Systeme Helmholz GmbH z Hannberger Weg 2 z 91091 Großenseebach z Germany

Phone: +49 9135 7380-0 z Fax: +49 9135 7380-110 z E-Mail: info@helmholz.de z Internet: www.helmholz.de

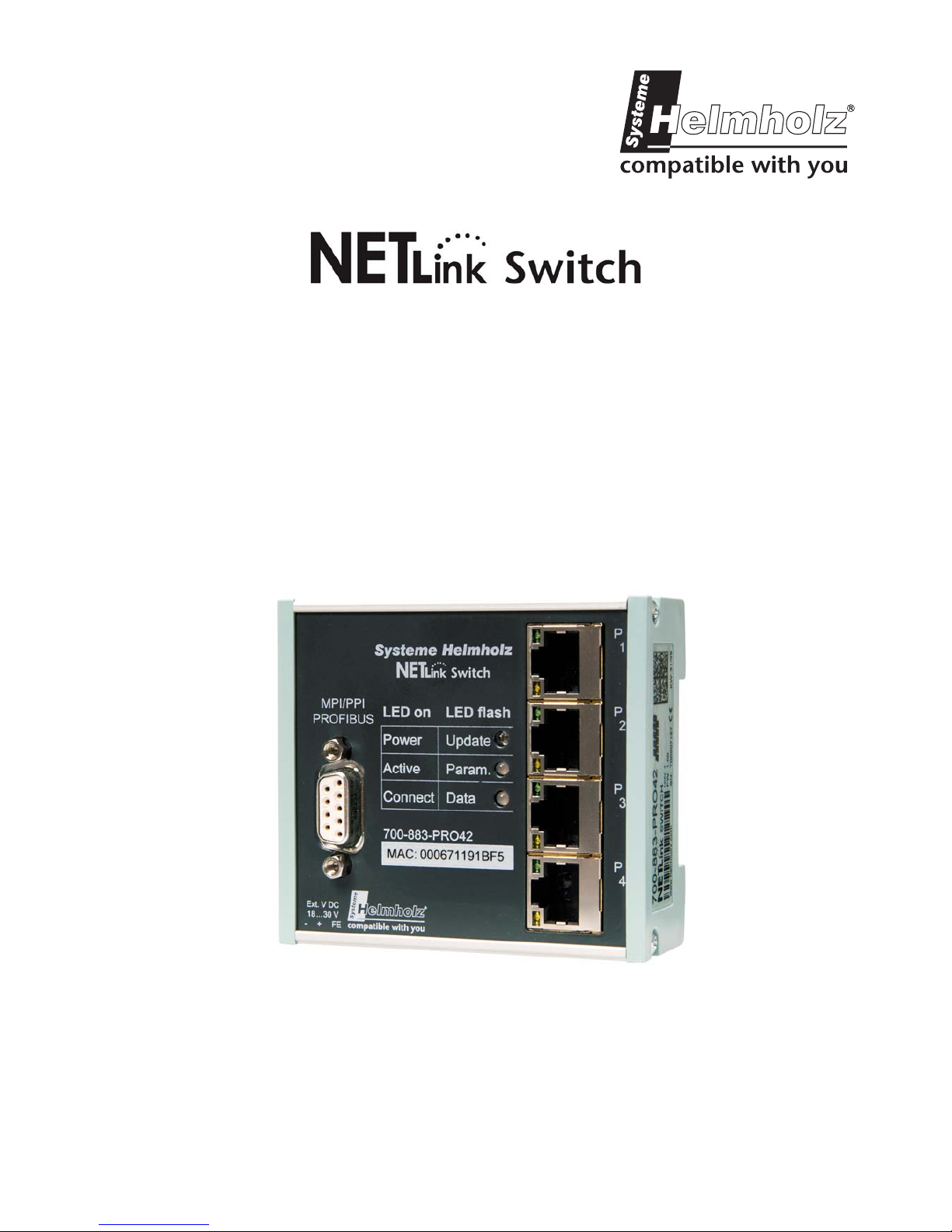

Ethernet Gateway for MPI/PPI/PROFIBUS

700-883-PRO42

User Manual

Edition 2 / 29.03.2010

HW 1-1, FW 2.30 and higher

Order number of manual: 900-883-PRO42/en

All rights are reserved, including those of translation, reprinting, and

reproduction of this manual, or parts thereof. No part of this manual

may be reproduced, processed, copied, or transmitted in any way

whatsoever (photocopy, microfilm, or other method) without the

express written permission of Systeme Helmholz GmbH, not even

for use as training material, or using electronic systems. All rights

reserved in the case of a patent grant or registration of a utility

model or design.

Copyright © 2009 by

Systeme Helmholz GmbH

Hannberger Weg 2, 91091 Grossenseebach, Germany

Note:

We have checked the content of this manual for conformity with

the hardware and software described. Nevertheless, because deviations cannot be ruled out, we cannot accept any liability for complete conformity. The information in this manual is regularly updated. When using purchased products, please heed the latest version of the manual, which can be viewed in the Internet at

www.helmholz.de, from where it can also be downloaded.

Our customers are important to us. We are always glad to receive

suggestions for improvement and ideas.

STEP ,Protool, Starter, Micromaster, and SIMATIC are registered trademarks of SIEMENS AG

MS-DOS and Windows are registered trademarks of Microsoft Corporation.

Revision history of this document:

