Page 1

M22 Transmitter

FGD-PDS-M22-Transmitter

M22 Transmitter

Dual Channel Universal Gas Monitoring

The Millennium II (M22) dual channel universal

transmitters have been engineered from the

ground-up to include the innovative features

that managers and operators in the field

demand, while providing rock solid day-to-day

operation, even in the most extreme conditions.

The Millennium II redefines what you expect

from a fixed gas detection solution.

M22 (SS & AL) shown with SX3 Series Sensors

One transmitter for two detection points

Universal Transmitter — compatible with all

sensor types (infrared, catalytic bead, and

electrochemical)

Wide voltage range allows for greater stability

and system compatibility

Lowest power consumption available

Mix and match all sensor types on a single

transmitter, greater coverage and fl exibility

Full diagnostics with event and data logging

Intuitive menu system provides operators with

non-intrusive set-up and calibration interface

eld selectable gas curves and ranges

Long range (+2,000 ft) sensor separation

Product Data Sheet

July 2016

Dual Channel Transmitter

A single transmitter which accepts two sensor inputs and

provides two separate output signals, reducing initial

purchasing and installation costs.

Universal Transmitter

The transmitter can be tted with a wide range of toxic

and/or combustible gas sensors. Sensors are pre-calibrated

and easily connected to the transmitter which recognizes a

newly tted sensor, automatically uploading sensors’ speci c

con guration pro le.

Digital Communications

Sensor and transmitter continuously communicate digitally,

giving you the con dence of stable, accurate protection with

fast response times even over long separation distances.

Easy To Use Menus

English, French, Portuguese, or Spanish display languages

included. The full text menu makes installation, operation, and

calibration simple. No manual necessary!

Superior OLED Display

The only full graphic OLED display available, easy to read in all

ambient lighting conditions.

Analog, Relay, Modbus® RS485 RTU

Multiple communication protocols allow the M22 to work

seamlessly with your new or existing system.

Field-proven Sensor Innovations

All of our sensors are engineered to be fast and reliable

with eld-proven performance in the harshest industrial

conditions possible. These include a full range of fast response

electrochemical toxic gas sensors. For combustible gas

detection, poison resistant catalytic bead technology with

SensorGuard, which greatly prolongs sensor life and infrared

sensor technology utilizing a dual beam design with no mirrors

that can become contaminated (“fogged up”) or misaligned.

Page 2

M22 Transmitter

Specifications

Table 1 - Millennium II M22 Dual Channel Transmitter

Electrical

Power Consumption 2.4 W @ 24 VDC (average - varies by sensor types/quantities)

Voltage Range 10.5 –32.0 VDC

EMC Compliance EN 50270: 2006 per EMC directive 2004/108/EC

Display Organic LED (OLED), Power/Status LED‘s

Environmental

Temperature -67 °F to +185 °F (-55 °C to +85 °C ) - Stainless steel

Relative Humidity 0–95 % RH non condensing

Ingress Protection IP66 (Aluminum), IP67 (Stainless Steel), IP64 (with sensors) Type 4X

Mechanical

Enclosure Material Cast Aluminum (A359) or Stainless Steel (SS316)

Conduit Opening ¾'' NPT (3X)

Outputs

Certifications North American

Sensors

Warranty 3 years

Mounting Surface Mount/Pipe Mount/Duct Mount

Weight Aluminum: 5.5 lbs (2.5 kg), Stainless steel: 7.0 lbs (3.2 kg)

-58 °F to +185 °F (-50 °C to+85 °C ) - Stainless steel - North American explosion-proof certication

