Page 1

Ultrasonic Pressurized Gas Leak Detector

User Operation Manual

Model: NSM-SU343

MAN-0129 Rev 0.3

December 8, 2010

Page 2

IMPORTANT INFORMATION

Net Safety Monitoring Inc.

Direct: (403) 219-0688

Corporate Headquarters

Facsimile: (403) 219-0694

2721 Hopewell Place NE

E-mail: nsmsales@net-safety.com

Calgary, AB Canada T1Y 7J7

Web-site: www.net-safety.com/

This manual is for informational purposes only. Although every effort has been made to ensure the

correctness of the information, technical inaccuracies may occur and periodic changes may be made

without notice. Net Safety Monitoring Inc., assumes no responsibility for any errors contained within this

manual.

If the products or procedures are used for purposes other than as described in the manual, without

receiving prior confirmation of validity or suitability, Net Safety Monitoring Inc., does not guarantee the

results and assumes no obligation or liability. No part of this manual may be copied, disseminated or

distributed without the express written consent of Net Safety Monitoring Inc.

Net Safety Monitoring Inc., products are carefully designed and manufactured from high quality

components and can be expected to provide many years of trouble free service. Each product is

thoroughly tested, inspected and calibrated prior to shipment. Failures can occur which are beyond the

control of the manufacturer. Failures can be minimized by adhering to the operating and maintenance

instructions herein. Where the absolute greatest of reliability is required, redundancy should be designed

into the system.

WARRANTY

Net Safety Monitoring Inc warrants its electronic assemblies against defective parts and workmanship

for a period of 18 months from date of purchase to 12 months from the date of commissioning,

whichever is the shorter period. No other warranties or liability, expressed or implied, will be honored by

Net Safety Monitoring Inc. Contact Net Safety Monitoring Inc. or an authorized representative for

details.

We welcome your input at Net Safety Monitoring. If you have any comments please contact us at the

phone/ address below or visit our website and complete our on-line customer survey: www.net-

safety.com/

If further language translation for this manual is required please contact:

CONTACT INFORMATION

© Net Safety Monitoring, Inc. 2010. All rights reserved.

MAN-0129 SU343 Rev 0.3 Page 2 of 50

Page 3

TABLE OF CONTENTS

1. Product Overview ............................................................................................................................. 4

1.1. Technical Specification ............................................................................................................... 5

1.2. Design Standards ....................................................................................................................... 6

2. General Operation ............................................................................................................................ 7

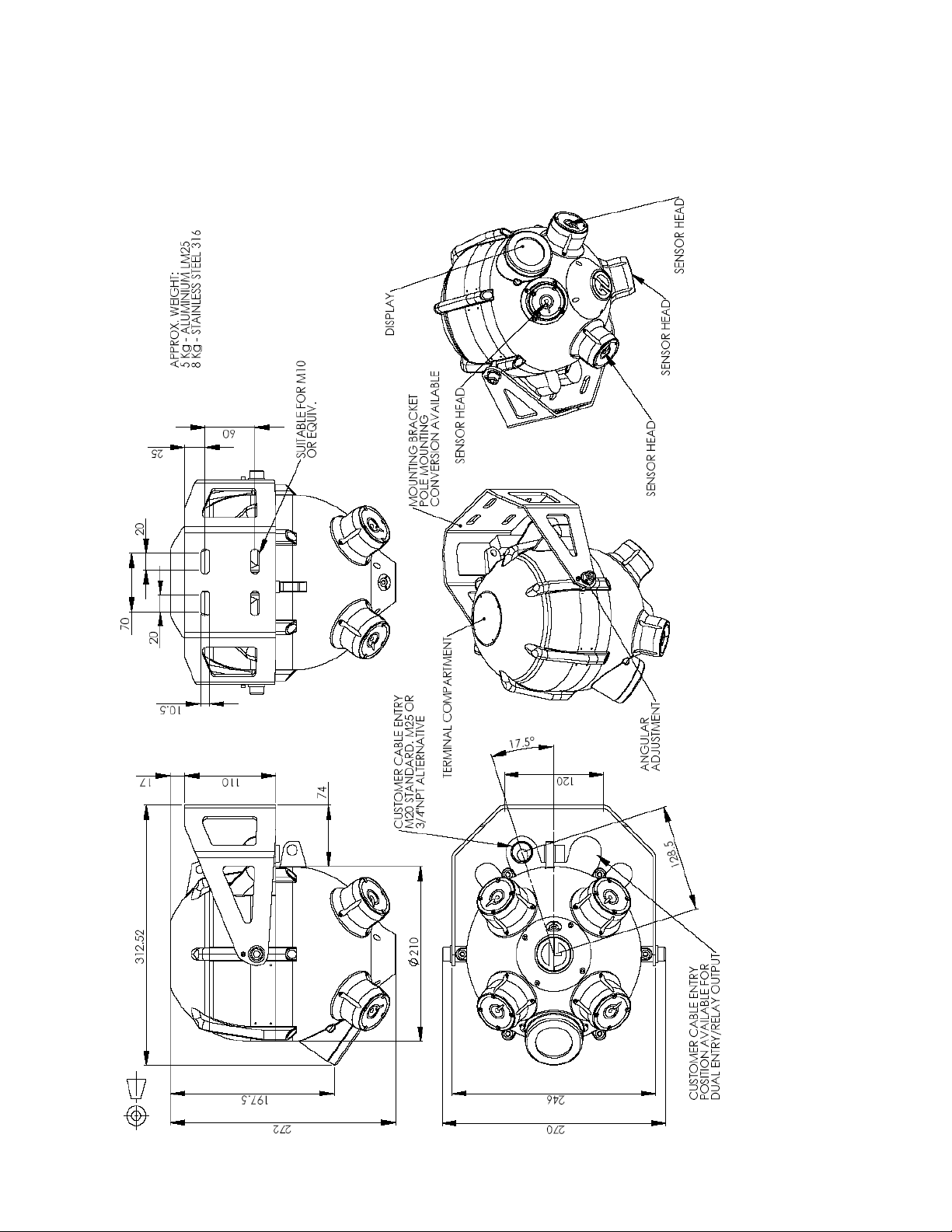

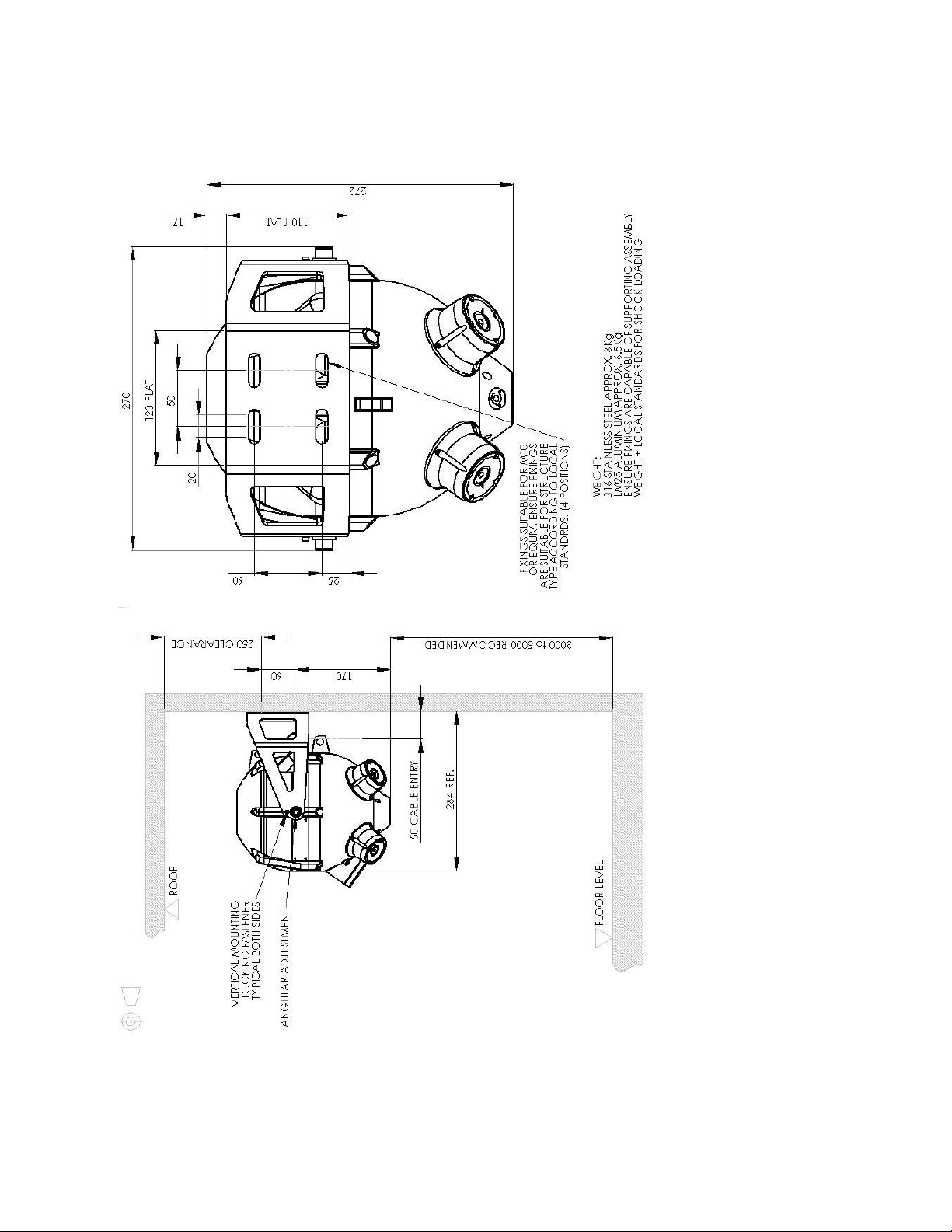

2.1. Overall Dimensions ..................................................................................................................... 8

