Page 1

Net Safety TM SafeGuard Controller

User Manual

Reference Manual

MAN-0115, Rev. A

April 2016

Page 2

Page 3

Important Instructions

Rosemount designs, manufactures, and tests products to function within specific conditions.

Because these products are sophisticated technical instruments, it is important that the owner and

operation personnel must strictly adhere both to theinformation printed on the product nameplate

and to all instructions provided in this manual prior to installation, operation, and maintenance.

Installing, operating, or maintaining the product improperly could lead to serious injury or

death from explosion or exposure to dangerous substances. Comply with all information on the

product, in this manual, and in any local and national codes that apply to the product. Do not

allow untrained personnel to work with this product. Use Net Safety parts and work

procedures specified in this manual.

No part of the hardware, software, or documentation may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any language or computer language, in any form or by

any means, without prior written permission of Rosemount. While great efforts have been made to

ensure the accuracy and clarity of this document, Rosemount assumes no liability resulting

from any omissions in this document of from misuse of the information obtained herein. The

information in this document has beencarefully checked and is believed to be entirely reliable with all

of the necessary information included. Rosemount reserves the rightto make changes to any

products described herein to improve reliability, function, or design and reserves the right to revise

this

document and make changes from time to time in content hereof with no obligation to notify any

persons of revisions or changes. Rosemount does not assume any liability arising out of the

application or any use of any product or circuit described herein; neither does it convey license under

its patent rights or the rights of others.

This manual should be read carefully by all individuals who hve or will have responsibility for

using, maintaining, or servicing this product.

The Detector is not field repairable due to the meticulous alignment and calibration of the

sensors and the respective circuits. Do not attempt to modify or repair the internal circuits or

change their settings, as this will impair the system’s performance and void the Rosemount

warranty.

Page 4

Warranty

Limited Warranty

Resale Products

Limitation of Remedy and Liability

1.

Liability) herein, Seller warrants that (a) the licensed firmware embodied in the Goods will

execute the programming instructions provided by Seller; (b) that the Goods manufactured by

Seller will be free from defects in materials or workmanship under normal use and care; and (c)

Services will be performed by trained personnel using proper equipment and instrumentation for

the particular Service provided. The foregoing warranties will apply until the expiration of the

applicable warranty period. Sensors and detectors are warranted against defective parts and

workmanship for 24 months from the date of purchase and other electronic assemblies for 36

months from the date of purchase. Products purchased by Seller from a third party for resale to

Buyer (

Buyer agrees that Seller has no liability for Resale Products beyond making a reasonable

commercial effort to arrange for procurement and shipping of the Resale Products. If Buyer

discovers any warranty defects and notifies Seller thereof in writing during the applicable

warranty period, Seller shall, at its option, (i) correct any errors that are found by Seller in the

firmware or Services; (ii) repair or replace FOB point of manufacture that portion of the Goods

found by Seller to be defective; or (iii) refund the purchase price of the defective portion of the

Goods/Services. All replacements or repairs necessitated by inadequate maintenance; normal

wear and usage; unsuitable power sources or environmental conditions; accident; misuse;

improper installation; modification; repair; use of unauthorized replacement parts; storage or

handling; or any other cause not the fault of Seller, are not covered by this limited warranty and

shall be replaced or repaired at Buyer’s sole expense and Seller shall not be obligated to pay any

costs or charges incurred by Buyer or any other party except as may be agreed upon in writing in

advance by Seller. All costs of dismantling, reinstallation, freight and the time and expenses of

Seller’s personnel and representatives for site travel and diagnosis under this limited warranty

clause shall be borne by Buyer unless accepted in writing by Seller. Goods repaired and parts

replaced by Seller during the warranty period shall be in warranty for the remainder of the

original warranty period or 90 days, whichever is longer. This limited warranty is the only

warranty made by Seller and can be amended only in a writing signed by an authorized

representative of Seller. The limited warranty herein ceases to be effective if Buyer fails to

operate and use the Goods sold hereunder in a safe and reasonable manner and in accordance

with any written instructions from the manufacturers. THE WARRANTIES AND REMEDIES SET

FORTH ABOVE ARE EXCLUSIVE. THERE ARE NO REPRESENTATIONS OR WARRANTIES OF ANY

KIND, EXPRESS OR IMPLIED, AS TO MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE OR

ANY OTHER MATTER WITH RESPECT TO ANY OF THE GOODS OR SERVICES.

. Subject to the limitations contained in Section 10 (Limitation of Remedy and

) shall carry only the warranty extended by the original manufacturer.

2.

DELAY IN PERFORMANCE. THE REMEDIES OF BUYER SET FORTH IN THE AGREEMENT ARE

EXCLUSIVE. IN NO EVENT, REGARDLESS OF THE FORM OF THE CLAIM OR CAUSE OF ACTION

(WHETHER BASED IN CONTRACT, INFRINGEMENT, NEGLIGENCE, STRICT LIABILITY, OTHER TORT

OR OTHERWISE), SHALL SELLER’S LIABILITY TO BUYER AND/OR BUYER’S CUSTOMERS EXCEED

THE PRICE TO BUYER OF THE SPECIFIC GOODS MANUFACTURED OR SERVICES PROVIDED BY

SELLER GIVING RISE TO THE CLAIM OR CAUSE OF ACTION. BUYER AGREES THAT IN NO EVENT

SHALL SELLER’S LIABILITY TO BUYER AND/OR BUYER’S CUSTOMERS EXTEND TO INCLUDE

INCIDENTAL, CONSEQUENTIAL OR PUNITIVE DAMAGES. THE TERM “CONSEQUENTIAL

DAMAGES” SHALL INCLUDE, BUT NOT BE LIMITED TO, LOSS OF ANTICIPATED PROFITS, REVENUE

OR USE AND COSTS INCURRED INCLUDING WITHOUT LIMITATION FOR CAPITAL, FUEL AND

POWER, AND CLAIMS OF BUYER’S CUSTOMERS.

. SELLER SHALL NOT BE LIABLE FOR DAMAGES CAUSED BY

Page 5

Contents

Section 1: Introduction ................................................1

Section 2: Operation ....................................................6

1.1 Important safety issues ....................................................................... 1

1.2 General description ............................................................................. 2

1.3 Data display screens ............................................................................ 3

Trend screen ........................................................................... 3

1.3.1

1.3.2 Bar Graphs screen .................................................................. 4

1.3.3 Combination screen ............................................................... 4

1.4 Specifications ...................................................................................... 4

1.4.1 DC power supply requirements ............................................... 4

1.4.2 150 watt AC– 24 Vdc power supply ......................................... 4

