Page 1

Operating instructions for

Netter pneumatic impactors

of the series PKL

These operating instructions apply to: PKL 190

PKL 450

PKL 740

Sept. 2017

No. 1468E

Page 1/26

PKL 2100

PKL 5000

PKL 10000

Page 2

2

Contents

1 General information 3

2 Safety 5

3 Technical data 7

4 Design and function 10

5 Transport and storage 11

6 Installation 12

7 Start-up and operation 21

8 Maintenance and serv ici ng 22

9 Troubleshooting 23

Scope of

delivery

Designation

Version

number

10 Spare parts and accessories 24

11 Disposal 25

12 Annex 26

Please refer to the delivery note for the scope of delivery.

Check the packaging for possible transport damage. In the event of

damage to the packaging, check the contents for completeness and

possible damage. Infor m the carr i er in the cas e of damag e.

The pneumatic impactors of the series PKL are hereafter referred to as

„PKL“.

document no. 1468E

version no. 1

date of issue Sept. 2017

Page 3

General information

3

1 General information

Use and

storage

Target group

Copyright

Limitation of

liability

Before installing the PKL read these operating instructions carefully. It is

the basis for any action when dealing with the PKL, and may be used for

training purposes. The operating instructions should be subsequently

stored at the operation site.

The target group for these operating instructions is technical staff, who

have basic knowledge in pneumatics and mechanics.

Therefore, only staff who are trained in these fields may work on the PKL.

The PKL may only be installed, put into operation, maintained, troubleshot

and disassembled by persons authorised by the operator.

This documentation is protec t ed by copyright.

NetterVibration reserves all rights such as translations, reprinting and re-

production of the operati ng instr uc tions, as well as parts thereof.

All technical information, data and instructions for installation, operation

and maintenance in these operating instructions are based on the latest

information available at the time of printing and take our past experience

to the best of our knowledge into account.

No claims can be derived from the information, illustrations and descriptions in these operating instructions.

The manufacturer does not assume liability for damages resulting from:

• failure to observe the operating instructions,

Directives /

standards

observed

Special features of the

PKL

• improper use,

• unauthorised repairs,

• technical modifications,

• use of non-permiss ibl e spar e part s.

Translations are made to the bes t o f our know l edg e.

NetterVibration does not assume liability for translation errors, even if the

translation was made by us or on our behalf. Only the original German text

remains binding.

The pn eum atic i mpa ctors of the series PKL comply with the EC Machinery

Directive 2006/42/EC.

In particular, the standard EN ISO 12100 has been observed.

• high impact force

• low air consumption

• reduced sound level due to an elastomer impact plate

Page 4

General information

4

DANGER

Disregard of this notice will result in death or severe bodily

WARNING

Disregard of this notice can result in death or severe bodily

CAUTION

Disregard of this notice can result in minor or moderate

Instruction

and warning

symbols

Personal

injuries

Material

damages

Notes

The following instruction and warning symbols are used in these operating

instructions:

signifies an immediate danger.

injuries.

signifies a potential danger.

injuries.

signifies a potentially dangerous situation.

bodily injuries.

NOTICE

signifies potential material damage.

Disregard of this notice can result in material damage.

IMPORTANT

indicates actions, methods or notes that are not relative to safety, e.g. useful information and tips.

Environmentally safe disposal

indicates the obligation of environmentally safe disposal.

Page 5

Safety

5

assumes no liability for personal injuries and material

damages if technical changes to the product were made or the notices and

DANGER

, construction parts as well as fastening and locking

The PKL 190, PKL 450 and PKL 740 are open on the

tionally with an impact plate and two damper rings

(flange and impact plate) or with an EE kit and a damper

operation and thereafter at regular intervals (generally

2 Safety

Intended use

Qualification

of qualified

personnel

Liability

Falling parts

General areas of application of the PKL are for knocking off adhesive bulk

materials from container walls (e.g. silos, hoppers, filter outlets, pipelines

and reactors) and for emptying residues from weighing containers. The

PKL also prevent bridging and rat-holing, so that the material can continuously flow.

The PKL can be used outdoors and in dusty environments, however not in

water or any other liquids.

PKL may only be operated with a timed on/off sequence.

Any other use is considered improper.

Installation, commissioning, maintenance and troubleshooting of the PKL

may only be performed by authorised qualified personnel

All handling of the PKL is the responsibility of the operator.

IMPORTANT

NetterVibration

regulations in these operating instructions were not obs er v ed.

Falling parts

The PKL

screws can come loose due to vibration. Falling parts lead to

severe personal injuries.

Use only Netter fastening kits (NBS) to fasten the PKL.

side of impaction. During installation ensure that the impact piston remains in the housing .

Mount the PKL 2100, PKL 5000 and PKL 10000 addi-

ring (flange).

Check the fastening and locking screws after one hour of

monthly).

Retighten the fastening and locking screws, if necessary.

