Lohstr.13-

58675

Hemer/

Postfach

4063-58663

Hemer

Telefon:

+49

2372

9274-0

Fax:

+49

2372

3304

DEUTSCHLAND

Operating

Manual

Spiral

Mixer

art.-no.

05-50710

www.neumaerker.de

MIXER

CONTENTS

1

GENERAL

INFORMATION

Purposeofthe

msnual

4

Manufacturer

and

machine

idenlification

4

Machine

descriptions

5

Technical

specifications

5

Overall

dimensions

6

Safely

devices

8

Safely

Information

8

Residual

risks

9

2

INSTALLATION

INFORMATION

Packaging

and

unpacking

10

Installation

area 10

ElectricaJ

connections

10

3

USE

AND

CLEANING

INFORMATION

Control

descriptions

11

Mixer

use

11

Whip

use

,

12

Recommendations

for

use

12

Endof

theday

cleaning

13

Extended

periodsofdisuse 13

4

TROUBLESHOOTING.

RECYCLING

Introduction

14

Problems,

causes,

Solutions

14

Disposal

and

recycling

14

ATTACHWIE

NTS

Spare

parts

catalogue

Wiring

diagram

GENERAL

INFORMATION

1

Purposeofthe

manual

This

manual

was

writtenbythe

Manufacturer

andisan

integral

partofmachine

equipment.

During design

and

construction

the

Manufacturer

has

carefülly

considered

possible

hazards

and

personal

risks

that

may

result

from

interaction

with

the

machine.Inaddition

to

observing

the

specific

lawsinforce.

the

manufacturer

has

adopted

all

"exemplary

construction

technique

principles".

The

purposeofthis

Information

istoadvise

the

userstoadopt

extreme

cautiontoavoid

risks.

However,

discretion

is

invaluable.

Safetyisalsointhe

handsofall

the

Operators

who

interact

with

the

machine.

Keep

this

manualina

suitable

place,

always

within

reach

for

consultation.

The

following

Symbols

are

includedtobetter

stress

some

passages:

DANGER-WARNING:

indicates

hazards

that

may

cause

serious

damages;

attention

is

required.

INFORMATION:

indicates

particularly

important

technical

Information.

The

following

is

enclosed

with

this

manual:

-

Warranty

certificate

describing

the

Manufacturer's

warranty

conditions.

-

Documents

that

prove

conformity

with

effective

health

and

safety

laws.

Contact

the

Authorised

dealer

for

any

Service

request,

Information

or

spare

parts

order.

Machine

and

manufacturer

identification

Manufacturer

Identification"

Serial

number

-

Conformity

markings

*

-•Ä

Qv.

o

V||H-'Kl!

W

Machine

model

Yearofmanufacture

Technical

speclfications

GENERAL

4

INFORMATION

■

Machine

descriptions

The

mixer

rängeismadeupof

the

following

modeis:

Mod.

MX25

was

designed

for

small

processing

needs.

The

Utensil

hasaclassic

vertical

hold

shape.

The

motor

unitisconstructed

withaplastic

structure

while

the

mixing

Utensilismadeupof stainless

steel,

aluminium

alloy

and

plastic

Clements.

The

machine

has

only

one

speed.

Mod.

MX40

was

designed

for

small-medium

work

needs.

The

Utensil

hasaclassic

vertical

hold

shape.

The

motor

unitisconstructed

withaplastic

structure

while

the

mixing

and

whip

Utensils

are

madeupof

stainless

steel,

aluminium

alloy

and

plastic

elements.

The

machine

has

one

mixer

speed

and

adjustable

whip

speed.

Mod.

FX40

was

designed

for

small-medium

work

needs.

The

Utensil

hasagun

handle

shape.

The

motor

unit

is

constructed

withaplastic

structure

while

the mixing

and

whip

Utensils

are

madeupof stainless

steel,

aluminium

alloy

and

plastic

elements.

The

machine

has

one

mixer

speed

and

adjustable

whip

speed.

Mod.

MX42S

was

designed

for

small-medium

work

needs.

The

Utensil

has a

classic

vertical

hold

shape.

The

motor

unitisconstructed

withaplastic

structure

while the

mixing

and

whip

Utensils

are

madeupof

stainless

steel,

aluminium

alloy

and

plastic

elements.