Edition Date Revision

1 18.08.2009 First Edition

2 29.03.2010

Change cross-cable in the scope of supply, new Web Interface features added

NETLink

®

Switch 5

Contents

1 Safety Information 8

1.1 General 8

1.2 Restriction of access 9

1.3 Information for the user 9

1.4 Use as intended 9

1.5 Avoiding use not as intended! 9

2 Installation and Mounting 10

2.1 Mounting orientation 10

2.2 Minimum clearance 10

2.3 Installing the module 10

3 System Overview 11

3.1 Application and function description 11

3.2 Connections 12

3.3 LED displays and Connectors 12

3.4 Items supplied 13

3.5 Accessories 13

3.5.1 Manuals 13

3.5.2 Software 13

3.5.3 Other accessories 13

3.5.4 PROFIBUS accessories 14

4 Installation of the driver software 15

4.1 Introduction 15

4.2 System requirements 15

4.3 Running the installation setup 15

4.3.1 Adding the interface to the PG/PC interface 16

4.3.2 Selecting the required interface parameterization 17

5 Configuration via the NETLink-S7-NET Driver 18

5.1 Bus settings 18

5.1.1 MPI 19

5.1.2 PROFIBUS configuration 20

5.1.3 PPI configuration 23

5.2 Local connection (TCP parameterization) 23

NETLink

®

Switch 6

5.2.1

Creating a station 24

5.2.2 Setting TCP parameters 26

5.2.3 Operation without the DHCP 27

5.2.4 DHCP 28

5.2.5 Additional features 28

5.3 Options of the driver 29

5.3.1 Language setting of the display elements 29

5.3.2 Version information 29

5.4 Diagnostics 30

5.4.1 Bus members 30

5.4.2 Bus parameters 30

5.5 Teleservice 31

6 The Tool: ‘NETLink® PRO Family Configuration’ 32

7 Possibilities of the Web Interface 33

7.1 Home page 33

7.2 Status page 34

7.3 Configuration page 38

7.4 Security page 41

7.5 Observing variables 43

8 RFC1006 Function (S7-TCP/IP) 46

9 Bus Parameters in Single Master Operation 47

9.1 Storing specified bus parameters 47

9.2 Addressing (rack/slot mode ON/OFF) 48

9.2.1 Addressed mode 49

9.2.2 Rack/slot mode 49

9.3 Example of configuration for WinCC V7.0 50

9.3.1 Using addressed mode 50

9.3.2 Use of rack/slot mode 53

10 Troubleshooting 57

11 Appendix 62

11.1 Technical Data 62

11.2 Pin assignments 62

11.2.1 MPI/PROFIBUS interface pin assignments 62

11.2.2 Assignment of the Ethernet interface (host interface) 62

11.2.3 Function overview of internal switch 63

NETLink

®

Switch 7

11.2.4

Power supply socket 63

11.3 Further Documentation 63

11.4 Information in the internet 63

11.5 Address conversion table 64

12 Glossary 65

NETLink

®

Switch 8

1 Safety Information

For your own safety and for the safety of others, always heed the

safety information given here. The safety information indicates

possible hazards and provides information about how you can

avoid hazardous situations.

The following symbols are used in this manual.

!

Caution, indicates hazards and sources of error

i

Gives information

Hazard, general or specific

Danger of electric shock

1.1 General

NETLink® Switch is only used as part of a complete system.

!

The operator of a machine system is responsible for observing

all safety and accident prevention regulations applicable to the application in question.

During configuration, safety and accident prevention rules spe-

cific to the application must be observed.

Emergency OFF facilities according to EN 60204 / IEC 204

must remain active in all modes of the machine system. The system

must not enter an undefined restart.

Faults occurring in the machine system that can cause damage

to property or injury to persons must be prevented by additional external

equipment. Such equipment must also ensure entry into a safe state in

the event of a fault. Such equipment includes electromechanical safety

buttons, mechanical interlocks, etc. (see EN 954-1, risk estimation).

Never execute or initiate safety-related functions using an operator terminal.

NETLink

®

Switch 9

1.2 Restriction of access

The modules are open equipment and must only be installed in

electrical equipment rooms, cabinets, or housings. Access to the

electrical equipment rooms, barriers, or housings must only be

possible using a tool or key and only permitted to personnel having received instruction or authorization.

1.3 Information for the user

This manual is addressed to anyone wishing to configure, use, or

install NETLink

®

Switch.

The manual tells the user how to operate NETLink

®

Switch and explains the signaling functions. It provides the installing technician

with all the necessary data.

NETLink

®

Switch is exclusively for use with a S7-200 and S7-

300/S7-400 programmable controller from Siemens.

NETLink

®

Switch is for use within a complete system only. For that

reason, the configuring engineer, user, and installing technician

must observe the standards, safety and accident prevention rules

applicable in the particular application. The operator of the automation system is responsible for observing these rules.

1.4 Use as intended

NETLink® Switch must only be used as a communication and signaling system as described in the manual.

1.5 Avoiding use not as intended!

Safety-related functions must not be controlled via NETLink®

Switch alone. Make sure in the software that uncontrolled restarts

cannot occur.

Only authorized persons

must have access to the

modules!

D

uring configuration,

safety and accident prevention rules specific to

the application must be

observed.

M

ake sure in the software that uncontrolled

restarts cannot occur.

NETLink

®

Switch 10

2 Installation and Mounting

Installation and mounting must be effected in compliance with

VDE 0100 / IEC 364. Because it is an IP20 module, you must install

it in a cabinet.

A maximum ambient temperature of 60 ºC must be ensured for reliable operation.

2.1 Mounting orientation

NETLink® Switch can be installed in any position.

2.2 Minimum clearance

Minimum clearances must be observed because

• Then it is possible to insert and remove NETLink

®

Switch with-

out having to remove other system components.

• There is enough space to connect existing interfaces and other

contacts using standard commercial type accessories.

For NETLink

®

Switch, a minimum clearance of 30 mm should be

left above and below and 10 mm at the sides.

2.3 Installing the module

NETLink® Switch is intended to be mounted on a DIN rail bracket.

It can be snapped into place by simply attaching it to the DIN rail

bracket. In order to do so, you hook NETLink

®

Switch into the rail

bracket at the upper groove of the DIN rail bracket and push NETLink

®

Switch in direction of the rail bracket. Thereupon, NETLink®

Switch should snap into place automatically. In order to remove

the hardware module from the rail bracket, it is necessary to push

NETLink

®

Switch up first and then remove it from the upper

groove.

B

efore you start installation work, all system

components must be

disconnected from their

p

ower source.

NETLink

®

Switch 11

3 System Overview

3.1 Application and function description

NETLink® Switch is a gateway between a TCP network and a MPI,

PPI, or PROFIBUS network.

Two protocols are available at the TCP end for exchange of useful

data with the automation system (multi-protocol operation):

• One is a proprietary protocol that is used to connect to the pro-

prietary NETLink-S7-NET driver

• The other is the S7-TCP/IP protocol often used by visualization

system manufacturers which is known as ‘RFC1006’ or ‘ISO on

top of TCP’.

Up to 16 TCP connections (10 Mbps or 100 Mbps) and up to 32

MPI/PPI/PROFIBUS connections (9.6 kbps to 12 Mbps) can be used

simultaneously.

The integrated 4-way switch makes it possible to connect further

Ethernet nodes to NETLink

®

Switch. If NETLink® Switch has to be

restarted via the driver or the web interface (e.g., due to new configurations), the Switch stays ready for use without a new initialization of the 4 ports.

On both the TCP and the field bus sides, the baud rate used can be

determined automatically (auto negotiation or autobaud).

NETLink

®

Switch needs to get 24 VDC power via the power sup-

plies at the lower left side of the case.

The connecting cable used to link NETLink

®

Switch with the pro-

grammable controller is to be connected to the front of NETLink

®

Switch. In case of a branch line it is to be executed actively (accessories, see chapter 3.5). When a node is integrated in the bus, the

connection can be carried out via a common PROFIBUS plug (accessories, see chapter 3.5).

The use of the NETLink-S7-NET driver makes it possible to use

NETLink

®

Switch as the following at the PC end

• Programming adapter,

• Teleservice unit, or

• Operator control and monitoring unit and

• Ethernet switch

The RFC1006 interface also enables you to use third-party software

that supports this protocol to communicate with S7-200/S7-300

and S7-400 systems.

NETLink

®

Switch can generally be connected to the PC via switch,

hub or directly via LAN cable in both cases.

NETLink

®

Switch 12

3.2 Connections

NETLink® Switch has the following connections:

• RJ45 socket for connecting the unit to a commercial type

switch or hub using a standard CAT5 TCP or Crossover-Cable.

Additional Ethernet nodes can be connected as well.

• Power supply socket for 24 V DC power supply.

Here, an additional connector for the function ground is provided. It is recommended to connect a function ground.

• Bus connector via interface at the front side.

NETLink

®

Switch needs to be connected to the bus via a common PROFIBUS plug. It can be connected at the beginning,

middle or end segment of the respective bus.

