Page 1

INSTALLATION INSTRUCTIONS

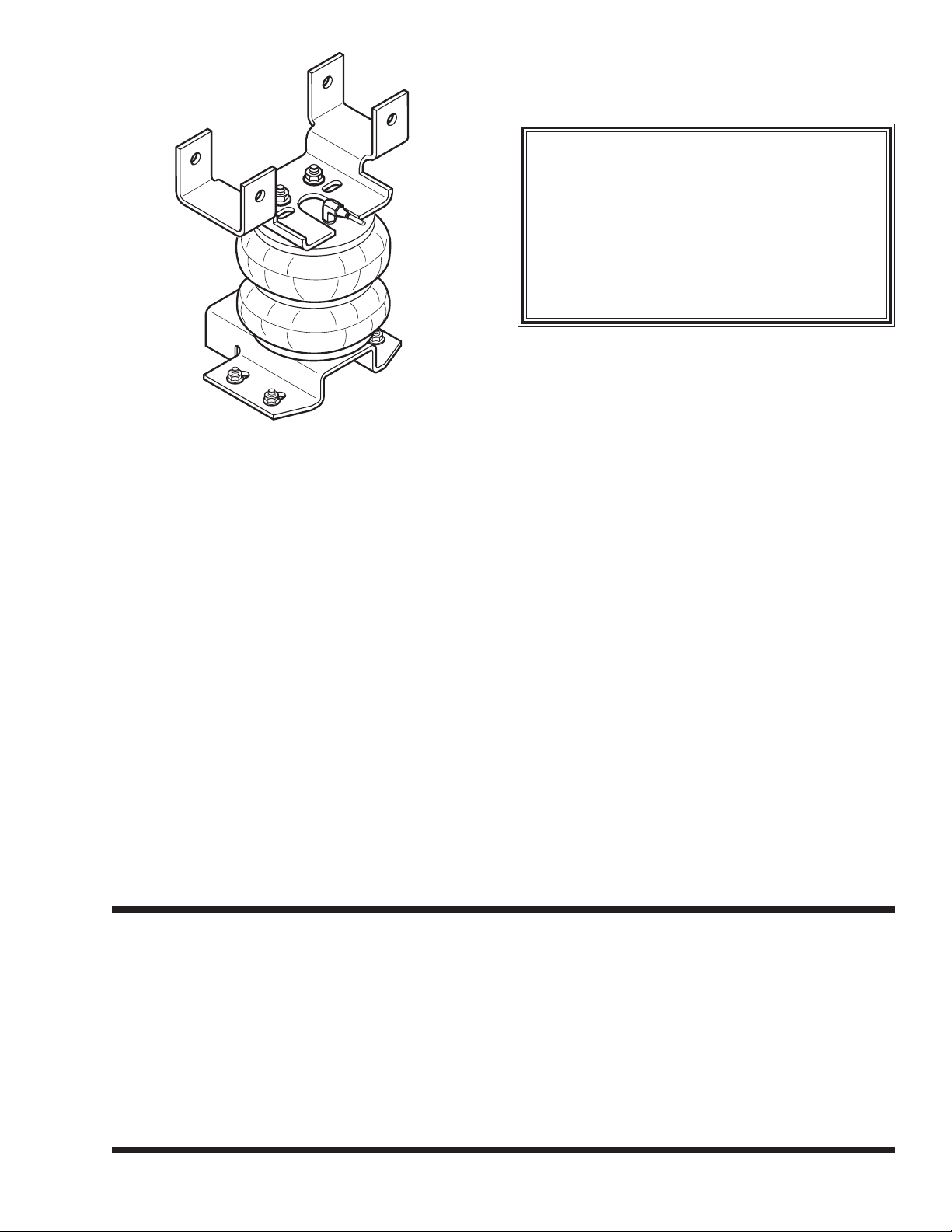

Congratulations - your new Air Helper Springs are quality

products capable of improving the handling and comfort of your

vehicle. As with all products, proper installation is the key to

obtaining all of the benefits your kit is capable of delivering.

Please take a few minutes to read through the instructions to

identify the components and learn where and how they are used.