-40 °F to +185 °F (-40 °C to +85 °C ) - Aluminum

Standard: Analog 4–20 mA

®

Optional: Four 5 A Form C Relays, and RS 485 Modbus

Class I, Division 1, Groups BCD T5

Class I, Zone 1, AEX/Ex d IIB+H2 T5

-50 °C ≤ Ta ≤ + 85 °C

NEMA Type 4X/IP67

FM6320, ANSI/ISA 12.13.01, CSA 22.2 No. 152:2006

IECEx

Ex d IIB+H2 T5 Gb

IECEx DNV 12.0014 (Aluminum) IP66, controller only

IECEx FMG 12.0006X (Stainless Steel) IP 67, controller only

IEC 60079-0: 2007-10 & IEC 60079-1: 2007-04

Inmetro

Ex d IIB+H2 T5 Gb IP67

Combustible Gases: SC3 Series Infrared and Catalytic Bead

Toxic Gases: ST3 Series Electrochemical

RTU

July 2016

Ordering Information

M22-A Dual Channel - Analog

M22-AR Dual Channel - Analog & Relay

M22-AD Dual Channel - Analog & Modbus

M22-ARD Dual Channel - Analog & Relay & Modbus

Enclosures Available: Aluminum (-A) Stainless Steel (-S)

Ordering Matrix Example:

M22-AD-S (Transmitter - Output - Enclosure Material)

Special Features

Current loop test jacks for each channel on faceplate

Non-intrusive one man calibration (magnetic switch)

Field selectable toxic gas ranges

Redundant menu access via push buttons

Sensor enable/disable option from menu (Cl1, Div2)

Alarm relays congurable/assignable to any channel

Displayed eventlogging (980 events)