The

machine has

only

one

speed.

Mod.

FX42S

was

designed

for

small-medium

work

needs.

The

Utensil

has a

gun

handle

shape.

The

motor

unitisconstructed

withaplastic

structure

while the

mixing

and

whip

Utensils

are

madeupof

stainless

steel,

aluminium

alloy

and

plastic

elements.

The

machine

has

only

one

speed.

Technical

specifications

Descriptions

Power

supply

Power

Maximum

motor

unit

speed

Net

weight

Packaged

weight

Hand-arm

vibrations

Unit

of

measure

V

Hz

Ph

kW

rpm

kg

kg

m/s2

Noise

level

Installation

Protection

level

Electrical

shock

protection

Directive

compliance

MX25

230V

50/60HZ

1Ph

0.25

15000

2,2

3,4

<2,5

MX40

230V

50/60HZ

1Ph

0.4

15000

4,5

6

<2.5

FX40

230V

50/60HZ

1Ph

0,4

15000

4,5

6

<2,5

MX42S

230V

50/60HZ

1Ph

0,4

15000

3,5

5

<2.5

FX42S

230V

50/60HZ

1Ph

0,4

15000

3,5

5

<2,5

Less

than70dB

(A)

Hand-held

Utensil

IPX3

Class

II

93/68/EC-98/37/EC-2003/108/EC-2002/72/EC

-

Regulation

(EC)n°1935/2004-2004/108/EC-2006/95/EC

GENERAL

4

INFORMATION

I

MX25

On

button

.

Motor

unlt

)

- - - -

'Lock

nut

.Mixer

'utensll

MX40-MX42S

Speed

~_regulator

(MX40

only)

"""Onbutton

Motor

unlt

Lock

nut

Mixer

*

Utensil

FX40-FX42S

Speed

regulator

(FX40

only)

"*""Onbutton

.

Motor

unlt

-Lock

nut

Whip

utensll

(FX-MX40

only)

Overall

dimensions

mm

MX25

MX40

FX40

MX42S

FX42S

A

270

400

400

400

400

B

410

500

500

500

500

C

170

170

170

170

170

GENERAL

4

INFORMATION

■

MX25

!U

'-

505

MX40-MX42S

:\

FX40-FX42S

n

■•

■<:.

!

I

•

k:\

GENERAL

4

INFORMATION

I

Safety

devices

Forced

retensiononbutton:

Releasing

the

button

cuts

off

powertothe

Utensil

and

turnsitoff,

stopping

the

Utensil

Switch

protection:

The

protection

protects

the

■"Operator

from

accidentally

starting

the

Utensil

in

normal

work

conditions.

Safety

Information

•

Careful

consultation

of

this

manual

before

installation

and

useisessential.

Continual

observanceofthe

indications

foundinthe

manual

guarantee

personal

and

machine

safety.

•

Never

tamper

with

safety

devices

for

any

reason.

•

Strict

observanceofthe

work

safety

regulations

issuedbythe

responsible

organisations

in

each

country

is

strongly

recommended.

•

The

manufacturer

is

not

liable

for

damagestopersonsorthings

duetothe neglectofsafety

regulations.

•

Correct

machine

placement,

illumination

and

cleanliness

are

important

conditions

for

personal

safety.

•

Do

not

expose

the

machinetothe

elements.

•

Machine

connections

and

start-up

must

onlybeperformedbyspecialised

technicians.

•

Make

sure

that

the

system

specifications

of

the

room

where

the

machineisinstalled

correspondtothe

Information

printedonthe

plate.

•

Make

sure

the

machineisconnectedtoa

grounding

system.

•

The

work

area

around

the

machine

must

alwaysbekept

clean

and

dry.

•

Use

the

garments

foreseenbywork

safety

regulations.

GENERAL

A

INFORMATION

•

This

Utensil

must

onlybeused

for

its

specific

purpose:

any

other

useisconsidered

improper

and

therefore

hssardous.

•

Check

the

stiitabitity

and

weightofproductstobe

processed;donot

overload

the

machine.

•

Introducing

objects,

tools,

hands

or other

things

within

hazardous

partsisforbidden

•

Keep

the

machine

away

from

children.