2.2. Electrical Connection Drawing .................................................................................................... 9

3. Installation / Commissioning / Maintenance ................................................................................ 10

3.1. Installation Procedure ............................................................................................................... 10

3.1.1. Mechanical Installation .................................................................................................... 10

3.1.2. Mechanical Positioning ................................ ................................................................... 11

3.1.3. Wall / Flat Surface Mounting ........................................................................................... 13

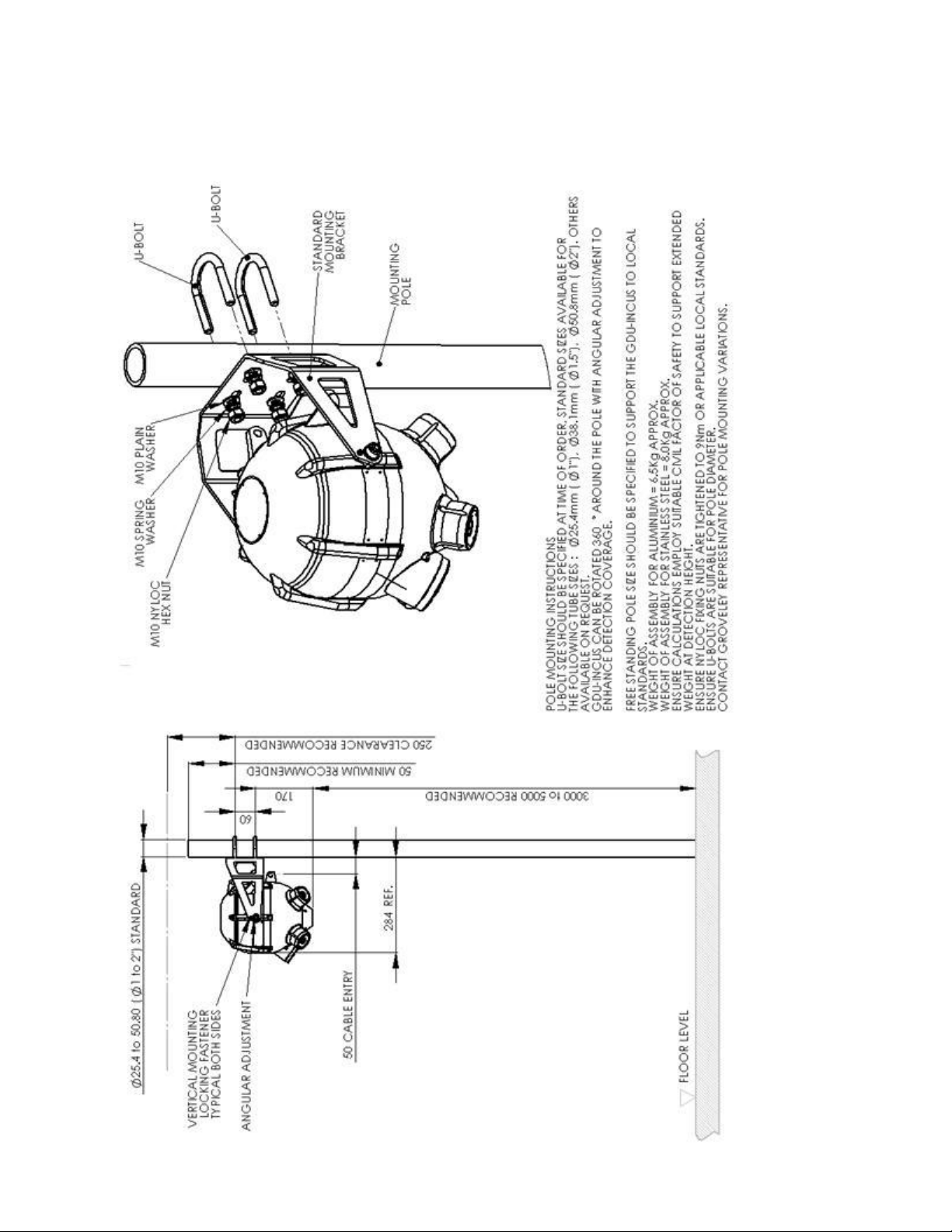

3.1.4. Pole Mounting ................................................................................................................. 14

3.1.5. Vibration Mounting .......................................................................................................... 15

3.1.6. Electrical Installation ....................................................................................................... 17

3.2. Commissioning ......................................................................................................................... 21

3.2.1. Visual .............................................................................................................................. 21

3.2.2. Power up ........................................................................................................................ 22

3.2.3. User Changeable Functions Set-up ................................................................................ 22

3.2.4. Function Check ............................................................................................................... 26

3.3. Operating Principles / Instruction .............................................................................................. 26

3.3.1. Normal Operation ........................................................................................................... 26

3.3.2. Alarm Level ..................................................................................................................... 27

3.3.3. Alarm Delay ................................................................................................ .................... 28

3.3.4. Self-Test and Self-Clean ................................................................................................. 30

3.3.5. Heating (Optional) ........................................................................................................... 31

3.3.6. Output Options ................................................................................................................ 32

3.4. Maintenance Procedures .......................................................................................................... 39

3.4.1. Hand held Test ............................................................................................................... 39

3.4.2. Verification Test .............................................................................................................. 40

4. Customer Interface Commands .................................................................................................... 40

4.1. RS485 Digital Interface ............................................................................................................. 40

4.1.1. Customer Commands ..................................................................................................... 40

5. Warnings......................................................................................................................................... 43

5.1. Use in Hazardous Areas ........................................................................................................... 43

5.2. Ownership & Confidentiality ...................................................................................................... 44

5.3. Accessories .............................................................................................................................. 44

5.4. Liability ...................................................................................................................................... 44

6. Accessories and Spare Parts ........................................................................................................ 45

6.1. Accessories .............................................................................................................................. 45

6.2. Spare Parts ............................................................................................................................... 46

6.3. Ordering Information ................................................................................................ ................. 47

6.4. Accessories .............................................................................................................................. 48

6.5. Spare Parts ............................................................................................................................... 48

MAN-0129 SU343 Rev 0.3 Page 3 of 50

Page 4

1. PRODUCT OVERVIEW

NSM-SU343 is an ultrasonic gas leak detector for detecting airborne ultrasound generated from

pressurized gas leaks.

Airborne ultrasound is generated when gas moves from a high-pressure area to a low pressure area

with a ratio of 1.8:1 upstream to downstream, however, NSM-SU343 is only recommended for pressures

down to 2 bar(29psi). The amount of airborne ultrasound generated is due to a number of factors

including but not limited to gas pressure, leak size and gas temperature.

NSM-SU343 uses 4 individual piezo ceramic sensing heads. The sensor design makes the sensing

heads virtually indestructible and totally immune to temperature, moisture and other contaminants found

in hazardous industry.

NSM-SU343 has a large dynamic range which allows use in a large range of applications from

laboratories to turbine houses. The multi-stage amplifier ensures a completely linear output across the

entire detector range without drop-off at each end of range.

NSM-SU343 is not designed to detect specific gas types, LEL or ppm, but instead responds

instantaneously to a wide range of leak sizes whilst being un-affected by even the most extreme weather

conditions. NSM-SU343 is rated to IP66 / IP67 to withstand harsh environments and continues to work

during temporary immersion.

NSM-SU343 uses a continuous background monitoring test feature alongside a broadband self-test and

clean facility to ensure complete functionality. The broadband self-test comprises a pressurized air jet

across both flat faces of the cylindrical piezo crystal so testing is confirmed using the medium of interest.

The broadband self-test can be requested on demand from the main control system or programmed to

activate at known intervals.

NSM-SU343 has an optional heating / cooling facility which enables the internal electronics to be kept

within normal parameters even at ambient temperatures such as -55°C (-67°F) to +85°C (+185°F).

Unlike most heating systems the NSM-SU343 has an ultra efficient heating system that reacts to the

environment allowing minimal power usage.

NSM-SU343 has complete customer flexibility and can be configured to mimic existing forms of detector

outputs and protocol featuring 4 – 20mA analogue output and RS485 digital interface.

NSM-SU343 also features infra-red communication which allows complete communication and setting

ability from up to 8m (26ft) range using the NSM -SU343 handheld series of intelligent communicators.

NSM-SU343 handheld series allows users to map for ultrasound, test ultrasonic detectors using a

powerful 40kHz sound source of 100dB at 1m (3ft), communicate and program the NSM-SU343 and

communicate via Infra-red interface. See section 6 Accessories and Spare Parts or contact a Net Safety

Monitoring representative for further details.

MAN-0129 SU343 Rev 0.3 Page 4 of 50

Page 5

1.1. TECHNICAL SPECIFICATION

General

Detection method

Floating Piezo Ceramic – non consumable, non ageing.

Gases detected

All pressurised gases, minimum leak pressure 2 bar, leak size

dependant

Self-test

Continuous background check and broadband pressurised gas

release on demand or via customer defined cycle

Calibration

Factory set. Broadband self-test check requires no field calibration

Performance

Detection range

25kHz to 100kHz

Dynamic range

50dB to 140dB

Response time

Instantaneous (alarm delay via 1 second variable increments –

customer programmable)

Detection coverage

2 to 40 meter (7 to 131 foot) radius (leak pressure, size and

background level dependant)

Test frequency

>2Hz to <100kHz ±2kHz at defined frequencies

Test sound pressure

100dB ±4dB at sensor

Start-up time

Less than 20 seconds

Output Signal

4 – 20mA

Current source 4 – 20mA, corresponds to 40 to 200dB SPL –

Maximum load resistance 500Ω standard (options available)

Digital

RS485 interface

Option

Current sink 4 – 20mA

Relay 1

Error / Fault (NO or NC option) Load: 2A max. Switch Voltage

220VDC max. Indication resistance 70 milliohm. See Section 3.3.6.1

Relay Options for further configurations.