A safety device with a safety cable is mandatory for criti-

cal mounting situations.

Page 6

Safety

6

Check the hose lines and connections after one hour of operation and

Ensure that the compressed air is disconnected from the supply lines

dB(A). Human

Use hearing protection during work in a noisy area if

are not mechanically closed on the side of impact. The impact

piston and/or the impact plate are loosely mounted. Falling parts can lead

Ensure that the impact piston and/or impact plate remain in the housing

Compressed

air

Sound level

Loose parts

WARNING

Compressed air

A loosened hose which is under pressure can lead to personal injuries.

Screw the hose lines on carefully.

thereafter regularly (generally monthly).

Retighten the hose lines, if necessary.

during all work on the PKL.

Prevent the PKL from being switched back on during all work.

WARNING

Sound level

Near the PKL or near constructions connected to the PKL E

the sound pressure level may exceed 80

hearing can be permanently damaged by high noise levels.

80 dB(A) is exceeded.

Mount the PKL preferably with an EE kit.

CAUTION

Loose parts

The PKL

to personal injuries and material damage.

when mounting and disman tl ing.

Page 7

Technical data

7

≤

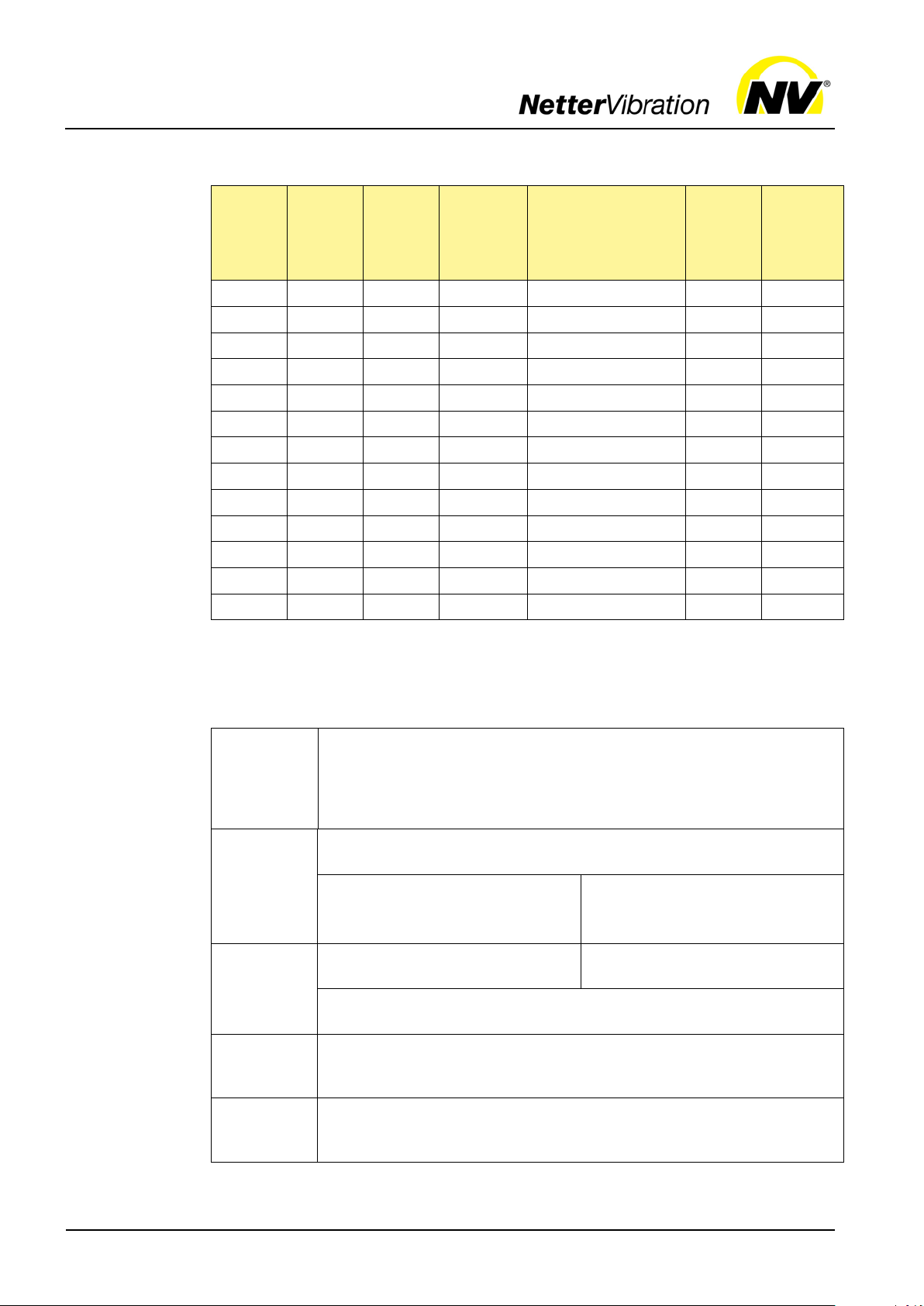

3 Technical data

Parameters

Type

designation

Permissible

operating

conditions

Type:

PKL...