•

Disconnect

the

power

cord

from

the

electrical

socket

when

the

machineisnotinuse.

■ In

the

eventofmalfunctions

and/or problems,donot

attempttorepsir

Ihe

machina.

Contact

the

authorised

dealer.

•

Use

original

spare

parts.

•

Before

cteaning

the

machine,

disconnect

the

power

supplybyunplugging

the

machine.

•

Do

not

ciean

with

high-pressure

jetsofwater.

Residual

risks

In

accordance

with

point

1.7.2

"Residual

risk

warnings"inMachine

Directive

98/37/EC

and

further

amendments.

please

note

that

the

safety

guards,

constructedinaccordance

with

said

Directive.donot

completely

eliminate

cutting

and

irapping

nskstoupper

limbs.

Ak.

DANGER-WARN1NG:

Nevcr

near

upper

Ümba

or

other

body

parts

to

the

indicated

Utensil

areas

when

insertctl

in

the

moter

imii.

Only

clean

Utensils

removed

fnim

the

niotor

11 ii

it.

INSTALLATION

INFORMATION

2

Packing

and

unpacking

The

machineispackagedincardboard

with

polyester

foam

insertstoguarantee

füll

integrity

during

transport.

•

Handle

the

packaging

accordingtothe

instructions.

•

Open

the

packaging

and

check

the

integrityofall

components.

Keep

packaging

for

future

moves.

•

Lift

the

machineasindicated

and

placeitin

the

installation

area.

Installation

area

The

arranged

area

mustbesuitably

illuminated

andanelectrical

socket

mustbeavailable.

The

resting

surface

mustbesufficiently

ample,

even

and

dry.

The

fry

top

mustbeinstaliedinrooms

with

non-explosive

environments.

In

any

case,

installation

must

alsobeperformedinconsideration

of

the

work

safety

laws

in

force.

Room

conditions

table

Descriptions

Working

temperature

Storage

temperature

Relative

humidity

Dustiness

Values

0+35°C(32+95

°F)

-15to+65"C(from

-6.8to+149

°F)

Maximum

80%

with20°C

room

temperature

Maximum

50%

with

room

temperature

between

20+60

°C

Less

than

0.03

g/m3

Electrical

connections

DANGER-WARNING:

Electrical

connectionstothe

supply

mains

must

be

performedbyspecialised

personnel.

Verify

the

efficiencyofthe

grounding

Systeminthe

building.

Make

sure

that

line

voltage

(V)

and

frequency

(Hz)

correspondtothoseofthe

machine

(See

the

identification

plate

and

wiring

diagram).

The

machine

is

equipped

withanelectrical

cord

that

connectstoa

multi

polar

plug.

The

plugistobeconnectedtoa

wall

switch

equipped

withacircuit

breaker.

i'■i

t

\

V:

/

J

Single

phase

230V-

.?.:

\

connection

1Ph

Ph N

o

•

-]