The terminating resistor must be connected (ON) if NETLink

®

Switch is at the beginning or end of a bus segment. If this is

not the case, the switch position must be OFF. If NETLink

®

Switch is to be operated with a branch line, the latter has to be

executed as ‘active line’ in order to avoid bus faults.

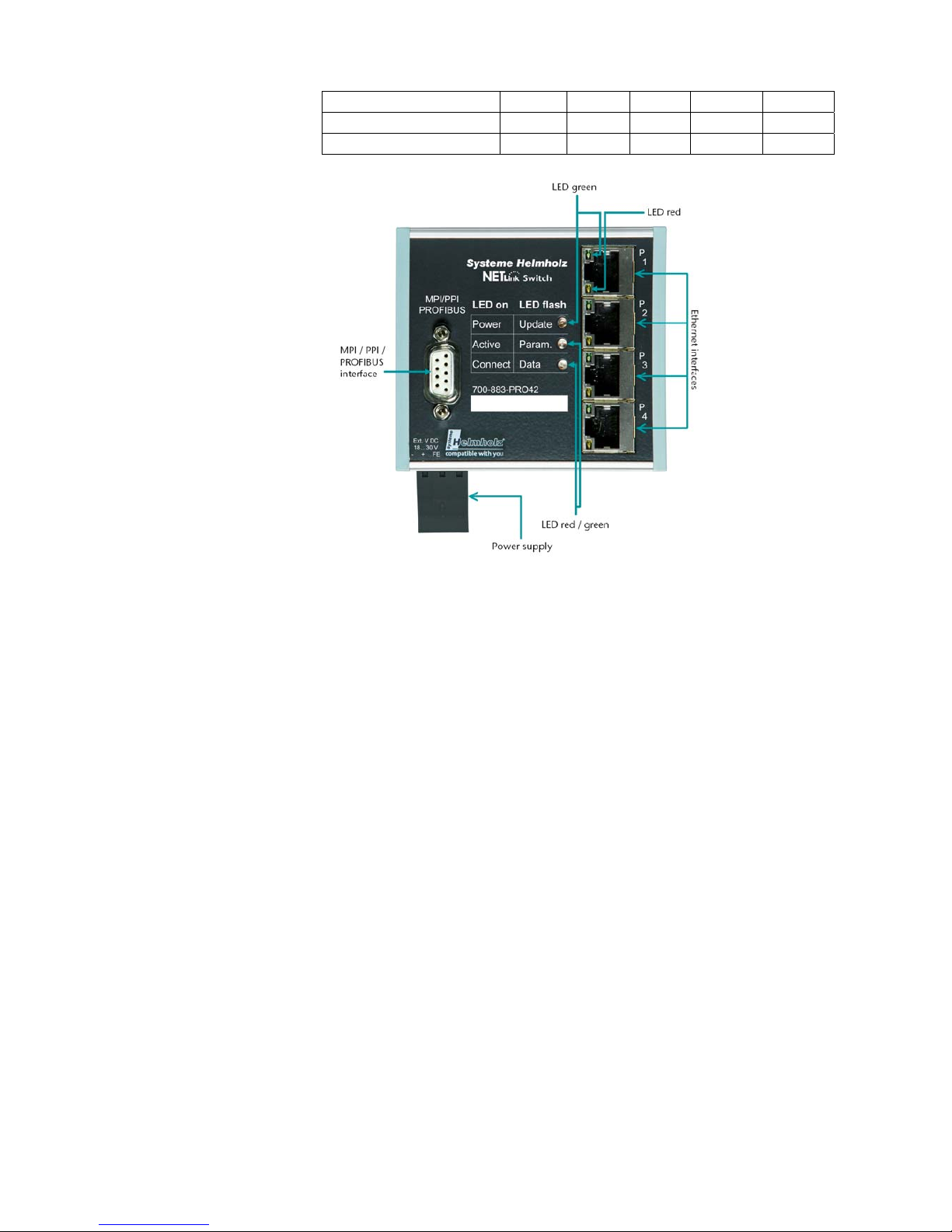

3.3 LED displays and Connectors

NETLink® Switch has three LEDs, including two two-color LEDs,

to indicate its operating status.

The two LEDs located on the four RJ45 sockets indicate by their

status, the state of the LAN that is connected to the respective

port.

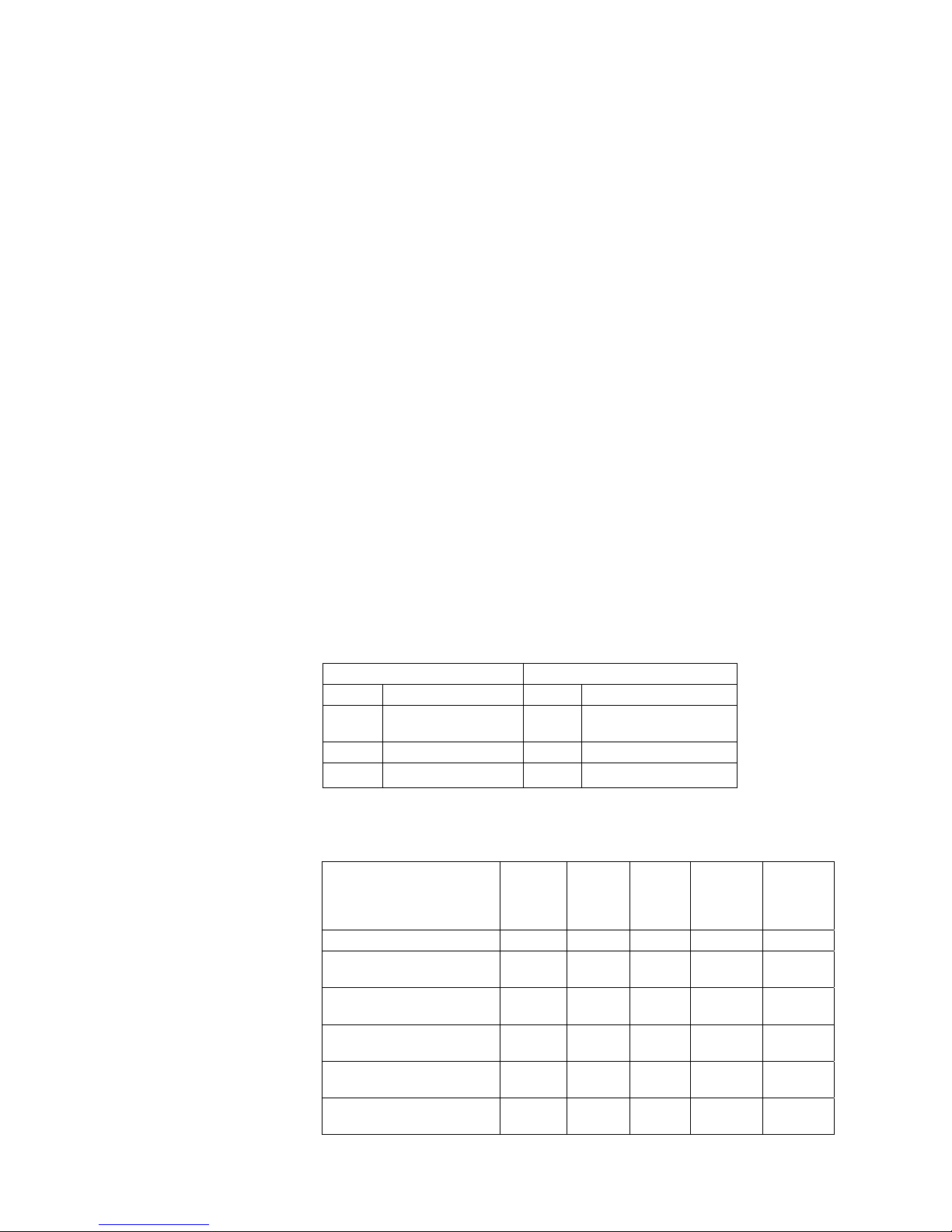

LINK LED (green) ACTIVE LED (yellow)

