Operating instructions for

Netter Electric External Vibrators

series NEA/NEG/NEG S/NES

Sept. 2020

No. 1929E

Page 1/35

These operating instructions apply to:

Series NEA

Series NEG

Series NEG S

Series NES

2

Document no.

1929E

Version no.

2

Date of issue

Sept. 2020

Scope of

delivery

Designation

Version of

document

Contents

1 General information 3

2 Safety 6

3 Technical data 11

4 Design and function 13

5 Transport and storage 14

6 Installation 15

7 Start-up and operation 19

8 Maintenance and servicing 26

9 Troubleshooting 31

10 Spare parts and accessories 33

11 Disposal 35

Please refer to the delivery note for the scope of delivery.

Check the packaging for possible transport damage. In the event of

damage to the packaging, check the contents for completeness and

possible damage. Inform the carrier in the case of damage.

The Electric External Vibrators of the series NEA, NEG, NEG S and

NES are hereafter referred to as "NEA/NEG".

General information

3

Use and

storage

Target group

Copyright

Limitation of

liability

Directives /

standards

observed

1 General information

Before installing the NEA/NEG read these instructions carefully. It is the

basis for any action when dealing with the NEA/NEG, and may be used for

training purposes. The instructions should be subsequently stored at the

operation site.

The target group for these instructions is technical staff, who have basic

knowledge of mechanics, electrics and explosion protection.

Only complying technical staff may work on the NEA/NEG.

The NEA/NEG may only be installed, put into operation, maintained, trou-

bleshot and disassembled by persons authorised by the operator.

This documentation is protected by copyright.

Netter

Vibration reserves all rights such as translations, reprinting and re-

production of the instructions, as well as parts thereof.

All technical information, data and instructions for installation, operation

and maintenance in these instructions are based on the latest information

available at the time of printing and take our past experience to the best of

our knowledge into account.

No claims can be derived from the information, illustrations and descriptions in these operating instructions.

The manufacturer does not assume liability for damages resulting from:

failure to observe the instructions,

improper use,

unauthorised repairs,

technical modifications,

use of non-permissible spare parts.

Translations are made to the best of our knowledge.

Netter

Vibration does not assume liability for translation errors, even if the

translation was made by us or on our behalf. Only the original German text

remains binding.

The Electric External Vibrators of the series NEA, NEG, NEG S and NES

comply with the EC Machinery Directive 2006/42/EC, the electromagnetic

compatibility directive 2014/30/EU and the low voltage directive

2014/35/EU.

In particular the standards EN ISO 12100, EN 60529 and DIN EN 60034-1

has been observed.

All Electric External Vibrators of the series NEA, NEG, NEG S and

NES, labelled with the Ex-Symbol on the type plate, comply with the ATEX

Directive 2014/34 EU for equipment group II.

NEA/NEG of housing size 50 and 60 are suitable for use in potentially explosive areas of the category 3D in the zone 22.

General information

4

DANGER

indicates an immediate danger.

Disregard of this notice will result in death or severe person-

al injuries.

WARNING

indicates a potential danger.

Disregard of this notice can result in death or severe per-

sonal injuries.

CAUTION

indicates a potentially dangerous situation.

Disregard of this notice can result in minor or moderate per-

sonal injuries.

NOTICE

indicates potential material damage.

Disregard of this notice can result in material damage.

Instruction

and warning

symbols

Personal

injuries

Material

damages

NEA/NEG from housing size 100 upwards are suitable for use in potentially explosive areas of the category 2D in the zone 21 and 22.

In particular the standards DIN EN IEC 60079-0 and DIN EN 60079-31

(IEC 60079-31) are observed.

Before using the NEA/NEG the operator must exclude the possibility that

the introduction of vibrational energy poses the risk of explosion.

The following instruction and warning symbols are used in these instructions:

General information

5

IMPORTANT

indicates actions, methods or notes that are not relative to safety, e.g. useful information and tips.

Environmentally safe disposal

indicates the obligation of environmentally safe disposal.

Explosion prevention

indicates information on explosion prevention.

Notes

ATEX-notes

Type designations

When operating the NEA/NEG in potentially explosive areas all notes,

marked with the Ex-symbol , must be observed.

Explanations of abbreviations in the type designation:

XXX YYZZZZ-WWW

XXX indicates the type of vibrator (three-phase or single-phase):

NEA = single-phase alternating current

NEG = 3-phase alternating current

NES = 3-phase alternating current (stainless steel housing)

YY indicates the polarity:

50 = 2 poles

25 = 4 poles

16 = 6 poles

12 = 8 poles

ZZZZ indicates the centrifugal force in daN (Decanewton).

WWW indicates special features:

K = 130°C PTC thermistor installed (standard from housing size 170

upwards)

K2 = 120°C PTC thermistor installed

TS = 130°C thermal protector with a normally closed (NC) switching

contact

TS2 = 120°C thermal protector with a normally closed (NC) switching

contact

H = 200-240V anti-condensation heater 0-50W

H110 = 100-120V anti-condensation heater 0-50W

HD = Fully encapsulated stator (heavy duty)

Suffix S behind the type designation = stainless steel housing

Safety

6

2 Safety

IMPORTANT

Netter

Vibration assumes no liability for personal injuries and material

damages if technical changes to the product were made or the notices and

regulations in these instructions were not observed.

DANGER

Electric shock

An electric shock will result in serious injury or even death.

The NEA/NEG must be free of voltage during assembly,

start-up, maintenance and troubleshooting.

Observe the following five safety rules:

1. Disconnect the NEA/NEG from the mains supply.

2. Secure the NEA/NEG against re-activation.

3. Establish that the NEA/NEG has no voltage.

4. Earth and short-circuit the power supply of the NEA/NEG.

5. Cover adjacent live parts or fence them off.

Intended use

Qualification

of qualified

personnel

Accessory

parts

Liability

Safety

rules

The NEA/NEG are intended for generating circular vibrations.

General applications are: loosening, conveying, sorting, compacting, sepa-

rating bulk materials and reducing friction. NEA/NEG are used for emptying bunkers, as drives for conveyor troughs, sieves and vibrating tables.

The NEA/NEG are designed for installation in machines and may only be

put into operation, if it has been assured that the complete machine complies with the regulations of the machinery directive.

Any other use is considered improper.

Installation, commissioning, maintenance and troubleshooting of the

NEA/NEG may only be performed by authorised qualified personnel.

All handling of the NEA/NEG is the responsibility of the operator.

All accessory parts connected to the NEA/NEG, which ensure correct

operation and safety, must have the appropriate degree of protection for

this specific purpose.

Safety

7

DANGER

Risk of electric shock due to high voltage

An electric shock leads to serious injuries or even death.

Observe the permissible protection class and earthing.

The NEA/NEG may only be operated with the correct

connection of the protective conductor.

Perform all work only with insulated tools suitable for the

application.

All work on the system may only be carried out in a volt-

free state.

Never open the terminal box cover when voltage is ap-

plied.

Never loosen or remove paint-sealed screws.

Never touch or remove safety covers.

Protect the NEA/NEG against falling parts during all

work. Metal parts can cause a short circuit within the

NEA/NEG.

WARNING

Spark formation

Opening the terminal box cover of the NEA/NEG in Exzones can cause spark formation and thus lead to an explosion due to ignition of an explosive atmosphere.

Never open terminal box covers in a potentially explosive

atmosphere or when voltage is applied.

If terminal box covers or unbalance covers are open,

check the condition and correct positioning of the seals.

Damaged seals must be replaced immediately.

The mechanical protection of the housing (IP6X) must be

assured after assembly of the covers.

High voltage

Spark

formation

Safety

8

WARNING

Spark formation

The impact of corroded steel parts on the aluminium housing at high speed can cause spark formation and thus lead

to an explosion.

Choose the installation position carefully, so that there

are no external impacts.

Fasten the NEA/NEG securely.

Check the fastening regularly (generally monthly).

WARNING

Hazard of electrostatic discharge

When cleaning the NEA/NEG with a dry cloth there is a risk

of electrostatic discharge. A electrostatic discharge can lead

to an explosion due to ignition of an explosive atmosphere.