190/4 0.19 0.43 4.0 0.20 0.8 1 - 2

190/6 0.19 0.60 6.0 0.20 0.8 1 - 2

450/4 0.44 0.56 4.0 0.40 1.6 1 - 3

450/6 0.44 0.92 6.0 0.60 1.6 1 - 3

740/3 0.74 1.30 3.0 0.50 2.6 2 - 4

740/4 0.74 1.80 4.0 0.70 2.6 2 - 4

740/5 0.74 2.10 5.0 0.80 2.6 2 - 4

740/6 0.74 2.70 6.0 1.00 2.6 2 - 4

2100/4 2.10 4.20 4.0 5.20 6.7 3 - 5

2100/5 2.10 6.20 5.0 6.50 6.9 3 - 5

5000/4 4.96 6.60 4.0 5.70 16.0 4 - 8

5000/6 4.96 10.60 6.0 8.60 16.5 6 - 12

10000/6 10.00 17.50 6.0 15.10 34.0 > 10

*) The force of impact corresponds to the impact of the given weight falling from a height of 1 m.

Weight

of piston

[kg]

Force of

impact *

[kg]

Optimum

operating

pressure

[bar]

Air consumption/impact at optimum pressure

[Nl]

Overall

weight

[kg]

Suitable

for wall

thickness

of...

[mm]

The type designation of the PKL has the suffix /3, /4, /5 or /6. The suffix is

derived from the optimum operating pressure, i.e. the PKL 740/4 achieves

the optimal effect at an operating pressure of 4 bar.

Drive

medium

NetterVibration recommends operating the PKL with clean, oiled com-

pressed air.

Filter

5 µm, quality class in accordance with ISO 8573-1

The PKL are, in principle, s uita bl e for operat io n with oi l -free compressed

air or nitrogen .

Lubrication ISO viscosity class in accordance with DIN 3448, VG 5 bis 15

Fill mist lubricator with acid- and resin-free compressed air oil.

Ambient

temperature*

Recommendation for temperatures

of up to 60 °C:

Klüber „AIRPRESS 15"

Standard: -20 °C to 60 °C HT versions: -20 °C to 160 °C de-

Recommendation for temperatures

over 60 °C with HT-versions:

Aral „Farolin U“ lubrication oil

pending on version

The permissible ambient temperatures must not fall below or exceed the

above temperatures during operation.

Operating

pressure*

Operating pressures must be between 2,0 bar and 6,0 bar.

The actual air pressure set on the regulator must not exceed the optimum

operating pressure by more than 1 bar.

Impact

frequency

The following impact sequence must not be exceeded:

Maximum 10 strokes in sequence at an impact frequency of

15 strokes/min and 180 strokes/h.

*) Higher operating pressures and temperatures are per mitted only after cons ultation with and written consent

by the application technicians of NetterVibration.

Page 8

Technical data

8

Noise level

Dimensions

PKL

190 /

450 /

740

The noise level of the PKL may exceed 80 dB(A) (single noise incident).

Depending on the impact sequence the continuous noise level is below

this value.

The PKL should be preferably mounted with the EE kit. The noise reduction is about ca. 5 dB(A) (single noise incident).

The sound em itted by the PKL can be dampened by hoods (on request).

This is only worthwhile if the impacted sheet metal is also insulated (e.g.

by heat insulation material).