Status Description Status Description

OFF

Not connected

OFF

No activity on the network

ON

Connected

ON

Activity on the network

BLINK

BLINK

Activity on the network

The three LEDs (two two-color LEDs) on the top of NETLink®

Switch indicate the operating status of the device itself:

LED status for operating

status

Power

LED

(green)

Active

LED

(green

)

Active

LED

(red)

Connect

LED

(green)

Connect

LED

(red)

Ready for operation

ON

Try to log on to the

MPI/PPI/PROFIBUS

ON

BLINK

Actively logged on to the

MPI/PPI/PROFIBUS

ON

ON

Active connection with a

programmable controller

ON

ON ON

Data exchange with a

programmable controller

ON

ON BLINK

Transferring firmware

update

BLINK

BLINK BLINK

i

The NETLink has the IP

address 192.168.4.49 on

deliver

y f

rom the factory.

NETLink

®

Switch 13

Storing firmware update

ON

ON ON

Exception at bus end

ON

BLINK

Exception at PC end

ON

BLINK

3.4 Items supplied

The scope of supply of NETLink® Switch includes:

• NETLink

®

Switch ready to run

• CAT5 TCP cable (cross-over) with a length of 3 meters

• CD with NETLink-S7-NET driver, additional info’s

• Manual (German/English)

3.5 Accessories

3.5.1 Manuals

Manual, German 900-883-PRO42/de

Manual, English 900-883-PRO42/en

3.5.2 Software

S7/S5 OPC server

with USB dongle 800-880-OPC20

3.5.3 Other accessories

Power su

pply adapter with plug 700-751-SNT01

Input: 100-240 V AC / 47-63 Hz / 400 mA

Output: 24 V DC / 625 mA

Active PROFIBUS plug cable 3m 700-901-4BD00

i

The NETLink has the

I

P address

192.168.4.49 on delivery from the factory.

NETLink

®

Switch 14

3.5.4 PROFIBUS accessories

EasyC

onnect

®

PROFIBUS plug without PG 700-972-0BA50

EasyConnect

®

PROFIBUS plug with PG 700-972-0BB50

EasyConnect

®

PROFIBUS plug for flexible lines, without PG

700-972-0FA50

EasyConnect

®

PROFIBUS plug for flexible ines, with PG

700-972-0FB50

EasyConnect

®

PROFIBUS plug axial axialer outlet

for inflexible lines 700-972-0CA50

EasyConnect

®

PROFIBUS plug axial axialer outlet

for flexible lines 700-972-0CF50

EasyConnect

®

PROFIBUS plug with diagnostics

without PG for inflexible cables 700-972-7BA50

EasyConnect

®

PROFIBUS plug with diagnostics

and PG for inflexible cables 700-972-7BB50

EasyConnect

®

PROFIBUS plug with diagnostics

without PG for flexible cables 700-972-7FA50

EasyConnect

®

PROFIBUS plug with diagnostics

and PG for flexible cables 700-972-7FB50

Bus connection plug for PROFIBUS 90° without PG 700-972-0BA12

Bus connection plug for PROFIBUS 90° with PG 700-972-0BB12

Bus connection plug for PROFIBUS 35° without PG 700-972-0BA41

Bus connection plug for PROFIBUS 35° with PG 700-972-0BB41

Bus connection plug for PROFIBUS axial 700-972-0CA12

Bus connection plug for PROFIBUS

with Atex license, without PG, Ex-Zone 2 700-973-0BA12

Bus connection plug for PROFIBUS

with Atex license, with PG, Ex-Zone 2 700-973-0BB12

PROFIBUS plug diagnostics without PG 700-972-7BA12

PROFIBUS plug diagnostics with PG 700-972-7BB12

PROFIBUS FLEXtra profiPoint 700-972-1AA02

PROFIBUS FLEXtra twinRepeater 700-972-2AA02

PROFIBUS Compact Repeater 700-972-0RB12

Dismantling tool for PROFIBUS 700-972-6AA00

NETLink

®

Switch 15

4 Installation of the driver software

With installation of the NETLink-S7-NET driver for NETLink®

Switch, it is easy to access controllers with a MPI/PPI/PROFIBUS

interface from the PC via TCP/IP.

4.1 Introduction

The NETLink-S7-NET driver is inserted in the PG/PC interface of

an existing Simatic application and can then be used from most

Simatic engineering tools (STEP7, ProTool, WinCC, etc.).

Access is possible to any controllers of the Simatic S7-200, S7-300,

or S7-400 series via NETLink

®

Switch.

4.2 System requirements

A PC with a 32-bit Windows operating system is required to operate the NETLink-S7-NET driver at the PU end. The Windows XP

(SP3) and Windows Vista operating systems can be used.

A further requirement is the existence of a Simatic engineering

tools, such as STEP7, Version 5.1 and higher or STEP7-Micro/Win

Version 4.0 and higher, which ensures that the PG/PC interface is

installed on the computer.

Installation under Windows 2000 and 64-bit operating systems is

possible but is not supported by the technical support team of

Systeme Helmholz GmbH. Please pay attention to the requirements of the Simatic package used.

A functioning network link using TCP/IP must have been set up

on the PCs that are used. The network configuration of the PC

must be known. Commercially network cards and, for the connection, cross-over- or 1:1 (straight) cables may be used.

The integrated auto-negotiation function automatically negotiates

the TCP/IP transmission speed between the stations. In this way,

the best performance is achieved in a local 100 Mbps network.

Status operation will be slowed down if older 10 Mbps network

cards and hubs are used.

4.3 Running the installation setup

After you have inserted the installation CD, user guidance starts

automatically, allowing the user to start the setup routine of the

NETLink-S7-NET driver.

If the user guidance does not start automatically, the setup file

can be launched manually in directory ‘CD drive:\Driver\’.

If necessary, you can download the latest NETLink-S7-NET driver

from our homepage (http://www.helmholz.de).

Please note

that for installation you have to log on as an adminis-

trator under the 32-bit Windows operating systems because the

setup program has to make entries in the Windows registry.

i

A

dministration rights

are required for installation.