Only clean the NEA/NEG with a wet cloth.

Remove dust deposits regularly.

The following warning label is located

on the NEA/NEG and must be observed:

WARNING

Static electricity

The discharge of charged, isolated conductive parts can

cause ignitable sparks.

Connect the earthing screw of the NEA/NEG to the po-

tential equalisation of the higher-level machine.

Include all components in the potential equalisation of

the machine.

Spark

formation

Static

electricity

Static

electricity

Safety

9

WARNING

Hot surface

If the permissible operating conditions and the maintenance

requirements are not observed or if the vibrator does not fit

the application, the housing surface may become very hot.

In Ex-zones there is a risk of ignition of an explosive atmosphere due to hot surfaces.

Observe all permissible operating conditions.

Carry out the specified maintenance work at the prede-

fined intervals.

Make sure that the vibrator is suitable for the application

and has been dimensioned correctly. Get advice from

application technicians of

Netter

Vibration.

For operating the NEA/NEG in potentially explosive at-

mosphere, it is mandatory to connect the PTCthermistor. This regulation does not apply if the vibrator

is not equipped with a PTC-thermistor.

WARNING

Risk of injury while handling heavy parts

Risk of serious injury due to weight during transport and installation of the

NEA/NEG.

Observe the weight information in Chapter Technical data, from page

11 on.

Only qualified personnel may transport and install the NEA/NEG.

Use suitable load handling devices and slinging equipment.

Wear suitable personal protective equipment.

Hot surface

Heavy parts

NEA/NEG from housing size 170 upwards are equipped with thermistors

type PTC 130 °C as standard. For smaller NEA/NEG available on request

as initial equipment.

Safety

10

WARNING

Falling parts

The NEA/NEG or parts of the construction can come loose due to vibration. Falling parts can lead to severe personal injuries.

Use only suitable fastening screws and safety washer to attach the

NEA/NEG.

For attachment

Netter

Vibration recommends using

Netter

fastening

kits NBS.

Check the fastening screws after one hour of operation and thereafter

regularly (generally monthly).

Retighten the fastening screws, if necessary. Use a torque wrench and

tighten the screws crosswise.

In critical installation situations suitable securing is mandatory.

WARNING

Risk of injury due to rotating unbalances

During operation of the NEA/NEG without unbalance covers there is risk of

injury due to rotating unbalances.

Operate the NEA/NEG only with mounted unbalance covers.

CAUTION

Risk of burns due to hot surfaces

NEA/NEG can strongly heat up during operation. Direct contact may cause

burns.

Do not touch the NEA/NEG or the cable near the cable gland during

operation or shortly after being switched off.

Only operate the vibrators within the permissible ambient temperature,

according to Ch. Technical data, page 11.

Falling parts

Rotating

Unbalances

Hot surfaces

Technical data

11

Nominal voltage, nominal

frequency

The main voltage and the main frequency must comply with the nominal voltage and nominal frequency indicated on the type plate.

Permissible Voltage deviation: +/- 5 %

Permissible frequency deviation: +/- 2 %

Possible power supply with:

fixed voltage and frequency or

frequency converter

The operation of NEG with frequency converters allows rotary speeds

> nominal frequency. If the NEG are operated with a frequency converter, the maximum centrifugal force must not be exceeded (according to the type plate). The compliance with the electromagnetic compatibility directive 2014/30/EU has to be ensured.

In the ATEX-zones 21 and 22 the frequency converter may regulate the frequency between 20 Hz and 50 Hz or 20 Hz and 60 Hz at a

constant torque load (linear volt-hertz-curve). Please observe the max.

frequency on the type plate. For operation with frequency converter in

ATEX-zones the PTC thermistor must be connected.

Rotary speed

ranges

2-pole: 3000 rpm 50 Hz / 3600 rpm 60 Hz.

4-pole: 1500 rpm 50 Hz / 1800 rpm 60 Hz.

6-pole: 1000 rpm 50 Hz / 1200 rpm 60 Hz.

8-pole: 750 rpm 50 Hz / 900 rpm 60 Hz.

Permissible

ambient temperatur*

-20 °C to 40 °C or

-20 °C to 55 °C

The maximum ambient temperature specified on the type plate must

not be exceeded.

These values are valid for operation with an ON-period of 100 %. For

the following operation modes special requirements apply:

cycled operation or

frequency-controlled operation or

synchronous operation.

These must be clarified with

Netter

Vibration on a case-by-case basis.

Thermal overload protection

From housing size 170 upwards with thermistor type PTC 130 °C as

standard.

For smaller vibrators available on request as initial equipment.

If the NEA/NEG is operated in environments with potentially explosive dust (zone 21/22), it is mandatory to connect the PTC-thermistor.

This regulation does not apply if the unit is not equipped with a PTCthermistor.

Sound level

Depending on type ≤ 70 dB(A)

The sound level is determined to a great extent by the surface upon

which the NEA/NEG is mounted (e.g. sheet metal). The sound level will

be amplified by non-silenced sheet metal.

Permissible

operating

conditions

3 Technical data

* Higher temperatures are only possible after consultation with and written approval from the application technicians of NetterVibration.

