Page 1

UV/IRS-H2 & UVS-H2 Flame Detectors

PMS - Uncoated

PMS - Coated

PMS

BCR-0040-00-011

Product Data Sheet

November 2012

UV/IRS-H2 & UVS-H2 Flame Detectors

Ultraviolet and Infrared Sensors for Hydrogen & Silane Flame

Net Safety’s Hydrogen flame detectors are specially tuned for

non-hydrocarbon based flame applications where accurate and

instant detection of difficult to see hydrogen and silane flame

is required. Our advanced optical sensors ensure the greatest

degree of UV and IR spectral bandwave matching to the radiant

energy emitted by invisible hydrogen and silane flame — and

the lowest degree of matching to non-fire stimuli. This provides

ultra-fast alarm, an unparalleled level of false alarm immunity,

as well as a field-of-view unmatched in the industry — a full

120° horizontal degrees!

Two Radiation Wavelengths Necessary For Alarm—

Minimize False Alarm Events (UV/IR-H2 only)

Extremely Low Power Consumption Increases

Uptime and Lowers Overall Costs

Manual and Automatic Testing of Optical Surfaces

— Constatly Monitors Internal Electronics

Designed for Extreme Conditions, Operational

From -50°C — +75°C

Global Certifications and Approvals

Enclosed in a rugged, explosion-proof housing, the UVS-H2

and UV/IRS-H2 are engineered for extreme applications and

utilize the latest in SMART microprocessor sensor technology.

They’re capable of stand-alone operation or can be connected

to a variety of control devices to create a dependable fire

monitoring system. The field user can define sensitivity and

time delay settings to further enhance false-alarm immunity

and the built-in testing routines ensure continuous operation.

The UVS-H2 and UV/IRS-H2 are ideally suited for specialized

applications where response time and a wide field-of-view are

most critical — industrial and commercial locations that utilize

Wide Voltage Range Allows For Greater Stability

and System Compatibility

Field-selectable Sensitivity and Delay Settings

Allows Operators To Fine Tune At Installation Site

Wide Area Coverage, Extended Range with Fast

Response Times

Analog, Relay, and HART® Outputs Available

3 Year Warranty Electronics / 2 Years on Sensors

hydrogen fuel cells, hydrogen gas generators, hydrogen

refilling stations, and storage tanks as well as semiconductor

facilities where silane combustion risks are commonly present.

Net Safety’s UVS-H2 and UV/IRS-H2 flame detectors are

globally certified for hazardous locations to CSA, ANSI-UL/ISA,

and ATEX technical and safety standards.

Net Safety has engineered superior UV/IR-H2 and UV-H2

flame detectors specially tuned to detect invisible H2 and

Silane flame that are also simple to operate and maintain

while delivering all the security and performance required

for high-risk, industrial installations!