NETLink

®

Switch 16

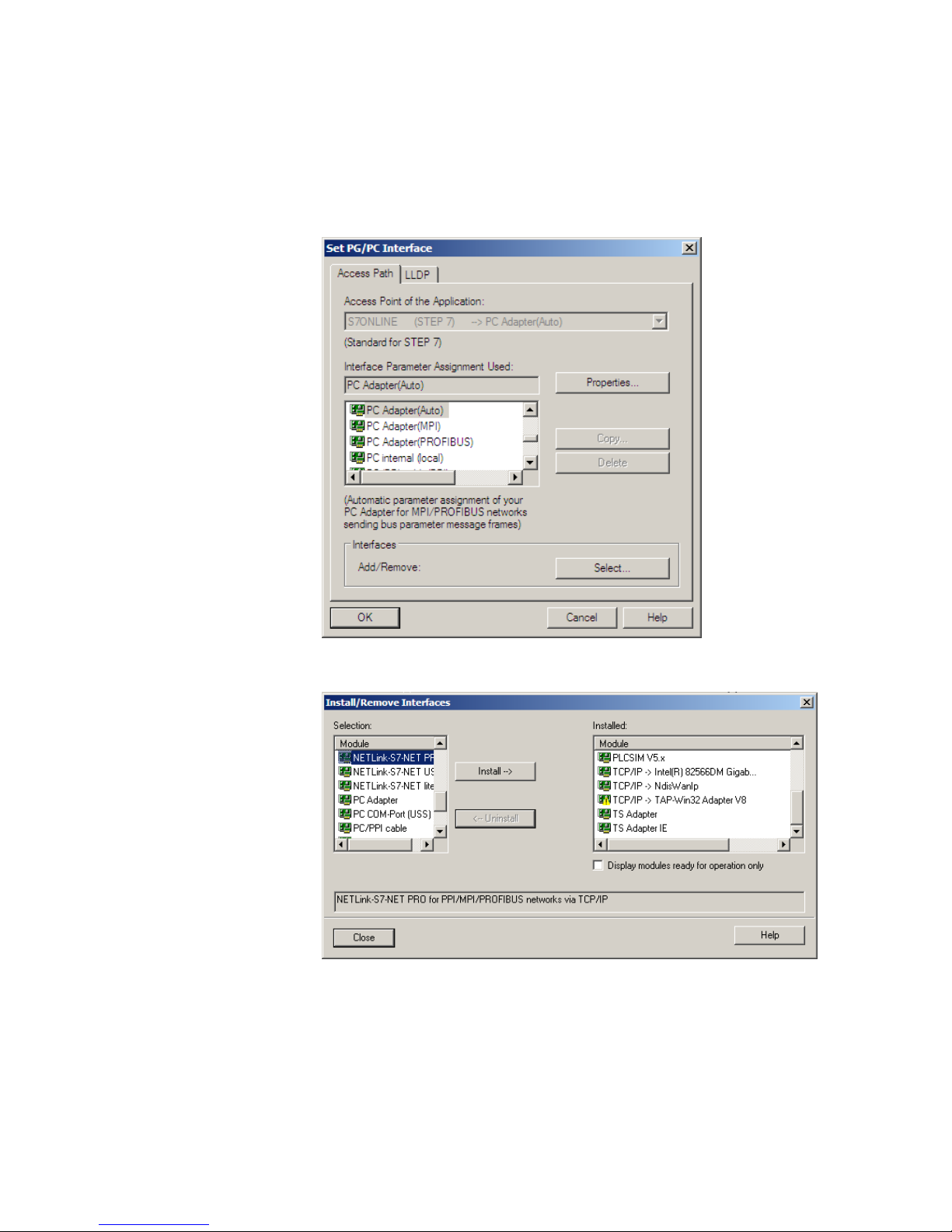

4.3.1 Adding the interface to the PG/PC interface

After initial installation, the new interf

ace parameter set ‘NET-

Link-S7-NET’ has to be set up. Administrator rights are necessary

for this.

After you have started ‘Set PG/PC Interface’ in the Control Panel,

click the ‘Select…’ button there.

This opens the ‘Install/uninstall interface’ dialog box.

After you have selected the entry ‘NETLink-S7-NET PRO family’

from the left-hand list, click the ‘Install-->’ button.

NETLink

®

Switch 17

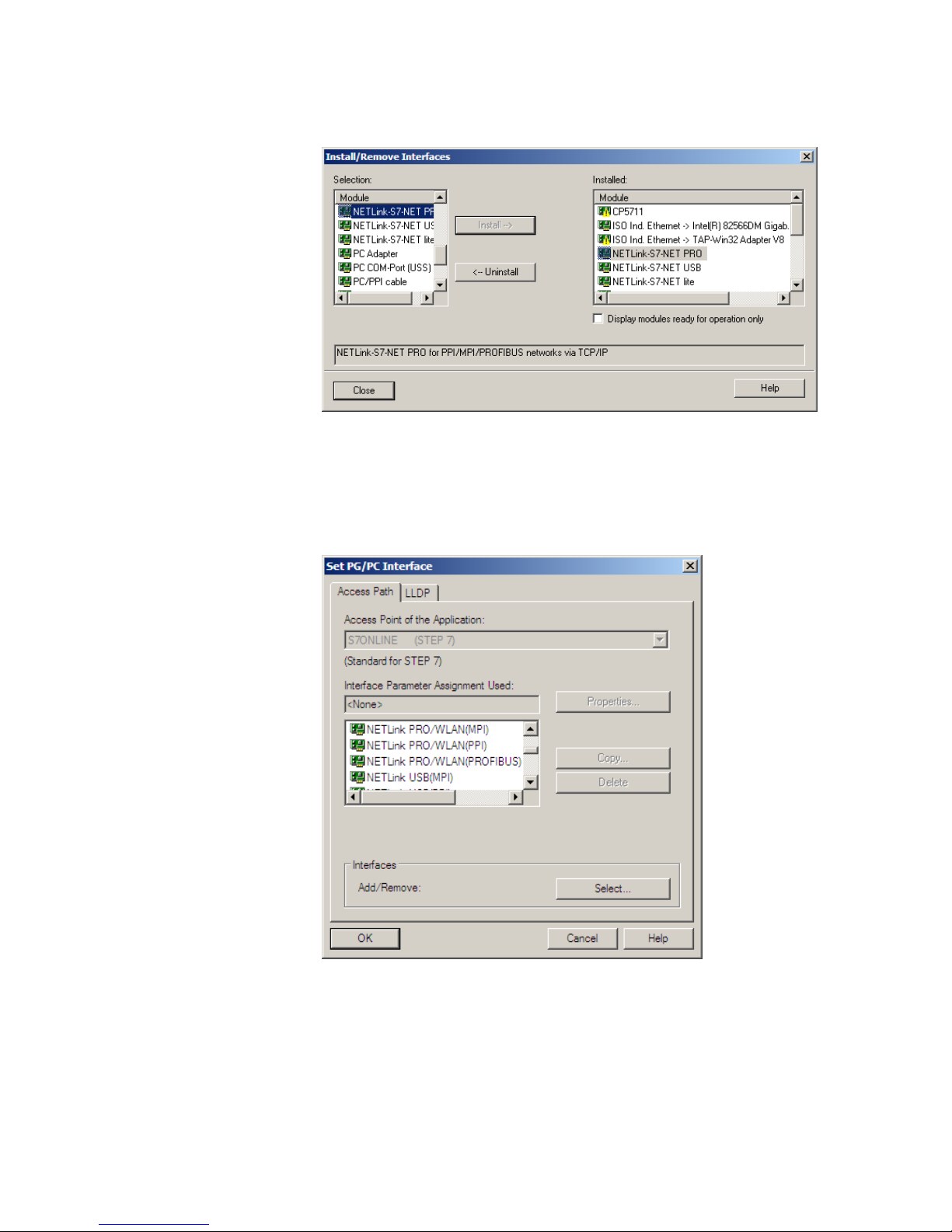

The ‘NETLink-S7-NET PRO’ has now been included in the selection list so that it is available for selection in future.