1.4.3 Relays ..................................................................................... 5

1.4.4 Ambient temperature range ................................................... 5

1.4.5 Humidity range ....................................................................... 5

1.4.6 Altitude ................................................................................... 5

1.4.7 Housings ................................................................................. 5

1.4.8 Non-intrusive magnetic keypad............................................... 5

1.4.9 Approvals ................................................................................ 5

2.1 Basic operation ................................................................................... 6

2.2 Setup menu configuration .................................................................. 6

2.2.1 Changing menu variables using the key pad ............................ 7

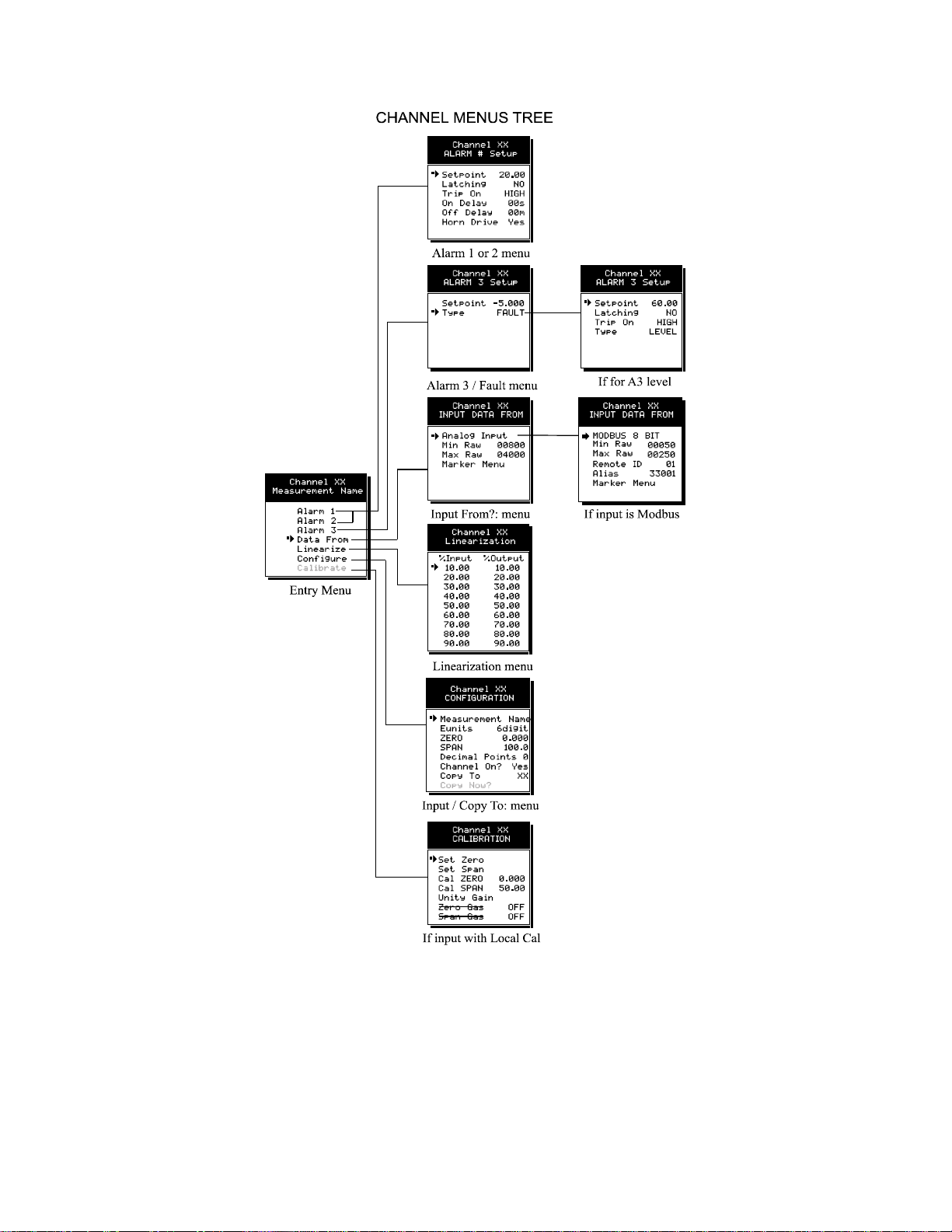

2.3 Channel configuration menus ............................................................. 7

2.3.1 Channel setup entry menu ...................................................... 8

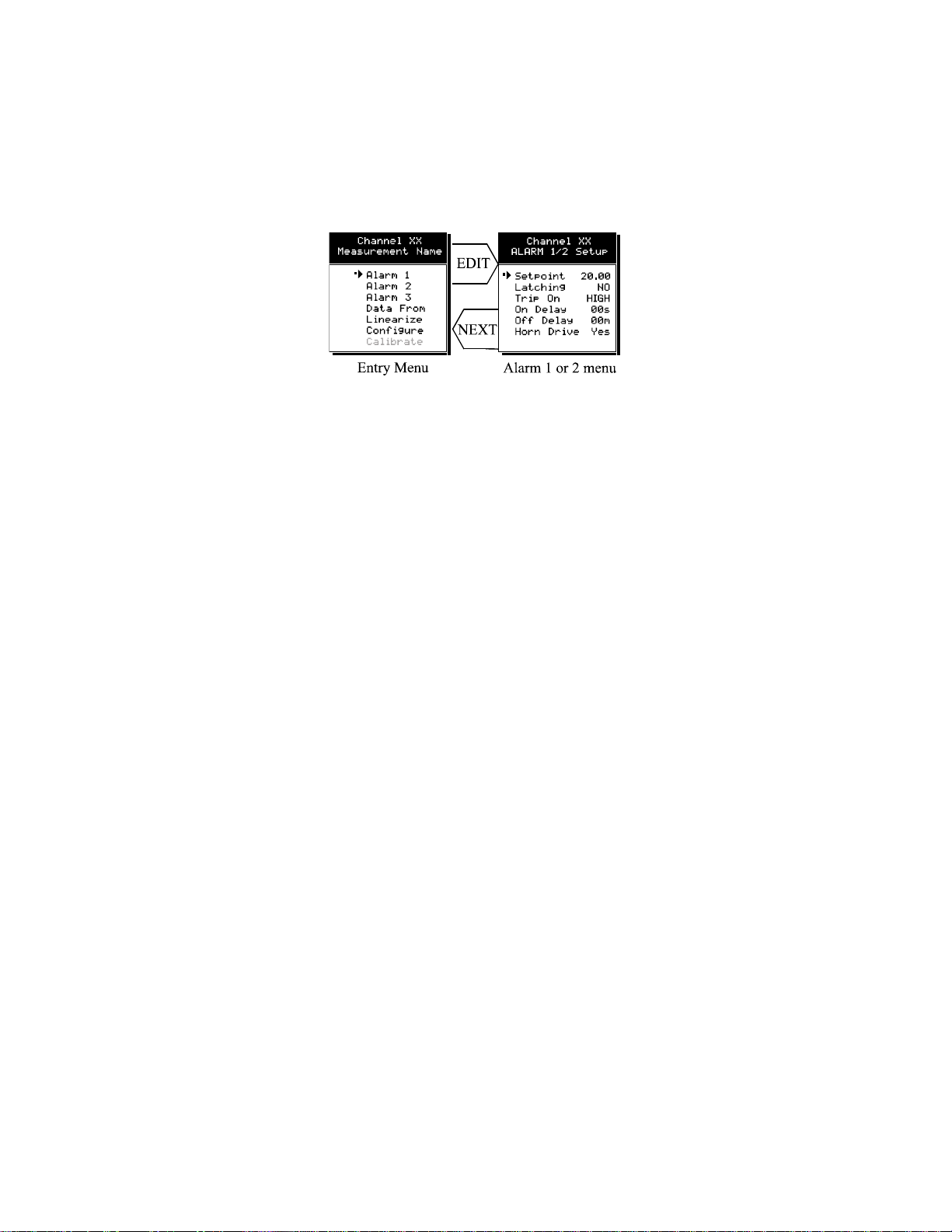

2.3.2 Alarm 1 / Alarm 2 / Horn Relay Setup menu ............................. 9

2.3.3 Alarm 3 / Fault Alarm menu ................................................... 10

2.3.4 Data from? menu to set input source .................................... 10

2.3.5 Min / Max Raw counts entries ................................................ 11

2.3.6 Marker menus ....................................................................... 12

2.3.7 Sensor Life detection (- this feature is not used at this time) .. 12

2.3.8 Linearization menu ............................................................... 13

2.3.9 Configure menu .................................................................... 13

2.3.10 Eunits / Measurement Name ASCII data fields ........................ 13

2.3.11 Input measurement range ..................................................... 13

2.3.12 Decimal point resolution ....................................................... 14

2.3.13 Turning off unused channels ................................................. 14

2.3.14 Copy Data to? ....................................................................... 14

2.3.15 Cal mode .............................................................................. 14

2.4 System configuration menus ............................................................. 15

2.4.1 Common Alarm Relays 1 and 2 .............................................. 16

2.4.2 SG10-0195 Discrete relay Failsafe mode ................................ 17

2.4.3 Common horn relay and local piezo....................................... 18

2.4.4 Comm Port menus ................................................................ 19

2.4.5 Eight / sixteen channel modes ............................................... 19

2.4.6 Sensor Information (this feature is not used at this time) ....... 20

2.5 Authorization mode .......................................................................... 20

2.6 LCD contrast adjustment ................................................................... 21

Page 6

Section 3: Inputs and Outputs .................................... 21

3.1 Main I/O interface PCB....................................................................... 21

3.1.1 Modbus Communication between SafeGuard and Digital

Millennium II Series Transmitters. .......................................... 22

3.2 Input/output optional PCBs ............................................................... 24

3.2.1 Optional analog input PCB # SG10-0158 ............................... 24

3.2.2 Optional discrete relay PCB # SG10-0195 .............................. 26

3.2.3 Optional 4-20mA analog output board # SG10-0167 ............. 28

3.2.4 Optional 24VDC 150 watt power supply ................................ 29

Section 4: System diagnostics .................................... 30

Section 5: Modbus ..................................................... 32

5.1 Modbus RS-485 ports ........................................................................ 32

5.2 Modbus slave register locations......................................................... 32

Section 6: Dimensions................................................ 39

6.1 SafeGuard PM panel / rack mount enclosure...................................... 39

6.2 SafeGuard n4 NEMA 4X wall mount fiberglass enclosure ................... 40

6.3 SafeGuard main I/O & option PCB footprint dimensions .................... 42

Section 7: How to return equipment .......................... 43

Section 8: Appendix ................................................... 44

Appendix A: Electrostatic sensitive device (ESD) ......................................... 44

Page 7

Page 8

1

MAN-0115 Rev A

WARNINGS:

Shock Hazard

WARNING- EXPLOSION HAZARD

WARNING- EXPLOSION HAZARD

WARNING- EXPLOSION HAZARD

WARNING:

!

Section 1: Introduction

operation. Failure to do so could result in serious injury or death.

Read & understand contents of this manual prior to

1.1 Important safety issues

The following symbols are used in this manual to alert the user of important

instrument operating issues:

•

• NEMA 4X wall mount models should be fitted with a locking mechanism

This symbol is intended to alert the user to the presence

of important operating and maintenance (servicing)

instructions.

This symbol is intended to alert the user to the presence of dangerous

voltage within the instrument enclosure that may be sufficient

magnitude to constitute a risk of electric shock.

instrument.

after installation to prevent access to high voltages by unauthorized

personnel (see Figure 6.2).

- Disconnect or turn off power before servicing this

• Only the combustible monitor portions of this instrument have been

assessed by CSA for C22.2 No. 152 performance requirements.

• This equipment is suitable for use in Class I, Division 2, Groups A, B, C, and

D or non-hazardous locations only.

•

•

•

• Use a properly rated CERTIFIED AC power (mains) cable installed as per

IMPAIR SUITABILITY FOR CLASS I, DIVISION 2.

HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE NONHAZARDOUS.

UNLESS POWER HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE

NON-HAZARDOUS.

local or national codes

- SUBSTITUTION OF COMPONENTS MAY

- DO NOT REPLACE FUSE UNLESS POWER

- DO NOT DISCONNECT EQUIPMENT

Page 9

MAN-0115 Rev A 2

• A Certified AC power (mains) disconnect or circuit breaker should be

Note: LEL Gas sensors are connected to the SafeGuard Controller via Net Safety

Transmitters. They are NOT connected directly to the SafeGuard Controller at this

time. Perform calibrations of the transmitter/sensor head. Calibrations may

however be performed at the SafeGuard if the transmitter/sensor configuration is

in a location not easily accessible. See Cal Mode.

mounted near the SafeGuard Controller and installed following applicable

local and national codes. If a switch is used instead of a circuit breaker, a

properly rate CERTIFIED fuse or current limiter is required to installed as

local or national codes. Markings for positions of the switch or

per

breaker should state (I) for on and (O) for off.

• Clean only with a damp cloth without solvents.

• Equipment not used as prescribed within this manual may impair overall

safety.