Technical data

12

1

type designation

2

rotary speed

3

nominal voltage

4

current

5

phases

6

serial number

7

year of manufacture / degree of protection

8

insulation class

9

power

10

nominal frequency

11

centrifugal force

12

duty cycle

13

ATEX certification

1

type designation

2

nominal voltage

3

current

4

phases / capacity

5

power factor

6

year of manufacture

7

serial number

8

max. ambient temperature

9

insulation class / degree of

protection

10

power output

11

power input

12

rotary speed / nominal frequency

13

centrifugal force

14

duty cycle

15

ATEX certification

Type

M4

M5

M6

M8

M10

M12

M16

M20

M22

M24

Fastening screws and

nuts, steel

Property class 8.8*

- - 10

25

50

87

210

411

559

711

Fastening screws for XSunbalances, steel

Property class 12.9**

- - -

42

83

146

360

710

970

1225

Fastening screws and

nuts, stainless steel

8.8

21.4

44

74

183 - -

-

Terminal plate nuts, steel

1.2

2.0

3.0

6.5

13.5

- - - - -

Type

M13x1

M15x1

M20x1

M25x1.5

M30x2

M45x1.5

Locking nuts

(Pos. 21) see page 29

30

50

100

170

340

500

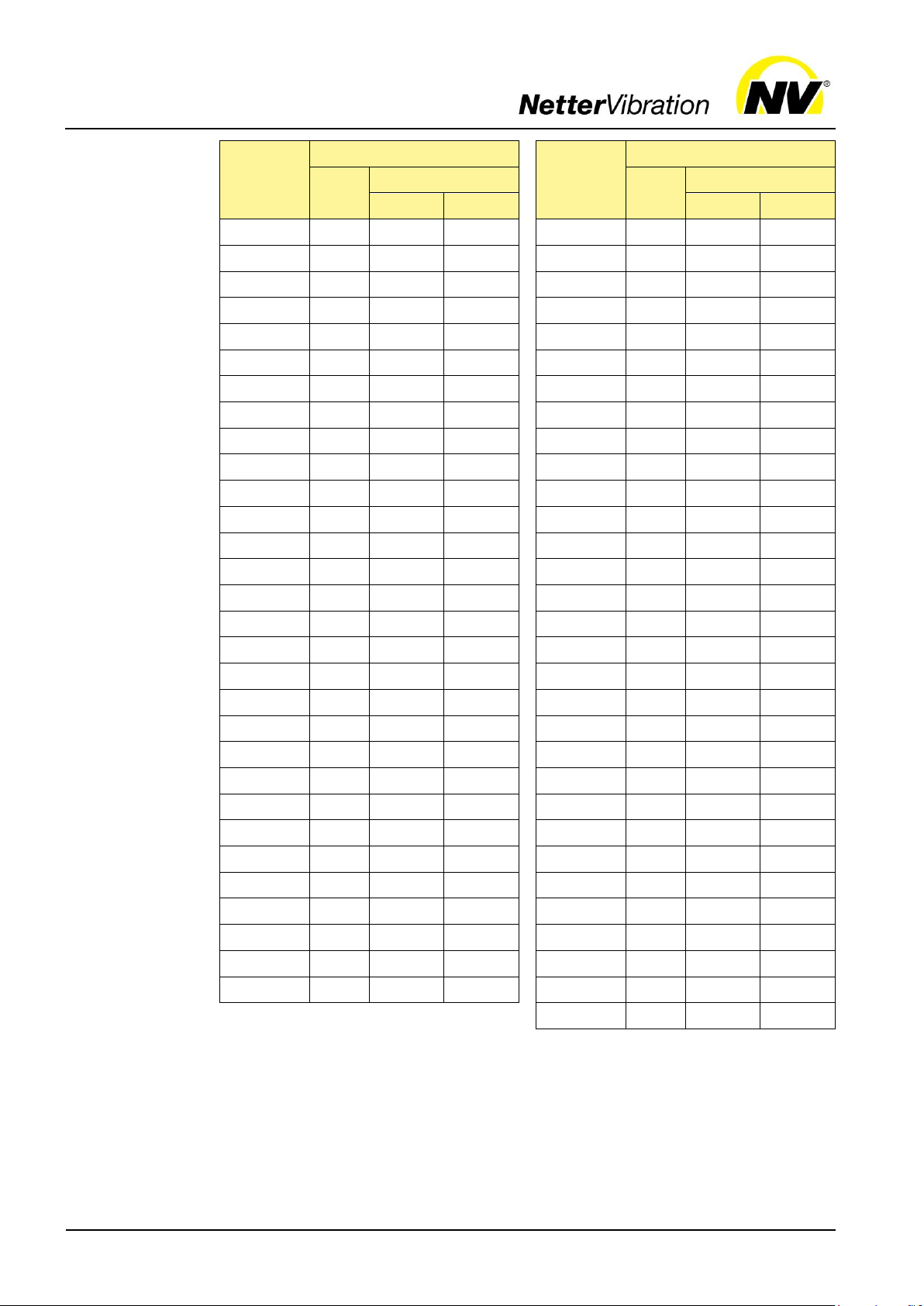

Type plate for

housing sizes

50 and 60

Type plate

from housing

size 100

Tightening

torques

The values can be found on the type plate. The type plate is located on the housing. For detailed technical data please refer to the brochure of the NEA/NEG.

Deviating customer-specific type plates (special designs) are possible.

Netter

Screws as supplied, without additional lubrication.

* coefficient of sliding friction 0.14 ** coefficient of sliding friction 0.15

Always use a torque wrench and tighten the screws crosswise.

Vibration recommends the following tightening torques [Nm]:

Design and function

13

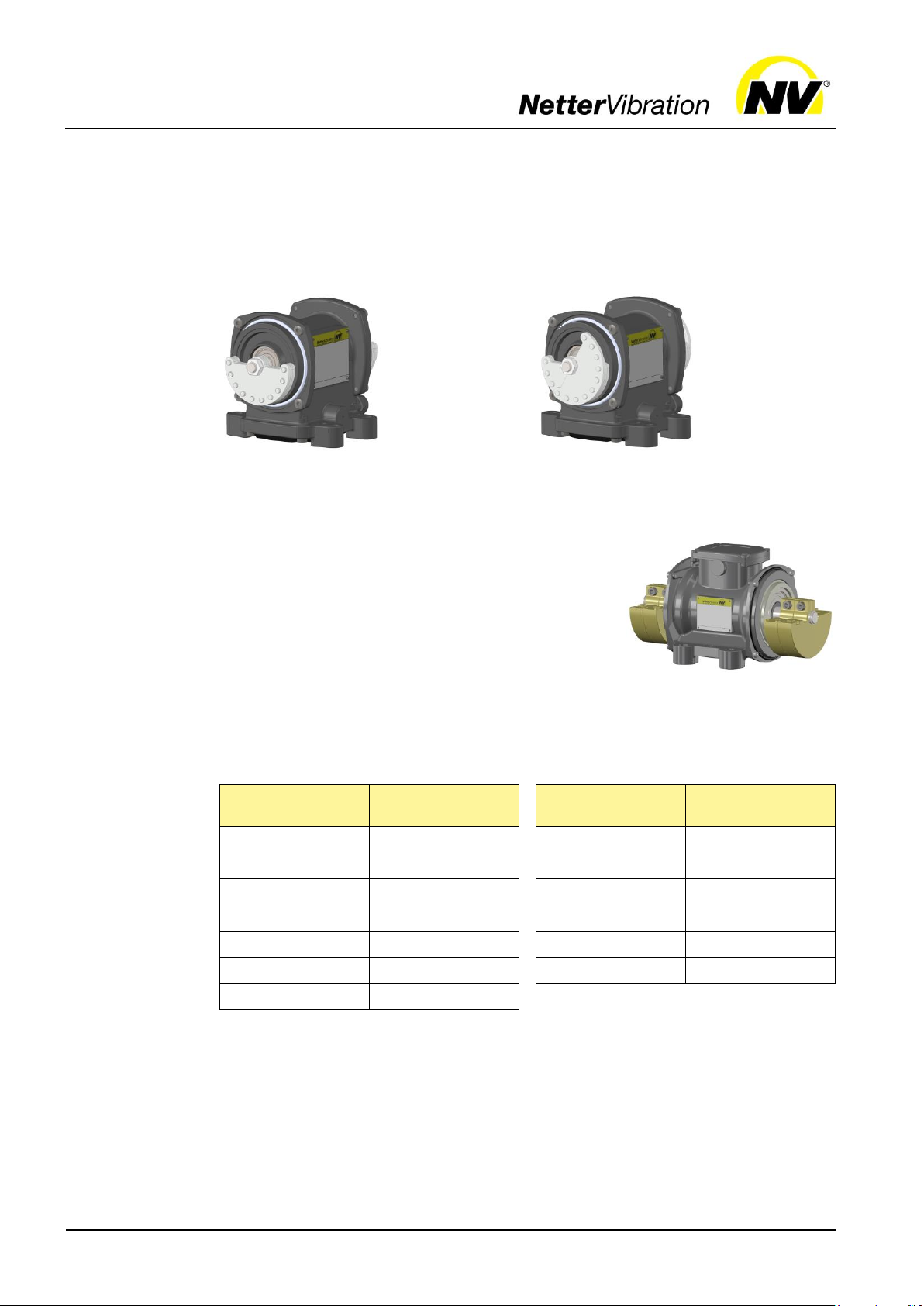

Example: NEG 501140

Example: NEG 50120

Nr.

Element

Function

1

Housing

Contains and protects the components of the

NEA/NEG.

2

Unbalance covers

Protect against grabbing into the unbalances.

3

Housing foot

Attach the NEA/NEG to the mounting surface.

4

Type plate

Shows model specific information and data.

5

Terminal box

Housing sizes 101 to 120:

terminal box integrated in housing

foot.

Contains the electrical connections.

6

Cable gland

(depending on type).

Connect the NEA/NEG.

Design

Function

4 Design and function

The Electric External Vibrators of the series NEA, NEG, NEG S and NES

are asynchronous motors with adjustable weights (unbalances) mounted

on their shaft ends.

The NEA/NEG generate circular vibrations, that means the vibrations act

in all directions of a plane.

The frequency can be controlled continuously with the help of frequency

converters.

The centrifugal force can be changed by adjustment of the unbalances.

Transport and storage

14

Observe the safety instructions in Ch. Safety, from page 6 on.

Please refer to the brochure for weights and dimensions.

Transportconditions

Packaging

Storage

5 Transport and storage

When transporting the NEA/NEG, ensure that the NEA/NEG is not subjected to strong impacts or vibrations that could damage the bearings.

Please observe the following notes:

Use only the transport eyelet/eyelets (1) for lifting the NEA/NEG. If the

vibrator is fitted with two transport eyes, both must be used for lifting.

The pulling direction must not exceed 45°.

Lifting tools are of the usual kind such as a pulley or a crane. When

moving loads, use suitable steel cables or hoisting slings which are sufficiently dimensioned for these weights.

Handle the NEA/NEG very carefully during transport.

The NEA/NEG are packed ready for installation.