i

j

10

USE

AND

CLEANING

INFORMATION

3

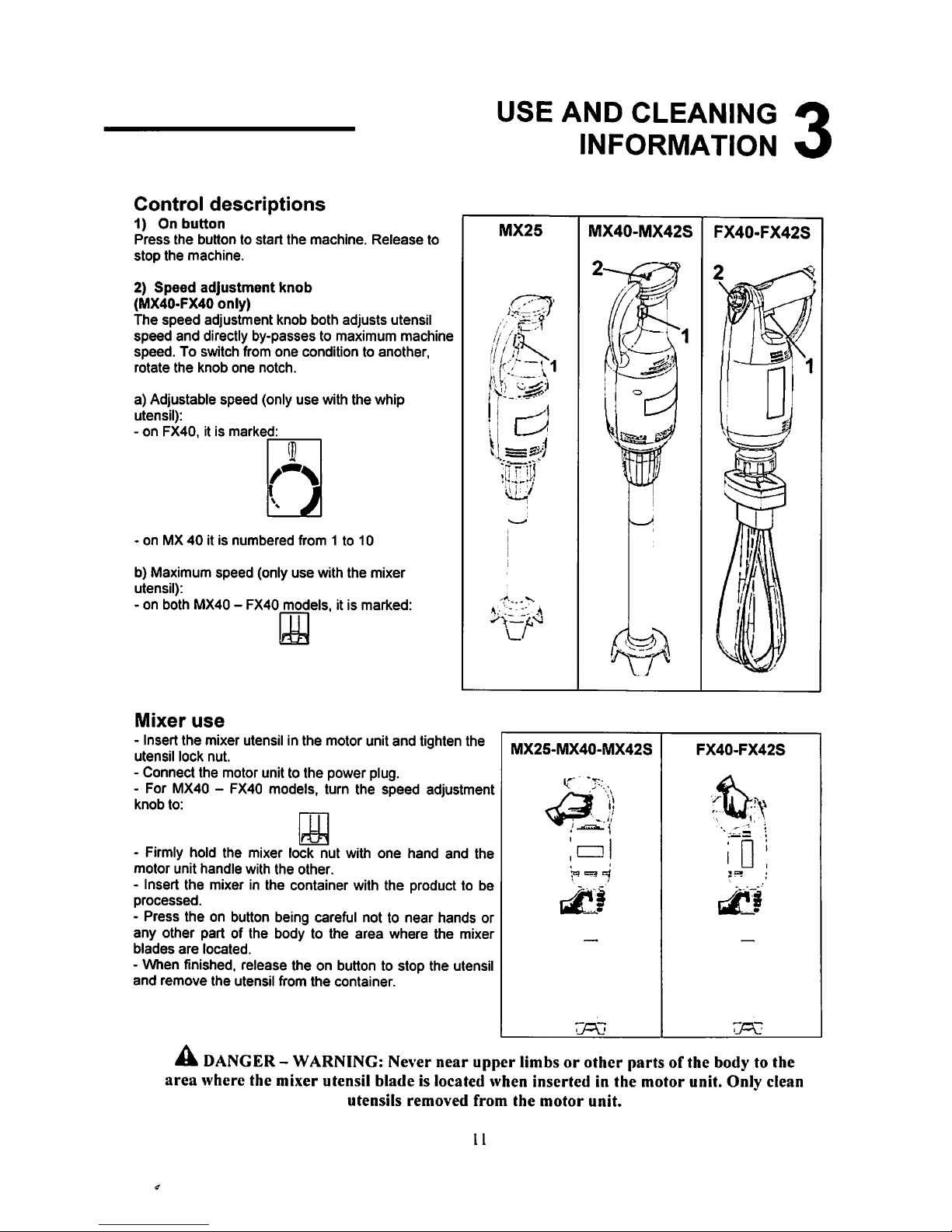

Control

descriptions

1)Onbutton

Press

the

buttontoStart

the

machine.

Release

to

stop

the

machine.

2)

Speed

adjustment

knob

(MX40-FX40

only)

The

speed

adjustment

knob

both

adjusts

Utensil

speed

and

directly

by-passestomaximum

machine

speed.Toswitch

from

one

conditiontoanother,

rotate

the

knob

one

notch.

a)

Adjustable

speed

(only

use

with

the

whip

Utensil):

-onFX40,itis

marked:

1\

Q

•onMX40itisnumbered

from1to

10

b)

Maximum

speed

(only

use

with

the

mixer

Utensil):

-onboth

MX40-FX40

modeis,itis

marked:

MX25

f/Es.

V

MX40-MX42S

2

Mixer

use

-

Insert

the

mixer

Utensilinthe

motor

unit

and

tighten

the

Utensil

lock

nut.

-

Connect

the

motor

unittothe

power

plug.

-

For

MX40-FX40

modeis,

turn

the

speed

adjustment

knob

to:

-

Firmly

hold

the

mixer

lock

nut

with

one

hand

and

the

motor

unit

handle

with

the

other.

-

Insert

the

mixerinthe

Container

with

the

producttobe

processed.

-

Press

theonbutton

being

careful

nottonear

hands

or

any

other

partofthe

bodytothe

area

where

the

mixer

blades

are

located.

-

When

finished,

release

theonbuttontostop

the

Utensil

and

remove

the

Utensil

from

the

Container.

4k

DANGER

-

WARNING:

Never

near

upper

limbs

or

other

parts

of

the

body

to

the

area

where

the

mixer

Utensil

bladeislocated

when

insertedinthe

motor

unit.

Only

clean

Utensils

removed

from

the

motor

unit.