1.2 General description

The Net Safety Monitoring Inc. SafeGuard 16 channel Controller is designed to

display and control alarm event switching for up to sixteen detectors (Flame

detectors or transmitters with gas sensor) data points. It may also be set as an

eight channel SafeGuard Controller for applications needing fewer inputs. Alarm

features such as ON and OFF delays, Alarm Acknowledge, and a dedicated horn

relay make the SafeGuard Controller well suited for many multi-point monitoring

applications. Data may be input to the SafeGuard Controller by optional analog

inputs or the standard Modbus® RTU master RS-485 port. A Modbus RTU slave RS485 port is also standard for sending data to PC’s, PLC’s, DCS’s, or even other

SafeGuard Controllers. Options such as analog I/O and discrete relays for each

alarm are easily added to the addressable I

and therefore require 2 boards for 16 channel applications.

2

C bus. Option boards have 8 channels

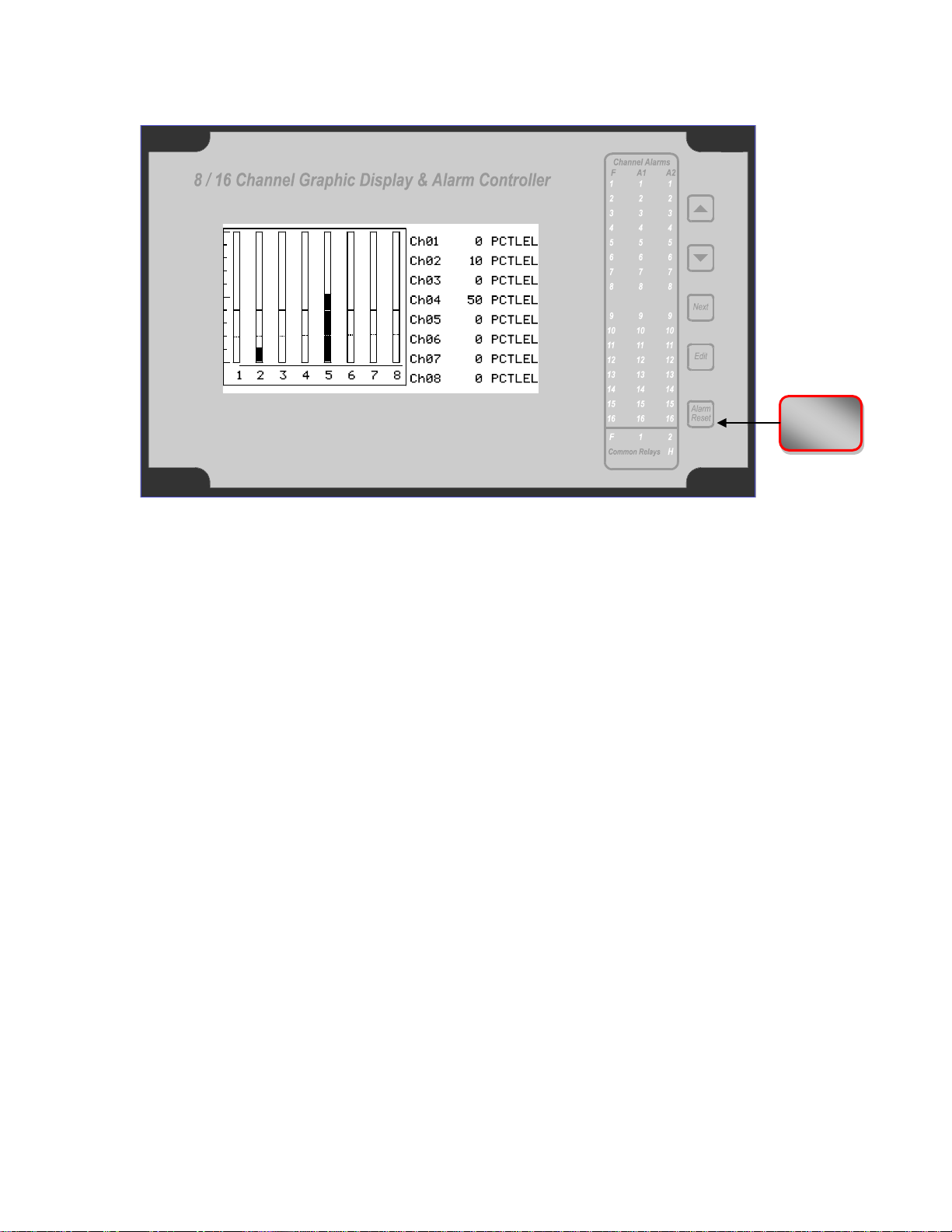

A 240 x 128 pixel graphic LCD readout displays monitored data as bar graphs,

trends and engineering units. System configuration is through user friendly

menus and all configuration data is retained in non-volatile memory during power

interruptions. The SafeGuard Controller’s front panel is shown below in Figure 1.0

displaying the 8 channel bar graph screen. Additional data screens are shown in

Figure 2.0.

Page 10

3

MAN-0115 Rev A

ALARM

RESET

Figure 1.0

1.3 Data display screens

The SafeGuard Controller offers 3 distinct graphic displays for depicting the

monitored data. These are Bar Graphs, 24 Hour Trend and Combination. Each is

shown in Figure 2.0.

1.3.1 Trend screen

The SafeGuard Controller’s Trend screen shown in Figure 2.0 displays a 24 hour

trend of input data for the channel selected. Horizontal tic marks are each hour

and vertical tic marks are each 10% of full scale. Dashed lines indicate alarm levels.

The graphic LCD is 240 pixels wide so each pixel represents 1/10 hour, or 6

minutes worth of data. The trend is 100 pixels high so each represents 1% of full

scale in amplitude. Since each data point must be collected for 6 minutes before

it may be displayed, it is likely input values will fluctuate during this interval.

Therefore, MAX, MIN and AVERAGE values are stored in RAM memory for each 6

minute subinterval. To accurately portray the trend, a vertical line is drawn

between MIN & MAX values for each 6 minute subinterval. The AVERAGE value

pixel is then left blank, leaving a gap in the vertical line. This is demonstrated in

the noisy area of the 24 hour trend in Figure 2.0. If the MAX & MIN values are

within 2% of each other there is no need for the vertical line and only the AVERAGE

value pixel is darkened as in the quiet areas.

The top portion of each trend screen indicates channel #, real time reading in

engrg. units, measurement name, range, and MIN, MAX & AVERAGE values for the

preceding 24 hour period. The SI field on the top right indicates number of

seconds remaining in the current 6 minute subinterval.

Page 11

MAN-0115 Rev A 4

1.3.2 Bar Graphs screen

When wiring transmitters (detectors) to the SafeGuard Controller refer to 3.1.1

Optional Analog Input PCB # SG10-0158 and Figure 3.3.

The SafeGuard Controller’s Bar Graphs screen shown in Figure 2.0 allows all active

channels to be viewed simultaneously. Both engineering units values and bar

graph values are indicated in real time. Lines across the bars indicate the alarm

trip points making it easy to identify channels at or near alarm. A feature in the

Systems menu tree allows new alarms to always force the LCD to the bar graphs

screen. This is useful for applications requiring channels with alarms to be

displayed.

1.3.3 Combination screen

The SafeGuard Controller’s Combination screen shown in Figure 2.0 offers a view

of a single channel but displays the data as a 30 minute trend, bar graph and large

engineering units. It is also useful for testing inputs for stability since MAX, MIN &

AVERAGE values refresh each time this screen is selected. For example, to test

stability over a one hour period for an input, begin timing as soon as the channel is

selected. One hour later record the MAX, MIN & AVERAGE values. The difference

between MAX & MIN indicates peak to peak excursions over the one hour period

and AVERAGE is the average for the hour. Longer or shorter tests may also be run.

The numeric value shown below the bar-graph indicates number of minutes

samples have been taken. After 999 minutes the AVERAGE buffer overflows and

the error message UPDATE appears in the AVERAGE field. Exiting this screen resets

the buffer and clears the error message.

1.4 Specifications

1.4.1 DC power supply requirements

Standard SafeGuard Controller power requirements are 10-30VDC @ 3 watts

applied to terminals 9 & 11 of TB2 on the standard I/O PCB (see section 3.0).

Optional features increase power consumption as described below:

• Discrete Relay PCB option; add 2 watts per PCB (assumes all 8 relays are

energized).

• Analog Input PCB option; add 1/2 watt.

• 4-20mA Output PCB option; add 1 watt.

• TB2 terminals 10 & 12 of the standard I/O PCB provide a maximum of

500mA fused output power for powering of auxiliary external devices

such as relays, lamps or transmitters. Power consumed from these

terminals should be considered when calculating system power

consumption.

1.4.2 150 watt AC– 24 Vdc power supply

*110-120 VAC @3.2A max

Page 12

5

MAN-0115 Rev A

RESISTIVE

IMPORTANT

!

*220-240VAC @ 1.6A max

* A slide switch on the front of the power supply selects AC input range.

The SG10-0172 150 watt power supply (Figure 3.6) is for powering the SafeGuard

Controller and up to 16 detectors. A minimum of 5 watts per channel is available

for powering of external transmitters.

1.4.3 Relays

Common relays are standard and menus provide voting logic for

ALARM 1, ALARM 2, FAULT and HORN. Discrete relays are optional.

Relays are Form C dry contacts and are rated at 5 Amp for 28 VDC

and 250 ~VAC

must be installed with inductive loads to prevent RFI noise spikes. Relay wiring

should be kept separate from low level signal wiring.

: Appropriate diode (DC loads) or MOV (AC loads) snubber devices

loads.

1.4.4 Ambient temperature range

-25 to +50 degrees C

1.4.5 Humidity range

0 to 90% R. H. Non-Condensing.

1.4.6 Altitude

Recommended up to 2000 meters

1.4.7 Housings

• *General purpose panel mount weighing 7 lbs and including hardware for

19” rack mounting (Figure 6.1).