The access path in the ‘Set PG/PC Interface’ dialog box is set when

this window is closed.

4.3.2 Selecting the required interface parameterization

The selection list for the interface para

meter sets now contains an

additional three items for NETLink PRO Family.

All relevant settings of a NETLink-S7-NET driver can be made via

the "Properties" access field. With the button ‘Diagnostics...’ it is

possible to show the nodes connected to the bus and the parameters the bus is working with. These fields are explained in Section

5.

NETLink

®

Switch 18

5 Configuration via the NETLink-S7-NET Driver

Once a NETLink® PRO Family has been selected in the ‘Set PG/PC

Interface’ window, it is possible to specify this access path more

precisely with the ‘Properties…’ button.

With the functionality behind the button ‘Diagnostics...,’ which is

visible when a NETLink

®

PRO Family is selected, it is possible to

read the bus configuration and scan connected nodes.

The properties of the access NETLink

®

PRO Family are divided

into three subareas:

• Bus settings

Here it is possible to state the bus configuration (e.g. station

address) with which the NETLink

®

Switch will enter the bus

system (Section 5.1).

• Local connection (TCP configuration)

Here, you set the IP address via which the required connection

with the programmable controller will be established (Section

5.2).

The NETLink

®

Switch hardware can also be parameterized in

this window.

• Options

Here it is possible to change the language of the NETLink-S7NET driver and to read out the version information of the

driver (Section 5.3).

Two functionalities are implemented for diagnostics at the connected bus:

• Bus members

a list of all active and passive nodes connected to the bus will

be displayed. By request the order numbers (MLFBs) will be

displayed also if this functionality is available by the nodes

(Section 5.4.1).

• Bus parameters

If possible, a list of all available bus parameters will be displayed (Section 5.4.2).

5.1 Bus settings

The NETLink® Switch can be operated on three different bus systems: MPI, PPI, and PROFIBUS.

From the NETLink

®

Switch user’s viewpoint, the three bus systems

only differentiates by the transmission rates that can be selected

and the additional options which are explained here.

The bus configuration is passed to the NETLink

®

Switch during

the runtime of the NETLink-S7-NET driver and is not stored in the

device.

It is possible to use the NETLink

®

Switch without specifying bus-

related information. The NETLink

®

Switch then automatically as-

certains the baud rate and the bus parameters, and can be oper-

NETLink

®

Switch 19

ated on different programmable controllers with different transmission rates without switching over the NETLink-S7-NET driver.