The packaging protects the NEA/NEG from transport damage. The packaging material has been selected from an environmentally safe and technically disposable point of view and is therefore recyclable.

The return of packaging to the material cycle conserves raw materials and

reduces the amount of waste.

Store the NEA/NEG in a dry and clean environment.

The permissible storage temperature is between -15 °C and +60 °C.

The permissible relative humidity is max. 60 %.

The storage time is max. 2 years.

If the vibrator is operated in areas with potentially explosive dust

(zone 21 or 22) a revision at

Netter

age time of more than one year.

Do not store the NEA/NEG outdoors. The electrical components are

not protected against corrosion.

Vibration is mandatory after a stor-

Installation

15

6 Installation

Observe the safety instructions in Ch. Safety, from page 6 on.

Please refer to the brochure for weights and dimensions.

3. Use an additional safety device for critical

installation situations, e.g. steel cable NSE.

Use the wire cable clamps to set the safety

cable to the shortest possible cable length.

The safety cable must always be tensioned.

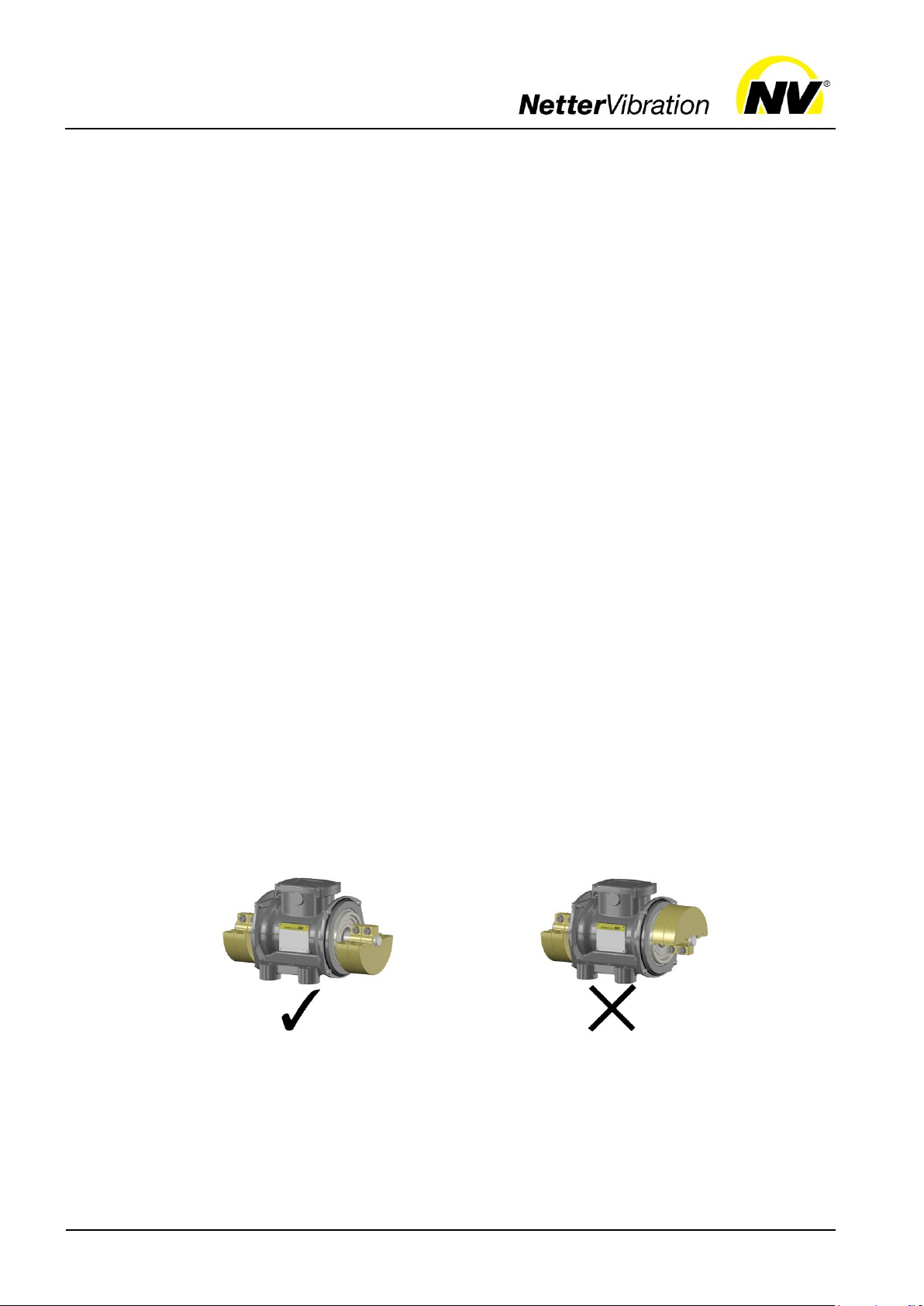

Fastening

the NEA/NEG

Important: For NEA/NEG with housing size 101 to 120 the terminal box is

integrated in the housing foot. These vibrators must be electrically connected before fastening.

The NEA/NEG can be operated in any position.

1. Notice: The feet of the NEA/NEG must lie completely on the surface

so that there is no tension in the housing when tightening the fastening screw/screws, which could cause mechanical damage. The

mounting surface has to be flat (±0.1 mm flatness) and clean with no

paint residues or burn-ins.

2. The vibrators can be fastened with fastening screws of quality 8.8

(DIN 931 or 933). These must be secured with appropriate locking devices and checked and retightened at regular intervals (usually monthly). For safe fastening

Netter

Vibration recommends the use of

Netter

NBS fastening kits consisting of a screw, a special lock washer and, if

applicable, a nut.

Fasten the NEA/NEG with the fastening screws on the mounting surface. Use a torque wrench and tighten the screws crosswise. Observe

the recommended values for screw sizes and tightening torques, see

chap. Technical data, from page 11. Higher tightening torques may

cause fracture of screws or tearing of threads.

Warning: Unsuitable screw connections may cause loosening of the

NEA/NEG by vibration. This can cause damage to persons and material.

Installation

16

A suitable overload protection (1) must be

pre-connected to each vibrator. The motor

protection switches must be interlocked with

each other in pairs, so that in the event of a

motor failure, the power supply from both

motors is interrupted at the same time in order not to cause uncontrolled vibrations

which can damage the system.

In zone 21/22 the motor protection

switches must be approved for applications

in potentially explosive areas.

In areas with potentially explosive

dust (zone 21/22), an external

grounding must also be made via the

earth connection on the housing foot.

Electrical

connection

The following requirements and conditions must be met to connect the

NEA/NEG electrically:

The permissible operating conditions must be met. Please refer to

chap. Technical data, page 11 for operating conditions.

If the vibrator is operated in areas with potentially explosive dust

(zone 21/22), it is compulsory to connect the PTC-thermistor. This regulation does not apply for NEA/NEG without a PTC-thermistor.

Only suitable, flexible supply cables must be used for connecting the

NEA/NEG. The conductors in the supply cable for the connection of the

NEA/NEG to the mains must be temperature-resistant and have a sufficiently large cross-section, which is adapted to the cable length used.

The temperature resistance of the cables depends on the maximum

surface temperature (temperature class T) stated on the type plate.

When selecting the connection cables, consider that the cables are

mechanically stressed by vibration. Recommended cable types for

mains operation at 400 V, in potentially non-explosive atmosphere:

rubber hose line H07 RN-F or oil flex cable 110 CY.

For other voltages or other ambient conditions, the cables must be

adapted to the respective conditions and designed accordingly.

All electrical cables must be carefully laid and must be protected from

high temperatures, lubricants and sharp edges. Care must be taken to

ensure that the cables are not chafed through by vibrating parts. The

correct condition of the electrical cables with their plugs must be

checked at regular intervals (usually every six months). Detected errors are to be eliminated immediately.

The cable fastening must be provided in close vicinity of the cable

entrance.

Installation

17

Tighten terminal plate nuts with pre-

scribed torque, see chap. Technical data, from page 11. Remember to put the

safety washer between the ring and the

nut and the vibration-damping insert

back.

The wire ends must be fitted with suita-

ble insulated cable lugs, in order to prevent the strands from splaying.