Page 2

UV/IRS-H2 & UVS-H2 Flame Detectors

PMS - Uncoated

PMS - Coated

PMS

BCR-0040-00-011

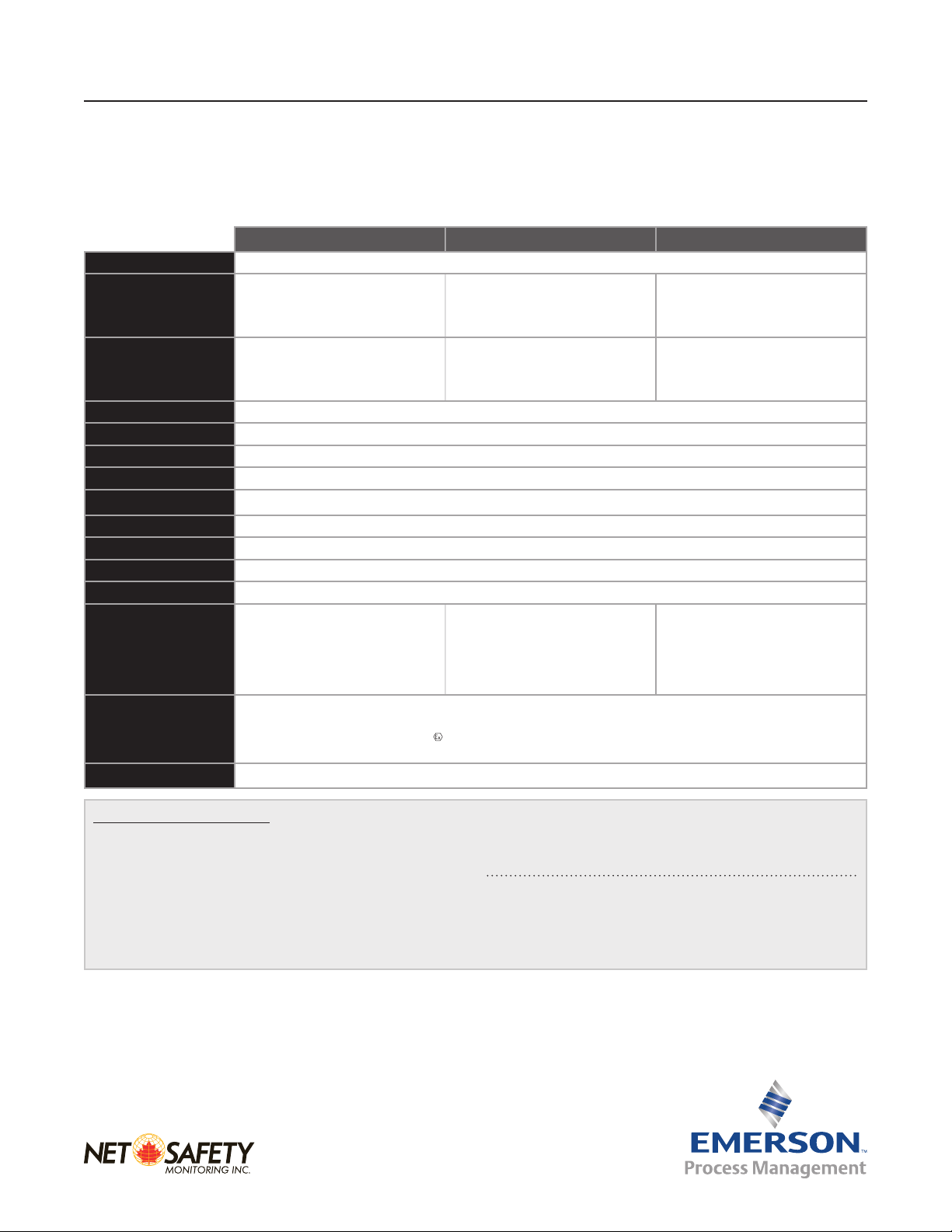

UV/IRS-H2 Flame Detector

Specifications

ANALOG RE LAY HART

Operating Voltage Range

Power Consumption

at 24 Vdc

*with Heater

Power Consumption

at 32 Vdc

*with Heater

Temperature Range

Field of View

Spectral Range

Time Delay

Sensitivity Settings

Response Time

Enclosure Material

Humidity Range

Weight (with swivel)

Outputs

Certifications/Approvals

Warranty

Nom 45 mA / 1.1 W

Max 115 mA / 2.76 W

*Nom 90 mA / 2.16 W

*Max 165 mA / 3.96 W

Nom 35 mA / 1.12 W

Max 105 mA / 3.36 W

*Nom 70 mA / 2.24 W

*Max 145 mA / 4.64 W

Certified -40°C to +75°C (-40°F to +167°F) / Operational -50°C to +75°C (-58°F to +167°F)

120 degrees horizontal / 95 degrees vertical

UV Radiation 185 to 260 nanometres (1850 to 2600 angstroms) | IR Radiation in the 3.09 micron range

Dip switch selectable to 0, 3, 5, 7 seconds

DIP switch selectable to 8, 16, 24 or 32 counts per second

<6 seconds [ depending on fuel source, fire size and distance ]

Red powdercoat with clear anodizing, copper-free aluminum (optional stainless steel), factory sealed housing

2.1 Kg/4.5 lb (Stainless Steel option 3.4 Kg/7.5 lb) - does not include junction boxes

0 to 20 mA - Into a maximum loop

impedance of 800 Ohms

at 32 V dc or 150 Ohms at 11.0 V dc.