• *NEMA 4X wall mount in fiberglass enclosure weighing 17 lbs (Figure

6.2).

1.4.8 Non-intrusive magnetic keypad

The SafeGuard Controller’s operator interface includes five front panel touch keys.

A magnetic keypad option offers these five keys with adjacent magnetic keys.

This option is included as a standard feature. It is useful in applications where it

may be inconvenient to open the enclosure’s door to access the touch keypad.

1.4.9 Approvals

CSA C22.2 No 1010.1 and ISA S82.02; CSA C22.2 No 152 for combustibles; UL

1604 / C22.2 No 213 (Div 2 Groups A,B,C,D); EN55011 & EN61000 (CE Mark). CSA

File # = 219995 and may be seen at: CSA-International.org.

Page 13

MAN-0115 Rev A 6

Section 2: Operation

UP/DOWN

NEXT

EDIT

UP/DOWN

EDIT

NEXT,

EDIT

UP/DOWN

EDIT

2.1 Basic operation

The SafeGuard Controller offers 3 graphic screens for viewing monitored data and

a Set-Up menu screen for operator interface to configuration menus. They are

shown below in Figure 2.0. The Bar Graphs screen allows viewing of all active

channels simultaneously. The Trend screen displays a 24 hour trend one channel

at a time. The Combination screen displays a bar graph, large engineering units

and a 30 minute trend one channel at a time. Input channels may be displayed in

sequence with the

data screens. When SafeGuard power is applied, the graphic LCD returns to the

screen active when power was last removed.

keys. The

key switches between the 3 graphic

Setup menus are entered by pressing

the desired menu using the

selected menu’s tree of variables. This Setup mode may be exited manually by

pressing

relays and front panel alarm LED indicators remain active during the Setup mode.

An AUTHORIZE menu offers a password feature to prevent tampering with the

SafeGuard Controller’s parameters.

or automatically when no keys are pressed for 5 minutes. Alarm

from any data screen, and scrolling to

keys. Pressing

again enters the

Figure 2.0

2.2 Setup menu configuration

Variables inside system and channel menu trees allow optimum SafeGuard

Controller configuration for a wide range of demanding multi-point monitoring

applications. Access to menus is via the Setup mode by pressing

activating the Setup screen shown in Figure 2.0. Menu trees are provided for each

of the 16 channels and another for system variables. Select the desired menu by

scrolling with

and

to enter the menus.

and

Page 14

7

MAN-0115 Rev A

UP/DOWN

YES/NO

ON/OFF

EDIT

EDIT

UP/DOWN

NEXT

EDIT

NEXT

2.2.1 Changing menu variables using the key pad

Upon entering a menu, a pointer controlled by the

selected variable. Some are simple

the

ASCII character possibilities. Allowed ASCII characters are as follows:

ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz blank space

!"#$%&`()*+,-./0123456789:;<=>?@.

the next position within a field. When the field is complete,

and loads it into non-volatile memory where it is retained indefinitely. With no

cursor present,

the most recent data display.

key. Others, such as Measurement Name and Eunits fields may have many

scrolls through each allowed entry. The

closes open menus in reverse order and returns the LCD to

or

places a cursor over the item and

keys indicates the

entries toggled by pressing

key moves the cursor to

clears the cursor

2.3 Channel configuration menus

Figure 2.1 illustrates the menu tree for configuring Channel variables. These items

affect only the specific channel selected. System specific variables are in the

menu tree shown in section 2.3.

Page 15

MAN-0115 Rev A 8

Figure 2.1

2.3.1 Channel setup entry menu

The entry menu shown on the left side of Figure 2.1 allows access to all

configuration variables for the selected channel. These are Alarm 1, Alarm 2,

Ala r m 3, Data From? Linearize, Configure and Calibrate.

Page 16

9

MAN-0115 Rev A

Setpoint

Latching

YES

Alarm Reset

YES

NO

TRIP ON

HIGH

LOW

ON DELAY / OFF DELAY

OFF

ON

OFF

Note:

ON DELAY

OFF

Alarm Reset

2.3.2 Alarm 1 / Alarm 2 / Horn Relay Setup menu

Alarms 1 and 2 are identical except A1 may not be acknowledged and front panel

LED indicators are yellow while A2’s are red. Since their configuration menus are

the same only one is shown in Figure 2.2 for clarity.

Figure 2.2

The first entry determines the

engineering units. For example, if a channel monitors 0-50 ppmH2S and the

alarm must trip at 10 ppm, the correct entry is 10.00.

•

•

• The

even though an alarm condition no longer exists.

alarm group’s common relay, front panel LED, and optional discrete relay

to latch.

soon as the alarm condition clears.

to determine if the alarm activates upon exceeding or falling below the

setpoint.

affecting how long the setpoint must be surpassed before an alarm event

transition occurs.

may be as long as 120 minutes. Delays are useful in many applications to

prevent nuisance alarms and unwanted cycling into and out of alarm

conditions.

For

determines either manual or automatic alarm reset operation.

requires a manual

allows all outputs for this alarm to automatically reset as

is set to

the alarm is activated after the ‘set time’ is reached. For

for increasing alarms or

delays are limited to 10 seconds while

value where the alarm trips. It is entered in

(see Figure 1) to unlatch the alarm

entries allow ON and

also causes this

for decreasing alarms

time delays

delays

DELAY the alarm remains activated for the duration of the ‘set

time’, after the alarm condition has passed.

• The HORN ON entry allows linking this alarm to the common horn relay.

NO causes the alarm to have no effect upon the horn relay. Entering YES

causes this alarm to turn the horn relay on steady, or, to pulse it

depending upon horn configuration in the system menu (see section

2.3.3).

Discrete LED indicators on the front panel indicate the status of each alarm and

relay. Any new alarm event causes the associated LED to flash until

Page 17

MAN-0115 Rev A 10

occurs causing an acknowledged steady on condition. Operators should recognize

Alarm Reset

RESISTIVE

Example:

This Option Board is

however not used at this time.

Note

EDIT

!

new alarms by a flashing LED.

horn relay until another new alarm occurs.

also acknowledges, or deactivates, the

All relays are rated at 5 Amp for 28 VDC and 250 ~VAC

loads. IMPORTANT: Appropriate diode (DC loads) or MOV (AC loads)

snubber devices must be installed with inductive loads to prevent RFI

noise spikes. Relay wiring should be kept separate from low level signal wiring.

2.3.3 Alarm 3 / Fault Alarm menu

The discrete channel alarms identified as Alarm 3/Fault may be configured either

rd

level alarm, or, as a Fault alarm indicating the input is out of range in the

as a 3

negative direction. When used as a level alarm, features such as on / off delays,

latching, and trip direction are also available. It is important to understand that

though discrete channel alarms (LED’s & optional discrete relays) may be set as

Alarm 3 level alarms, the common relay for this group is always a Fault alarm. The

fault out of range threshold for the channel is the most recent Fault trip point

entered prior to changing the menu to Alarm 3. The following example describes

how to configure both the Fault out of range and Alarm 3 level trip points for a

channel.

negative 10% of full scale, and, the discrete alarms trip as the input exceeds a

level, then the –10% Fault setpoint must be entered first. Toggle the TYPE menu

entry to FAULT and enter –10.00% into the setpoint entry. Next, toggle the menu

back to LEVEL and enter the desired Alarm 3 level setpoint. The -10% Fault value

is retained in memory even though it no longer appears on the menu.

If the common Fault relay must trip as the input falls below

Figure 2.3

2.3.4 Data from? menu to set input source

Channels may be independently configured to accept input data from the

following sources (also see Figure 2.4):

• An analog input PCB attached to the I

• A sensor input PCB may be attached to the I

• The Modbus RS-485 master port connected to modbus slave devices.

: Each Modbus menu selection also requests the RTU # and the Alias

register # location of the data to be retrieved from the RTU. Alias register

numbers define the location of the variable representing the input value

and must be obtained from the manufacturer of the Modbus RTU device.

toggles the Data From: entry between Analog, Analog with Local Cal and

Modbus RTU (signed, unsigned & floating point).

2

C bus.

2

C bus.

Page 18

11

MAN-0115 Rev A

Analog Input

calibrated

Sensor

Direct

Analog Input with Local Cal

Sensor

Direct

or

Analog Input with Local Cal

Analog

Input with Local Cal

.

Sensor Direct

*

*

transmitter or monitoring device with a

should be selected when the channel’s input comes from a

is identical to

output such as 4-20mA.

and both activate the SafeGuard

Controller’s Cal Mode features. Problems may arise if calibrations are performed in

two places upon the same signal so Cal Mode menus are only visible when

is selected. These applications would require

the SafeGuard Controller to be used as the calibration point; when calibration

transmitter and sensor configuration at the SafeGuard Controller, select

SafeGuard Controller at this time, hence

Note that gas sensors are not connected directly to the

is not used.

Direct Gas Sensor inputs

are not used at this time *

The Wireless Option and features

are not used at this time *

Figure 2.4

2.3.5 Min / Max Raw counts entries

The Min Raw and Max Raw counts entries included in Input Data From: menus

define the range of input counts that provide Measurement Range read-out values

described in section 2.2.6b. This menu entry is determined by the A/D converter

resolution of the channel’s input. For example, if the input is a 10 bit Modbus®

device with zero at 200 counts and 100% at 1000 counts, then this menu’s MIN

should be set at 200 and MAX at 1000. If communicating with the SafeGuard

Controller’s optional 12 bit Analog Input PCB the MIN should be 800 and the MAX

4000.

If the input device’s resolution is unknown, the live counts variable on the bottom

of the screen displays actual raw A/D counts currently being read by this channel.

This reading may be used to test the input device for what A/D counts are

provided for zero and 100% if these values are unknown. Forcing the input device

to read zero should provide the A/D counts value needed to make this channel’s

display also read zero. Likewise, forcing the input device to read 100% should

provide the A/D counts value needed to make the SafeGuard channel’s display

also read 100%.