1

Earthing terminal for protective

conductor

(green-yellow)

2

PTC-Thermistor connection

(depending on the NEG-type)

Connection

examples NEG

The electrical parameters U, I, P on the type plate must be ob-

served.

For operating the NEA/NEG in areas with potentially explosive dust

(zone 21/22) the mechanical protection of the housing must be guaranteed (degree of protection IP66, housing size 50 and 60: IP65). After

having disassembled the terminal box cover or weight covers, the condition and correct positioning of the seals has to be checked.

Open the terminal box to connect the NEG according to the type plate as

follows:

Connect the NEG according to the type plate and the following circuit diagrams.

The green-yellow protective conductor must only be connected to the

earthing terminal.

Installation

18

Series NEG / 3-phase current

Smaller voltage

Higher voltage

1: Earthing terminal for protective conductor

2: PTC-Thermistor connection (depending

on the type)

1: Earthing terminal for protective conductor

2: PTC-Thermistor connection (depending

on the type)

1

capacitor box

L1

outer conductor (brown)

N

neutral conductor (blue)

PE

protective conductor

(green-yellow)

Cable with capacitor box

Capacitor in cable

Connection

examples NEA

Connection diagram

Connect the NEA according to the type plate:

Start-up and operation

19

Observe the safety instructions in Ch. Safety, from page 6 on.

Permissible

operating

conditions

Regulations

Measures

7 Start-up and operation

Please refer to Ch. Technical data, page 11 for permissible operating conditions.

When commissioning the NEA/NEG, the rules and regulations of the

local associations for electrical engineering (e.g. VDE) and the valid

accident prevention regulations must be observed.

The NEA/NEG must always be switched on and off at the main switch.

When operating the NEA/NEG with a frequency converter, compliance

with the EMC directive must be ensured.

If the speed is controlled with a frequency converter, the maximum

centrifugal force (according to the type plate) must not be exceeded.

NEA/NEG must be adapted to your application by adjusting the unbalances. You can directly influence the vibration amplitude, centrifugal

force and current consumption.

The NEA/NEG must not be operated without the covers for the unbal-

ances. The rotating unbalances cause a risk of injury.

On initial start-up, the current consumption must be measured individ-

ually in all three phases and must correspond to the specifications on

the type plate.

The terminal box cover must never be opened in the presence of volt-

age.

Special regulations for operation in an potentially explosive at-

mosphere:

In ATEX-zones 21 and 22, the frequency converter may control the

frequency between 20 Hz and 50 Hz or 20 Hz and 60 Hz at constant

torque (linear Volt-Hertz curve). Observe maximum frequency on the

type plate.

For operation with frequency converter in ATEX-zones the PTC ther-

mistor must be connected.

The terminal box cover must never be opened in a potentially explosive

atmosphere.

NEA/NEG may only be operated in atmospheres that do not damage

the material of the vibrators.

Carry out the following measures before start-up:

1. Check that the NEA/NEG have been mounted correctly and are in perfect condition.

2. Check that the NEA/NEG have been properly connected and earthed.

Start-up and operation

20

Power supply

Supply line

connection

Adjustment of

unbalances

3. Check that the cables are undamaged and laid according to the

known regulations and standards.

4. Check that all permissible operating conditions have been observed.

5. Check that all protective measures on the system have been observed.

6. Eliminate possible errors before start-up.

7. Screw connections must be checked and, if necessary, retightened

after 1 h operating time (after initial start-up) and thereafter regularly

(generally monthly). Observe the recommended values for screw sizes and tightening torques, see chap. Technical data, from page 11

Standard network forms are TN and TT networks with an earthed star

point, as in Germany.

For overseas countries, also for countries within the EU, the mains voltage, the network configuration and the directives applicable there must

also be observed. In the case of deviations, the country, the standards, the

environmental conditions, as well as possible special features in the order,

must be agreed on in writing. If the NEA/NEG are operated and/or powered by another network configuration unknown to us, the guarantee expires completely and immediately.

The supply line must be protected according to the cross-section and the

nominal power of the NEA/NEG. The short circuit strength of this fuse

should be 25 kA.

Netter

Vibration recommends a three-phase tripping (e. g. Schneider Elec-

tric GV2 L, Tesys Model U oder Compact NS).

For all NEA/NEG there is the possibility of unbalance adjustment to direct-

ly influence vibration amplitude, centrifugal force and current consumption.

Unless otherwise specified by you, the NEA/NEG were delivered with the

standard setting (100 %). If specifications have been made by the customer, there are stickers with the current setting on the unbalance covers.

Notice: The unbalances may only be set mirror-symmetrically!

Start-up and operation

21

Type:

NEA

Unbalance

Type

Quantity

50 Hz

60 Hz

504

XL 8 8

5020

XL 8 8

5050

XL

18

18

5060

XLs 4 4

50120

XLs 6 6

50200

XLs

10

8

50300

XLs 8 6

50550

XLs

10

6

50770

XLs 8 6

2530

XLs 6 6

2570

XLs

16

10

25210

XS 4 4

25420

XS 4 4

25540

XS 4 4

25700

XS 4 4

Type:

NEG

Unbalance

Type

Quantity

50 Hz

60 Hz

5020

XL 8 8

5050

XL

18

18

5060

XLs 4 4

50120

XLs 6 6

50200

XLs

10

8

50300

XLs 8 6

50550

XLs

10

6

50770

XLs 8 6

501140

XLs

12

8

501540

XLs

12

8

501800

XLs

14

10

502020

XLs

16

10

502270

XLs

18

12

503400

XLs

12

8

503820

XLs

14

10

506220

XS 4 4

508830

XS 4 4

Number of

unbalances

Procedure:

1. Switch off the NEA/NEG at the main switch, secure against unintentional starting and ensure that there is no voltage.

2. Loosen both unbalance covers.

3. Loosen the locking nuts or locking screws.

4. Bring the unbalances to the desired setting according to the following

descriptions for the various unbalance discs. Note the mirrorsymmetrical setting.

5. Retighten the locking nuts or locking screws. Observe the recommended tightening torques, see chap. Technical data, from page 11

6. Fasten both covers for the unbalances.

The tables below show the type of unbalance and the number of unbalances per vibrator at the default setting of 100%:

Start-up and operation

22

Type:

NEG

Unbalance

Type

Quantity

50 Hz

60 Hz

2530

XLs 6 6

2570

XLs

16

10

25210

XS 4 4

25420

XS 4 4

25540

XS 4 4

25700

XS 4 4

25930

XS 4 4

251410

XS 4 4

251800

XS 4 4

252060

XS 4 4

252370

XS 4 4

253050

XS 4 4

253720

XS 4 4

254310

XS 4 4

254900

XS 4 4

256460

XS 4 4

258040

XS 4 4

258260

XS 4 4

2511210

XS 4 4

2513850

XS 4 4

1630

XLs 8 8

1690

XS 4 4

16190

XS 4 4

16310

XS 4 4

16410

XS 4 4

16500

XS 4 4

16810

XS 4 4

161130

XS 4 4

161420

XS 4 4

161610

XS 4 4

Type:

