Page 1

Reference Manual

Millennium II Basic Transmitter

Part Number: MAN-0082, rev. 08

Release: June 2016

Page 2

Page 3

Important Instructions

Installing, operating or maintaining a Net Safety Product improperly could lead to serious injury or

death from explosion or exposure to dangerous substances. Comply with all information on the

product, in this manual, and in any local and national codes that apply to the product. Do not allow

untrained per sonnel to work with this product. U se Net Safety part s and work procedur e s specified in

this manual.

Net Safety Monitoring, Inc (Net Safety) designs, manufactures and test s pr o d ucts to function within

specific conditio ns. Be c ause these products ar e sophisticated technical instrumen ts, i t is important

that the owner and operation personnel must strictly adhere both to the information printed on the

product nameplate and to all instructions provided in this manual prior to installation, operation, and

maintenance.

Page 4

Notice

The contents of this publication are presented for informational purposes only, and while every effort

has been made to ensure t heir accuracy, they are not to be construed as warranties or guarant e e s,

expressed or implied, regarding the products or services described herein or their use or applicability.

All sales are governed by Net Safety’s terms and conditions, which are available upon request. We

reserve the right to modify or improve the designs or specifications of such products at any time .

Net Safety does not assume responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use and maintenance of any Net Safety products remains solely with

the purchaser and end-user.

To the best of Net Safety’s knowledge the information herein is complete and accurate. Net Safety

makes no warranties, expressed or implied, including implied warranties of merchantability and fitness

for a particular purpo se wi th respect to this manu al an d, in no event, shall Net Safety be liable for any

incidental, punitive, special or consequential damages including, but not limited to, loss of production,

loss of profits, loss of revenue or use and costs incurred including without limitation for capital, fuel and

power, and claims o f third parties.

Product names used herein are for manufacturer or supplier identification only and may be

trademarks/registered trademarks of these companies.

Net Safety and the Net Saf ety logo are reg i ste r e d t r ade marks of Net Safety Monitoring, Inc. The

Emerson logo is a trademark and service mar k o f the Emerson Electric Company.

Copyright © 2016 by R o se mount, Shakopee, M N .

All rights reserved. No part of this work may be reproduced or copied in any form or by any means - graphic,

electronic, or mechanical without first re c e iving written pe rmission of Rosemount, Sha k opee, MN.

Page 5

Warranty

Limited Warranty

Resale Products

Limitation of Remedy and Liability

1.

and Liability) herei n, Se l l e r warrants that (a) the licensed firmware embodied in the Goods will

execute the programming instructions provided by Seller; (b) that the Goods manufactured by

Seller will be free from defects in materials or workmanship under normal us e and ca re; and (c)

Services will be performed by trained personnel using proper equipment and instrumentation

for the particular Service provided. The foregoing warranties will apply until the expiration of

the applicable warranty period. Sensors and d et ectors are warrante d ag ainst defectiv e parts

and workmanship for 24 m onths from the date of pur chase and other electr onic assemblies fo r

36 months from the date of purchase. Products purchased by Seller from a third party for

resale to Buyer (

manufacturer. Buyer ag r e es that Seller has no liab ility for Resale Products b e y o n d making a

reasonable commercial effort to arrange for procurement and shipping of the Resale Products.

If Buyer discovers any warranty defects and no t i fies Seller thereof in writing during the

applicable warranty period, Seller shall, at its option, (i) correct any errors that are found by

Seller in the firmware or Services; (ii) repair or replace FOB point of manufacture that portion of

the Goods found by Seller to be defective; or (iii) refund the purchase price of the defective

portion of the Goods/Services. All replacements or repairs necessitated by inadequate

maintenance; normal we ar and usage; unsuitable power sources or environmental c o nditions;

accident; misuse; improper installation; modification; repair; use of unauthorized replacement

parts; storage or handl i n g; or any other cause not the f ault of Seller, are not covered by this

limited warranty and shall be replaced or repaired at Buyer’s sole expense and Seller s hal l not

be obligated to pay any costs or charges incurred by Buyer or any other party except as may be

agreed upon in writing in advance by Seller. All costs of dismantling, reinstallation, freight and

the time and expenses of Seller’s per so nn el and representativ e s for site travel and dia g no sis

under this limited warranty clause shall be borne by Buyer unless accepted in writing by Seller.

Goods repaired and p ar ts r eplaced by Seller d ur i n g t he warranty period shal l be in warranty for

the remainder of the original warranty period or 90 days, whichever is longer. This limited

warranty is the only warranty made by Selle r and c an b e amended only in a wr i ting signed by an

authorized representative of Seller. The li mited warranty herein ceases to be effective i f Buyer

fails to operate and use the Goods sold hereunde r i n a safe and reasonable manner and in

accordance with any wr i t ten instructions from t he m anufacturers. THE WARRANTIES AND

REMEDIES SET FORTH ABOVE ARE EXCLUSIVE. THERE ARE NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND, EXP R ESS OR IMPLIED, AS TO MERCHAN T ABILITY, FITNESS FOR

PARTICULAR PURPOSE OR ANY OTHER MATTER WITH RESPEC T TO ANY OF THE GOODS OR

SERVICES.

. Subject to the limitations contained in Section 10 (Limitation of Remedy

) shall carry only the warr an ty e xtended by the original

2.

DELAY IN PERFORMANCE. T HE REM EDIES OF BUYER SET FORTH IN T HE AGREEMENT ARE

EXCLUSIVE. IN NO EVENT, REGARDLESS OF THE FORM OF T HE C LAI M OR C AUSE OF ACTION

(WHETHER BASED IN CONTRACT, INFRINGEMENT, NEGLIGENC E, STRIC T L IABILITY, OTHER

TORT OR OTHERWISE), SHALL SELLER’S LIABILITY TO BUYER AND/OR BUYER’S CUSTOMERS

EXCEED THE PRICE TO BUYER OF THE SPECIFIC GOODS M AN UF AC TURED OR SERVICES

PROVIDED BY SELLER GIVING RISE TO THE CLAIM OR CAUSE OF ACTION. BUYER AGREES THAT

IN NO EVENT SHALL SELLER’S LIABILITY TO BUYER AND/OR BUYER’S CUSTOMERS EXTEND TO

INCLUDE INCIDENTAL, CONSEQUENTIAL OR PUNITI VE DAMAGES. THE TERM

“CONSEQUENTIAL DAMAGES” SHALL INCLUDE, BUT NOT BE LIMITED TO, LOSS OF

ANTICIPATED PROFITS, R EVENUE OR USE AND COSTS INC UR R ED I N C L UDI NG WITHOUT

LIMITATION FOR CAPITAL, FUEL AND POWER, AND CLAIMS OF BUYER’S CUSTOMERS.

. SELLER SHALL NOT BE LIABLE FOR DAMAGES CAUSED BY

Page 6

Page 7

Reference Manual Table of Contents

Table of Contents i

MAN-0082, Revisio n 08 June 2016

Contents

Section 1: Introduction ...................................................................... 1

1.1 Models covered ................................................................................................................... 1

1.2 Service support ................................................................................................................... 1

1.3 Return of material ............................................................................................................... 1

1.4 Product recycling/disposal .................................................................................................. 1

Section 2: Installation ........................................................................ 2

2.1 Unpacking and inspection ................................................................................................... 2

2.2 Dimensions ......................................................................................................................... 2

2.3 Mounting ............................................................................................................................ 2

2.4 Wiring ................................................................................................................................. 3

2.4.1 Gener al requi rements ........................................................................................... 3

2.4.2 Terminal connection ............................................................................................. 3

2.4.3 Cable choice and guidelines .................................................................................. 4

2.4.4 Important wiring guidelines .................................................................................. 4

2.4.5 Exter nal ground .................................................................................................... 5

2.4.6 Seals ..................................................................................................................... 5

2.4.7 Analog output, isolated supply, non-isolated supply and jumper configuration ..... 5

2.5 Wiring drawings .................................................................................................................. 7

2.6 Remote mounting of sensor ................................................................................................ 8

2.6.1 Wiring drawings for remote sensor wiring ............................................................. 9

2.7 Installation checklist .......................................................................................................... 10

Section 3: Operation ........................................................................ 11

3.1 Transmitter and faceplate description ............................................................................... 11

3.2 Intrusive access ................................................................................................................. 11

3.3 Non-intrusive access (magnetic Reed switch Access) ......................................................... 11

Section 4: Output configurations ..................................................... 13

4.1 Analog board assembly ..................................................................................................... 13

4.2 Analog/HART board assembly ........................................................................................... 14

4.3 Relay board assembly/configuration ................................................................................. 15

4.4 Digital board assembly/configuration................................................................................ 16

Section 5: Operation ........................................................................ 17

5.1 DIP switch settings ............................................................................................................ 17

5.1.1 Infr ar e d sensor (SC311) gas cur ve selection ........................................................ 17

5.1.2 Hydro gen sulfide sensor (ST320) range selection ................................................ 17

5.1.3 C ar b on monoxide sensor (ST360) range selection ............................................... 18

5.1.4 DIP switch settings for relay configuration .......................................................... 18

5.1.5 Digital Modbus DIP switch settings ..................................................................... 19

5.1.6 Anal o g and analog/HART DIP switch se tti ngs ...................................................... 20

Section 6: Calibration procedure ...................................................... 21

6.1 Calibration procedure ....................................................................................................... 21

6.1.1 Guidelines........................................................................................................... 21

6.1.2 Full calibration procedure ................................................................................... 21

6.2 Zeroing procedure ............................................................................................................ 22

6.3 Status conditions during calibration .................................................................................. 24

6.4 Calibration failures ............................................................................................................ 24

6.5 Manual reset ..................................................................................................................... 24