Non-isolated loop supply

CSA - Class I, Division 1, Groups B, C and D - Temperature code T5 - CANADA: Class 1, Zone 1, Ex d IIB + H2 T5

ANSI/UL - Class I, Division 1, Groups B, C and D - Temperature code T5 - UNITED STATES: Class 1, Zone 1, AEx d IIB + H2 T5

ATEX/IECEx - II 2 G Ex d II B+H2 T5 Gb INMETRO - Ex d II B+H2 T5 Gb

Form C contacts rated 1 Amp at 30

Vdc, 0.5 Amp at 125 Vac. Selectable

latching/non-latching Fire relay Fault

relay factory set as energized/non-

NEMA Type 4X • IP66 - Enclosure ratings

3 Years Electronics / 2 Years Sensors

10 to 32 Vdc

Nom 45 mA / 1.1 W

Max 115 mA / 2.76 W

*Nom 90 mA / 2.16 W

*Max 165 mA / 3.96 W

Nom 35 mA / 1.12 W

Max 105 mA / 3.36 W

*Nom 70 mA / 2.24 W

*Max 145 mA / 4.64 W

0 to 95% RH, non-condensing

energized/de-energized,

latching, cannot be modified

Product Data Sheet

November 2012

“SMART” Gas Detector Series

®

Nom 71 mA / 1.7 W

Max 173 mA / 3.36 W

*Nom 106 mA / 2.22 W

*Max 223 mA / 5.36 W

Nom 57 mA / 1.72W

Max 158 mA / 5.06 W

*Nom 92 mA / 2.84 W

*Max 198 mA / 6.34 W

HART® Communication Protocol

ORDERING INFORMATION

UV/IRS-H2-A 4-20mA Analog Output

UV/IRS-H2-AR 4-20mA Analog output with Fire and Fault alarm

relays (JB-MPR-A/S included)

UV/IRS-H2-AH 4-20mA Analog Output and HART

Protocol (JB-MPHF-A/S included)

UV/IRS-H2-AHR 4-20mA Analog Output, Fire and Fault alarm relays,

and HART® Communication Protocol (JB-MPHFR-A/S

included)

®

Communication

ADDITIONAL APPROVALS : —X (ATEX/IECEx)

ENCLOSURE MATERIAL: Stainless Steel (—SS) [ Aluminum is Standard ]

ADDITIONAL FEATURES : —H (Heated Optics)

Ordering Matrix Example:

UV/IRS-H2-AHR-X-SS-H

(Detector - Output - Additional Approval - Enclosure Material - Optional Features)

NOTE: Specify flammable source when ordering

Page 3

UV/IRS-H2 & UVS-H2 Flame Detectors

PMS - Uncoated

PMS - Coated

PMS

Field of View at Indicated D istance

in F eet for n-Heptane

0°

15 °

15 °

30 °

45 °

30 °

45 °

Field of View at Indicated Distance

in F eet for n-Heptane

0 °

15 °

45 °

15 °

30 °

30 °

Vertical Field Of View

With Detector At 45˚

From Horizontal

100

80

60

40

20

120

140

60˚60˚

75˚75˚

80

60

40

20

0°

15 °

15 °

30 °

45 °

30 °

45 °

Field of View at Indicated Distance

in F eet for n-Heptane

0 °

15 °

45 °

15 °

30 °

30 °

Vertical Field Of View

With Detector At 45˚

From Horizontal

100

80

60

40

20

120

140

Product Data Sheet

BCR-0040-00-011

UV/IRS-H2 Flame Detector

Specifications con’t - Termination Boxes - Accessories

November 2012

Summary of Distances

Fuel Fire Size Typical Response

Example Field of View - Hydrogen

24” plume - indicated in feet - consult factory for other flame types

Hydrogen 24” plume 1.8 sec @ 55 ft.

Silane 24” plume 2.0 sec @ 60 ft.

60˚60˚

75˚75˚

Immunity False Alarm Stimuli

Stimuli Immunity Range

Direct/Indirect Sunlight total

1500W Heater 10 ft

Halogen, Incandescent Light 3 ft

Florescent Light 10 ft

Arc Welding 30 ft

TERMINATION BOXES

Class 1, Division 1, Groups BCD - Class 1, Zone 1 -- Enclosure rated NEMA 4X, IP67 (See man-0081 for full specifications)

JB-MPS-A/S Termination box - Analog Output - Switch (for remote MVI testing) & Test Jacks - Aluminum or Stainless Steel

ACCESSORIES

LAT-120 Laser alignment tool assembly - used to define area of coverage for all NSM flame detectors

AIR-SHIELD-002 Air Shield assembly (aluminum), supplied clean instrument air keeps lens clear in areas with heavy airbourne particulate