MX2S-MX40-MX42S

SU!

FX40-FX42S

1n•

JFf

11

USEANDCLEANING

INFORMATION

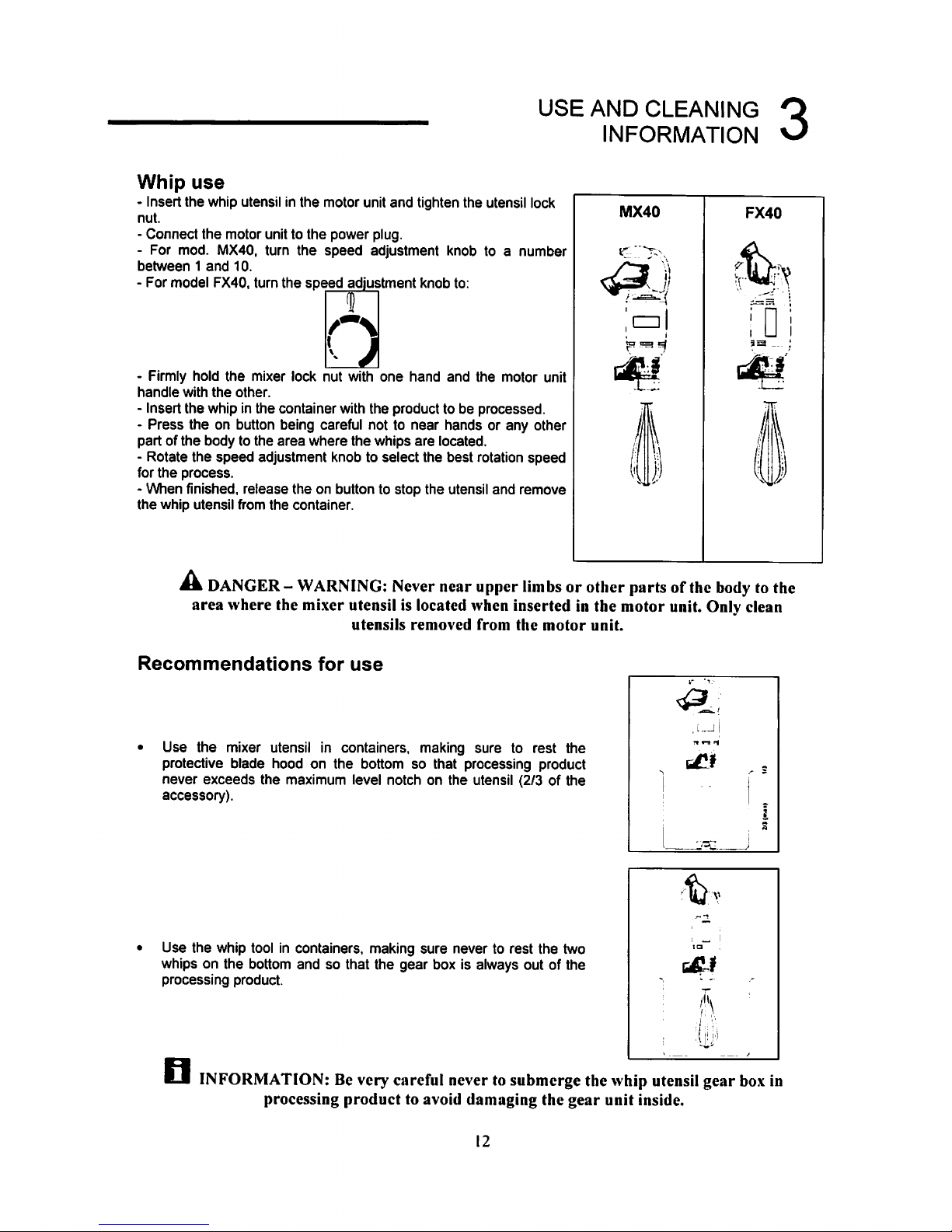

Whip

use

•

Insert

the

whip

Utensilinthe

motor

unit

and

tighten

the

Utensil

lock

nut.

-

Connect

the

motor

unit to

the

power

plug.

-

For

mod.

MX40,

turn

the

speed

adjustment

knobtoa

number

between1and

10.