Page 8

Table of Contents Reference Manual

ii Table of Contents

June 2016 MAN-0082, Re vision 08

Section 7: Monitoring and outputs .................................................. 25

7.1 Analog 4-20mA ................................................................................................................. 25

7.2 HART Communication (Optional) ...................................................................................... 25

7.2.1 HART Menu Structure ......................................................................................... 25

7.3 Relays (Optional) ............................................................................................................... 28

7.3.1 Al ar m r e l ay s ........................................................................................................ 28

7.3.2 F aul t r e l ay ........................................................................................................... 28

7.4 RS-485 Modbus RTU (Optio nal) ......................................................................................... 28

7.4.1 Mo dbus registers ................................................................................................ 29

7.5 Transmitter output operation............................................................................................ 30

7.6 Fault monitoring ............................................................................................................... 31

7.7 Fault conditions ................................................................................................................ 31

7.7.1 Transmitter fault conditions ................................................................................ 31

7.7.2 Sensor fault conditions ....................................................................................... 32

Section 8: Maintenance ................................................................... 33

8.1 Periodic response check .................................................................................................... 33

8.2 Troubleshooting ............................................................................................................... 33

8.3 Storage ............................................................................................................................. 33

8.4 Spare parts and accessories ............................................................................................... 34

Section 9: Electrostatic sensitive device ........................................... 35

Section 10: Wire resistance table ....................................................... 36

Section 11: Specifications .................................................................. 37

11.1 Electrical ........................................................................................................................... 37

11.1.1 Operating voltage range ..................................................................................... 37

11.1.2 Power consumption ............................................................................................ 37

11.1.3 EMC compliance ................................................................................................. 37

11.2 Environmental................................................................................................................... 37

11.2.1 Operating temperature ...................................................................................... 37

11.2.2 Relative humidity ................................................................................................ 37

11.2.3 Ingress protection ............................................................................................... 37

11.3 Mechanical ........................................................................................................................ 37

11.3.1 Enclosure material .............................................................................................. 37

11.3.2 Conduit opening ................................................................................................. 37

11.3.3 Weight ............................................................................................................... 37

11.4 Warranty ........................................................................................................................... 38

Section 12: Certifications ................................................................... 39

12.1 North American................................................................................................................. 39

12.2 IECEx ................................................................................................................................. 39

12.3 FC Models ......................................................................................................................... 39

12.3.1 North America .................................................................................................... 39

12.3.2 IECEx .................................................................................................................. 39

Section 13: Ordering information ...................................................... 40

Page 9

Reference Manual Introduction

Introduction 1

Rosemount

6021 Innovation Boulevard

Shakopee, MN 55379

RMA number

MAN-0082, Revisio n 08 June 2016

Section 1: Introduction

1.1 Models covered

A Millennium II Basic gas detectio n system is composed of a field mounted transmitter and Millennium

II series sensors whi c h m ay be integrally mounted to the transmitter or remotely mounted.

The transmitter is cer tified for use in hazardous locations and i s available as a single sensor system.

Some operator controls including calibration can be accessed without opening the enclosure (housing)

by using other commu nication devices and the attached magnet t o ac tuate the reed switch. Available

outputs are: conventional 4 to 20 mA analog, Analog/HART, electromechanical relays, or Modbus RTU

digital.

1.2 Service support

Technical support for this product can be provided by contacting your local Emerson Process

Management representative or by contacting the Technical Support department at +1 866 347 342 7

(toll free) or Safety.CSC@Emerson.com

1.3 Return of material

To expedite the return of this product, prope r c o mmuni cation between the customer and the factor y i s

important. Before returning a product, call +1 866 347 3427 (tol l f r ee ) o r e -mail

Safety.CSC@Emerson.com

On the return of the equipment, include the following information:

1. RMA number provided to you by Rosemount

2. Company name and contact information

3. Ship all equipment, prepaid to:

4. Mark all packages wit h the

Pack items to protect them from damage and use anti-stati c b ag s o r aluminum-backed cardboard as

protection from electrostatic damage.

All equipment must be shipped prepaid. C o l lec t shipment s wil l not be accepted.

for a Return Material Authorization (RMA) number.

.

and type of return (e.g. return for evaluation)

1.4 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of in

accordance with local and national legislations/regulations.

Page 10

Installation Reference Manual

2 Installation

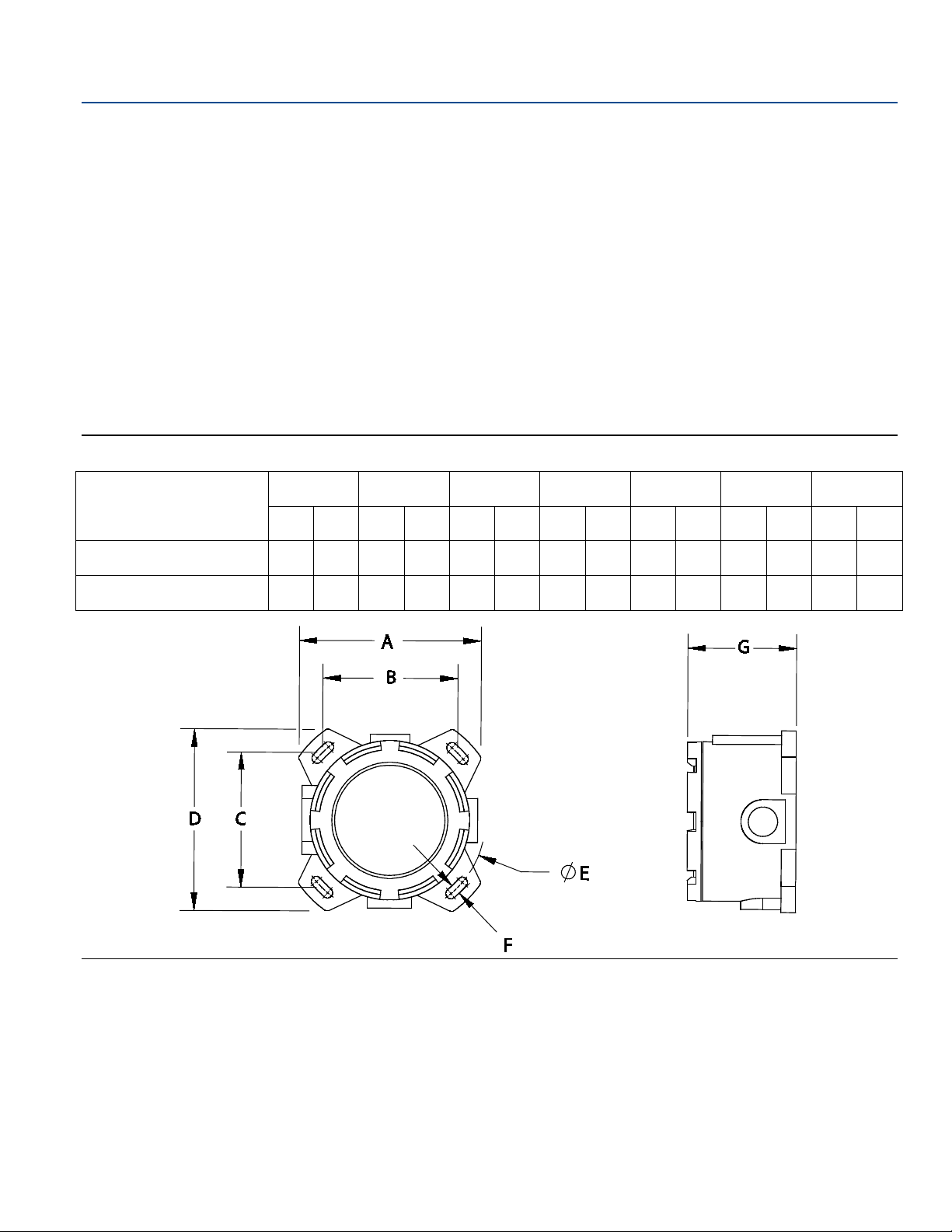

Figure 2-1 Dimensions

A B C D E F G

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

Transmitter (AL)

4.8

122

3.6

91

3.6

91

4.8

122

5.1

130

0.3

7.6

3.0

76

Transmitter (SS)

4.7

119

3.6

91

3.6

91

4.7

119

5.1

130

0.3

7.6

3.2

81

June 2016 MAN-0082, Re vision 08

Section 2: Installation

2.1 Unpacking and inspection

Carefully remove all of the components from the packaging and verify t hem against the enclo sed

packing list. Inspect all components for any obvious damage such as broken or loose parts. If you find

any components missing or damaged, notify your local Net Safet y r ep r e sentative or the factory

immediately.

2.2 Dimensions

The Millennium II Basic transmitter enclosur e i s available in alumi num (6061) and stainle ss steel

(SS316). Dimensions ar e p rovided in Figure 2-1 below.

2.3 Mounting

Ensure transmitter and sensor are securely mounted as per local regulations. The transmitter has

mounting holes to allow mounting to a wall or pole as desired. Mounting kit hardware is required when

mounting the transmitter a pole. Contact your local Net Safety representative for detailed information

on the pole mounting kits. The transmitter should be mounted at eye-level and be easily accessible for

monitoring and maintenance purposes.

Page 11

Reference Manual Installation

Installation 3

Failure to follow these installation guidelines could result in death or serious injury. Ensure that only

qualified personnel perform the installation.

Electrical shock could cause death or serious injury. Use extreme caution when making contact with

the leads and terminals.

Do not open the transmitter, sensor, or junction box enclosure when in a classified area or when an

explosive at mosphere may be present unless the p ower to the transmitter has been removed.

Wiring codes and regulations may vary. Wi r ing

the installation of electrical equipment in a hazardous area and is the responsibility of the installer. If in

doubt, consult a qualified official before wiring the system.