NEG

Unbalances

Type

Quantity

50 Hz

60 Hz

162110

XS 4 4

162550

XS 4 4

163030

XS 4 4

163820

XS 4 4

164700

XS 4 4

165190

XS 4 4

166270

XS 4 4

166670

XS 4 4

167890

XS 4 4

168500

XS 4 4

169510

XS 4 4

1612060

XS 4 4

1613890

XS 4 4

1617000

XS 4 4

12100

XS 4 4

12180

XS 4 4

12230

XS 4 4

12460

XS 4 4

12640

XS 4 4

12900

XS 4 4

121430

XS 4 4

122150

XS 4 4

122640

XS 4 4

122920

XS 4 4

123530

XS 4 4

124440

XS 4 4

127640

XS 4 4

128520

XS 4 4

1211070

XS 4 4

1213160

XS 4 4

1217670

XS 4 4

Start-up and operation

23

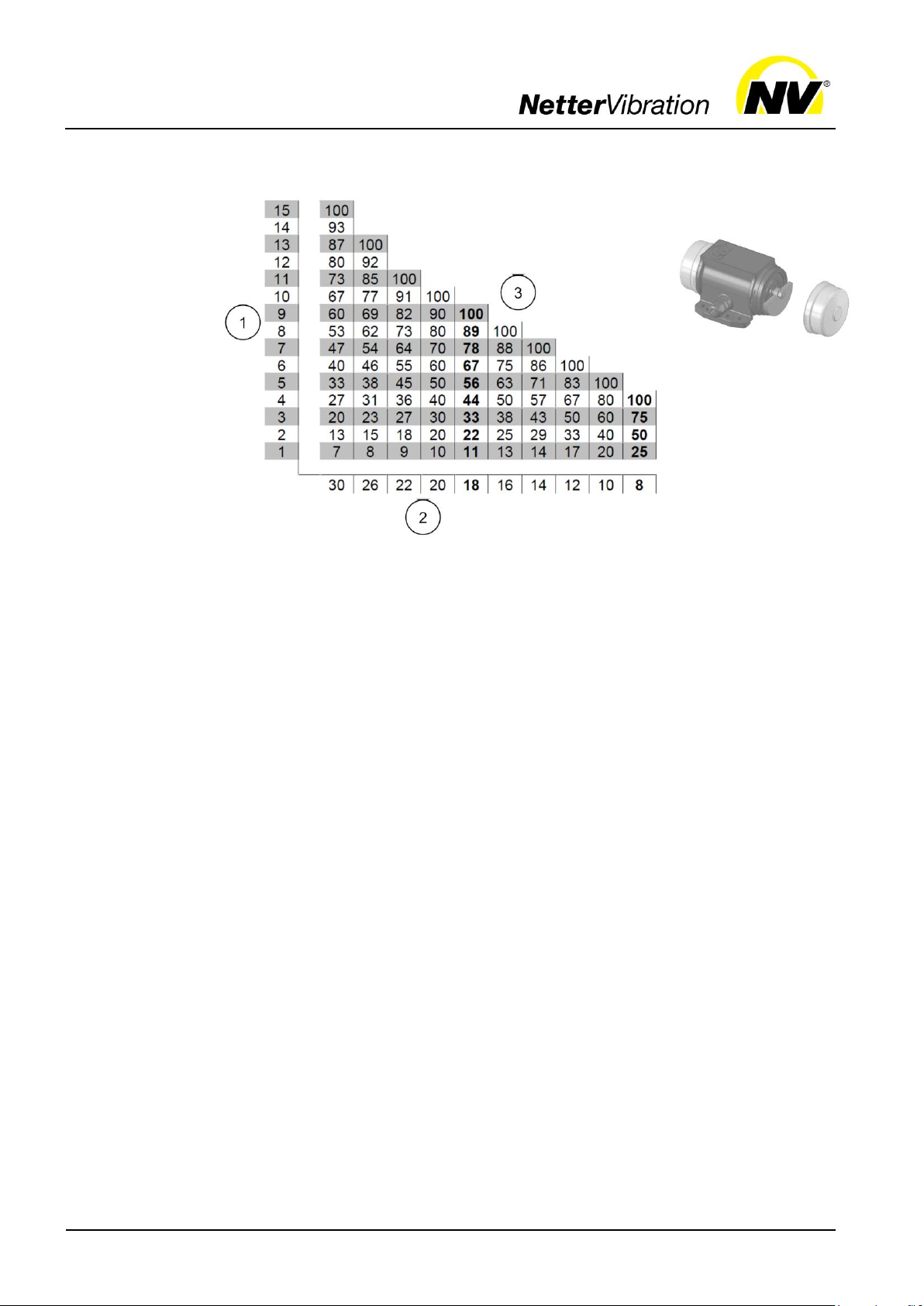

1: Number of unbalance discs per side

2: Default number of unbalance discs per vibrator

3: Centrifugal force in %

Unbalance

discs

type XL

The centrifugal force is adjustable with the unbalance discs (lamella) of

type XL in the following steps:

There are 2 possibilities to adjust the unbalances:

1. The unbalance adjustment (fine adjustment) is carried out by removing one unbalance disc on each side. All centrifugal values in % can

be adjusted as specified in the table.

The removed unbalance discs must be replaced by compensation

washers of identical thickness and identical inner diameter. These are

available from

Netter

Vibration.

2. The unbalance adjustment (coarse adjustment) is performed by turning one unbalance disc on each side by 180° on the shaft.

Twice the number of unbalance discs turned by 180° becomes ineffective.