Relay 2

Alarm (NO or NC option)

Relay 3

Maintenance (Alert for next maintenance schedule – non urgent)

Detector Faults

0mA

No power or microprocessor fault

0.5mA

Over temperature fault

1.0mA

Watchdog fault, electronic test fault, high/low voltage fault.

2.0mA

Test Fault

2.5 to 3.0mA

Function Fault

Power

Supply

24V DC, range 15 – 30 V DC

Current Consumption

250mA normal operation

3A maximum at -55°C (-67°F) heated option

Cable entry

M20 x 2 Ex d cable gland (M25 x 2, ½” NPT x 2, ¾ NPT x 2 or any

combination option)

M20 x 2 serial link option

MAN-0129 SU343 Rev 0.3 Page 5 of 50

Page 6

Temperature Range

Storage

-40°C to +70°C (-40°F to +158°F)

Operating

-40°C to +85°C (-40°F to +185°F)

Operating option

-55°C to +85°C (-67°F to +185°F)

Humidity (operating)

0 to 100% relative humidity

Ingress Protection

IP66 / IP67

Approvals

ATEX

II 2 G Ex d ib IIB+H₂ T4 Gb (Tamb -55°C to +85°C)

ITS09ATEX16836X

IECEx

Ex d ib IIB+H2 T4 Gb (Tamb -55°C to +85°C)

IECEx ITS 10.0004X

Enclosure

Stainless steel AISI 316.

Weight Approx. 8kg (17.5 lb)

Aluminium LM25TF BS1490.

Weight Approx. 6.5kg (14.3 lb)

Dimensions (without bracket)

Ø210 x 272mm (Ø8 1/4 “ x 10 3/4 “)

1.2. DESIGN STANDARDS

IEC / EN60079-0:2009 Electrical apparatus for potentially explosive atmospheres – Part 0: General

requirements

IEC/EN60079-1:2007 Electrical apparatus for potentially explosive atmospheres – Part 1: Equipment

protection by flameproof enclosures “d”

EN60079-11:2007 Electrical apparatus for potentially explosive atmospheres – Part 11: Equipment

protection by intrinsic safety “i”

EN60529:1992 Specification for degrees of protection provided by enclosures (IP code)

MAN-0129 SU343 Rev 0.3 Page 6 of 50

Page 7

2. GENERAL OPERATION

NSM-SU343 is omni-directional and is recommended to be mounted between 3 to 5 meters (10 to 16

feet) above the area of interest to eliminate ground absorption and reflections.

It is recommended that the area where the NSM-SU343 is to be situated is ultrasonically mapped prior

to installation or at commissioning whilst all process is running to establish a background noise level for

alarm purposes. Alarm level should be set 6dB above the background noise level at levels below 70dB

and then the value above background shown in the alarm level graph in section 3.3.2 Alarm Level.

Please contact a Net Safety Monitoring representative to request a mapping survey or mapping tools.

NSM-SU343 responds to pressurized gas leaks or sources of ultrasonic noise between 25kHz and

100kHz instantaneously, it is, therefore, recommended that a time delay is built in to the control system

or internally in the NSM-SU343 to prevent spurious alarms. This is especially important in areas with

pressure relief valves or areas of high human involvement or maintenance work. The alarm delay is

recommended at a minimum of 10 seconds but this should be increased in response to the process

located near to the detector as shown in the graph in section 3.3.3 Alarm Delay.

Area monitored by NSM-SU343 is affected by several factors such as background noise level, gas

pressure, leak size, temperature of gas and environmental conditions. Net Safety Monitoring has

formulated a series of calculations and built up a database of detection radius using gas leak testing to

determine accurate coverage information for most situations. Please contact Net Safety Monitoring or a

Net Safety Monitoring representative to advise on appropriate coverage for each installation.

NSM-SU343 detection coverage can be verified at installation or as part of a maintenance schedule

using the NSM-PTV Performance Target Verification Kit to simulate an actual gas release of known size

and pressure at the perimeter of the NSM-SU343 detection radius. See section 6 Accessories and

Spare Parts or contact a Net Safety Monitoring representative for further details.

Compared to other Ultrasonic and traditional forms of detection, the NSM-SU343 has the following

advantages:

Presence of gas is not required

Unaffected by weather conditions

Sensors are unaffected by temperature, pressure, moisture and contaminant build-up

Multiple sensor redundancy in each unit

Continuous and forced self-test function

Self-clean function

No calibration required results in cost saving over detector life cycle

Can be remotely tested from up to 8m (26ft) distance saving on maintenance scaffold costs

Can be remotely programmed from control room or 8m (26ft) distance using handheld

communicator

Can be programmed to mimic any detector inputs to suit existing control system

Can be set-up to act as a standalone unit

Multiple Detectors can be linked together to save control system I/O

MAN-0129 SU343 Rev 0.3 Page 7 of 50

Page 8

2.1. OVERALL DIMENSIONS

MAN-0129 SU343 Rev 0.3 Page 8 of 50

Page 9

2.2. ELECTRICAL CONNECTION DRAWING

MAN-0129 SU343 Rev 0.3 Page 9 of 50

Page 10

3. INSTALLATION / COMMISSIONING / MAINTENANCE

Warnings:

The area in which the detector may be mounted must be in accordance with the certification of

the apparatus and in accordance with the standards of the appropriate authority in the country

concerned.

Do not modify the enclosure or component parts as this will compromise the Hazardous Area

Certification.

Ensure all wiring and power supply to the detector is within specified operating parameters.

NSM-SU343 is a sealed unit with the exception of the terminal cover; the main enclosure is not to

be opened by anybody other than Net Safety Monitoring or Net Safety Monitoring authorized

personnel. All warranties and certification are nullified if these seals are broken or tampered

with.

NSM-SU343 is supplied without cable glands. Ensure all cable entry threads are sealed with an

appropriate plug to eliminate water ingress and thread damage. At installation all shipping cable

entry plugs are to be removed and replaced with suitably approved Ex d cable glands or plugs.

3.1. INSTALLATION PROCEDURE

Mounting height of NSM-SU343 is recommended between 3 and 5 meters (10 and 16 feet) above floor

level to eliminate ground reflections and absorption. NSM-SU343 may be used lower than 3 meters (10

feet) but coverage may be reduced, please contact Net Safety Monitoring or a Net Safety Monitoring

representative for details.

It is recommended that all identification tags are firmly secured to prevent unwanted locally generated

ultrasonic noise.

Observe the area of installation for equipment capable of generating high levels of spurious airborne

noise that would not be classified as normal background noise such as pressure release valves,

helipads, sirens etc. If any are present in the detector range of coverage please contact Net Safety

Monitoring or monitor detector when activated to ensure immunity.

3.1.1. MECHANICAL INSTALLATION

NSM-SU343 incorporates a dedicated flameproof terminal compartment certified to Ex d, a flameproof

main electronics compartment certified to Ex d, and a pump compartment which contains no electrical

devices, all are sealed to IP66/IP67.

NSM-SU343 has a large detection radius capability and care should be taken when positioning to utilize

the maximum detector coverage and eliminate blind spots and spurious alarms.

NSM-SU343 has a variety of fixing options to incorporate installation into most situations found in

industrial environments such as wall / flat surface (section 3.1.3), vertical / horizontal pole (section 3.1.4)

and vibrating surfaces (section 3.1.5). If fixing is required to mount the detector into a position which falls

outside of the scope of the standard mounting options please contact a Net Safety Monitoring

representative for details of specialist design service.

NSM-SU343 can be mounted in any orientation but care should be taken to position the display facing

an area with ease of access to allow the information to be viewed. Note: The infra-red send and receive

ports are located above the display, if remote programming is required then care should be taken that

line of sight to the display can easily be achieved up to a maximum distance of 8m (26ft).

MAN-0129 SU343 Rev 0.3 Page 10 of 50

Page 11

3.1.2. MECHANICAL POSITIONING

Figure 1

NSM-SU343 utilizes 4 independent sensors heads for full coverage. Figure 1 shows a 3D view of the

coverage (detector not to scale) at a 3m (10ft) height above floor level with the detector pointing

vertically downwards. NSM-SU343 coverage is specified as meters radius at the floor level as this is the

minimum sensing distance. As shown the entire area below the detector is covered as well as some of

the area above and around the detector. Each sensor overlaps the next so areas underneath the

detector are covered by multiple sensors.

Note: The figure shows coverage stopping at 75° perpendicular from the sensor face, in reality it will

decrease so the area above the detector will also have some limited coverage.

Figure 2 shows a 2D view of coverage when the detector is mounted vertically downwards and

highlights that the radius coverage stated is the minimum area covered.

MAN-0129 SU343 Rev 0.3 Page 11 of 50

Page 12

Figure 2

Figure 3

Figure 3 shows coverage when the detector is mounted at an angle, this method is recommended when

the detector is mounted close to a wall or in an enclosed space to increase the coverage area.

MAN-0129 SU343 Rev 0.3 Page 12 of 50

Page 13

3.1.3. WALL / FLAT SURFACE MOUNTING

When mounting on a vertical flat surface such as a wall with no significant vibration (<20kHz) it is

sufficient to use just the standard mounting bracket supplied with the NSM-SU343.

MAN-0129 SU343 Rev 0.3 Page 13 of 50

Page 14

3.1.4. POLE MOUNTING

MAN-0129 SU343 Rev 0.3 Page 14 of 50

Page 15

In large open areas it is recommended that the NSM-SU343 is pole mounted to take advantage of the

large omni-directional detection coverage. The detector should be mounted 3 to 5 meters (10 to 16 feet)

high to eliminate reflections and ground absorption. NSM-SU343 may be used lower than 3 meters (10

feet) but coverage may be reduced, please contact Net Safety Monitoring or a Net Safety Monitoring

representative for details.