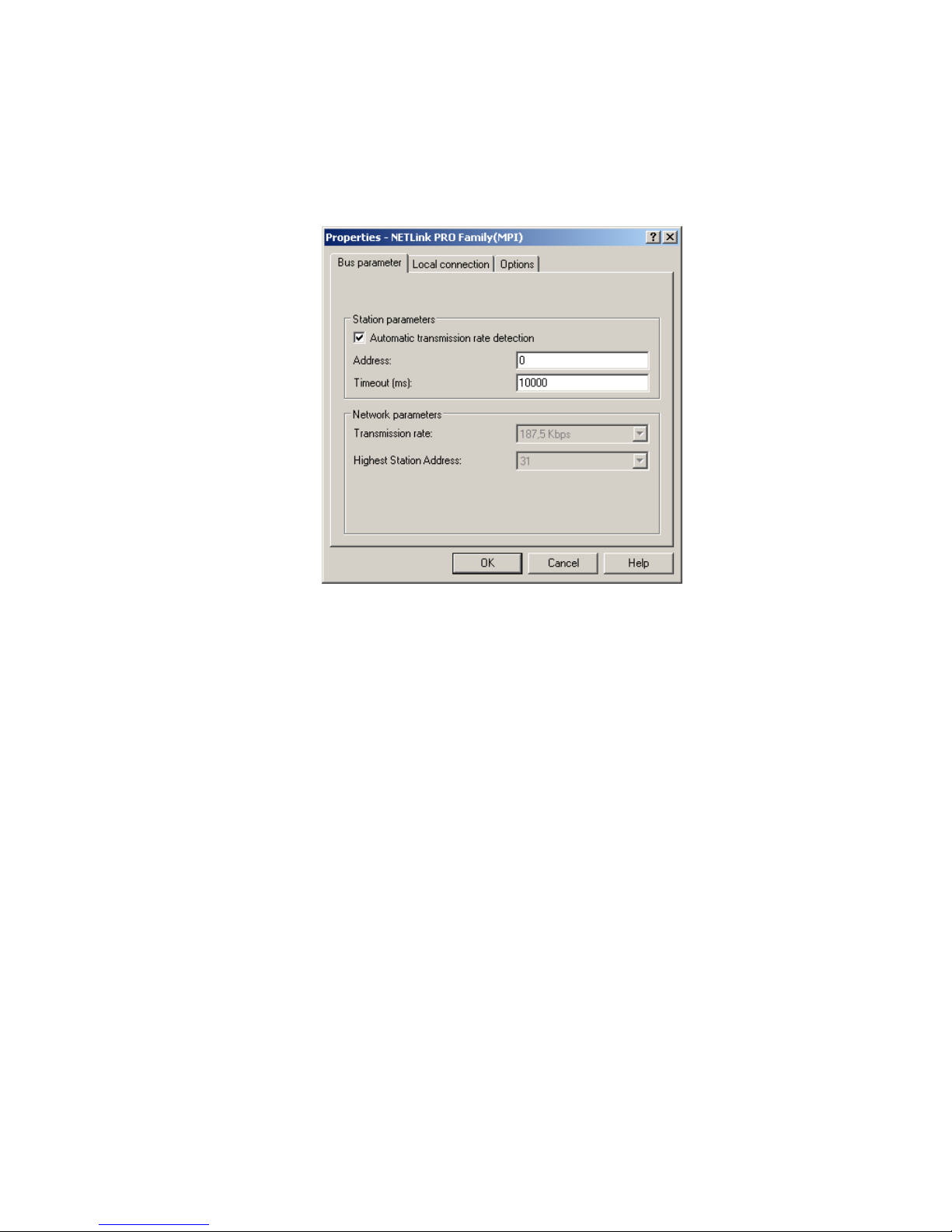

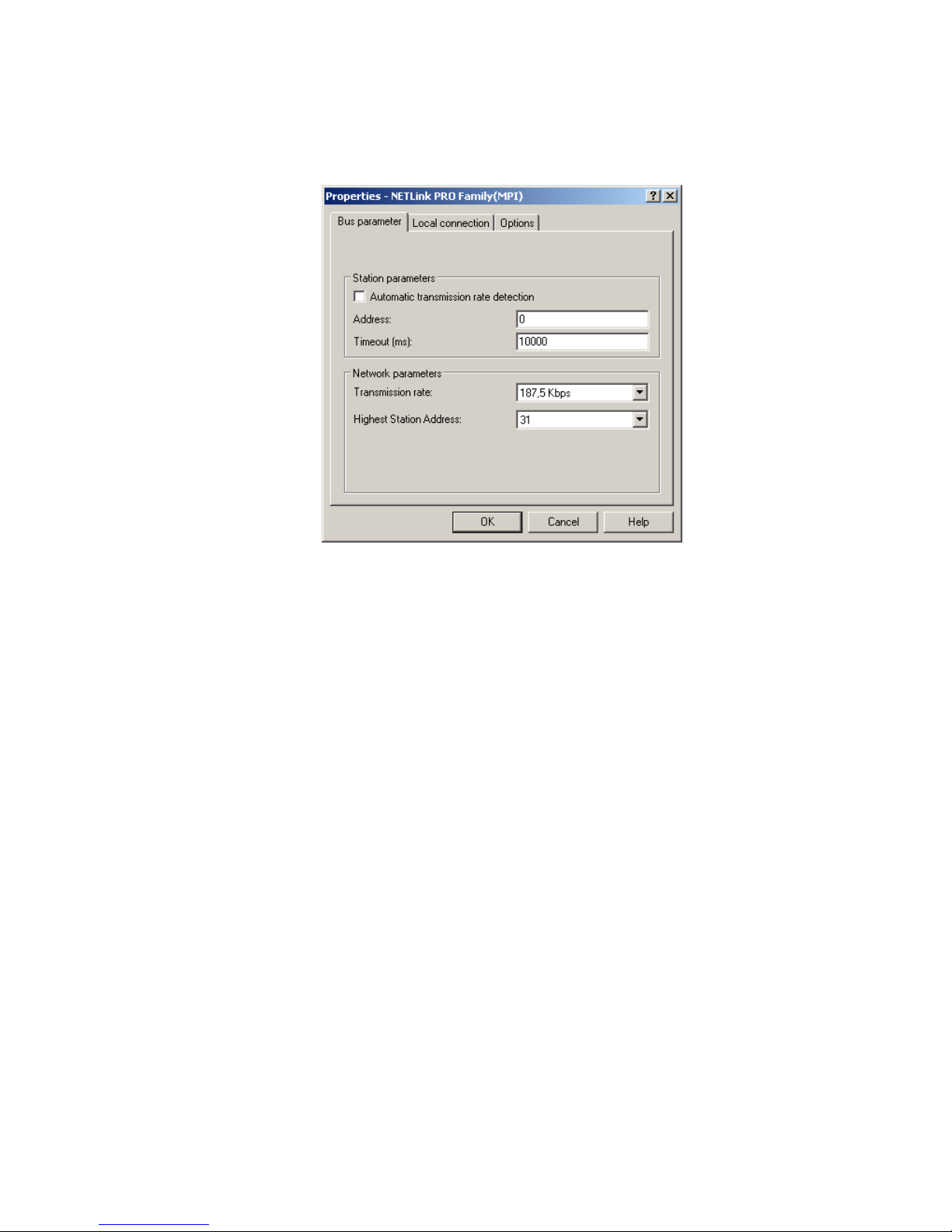

5.1.1 MPI

The MPI co

nfiguration contains station and network-related set-

tings.

The most important setting concerning bus configuration is assignment of the station address. This refers to the address the

NETLink

®

Switch will have on the bus when it goes online.

The station address can have any value from ‘0’ and ‘126’ if the

selected address is lower than or equal to the highest station address (HSA).

Example: HSA = 31

Any value between ‘0’ and ‘31’ can be specified for the station address if this address does not yet exist on the bus.

The local timeout of the NETLink-S7-NET driver can be parameterized in the station-related settings. If the driver does not receive a response to a request within the set timeout, a communication error is signaled to the Simatic application.

The network settings can be adapted manually if the checkmark

next to “Automatic Baud Rate Detection” is removed. This is usually

only necessary if the NETLink

®

Switch fails to sign onto the bus

system automatically (can happen with passive bus participant).

NETLink

®

Switch 20

Some older Siemens CPUs do not support the auto baud function

on the MPI. PPI systems do not usually support this function either. In such cases, the network-related parameters should be

adapted manually.

The transmission speed and the HSA of the PLC being addressed

must be known and identical to all connected bus nodes.

It is also possible that the auto baud function may not function

reliably at transmission rates slower than or equal to 19.2 Kbps or

with increased use of communication via global data exchange,

because the relevant frame is transmitted more irregularly by the

CPUs. In such cases it may be advantageous to assign the bus parameters manually.

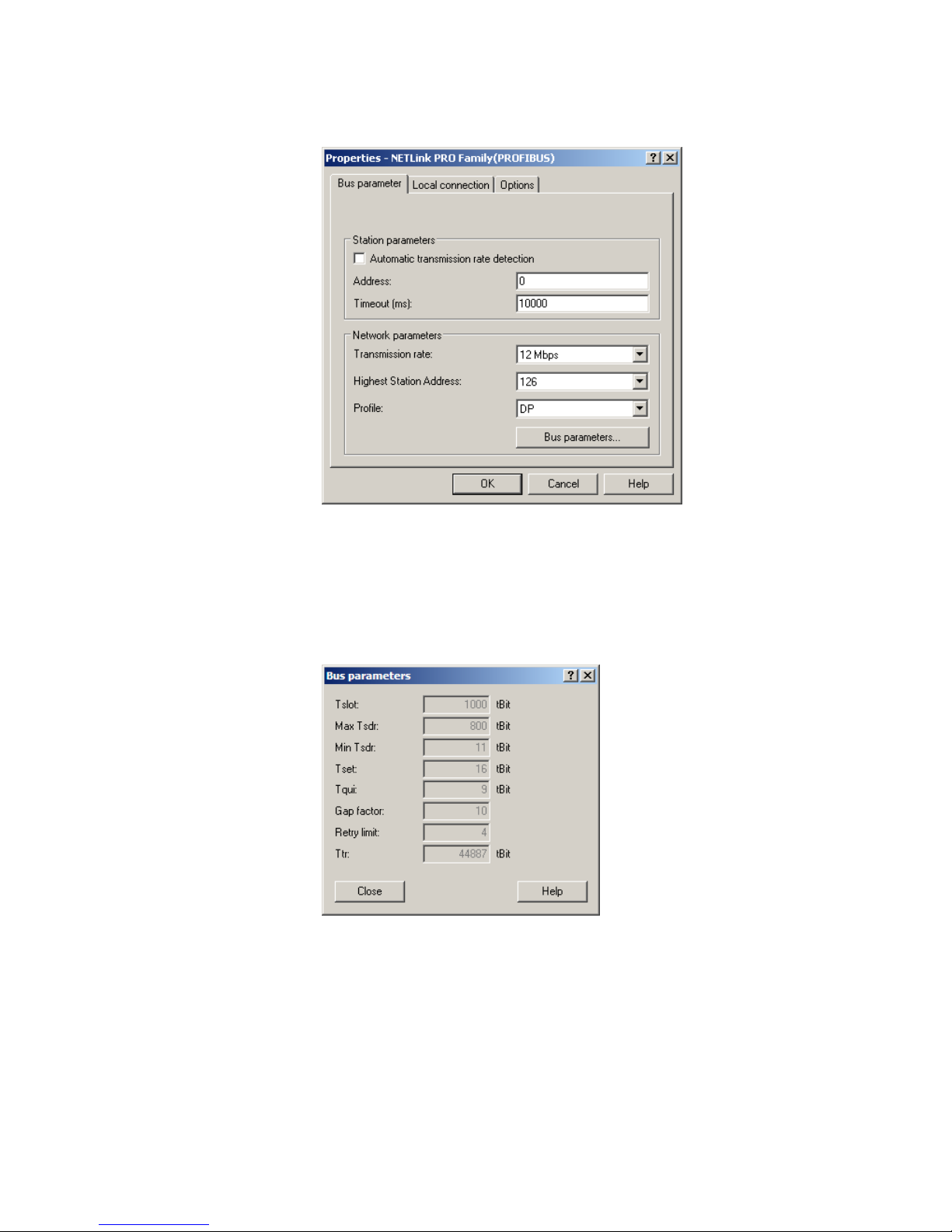

5.1.2 PROFIBUS configuration

Basically, the same applies to PROFIBUS configurati

on as to MPI

configuration. However, the network-related parameters are more

extensive.