Start-up and operation

24

Settings

Unbalance

per side

Type

50

Hz

60

Hz

fixed

adjust-

able

1

1

1

NEG/NEA 5060

X X

2

2

NEG/NEA 50200

NEG 501140

NEG 501540

NEG 503400

X NEG 1630

X X

NEG/NEA 50300

NEG/NEA 50770

X

3

3

NEG 501140

NEG 501540

NEG 503400

X

NEG 502270

X

4

4

NEG/NEA 2570

NEG 502020

X

2 2

1

NEG/NEA 50120

NEG/NEA 2530

X

X 2 2

1

NEG/NEA 50300

NEG/NEA 50770

X 2 2

1

NEG/NEA 50550

X

3

3

2

NEG/NEA 50200

NEG/NEA 50550

X

3

3

2

NEG/NEA 2570

NEG 501800

NEG 502020

NEG 503820

X

4

4

3

NEG 501800

NEG 503820

X

5 5

4

NEG 502270

X

Unbalances

type XLs

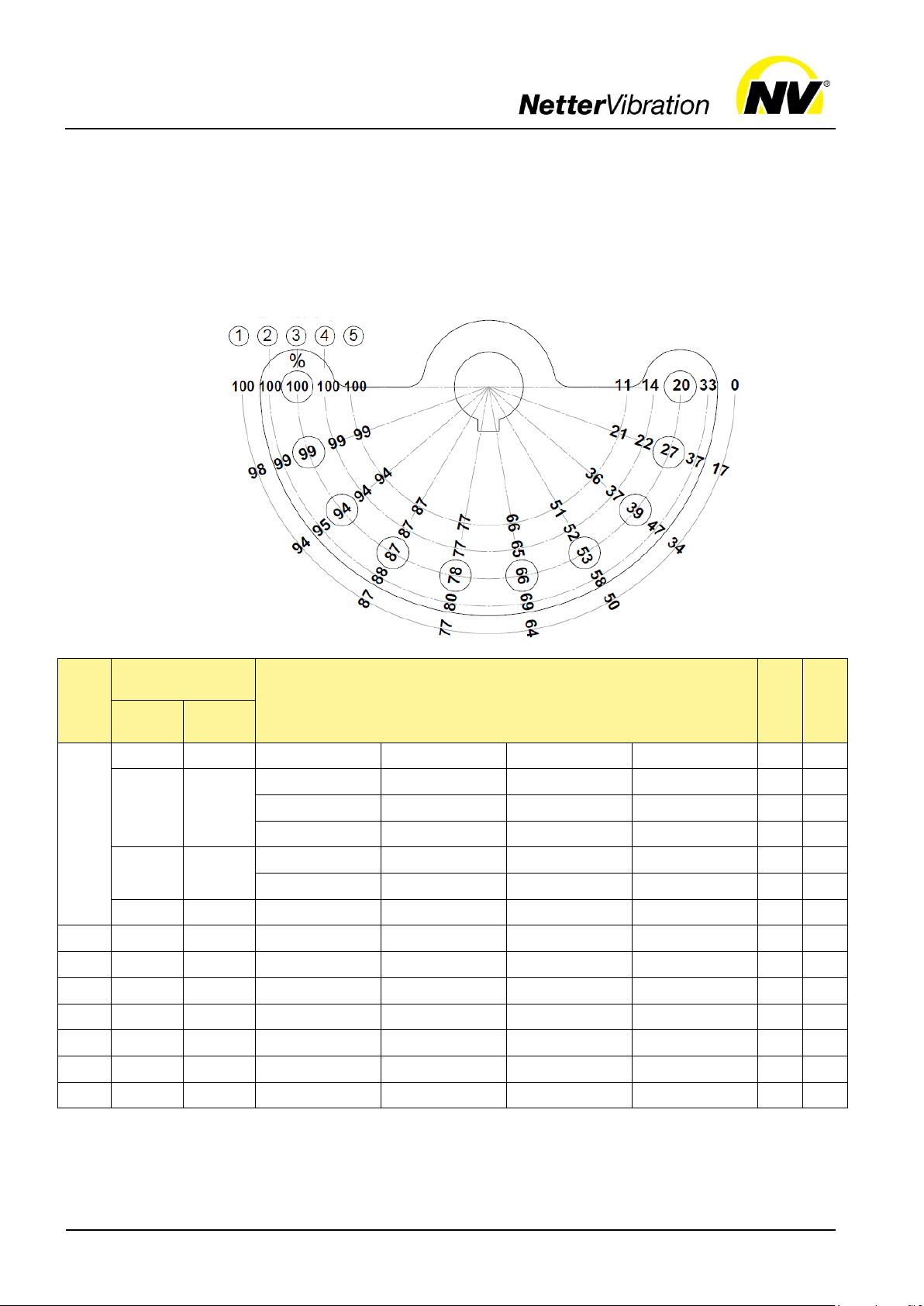

The centrifugal force is adjustable with the unbalance discs (lamella) type

XLs. Adjustment of the unbalances is carried out according to a scale disc

or the supplementary sheet in the terminal box of the NEA/NEG.

By rotating the outer, adjustable unbalance disc(s) to another position, the

percentage of the centrifugal force changes as shown in the illustration

below. The grid position is defined by position pins.

Settings:

Start-up and operation

25

centrifugal force 100 %

centrifugal force 88 %

The unbalance setting of the unbalance discs

of the type XS is carried out on the scale on

the fixed unbalance.

The centrifugal force can be steplessly adjusted by turning the outer unbalance discs and

adjusting them at the partial strokes. After adjusting the unbalances, the nuts and screws

must be tightened with the specified torque.

Observe the recommended values for screw

sizes and tightening torques in chap. Technical

data, from page 11.

Adjustment

Centrifugal force in

%

0°

100

15°

98.5

30°

97

45°

92

60°

87

75°

78.5

90°

70

Adjustment

Centrifugal force in

%

105°

60

120°

50

135°

37.5

150°

25

165°

12.5

180°

0

Unbalances

type XS

Example:

NEG 50120 / 50 Hz has a total of 6 unbalance discs (3 discs per side: 2

fixed, 1 adjustable).

If a centrifugal force of 88% is desired, the adjustable unbalance discs are

rotated anticlockwise on both sides into the fourth grid position.

The centrifugal force can be adjusted according to the following table:

Maintenance and servicing

26

Observe the safety instructions in Ch. Safety, from page 6 on.

Interval

Action

If required (depending on operating

conditions)

Clean the NEA/NEG regularly with a wet cloth to remove dust

deposits.

After one hour operation after initial

start-up

Check screw connections and retighten if necessary.

Every 1000 operating hours

NEA/NEG from housing size 130 up, with speeds > 3000 rpm:

lubricate bearing with grease of the type KLUEBER

Isoflex NBU 15.

Every 5000 operating hours

NEA/NEG from housing size 130 up, with speeds < 3000 rpm:

replace the grease of the roller bearings completely, with grease

of the type KLUEBER Staburags NBU 8.

Technical data

Expertise and

regulations

Maintenance

plan

8 Maintenance and servicing

Information regarding tightening torques for screws and nuts can be found

in Ch. Technical data, page 11.

Maintenance and servicing of the vibrators may only be performed by regularly trained, authorised and qualified personnel. Work on the electrical

system may only be carried out by a qualified electrician.

The qualified personnel has to work exclusively with tools suitable for the

application.

In the case of unauthorised intervention in the NEA/NEG there is no longer

any warranty claim.

Before all maintenance and servicing work the NEA/NEG must be safely

disconnected from the electrical mains. The procedure is as follows:

1. Switch off NEA/NEG.

2. Secure against unintentional switching on.

3. Determine that NEA/NEG are voltage free.

4. Earth and short-circuit.

5. Cover and fence off neighbouring live parts.

Interventions in the NEA/NEG, such as lubricating/changing of bearings or opening the terminal box, must not be performed in potentially explosive atmospheres.

When operating in a potentially explosive dust atmosphere, the operator must regularly check the condition of the bearings and the duration of

operation of the vibrators. Damaged bearings or bearings whose service

life has been reached, must be replaced immediately. Alternatively, the

vibrators can also be sent to

Netter

Vibration for replacement of the bear-

ings.

Maintenance of the NEA/NEG must be carried out as follows:

Maintenance and servicing

27

Interval

Action

Monthly

Check screw connections and retighten if necessary.

Check ball or roller bearings and relubricate if necessary, see

section "lubrication".

Damaged bearings or bearings whose service life has been

reached, must be replaced immediately.

Check cable supply line.

Every 6 month

Check proper condition of connecting cables and plugs.

Every 2 years

Replace O-rings and plastic seals .

At least every 4

years

Check proper condition of electrical systems and stationary electrical equipment.

Type

NEA

Lubrication

Bearing

life [h]

50 Hz

Bearing

life [h]

60 Hz

504

PL*

> 100,000

> 100,000

5020

PL*

92,118

22,745

5050

PL*

8,087

2,236

5060

PL*

> 100,000

5,044

50120

PL*

18,075

18,075

50200

PL*

3,363

2,572

50300

PL*

4,003

3,588

50550

PL*

4,148

4,219

Type NEA

Lubrication

Bearing

life [h]

50 Hz

Bearing

life [h]

60 Hz

50770

PL*

7,509

6,257

2530

PL*

> 100,000

> 100,000

2570

PL*

> 100,000

> 100,000

25210

PL*

23,406

19,200

25420

PL*

15,135

12,635

25540

PL*

6,266

4,224

25700

PL*

19,477

16,231

Notes on

lubrication

Lubrication /

bearing life

NEA

Other maintenance and repair work are to be carried out exclusively by

Netter

Vibration.

NEA/NEG up to the housing size 130 have ball bearings. These are lubricated for their service life (permanent lubrication).

NEA/NEG from the housing size 130 up have roller bearings. These are

lubricated with the grease of the type KLUEBER Staburags NBU 8 EP. At

speeds up to 3000 rpm the bearings are lubricated for a period of at least

5000 operating hours. After this time the grease of the bearings has to be

replaced completely.

The lubrication intervals must be considerably shortened under more difficult operating conditions.

The housing sizes can be found in the brochure of the NEA/NEG.

Type of lubrication of the bearings and bearing life of the NEA:

*PL = permanent lubrication

Maintenance and servicing

28

Type

NEG

Lubrication/

grease

quantity [g]

Bearing

life [h]

50 Hz

Bearing

life [h]

60 Hz

5020

PL*

92,118

22,745

5050

PL*

8,087

2,236

5060

PL*

> 100,000

5,044

50120

PL*

18,075

18,075

50200

PL*

3,363

2,572

50300

PL*

4,003

3,588

50550

PL*

4,148

4,219

50770

PL*

7,509

50980 9 5,062

4,833

501140 9 3,029

4,219

501540

16

4,038

4,219

501800

16

2,416

1,833

502020

30

7,070

8,372

502270

30

4,775

4,558

503400

40

8,672

10,267

503820

40

5,856

5,591

506220

120

5,743

4,636

508830

150

9,029

2,790

2530

PL*

> 100,000

> 100,000

2570

PL*

> 100,000

> 100,000

25210

PL*

23,406

19,200

25420

PL*

15,135

12,635

25540

PL*

6,266

4,224

25700

PL*

19,477

16,231

25930 9 12,103

10,190

251410

16

10,870

8,330

251800

30

22,231

20,009

252060

30

14,300

12,300

252370

35

16,159

13,032

253050

35

7,100

5,900

253720

40

12,228

11,086

Type

NEG

Lubrication/

grease

quantity [g]

Bearing

life [h]

50 Hz

Bearing

life [h]