Pole should be mounted to local standards and be capable of supporting the detector weight at the

installation height when environmental factors are taken into consideration.

NSM-SU343 is attached to the pole using 2 U-bolts fixed to the mounting bracket. Suggested U-bolt

torque is 9Nm but local standards should be used in the first instance.

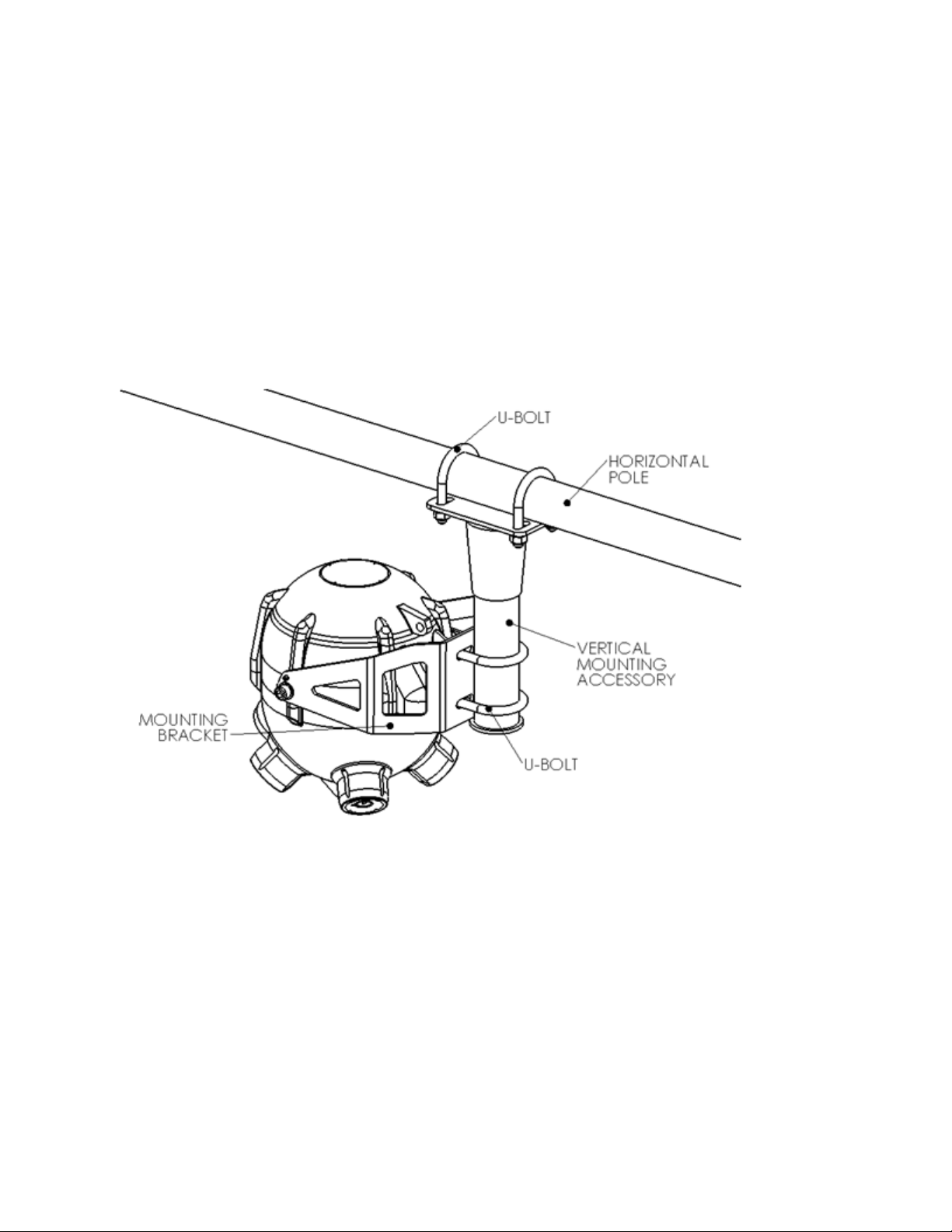

NSM-SU343 can be supplied with a vertical mounting accessory that allows the detector to be mounted

on a ceiling / upper deck or a horizontal pipe.

Figure 4

Figure 4 shows typical mounting arrangement for a horizontal pole. If ceiling or upper deck mounting is

required the upper U-bolts can be replaced using appropriate fixings.

3.1.5. VIBRATION MOUNTING

If significant vibration (resonance) is found at the mounting point (below 20kHz) it is recommended that

the vibration plate is used to eliminate excessive stress on the fixings and internal components of the

detector.

If significant vibration is found at the mounting point in the detector sensing range (between 20kHz and

100kHz) the vibration plate must be used to avoid spurious results.

NSM-SU343 can mounted on a wall / flat surface or a pole subject to vibration as described in sections

3.1.3 and 3.1.4 using the vibration damping plate accessory.

MAN-0129 SU343 Rev 0.3 Page 15 of 50

Page 16

The vibration damping plate assembly can be supplied with a range of different frequency dampers to

eliminate vibrations for all applications and can easily be attached to both the wall / flat surface or pole

mounting as follows;

Figure 5

MAN-0129 SU343 Rev 0.3 Page 16 of 50

Page 17

Figure 6

Warnings:

Figure 5 and Figure 6 show general details for mounting on a surface or pole that has severe vibration in

the detector range or which may affect operation.

If vibration at fixing point is suspected please contact Net Safety Monitoring or a Net Safety Monitoring

representative for details.

3.1.6. ELECTRICAL INSTALLATION

NSM-SU343 terminal cover is certified to flameproof standards and should not be opened whilst

energized.

The detector housing should be connected to local ground via the external earth point as shown

in Figure 7. Wire should be minimum of 4mm² (8 AWG) and as short as possible. Termination at

detector should be suitable for M6 (0.25”) fastener. Ensure earth wire is attached using the

supplied spring washer.

NSM-SU343 is temperature rated between -55°C and +85°C (-67°F and +185°F) ensure that all

cable is rated to the appropriate temperature of installation. See section on external cables later

in this section.

General

To gain access to the terminal compartment undo the six terminal cover fixing screws and raise the

terminal cover until it reaches the pivot point then rotate towards the back of the detector. The captive

mechanism has 3 locking positions to allow the terminal cover to be held open at different heights to aid

cable termination. The terminal cover release pin should be pulled outwards to allow the terminal cover

to be opened as required. Upon completion of wiring pull the terminal cover release pin outwards and

rotate the terminal cover lid until parallel with the detector main body and lower back into position.

Tighten the six terminal cover fixing screws to a torque of 9Nm.

MAN-0129 SU343 Rev 0.3 Page 17 of 50

Page 18

Figure 7

Cable entry is via suitable hazardous area approved and ingress protection certified

cable glands (customer supply). NSM-SU343 has 2 positions (1 standard, 1 optional)

for cable gland sizes M20, M25, ½”NPT or ¾”NPT. Cable glands should be fitted in

accordance with cable gland manufacturers instructions for assembly to a certified

flameproof enclosure. All unused cable glands should be sealed using a flameproof

certified plugging device. Ensure all cable gland and plugging devices are ingress

protected to the same standard as the enclosure to maintain certification and are

suitable for the size of cable used.

Note: Thread size for cable entry is specified for each position on the terminal cover label.

MAN-0129 SU343 Rev 0.3 Page 18 of 50

Page 19

The terminal cover contains two sealed O rings to prevent water ingress into the terminal compartment.

Before closing it is recommended that a visual inspection is undertaken to ensure the O rings are in

place and undamaged. Also check the flame paths of the terminal cover and main enclosure for signs of

damage. Send the detector to Net Safety Monitoring for repair if the flame path is damaged. See Figure

8 for O ring and flame path positions.

Figure 8

Cable shield should be connected to instrument earth in the control room only unless extra RFI

protection is required and all local and site grounding regulations are met in which case the shield is to

be terminated to local ground via one of the internal earth points shown in Figure 9.

MAN-0129 SU343 Rev 0.3 Page 19 of 50

Page 20

Figure 9

Figure 9 shows a view of the NSM-SU343 with the terminal cover removed. For single entry enclosures

customer cable entry is via position 1 whereas dual entry enclosures will use positions 1 and 2.

The terminals are separated into power and communications for terminal row 1 and relay outputs for

terminal 2.

Wiring Configurations

Figure 10

Figure 10 shows descriptions for cable entries for terminal rows 1 & 2.

MAN-0129 SU343 Rev 0.3 Page 20 of 50

Page 21

Current source is the standard default operation, current sink is an option and should be specified at

Customer cable should be chosen in accordance with Hazardous Area Certification

and applicable local regulations. Note: NSM-SU343 has a temperature rating of +85°C

(185°F), when used in areas with an ambient temperature above 60°C (158°F) ensure

cable has a rating that is equal to or exceeds the proposed maximum working

temperature.

Conductor CSA

0.5mm²

1.0mm²

1.5mm²

2.5mm²

24 VDC no heater cable length

355M

695M

1095M

1805M

24 VDC with heater cable length

40M

76M

120M

200M

time of order.

For standard 3 wire connection inputs should be connected to Terminal Row 1 in positions +24V and 0V

with 4 – 20mA output connected to the mA terminal. Maximum load resistance : 500 Ω.

Relay data : 2A, 250VDC switch voltage, 70 milliohm on-resistance.

For a full description of fault relays refer to section 3.3.6.1 Relay Options.

External cables:

The following data indicates maximum cable length restriction due to voltage drop:

Note: Figures shown for the heater option are for indication only and can usually be improved depending

upon environmental factors as it is extremely unlikely full heating power will be required.