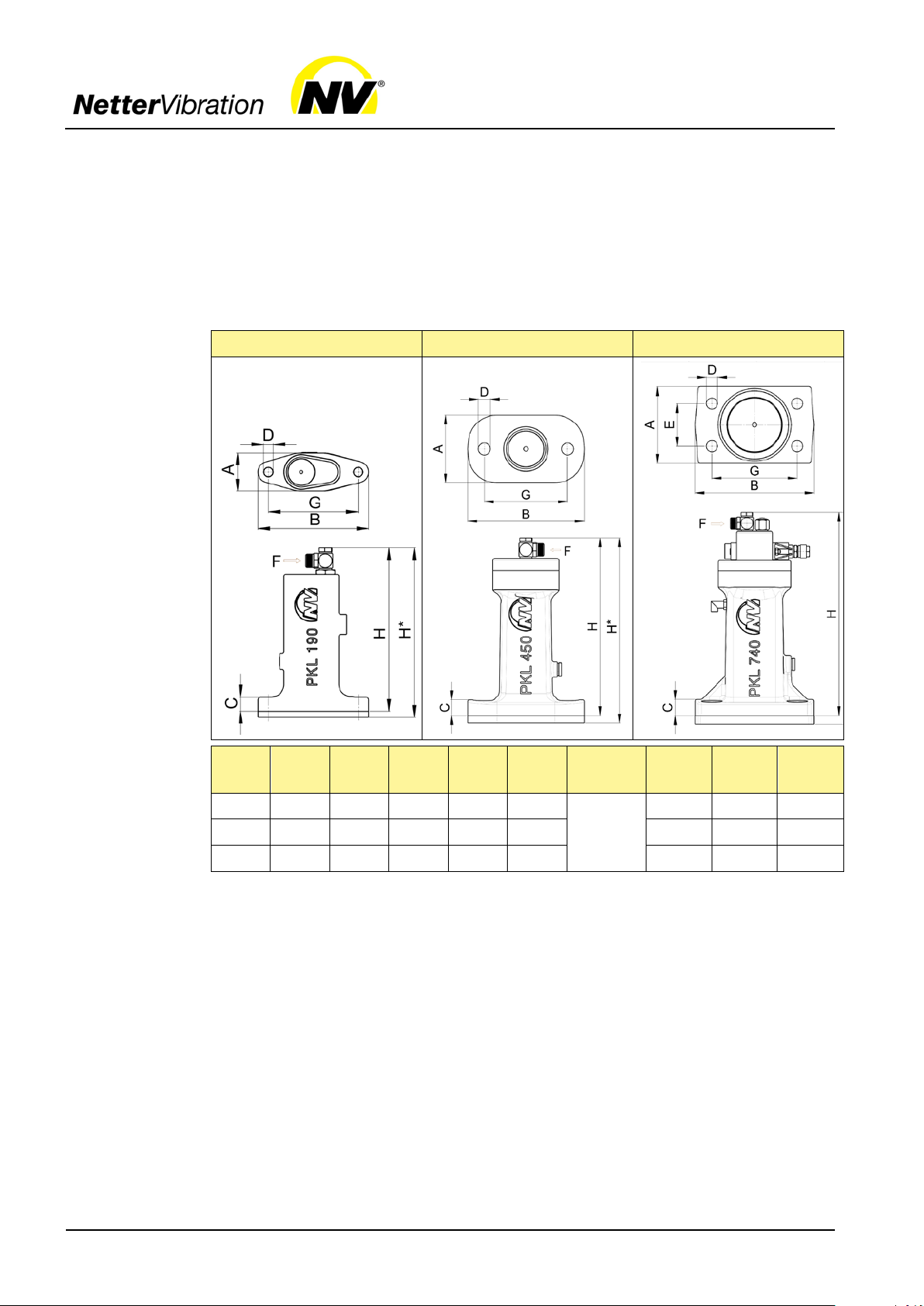

PKL 190 PKL 450 PKL 740

Type:

PKL... A [mm] B [mm] C [mm]

190 38.0 111 15 9.0 - G 1/8,

450 73.5 126 14 13.0 - 90.0 192.0 200.0

740 90.0 140 15 13.0 50 100.0 238.5 248.5

*) with EE kit

Ø D

[mm] E [mm] F

NW 6 × 1

G

[mm] H [mm]

90.0 163.5 169.5

H*

[mm]

Page 9

Technical data

9

Dimensions

PKL

2100 /

5000 /

10000

PKL 2100

PKL 5000

PKL 10000

Type:

PKL...

2100 Ø120.0 Ø180 17 13.0 - G 1/8,

5000 Ø114.3 Ø180 22 17.0 - Ø152 376.5

10000 Ø 145.0 Ø220 25 17.0 - Ø185 445.0

A

[mm]

B

[mm] C [mm]

Ø D

[mm] E [mm] F

G

[mm] H [mm]

Ø152 300.5

NW 6 × 1

Page 10

Design and function

10

1

Quick air-exhaust valve

2

Silencer

3

Springs

4

Piston

5

Flange

6

Impact plate

4 Design and function

Design

Function

Features of

PKL 740

ST kit

EE kit

p Compressed air

F Impact force

The PKL is a pneumatic „hammer“. Compressed air (p) goes under the

piston (4) and presses it against one or two springs (3).

When exhausting, the air chamber beneath the piston empties abruptly via

the quick air-exhaust valve (1).

The piston (4) (hammer) is struck by the spring force against an impact

plate (6), which then passes the impact force (F) on. For PKL without an

impact plate (PKL 190, PKL 450 and PKL 740), the piston strikes directly

against the fastening surface. The impact plate in the standard types (PKL

2100, PKL 5000 and PKL 10000) is always made of steel and can also be

replaced by an elastomer impact plate, if necessary.

The air escapes via the silencer (2).

The PKL only work when mounted, as the piston chamber is then sealed

by a built-in O-ring in the mounting surface.

A quick-air exhaust valve and a 3/2-way valve are integrated in the valve

head of the PKL 740. Therefore, the control valve on the customer's site

can be mounted at any distance away from the PKL 740.

The control air must be connected at the side. A silencer is mounted on

the exhaust air outlet.