If Modbus 32 BIT is selected, a Byte Order entry appears at the bottom of the

menu. This determines WORD and BYTE alignment of data at the remote Modbus

transmitter when sending its 4 byte IEEE Floating Point values. With the pointer

on this entry, the EDIT key toggles between the 4 possible modes. Min / Max Raw

values are not used in this mode.

Page 19

MAN-0115 Rev A 12

Note: Each Data From: item has a matching default Min/Max counts value of 20%

Marker Enabled

Marker %

Net Safety Flame Detectors the current output

for a visual integrity fault is 2.0 mA this corresponds to a Marker % of -

12.5%. For Net Safety Gas Sensor Fault Condition, the current output is

2.5 mA which would correspond to a Marker % of approximately -9.4 %.

Mark As

Sensor Life

Sensor Life

Sensor Life

Sensor Life

to 100% with ± 5% over/under range applied. If the default value is incorrect for

the input device it should be edited.

2.3.6 Marker menus

Some transmitters or monitoring devices providing SafeGuard Controller inputs

also indicate special modes of operation, such as Calibration, Maintenance or Fault,

by transmitting a special <4mA or negative “Marker” value. The SafeGuard

Controller offers channel Marker menus for detecting and indicating such events

(see Figure 2.5). While active, the SafeGuard Controller displays a 6-digit ASCII

message to indicate the special event and if equipped with SG10-0167 4-20mA

output option, the SafeGuard Controller also transmits the same <4mA value

.

•

• The negative Marker value is entered into the

• It should be noted that for

• The

Figure 2.5

percent of full scale. For example, -15.62% of full scale detects a marker

value of 1.5mA (1.5mA is -15.62% of full scale when 4-20mA is the range).

displayed when the marker is detected.

turns the marker feature ON and OFF

menu allows user entry of the 6-digit ASCII message to be

field as a negative

2.3.7 Sensor Life detection (- this feature is not used at

this time)

when a sensor life value is transmitted after each calibration. For

record properly the monitor must perform as follows: After the Calibration Marker

interval, 4.0mA transmits for 10 seconds to indicate its calibration mode is

complete. The monitor then transmits between 4.0mA and 5.0mA for five

seconds depending on remaining sensor life where 4.0mA = 0% and 5.0mA = 100%

remaining sensor life. The SafeGuard Controller reads this value and records it as

the channel’s

modbus database and displayed as a bar-graph in the Sensor Info screen (see

section 2.3.6). It is a useful tool for planning sensor replacement schedules.

should only be activated when the Marker event is Calibration and

.

is stored in the SafeGuard Controller’s

to

Page 20

13

MAN-0115 Rev A

EDIT

NEXT

Entry menu

Ch a n n e l XX

Me a s u r e me n t Na me

Linearization menu

Ch a n n e l XX

L i n e a r i z a t i o n

%I n p u t

%Ou t p u t

10 . 0 0

2 0 . 0 0

3 0 . 0 0

4 0 . 0 0

5 0 . 0 0

6 0 . 0 0

7 0 . 0 0

8 0 . 0 0

9 0 . 0 0

10 . 0 0

2 0 . 0 0

3 0 . 0 0

4 0 . 0 0

5 0 . 0 0

6 0 . 0 0

7 0 . 0 0

8 0 . 0 0

9 0 . 0 0

Al a r m 1

Al a r m 2

Al a r m 3

Da t a F r o m

Ca l i b r a t e

L i n e a r i z e

Co n f i g u r e

Entry menu

Ch a n n e l X X

Me a s u r e me n t Na me

Al a r m 1

Al a r m 2

Al a r m 3

Da t a F r o m

Ca l i b r a t e

L i n e a r i z e

Co n f i g u r e

EDIT

NEXT

Input / Copy To: menu

Ch a n n e l X X

CON F I GU R A T I ON

Me a s u r e me n t Na me

Eu n i t s

Z e r o

Sp a n

De c i ma l Po i n t s

P CT L EL

0 . 0 0 0

Co p y N o w ?

10 0 . 0

Ch a n n e l On ?0Y E S

Co p y T o XX

2.3.8 Linearization menu

The linearization menu allows each channel to have its own linearization curve

stored in the SafeGuard Controller’s non-volatile memory. Input versus output

points must be entered in percent of full scale values. This means if the range is 0200 ppm H2S then 100 ppm is 50% of full scale. Zero input will provide a zero

output and 100% input a 100% output. Nine intermediate points may be entered

to define the curve.

Figure 2.6

2.3.9 Configure menu

From the entry level setup menu in Figure 2.7 the CONFIGURE menu may be

entered for setting variables defining how the SafeGuard Controller presents

monitored data to the various graphic displays.

Figure 2.7

2.3.10 Eunits / Measurement Name ASCII data fields

The first two items in this menu are for entering the 6 character engineering unit

and 16 character Measurement Name ASCII fields. Eunits should define the units of

measure for what this channel is to display. Measurement Name should describe

the source of this data in the user’s terminology. Section 2.1.1 of this manual

describes how to use the front keypad to modify these fields.

2.3.11 Input measurement range

The ZERO / SPAN entries allow configuration of the measurement range

displayed by the channel. Measurement Range works along with A/D Counts

menus, described in section 2.2.4a, to define the range of the input signal’s

engineering units. For example, if a channel’s input is 4-20mA from a transmitter

monitoring 0 to 10ppm H2S, then the Zero value should equal 0.000 and the

Span value equal 10.00. The six ASCII engineering units previously entered are

Page 21

MAN-0115 Rev A 14

automatically displayed at the top of each menu as a reminder. Four digits must

0.000

100.0

0.0

100.0

0

100

Channel On?

EDIT

UP/DN

EDIT

Sensor Direct

Analog

Input with Local Cal.

Analog Input with Local Cal

EDIT

appear in this entry so trailing 0’s may appear here that are not displayed on other

data screens.

2.3.12 Decimal point resolution

Resolution of displayed channel values is configured in this menu by setting the

number digits trailing the decimal point. Values are limited to a maximum of four

digits, and a polarity sign. An auto-ranging feature displays the highest resolution

allowed by this menu’s decimal point entry. For example, if three decimal points

are entered, and the range is 0 to 100ppm, the reading will be

at 100ppm. However, this may be undesirable due to the high resolution at

zero unless the detector’s output is extremely stable. If decimal points are limited

to one, the 0ppm reading becomes

Resolution may be limited further by setting decimal points to 0. In the above

example, this would cause 0ppm to display

and the 100ppm reading remains

2.3.13 Turning off unused channels

The

will cause the SafeGuard Controller to never process inputs applied to this channel

and no alarms will be tripped or data displayed. Inactive channels have a line

drawn through them on the Setup screen as indicated by channels 15 & 16 in

Figure 2.0. If less than 9 channels are to be activated, the SafeGuard Controller

may be set for 8 channel mode, deactivating channels 9-16. This is done in the

System Setup menu described in section 2.3. The SafeGuard Controller will only

allow 15 channels to be turned off. At least one channel must remain on.

entry determines if this channel is to be utilized. Turning it off

and 100ppm to display

at 0ppm and

.

.

2.3.14 Copy Data to?

This menu simplifies the Setup procedure by allowing similar channels to be

copied from one to another. For example, if all channels are identical except for

the Measurement Name entry, channel 1 could be configured and copied to

channels 2 – 16. Only Measurement Name then must be configured on channels 2

– 16. Use

Press

to increment channel numbers and

once more to copy.

2.3.15 Cal mode

This SafeGuard Controller feature is only accessible when

used if the transmitter and sensor connected to the controller are located in an

area not easily accessible. A calibration tube should be fitted to the sensor and run

to an easy access location where a gas canister is fitted and calibration performed

using the calibration menu. It should be noted that the current output from the

SafeGuard Analog Output Board will be 1.5 mA when the device is in calibration

mode.

The CALIBRATION MENU allows entering the correct Cal ZERO & Cal SPAN setpoint values needed to calibrate the sensor. These are entered in the same

engineering units as input range. Set Zero & Set Span controls in this menu

allow pushbutton calibration by moving the pointer to each and pressing the

key. A live reading of the channel’s value allows calibration checks to see if an

adjustment is needed. Unintentional calibrations are reset by the Unity Gain

is selected. The

to point to Copy Now?

or

. option may be

Page 22

15

MAN-0115 Rev A

EDIT

EDIT

EDIT

EDIT

menu item. Unity Gain resets zero offset to 0 and span gain to 1. It is useful for

returning the calibration to a known starting place. Sensor aging may be

monitored by recording zero and span readings at Unity Gain when it is new, and

again at later dates when degradation may have occurred.

To check zero calibration, apply the ZERO calibration value to the sensor and

observe the live reading. If the zero reading differs from the zero setpoint, a

calibration is needed. To calibrate zero, move the pointer to Set Zero and press

. A warning message explains that pressing

calibration and any other key will exit. The procedure for span calibration is

identical. For example, if an LEL combustible sensor is to be spanned with 50% LEL

span gas, the span set-point must be 50%. If 45% LEL is to be used later, the span

set-point must be changed to 45% to match the span calibration gas. If the

reading is only 40% LEL with the 50% gas applied a span calibration is needed.

Move the pointer to the Set Span entry and press

used at anytime to cancel incorrect calibrations and start again. See Figure 2.8.

again will change the zero

twice. Unity Gain may be

Figure 2.8

2.4 System configuration menus

Some items needing configuration are not specific to a channel but affect the

entire SafeGuard Controller system. These are located in the system entry menu

shown on the left side of Figure 2.9. System menus are accessed by pointing to

the desired item and pressing

.

Page 23

MAN-0115 Rev A 16

READ THIS SECTION CAREFULLY AND TEST ALL SETTINGS BY

SIMULATING INPUT CONDITIONS THAT SHOULD ACTIVATE THESE

ALARM RELAYS!