When separating the se nsor

meet electromagnetic compatibility (EMC) requirements and to pro tect against interference caused by

extraneous electrical or electromagnetic noise

the conduit must not be used for wiring to other equipment.

MAN-0082, Revisio n 08 June 2016

2.4 Wiring

2.4.1 General requirements

must comply with all applicable regulations relating to

from the transmitter, the use of shielded cable is highly recommended to

If the 4-20 mA signal is not used, c o nnect a jumper between the 4 – 20 mA terminal and the common

terminal to allow analog current levels to be monitored at the test jacks on the transmitter board.

In applications where wiring is installed in conduit, conduit must not be used for wiring to any other

electrical equipment.

For effective comm uni c ation, Net Safety li m i t s sensor separation to 2000 f eet (600 meters) using 16

AWG wires.

Modbus RS-485 connection 2-wire mode, multipoint serial line available. Up to 16 addresses allowed.

When developing a RS-485 chain of devices, the last devi c e i n t he c hai n r eq uires an end of line

termination resisto r (120 Ohms).

2.4.2 Terminal co n nection

When connecting cable wir es, use a small screwdri v e r to gently press down and ho l d the spring

connector open. Insert the appropriate wire into the open connector hole, releasing the screwdriver to

secure the wire as shown in Figure 2-2.

. In applications where the wiring is installed in conduit,

The connector will ac c o m modate wire sizes be tween 14 and 20 AWG.

Page 12

Installation Reference Manual

4 Installation

Figure 2-2 Terminal connection

June 2016 MAN-0082, Re vision 08

2.4.3 Cable choice and guidelines

Radio frequency interference (RFI) can be caused by near by el ectri cal dev i ces (e.g. transformers or high

voltage equipment) as well as handheld co m m unication devic e s/rad i os, which when activated, may

impede the proper functioning of the transmitter and sensor. Selecting the right instrumentation cable

and making proper grounding connections within the junction box will reduce or eliminate

interference. Visible symptoms of RFI include inconsistent, incorrect, and erratic LEL and ppm readings.

2.4.4 Important wiring guidelines

Gas detection instruments are an impor tan t p art of a safety alarm and shutdown system. T he sy ste m is

composed of:

• Detection instruments

• Customer connected equipment

• Wiring

Net Safety designs and manufactures its detection equipment under rigid q ual i ty c o ntr o l m anagement

systems and makes every effort to design fo r the har shest of industrial environments. T he other

components of the system – the customer-connected equipment and wiring – are also important

contributors to the overall quality and performance of the safety system.

It is important to implement wiring that ensures the reliability and integrity of the safety system. Field

wiring practices and the choice of cable type specified vary from project to project. Poor practices and

choices are often fou nd to be the source of unwante d system disruptions. RFI and electromagnetic

interference (EMI) are usually very powerful disruptive fo rces in i ndustrial facil iti es a nd these forces act

upon the system thro ug h the wiring.

The cable used should be a very high quality instrument grade, certified for the application conditions,

consisting of a rugged protective outer jacket, an overall electrical shield of fine braided copper or

metallic foil, and internal pairs or triads of foil shielded copper wire of suitable gauge for the power

conducted over the specified length.

The shields must be electrically continuous from the instrument junction box through other junction

boxes and finally to the connected equipment. The shield must be connected to a suitable g r o u nd si nk

as specified in the instrument manual in order to protect the system from electrical disturbances.

In general, communication cables and power cables should not run in parallel for any significant length,

and should not be carr ied i n the same cable tray. Through inductance, high currents i n power cables

can induce significant ‘noise’ in communication cables running parallel alongside power cables.

Page 13

Reference Manual Installation

Installation 5

MAN-0082, Revisio n 08 June 2016

2.4.5 External ground

In order to ensure proper operation of the sensor, an external earth grou nd is recommended. Net

Safety recommends that the external gro und b e co nnected to the grounding point on the enclosure.

2.4.6 Seals

The use of seals is recommended to further pr o te ct the system against water ingression , and

equipment should be installed according to applicable local electrical codes. Seals are especi ally

recommended for installations that use hi gh-pressure or steam cleaning devices in proximity to the

transmitter.

• Waterproof and explosionproof conduit seals are recommended to prevent water accumulation

within the enclosure

• Seals should be locat ed as c lose to the device as possible and not more than18 inches (46 cm) a way

• Explosionproof installations may require an additional seal where conduit enters a non-hazardous

area; ensure conformity with local wiring codes

• When pouring a seal, u se a fiber dam to ensure proper formation of the seal. Seals should never be

poured at temperatures below freezing

• The jacket and shielding of the cable should be stripped back to permit the seal to form around the

individual wires. This will prevent air particles and water leakage through the inside of the shield

and into the enclosure

• It is recommended that explosionproof drains and conduit breathers be used. In some applications,

changes in temperatur e and barometric pressure can cause breat hing which allows mo i st ai r to

enter and circulate inside the conduit. Joints in the conduit system are seldom tight enough to

prevent this breathin g

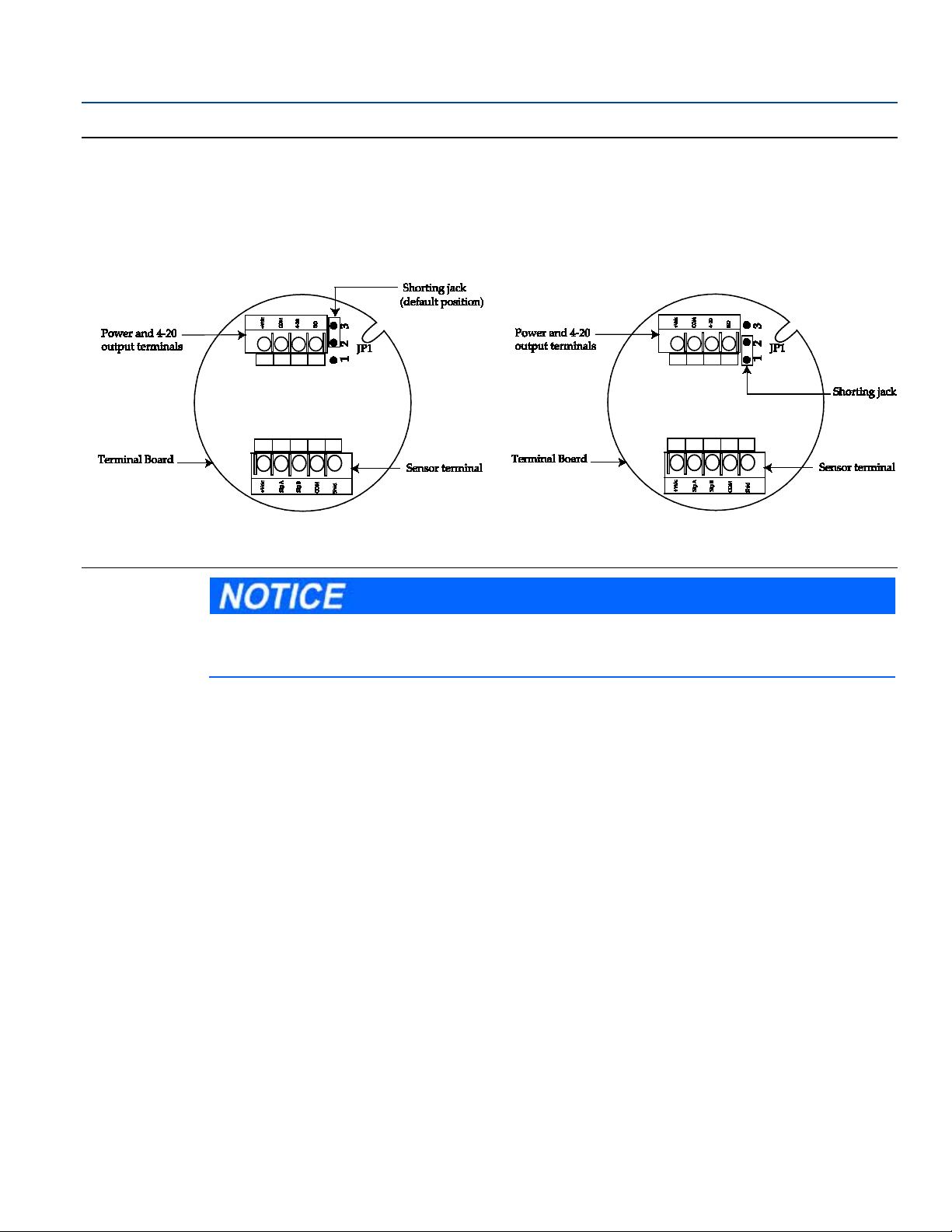

2.4.7 Analog output, isolated supply, non-isolated supply and jumper configuration

The analog output may be powered from the main instrument power supply or a separate,

independent power supply in which case an isolated wiring configuration is necessary. These

configurations only apply to Analog and Analog/HART model transmitters.

To set a non-isolated or isolated current output, simply move the jumper/shorting jack located at JP1

near the power and output terminals, to either the non-isolated or isolated current position. For nonisolated current out p ut, e nsure pins 3 and 2 at JP1 l o cation on the terminal board are jumpered

(shorted). See Figure 2-3 for reference. F ac tory standard models ship with jumper in t he n o n -isolated

current output position.

For isolated current output, pins 1 and 2 at JP1 should be jumpered (shorted). See Figure 2-3 for

reference.

Page 14

Installation Reference Manual

6 Installation

Figure 2-3 Non-isolated and isolated current jumpers

Always ensure that JP

configuration chosen

Non-isolated current output

Isolated current output configuration.

June 2016 MAN-0082, Re vision 08

configuration (default).