The ST kit allows a continuous impact sequence with permanent compressed air supply.

The EE kit reduces the noise level and generates a rubber hammer effect.

Page 11

Transport and storage

11

1

Plastic fastening

4

Corrugated cardboard disc

2

Damper ring (for steel impact plate)

5

Damper plate (flange)

3

Impact plate

5 Transport and storage

Transport

conditions

Packaging

Transport

safety device

PKL

2100 /

5000 /

10000

Special transport conditions are not required.

When moving the PKL 10000, use the mounted transport lugs at the top of

the housing.

The PKL are packed and ready for assembly. Accessories and add-on

parts are delivered unmounted, unless otherwise agreed upon.

The packaging protects the PKL from transport damage. The packaging

material has been selected from an environmentally safe and technically

disposable point of view and is therefore recyclable.

The return of packaging to the material cycle conserves raw materials and

reduces the amount of was te.

Storage

The PKL 2100, PKL 5000 and PKL 10000 are delivered with a transport

safety device at the bottom. The transport safety device consists of 2 plastic fastenings and a corrugated cardboard disc. It prevents the impact plate

from falling out during transport and must be removed before installation.

Take care that the impact plate and damper plate retain their position on

the PKL, as they must be mounted with the PKL.

• Store the PKL in a dry and clean environment.

• The storage temperature is between -20 °C and +60 °C.

• Close all openings when re-storing.

• Preserve the PKL befor e storag e:

1. Screw or clamp the PKL on a plate. The impact plate of the PKL

2100, PKL 5000 and PKL 10000 must be inserted.

2. Apply anti-corrosion oil to the air inlet and briefly activate the PKL.

Page 12

Installation

12

6 Installation

IMPORTANT

1

Elastomer disc

2

Spacer plate

3

O-ring

The spacer plate is delivered together with

Safety

instructions

Procedure

Instructions

for EE kit

PKL

190 /

450 /

740

Observe the safety instructions in Ch. Safety, page 5.

When installing the PKL carry out the following steps in succession:

Install the EE kit on the PKL 190 / 450 / 740 between the flange of the PKL

and the mounting surface so that

• the piston of the PKL strikes the elastomer disc (1).

• the O-ring (3) is between the spacer plate (2) and the mounting sur-

face.

Example: PKL740

For detailed information, please refer to the mounting instructions for the

respective PKL type.

EE kit:

the O-ring.

Page 13

Installation

13

1. Remove the steel impact plate with the O-ring (2) and the damper ring

ring (3) in such a way that the

1

Damper ring

(impact plate)

2

Steel impact plate with O-ring

3

EE kit:

EE impact plate with O-ring

The EE impact plate is delivered

Instructions

for EE kit

PKL

2100 /

5000

Install the EE kit on the PKL 2100 / 5000 as foll ows:

(impact plate, 1).

2. Insert the EE impact plate with the Opiston of the PKL strikes against the EE impact plate (3).

Ensure that the damper ring (flange, x) is between the flange of the PKL

and the mounting surface.

x Damper ring (flange)

x Damper ring (flange)

together with the O-ring.

Example: PKL 2100

For detailed information, please refer to the EE kit mounting instructions

for PKL 2100 / 5000.

Page 14

Installation

14

1

Saddle plate

2

Weld-on plate

3

EE kit

4

NBS G (fastening set for

tapped hole)

Fastening

devices

NetterVibration delivers the appropriate fastening devices for installation

of the PKL:

weld-on consoles or weld-on plates (±0.3 mm flatness)

• Weld the consoles directly onto the c o ntai n er walls.

• Weld the plates onto previously mounted saddle plates (1.5 times the

sheet thickness of the container).

Weld-on console, plane (left) and round (right)

Fastening

kits

Weld-on plate

For safe and permanent fixation of the PKL to the device use the compulsory fastening kits.

The following versions are available for every PKL type:

Description Difference

NBS ... G (e.g. NBS 5000 G) for tapped hole

NBS ... D (e.g. NBS 740 D) for through-hole

NBS ... (e.g. NBS 190) without screws

... corresponds to the PKL type: 190 / 450 / 740 / 2100 / 5000 / 10000

Page 15

Installation

15

1

Hexagon bolt

2

NBS lock plate

3

Washer

4

Damper spring

5

Washer

(only for NBS D)

6

Tab washer with long tap

(only with NBS D)

7

Nut (only for NBS D)

The damping springs must be

Tighten the screw connections

Loosen the screw connections

ng roundings

of the lock plates towards all bolt

heads, with NBS D also towards all

For NBS D fold all long taps of the

tab washers towards the mounting

Instructions

fastening kit

Components of the fastening kit using the

example NBS D:

mounted on the flange of the PKL.

1.

evenly, until the damping springs

are completely pressed together.

2.

by one revolution.