Refer to section 3.3.5 Heating for description and power requirements for optional heating function or

contact a Net Safety Monitoring representative for further details.

3.2. COMMISSIONING

3.2.1. VISUAL

Before powering up NSM-SU343 the following should be inspected:

Ensure detector is correctly situated for area of detection.

Ensure mounting bracket is secured to mounting points on the detector and mounting surface /

pole.

Check pole mount (if present) for suitability to withstand detector weight and environment.

Ensure External earth is correctly attached using spring washer.

Ensure correct cable gland installation and appropriate certification or local regulations have

been observed.

Ensure external cable is suitable for operating environment.

Check correct cable installation in the terminal compartment, ensure terminal compartment flame

paths and seals are intact. Tighten terminal cover bolts to 9Nm recommended torque.

Ensure main enclosure bolts are in place and tighten to 9Nm recommended torque.

Check display glass for damage or contaminants that may obscure display or Infra-red ports.

Check sensors, sensor pods and cleaning nozzles for signs of damage.

Ensure pump compartment is secure and check breather membrane for signs of damage or

blockage.

Ensure correct operating supply voltage.

MAN-0129 SU343 Rev 0.3 Page 21 of 50

Page 22

Figure 11

Ensure that all Installation procedures have been applied.

3.2.2. POWER UP

Upon power up a brief diagnostic check will run to ensure detector functionality which will last for no

more than 20 seconds. Once completed NSM -SU343 will go into normal operation using the

factory/customer defaults specified at time of order or signal any faults that may be present. Factory

default options can be found in section 3.3.1 Normal operation and a list of faults can be found in section

3.3.6.4 Fault Outputs.

In addition, the display will show the real-time ultrasonic sound level and the detector will become

responsive to RS485, Infra-red commands for function set-up and all relays will be energized or deenergized as per defaults.

Note: If NSM-SU343 has been factory set for specific site requirements it is recommended to carry out

the steps outlined in section 3.2.4 Function Check before completion of Commissioning.

3.2.3. USER CHANGEABLE FUNCTIONS SET-UP

NSM-SU343 is supplied with a range of defaults designed to ensure safe working without adjustment but

to enable the detector to work to maximum effect it is also possible to change a number of settings to

increase the detection range and sensitivity, increase speed of response, decrease the possibility of

spurious alarms and increase or decrease the internal safe-working safety checks contained within the

detector.

It is recommended that certain parameters are only to be changed after detailed analysis of the

installation position and site safety protocol. Therefore, the following user changeable functions are

listed using a scale of 1 to 4 to signify potential risk of change, 1 representing safe change, 2

representing minor risk, 3 representing medium risk and 4 representing high risk. All functions can be

disabled or password protected to fit site or local regulations.

MAN-0129 SU343 Rev 0.3 Page 22 of 50

Page 23

Function

Change Level

Set Display Brightness

1

Set Pulse Filter

1

Set „CLEAN‟ Display

1

Start Cleaning Cycle

1 to 2

Set Relays Normally Open

1 to 4

Set Relays Latching

2

Set Heat Enable

2

Reset Alarms

2 to 3

Set Test Interval

3

Initialise Factory Defaults

3

Set Alarm Level

3 to 4

Set Alarm Delay

3 to 4

Set Unit Address ID

4

Function Definition

Set Display Brightness:

Changes LED intensity to suit environment or increase viewing

distance. See section 3.3.6.2 Display Options for full definition.

Setting values; 0 to 32 with 0 representing off and 32 representing

maximum. Factory default value = 12.

Potential change risk = safe. Changing the display brightness will have

no impact on safe working of the detector. It is recommended that the

display is not changed to a value less than 7 as light emitted is

extremely low and, therefore, difficult to see in most environments. Also

setting the display at maximum may shorten the life of the LED.

Set Pulse Filter:

Changes display response time to cancel out spikes of ultrasonic noise.

See section 3.3.6.2 Display Options for full definition.

Setting values; 0 to 127 seconds. Factory default value = 0 seconds

(instantaneous). Note: It is recommended to keep pulse filter duration

less than alarm delay duration.

Potential change risk = safe. Changing pulse filter duration will have no

impact on safe working of the detector.

Set „tESt‟ Display:

Changes display information during test cycle. See section 3.3.6.2

Display Options for full definition.

Setting values; 0 or 1 with 0 representing the word „tESt‟ and 1 showing

numerical code for test sequence pass, see section 3.3.6.2 Display

options for full details. Factory default value = 0.

Potential change risk = safe. Changing „tESt‟ display will have no impact

on safe working of the detector.

Start Cleaning Cycle:

Initiates a forced cleaning cycle. See section 3.3.4 Self Test and Self

MAN-0129 SU343 Rev 0.3 Page 23 of 50

Page 24

Clean for full definition.

Potential change risk = safe to minor. Used intermittently in conjunction

with the built-in cleaning cycle interval the forced cleaning cycle is safe

to use. The change risk increases if the forced cleaning cycle is used

regularly as it temporarily reduces detection coverage and increases

detector reaction time if it coincides with the start of a leak.

Set Relays Normally Open:

Allows relay configuration to be switched between energised in normal

operating condition or energised when in fault condition. Factory default

= energised in normal operating condition.

Potential change risk = safe if changed to energised in normal operating

condition, high risk if changed to energised when in fault condition if

power supply is not independently monitored. Changing relay operating

state will cause a local alarm under normal conditions, other

communication with control room will be unaffected.

Set Relays Latching:

Allows relays to be latching or non-latching. Factory default = nonlatching.

Potential change risk = minor. Local alarms will turn off when detector

comes out of alarm if left unlatched or stay in alarm after the detector

comes out of alarm, other forms of communication with control room will

be unaffected.

Set Heat Enable:

Allows optional heating function to be turned permanently on or off or

automatic to adjust to the environment. See section 3.3.5 Heating for full

definition. Setting values 0 to 2 with 0 representing off, 1 representing

automatic and 2 representing on. Factory default = 1.

Potential change risk = minor. NSM-SU343 will work with or without

heating enabled but it is recommended to leave the heat setting in

automatic to ensure the cleaning function is unaffected by ice build-up

at low temperatures.

Reset Alarms:

Allows latching relays to be reset.

Potential change risk = minor to medium. Operation of NSM-SU343 is

unaffected but it is recommended that only qualified personnel as

dictated by site protocol are allowed to reset alarms.

Set Test Interval:

The test cycle interval defines the duration between detector self-check.

Test cycle consists of two functions on each sensor, a broadband selftest and cleaning of the sensor face to remove contaminant. See

section 3.3.4 Self Test and Self Clean for full definition.

Setting values; 0 to 127 in increments of 1 minute with 0 representing

off, 1 representing 1 minute and 127 representing 127 minutes. Factory

MAN-0129 SU343 Rev 0.3 Page 24 of 50

Page 25

default setting 15 minutes.

In areas of low background noise it is recommended that the cleaning

interval is set to 15 minutes but may be changed to suit existing site

protocol.

Potential change risk = medium. Operation of the NSM-SU343 is

unaffected but it is recommended that the test cycle interval is set as

per site protocol and only qualified personnel as dictated by site protocol

are allowed to change duration time.

Initialise to Factory

Defaults:

Changes all function settings back to default values. See section 3.3.1

Normal Operation for full definition.

Potential change risk = medium. NSM-SU343 factory default settings

are defined to provide safe working conditions but once NSM-SU343 is

set-up to provide optimum detection coverage it is recommended that

only qualified personnel as dictated by site protocol are allowed to

restore Factory Defaults.

Set Alarm Level:

Changes dB level of detector alarm. See section 3.3.2 Alarm Level for

full definition.

Setting values; 40 to 127 in increments of 1dB with 40 representing

40dB and 127 representing 127dB. Alarm level default = 70 (70dB).

Potential change risk = medium to high risk. If alarm level is raised too

high above the background level it will reduce detector sensitivity. It is

recommended that only qualified personnel as dictated by site protocol

in conjunction with Net Safety Monitoring personnel are allowed to

change alarm levels.

Note: Alarm level can also be set at control room or panel.

Set Alarm Delay:

Changes duration of time that constant alarm dB level must be

experienced before alarm is activated. See section 3.3.3 Alarm Delay

for full definition.

Setting values; 0 to 99 in 10 second increments and 100 to 127 in 1

second increments. 0 and 100 represent „off‟ instantaneous alarm, 1

represents 10 seconds and 99 represents 990 seconds. 101 represents

1 second and 127 represents 27 seconds.

Factory default = 3 (30 seconds).

Potential change risk = medium to high. If delay is too short spurious

alarms may occur, if delay is too long, dangerous gas build up may

occur. It is recommended that only qualified personnel as dictated by

site protocol in conjunction with Net Safety Monitoring personnel are

MAN-0129 SU343 Rev 0.3 Page 25 of 50

Page 26

allowed to change alarm delay times.

Note: Alarm delay level can also be set at control room or panel.

Set Unit Address ID:

Changes RS485 unique identity.

Setting values; 1 to 31 (126 option). Factory default = 1.

Potential change risk = high. If two units are given the same RS485 ID

then it is impossible to relay information to individual detectors on the

same control loop.

It is recommended that set-up of ID address is undertaken by qualified

personnel as dictated by site protocol in conjunction with Net Safety

Monitoring personnel and upon completion changes are tightly

controlled.

3.2.4. FUNCTION CHECK

NSM-SU343 sensors are factory calibrated and require no adjustment before operation but functionality

checks are recommended to ensure correct installation.

On power up the NSM-SU343 will perform a diagnostic check to ensure all main functions are

operational but the following additional checks may be undertaken:

Sensor Functionality

Sensor functionality can be checked in a number of ways;

Internal forced test cycle – faulty sensor(s) will be shown as a fault on the display and via 4 – 20 mA

signal output. See section 3.3.6.4 Fault Outputs.