!

Figure 2.9

2.4.1 Common Alarm Relays 1 and 2

Common Relay 1 & Common Relay 2 menus are identical and therefore

discussed only once. It is very important to fully understand these menus since

they determine the functions of each common relay.

Page 24

17

MAN-0115 Rev A

Group

1-16, 1-

8

9-16

Group

Failsafe

Failsafe ON

A1 and A2 Votes

A1 Votes = 01

A2 Votes = 00

A1 Votes = 00

A2 Votes = 01

A1 Votes = 02

A2 Votes = 01,

Group

Acknowledge ON

Alarm Reset

RESISTIVE

Figure 2.10

• The

channels trip this menu’s common alarm relay. The 3 choices are

or

detectors in different areas connected to the same SafeGuard Controller.

In these cases, it may be undesirable for a detector on channel 9 to trip

the same relay as a detector on channel 2. The

this. For example, channels 1-8 might be set to trip common relay 1 while

channels 9-16 trip common relay 2. Another possibility is channels 1-8 be

set to trip common relay 1 while channels 9-16 trip relays on an optional

discrete relay PCB configured for Alarm 1 (see section 3.1.2).

•

•

causes the relay to de-energize during alarm conditions and energize

when there is no alarm. Thereby, a power failure forces the relay contact

to the alarm position. Note the common Fault relay is always failsafe and

may be monitored separately to indicate loss of power conditions in many

applications.

control common relay 1 & common relay 2. Default settings for common

relay 1 are

any channel has an A1 level alarm active. Default settings for common

relay 2 are

any channel has an A2 level alarm active. Example: If either default

setting is modified such that

two channels must have an A1 level alarm active and any one channel

must have an A2 level alarm active to trip that relay. REMEMBER! One of

the A1’s and the A2 could be on the same channel. These level alarms

must come from a channel included in the

menu entry offers additional flexibility by controlling which

. Some applications have different types of detectors, or,

menus may restrict

controls relay activation for this common relay.

allows creation of logical AND function equations that

and

and

which causes relay 1 to trip if

which causes relay 2 to trip if

and

entry described above.

then any

• Turning

relay to be deactivated during alarm conditions by an

useful if an audible device is being driven by the relay.

noise spikes. Relay wiring should be kept separate from low level signal wiring.

All relays are rated at 5 Amp for 28 VDC and 250 ~VAC

loads. IMPORTANT: Appropriate diode (DC loads) or MOV (AC loads)

snubber devices must be installed with inductive loads to prevent RFI

(not available on Alarm 1) allows the common

2.4.2 SG10-0195 Discrete relay Failsafe mode

SG10-0195 Discrete relay options may also be configured to function in a Failsafe

mode using the System Setup menu shown in Figure 2.11. Entering YES causes

these discrete relays to have energized coils when no alarm condition exists for

. This is

Page 25

MAN-0115 Rev A 18

the associated channel and de-energized coils when the alarm occurs. Failsafe is

Important:

SG10-0195 zoning jumpers (see Figure 3.4) should not be used when Discrete

Relays menus are set for failsafe.

useful for indicating failed relay coils and loss of power conditions.

energize ALL other relays in the same zone. Zoning of failsafe relays may be

accomplished with wiring at the relay contact terminals.

Figure 2.11

Zoning jumpers cause ANY relay in the zone to

2.4.3 Common horn relay and local piezo

The SafeGuard Controller is equipped with a low decibel audible piezo which

chirps when keys are pressed and may be configured to audibly indicate alarm

conditions. The common horn relay is similar to the common A1 & A2 common

relays.

Figure 2.12

• Turning Piezo Alarm ON causes the audible piezo to duplicate the

action of the horn relay. This feature may be used to provide a low

decibel indication of the status of the system’s horn.

• Alarm 1 & Alarm 2 menus control how the alarm level from each

channel will affect the common horn relay. Choices are OFF, ON or

BEEP (one Hz. Pulsating). As an example, A2 conditions might pulse the

horn (BEEP) and A1 conditions cause a steady horn (ON). Any other

combination of these 3 choices is possible for A1 and A2 levels affecting

the horn relay. This feature is very useful since it allows the horn relay to

serve as another level A1, level A2, or both; for channels 1-16, 1-8 or 9-16.

Individual channel alarms may also be configured to not affect the Horn

relay on a channel by channel basis (see section 2.2.2).

• Failsafe & Horn Group menu entries are identical to the descriptions

for menus Common Relay 1 & Common Relay 2 in section 2.3.1.

Page 26

19

MAN-0115 Rev A

Slave ID

Slave Baud

Parity

UART Timer

UART Timer

Mastr TO

Mastr PR

• Turning Acknowledge OFF allows the common Horn relay to drive

devices other than horns or sirens such as a light or a fan.

• Display Alm YES forces the LCD to display the Bar Graphs screen upon

any new alarm. This feature is offered to satisfy applications requiring

channels in alarm to be displayed automatically (all channels are

displayed on the Bar Graphs screen).

2.4.4 Comm Port menus

The system Comm Port menu allows setting RTU

and

rate,

master port ID settings are per channel as described in section 2.2.4). This slave

port may be used to transfer the SafeGuard Controller data to a host device such

as a PC, PLC, DCS or even another SafeGuard Controller. The slave port is

addressable, allowing many SafeGuard Controllers to be connected to a single RS485 cable. The

a value causes the comm2 slave Modbus serial port to reinitialize if no modbus

query is processed within this time period. This ensures against serial port lockup.

Section 5 of this manual provides important information describing how to

interface to the SafeGuard Controller’s Modbus slave port.

for the comm2 slave Modbus serial port (comm1

setting is disabled with 00 seconds entered. Entering

address,

The

the SafeGuard Controller’s master Modbus port. Time out sets length of time in

milliseconds before a communications error. Three consecutive timeout errors

must occur before a communication error is indicated. This item is useful for

optimizing throughput to the SafeGuard Controller from other slave RTU’s. Poll

Rate sets frequency of data requests to the RTU’s in milliseconds. This is useful

when an RTU is limited in how fast it may respond to consecutive data requests.

(master time out) and

(master poll rate) menu items affect

Figure 2.13

2.4.5 Eight / sixteen channel modes

The system menu allows setting the SafeGuard Controller to accept either 8, or,

16 channels. If 8 channels are selected by this menu they are channels 1-8 and 916 are disabled. One way the SafeGuard Controller cost is kept low is Input /

Output option PCB’s are arranged into groups of 8 channels. Therefore, users with

less than 9 channels require only 1 PCB and do not pay for I/O hardware for 16

channels. If more than 8 channels are needed a second I/O option PCB may be

required.

Page 27

MAN-0115 Rev A 20

Sensor Info

Sensor Life

Marker

Sensor Info

Sensor Life

Option Disabled

Sensor Life

Cal Required

Cal Required

AUTHORIZATION

Locked

Enter Code

Unlock System

EDIT

Figure 2.14

2.4.6 Sensor Information (this feature is not used at this

time)

sensor status as illustrated in Figure 2.15. Channels with

indicate

is enabled, the channel will have its Measurement Name above the bar, or, an

empty bar with a

value has been received by the SafeGuard Controller.

is available when at least one channel has

menu (see section 2.2.4b). The

above the corresponding empty bar-graph. If

label.

screen displays each channel’s

indicates no Calibration Marker

activated in the

disabled

Figure 2.15

2.5 Authorization mode

A password entered in the

Viewing menus is not denied but attempts to edit variables flashes the

message on the LCD.

Authorized individuals locking the system should first enter a name, phone #, or

other contact information into the 10 digit field. To lock or unlock the system the

correct 4 digit authorization number must be entered into the

Point to the

procedure.

It is very important to record the 4 digit code. However, if lost it may be displayed

briefly at power up using the following procedure:

Remove power from the SafeGuard Controller. Reapply power and as the alarm

LED's begin scrolling down, hold the following keys simultaneously "UP", "DOWN",

menu entry and press

menu allows locking all menus.

to complete the unlock

field.

Page 28

21

MAN-0115 Rev A

IMPORTANT!

Au t h o r i z a t i o n

E N T ER NA ME

E n t e r Co d e

L o c k S y s t e m

### #

CONTRAST

CONTRAST

EDIT

UP/DOWN

WARNING:

HIGH VOLTAGES SUCH AS 115 VAC APPLIED TO THESE

TERMINALS MAY CAUSE SEVERE DAMAGE!

master

slave

!

"NEXT", & "EDIT". Watch closely. The 4-digit authorization code appears briefly at

bottom left of the screen.

cold boot and returns all settings back to factory defaults.

DO NOT hold the keys before applying power since this causes a

Figure 2.16

2.6 LCD contrast adjustment

The Setup menu item identified as

contrast to a level suitable to the ambient lighting. Selecting

pressing

causes the

keys to increase and decrease LCD contrast.

allows users to adjust the LCD

Section 3: Inputs and Outputs

3.1 Main I/O interface PCB

The most basic SafeGuard Controller requires only the I/O PCB shown in Figure 3.1

for interfacing to field wiring. The SafeGuard Controller’s primary power supply is

applied to terminals 9 & 11 of TB2. This may be from 10 – 30 VDC.

DC output terminals 10 & 12 on TB2 provide up to 500mA

of output power for powering remote devices such as

lamps, transmitters etc.

and

This PCB includes both

ports, 5 amp form C relays for each common alarm event (A1, A2, FAULT/A3 &

HORN), and power supply I/O terminals. JP1 allows the RS-485 ports to be

configured for 2 or 4 wire operation. A 26 pin ribbon cable connects the I/O PCB

to the SafeGuard Controller’s CPU and Display nest assembly. Two I

connectors allow addition of optional functions such as analog I/O and discrete

alarm relays for each channel.