1 jumpers are in the correct po si ti on depending on the current outp ut

Pin 1 and Pin 2 jumpered at JP1

Page 15

Reference Manual Installation

Installation 7

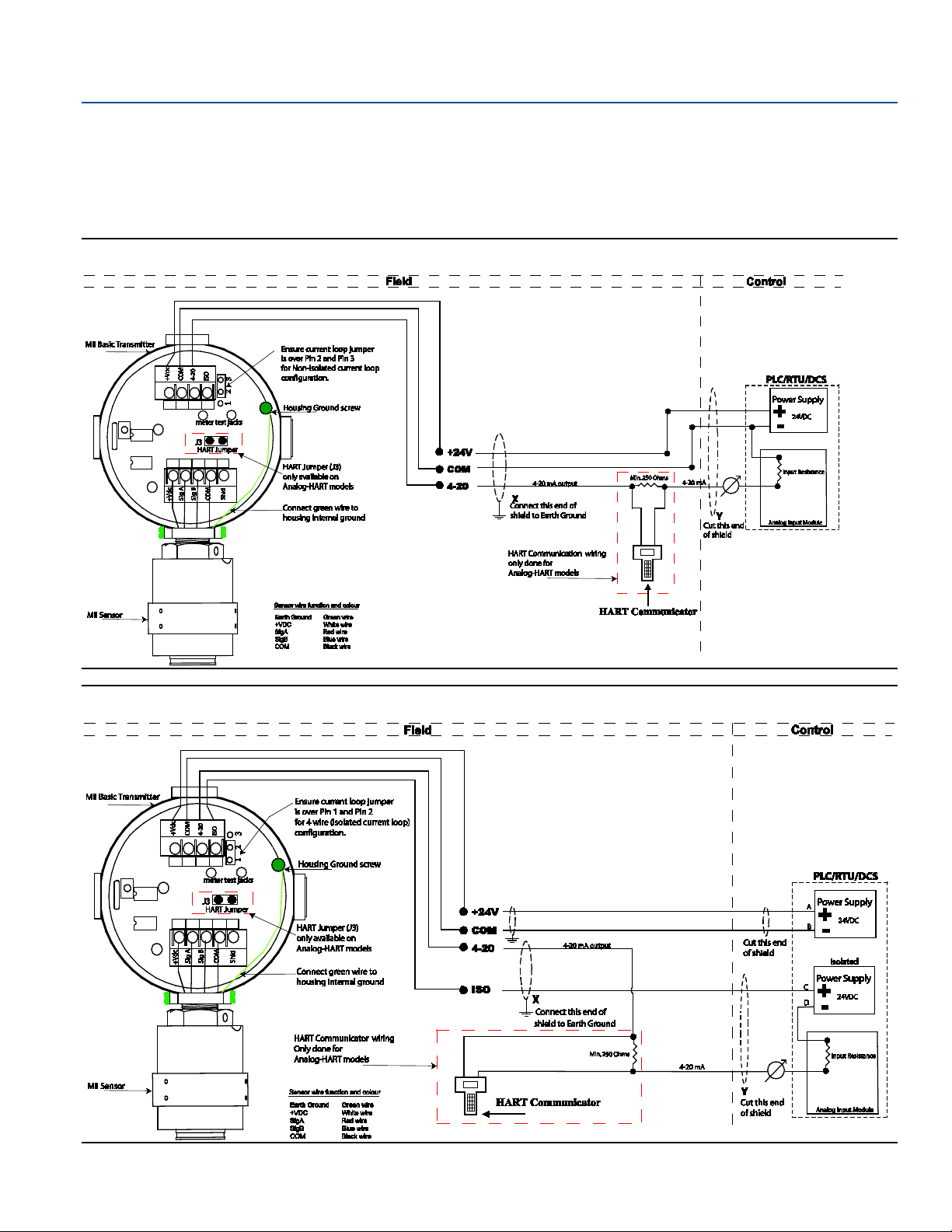

Figure 2-4 Non-isolated terminal connection (for Analog and Analog/HART models)

Figure 2-5 Isolated terminal connection (for Analog and Analog/HART models)

MAN-0082, Revisio n 08 June 2016

2.5 Wiring drawings

The drawings below are general ways in wiring the system showing analog signal output. Consult

qualified personnel on specific wiring requirements.

Page 16

Installation Reference Manual

8 Installation

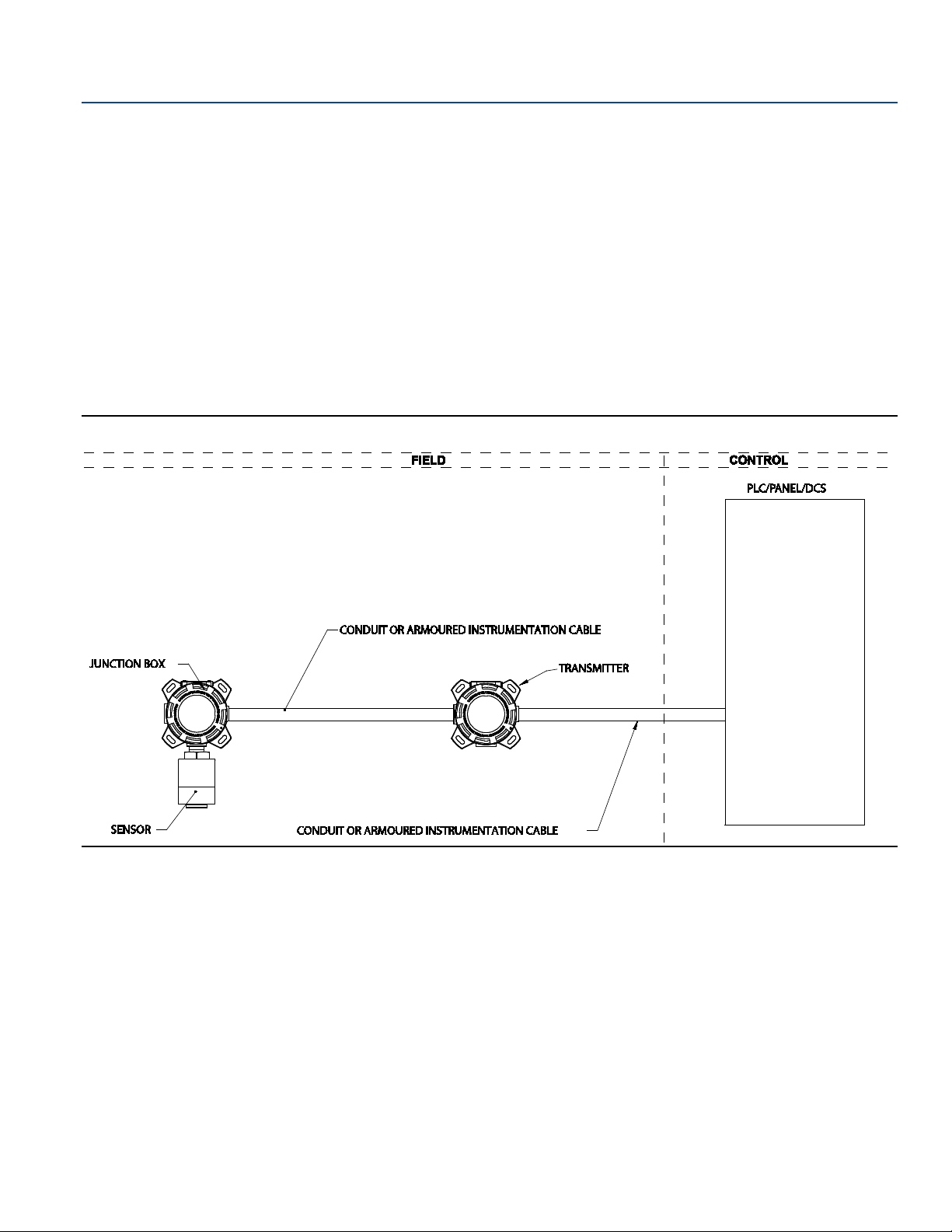

Figure 2-6 Remote mounting of sensor

June 2016 MAN-0082, Re vision 08

2.6 Remote mounting of sensor

When necessary to mo unt sensor remotely ( sep arated from transmitter) by way of junction box and

conduit, it is important that the installer follow the necessary requirements and guidelines relating to

sensor separation a nd c able selection. See Figure 2-6 for typical remote mounting of the sensor.

When sensors are bein g m ounted remotely, co nsult the multi-purp o se junction box manual

(MAN-0081) for wiring instructions. Alway s e nsure that the transmitter is supplying 10.5 - 32 VDC

across the sensor po we r te rminals of Net Safety junction box (JB-MPD-A/S).

The maximum distan ce b etween the sensor and tr ansmitter is limi ted b y the r e si stance of the

connecting wiring, which is a function of the gauge of the wire being used. For effective

communication, Net Safety limits the separation distance between senso r and tr ansmitter to 2000 feet

(600 meters) using 16 AWG wire. See Section 10 for information on wire gauge and resistance.

Page 17

Reference Manual Installation

Installation 9

Figure 2-7 Non-isolated terminal wiring with remote sensor wiring (for Analog and Analog/HART models)

Figure 2-8 Isolated terminal wiring with remote sensor wiring (for Analog and Analog/HART models)

MAN-0082, Revisio n 08 June 2016

2.6.1 Wiring drawings for remote sens o r wiring

The drawings below are an analog output drawing showing wiring of sensor to transmitter remotely via

a junction box. Consult qual i fi e d p er so nnel on specific wiring requirements.

Page 18

Installation Reference Manual

10 Installation

June 2016 MAN-0082, Re vision 08

2.7 Installation checklist

Review the following checklist prior to turning the power on to the transmitter after install ation has

been completed:

□ Ensure that the transmitter and se nsor are properly and firmly mounted.