NSM-SU343 hand held series test transmitter sound source. Ensure that the background ultrasonic level

is suitable for the distance of proposed test transmitter test. Aim the transmitter at the sensor face at a

known distance, NSM-SU343 display dB level will rise according to hand held device used and distance.

Check all 4 sensors if possible by moving round the detector and repeating.

Test Verification kit – a pressurized gas release of a known pressure and size at a known distance.

NSM-SU343 display level will rise according to the size, pressure and distance used.

Check all other user required variables as described in section 3.2.3 User Changeable Functions

Set-up.

3.3. OPERATING PRINCIPLES / INSTRUCTION

3.3.1. NORMAL OPERATION

On power up the NSM-SU343 initializes a diagnostic check and then enters normal operation mode as

per factory defaults supplied.

Factory default 1 settings;

4 – 20mA set to linear dB output.

Display brightness set to 12. Viewing distance +10M outdoor environment.

MAN-0129 SU343 Rev 0.3 Page 26 of 50

Real time instantaneous ultrasonic sound level shown on display in dB.

Page 27

Display shows „tESt‟ when in Self-Test and Self-Clean mode.

Forced Clean enabled.

Relays are energized open, loss of power causes alarm (fail-safe).

Relays are set to non-latching.

Heating set to automatic, system activates below 5°C (41°F).

Reset alarms enabled, allows latched relays to be reset and restarts alarm delay.

Self-Test and Self-Clean set to activate at 15 minute intervals.

Alarm level set at 70dB.

Alarm delay set to 30 seconds.

RS485 ID set to 1.

In addition all communication ports are active and ready to receive commands.

Factory default 2 settings;

4 – 20mA set to 4mA when in fully functioning non-alarm condition.

Display brightness set to 12. Viewing distance +10M outdoor environment.

Display shows „CLEAN‟ when in Self-Test and Self-Clean mode.

Forced Clean enabled.

Relays are energized open, loss of power causes alarm (fail-safe).

Relays are set to non-latching

Heating set to automatic, system activates below 5°C (41°F).

Reset alarms enabled, allows latched relays to be reset and restarts alarm delay.

Self-Test and Self-Clean set to activate at 15 minute intervals.

Alarm level set at 70dB

Alarm delay set to 30 seconds

RS485 ID set to 1

In addition all communication ports are active and ready to receive commands.

Further default settings are available on request.

3.3.2. ALARM LEVEL

To avoid false alarms it is recommended to set the alarm level above the background level found

through mapping when all process is operational. If the background level is unknown it is recommended

to analyze the background using the detector. Care should be taken to observe process that may cause

intermittent ultrasonic noise such as pressure relief valves.

Please contact Net Safety Monitoring or a representative for advice on alarm levels.

Note: the higher the alarm level the smaller the detector coverage radius, it is therefore important to

establish a safe alarm level at the lowest permissible value.

MAN-0129 SU343 Rev 0.3 Page 27 of 50

Page 28

Figure 12

Figure 12 shows suggested alarm level settings for known background sound level. The values shown

have been found to provide sufficient immunity against most spurious alarms but care should be taken to

survey the area of installation for potential spurious noise such as pressure relief valves, audible alarms

with resonance or maintenance hotspots.

If background levels are unknown typical historical process background levels can be used along with a

safety factor. Please contact Net Safety Monitoring or a representative for historical values and

guidance.

Alarm levels can be set at the detector or at the control panel if functionality is available.

Factory Default standard alarm level is 70dB. See section 3.2.3user changeable functions.

3.3.3. ALARM DELAY

To avoid spurious alarms it is recommended that an alarm delay is used for non-toxic applications or

when instantaneous detection is not required. The alarm delay is intended to activate once the ultrasonic

noise alarm level threshold is reached. The alarm delay will then monitor the sound level to ensure that it

does not drop below the alarm level threshold for the duration of the delay. If the ultrasonic noise drops

below the alarm level threshold the delay time will be reset as shown in Figure 14. If the ultrasonic noise

level remains above the alarm level threshold for the duration of the delay the alarm will be activated as

shown in Figure 13.

Spurious ultrasonic noise is usually found in short time-cycles such a pressure relief valves and manmade maintenance operations such as hammering or use of pneumatic hand tools and therefore are

eliminated by the delay.

MAN-0129 SU343 Rev 0.3 Page 28 of 50

Page 29

Alarm delay time should be assessed with regards to the following;

Detector proximity to release valves and intermittent ultrasonic noise sources

Process leak severity, toxic / non-toxic, acceptable leak size before alarm

Existing site protocols and local regulations

Note: If a gas leak occurs during spurious noise the delay time will continue from the first instance of

noise above the alarm threshold level.

Factory Default standard alarm delay is 30 seconds. See section 3.2.3 User Changeable functions.

Figure 13

Figure 14

MAN-0129 SU343 Rev 0.3 Page 29 of 50

Page 30

In Figure 14 noise 1 and 2 are spurious noise spikes of approx. 1.5 seconds, typical of man-made

ultrasonic noise produced through normal maintenance procedures. Noise 3 is a longer spurious noise

of approx. 13 seconds typical of a pressure relief valve. Delay time is introduced to ignore spurious noise

spikes as the detector will reset when noise level drops below the alarm level before the delay time is

reached.

Figure 15

Figure 15 shows detector response when a leak is encountered during a spurious noise spike such as a

pressure relief valve. Noise 1 represents a pressure relief valve actuating for approx. 13 seconds before

a leak (noise 2) occurs. The detector starts the delay time when the pressure relief valve opens and

continues to monitor for leaks. If a leak occurs during a spurious noise spike the delay time will be

reduced by the duration of the spurious noise spike.

Note: It is important that all spurious noise spikes of significant duration within the detector coverage are

identified. It is recommended that the alarm delay is set to a value greater than the maximum spurious

noise spike operating duration. If two or more spurious noise spikes are situated in the detector

coverage it is recommended to establish if operation will overlap and that the delay time is adjusted

accordingly.

3.3.4. SELF-TEST AND SELF-CLEAN Self-Test

To ensure correct detector operation NSM-SU343 incorporates an internal self-test function which uses

a compressed air jet to simulate an actual gas release. The jet is forced through a nozzle designed to

produce a sound pressure level in excess of 100dB across the entire detector sensing range

(broadband) allowing system check to be carried out in environments with a background as high as

95dB.

The self-test is delivered to all four sensing heads independently using a self contained direct drive

pump to an internal sensor chamber which is protected from the environment to allow accurate

MAN-0129 SU343 Rev 0.3 Page 30 of 50

Page 31

repeatable testing without emitting any noise externally. This allows other ultrasonic detectors to be

situated close by without causing spurious alarms.

Self-Clean

To allow NSM-SU343 to operate in extremely harsh environments a Self-Clean function has been

incorporated. Under most conditions Ultrasonic detectors will continue to work without loss of coverage

providing that debris has not built up on the sensing heads and produced air pockets which force the

sound pressure level to travel through a decreasing then increasing medium density (refer to section

3.3.5. Heating for removal of ice). NSM-SU343 can be mounted in any orientation, when mounted

horizontally or vertically downwards build up of debris is virtually eliminated. If NSM-SU343 is mounted

vertically upwards or upwards of 45° to the horizontal, debris may build up. To ensure this does not

occur the Self-Clean operates in conjunction with the self test function to remove all debris from the

sensor detecting face. The Self-Test uses a compressed air jet directed at the sensing face which

removes debris before build up can occur. The Self-Clean uses a nozzle designed to produce nominal

amounts of ultrasonic noise so that detector functionality is not affected during use.

Test Cycle

In standard Factory Default operating mode the test cycle (combined Self-Test and Self-Clean) will

activate every 15 minutes (or when one of the continuous self-testing electronic checks signals an

abnormal operating parameter) and lasts for approximately 6 seconds.

Testing consists of a background noise check and self-clean to clear debris followed by an internal

ultrasonic compressed air jet test to check sensor functionality for each sensor position (1 through 4

standard). Each sensor head is checked in turn to enable the detector to continue to monitor the

coverage zone for leaks that may occur during testing.

The detector will analyze the sound produced by the air jet test to establish if the sensors fall within a

factory determined tolerance. If the results fall outside of acceptable parameters the test will activate

again and produce a test fault if correct functionality cannot be determined. If the background level

exceeds 97dB before the test initiates the detector will produce a test inconclusive fault.

For a full list of fault outputs refer to sections 3.3.6.3 4-20mA Output, 3.3.6.4 Fault Outputs.

Factory Default standard self-clean is 15 minutes. See section 3.2.3 User Changeable functions.

3.3.5. HEATING (OPTIONAL)

NSM-SU343 is available with an optional environmentally controlled heating circuit to ensure

functionality at temperatures as low as -55°C (-67°F) and eliminate any ice buildup over the sensor

covers.

If NSM-SU343 is mounted facing upwards of 45° to the horizontal water may build up on the sensor

face. Although this has no influence on the sensor performance and will normally be removed during

self-clean it may cause problems if the environment is sufficiently cold to allow ice to form between selfclean cycles. Air pockets may form in the ice and this may cause a small loss of sensitivity due to the

change in densities. When the heating circuit is enabled it will activate when the sensor head is just

above freezing and stop ice buildup, it can then be removed by the self-clean function. In most

conditions the loss of sensitivity has been built into the detector coverage, enabling the heating circuit

allows for greater consistent coverage in all temperatures and environments irrespective of mounting

orientation.

The heating circuit is extremely efficient as heat is only transferred to areas that require it when the

temperature drops below a certain value. The external temperature is constantly monitored and the

heating circuit can be set to turn on at any temperature, 5°C (41°F) as standard Factory Default.