Horizontal jumpers installed in JP1 connect the RS-485 port’s RX & TX lines,

simplifying 2 wire daisy chains by providing additional terminals for incoming and

outgoing cables. For example, installing the 2 COM 1 jumpers connects screw

(COMM 1) and

(COMM 2) RS-485 Modbus

2

C bus

Page 29

MAN-0115 Rev A 22

terminals 1 & 5 and terminals 3 & 7. Socketed RS-485 terminating resistors R6

Examples:

M2X-AD/ARD menu settings (See MAN-0076):

09600 bps

not end of path)

TB2 terminals 10 & 12 provide

Aux. Relay piggy

(COMM 1) and R12 (COMM 2) are located on the MAIN I/O board. These resistors

should be removed if communication wire lengths are very short (less than 25

feet), or, if the port is not at the end of the communication line.

An Auxiliary Relays piggyback PCB may be added to the I/O PCB via ribbon cable J4.

These add another form C contact set to the common A1, A2 and HORN alarms.

Auxiliary Relay contacts are available at the TB1 (AUX) terminals shown in Figure

3.1.

back Board shown

in dotted lines

RS-485 terminating resistors

(remove for short wire paths &

when the SafeGuard Controller is

Fused 24VDC power to the

SafeGuard Controller option

boards requiring such power

Figure 3.1

3.1.1 Modbus Communication between SafeGuard and

Digital Millennium II Series Transmitters.

Refer to MAN-0076 prior to attempting setup. Power up the unit and enter the

transmitter Modbus menu option, (‘Modbus Setup’).

Select address 001 or the desired address for each unit.

Choose Baud Rate of

.

Page 30

23

MAN-0115 Rev A

M2B-D DIP Switch settings (See MAN-0082):

9600 bps

Connection between the Digital Millennium II Transmitter series and

SafeGuard:

SafeGuard settings:

Note:

'Data From',

Select ‘NO’ under parity. Note that the unit will retain its settings if power is

removed.

1. Refer to MAN-0082 prior to setup. Select the desired address for the

device. Example: DIP Switch 1 positions 1, 2, 3, 4 “ON”. This corresponds

to a Modbus Address of 1. Refer to MAN-0082.

2. Set DIP Switch 2 position 1 “OFF” and position 2 “ON”. This corresponds

to a Baud Rate of

3. Set DIP Switch 2 positions 3 and 4 in “OFF”. This allows 8 data bits, no

parity bit, 2 stop bits (also compatible to 1 stop bit)

.

1. Prior to connection, ensure that the SafeGuard and the transmitter are

not powered up.

2. Check to make sure the Millennium II Sensor is properly connected to the

Millennium II Transmitter.

3. Connect the transmitter power terminals to the "DC Out" TB2 terminals

(terminals 10 and 12) on the SafeGuard. Take note of the SafeGuard's

positive and negative terminals at DC Out.

4. Connect the transmitter Modbus terminal "A" to the SafeGuard Master

Comm 1 terminal 1 or Master Comm 1 terminal 5 on SafeGuard.

5. Connect the transmitter Modbus terminal "B” to the SafeGuard Master

Comm 1 terminal 3 or Master Comm 1 terminal 7 on SafeGuard. Note

that the SafeGuard's Master Comm1 terminals are the top terminals 1, 3,

5, 7. See Figure 3.1.

6. Jumper the transmitter’s ‘COM’ (-VDC) terminal and the Communication

'COM' terminal (tie them together).

7. Power up the SafeGuard.

Leave Jumpers at JP1 in place for two wire RS-485 operation. See Figure 3.1.

1. Choose a Channel and

settings:

• Modbus 16 Bit

• Min raw: 00000

select

then choose the following

Page 31

MAN-0115 Rev A 24

• Max raw: 00100

System”

Comm Ports

Note:

A NA L OG

PRE S S NE X T K E Y T O E X I T

I NP U T

1- 8

F OUND

ANA L OG

I N P UT

9 - 16

F OUND

ANA L OG

OU T P U T

1- 8

F OUND

ANA L OG

OU T P U T

9 - 16

F OUND

A L AR M2

Re l a y

1- 8

F OUND

AL ARM2

I NP U T

9 - 16

F OUN D

EXC

IN LO

IN HI

• Remote ID: 01

• Alias: 40001

2. Under “

, select "

" and choose the settings as follows:

• Slave ID: 01

• Slave Baud rate: 9600

• Parity: None

• UART Timer: 155 s

• Mastr TO 0200 ms

• Mastr PR 0200 ms

• ECHO ACK OFF

Proper communication between the two devices will be confirmed by the TX1 and

RX1 LEDs.

When configuring other Net Safety products refer to specific user manual.

3.2 Input/output optional PCBs

Telephone style RJ11 connections are used to add optional 8 channel analog and

digital I/O. A screen appears briefly after power up indicating what options are

connected and for which channels. This information is also available from the

Diagnostics Mode described in Section 4.

3.2.1 Optional analog input PCB # SG10-0158

Figure 3.2

Many transmitters (detectors) have analog output signals and the 12 bit Analog

Input PCB, shown in Figure 3.3, is available to accept these. TB1, with 24 positions,

offers 3 terminals per channel for distributing power and receiving analog inputs.

These are

the power supply for powering external transmitters. Precision 100 ohm resistors

(R1 – R8) between each channel’s

and HI / LO inputs. TB2, with only two positions, is for connecting

and

terminals are socketed

Page 32

25

MAN-0115 Rev A

EXC

IN LO

EXC

IN LO

EXC / IN LO

EXC

LO

HI

EXC

HI

termination resistors for 4-20mA inputs. These may be removed if voltage inputs

are to be applied.

and

terminals are bussed together internally.

directly to TB2-1 (+) and

terminals are tied to TB2-2 (-). Bussing allows

terminals are tied

transmitter power to be brought into the system at a single point (TB2) and

distributed back out at each channel’s

terminals to simplify field

wiring. Figure 3.3 includes typical wiring to 2 & 3 wire 4-20mA transmitters.

JP1 determines if the 8 analog inputs are applied to channels 1-8 or channels 9-16.

Connecting more than 8 analog inputs requires 2 PCB’s with one’s JP1 set for

channels 1-8 and the other set for channels 9-16.

For a 3 wire transmitter (detector), the power (+) wire from the transmitter is

connected to the

) wire is connected to

20mA signal wire is connected to

terminal on the SafeGuard Analog Input Board, the power (-

terminal on the SafeGuard Analog Input Board and the 4-

terminal on the SafeGuard Analog Input

Board .

For a 2 wire transmitter (detector), the power (+) wire is connected to the

terminal on the SafeGuard Analog Input Board, and the 4-20mA signal wire is

connected to

terminal on the SafeGuard Analog Input Board. See Figure 3.3

Page 33

MAN-0115 Rev A 26

R2

R1

ANALOG INPUTS

R3

R4

R7

R6

R5

+EXC-

DC PWR

TB2

R8

JP1

ST-71 ANALOG INPUT BOARD

0010-1115 ASSY# 10-0158

J2

J1

J1 & J2 are interchangable I2C

connectors used to add option

PCB assemblies to the ST-71.

JP1 determines if this 8 channel

Analog Input PCB provides inputs

for CH’s 1-8 or 9-16. 2 PCB

assemblies are required for 16

channels.

Socketed precision resistors R1-R8

are 100 ohm terminations for 4-20mA

inputs. 0-2 VDC voltage inputs may

be accepted by removing resistor.

TB2 is for powering bulk power to transmitters

or other powered input devices. EXC+ is

wired internally to channel “EXC’s” and EXCto channel “LO’s”.

CH1/9

EXC HI

CH7/15

HIEXC

CH3/11

EXC LOHILO

CH5/13

LOHI EXC LO

CH2/10

HIEXC

CH8/16CH4/12

EXC LOHILO EXC

CH6/14

EXC LOHI LOHI

8 Channel Analog Input Option #10-0158

EXC LOHI

2 Wire 4-20mA

Transmitter

+Pwr

Sig

3 Wire 4-20mA

Transmitter

EXC LOHI

+Pwr

Sig

Com

Typical 2 & 3 wire 4-20mA

transmitter wiring (connect

correct power, 24VDC or

other, to TB2).

CH # (1-8) CH # (1-8)

Controller.

PART # SG10-0158 SafeGuard

Analog Input board.

J1 & J2 are interchangeable I2C

connectors used to add option PCB

assemblies to the SafeGuard

3.2.2 Optional discrete relay PCB # SG10-0195

8 channel Analog Input Board Part # SG10-0158

Figure 3.3

An optional Discrete Relay PCB, shown in Figure 3.4, adds eight 5 amp (resistive)

form C relays per sixteen channel alarm group (2 PCB’s required when utilizing

more than 8 channels). Each PCB may be configured via rotary switch S1 to

function for ALARM 1, ALARM 2 or ALARM 3/FAULT for channels 1-8 or 9-16. A

one (1)-minute time delay after power, is provided to inhibit relay actuation until

the system has had time to stabilize. Alarm groups, or zones, may be created by

connecting adjacent channels together using JP4 as shown. This creates a wire OR

function with selected channels, causing any alarm included within the zone to

actuate ALL zone relays. Failsafe operation of SG10-0195 discrete relays may be

programmed in the system menu as described in section 2.3.2. Many SafeGuard

Page 34

27

MAN-0115 Rev A

RESISTIVE

8 Channel Discrete Relay Option #10-0195

!

Controller applications utilize the common alarm relays (see section 3.0) and do

not require discrete relays for each of the 48 alarm events (16 A1’s, 16 A2’s & 16

A3’s). If discrete relays are needed for all 48 alarms, then six PCB’s are required.

5 VDC power to the discrete relay option PCB’s is normally supplied from the

SafeGuard Controller via the slender I

2

C cables are limited in ability to carry this power further than a few feet without a

I

significant voltage drop. Some SafeGuard Controller applications with relays for

all 48 alarms may require up to 6 boards. TB2 allows a heavier 5VDC power cable

to be connected from terminals on the back of the SafeGuard Controller front

panel assembly, bypassing the I

the several TB2’s is sufficient when these boards are in close proximity to each

other.