□ Ensure that stopping plugs are securely ti g htened on any unused conduit entr i e s .

□ Ensure that the transmitter and sensor are not obstruc ted; transmitter and s e n so r are accessible

and target gas is not inhib ited from reaching the sensor.

□ Ensure adherence to applicable local guidelines and requirements on wiring and sealing of

equipment in hazardous and non-hazardous area s.

□ Ensure that proper shielding and grounding practices are adhered to and local codes are being

followed.

□ Check system operational voltage and conditions; ensuring that they ar e wi thin the applicable

specifications of the transmitter and sensor.

□ Verify wiring at all termination and junction points (transmitter, junction box, and power supply).

□ Ensure that the transmitter housing co ver and sensor cap are secured tightly.

Page 19

Reference Manual Operation

Operation 11

Figure 3-1 Faceplate description

Do not open the transmitter, sensor, or junction box enclosure when in a classified area or when an

explosive at mosphere may be present unless the power to the transmi tter has been removed.

MAN-0082, Revisio n 08 June 2016

Section 3: Operation

3.1 Transmitter and faceplate description

After wiring is completed and power is applied, indicated by the green power LED, a warm-up routine

will begin, where the sensor is automatically tested to ensure proper operation. The Status LED will

slowly flash red and the current output will be 3.0 mA (indicated by Analog models). Once the war m up routine has been completed, the LED will flash green, indicating normal operation. The time taken

for the transmitter to complete its warm-up cy cl e i s dependent on t he type o f sensor b eing used.

The transmitter faceplate shows the posi ti o n of the magnetic switch, the status LED, and the status L ED

states. See Section 7 for more information on the Status LED.

3.2 Intrusive access

This involves the r emo v al of the top cover and faceplate to access the pushbutton switch when

calibrating and rese tting the transmitter . Pressing and hold i ng the pushbutton down for up to three (3)

seconds resets the transmitter; latched alar ms are cleared and sensor performed self-tests. Holding

down the pushbutton for up to fi ftee n ( 15) seconds sends the transmitter into full calibration mode.

See Section 6 for more information on calibration and manual reset.

3.3 Non-intrusive access (magnetic Reed switch Access)

This involves pl ac i ng and holding the attached mag net next to the base of the l ab el mount as indicated

in Figure 3-2. When the magnet is held for up to three (3) seconds, a manual reset will be initiated. If

Page 20

Operation Reference Manual

12 Operation

Figure 3-2 Positioning of magnet

June 2016 MAN-0082, Re vision 08

the magnet is held for up to fi ftee n ( 15) seco nds a full calibration procedure will begin. See Section 6 for

more information on calibration and manual reset.

Page 21

Reference Manual Output configurations

Output configurations 13

Sensor Terminals

Sensor Wire

White

Red

Blue

Black

Green

Marked

+VDC

Sig A

Sig B

COM

Function

10.5 - 32 VDC

A B Comm

Earth Ground

Output Terminals

Marked

+VDC

COM

4 – 20

ISO

Function

Power (+)

(10.5-32 VDC)

Power (-)

Current loop output

Isolate the power for

current loop

Figure 4-1 Analog circuit boa r d assembly

MAN-0082, Revisio n 08 June 2016

Section 4: Output configurations

4.1 Analog board assembly

The Analog model Millennium II Basic Transmitter provides a 4-20 mA signal output, allowing the

user/operator wit h a signal represent i ng various conditions and states of the transmitter. See the

following table for current output and meaning.

Page 22

Output configurations Reference Manual

14 Output configurations

Sensor Terminals

Sensor Wire

White

Red

Blue

Black

Green

Marked

+Vdc

Sig A

Sig B

COM

Function

10.5 - 32Vdc

A B Comm

Earth Ground

Output Terminals

Marked

+VDC

COM

4 – 20

ISO

Function

Power (+)

(10.5-32 VDC)

Power (-)

Current loop output

Isolate the power for

current loop

Figure 4-2 Analog/HART circuit board assembly

For Hart Communicator connection in isolated or non

must be a minimum of 250 Ohms to a maximum of 600 Ohms. Do not install r esistor within

Millennium II Basic Transmitter.

June 2016 MAN-0082, Re vision 08

4.2 Analog/HART board assembly

The Analog/HART Millennium II Basic Transmitter provides the user/operator with the option of using a

HART Communicator to gain access to the transmitter settings and output. This allows reviewing,

logging, and monitoring of data which is ideally suited for maintenance. See 7.2 for more information.

-isolated configuration, the total loop resistance

the

Page 23

Reference Manual Output configurations

Output configurations 15

Sensor Terminals

Sensor Wire

White

Red

Blue

Black

Green

Marked

+VDC

Sig A

Sig B

COM

Function

10.5 - 32 VDC

A B Comm

Earth Ground

Output

Terminals

Marked

RST

+VDC

COM

FNO

FCOM

FNC

A1NO

A1COM

A1NC

A2NO

A2COM

A2NC

Function

Remote

Power

VDC)

Power

Fault

Alarm 1

Alarm 2

Relay definitions:

Figure 4-3 Relay circuit bo ard a ss embly

MAN-0082, Revisio n 08 June 2016

4.3 Relay board assembly/configuration

This assembly has thr e e (3) relays; a fault alar m r e l ay , a low alarm relay and a high alarm relay. The fault

alarm relay is fixed as energi zed and non-latching and ca nnot be changed. The low alarm relay and the

high alarm relay may be configured as energized or de-energized and latching or non-latching. By

default the low and high alarm relay cont act s are de-energized and non-latching. For more information

on adjusting the relay settings refer to 7.3.

Reset

(+)

(10.5-32

(-)

(Low Alarm)

(High Alarm)

Fault Alarm contacts: Fault Normally Open (FNO), Fault Common (FCOM), and Fault Normally Closed

(FNC).

Low Alarm contacts : Al ar m 1 Normally Open (A1NO), Alarm 1 Common (A1C OM ) and Alarm 1

Normally Closed (A1NC).

High Alarm contact s: Al arm 2 Normally Open (A2NO), Alarm 2 Commo n ( A2COM) and Alarm 2

Normally Closed (A2NC).

Page 24

Output configurations Reference Manual

16 Output configurations

Sensor Terminals

Sensor Wire

White

Red

Blue

Black

Green

Marked

+VDC

Sig A

Sig B

COM

Function

10.5 - 32 VDC

A B Common

Earth Ground

Output

Terminals

Marked

+VDC

COM

A(positive )

B(negative)

COM

Shld

Function

Power (+)

Power (-)

Modbus RTU

Modbus RTU

Modbus RTU

Shield

Figure 4-4 Digital circuit board assembly

June 2016 MAN-0082, Re vision 08

4.4 Digital board assembly/configuration

This assembly allows digital output utilizing Modbus Digital RS-485 protocols. See 7.4 for more

information.

(10.5-32 VDC)

Terminal A

Terminal B

Terminal

Common

Page 25

Reference Manual Operation

Operation 17

The gas curve or range sho uld only be changed wh e n the sensor and transmitte r ar e i n

After powering up, the transmitter

state. The system sho ul d b e recalibrated wit h 50% of

changed.

Position 1

Position 2

Position 3

Position 4

Gas Curve

OFF

OFF

OFF

OFF

Methane (0)

ON

OFF

OFF

OFF

Propane (1)*

OFF

ON

OFF

OFF

n-Butane (2)*

ON

ON

OFF

OFF

Iso-Pentane (3)*

OFF

OFF

ON

OFF

n-Pentane (4)*

ON

OFF

ON

OFF

Ethane (5)

OFF

ON

ON

OFF

Iso-Butane (6)*

ON

ON

ON

OFF

Ethylene (7)

OFF

OFF

OFF

ON

Hexane (8)*

ON

OFF

OFF

ON

Propylene (9)*

Position 1

Position 2

Position 3

Position 4

Range(Setting)

ON

OFF

OFF

OFF

Range 1 (20ppm)

OFF

ON

OFF

OFF

Range 2 (50ppm)

OFF

OFF

ON

OFF

Range 3 (100ppm)

MAN-0082, Revisio n 08 June 2016

Section 5: Operation

5.1 DIP switch settings

5.1.1 Infrared sensor (SC311) gas curve selection

When using the SC311 sensor with the Millennium II Basic transmitter, DIP switch 2 on the transmitter

should be set up as follows:

normal state.

, the status LED will slowly flash green to indicate normal operating

the specific target gas if the sensor’s range is

*Indicates gases are no t third party perform anc e verified

5.1.2 Hydrogen sulfide sensor (ST320) range selection

Page 26

Operation Reference Manual

18 Operation

Position 1

Position 2

Position 3

Position 4

Range(Setting)

ON

OFF

OFF

OFF

Range 1 (500ppm)

OFF

ON

OFF

OFF

Range 2 (1000ppm)

DIP Switch 1 Settings

Position

Status

Value

Function

Position 1

On

16%

DIP Switch 1 positions are used in conjunction with DIP

Off

0%

Position 2

On

8%

Off

0%

Position 3

On

4%

Off

0%

Position 4

On

2%

Off

0%

June 2016 MAN-0082, Re vision 08

5.1.3 Carbon monoxide sensor (ST360) range selection

5.1.4 DIP switch settings for relay configu ration

DIP switch 1 and DIP swi tch 3, as se en in the tables below, show the settings for relay al ar m l e v e l s an d

status. DIP switch 3 position 4, is used in conjunction with DIP switch 1, if needed to set up the alarm

level. The user is allowed to fully utilize, if necessary, all the percentages offered. To arrive at the desired

low alarm level, add different percentages, while taking note of the sensor’s range/scale. The high

alarm level (A2) is automatically set to twice the low alarm level (A1).