It is a good idea to start by comparing the parts in your kit with

the parts list below.

The heart of the Air Helper Spring kit is, of course, the air

helper springs. Remember that the air helper springs must flex

and expand during operation, so be sure that there is enough

clearance to do so without rubbing against any other part of the

vehicle.

Be sure to take all applicable safety precautions during the

installation of the kit. The instructions listed in this brochure

and the illustrations all show the left, or driver’s side of the

vehicle. To install the right side assembly simply follow the same

procedures.

PARTS LIST

2190

WARNING!

Do not inflate this assembly when it is

unrestricted. The assembly must be restricted by

the suspension or other adequate structure. Do

not inflate beyond 100 P.S.I. Improper use or

over inflation may cause property damage or

severe personal injury.

Your kit includes separate inflation valves and air lines for

each air helper spring. This will allow you to level your vehicle

from side to side as well as from front to back. If you would rather

have a single valve inflation system, your dealer can supply the

required "T" fitting.

IMPORTANT!

For your safety and to prevent possible damage to your

vehicle, do not exceed the maximum load recommended by

the vehicle manufacturer (GVWR). Although your Air Helper

Springs are rated at a maximum inflation pressure of 100

psi, this pressure may allow you to carry too great a load on

some vehicles. It is best to have your vehicle weighed once

it is completely loaded and compare that weight to the

maximum allowed. Check your vehicle owner’s manual or

data plate on driver side door for maximum loads listed for

your vehicle.

When inflating your Air Helper Springs, add air pressure in small quantities, checking pressure frequently during inflation. The air spring requires much less air volume

than a tire and, therefore, inflates much quicker.

