.

3.

Torx size

T8

Torque Value 0.7 Nm

1.

Slide the cable into the contacts and clamp with

the screw with Torx size T8.

Wiring VDE UL

Þ

L brown black

-

-

-

-

w

w

w

w

green / yellow green

Þ

N blue white

Þ

T

JE

P S

E

0

2

50

2

2.

-

-

w

w

Slide chuck onto insert (1) and then both into

housing (2).

Important: Align the chuck by positioning the

nose into keyway.

Torque Value 2.0Nm

G

PRESS FIRMLY

4.

Wrench size

13 mm

1.

Disassembly (open twist lock):

1. Press with screw driver to unlock

2. Turn bushing while still pressing locking.

-w

5.

J

S

P

E

0

2

0

5

2

-w

ET

6.

Slide the cable clamp (3) bushing up the cable

and tighten it with the tool (4) as shown (5).

Important: Yellow O-ring to hide to achieve IP

protection (6).

(Tool available: Art. No. HTAC)

CAUTION

X-W

3M

C

NA

6

1

250

L

IEC

H

T

0

EN

2.

2

S

0

T

5

P S

2

EIN

E

20

250

To ensure protection

T

E

J

category, do not expose

the connection to

bending forces (e.g. do

FORCE

not attach loads to the

cable, no free-dangling

cable windings etc.).

NEUTRIK AG LI T: +423 / 237 24 2 4 F: +423 / 232 53 93

NEUTRIK USA Inc. USA T: +1 704 / 972 3050 F: +1 704 / 438 9202

NEUTRIK UK Ltd. UK T: +44 1983 / 811 441 F: +44 1983 / 811 439

NEUTRIK Vertriebs Gm bH DE / NL / AT/DK T: +49 8131 / 280 890 F: +49 8131 / 280 830

Draft. Nr.: BDA 378 Update: 08.04 .2014

www.neutrik.c om

( )

I I

Data subject t o change without prior n otice. 2014 NEUTRI K . ALL RIGHTS RESERVED. NEUTRIK are re gistered trademark.

©

Page 2

NEUTRIK France FR T: +33 1 / 4131 6750 F: +33 1 / 4131 0511

NEUTRIK Tokyo Ltd. JP T: +81 3 / 3663 473 3 F: +81 3 / 3 663 4796

NEUTRIK Hong Kon g Ltd. HK T: +852 / 2687 6 055 F: +8 52 / 2687 6052

NEUTRIK India Pvt. Ltd. IND T: +91 / 982 05 43 424 F: +9 1 / 22 26163 540

® ®

Loading...

Loading...