Example: For a sensor wi th range/scale of 50 ppm, and DIP switch 1 set with positions 2 and 4 ‘On’ (8 %

+2 %) the low level alarm point would be (10 % of 50 ppm) whic h i s 5 ppm’ automatically making the

high level alarm point 10 ppm.

Switch 3, *position 4*, if needs be, to set the Alarm

point (% of full scale or range)

Page 27

Reference Manual Operation

Operation 19

DIP Switch 3 Settings

Position

Status

Value

Function

Position 1

ON

RFU

Not used now

OFF

RFU

Position 2

ON

Energized

Defines Relay Coil Status

OFF(default)

De-energized

Position 3

ON

Latching

Defines Relay Latch Status

OFF(default)

Non-Latching

Position 4

ON

32%

*Used with DIP Switch 1 to set the Alarm Point, (% of full

OFF

0%

DIP Switch 1

Position 1

Position 2

Position 3

Position 4

MODBUS Address

OFF

OFF

OFF

OFF

16

ON

OFF

OFF

OFF

15

OFF

ON

OFF

OFF

14

ON

ON

OFF

OFF

13

OFF

OFF

ON

OFF

12

ON

OFF

ON

OFF

11

OFF

ON

ON

OFF

10

ON

ON

ON

OFF

9

OFF

OFF

OFF

ON 8 ON

OFF

OFF

ON 7 OFF

ON

OFF

ON

6

ON

ON

OFF

ON

5

OFF

OFF

ON

ON 4 ON

OFF

ON

ON 3 OFF

ON

ON

ON 2 ON

ON

ON

ON

1

MAN-0082, Revisio n 08 June 2016

scale/range) if needs be*.

5.1.5 Digital Modbus DIP sw itch setting s

DIP switch 1 selects the Modbus address. DIP switch 2 defines the Modbus settings. Positions 1 and 2 of

DIP switch 2 select the baud rate of the Modbus system. Positions 3 and 4 of DIP switch 2 select the

data format of the Modbus data link. T he se DIP switches must be set before the Millenni um I I Basic is

powered up. Once the device is powered up the setting will be locked until another power down and up

cycle. Refer to the following tables for DIP switch positions.

Page 28

Operation Reference Manual

20 Operation

DIP Switch 2 settings for b aud rate

Position 1

Position 2

BAUD Rate

OFF

OFF

19200

OFF

ON

9600

ON

OFF

4800

ON

ON

2400

DIP Switch 2 for fo r mat bits

Position 3

Position 4

Date Format

OFF

OFF

8 bits data, no parity bit, 2 stop bits (also compatible to 1 stop bit)

OFF

ON

8 bits data, no parity bit, 2 stop bits

ON

OFF

8 bits data, odd parity bit, 1 stop bits

ON

ON

8 bits data, even parity bit, 1 stop bits

June 2016 MAN-0082, Re vision 08

5.1.6 Analog and analog/HART DIP switch settings

DIP switch 1 is not utilized when using the Millennium II Basic analog and analog/HART models. DIP

switch 2 settings/positions, are utilized for different gas curves when using IR sensors (SC311) and for

changing toxic sensor r anges (ST3XX). Refer to specific sensor manuals to see the combinations of DIP

switch 2 positions and when it is utilized.

Page 29

Reference Manual Calibration procedure

Calibration procedure 21

All systems should be bypassed during calibratio n a nd bu mp te stin g to avo i d un wanted alarms.

MAN-0082, Revisio n 08 June 2016

Section 6: Calibration procedure

6.1 Calibration procedure

Prior to attempting calibration read and understand the calibration procedure below. Also see Figure

6-1 for additional reference.

The following calibration procedure should be followed to ensure an accurate correlation between the

output signals and the gas concentration. For accurate performance, the Millennium II Basic

Transmitter is calibrated using 50% span gas.

6.1.1 Guidelines

Calibration is recommended after the Millennium II Basic and sensor are installed. Calibration should be

performed after the sensor has been powered for at l east 24 hours. Refer to specific sensor manuals for

details on calibrating.

6.1.2 Full calibration procedure

1. Confirm successful power-up of transmitter, (green or red flashing of status LED).

2. For analog model connect a standard ammeter to the transmitter Tes t J acks (not required but

gives visual confirmation). See figures in Section 4 for Test Jacks location.

3. Press and hold the pushb utton, or activ ate the Reed switch using the mag net, for at least fifteen

(15) seconds; the status LED flashes green fast, and then goes solid green (first soli d g reen), keep

holding the pushbutton or magnet, after which, the status LED goes solid red. Release the

pushbutton or remove mag net.

4. When the current output i s 3 mA (indicated by anal og models) and the stat us L ED is once again

solid green (second solid green). Apply zero gas (clean air). Recommendation: Flow clean air at a

rate of 0.5 liter per minute or more to the sensor for best results.

5. When the current output i s 3.3 mA (indicated by analog models) and the status LED is flashing

red, apply the calibration ga s ( 50% o f f ul l span) to the sensor . R ecommenda tion: Flow span gas at

a rate of 0.5 liter per minute to the sensor for direct sensor calibration. If the sensor is separated

with long tubing runs, increase the gas flow rate to ensure tubing does not affect calibration

results.

6. When the current output is 3.6 mA (indicated by analog models) and the status LED is solid

green, remove the calibration gas.

7. Apply zero gas (clean air) again to purge the system if calibrati o n tu bing is used.

8. After the sensor is purge d o f gas, the transmitter will return to normal operation.

Page 30

Calibration procedure Reference Manual

22 Calibration procedure

Zeroing does not require the application of a calibration gas. It does, however,

contaminated gas i s pr e se nt in the ambient air, i f the sur rounding air is bei ng used .

Zeroing is not a substitute for performing a full calibration. Zeroing can be completed on an interim

basis; however, It is highly recommended t hat a full

June 2016 MAN-0082, Re vision 08

6.2 Zeroing procedure

This option is useful if the sensor’s zero point has drifted as a result of a change in the ambient

conditions.

require that no

calibration be completed whenever possible.

1. Confirm successful power-up of transmitter, (green flash i ng o f statu s L ED ev er y sec ond: no fault

indicated).

2. For analog model connect a standard ammeter to the transmitter Tes t J acks (not required but

gives visual confirmation). See figures in Section 4 for Test Jacks location.

3. Press and hold the pushb utton, or activ ate the Reed switch using the magnet, until the status

LED flashes green fast, and then goes solid g r e en. Release the pushbutton or deactivate the Reed

switch.

4. When the status LED is solid green, the current output will be 3 mA (indicated by analog models).

Apply zero gas (clean air). Recommendation: Flow clean air at a rate of 0.5 liter per m i nu te or

more to the sensor.

5. Zeroing is complete when the current output is 3.6 mA (indicated by analog models) after which,

the Status LED flashes green every second (current output of 4 mA). Remove the zero g as, or

allow the transmitter to return to normal operation if ambient (clean surrounding) air was used.

6. Normal operation is confirmed by a current output of 4 mA (indicated by analog models) and the

status LED flashing green every second.

Page 31

Reference Manual Calibration procedure

Calibration procedure 23

Figure 6-1 Calibration procedure

LED and analog

Zero Calibration

MAN-0082, Revisio n 08 June 2016

Activate/hold calibrati on

switch for six to t en seconds

Full Calibration

Activate/hold calibrati on sw it c h f or

ten to fifteen seconds until status

LED turns red

Status LED flashes

fast green

Status LED goes

solid green

3.0 mA output

Apply air from canister or use

clean ambient air to perform

zero

output

indication

Status LED solid

red

Status LED goes

solid green

3.0 mA output

Apply air from canister or use

clean ambient air to perform

zero

Status LED flashed

Red

3.3 mA output

Status LED alternating red

and green

3.0/3.3 mA output

Status LED solid green

3.6 mA output

Apply 50% span target gas to

perform span

Calibration Failed

Perform manual reset and

complete calibration

procedure again

Calibration Successful

Remove calibration gas and

purge calibration lines if used

Page 32

Calibration procedure Reference Manual

24 Calibration procedure

Condition

Current output

LED indication

Relay outputs

Fault

Alarm

Zero calibration initiated

4.0 mA

Fast flash green

Normal state

Normal state

Full calibration initiated

4.0 mA

Solid red

Normal state

Normal state

Zero calibration being completed

3.0 mA

Solid green

Normal state

Normal state

Apply span calibration gas

3.3 mA

Flashing red

Normal state

Normal state

Successful calibration

3.6 mA

Solid green

Normal state

Normal state

Calibration failed

3.0/3.3

Alternating red and green

Fault state

Normal state

June 2016 MAN-0082, Re vision 08

6.3 Status conditions during calibration

6.4 Calibration failures

If the calibration pro c ed ur e fails, the Status LED will alternate red and g r ee n wi th the analog output

changing back and fo r th fr om 3.0 mA to 3.3 mA. The unit will remain in a failed state until it is manually

reset.

6.5 Manual reset

A manual reset is requir e d after a calibration failure or to clear a latched alarm. Simply press an d hold

down the pushbutton for up to three (3) seconds, cycle power, or place and hold the flat surface of the

magnet near the Reed switch for up to three (3) sec o nds. The status LED will fast flash gree n, then

slowly flash red, indi c ati ng reset, after whic h, the status LED will flash green slowly, to indicate normal

operation.

Page 33

Reference Manual Monitoring and outputs

Monitoring and outputs 25

When remote HART Communication is being

pins at J3. See

MAN-0082, Revisio n 08 June 2016

Section 7: Monitoring and outputs

7.1 Analog 4-20mA

The Millennium II Basic transmitters (with the exception of the M2B-R) offer a variable 4-20 mA analog

output. This output will provide gas concentration through the 4-20 mA range, where 4 mA equals

zero gas concentrati o n and 20 mA equals the hig h r ang e of the sensor (e.g. 10 0% LEL or 100 ppm).