AIR SPRING 6781 2

UPPER BRACKET 5178 2

LOWER BRACKET 5250 2

FRAME BRACE (LEFT) 5249 1

FRAME BRACE (RIGHT) 5248 1

18 ft. TUBING 0938 1

3/8"-16 X 4" HEX BOLT 4

3/8"-16 FLANGED LOCK NUT 8

3/8"-16 X 3/4" FLANGED HEX BOLT 2

21-8178 12-03 NCD-6037-2

5/16" FLAT WASHER 4

J-BOLT 8

5/16" -18 FLANGED LOCK NUT 8

HEAT SHIELD 1004 1

PUSH-TO-CONNECT

INFLATION VALVE 3101 2

PUSH-TO-CONNECT ELBOW 3098 2

THERMAL SLEEVE 0899 2

NYLON TIES 7

Page 2

2190 / 6011

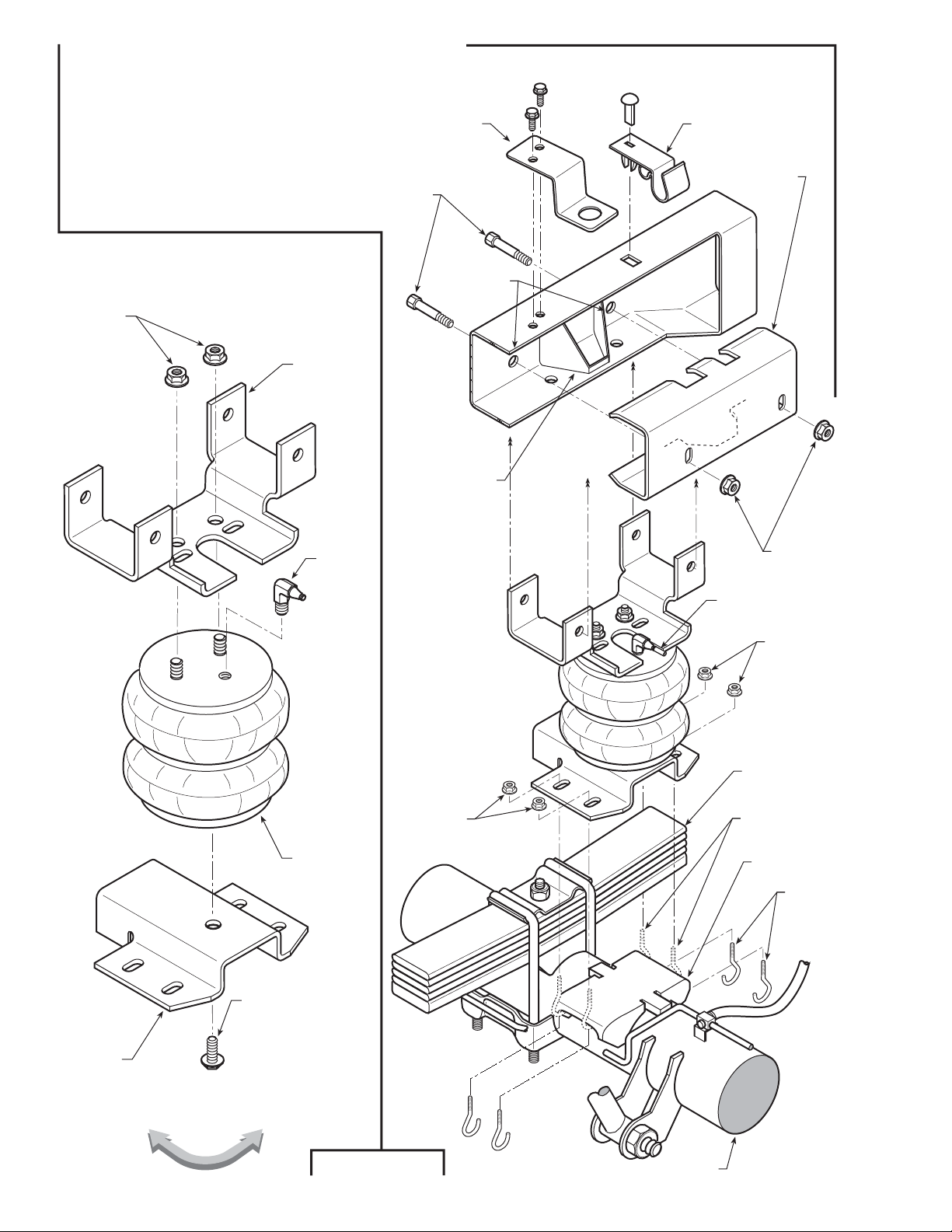

KIT TO FRAME ASSEMBLY

NOTE:

Both illustrations are of the left,

or drivers side, of the truck. Refer to

step 3 for the proper lower bracket

alignment.

KIT ASSEMBLY

3/8” -16

FLANGED

LOCK NUT

UPPER

BRACKET

AIR

FITTING

BRAKE-LINE

BRACKET

3/8” -16 x 4”

HEX BOLTS

JOUNCE BUMPER

DRILL TWO

7/16” HOLES

BRACE

BRAKE-LINE / AXLE

VENT TUBE CLIP

FRAME BRACE

FRAME

3/8” -16

FLANGED

HEX NUT

AIR

SPRING

3/8” -16 x 3/4”

FLANGED HEX BOLT

5/16” -18

FLANGED

HEX NUT

AIR

LINE

LEAF STACK

J-BOLT

INSTALLATION

LOCATION

JOUNCE

PAD

5/16” -18

FLANGED

HEX NUT

J-BOLT

LOWER

BRACKET

WHEEL

FRONT

FIGURE "A"

AXLE

Page 3

FRAME RAIL

FACTORY

BOLTS

BRAKE-LINE

BRACKET

AIR SPRING

LOWER

BRACKET

DRIVER'S SIDE

FRONT

FIGURE "B"

PIN

FIGURE "C"

FRAME

BRACE

UPPER

BRACKET

J-BOLT

BRAKE

LINE

JOUNCE PAD

PLASTIC PIN

BRAKE-LINE/

AXLE VENT TUBE

CLIP

E

M

A

R

F

JOUNCE

BUMPER

SHOCK

BRACKET

STEP 1 - PREPARE THE VEHICLE

Remove the positive battery cable. With the vehicle on a solid, level surface

chock the front wheels. Raise the vehicle by the axle and remove the rear wheels.