TB2 is used to supply external

5VDC power to Alarm boards

when they are mounted > 5

feet from the controller. I2C

cables provide 5VDC but losses

occur with longer cable lengths.

WARNING: Voltages exceeding

6 volts may cause extensive

damage to entire controller.

Standard configuration has a 1

minute POWER ON time delay

preventing relay actuation during

the delay. SB1 increases delay

time to 8-minutes. SB2 removes

all time delay.

2

C cables connected to J2 and J3. However,

2

C cable. A 20AWG pair connected to only one of

All relays are rated at 5 Amp for 28 VDC and 250 ~VAC

IMPORTANT: Appropriate diode (DC loads) or MOV (AC loads) snubber

devices must be installed with inductive loads to prevent RFI noise

spikes. Relay wiring should be kept separate from low level signal

wiring.

S1 controls if discrete relays are tripped by

A1, A2, or A3 alarms for Ch’s 1-8 or 9-16.

See Chart.

0

J2

S1

U1

J3

U2

ZONE

JUMPERS

vertically

to create

Ch. zones

8-CH CHART

S1-2=Ch9-16 A1

S1-3=Ch9-16 A2

S1-4=Ch9-16 A3

S1-5=Ch1-8 A1

S1-6=Ch1-8 A2

S1-7=Ch1-8 A3

JP4

Install

J2 & J3 are interchangable I2C

connectors used to add

PCB assemblies to the controller.

JP4 allows “zoning” of adjacent

Ch1

channel alarms. All zoning jumpers

Ch2

Ch3

are placed vertically. Dwg. exhibits

Ch4

channels 1-4 and channels 5-7

Ch5

creating 2 zones. All relays in a zone

Ch6

switch together. Unused jumpers

Ch7

Ch8

may be stored horizontally.

option

Wire TO CPU

5VDC if > 5’

from controller

5VDC ONLY!

+

-

TB2

Q2

ASSY# 10-0195 8-CH DISCRETE RELAY

WITH 8 RELAYS:

S1 selects Ch’s 1-8

or 9-16 for A1, A2 &

A3 (Flt) See chart--->

U3

SB2

SB1

loads.

NCNO C NO NCC NO NO CNCC NC

CH1/9 CH3/11 CH7/15CH5/13

NCNO C NO NCC NO NO CNCC NC

CH2/10 CH4/12 CH8/16CH6/14

5 amp form C dry contacts. Contacts are unfused. Switching

inductive loads may create high levels of RFI. Use appropriate

“RFI Snubbers” on inductive load devices.

TB1

Figure 3.4

Page 35

MAN-0115 Rev A 28

3.2.3 Optional 4-20mA analog output board # SG10-

TB1

Q4

Q6

Q2

Q10

Q12

Q8

D2

Q16

Q14

HIHI HIHI HI HI HIHI

U11

ST-71 mA OUTPUT BOARD

Q1

LO LO LOLO

LO LOLO LO

Q5

Q3

Q7

PCB # 0010-1121

Assy # 10-0167

C3

High's

Milliamp

Low's

Outputs

Rev 0

CR1

C6

R26

C7

U9

Q13

Q11

Q9

C4

C1

J2

C2

J1

D1

U8

Q15

U10

TP1

Q17

J1 & J2 are interchangable I2C

connectors used to add option

PCB assemblies to the ST-71.

8 Channel 4-20mA Output Option #10-0167

JP1 determines if this 8 channel

Analog Output PCB provides

outputs for CH’s 1-8 or 9-16.

2 PCB assemblies are required

for 16 channels.

Ref. Adj. allows trimming voltage

on TP1. 2.048 volts provides

20mA (

+1%) outputs with 100%

of full scale readings.

-+

Connect to

“DC OUT”

on I/O PCB

24 VDC

INPUT

24 VDC power for output

current loops must be

supplied through TB2.

Connect to main I/O PCB

terminals 10 & 12 of TB2.

TB2

J1 & J2 are interchangeable I2C

Controller.

0167

An optional 10 bit 4-20mA analog output board, shown in Figure 3.5, may be

connected to the I

and 20mA for 100% readings. Loop drive capability depends upon the level of the

SafeGuard Controller’s primary DC power supply. With at least 20 volts DC

primary power they are capable of driving 20mA through a 750 ohm load.

Outputs are self powered and DC power should not be provided by the receiving

device. Note: This PCB requires nominal 24VDC power be connected to TB2

terminals 1 & 2 as shown in Figure 3.5. Suitable power is available from the

SafeGuard Controller’s Main I/O board’s TB2 terminal 10 & 12 (see Figure 3.1). The

current loop (Milliamp output) is completed between High and Low Terminals.

Note that the Low Terminal is the negative end (common) of the loop.

Since the PCB has 8 channels, two PCBs are required for 16 channel applications.

JP1 configures the outputs for channels groups 1-8 or 9-16. Also see 2.2.4b Marker

Menu to configure the SafeGuard Controller for current output for a fault

condition of a detector or transmitter and gas sensor configuration.

2

C bus. Each channel’s output will transmit 4mA for 0% readings

connectors used to add option PCB

assemblies to the SafeGuard

Figure 3.5

Channel 4-20 mA Output Board Part # SG10-0167

SafeGuard mA Output

Board. Assy# 10-0167

PCB#0010-1121 Rev 0

Page 36

29

MAN-0115 Rev A

3.2.4 Optional 24VDC 150 watt power supply

The SafeGuard Controller may be powered from 10-30VDC. However, many

applications require 24VDC power for the monitors or transmitters providing

inputs to the SafeGuard Controller. A 150 watt AC / DC power supply may be

included for these applications (115VAC or 230 VAC selected via slide switch).

When ordered from the factory, it is pre-wired to provide 24VDC primary power

for the SafeGuard Controller as well as any transmitters or monitors that may be

connected by the end user.

150 Watt 24 VDC Power Supply Option # SG10-0172

Figure 3.6

Page 37

MAN-0115 Rev A 30

Section 4: System diagnostics

NEXT

CHANNEL

INPUT DATA IS NOT PROCESSED DURING THE DIAGNOSTICS MODE

!

!

A System Diagnostic Mode shown in Figures 4.1 and 4.2 may be entered during

normal operation from the Setup menu. The entry menu indicates firmware

revision and offers useful routines for testing front panel LED’s, relays, serial ports

and analog I/O. It is exited manually by pressing

keys are pressed for 5 minutes. It is very important to understand that

to miss important input values while utilizing this mode and appropriate

safeguards should be in place. However, the Diagnostics Mode can prove

invaluable when testing I/O since relays and analog outputs may be stimulated

without driving inputs to precise levels.

and automatically if no

. It is possible

Figure 4.1

Page 38

31

MAN-0115 Rev A

* Note: The Printer Option is not

used at this time.*

Figure 4.2

Page 39

MAN-0115 Rev A 32

Section 5: Modbus

Channel Tag

12

40489

40496

3

n/a

2 characters per register

5.1 Modbus RS-485 ports

The SafeGuard Controller is equipped with Master (COMM 1), and Slave (COMM 2),

modbus RTU ports. Port configurations are described in sections 2.2 and 2.3 of

this manual. Section 5.0 defines register locations of data available via the

SafeGuard Controller’s slave port.

5.2 Modbus slave register locations

The following tables describe the SafeGuard Controller’s modbus slave database.

Any portion of this data may be read by a modbus master device such as a PC, PLC

or DCS. Since the modbus port is RS-485, many SafeGuard Controllers may be

multi-dropped onto the same cable.

Memory Integer ASCII:

Notes: ASCII may be read 2 characters at a time or in strings using a multiple register read.

Sixteen character channel tag name

Type Channel First Last Read FC

Channel Tag 1 40401 40408 3 n/a 2 characters per register

Channel Tag 2 40409 40416 3 n/a 2 characters per register

Channel Tag 3 40417 40424 3 n/a 2 characters per register

Channel Tag 4 40425 40432 3 n/a 2 characters per register

Channel Tag 5 40433 40440 3 n/a 2 characters per register

Channel Tag 6 40441 40448 3 n/a 2 characters per register

Channel Tag 7 40449 40456 3 n/a 2 characters per register

Channel Tag 8 40457 40464 3 n/a 2 characters per register

Channel Tag 9 40465 40472 3 n/a 2 characters per register

Channel Tag 10 40473 40480 3 n/a 2 characters per register

Channel Tag 11

Channel Tag 13 40497 40504 3 n/a 2 characters per register

40481 40488 3 n/a 2 characters per register

Write

FC

Notes

Channel Tag 14 40505 40512 3 n/a 2 characters per register

Channel Tag 15 40513 40520 3 n/a 2 characters per register

Channel Tag 16 40521 40528 3 n/a 2 characters per register

Page 40

33

MAN-0115 Rev A

EUNITS

6

40544

40546 3 n/a

2 characters per register; 3 registers per channel

Six character Eunits Tag

Type Channel First Last Read FC Write FC Notes

EUNITS 1 40529 40531 3 n/a 2 characters per register; 3 registers per channel

EUNITS 2 40532 40534 3 n/a 2 characters per register; 3 registers per channel

EUNITS 3 40535 40537 3 n/a 2 characters per register; 3 registers per channel

EUNITS 4 40538 40540 3 n/a 2 characters per register; 3 registers per channel

EUNITS 5 40541 40543 3 n/a 2 characters per register; 3 registers per channel

EUNITS 7 40547 40549 3 n/a 2 characters per register; 3 registers per channel

EUNITS 8 40550 40552 3 n/a 2 characters per register; 3 registers per channel

EUNITS 9 40553 40555 3 n/a 2 characters per register; 3 registers per channel