-

For

model

FX40,

turn

the

speed

adjustment

knob

to:

Tl

a

-

Firmly

hold

the

mixer

lock

nut

with

one

hand

and

the

motor

unit

handle

with

the

other.

-

Insert

the

whipinthe

Container

with

the

producttobe

processed.

-

Press

theonbutton

being

carefui

nottonear

handsorany

other

partofthe

bodytothe

area

where

the

whips

are

located.

-

Rotate

the

speed

adjustment

knobtoselect

the

best

rotation

speed

for

the

process.

-

When

finished,

release

theonbuttontostop

the

Utensil

and

remove

the

whip

Utensil

from

the

Container.

DANGER-WARNING:

Ncver

near

upper

limbsorother

partsofthe

bodytothe

area

where

the

mixer

Utensilislocated

when

insertedinthe

motor

unit.

Only

clean

Utensils

removed

from

the

motor

unit.

Recommendations

for

use

Use

the

mixer

UtensilinContainers,

making

suretorest

the

protective

blade

hoodonthe

bottomsothat

processing

product

never

exceeds

the

maximum

level

notchonthe

Utensil

(2/3ofthe

accessory).

I

Use

the

whip

toolinContainers,

making

sure

nevertorest

the

two

whipsonthe

bottom

andsothat

the

gear

boxisalways

outofthe

processing

product.

INFORMATION:Bevery

carefui

nevertosubmcrge

the

whip

Utensil

gear

box

in

processing

producttoavoid

damaging

the

gear

unit

inside.

12

USEANDCLEANING

INFORMATION

Endofthe

day

cleaning

•

Unplug

the

motor

unit

from

the

power

socket.

•

Remove

Utensils

from

the

motor

unit.

Wash

the

mixer

Utensil

under

running

water

(only

when

the

Utensil

is

removed

from

the

motor

unit).

•

Remove

the

whips

from

the

whip

Utensil

and

wash

them

under

running

water

(only

when

the

Utensilisremoved

from

the

motor

unit).

•

Hang

the

Utensils

with

the

mixer

ends

(mixer

bladeorwhips)

facing

down.

•

Clean

external

motor

unit

parts

withadamp

sponge

and

dry

(only

perform

this

Operation

when

unplugged

from

the

power

socket).

•

Do

not

use

metallic

pads

and

abrasive

detergents.

•

Accurately

clean

using

neutral

products.

Extended

periodsofdisuse

For

extended

periodsofdisuse,

unplug

the

Utensil

from

the

power

socket,

clean

the

Utensil

and

coveritwith

a

clothtoprotectiffrom

dust.

13

TROUBLE

SHOOTING,

RECYCLING

Introduction

In

the

eventofbreakdownormaifunctioning,

turn

off

the

wall

fuse

and

contact

your

Dealer's

Service

centre.

Avoid

dismantling

internal

machine

parts.

The

manufacturerisnot

liable

for

any

machine

tampering!

Problems,

causes,

Solutions

Problem

The

machine

does

not

Start

Cause

Main

switch

off

No

power

reaches

the

motor

unit.

Solution

Turnonmain

switchto"1"

Contact

your

dealer's

Service

centre

Disposal

and

recycling

The

markings

illustrated

here

(barred

garbage

bin),onthe

Utensil

data

plate,

indicates

thatatthe

endofits

working

life,

the

Utensil

mustbedisposedofand

recycled

accordingtoEuropean

Directive

2002/96/EC

and

subsequent

amendments.

The

Directive

provides

for

the

separate

collectionofelectric

and

electronic

equipmentbya

collection

System

called

RAEE.

Upon

purchasing

a

new

Utensil,

the

user

must

not

dispose

of

the

Utensilasurban

waste

but

must

return

it,ina

one-to-one

exchange,tothe dealerordistributor.

The

dealer

may

disposeofthe

Utensil

following

the

procedures

setbythe

RAEE

collection

System.Inthe

event

the

user

disposesofthe

Utensil

without

purchasing

a

new

one,inItaly

contact

the

manufacturer

who

will

provide

suitable

information

on

machine

disposalatthe

collection

centre

dosesttothe

user.

Users

who

do

not

resideinItaly

must

contact

the

Ministryofthe

Environmentintheir

countries

who

will

provide

information

necessary

for

correct disposal.