After the removal of the wheels lower the vehicle so the axle rests on jack stands

rated to support your vehicles weight. This installation assumes that there is no

load in the bed of the truck.

Your vehicle is equipped with rubber jounce bumpers. The bumpers are

attached to the frame directly above the axle. Remove these bumpers by unbolting

from the inside of the frame flange see Figure "C". This bumper will not be reused

with this kit.

The brake line bracket and brake-line/axle vent tube clip will need to be loosened

and removed to allow installation of the frame brace. The brake-line bracket is

attached to the top flange of the frame with two hex bolts. Remove the hex bolts

to allow the brake-line bracket to be moved far enough to facilitate installation of

the frame brace. The brake-line/axle vent tube clip is attached to the top of the upper

frame flange with a plastic pin. Remove the pin with a panel tool or screw driver

see Figure "C". Pull the clip out of the way of the frame brace.

STEP 2 - PRE-ASSEMBLE THE KIT

Pre-assembly will begin with the left (driver's) side of the vehicle. All pictures

depict the installation on the left side of the vehicle unless noted otherwise. Select

one of the air springs and install the push-to-connect air fitting in the top threaded

hole and tighten securely. Tighten the air fitting so as to make contact with the

nylon ring and then tighten 1/4 turn to snug fitting. No thread sealant is needed.

Secure the upper bracket to the air spring using 3/8" -16 flanged lock nuts. Next,

select a lower bracket and secure to the air spring using a 3/8" -16 x 3/4" flanged

hex bolt see Figure "A". Be sure that the lower bracket is attached to the air

spring so that the bracket orientation is perpendicular to the upper bracket. When

the upper bracket of the air spring assembly is attached to the frame rail, the

lower bracket should rest in-line on top of the axle without twisting the air spring

see Figures "A" & "B".

TIE RIGHT PARKING BRAKE-LINE

TO BRAKE-LINE BRACKET ON AXLE

FIGURE "D"

HEAT SHIELD

FIGURE "E"

STEP 3 - INSTALL THE ASSEMBLY TO THE VEHICLE

Insert the left-side frame brace into the frame rail so that it straddles the jounce

bumper brace see Figure "A". Ensure that the frame brace does not pinch any

existing brake, electrical, or fuel lines that may be inside the frame rail. The brakeline bracket and brake-line/axle vent tube clip will have to be held clear to allow

installation of the frame brace.

Place the air spring assembly on top of the jounce bumper pad on top of the

axle housing. Align the air spring over the axle. Slide the upper bracket onto the

frame rail and frame brace. Visually align the holes in the upper bracket with the

slots in the frame brace. It may be necessary to use a rubber mallet to force the upper

bracket onto the frame. Mark the frame with a center punch in the center of the holes

on the upper bracket. Use the upper bracket as a template to drill two 7/16" mounting

holes in the frame rail see Figure "A". Before drilling the holes make sure all

electrical, brake, and fuel lines are cleared from the path of the drill. In order to

prevent any damage to these lines it is recommended that a thin piece of wood be

placed between the frame rail and the existing lines. Attach the upper bracket with

the 3/8"-16 x 4" hex bolts and 3/8" -16 flanged hex nuts see Figures "A" & "B".

With the assembly attached to the frame rail, the next step is to attach the lower

bracket to the jounce pad on the axle housing. Center the lower bracket on the

jounce pad. Use the J-bolts and 5/16" -18 flanged lock nuts to secure the lower

bracket to the jounce pad see Figures "A" & "B". Spin the nuts on as far as possible

by hand. While making sure that the lower bracket stays centered on the jounce

pad, tighten each nut two turns at a time with a wrench, switching to opposite nuts

to ensure that the bracket is mounted evenly on the jounce pad. After the

installation of the left-side assembly is complete, re-attach the brake-line bracket

and brake-line/axle vent tube clip to the frame.

Page 4

Important: In order for the air spring to function properly, there must be

a minimum of 1/2" of clearance around the air spring. The right-side parking

brake-line must be tied to the brake-line bracket on the axle housing to prevent

it from interfering with the normal operation of the left-side air spring see

Figure "D".