The heating option is recommended in areas that are prone to extreme low temperatures.

MAN-0129 SU343 Rev 0.3 Page 31 of 50

Page 32

The heating circuit has three operating modes, permanently off, automatic and permanently on.

Relay 1 : Fault

Energized in normal operating condition, de-energized in fault

condition, non-latching.

Relay 2 : Alarm

Energized in normal operating condition, de-energized in alarm

condition, non-latching.

Relay 3 : Maintenance (alert for non urgent maintenance condition)

Energized in normal operating condition, de-energized in

maintenance condition, non-latching.

Heating off – heating will remain off in all conditions. All functionality remains but detector may be prone

to icing in cold wet environments. It is not recommended to use the detector for long periods below 40°C (-40°F) as undue stress may be placed on internal components and may shorten the operating life

of the detector. Note: the detector is safe to use to -55°C (-67°F) without heating enabled.

Heating Automatic – heating will activate once ambient temperature drops below a predetermined level,

5°C (41°F) as standard although this figure can be changed at time of order.

Heating on – heating will remain on in all conditions. The heating circuit will reach a maximum internal

temperature of 70°C (158°F) irrespective of the ambient temperature using an internal temperature

sensor, if the internal temperature sensor fails the temperature is limited to 117°C (242°F) with the use

of dual thermal fuses.

Note: the heating circuit requires 3A to fully function, if current is not sufficient then the heating circuit

may be intermittent or not function.

Factory Default standard heating is set to automatic. See section 3.2.3 User Changeable functions.

3.3.6. OUTPUT OPTIONS

NSM-SU343 comes with most industry standard recognized forms of communication as standard, this

enables the detector to be operated as part of a system, a standalone unit, hard wire linked to form a

sub network or wireless linked to form a self replicating mesh network.

3.3.6.1. RELAY OPTIONS

NSM-SU343 has three relays configured as follows for the standard Factory Default;

MAN-0129 SU343 Rev 0.3 Page 32 of 50

Page 33

Relay configuration can be changed to suit installation requirements using the user changeable

Example of real-time dB level display „53db‟

Example of Self-Test display

Indicates test and clean pass in all 4 sensors

Indicates test and clean pass for sensors 1, 3 and 4,test pass and clean

fail for sensor 2

Indicates test and clean pass for sensor 1, test and clean fail for sensor

2,test pass and clean fail for sensors 3 and 4

Indicates test and clean fail For all sensors

functions, options include Normally Open / Normally Closed condition and latching / non-latching.

See section 3.2.3 User changeable functions set up.

3.3.6.2. DISPLAY OPTIONS

NSM-SU343 incorporates a 5 digit, 7 segment, 8mm high x 4mm wide character LED display with red

numerals as standard.

In standard Factory Default option the real-time dB level is continuously shown whilst below alarm level

and flashing when above alarm level. Alternative options are available that include real-time mA value

and display delay. When in stepped mA output mode the display will continue to display the real time dB.

During the Self-Test cycle the display will show „tESt‟ for the duration of the test cycle as factory default.

Test option is to display test status in numerical form for the duration of the test with 0 meaning test fail,

1 test pass and 2 test and clean pass with numeral position indicating sensor head number.

If a maintenance/minor fault occurs the display will continue to display the real-time dB value.

If a major test fault occurs the display will continue to display the real-time dB value when test is

completed.

MAN-0129 SU343 Rev 0.3 Page 33 of 50

Page 34

If a major fault occurs the display will shut down.

Real-time mA value mimics the mA output value sent to the control room.

Display delay can be set to delay the results shown on the LED to eliminate any spiked spurious noise

events and display a more consistent value.

Stepped mA output enables connection to systems requiring inputs which mimic other forms of gas

detection such as point IR detectors. Standard Factory Default option is set to continuous real-time dB

when below alarm level and flashed real-time dB when in alarm.

Display settings can be changed using the user changeable functions, options include brightness, delay

and self test text setting. See section 3.2.3 User Changeable functions Set-up.

3.3.6.3. 4-20MA OUTPUT

Figure 16

MAN-0129 SU343 Rev 0.3 Page 34 of 50

Page 35

Figure 16 shows the 4 – 20mA output values for all detector variants and various fault conditions

depending on detector set up. Value on the left side shows the mA output tolerance band, Test fault is

set for a 2.0mA output with a tolerance of 1.8 to 2.2mA for example.

Normal operation is shown with an upper tolerance of 4.7mA (+/-0.3mA) as the gain is usually set to a

minimum working level of 47dB.

mA outputs are grouped in descending order to signify importance and to allow for instant status

recognition, see section 3.3.6.4 Fault Outputs for options;

Normal operation between 4 to 20mA (+/- 0.2mA) – detector working, no fault conditions.

Inhibit 3.5mA (+/- 0.2mA) – Maintenance mode, detector is in self-test mode (option) or receiving

communication via RS485 or infra-red.

Error – Maintenance between 2.5 to 3mA (+/- 0.2mA) – detector still functioning safely but requires

maintenance in area described by mA output. Maintenance errors are signaled using an optional pulsed

interrupt output via the 4-20mA signal during the normal operation signal.

Detector shut down 0 to 2mA (+ 0.2mA) – detector has stopped functioning due to serious known fault

,0.5 to 2mA, or serious unknown fault ,0mA. Note: Optional 2.0mA pulsed signal output falls into Error –

Maintenance classification.

Serious known faults include test fault, microprocessor watchdog fault, circuit test fault or high voltage

fault up to 40VDC

Serious unknown faults include microprocessor fault, low voltage input, high voltage input above 40VDC

or loss of power.

3.3.6.4. FAULT OUTPUTS Option 1 Standard

2.0mA Test Fault

Test fault when three or more sensor heads fail to respond to test leak (when background is below

95dB). Output is continuous until reset or test is passed successfully.

All alarm conditions (gas leak) or major faults will override this fault condition.

1.0mA Internal Process Fault

Continuous 1.0mA (+/-0.2mA) output for any known internal or external faults which include

microprocessor watchdog fault, circuit test fault, high/low external voltage, blown fuse or high/low

internal voltage. The output can be reset via control room.

0.5mA Over Temperature Fault

If the detector is subject to an ambient temperature of 87°C (188°F) or above the output is a continuous

0.5mA (+/-0.2mA) and can only be reset by Net Safety Monitoring or a Net Safety Monitoring

representative due to certification restrictions.

0mA Major Fault

Output is the result of a loss of power to the detector or a serious microprocessor fault. If fault occurs

due to loss of power fault will be reset when power is supplied to the detector. If fault occurs due to the

microprocessor the NSM-SU343 should be returned to Net Safety Monitoring or a Net Safety Monitoring

representative for repair.

Option 2 (Specify at time of order)

3.0mA Cleaning Fault

MAN-0129 SU343 Rev 0.3 Page 35 of 50

Page 36

Pulsed output of 3.0mA (+/-0.2mA) for 5 seconds every minute if cleaning function is unsuccessful for 5

times in a row. Pulse output is reset if clean function is performed successfully.

All alarm conditions (gas leak) or major faults will override this fault condition.

2.5mA Heating Fault

Pulsed output of 2.5mA (+/-0.2mA) for 2 seconds every minute if either one of the internal temperature

sensors is in fault.

Pulsed output of 2.5mA (+/-0.2mA) for 5 seconds every minute if heating circuit is in fault.

All alarm conditions (gas leak) or major faults will override this fault condition.

2.0mA Test Fault

Test fault when three or more sensor heads fail to respond to test leak (when background is below

95dB). Output is continuous until reset or test is passed successfully.

All alarm conditions (gas leak) or major faults will override this fault condition.

Pulsed output of 2.0mA (+/-0.2mA) for 10 seconds every minute if the test is inconclusive due to high

background noise (+95dB). Output is reset if the test is completed satisfactorily.

All alarm conditions (gas leak) or major faults will override this fault condition.

Pulsed output of 2.0mA (+/-0.2mA) for 8 seconds every minute if test cannot be performed due to pump

motor overload. Output is reset if the test is completed satisfactorily.

All alarm conditions (gas leak) or major faults will override this fault condition.

Individual sensor head faults;

Sensor head 1 fault – pulse 2.0mA (+/-0.2mA) for 1 second every minute.

Sensor head 2 fault – pulse 2.0mA (+/-0.2mA) for 2 seconds every minute.

Sensor head 3 fault – pulse 2.0mA (+/-0.2mA) for 3 seconds every minute.

Sensor head 4 fault – pulse 2.0mA (+/-0.2mA) for 4 seconds every minute.

Any two heads fault – pulse 2.0mA (+/-0.2mA) for 5 seconds every minute.

Output is reset if the test is completed satisfactorily.

All alarm conditions (gas leak) or major faults will override these fault conditions.

1.0mA Internal Process Fault

Continuous 1.0mA (+/-0.2mA) output for any known internal or external faults which include

microprocessor watchdog fault, circuit test fault, high/low external voltage, blown fuse or high/low

internal voltage. The output can be reset via control room.

0.5mA Over Temperature Fault

If the detector is subject to an ambient temperature of 87°C (188°F) the output is a continuous 0.5mA

(+/-0.2mA) and can only be reset by Net Safety Monitoring or a Net Safety Monitoring representative.

0mA Major Fault

Output is the result of a loss of power to the detector or a serious microprocessor fault. If fault occurs

due to loss of power fault will be reset when power is supplied to the detector. If fault occurs due to the

microprocessor the NSM-SU343 should be returned to Net Safety Monitoring or a Net Safety Monitoring

representative for repair.