HPT-001 HART® Communicator port - Instrincially Safe connection mounts to connected JB-MPHF & JB-MPHFR

FH-SHROUD Field of View Restrictor Anodized (Red) for “S” series fire detectors (aluminum)

UN-MK-41 1” Pipe Mounting kit - Stainless steel

UN-MK-42 2” Pipe Mounting kit - Stainless steel

UN-MK-43 3” Pipe Mounting kit - Stainless steel

SSK-4 Sun shade kit/rain guard for “S” series flame, stainless steel - mounts directly to flame detector

SSK-1 Sun shade kit for “S” series flame, stainless steel - mounts directly to flame detector

TL-MP-KIT Universal test lamp kit - certified rechargeable hand-held unit - produces accurate fire simulation (UV and IR sources)

TL-MP-KIT-X Universal test lamp kit [ATEX] - certified rechargeable hand-held unit - produces accurate fire simulation (UV and IR sources)

Page 4

UV/IRS-H2 & UVS-H2 Flame Detectors

PMS - Uncoated

PMS - Coated

PMS

BCR-0040-00-011

UVS-H2 Flame Detector

Specifications

ANALOG RE LAY HART

Operating Voltage Range

Power Consumption

at 24 Vdc

Power Consumption

at 32 Vdc

Temperature Range

Field of View

Spectral Range

Time Delay

Sensitivity Settings

Response Time

Enclosure Material

Humidity Range

Weight (with swivel)

Outputs

Certifications/Approvals

Warranty

Nom 45 mA / 1.1 W

Max 115 mA / 2.76 W

Nom 35 mA / 1.12 W

Max 105 mA / 3.36 W

Certified -40°C to +75°C (-40°F to +167°F) / Operational -50°C to +75°C (-58°F to +167°F)

120 degrees horizontal / 95 degrees vertical

UV Radiation 185 to 260 nanometres (1850 to 2600 angstroms)

DIP switch selectable to 0, 3, 5, 7 seconds

DIP switch selectable to 8, 16, 24 or 32 counts per second

<6 seconds [ depending on fuel source, fire size and distance ]

Red powdercoat with clear anodizing, copper-free aluminum (optional stainless steel), factory sealed housing

2.1 Kg/4.5 lb (Stainless Steel option 3.4 Kg/7.5 lb) - does not include junction boxes

0 to 20 mA - Into a maximum loop

impedance of 800 Ohms

at 32 V dc or 150 Ohms at 11.0 V dc.

Non-isolated loop supply

CSA - Class I, Division 1, Groups B, C and D - Temperature code T5 - CANADA: Class 1, Zone 1, Ex d IIB + H2 T5

ANSI/UL - Class I, Division 1, Groups B, C and D - Temperature code T5 - UNITED STATES: Class 1, Zone 1, AEx d IIB + H2 T5

ATEX/IECEx - II 2 G Ex d II B+H2 T5 Gb INMETRO - Ex d II B+H2 T5 Gb

Form C contacts rated 1 Amp at 30

Vdc, 0.5 Amp at 125 Vac. Selectable

latching/non-latching Fire relay Fault

relay factory set as energized/non-

NEMA Type 4X • IP66 - Enclosure ratings

3 Years Electronics / 2 Years Sensors

10 to 32 Vdc

Nom 45 mA / 1.1 W

Max 95 mA / 2.28 W

Nom 35 mA / 1.12 W

Max 80 mA / 2.56 W

0 to 95% RH, non-condensing

energized/de-energized,

latching, cannot be modified

Product Data Sheet

November 2012

“SMART” Gas Detector Series

®

Nom 71 mA / 1.7 W

Max 173 mA / 3.36 W

Nom 57 mA / 1.72W

Max 158 mA / 5.06 W

HART® Communication Protocol

ORDERING INFORMATION

UVS-H2-A 4 -20mA Analog Output

UVS-H2-AR 4-20mA Analog output with a Fire and Fault alarm relay

(JB-MPR-A/S included)

UVS-H2-AH 4 -20mA Analog Output and HART

Protocol (JB-MPHF-A/S included)

UVS-H2-AHR 4-20mA Analog Output, Fire and Fault Alarm Relays, and

HART® Communication Protocol (JB-MPHFR-A/S included)

®

Communication

ADDITIONAL APPROVALS : —X (ATEX/IECEx)