AIR

SPRINGS

AIR HOSE

STEP 4 - INSTALL THE PASSENGER'S SIDE ASSEMBLY

Follow steps 2 - 5 for assembly and installation of the passenger's side

assembly. Note: The use of a heat shield is required on the passenger's side of

BUMPER

INFLATION

VALVES

the vehicle. The heat shield will mount between the upper bracket and the air helper

spring see Figure "E". Position the shield halfway between the nearest point of

FIGURE "F"

the exhaust pipe to the rubber air spring. Ensure that the heat shield will not interfere

with the normal operation of the air spring or the vehicle's suspension. Do not

position the face of the shield directly over the axle, as it may contact the axle on

full suspension compression.

AIR LINE

FLAT WASHER

STEP 5 - INSTALL THE AIR LINE AND INFLATION VALVE

Uncoil the air tubing and cut it in two equal lengths. DO NOT FOLD OR KINK

THE TUBING. Make the cut as square as possible. Insert one end of the tubing

into the push-to-connect elbow fitting installed in the top of the air helper spring

as far as possible.

Select a location on the vehicle for the air inflation valves. The location can be

on the bumper or the body of the vehicle, as long as it is in a protected location so

the valve will not be damaged, but still maintain accessibility for the air chuck see

Figure "F". Drill a 5/16" hole and install the air inflation valve using two 5/16" flat

washers per valve as supports see Figure "G". Run the tubing from the air helper

spring to the valve, routing it to avoid direct heat from the engine, exhaust pipe, and away from sharp edges. Thermal sleeves

have been provided for these conditions. The air line tubing should not be bent or curved sharply as it may buckle. Secure the

tubing in place with the nylon ties provided. Push the end of the air line tubing into the inflation valve see Figure "G".

PUSH-TO-CONNECT

INFLATION VALVE

BODY OF

VEHICLE

HEX NUT

FIGURE "G"

VALVE CAP

STEP 6 - CHECK THE AIR SYSTEM

Once the inflation valves are installed, inflate the air helper springs to 70 psi and check the fittings for air leaks. Using a spray

bottle, apply a solution of soap and water to the fittings. If a leak is detected at a airline tubing connection then check to make

sure that the airline tube is cut as square as possible and that it is pushed completely into the fitting. The airline tubing can easily

be removed from the fittings by exhausting all the pressure in the air springs and then pushing the collar towards the body of the

fitting and then, with a pull, remove the airline tubing. Reinstall the tubing and reinflate the air springs and check for leaks as noted

above. If a leak is detected where the air fitting screws into the spring, just screw the air fitting into the air spring until the leak

stops.

This now completes the installation. Install the wheels and torque the lug nuts to the manufacturer's specification. Raise

the vehicle by the axle and remove the jack stands. Lower the vehicle to the ground. Reattach the negative battery cable and

remove the wheel chocks from the front wheels. Before proceeding, check once again to be sure you have proper clearance

around the air springs. With a load on your vehicle and the air helper springs inflated, you must have at least 1/2" clearance around

the air springs. As a general rule, the air helper springs will support approximately 50 lbs. of load for each psi of inflation pressure

(per pair). For example, 50 psi of inflation pressure will support a load of 2500 lbs. per pair of air helper springs. FOR BEST

RIDE use only enough air pressure in the air helper springs to level the vehicle when viewed from the side (front to rear). This

amount will vary depending on the load, location of load, condition of existing suspension and personal preference.

NOTE:

Too much air pressure in the air helper springs will result in a firmer ride, while too little air pressure will allow the air helper spring

to bottom out over rough conditions. Too little air pressure will also not provide the possible improvement in handling. TO

PREVENT POSSIBLE DAMAGE, MAINTAIN A MINIMUM OF 5 P.S.I. IN THE AIR HELPER SPRINGS AT ALL TIMES.

NOTE:

Once the air helper springs are installed, it is recommended that the vehicle not be lifted by the frame, as over-

extension may occur, resulting in damage to the air helper springs. However, should it become necessary to raise the vehicle

by the frame, deflate both air helper springs completely.

Loading...

Loading...