MAN-0129 SU343 Rev 0.3 Page 36 of 50

Page 37

3.3.6.5. RS485 DIGITAL

NSM-SU343 incorporates an RS485 digital interface as standard which allows the operator to change

and receive status and setting information. A maximum of 32 NSM-SU343 can be connected into the

RS485 interface and the communication line should be terminated between the controller and the last

detector with a 150 ohm resistor. Note: NSM-SU343 main PCB can be set up as the last in line

communicator if specified at the time of order. Contact Net Safety Monitoring or a Net Safety Monitoring

representative for further details.

NSM-SU343 is supplied as standard with an address ID of 1 and cannot initiate communication,

therefore care should be taken to assign detector address ID upon installation.

The controller should broadcast an address, a command, a variable and a checksum which will initiate a

response, a variable and a checksum from the detector with the appropriate address. If data corruption

occurs the checksum will initiate a repeat send of information and the initial information is disregarded.

RS485 interface uses a Baud rate of 2400 (9600 option) and should be made via shielded „twisted pair‟

cable to reduce interference.

Figure 17

Figure 17 shows a typical set-up to allow fields to be distinguished. D7 is set in the control address field

and cleared in all other fields.

See section 4. Customer Interface Commands for further details.

3.3.6.6. INFRA-RED

NSM-SU343 has Infra-red communication capability which allows all user variable functions to be

changed and full functionality to be checked via a portable handheld device. The device can

communicate over a distance of up to 8M allowing commissioning and maintenance procedures to be

undertaken without the need of scaffolding.

MAN-0129 SU343 Rev 0.3 Page 37 of 50

Page 38

Figure 18

Figure 18 shows the extent of angular Infra-red reception when face on to the detector, angular

reception from side to side is approximately 25° either side of the detector centre.

Ensure that the area in front of the detector has ease of access if Infra-red communication is required.

MAN-0129 SU343 Rev 0.3 Page 38 of 50

Page 39

Figure 19

Figure 19 shows the position of the Infra-red receiver and transmitter with relation to the display. It is

recommended that the display is visible to the user when using the Infra-red communicator to ensure

correct communication.

3.4. MAINTENANCE PROCEDURES

3.4.1. HAND HELD TEST

GDU-01-TT Test Transmitter and NSM-SU343 Communicator can be used to emit an ultrasonic tone of

40kHz with a sound pressure level of 100dB at 1m (3ft). Using either handheld device makes testing the

NSM-SU343 and other types of Ultrasonic detector quick and cost effective as it may be undertaken at

floor level at distances of up to 8m (26ft) (dependant on background noise) provided line of sight with the

sensor can be achieved. It is recommended that all alarms are disabled and the 4-20mA output is

monitored from the control room or observed on the display. Testing is carried out to ensure that the

sensors are functioning correctly in addition to any internal test function contained within NSM-SU343. It

is recommended that a handheld test is undertaken in line with existing site maintenance procedures.

MAN-0129 SU343 Rev 0.3 Page 39 of 50

Page 40

Note: ensure that any internal test functions are disabled or not activated when undertaking a handheld

test to avoid spurious results.

3.4.2. VERIFICATION TEST

GDU-PTV Performance Target Verification Kit can be used to provide an accurate method to test both

functionality and performance of ultrasonic gas detectors by generating a „burst release‟ representative

of that expected in the event of a gas leak. GDU-PTV should be used at the perimeter of the detector

coverage to ensure that all leaks will be detected. It is recommended that all alarms are disabled and the

4-20mA output is monitored from the control room or observed on the display. Testing is carried out to

ensure that the sensors are functioning correctly in addition to any internal test function contained within

NSM-SU343 with respect to sensor response and coverage. It is recommended that a verification test is

undertaken at installation and in line with existing site maintenance procedures.

4. CUSTOMER INTERFACE COMMANDS

4.1. RS485 DIGITAL INTERFACE

NSM-SU343 has a range of user changeable settings and defaults settings to allow complete flexibility

for any installation environment.

4.1.1. CUSTOMER COMMANDS

NSM-SU343 starts in customer command mode to allow modification of user changeable settings which

are detailed in the following table to allow the end user to write PC code to communicate with the

detector. Net Safety Monitoring can also supply Graphical User Interface software that can be installed

directly into the control PC for communication purposes.

MAN-0129 SU343 Rev 0.3 Page 40 of 50

Page 41

Master

NSM-SU343

Action

Address

Command

Variable

Checksum

ID

Response

Variable

Checksum

Set Alarm

Level (dB)

ADR

1

50 to 127

(50to127dB)

Checksum

ID 0 CONF

Checksum

Read Alarm

Level (dB)

ADR

11

##

Checksum

ID

0

50 to 127

(50 to 127dB)

Checksum

Set Alarm Delay

(10 & 1 second

increments)

ADR

2

0 to 99

(0=0sec,

99=990sec)

100 to 127

(100=0sec,

127=27sec)

Checksum

ID 0 CONF

Checksum

Read Alarm

Delay

(10 & 1 second

increments)

ADR

12

##

ID

12

0 to 99

(0=0sec,

99=990sec)

100 to 127

(100=0sec,

127=27sec)

Checksum

Set Relays

Normally Open /

Normally Closed

ADR

3

0 NC

1 NO

Checksum

ID 0 CONF

Checksum

Read Relays

Normally Open /

Normally Closed

ADR

13

##

Checksum

ID

13

0 NC

1 NO

Checksum

Set Relays

Latching

ADR

4

0 Off

1 On

Checksum

ID 0 CONF

Checksum

Read Relays

Latching

ADR

14

##

Checksum

ID

14

0 Off

1 On

Checksum

Read Sound

Level (dB)

ADR

20

##

Checksum

ID

20

47 to 200

(47 to 200dB)

Checksum

Read Alarm

Data

ADR

21

##

Checksum

ID

21

Bit 0 = Low

Supply

Bit 1 = Test

Bit 2 = Internal

Fault

Bit 3 = Inhibit

Checksum

Read Case

Temperature

ADR

28

##

Checksum

ID

28

0 to 127 (-40 to

87°C)

Checksum

Read Supply

Voltage

ADR

29

##

Checksum

ID

29

15 to 20 (15V to

30V)

Checksum

Read Heater

Temperature

ADR

2A

##

Checksum

ID

2A

0 to 127 (-40 to

87°C)

Checksum

Set to Factory

Defaults

ADR

30

##

Checksum

ID 0 CONF

Checksum

Reset Alarms

ADR

31

##

Checksum

ID 0 CONF

Checksum

Start Cleaning

Cycle

ADR

32

##

Checksum

ID 0 CONF

Checksum

Set Pulsefilter

(1sec

increments)

ADR

40

0 – off

1 to 127 (sec)

Checksum

ID 0 CONF

Checksum

Read Pulsefilter

(1sec

increments)

ADR

41

##

Checksum

ID

41

0 – off

1 to 127 (sec)

Checksum

Set Display

Brightness

ADR

42

0 – off

32 maximum

Checksum

ID 0 CONF

Checksum

Read Display

Brightness

ADR

43

##

Checksum

ID

43

0 – off

32 maximum

Checksum

Set Heat Enable

ADR

44

0 – off

1 – auto

2 – on

Checksum

ID

44

CONF

Checksum

Read Heat

Enable

ADR

45

##

Checksum

ID

45

0 – off

1 – auto

2 – on

Checksum

MAN-0129 SU343 Rev 0.3 Page 41 of 50

Page 42

Master

NSM-SU343

Action

Address

Command

Variable

Checksum

ID

Response

Variable

Checksum

Set Cleaning

Interval

ADR

46

0 – off

1 to 127 – on

Checksum

ID 0 CONF

Checksum

Read Cleaning

Interval

ADR

47

##

Checksum

ID

47

0 – off

1 to 127 – on

Checksum

Set „TeST‟

Display

ADR

48

0 – mA

1 – TEST

Checksum

ID 0 CONF

Checksum

Read „TEST‟

Display

ADR

49

##

Checksum

ID

49

0 – mA

1 – TEST

Checksum

Initialize

Customer

Defaults

ADR

70

##

Checksum

ID 0 CONF

Checksum

Set Unit

Address ID

ADR

71

1 to 31

Checksum

ID 0 CONF

Checksum

## - Any Value

CONF – Confirmation (06 HEX)

Command and Response in HEX

MAN-0129 SU343 Rev 0.3 Page 42 of 50

Page 43

5. WARNINGS

The specification and information included in this documentation may be subject to

modification without notice to ensure certification compliance and improve

functionality.

Please ensure that the following safety guidelines are observed at all times.

5.1. USE IN HAZARDOUS AREAS NSM-SU343 should be installed and operated in compliance with the applicable standards

relating to electrical installations in hazardous areas.

Please read the NSM-SU343 Ultrasonic Gas Leak Detector Operation Manual before installation.

All assembly work, electrical installations, operation and maintenance work must be performed

by qualified personnel trained in handling products in hazardous areas.

All national regulations applicable to the installation, maintenance and repair of instruments in

hazardous areas must be observed at all times.

Do not modify the enclosure or component parts as certification may be void.

The temperature class based on the ambient temperature must correspond to the temperature

class on the EX type label.

The main enclosure should never be opened, certification and any warranties will be void.

Never open the terminal cover when an explosive atmosphere is present or when energised.

All enclosure and terminal cover fasteners to be tightened to a torque of 9Nm.

Only use a moist cloth or antistatic products to clean the display glass.

If NSM-SU343 is to be installed in areas with an ambient temperature greater than 60°C (158°F)

ensure cable has a rating that is equal to or exceeds the proposed maximum working

temperature.

Only certified, Ex d cable glands should be used in hazardous areas. Please refer to Cable gland

manufacturers instructions for correct installation instructions.

All unused cable entries and glands in hazardous areas should be sealed using certified, type Ex

d plugs. Please refer to Cable plug manufacturers instructions for correct installation

instructions.

Earth wire to be connected to local earth. Ensure earth wire is attached using the supplied spring

washer.