Other conditions such as faults and calibration notifications (e.g. apply gas) are indicated in the 0-3.9

mA range. Faults are ind i c ated at either 0 mA or 2.5 mA.

7.2 HART Communication (Optional)

The HART protocol is a powerful communication technology enabling users to exploit the full

functionality of the Millenni u m I I Basic Transmitter.

The HART Communicator may be connected to the Analog/HART model Millennium II Basic

Transmitter via the HART Port connector (HPT -001) which prov i d e s the nec e ssary interface for

communication on the analog output wires. The HART Port connector is fitted to one of the ¾” NPT

conduit entries and its communication wires fitted to the HART Pins located at J3 on the Analog/HART

PCB. The HART Communicator probe wires (leads) are then connected to HART Port connector contact

points.

Figure 4-2 for the location of J3. By default the jumper is connected across the pins.

When the system is power ed-up, the communicator will search for the Millennium II Basic Transmitter

and when a connection is established, the communicator will show the device information. If the

Millennium II Basic Transmitter Device Description (DD) is loaded into the communicator, the

communicator can access all the information and features of the Millennium II Basic Transmitter. If the

communicator is not programmed with the specific DD, the Millennium II Basic Transmitter can still

work with the communicator as a generic device.

7.2.1 HART Menu Structure

The Hart Menu structur e e xists when using the HAR T Communicator and allows the user to see al l

existing options, Device status, Calibration information and History. Refer to Figure 7-1 and Figure 7-2

for the HART menu structur e and tre e.

completed, ensure the HART Jumper is connected across

Page 34

Monitoring and outputs Reference Manual

26 Monitoring and outputs

Figure 7-1 HART menu tree - page 1

Loop test

Zero only

Z&Span Calibration

See next page “History”

See next page

Num resp preams

Zero calibration

June 2016 MAN-0082, Re vision 08

This section displays a g eneral menu tree for M i llennium II series sensors. Additional menus may exist when using

communicator but should be ignored if they are not available in this menu tree.

Process

variables

Diag/Service

Device setup.

Device status

PV Value xx % LEL/PPM

PV Current xxmA

PV LRV 0% LEL/PPM

PV URV 100% LEL/PPM

Basic setup

Detailed

setup

Review

PV Value xx % LEL/PPM

PV % rnge xx%

Loop current xx mA

Test device

Calibration

Device status

History

Tag xxxx

Long Tag xxxxxxxx

PV unit % LEL/PPM

PV Xfer fnctn Linear

Range values

Device information

Sensor

Signal condition

Output condition

Device information

See next page

“Review”

Device reset

Zero & Span

PV mA

Manufacturer Net Safety

Model Millennium II Basic

Dev ID xxxxx

Cfg Chng count xxxxx

Tag xxxxxxxxxxxx

Long Tag xxxxxxxxxxxxx

Date xx/xx/xx

Descriptor xxxxxxxx xxxxx

Message xxxxxxxxxxxx

Final asmbly num xxxxx

Revision #’s

PV LRV 0% LEL/PPM

PV URV xx % LEL/PPM

PV % rnge xx %

Xfer fnctn, linear

Analog Output

HART Output

PV Value xx % LEL/PPM

Loop current xx mA

Current gas type

PV

PV

Range value

Loop current xx mA

Loop test

Loop current mode

Poll Addr xx

Num reg preams xx

Page 35

Reference Manual Monitoring and outputs

Monitoring and outputs 27

Figure 7-2 HART menu tree - page 2

“History”

“Sensor”

“Review”

Sensor

Reset Max Min Temperature

MAN-0082, Revisio n 08 June 2016

Max Temperature xxx Deg C

Max Temperature

Min Temperature

Calibration Log

Catalytic Bead Sensor, IR

combustible, H2S toxic

Max Temperatur e S ince Reset xx Deg C

Reset Date xx/xx/xxxx

Reset Time xxxx

Reset Max Min Temperature

Min Temperature xxx Deg C

Min Temperature Sin ce Reset xx Deg C

Reset Date xx/xx/xxxx

Reset Time xxxx

Calibration Date xx/xx/xxxx

Calibration Time xxxx

Cal Event Type xxxxxxxxx

Next Log

Previous Log

Most Recent Log

Sensor Class Cat Bead Combustible, Infrared Combustible,

PV xx % LEL

PV Unit % LEL

H2S toxic, CO toxic

Sensor Temperat u r e xxx Deg C

Sensor Remain Time xxxx Days

Current gas type

PV LSL 0% LEL/PPM

PV USL 100% LEL/PPM

PV Min span 1% LE L/PPM

Gas type and range

Current gas type

Custom K factor

PV U SL

Support gas type

Support USL(range)

Manufacturer Net Safety

Model Millennium II Basic

Dev ID xxxxxx

Tag xxxxxxxxxxx

Long Tag xxxxxxxxxxxxxx

Descriptor xxxxxxxx xxxxxx

Message xxxxxxxxxxxxxx

Date xx/xx/xx

Final asmbly num xxxxxxx

Universal rev 7

Fld dev rev xx

Software rev xx

Poll addr xx

Loop current mode Disabled/Enabled

Num reg preams xx

Num resp preams xx

Sensor gas 1

Sensor gas 2

Sensor gas 3……….16

Sensor range 1

Sensor range 2

Sensor range 3…….5

Page 36

Monitoring and outputs Reference Manual

28 Monitoring and outputs

The fault relay output is not commonly used to imitate an

indicates a potential problem with the transmitter not an alarm condition.

June 2016 MAN-0082, Re vision 08

7.3 Relays (Optional)

7.3.1 Alarm relays

The Millennium II Basic transmitters com e compl ete with two (2) programmable al arm relays. These

relays will change the i r st ate from their non-alar m state to an alarm state when gas concentrati o ns, as

read by the sensor, go ab o ve the programmed alar m points set in the transmit ter .

The alarm relays can be programmed to be energized or de-energized under normal conditi o ns, and

then either latching or non-latching.

7.3.2 Fault relay

Millennium II Basic transmitters and sensors complete conti nu al c hecks for situations that may prevent

the transmitter and sensor from providing an expected response to ambient conditions and records

these as a fault condition in the message log and the output(s) of the tr ansmitter. When a syste m fault

is detected, the Red Status LED will flash fa st (250 millisecond s o n, 250 milliseconds off), the analog

output will output a 2.5 mA signal, and the fault relay will change st ates (de-energize to provide a fault

condition).

The fault relay is normally energized when no fault conditions are present and is set up for non-latching.

The operation of the fault relay is not configurable.

The Millennium II Basic transmitter provides various fault conditions to indicate that the transmitter or

connected sensor(s) are not operating as expected. These fault conditions will override any alarm

conditions because the sensor may be unable to detect a gas exposure reliably. Examples of fault

conditions can range from no detection due to memory or communication errors and sensor failure.

Other faults can provide unreliable detection due to sensor drift or sensor nearing the end of its life.

When a Millennium II Basic transmitter is in fault mode, immediate action should be taken to determine

the source and correct the fault condition.

automatic shutdown. The fault output

7.4 RS-485 Modbus RTU (Optional)

Modbus digital RS-485 Modbus RTU protocol is used.

The Millennium II Basic transmitter utilizes 2- wire Modbus RS-485 multi serial mode. This Modbus

solution implements a 2-wire electrical interface in accordance with the EIA/TIA-485 standards. F or this

Modbus configuration, it is important that a third wire be used for connecting all the commons (COM)

in the chain. Also a 120 Ohm line termination is required for the last device in the line. See Figure 7-3.

The Instrument Engineer is responsible for calculating line length and adhering to Modbus protocols.

Page 37

Reference Manual Monitoring and outputs

Monitoring and outputs 29

Figure 7-3 Two-wire Modbus configuration

Reg#

Meaning

Readable

Writeable

40001

Concentration value as calculated by sensor (RTUsensor_out), Channel 1

X

40002

Sensor status (RTUsensor_stat)

X

40003

Temperature of sensor element housing in Kelvin (RTU temperature)

X

40011

Calibration gas value

X

40021

Sensor class

X 40022

Low alarm value

X X 40023

High alarm value

X X 40027

Current sensor range

X

X

40101

Reset sensor

X

40102

Full calibration

X

40104

Zero calibration

X

MAN-0082, Revisio n 08 June 2016

7.4.1 Modbus registers

Page 38

Monitoring and outputs Reference Manual

30 Monitoring and outputs

Condition

Current output

LED indication

Relay outputs

Fault

Alarm

No gas present

4 mA

Slow green

Normal state

Normal state

Gas present, concentration below alarm points

4-20 mA depending

on gas concentration

Slow red

Normal state

Normal state

Gas present, concentration above alarm points

4-20 mA depending

on gas concentration

Slow red

Normal state

Alarm state

Fault condition present, no gas present

2.5 mA

Very fast red

Fault state

Normal state

Fault condition present, gas present

2.5 mA

Very fast red

Fault state

Normal state

Fault condition present, gas above alarm points

2.5 mA

Very fast red

Fault state

Normal state

Electrochemical XChem sensors only:

Very fast red

Fault state for 5

55 seconds

Normal state

Fault relay:

LED indications:

Flash description

On

Off

Slow

50 milliseconds

1 second

Fast

250 milliseconds

250 milliseconds

Very fast

50 milliseconds

50 milliseconds

Alarm relay(s):

June 2016 MAN-0082, Re vision 08

7.5 Transmitter output operation

The following table outlines the operation of the outputs of the Millennium II Basic transmitter under

different conditions. These outputs include the analog output, LED indications, and the relay outputs.