Then fold all protrudi

nuts, as follows:

For detailed information, please refer to the respective Mounting Instructions (NBS G mounting kits or D mounting kits).

plate.

Page 16

Installation

16

Instructions

for ST kit

Components

for all

installations

Specifications

for valves and

hoses

The ST kit connects the control port to the piston chamber. The PKL

equipped with the ST kit strikes as long as there is compressed air.

• For PKL 190 / 450 proceed as follow s :

- Mount the ST screw fitting (after the NBS).

- A 3/2-way valve with air supply is necessary.

• For PKL 740 proceed as follows:

- Replace the silencer with the compressed air connection.

- Only one air supply is necessary.

• Order the PKL 2100 directly with the ST control.

• For PKL 5000 proceed as follow s:

- Mount the control valve of the ST control to the PKL.

- The control valve is connected internally to the piston chamber, the

ST control is integrated in the PKL.

For detailed information, please refer to the Assembly Instructions for the

ST kit.

For all installations, use a ball valve to shut off the main line and a maintenance unit.

The maintenance unit should comprise a filter, a regulator and a mist lubricator (see Ch. Technical data, page 7; "Drive medium").

Connect the PKL with the pneumatic hose according to the following depicted pneumatic circuit diagrams.

Define the impact sequence of the PKL with an electrical control, e.g. the

Netter Electronic Timer AP 117. Electrical or pneumatic controls are available on request.

Recommended cross-sections for control lines, control valves and main air

supply: NW 6 × 1

To connect the control valve to the PKL:

• NW 6 should be used and

• a length of 15 m should not be exceeded.

For simultaneous oper ati on o f sev er al PKL

• larger cross-sections are to be provided for the main line up to distribution to the individual PKL.

• the total length of the compressed air supplies is max. 50 m.

Page 17

Installation

17

1

Electronic Timer AP

2

Ball valve

3

Maintenance unit

4

3/2-way v alve

1

Electronic Timer AP

2

Ball valve

3

Maintenance unit

4

Actuating valve on customer's site

5

Control line

6

Main air

only PKL

way valve integrated

t at

the valve head. The control line

(5) from the actuating valve on

the customer's site (4) to the

may be very long (e.g. 50

m). The charging time of the

is several seconds for

For long air lines, set a pause

and duty time on the Electronic

least 5 seconds. If shorter lines

hese times

Standard

installation

PKL 190 /

450 /

2100 /

5000 /

10000

Example: PKL 450

Use a 3/2-way valve (4) for actuation.

By switching the valve, the piston chamber is vented and exhausted and the PKL therefore

strikes.

Mount the 3/2-way valve (4) at a

distance of max. 15 m.

Standard

installation

PKL 740

The PKL 740 is the

with a 3/2in the valve head.

By switching the valve, the piston chamber is vented and exhausted and the PKL therefore

strikes.

The main air (6) is presen

PKL

PKL

longer supply and control lines.

Timer AP (1) to a minimum of at

are used, reduce t

accordingly, e.g. to 2-3 seconds.

Page 18

llation

18

1

Electronic Timer AP

2

Ball valve

3

Maintenance unit

4

Actuating valve on customer's site

5

3/2-way air valve

The main air is always at the

way air valve (5) max. 1 m

line from the actuating valve (4)

on the customer's site to the

For longer supply and control

lines, the charging time of the

is several seconds. For

a pause and

er AP (1) to a minimum of at

least 5 seconds. If shorter lines

are used, reduce these times

1

Electronic Timer AP

2

Ball valve

3

Maintenance unit

4

Actuating valve on customer's site

5

3/2-way air valve

Operate several PKL in parallel

The connection lines from the

long, otherwise the

the PKL moves too slowly and

If required, install the actuating

valve (4) at a larger distance if

way air valves (5)

Installation

with long

supply line

PKL

190 /

450 /

2100 /

5000

Example: PKL 450

Insta

3/2away from the PKL. The control

PKL may be longer (e.g. 50 m).

PKL

long air lines, set

duty time on the Electronic Tim-

accordingly, e.g. to 2-3 seconds.

Installation

Example: PKL 450

of several PKL

with just one control and an actuating valve (4), if required.

3/2-way valve (5) to the PKL must

be max. 1 m

control piston or the membrane in

does not reach the end position.

additional 3/2are used.

If several PKL are in operation,

the supply line must not be longer

than 50 m.

Page 19

Installation

19

1

ST kit

2

Electronic Timer AP

3

Ball valve

4

Maintenance unit

5

Non-return throttle valve

6

3/2-way v alve

quency of up to one

duced to the permissible impact

(5) inserted in the

equipped with

kit at a larger distance (up

1

ST kit

2

Electronic Timer AP

3

Ball valve

4

Maintenance unit

5

Non-return throttle valve

6

2/2-way v alve

The PKL 740, equipped with an

imum impact frequency of up to

one strike/second, which must be

(5) inserted in the

bles operation of the PKL 740

Installation

with ST kit

PKL 190 / 450 /

2100 / 5000 /

10000

Example: PKL 450

The PKL, equipped with an ST

kit (1), strikes as long as pressure

is applied. The PKL thereby

achieves a maximum impact fre-

strike/second, which must be refrequency (e.g. with a non-return

throttle valve

supply line).