60 Hz

254310

40

8,200

7,300

254900

80

9,930

8,648

256460

120

10,478

8,451

258040

150

9,029

7,575

258260

180

11,460

7,881

2511210

260

10,576

8,718

2513850

300

9,000

6,200

1630

PL*

> 100,000

> 100,000

1690

PL*

> 100,000

> 100,000

16190

PL*

> 100,000

72,171

16310

PL*

> 100,000

> 100,000

16410

9

> 100,000

> 100,000

16500

9

> 100,000

39,516

16810

PL*

> 100,000

60,144

161130

PL*

54,020

42,632

161420

PL*

25,100

20,000

161610

30

29,165

29,270

162110

30

11,800

10,400

162550

32

17,701

12,292

163030

32

41,500

30,500

163820

60

13,073

10,842

164700

80

18,364

15,425

165190

100

19,206

15,157

166270

120

15,786

13,144

166670

120

13,767

14,000

167890

150

14,431

12,276

168500

150

11,266

9,379

169510

180

10,728

10,972

1612060

260

11,000

11,800

1613890

300

13,327

11,510

1617000

360

11,273

10,404

Lubrication /

bearing life

NEG

Type of lubrication or grease quantity of the bearings and bearing life of

the NEG:

*PL = permanent lubrication

Maintenance and servicing

29

Type

NEG

Lubrication/

grease

quantity [g]

Bearing

life [h]

50 Hz

Bearing

life [h]

60 Hz

12100

PL*

> 100,000

> 100,000

12180

PL*

> 100,000

> 100,000

12230

9

> 100,000

> 100,000

12460

PL*

> 100,000

> 100,000

12640

PL*

> 100,000

> 100,000

12900

30

> 100,000

65,414

121430

32

> 100,000

39,702

122150

60

> 100,000

29,320

122640

80

> 100,000

41,200

Type

NEG

Lubrication/

grease

quantity [g]

Bearing

life [h]

50 Hz

Bearing

life [h]

60 Hz

122920

100

> 100,000

43,076

123530

120

> 100,000

35,405

124440

150

> 100,000

32,368

127640

180

29,652

10,982

128520

260

52,762

18,667

1211070

300

37,822

15,233

1213160

360

35,257

12,684

1217670

400

22,520

9,347

Lubrication

or replacement of

bearings

*PL = permanent lubrication

The item numbers refer to the spare parts list.

Maintenance and servicing

30

3. Disassemble unbalances type XS:

After removing the circlip (20) and loosening the clamping screws (16), the unbalances can be removed.

Disassemble unbalances type XL and

type XLs:

Screw a long screw with the same thread

into a tapped hole for the fastening screws

(24) of the unbalance cover. Put a lever between the unbalance discs and this long

screw. After loosening the locking nut (21),

the unbalances can be removed from the

shaft.

1. Switch off NEA/NEG, secure against switching on again and ensure

that it is volt-free.

2. Loosen screw (24) and remove unbalance covers (23).

4. Remove bearing (10):

up to housing size 120: Remove circlip (40).

Starting from housing size 130: loosen screws (4) and remove

flange (3). Remove circlip (40) from flange (3).

5. Replace both bearings (10) or remove old grease (e. g. with benzine)

and smear the specified amount (see table) of new grease (according

to the maintenance plan) evenly.

6. Assembly is carried out in the reverse order.

7. Tighten locking nuts (21) and screws (4, 16) to the specified tightening

torque.

Troubleshooting

31

Observe the safety instructions in Ch. Safety, from page 6 on.

Fault

Possible cause

Troubleshooting

Action

Vibrator does not start or

runs at too low speed

Phase interruption

Check fuse and connection

cable

Replace fuse and/or connection cable

Mains voltage too low

Check mains voltage and

cable cross-section

Correct mains voltage, replace cable

Vibrator speed drops under

load

Wiring wrong

Check circuit diagram

Inadequate contact of a

connection point

Check connections in the

terminal box

Tighten terminal plate nuts

Phase interruption

Check fuse and connection

cable

Replace fuse or connection

cable

Incorrectly dimensioned

connection cable

Check cable cross section

Replace cable

Overload

Check setting of unbalance

Reduce unbalances

Mains voltage too low

Check mains voltage and

cable cross-section

Correct mains voltage, replace cable

Expertise and

regulations

Troubleshooting

9 Troubleshooting

Troubleshooting of the vibrators may only be performed by regularly

trained, authorised and qualified personnel. Work on the electrical system

may only be carried out by a qualified electrician.

The qualified personnel has to work exclusively with tools suitable for the

application.

In the case of unauthorised intervention in the NEA/NEG there is no longer

any warranty claim.

Before any troubleshooting the NEA/NEG must be safely disconnected

from the electrical mains. The procedure is as follows:

1. Switch off NEA/NEG.

2. Secure against unintentional switching on.

3. Determine that NEA/NEG are voltage free.

4. Earth and short-circuit.

5. Cover and fence off neighbouring live parts.

Interventions in the NEA/NEG must not be performed in potentially ex-

plosive atmospheres.

Troubleshooting

32

Fault

Possible cause

Troubleshooting

Action

Excessive heating

of the vibrator

Wiring wrong / overload

Check circuit diagram

Mains voltage too low

Check mains voltage and

cable cross-section

Correct mains voltage, replace cable

Too much grease in bearings

Fill in correct ammount of grease

No grease or not enough

grease in bearings

Fill in correct ammount of grease

Foreign body in bearings

Clean bearings, replace if necessary

Vibrator hums

Phase interruption

Check fuse, mains voltage

and connection cable

Correct mains voltage, replace fuse or cable

Short-circuit between turns in

the stator winding

Replace vibrator

Circuit braker fails when

switched on

Phase interruption

Check fuse and connection

cable

Replace fuse or connection

cable

Overload

Check unbalance settings

Reduce unbalance

Short circuit in winding

Replace vibrator

High current consumption

Natural resonance range of

vibration system

Measure current consumption

Stiffen device

Bounce impacts

Measure current consump-

tion

Reduce power of vibrator

Loose fastening

Tighten screws

Spare parts and accessories

33

Ordering of

spare parts

10 Spare parts and accessories

Please provide the following details when ordering spare parts:

type designation according to the type plate

serial number according to the type plate

description and position number of spare part

required amount

Example NEG 50300

Example NEG 501140

Spare parts and accessories

34

Component

Description

Shim washers

Compensation for removed unbalance discs.

CC-unbalances

Depending on the direction of rotation, two different

unbalances can be achieved.

Fastening kit NBS

Recommended for secure and permanent fastening of

the NEA/NEG.

Frequency converters

For frequency-controlled operation.

Brake accessories

Enable rapid deceleration of vibrators.

PTC thermistor

PTC 120°C thermistor for safe operation of the vibrators.

Special versions

NEA/NEG are also available in special versions, e.g. for

special voltages or the use in potentially explosive atmospheres. Information on request.

Accessories

The following accessories are available for NEA/NEG:

Further electrotechnical accessories on request.

Disposal

35

11 Disposal

All parts of the NEA/NEG must be properly disposed of according to the material specifications. The valid disposal prices of

the NEA/NEG are available on request.

Material

Part

Stainless steel

Unbalance covers

Steel

Rotor, unbalances, flange, bearings, screws, washers, nuts

Aluminium

Housing, type plate

Plastic

Seals, terminal box block

Copper with resin

Winding

Material

Part

NEG housing types

I, II and III

NEG housing type

IV

NES and NEG S

Stainless steel

Unbalance covers

Housing, unbalance

covers, terminal box

block and cover

Steel

Housing size 140

and 160, rotor, unbalances, flange,

bearings, screws,

washers, nuts

Housing, rotor, unbalances, flange,

bearings, screws,

washers, nuts

Rotor, unbalances,

flange, bearings,

screws, washers,

nuts

Aluminium

Housing, type plate,

terminal box cover

Housing size 150

and 170 up to 210,

unbalance covers,

type plate, terminal

box cover

Type plate

Plastic

Seals, terminal box

block

Seals, terminal box

block

Seals

Copper with resin

Winding

Winding

Winding

Prices

Materialspecifications

All parts of the NEA/NEG can be recycled.

Type: NEA

Type: NEG and stainless steel versions NES and NEG S

Loading...

Loading...