For the outputs’ status, refer to the descriptions below the table.

Sensor end of life condition present, gas above or below

alarm points

Fault state means that t he r elay is in the de-energized state. Normal state means that the

relay is in the energized state.

Flash rates are outlined in the following table:

Alarm state means that if the r elay is programmed for normally de-energized, the relay

will energize to alarm; if the relay is programmed for normally energized, the relay will de-energize to

alarm. Normal state is what state that the relay i s p r ogrammed for (e.g. normally energized o r normally

de-energized).

2.5 mA for 10

seconds, 4-20 mA

for 50 seconds

seconds,

normal state for

Page 39

Reference Manual Monitoring and outputs

Monitoring and outputs 31

The fault detection circuitry does not monitor the operation of external response equipment or

external wiring to the transmitter. It is important that extern al equi pment and wiring be checked

periodically to ensure they are operational.

Fault conditions will override any alarm conditions because the sensor may be unable to detect a gas

exposure reliably, as such, the alarm relay will not provide an output.

Fault conditions provided by an instrumentation device are critical indicators that the device is not

operating as expected; therefore, when a fault condi ti o n is present, immediate a ttention to that fault

condition is required.

Net Safety strongly recommends that the 2.5 mA analog fault condition and fault relay (if used) be

monitored in conjunction with alarm levels on the analog output and the alarm relay, if used.

Fault condition

M2B

Input voltage less than 8 VDC

Critical memory fault

Onboard power supply fault

MAN-0082, Revisio n 08 June 2016

7.6 Fault monitoring

Self-testing circuitry continuously checks for problems that could prevent proper response. When

power is applied to the Millennium II Basic Transmitter, a microcontroller automatically tests the

system to ensure that it is functioning properly. During normal operation, it continuously monitors the

signal from the internal sensor source. In addition, a watchdog timer is maintained to ensure the

program is running cor r e c tl y. When a system faul t i s d e tected, the Status LED will have a red fast flash

and the fault signal will output a 2.5 mA signal. The transmitter’s event log may be viewed in order to

distinguish the fault condition.

7.7 Fault conditions

7.7.1 Transmitter fault condit ions

Fault conditions that t he tr ansmitter detects ar e as follows:

P

Input voltage more than 33 VDC

P

P

P

Page 40

Monitoring and outputs Reference Manual

32 Monitoring and outputs

Fault condition

SC310

SC311

ST322

ST332

ST340

ST320

ST330

ST341

ST360

Zero calibration failure

Span calibration failure

Low temperature

High temperature

Low power

P P P P P

High power

P P P P P

Replace sensor

P P P P P P P P P

Zero drift

P P P P P

Signal invalid

P

Over-range

P P P P P

Memory fault

Power supply fault

Sensor end of life

Sensor weak signal

Sensor thermistor fault

June 2016 MAN-0082, Re vision 08

7.7.2 Sensor fault conditions

Fault conditions that the various Millennium II sensors detect are as follows:

P P P P P

P P P P P P P P P

P P P P

P P P P

P P P P P P P P P

P P P P P

P P P P P P

P P P P

P

Page 41

Reference Manual Maintenance

Maintenance 33

MAN-0082, Revisio n 08 June 2016

Section 8: Maintenance

8.1 Periodic response check

Net Safety Monitoring recommends that a bump test be performed every ninety (90) days to ens ur e

continued functionality and accuracy of the detection system. Full calibration is recommended when

the sensor fails to meet acc eptable accuracy standards. This involves the application of calibration gas

to the sensor, then the o b servation of the response LEDs, analog output, and external monitoring

equipment. Be sure to prevent unwanted response of external monitoring dev i ces an d eq uipment

during this procedure. If the Millennium II Basic’s response to calibration gas is within the specified

accuracy then it is not ne c essary to perform a calibration.

Example: When 50% of full scale is applied, the response is expected to be between 1 1.5 mA (4 7% of full

scale) and 12.5 mA (53% o f full scale). An additional consideration i s the ac cu racy tolerance of the

calibration gas whic h m ay be plus or minus a few percent. If the calibrati o n g as i s ±10% of full scale then

the reading may be fro m 10.7 mA (42% of full scale) to 13.3 mA (58% of full sc ale).

8.2 Troubleshooting

Response to the input should be checked and, if necessary, calibration should be performed whenever

the accuracy of this check is not satisfactory . The system should also be checked when sen so r o r

transmitter is added or removed. If problems should develop, first check for faulty wiring, confirm

proper voltage to transmitter and attempt a cal i br atio n. If pr o bl e ms per sist, pl ease contact Net

Safety’s support department first by phone to t r y and r esolve any issues. If i ssues cannot be resolv e d,

please follow the procedure on how to return equipment.

8.3 Storage

The transmitter and its electronic components/parts should be stored in locations free from dust and

moisture. The storage temperature should be well within the limits of the certified temperatures of the

equipment. See Section 11 for storage temperatures.

Page 42

Maintenance Reference Manual

34 Maintenance

Description

Part Number

3/4 NPT ATEX certified plug - Aluminum

CP-AL-002

3/4 NPT ATEX certified plug - Stainless Steel

CP-SS-001

Conduit reducer - 3/4” to M20 - Aluminum

M20R

Conduit reducer - 3/4” to M20 - Stainless Steel

M20R-SS

Aluminum separation kit

JB-MPD-A

Stainless Steel separation kit

JB-MPD-S

Magnet assembly

MAGNET-1

Sun shade kit - Requires UN-MK-1

SSK-2

1" Pipe Mounted Sun shade kit/rain guard - Includes UN-MK-31

SSK-51

2" Pipe Mounted Sun shade kit/rain guard - includes UN-MK-32

SSK-52

3" Pipe Mounted Sun shade kit/rain guard - Includes UN-MK-33

SSK-53

Millennium II Basic transmitter board - Analog output

TX-M2B-A

Millennium II Basic transmitter board - Analog/HART output

TX-M2B-AH

Millennium II Basic transmitter board - Analog/HART output for wireless

TX-M2B-AH-FC

Millennium II Basic transmitter board - Modbus output

TX-M2B-D

Millennium II Basic transmitter board - Relay output

TX-M2B-R

2" Pipe Mounting kit (stainless steel)

UN-MK-1

1" Pipe Mounting kit - All Millennium II & ECO-SENSE Gas Detectors

(stainless steel)

UN-MK-31

2" Pipe Mounting kit - All Millennium II & ECO-SENSE Gas Detectors

(stainless steel)

UN-MK-32

3" Pipe Mounting kit - All Millennium II & ECO-SENSE Gas Detectors

(stainless steel)

UN-MK-33

June 2016 MAN-0082, Re vision 08

8.4 Spare parts and accessories

capable transmitters

Page 43

Reference Manual Electrostatic sensitive device

Electrostatic sensitive device 35

MAN-0082, Revisio n 08 June 2016

Section 9: Electrostatic sensi ti ve d evi ce

Definition: Electrostatic discharge (ESD) is the transfer, between bodies, of an electrostatic charge

caused by direct contact or induced by an electrostatic field.

The most common cause o f E SD i s p hysical contact. Tou ching an object can cause a discharge of

electrostatic energy. If the charge is sufficient and occurs near electronic components, it can damage

or destroy those comp o ne nts. In some cases, damage is instantaneo us and an immediate m al function

occurs. However, symptoms are not always im mediate—performance may be marginal or seemingly

normal for an indefinite period of time, followed by a sudden failure.

To eliminate potential ESD damage, review the following guidelines:

• Handle boards by the sid es —taking care not to touch electronic components.

• Wear grounded wrist o r foot straps, ESD shoes or heel gro unders to dissipate unwant ed static

energy.

• Prior to handling boards, dispel any charge in your body or equipment by touching a grounded

metal surface.

• Ensure all compone nts are transported and sto r ed i n ESD safe packaging.

• When returning boards, carefully package in the original carton and static protective wrapping.

• Ensure ALL personnel are ed uc ated and trained in ESD Control Pr o ce dur e s .

In general, exercise accepted and proven precautions normally observed when handling electrostatic

sensitive devices.

Page 44

Wire resistance table Reference Manual

36 Wire re s istance table

Distance

Feet (Meters)

AWG #20

0.5 mm2

AWG #18

0.8 mm2

AWG #16

1.0 mm2

AWG #14

2.0 mm2

100 (30.5)

1.02

0.64

0.40

0.25

200 (61)

2.03

1.28

0.80

0.51

300 (91.4)

3.05

1.92

1.20

0.76

400 (121.9)

4.06

2.55

1.61

1.01

500 (152.4)

5.08

3.20

2.01

1.26

600 (182.9)

6.09

3.83

2.41

1.52

700 (213.4)

7.11

4.47

2.81

1.77

800 (243.8)

8.12

5.11

3.21

2.02

900 (274.3)

9.14

5.75

3.61

2.27

1000 (304.8)

10.20

6.39

4.02

2.53

1250 (381)

12.70

7.99

5.03

3.16

1500 (457.2)

15.20

9.58

6.02

3.79

1750 (533.4)

17.80

11.20

7.03

4.42

2000 (609.6)

20.30

12.80

8.03

5.05

2250 (685.8)

22.80

14.40

9.03

5.68

2500 (762)

25.40

16.00

10.00

6.31

3000 (914.4)

30.50

19.20

12.00

7.58

3500 (1066.8)

35.50

22.40

14.10

8.84

4000 (1219.2)

40.60

25.50

16.10

10.00

4500 (1371.6)

45.70

28.70

18.10

11.40

5000 (1524)

50.10

32.00

20.10

12.60

5500 (1676.4)

55.80

35.10

22.10

13.91

6000 (1828.8)

61.00

38.30

24.10

15.20

6500 (1981.2)

66.00