Failuretoobserve

the

disposal

procedure

may

cause

harmful

effectsonthe

environment

and

people.

Therefore,

totalorpartial

illicit

Utensil

disposalbyusersispunishablebylocal

authorities.

14

CATÄLOGO

PARTIDIRICAMBIO•SPARE

PARTS

CATALOGUE

•

CATALOGUE

PIECESDERECHANGE•ERSATZTEILKATALOG

•

CATÄLOGODEREPUESTOS

•

CATÄLOGODEPECAS

SOBRESSALENTES

•

KATAJ10r3AnHACTEM

MX40

MX42S

37—

28

29!

19!

36

-31!

CATÄLOGO

PARTIDIRICAMBIO•SPARE

PARTS

CATALOGUE

•

CATALOGUE

PIECESDERECHANGE•ERSATZTEILKATALOG.

CATÄLOGODEREPUESTOS

•

CATÄLOGODEPECAS

SOBRESSALENTES

•

KATAJlOr

3AT1HACTEM

MX40

MX42S

Rif

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

25

25

25

26

28

29

30

30

30

30

31

32

"34~

3b

36

36

36

"37~

38

Codice

Code

SL0762

SL3382

SL2997

SL3414

SL0757

SL3080

SL3081

SL3444

SL3443

SL3446

SL3445

SL2899

SA1063

SL3611

SL3612

SL0739

SL0746

SL0740

SL0271

SA1002

SA8900

SA8800

SL0733

SL0743

SL0976

SL0776

SL0978

SL0979

SL0741

SL3391

SL0879

SL0773

SL0972

SL0747

SL0974

SL0975

SL3415

SL1454

SL0772

SL0744

ME4030

ME4040

ME4050

FRUSTAFM3

SL3413

•

•

•

•

•

•

•

•

•

(*):

fuori

produzlone/c

Caratterlstlche

Characteristics

Green

230V/1Ph/50-60Hz

(MX40)

(MX42S)

Green

Green

Green

Green

Green

Green

230V/1Ph/50-60Hz

Green

(MX40)

8x18x5

608H21inox

Assemblv

(MX40)

(MX40)

(MX40)

(MX40)

(1)4X40)

L=300mm

L=400mm

(Standard)

L=500mm

L=600mm

OR128

L=300mm

L=400mm

(Standard)

L=500mm

L=600mm

8x18x6

vTs

L=300mm

assembly

L=400mm

assemblv

(Standard)

L=500mm

assembly

Assembly

(MX40)

(MX40)

utofproduction

Descrizione

Oescription

Passacavo

Cable

damp

Piastra

Plale

Scheda

eletlronica

Electronic

card

Inserto

Insert

Pulsante

Push

bullon

Copertura

Covering

Copertura

Coverina

Tappo

Cap

Tappo

Cap

Tappo

Cap

Tappo

Cap

Motore

Motor

Giunto

Joint

Inserto

insert

Flangia

Flanae

Ingranaqqio

Gear

Paraolio

Oil

seal

Boccola

Bush

Cuscinetto

Bearinq

Supporto

Support

Inqranaggio

Gear

Ingranaaaio

Gear

Scatola

Box

Frusta

VVhisk

Albero

Shaft

Albero

Shaft

Albero

Shaft

Albero

Shaft

Supporto

Support

Ghiera

Locking

ring

Boccola

Bush

O-rinq

O-rinq

Tubo

Tube

Tubo

Tube

Tubo Tube

Tubo Tube

Protezione

Protection

Paraolio

Oil

seal

V-ring

V-rinq

Coltello

Cutter

Utensile

mescolatore

Mixer

tool

Utensile

mescolatore

Mixer

tool

Utensile

mescolatore

Mixer

tool

Utensile

frusta

Whisk

tool

Rotella

Wheel

9:

ricamblo

conslgllato

/

spare

part

suggested

«RKIS

OUGRAM•SCHEMA

ELECTRIQUE•ELEKTRISCHER

ELECTRICO•ESQUEMA

ELECTRICO

•

3JIEKTPMMECKAJ1

CXEMA

MX40

FX40

DD

ID

D

o

c

K

i

i—

Push

button

//

/T\

Speed

variator

n

Motor

Loading...

Loading...