Retrieve last calibration info from sensor

Four languages - English, French, Spanish, Portuguese

Accessories

Mounting Bracket Complete With Hardware

Sun Shade/Deluge Protection

Duct Mount and Hardware Kit

2 EmersonProcess.com/FlameGasDetection

Page 3

July 2016

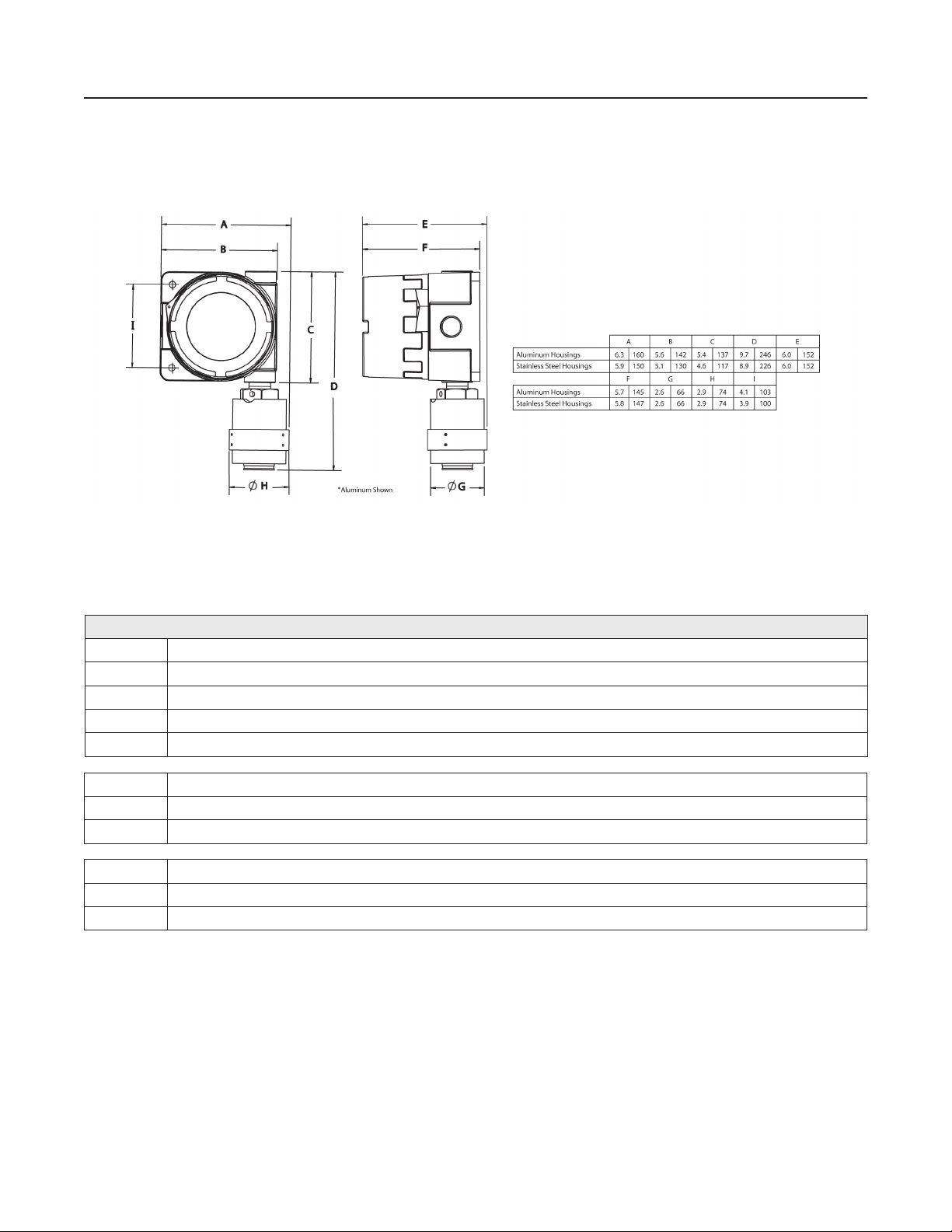

Figure 1 - Millennium II M22 Dual Channel Transmitter Dimensions

M22 Transmitter

Accessories

Table 2 - Accessories

Accessories

UDM-001 Universal duct mount assembly with 1 m inlet sampling pipe - Stainless Steel

UDM-002 Universal duct mount assembly with 1.5 m inlet sampling pipe - Stainless Steel

UDM-003 Universal duct mount assembly - Stainless Steel

UDM-EX1 1 m extension - for use with UDM-001 and UDM-002 - Stainless Steel

UDM-EX2 1.5 m extension - for use with UDM-001 and UDM-002 - Stainless Steel

UN-MK-31 1'' Pipe Mounting kit c/w stainless steel mounting bracket and hardware

UN-MK-32 2'' Pipe Mounting kit c/w stainless steel mounting bracket and hardware

UN-MK-33 3'' Pipe Mounting kit c/w stainless steel mounting bracket and hardware

SSK-51 1'' Pipe Mounted Sun shade kit/rain guard - Stainless steel - includes UN-MK-31 Mounting Kit

SSK-52 2'' Pipe Mounted Sun shade kit/rain guard - Stainless steel - includes UN-MK-32 Mounting Kit

SSK-53 3'' Pipe Mounted Sun shade kit/rain guard - Stainless steel - includes UN-MK-33 Mounting Kit

3EmersonProcess.com/FlameGasDetection

Page 4

M22 Transmitter

FGD-PDS-M22-Transmitter

EmersonProcess.com/FlameGasDetection

Product Data Sheet

July 2016

YouTube.com/user/RosemountAnalytical

Twitter.com/Rosemount_News

Americas

Emerson Process Management

6021 Innovation Blvd.

Shakopee, MN 55379

USA

T + 1 866 347 3427

F + 1 952 949 7001

Safety.CSC@Emerson.com

Europe

Emerson Process Management AG

Neuhofstrasse 19a P.O. Box 1046

CH-6340 Baar

Switzerland

T + 41 (0) 41 768 6111

F + 41 (0) 41 768 6300

Safety.CSC@Emerson.com

©2016 Emerson Process Management. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Rosemount and

the Rosemount logotype are registered trademarks of Rosemount Inc. All other marks are the

property of their respective owners.

The contents of this publication are presented for information purposes only, and while effort

has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their

use or applicability. All sales are governed by our terms and conditions, which are available on

request. We reserve the right to modify or improve the designs or specications of our products

at any time without notice.

Analyticexpert.com

Facebook.com/Rosemount

Middle East & Asia

Emerson Process Management

Emerson FZE

Jebel Ali Free Zone

Dubai, UAE

P.O. Box 17033

T + 971 4 811 8100

F + 971 4 886 5465

Safety.CSC@Emerson.com

Asia Pacific

Emerson Process Management

1 Pandan Crescent

Singapore 128461

Singapore

T + 65 777 8211

F + 65 777 0947

Safety.CSC@Emerson.com

Loading...

Loading...