A 3/2-way valve (6) enables operation of the PKL

an ST

to 50 m).

Installation

with ST kit

PKL 740

ST kit (1), strikes as long as pressure is applied.

The PKL thereby achieves a max-

reduced to the permissible impact

frequency (e.g. with a non-return

throttle valve

supply line).

A 2/2- or 3/2-way valve (6) enaequipped with an ST kit at a larg-

er distance (up to 50 m).

Page 20

Installation

20

1

Ball valve

2

Maintenance unit

3

Opening cylinder

4

Non-return throttle val ve

is equipped with an

kit, then it can be coupled

with another function without a

control or a pulse generator.

The adjacent illustration shows

the coupling with an opening

is now not actuated.

When opened, it strikes at the

set number of cycles on the

(4), as

mounted with damper

Ball valve, maintenance unit (filter, regulator, mist lubricator),

Fastening screws and hose lines secured with an adhesive

in critical assembly situations secured against falling by

Installation

with coupling

to other functions

Checklist

installation

Example: PKL 2100

If the PKL

ST

cylinder (3) of a weighing container.

The PKL

non-return throttle valve

long as the flap is open.

Check that the following steps have been carried out:

Permissible ambient temperat ures observed?

Fastening device mounted (±0.3 mm flatness)?

PKL mounted with NBS fastening set?

PKL 2100, PKL 5000 and PKL 10000

ring (flange)?

valve and supply line mounted?

Information on hose length and nominal width observed?

(e.g. Loctite®), if required?

PKL

means of a safety cable?

Page 21

Start

-up and operation

21

IMPORTANT

7 Start-up and operation

Safety

instructions

Observe the safety instructions in Ch. Safety, page 5.

Permissible

operating

conditions

Design of

mist lubricator

Setting mist

lubricator

Regulation

impact

frequency

Regulation

impact force

Checklist

start-up

Please refer to Ch. Technical data, page 7 for permissible operating conditions.

When selecting the mist lubricator, take into consideration that the air consumption of the PKL is very low. The choice of mist lubricator depends on

how many PKL are oper ated simul t an eous l y .

Mist lubricators with 1/8”- and 1/4”-connections are recommended. Larger

mist lubricators may not react.

Set the mist lubricator to the smallest safely adjustable number of drops

while the PKL is running. The PKL is ready for operation only after adjustment and correct functioning of the mist lubricator.

PKL with ST control: impact frequency can be set by the non-return throttle

valve.

PKL without ST control: regulation of impact frequency is set by an external control, e.g. a 3/2-way valve and a Netter Electronic Timer (AP).

The impact force can be reduced by lowering the pressure (exception PKL

with ST kit). Throttling the air supply (by using a non-return throttle valve,

shut-off valve, etc.) does not reduce the impact force but delays the charging time.

Check that the following steps have been carried out:

Hose connections checked before installation?

For installation without ST kit:

Desired impact force set on pressure regulator?

For installation with ST kit and impact frequency control with a

non-return throttle valve:

Impact frequency set optimally?

Note that a high impact frequency reduces the service life and

leads to a high sound level.

Mist lubricator set, if applicable?

After one hour of operation:

Hose supply connections, fastening and locking screws checked

and tightened, if neces sar y?

Observe the maintenance plan.

Page 22

Maintenance and servicing

22

IMPORTANT

8 Maintenance and servicing

Safety

instructions

Observe the safety instructions in Ch. Safety, page 5.

Maintenance

plan

Maintenance of the PKL must be carried out as follows:

Interval Action

Cleaning

Maintenance

intervals

Implementation by Netter

After one hour of operation after initial commissioning

Check fastening and locking screws.

Check hose screw connections and hose connections and

retighten, if necessary.

Monthly Check fastening and locking screws.

Check hose screw connections and hose connections and

retighten, if necessary.

Check hose supply connections for permeability and kinks. If

necessary, clean and remove kinks.

Check the function of the silencer.

Check impact effect.

Ensure that mist lubricator operates according to regulations

(content decreases? number of drops/h? Refill oil.

Empty the filter of the maintenance unit if necessary, clean

the filter insert (wash out) and replace if necessary.

At the latest after a total

of 500,000 strokes

Carry out the general overhaul, in which all wear parts must

be replaced.

In the course of its service life, a film can form due to wear, which impairs

functioning. If loss in performance or standstill is noticed, proceed as follows:

1. Remove piston.

2. Clean piston.

3. Replace guide ring and piston seal, if necessary.

4. Reinsert piston.

Special tools are needed for inserting piston, guide rings and piston seal

(available on request).