ENCLOSURE MATERIAL: Stainless Steel (—SS) [ Aluminum is Standard ]

Ordering Matrix Example:

UVS-H2-AHR-X-SS

(Detector - Output - Additional Approval - Enclosure Material - Optional Features)

NOTE: Specify flammable source when ordering

Page 5

UV/IRS-H2 & UVS-H2 Flame Detectors

PMS - Uncoated

PMS - Coated

PMS

0°

15 °

15 °

30 °

45 °

30 °

45 °

Field of View at Indicated Distance

in F eet for n-Heptane

0 °

15 °

45 °

15 °

30 °

30 °

Vertical Field Of View

With Detector At 45˚

From Horizontal

100

80

60

40

20

120

140

Field of View at Indicated D istance

in F eet for n-Heptane

0°

15 °

15 °

30 °

45 °

30 °

45 °

Field of View at Indicated Distance

in F eet for n-Heptane

0 °

15 °

45 °

15 °

30 °

30 °

Vertical Field Of View

With Detector At 45˚

From Horizontal

100

80

60

40

20

120

140

60˚60˚

75˚75˚

80

60

40

20

Product Data Sheet

BCR-0040-00-011

UVS-H2 Flame Detector

Specifications con’t - Termination Boxes - Accessories

November 2012

Summary of Distances

Fuel Fire Size Typical Response

Example Field of View - Hydrogen

32” plume - indicated in feet - consult factory for other flame types

Hydrogen 24” plume 1.8 sec @ 55 ft.

Silane 24” plume 2.0 sec @ 60 ft.

60˚60˚

75˚75˚

Immunity False Alarm Stimuli

Stimuli Immunity Range

Direct/Indirect Sunlight total

1500W Heater 10 ft

Halogen, Incandescent Light 3 ft

Florescent Light 10 ft

TERMINATION BOXES

Class 1, Division 1, Groups BCD - Class 1, Zone 1 -- Enclosure rated NEMA 4X, IP67 (See man-0081 for full specifications)

JB-MPS-A/S Termination box - Analog Output - Switch (for remote MVI testing) & Test Jacks - Aluminum or Stainless Steel

ACCESSORIES

LAT-120 Laser alignment tool assembly - used to define area of coverage for all NSM flame detectors

AIR-SHIELD-002 Air Shield assembly (aluminum), supplied clean instrument air keeps lens clear in areas with heavy airbourne particulate

HPT-001 HART® Communicator port - Instrincially Safe connection mounts to connected JB-MPHF & JB-MPHFR

FH-SHROUD Field of View Restrictor Anodized (Red) for “S” series fire detectors (aluminum)

UN-MK-41 1” Pipe Mounting kit - Stainless steel

UN-MK-42 2” Pipe Mounting kit - Stainless steel

UN-MK-43 3” Pipe Mounting kit - Stainless steel

SSK-4 Sun shade kit/rain guard for “S” series flame, stainless steel - mounts directly to flame detector

SSK-1 Sun shade kit for “S” series flame, stainless steel - mounts directly to flame detector

TL-MP-KIT Universal test lamp kit - certified rechargeable hand-held unit - produces accurate fire simulation (UV and IR sources)

TL-MP-KIT-X Universal test lamp kit [ATEX] - certified rechargeable hand-held unit - produces accurate fire simulation (UV and IR sources)

Page 6

UV/IRS-H2 & UVS-H2 Flame Detectors

PMS - Uncoated

PMS - Coated

PMS

BCR-0040-00-011

Product Data Sheet

November 2012

HEADQUARTERS:

FLAME AND GAS DETECTION

Emerson Process Management

Net Safety Monitoring Inc.

2721 Hopewell Place NE

Calgary, Alberta, Canada T1Y 7J7

T +1 (403) 219 0688

T 1 866 FIREGAS

F +1 (403) 219 0694

www.net-safety.com

©2012 Emerson Process Management. All rights reserved.

Emerson Process Management, Rosemount Analytical, and Net Safety Monitoring are marks of Emerson Process Management group of

companies. All other marks are the property of their respective owners.

The contents of this publication are presented for information purposes only, and while effort has been made to ensure their accuracy, they

are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or

applicability. All sales are governed by our terms and conditions, which are available on request. We reserve the right to modify or improve the

designs or specifications of our products at any time without notice.

∞

Please refer to manuals for complete specifications.

Loading...

Loading...