The maintenance intervals depend essentially on the service life, how

clean the drive medium is and the lubricant used. Unfiltered compressed

air leads to high wear, blockage of the silencer and complete breakdown

of the PKL.

Maintenance, repair and general overhaul of the PKL may alternatively be

performed by NetterVibration.

Page 23

Troubleshooting

23

9 Troubleshooting

Disturbances

and causes

In the case of disturbances of the PKL proce ed as foll ows:

Possible causes Troubleshooting Corrective actions

Disturbance: does not function

Mounting surface not

flat

Malfunction of valve

and control

Air supply Check pressure. Set operating pressure.

Disturbance: does not function and has leakage at top

Wear of seals Check seals of impact piston

General wear Housing, membranes and

Disturbance: does not function and has leakage on mounting surface

PKL incorrectly mount-

ed

Mounting surface not

flat

Loss of pressure via O-ring? Establish ±0.3 mm flatness on

mounting surface.

Check PKL without valve and

control.

Check 3/2-way valve and control, and replace if necessary.

Check valve connection. Replace valve, if necessary.

Replace seals of impact piston

and control piston (PKL 190).

and control piston.

Replace affected parts and

control piston worn out?

seals.

Check fastening screws. Tighten fastening screws and

replace, if necessary.

Check mounting surface. Establish ±0.3 mm flatness on

mounting surface.

Check O-ring. Insert O-ring in groove, re-

place if damaged.

Disturbance: does not function with ST kit

Operating pressure

insufficient

Check PKL model.

Check pressure.

Increase pressure.

Disturbance: impact weak

Air supply Check pressure. Set pressure.

Contamination of con-

trol valve

Contamination of si-

Check control valve. Clean control valve or replace,

if necessary.

Check silencer. Clean silencer.

lencer

Wear, leakage Replace seals.

Page 24

s

24

10 Spare parts and accessories

Spare parts and accessorie

Ordering of

spare parts

Possible

accessories

Please provide the following details when ordering spare parts:

• required amount

• description and position of spare part

• type designation of PKL

Following accessories for the PKL are available:

Component Description

NBS fastening sets Compulsory for safe and permanent mounting (see Ch.

Installation, page 14)

ST kit When using these controls, sufficiently long pauses

must be maintained between the individual impact sequences (see Ch. Installation, page 19).

Hose material and

hose screw connections

Way valves Electrical, pneumatic, manual

Non-return throttle valves For clock control of PKL with ST kit

Maintenance units Filter, control unit with manometer, mist lubricator

Netter Electronic Timers Electric (also for special voltages) or pneumatic controls

For air supply (operational air, control air), in various

qualities and dimensions

Fastening consoles For round and rectangular containers, also for applica-

tion on insulated containers, hoppers, etc.

Vacuum mounts,

For quick relocation on containers, etc.

quick clamp devices

Sound protection hoods,

For noise reduction

EE kit

Safety cable For critical mounting situations

Flange in other dimensions;

Special versions; further infor mation on request

NBS in stainless steel

Following special models available on request:

• PKL for ATEX area,

• high and low temperature versions,

• stainless steel versions.

Page 25

Disposal

25

11 Disposal

Disposal costs

Material specifications

All parts of the PKL must be properly disposed of according to

the material specifications. The valid disposal costs of the PKL

are available on request.

Type Stainless

PKL 190 impact piston,

PKL 450 /

740

PKL 2100 ST pipe

Steel Aluminium PTFE, PU,

steel

compression springs

impact piston,

compression

springs,

screws (galvanised)

PKL 2100 S:

top cover,

flange,

outer pipe,

reducer

impact piston,

compression

springs,

impact plate,

screws (galvanised)

housing,

control piston,

EE spacer plate

housing,

top cover,

EE spacer plate

inner pipe,

top cover,

flange,

outer pipe,

reducer,

ST ring,

ST plate

PKL 2100 S:

inner pipe

VITON®, NBR

seals,

spring guide,

impact ring

seals,

membranes

seals,

damper rings,

EE impact plate

PKL 5000 outer pipe,

reducer,

ST pipe,

ST plate,

ST connection

angle

PKL 5000 S:

outer pipe,

reducer,

ST pipe,

ST plate,

ST connection

angle,

top cover,

flange

impact piston,

compression

springs,

impact plate,

inner pipe,

top cover,

flange,

screws (galvanised)

PKL 5000 S:

impact piston,

compression

springs,

impact plate,

inner pipe,

screws (galvanised)

PKL 10000 impact piston,

compression

springs,

seals,

damper rings,

EE impact plate

seals,

damper rings,

EE impact plate

impact plate,

inner pipe,

top cover,

flange,

outer pipe,

reducer,

screws (galvanised)

The valves and screw connections used for all types of PKL are made of

plastics, brass and/or aluminium.

Page 26

Annex

26

12 Annex

Loading...

Loading...