In addition to the parameters transmission rate and highest station address mentioned in Section

5.1.1, PROFIBUS also has pa-

rameter field for selecting the bus profile and bus parameters.

If the NETLink

®

Switch is the only active station on the

PROFIBUS, it operates in so-called single-master mode, i.e. it generates the token cycle with the set bus parameters.

If the bus speed on the PROFIBUS is set to a value less than 187.5

Kbps, please remember that it may take up to half a minute for

the bus parameters to be recognized.

NETLink

®

Switch 21

In this case, the timeout value should be increased correspondingly.

Profile:

• Under PROFIBUS, there are usually the profiles DP, Standard

und User defined.

• The profile must be selected that is already used in the pro-

grammable controller.

Bus parameters:

• Unlike the MPI bus profile, the bus parameters for PROFIBUS

are not constant and change with the type and number of

PROFIBUS stations used.

• Always set the PROFIBUS parameters that are set in the cur-

rently used programmable controller (see current STEP7 project).

In order to simplify these procedures, it makes sense to use of the

auto baud function under PROFIBUS.

NETLink

®

Switch 22

The bus parameters are then calculated automatically.

Under PROFIBUS, please note that the auto baud function works

best if the ‘Cyclic distribution of the bus parameters’ function is activated in the programmable controller used.

The screenshot above of a hardware configuration of a randomly

chosen PROFIBUS CPU shows where to find the switch for cyclic

distribution of the bus parameters.

NETLink

®

Switch 23

5.1.3 PPI configuration

Basically, the same applies to PPI configu

ration as to MPI configuration. However, the network-related parameters are more extensive.

In addition to the parameters transmission rate and highest station address mentioned in Section 5.1.1, PROFIBUS also has a parameter f

ield for selecting the bus profile and bus parameters:

According to current knowledge, all S7-200 CPUs of the product

line 22x should be able to communicate with ‘Advanced PPI.’ It is

recommended to use ‘Advanced PPI’ if possible.

5.2 Local connection (TCP parameterization)

There are three basic ways of parameterizing NETLink® Switch at

the TCP end:

• Parameterization via ‘Set PG/PC interface

Existing stations can be reparameterized using the ‘Change’

button

• Parameterization via the ‘NETLink PRO Family configuration’

tool (see Section 6).

• Parameterization via the web interface of the

NETLink

®

Switch

(see Section

7.3).

If the NETLink

®

Switch is configured via the NETLink-S7-NET

driver, the following points must be considered:

If the NETLink

®

Switch is active on the bus when reparameterization is required (e.g. a variable table or block is being viewed),

reparameterization is not performed.

!

Normally the baud rate

cannot be detected automatically at PPI systems.

NETLink

®

Switch 24

The ensuing reset would interrupt the NETLink

®

Switch link

• The NETLink

®

Switch can be protected against unauthorized

reparameterization via a password (default password: “admin”).

If an attempt is made to save a parameter set with an incorrect

password, the following messages is displayed:

• If the password is correct during parameterization, the new pa-

rameter set will be saved and the following message displayed:

• NETLink

®

Switch is now restarted. This can take up to 15 sec-

onds.

5.2.1 Creating a station

The ‘New’ button takes

you to an input dialog box in which you

can store the known IP address of an existing NETLink

®

Switch

and any name for easier assignment.

To able to access a NETLink

®

Switch with the NETLink-S7-NET

driver, a station must be set up first. This station is virtually and is

not stored in the NETLink

®

Switch hardware – it permits easier

differentiation if several NETLink

®

Switch and/or other devices

from the NETLink

®

family are used.

Is the desired NETLink

®

Switch behind a router (e.g. internet tele-

service), the network administrator is able to configure the router

!

The password query must

be answered correctly and

confirmed with OK.

i

R

ebooting can take up to 15

seconds.

i

The NETLink has the IP

address 192.168.4.49 on

deliver

y f

rom the factory.

i

The default password is

‘admin.’

i

I

f NAT/PAT is used, a port

can be defined if ‘Internet

teleservice’ is selected.

NETLink

®

Switch 25

via NAT/PAT. So all frames going to a specific port of the router

going to a specific NETLink

®

Switch behind the router.

Using this functionality makes it possible to communicate to

more as one NETLink

®

Switch behind a router, if each station gets

a specific port configuration.

Is the NETLink

®

Switch connected to the local network, the

‘Internet teleservice’ option must be deselected.

‘OK’ stores this station, which can now be used.

It is easier to search for an existing NETLink

®

Switch in the local

area network. Just click the ‘Search NETLink PRO Family…’ button.

If you now select the required NETLink® Switch and click the

‘Close + Get’ button, the following dialog box will appear again:

This station can also be saved with ‘OK’ and is then available.

If you do not want the name that is stored in the NETLink

®

Switch to be the same as the station name, you can overwrite the

station name (e.g. replacing the name ‘Helmholz_test’ with the

name ‘Workshop’ in the example below).

NETLink

®

Switch 26

This completes parameterization of the driver.

It may now be necessary to adapt the NETLink

®

Switch to the

situation in the existing TCP/IP network.

5.2.2 Setting TCP parameters

To change the TCP parameters, sel

ect the station in question and

open the following dialog box with the ‘Edit’ button.

NETLink

®

Switch 27

The ‘Parameterize NETLink …’ button takes you to a new input

form that already contains the current parameters of the NETLink

®

Switch:

If no NETLink

®

Switch can be accessed via the stated IP address,

the following message will appear:

This message can have two causes:

• There is no NETLink

®

Switch with the stated IP address (e.g. the

device has not yet been switched on or is still starting up).

• The IP configuration of the computer used does not match the

IP configuration of the stated NETLink

®

Switch (e.g. different

subnet mask settings).

From the parameterization form shown, it can be seen that not

only static IP address allocation but also IP parameter assignment

via DHCP is possible.

Both these options are now explained in more detail.

5.2.3 Operation without the DHCP

If NETLink

®

Switch is used in a network without a DHCP server

(or you want the NETLink

®

Switch to work with the same IP address on the network despite the presence of a DHCP server) the

required IP parameters are stored in the input forms for ‘Static pa-

rameters.’

In this case, the checkmark is not set in the field ‘Get IP address

automatically (DHCP).’

Clicking the ‘Save in NETLink PRO Family’ button saves the parameters in the NETLink

®

Switch.

NETLink

®

Switch 28

5.2.4 DHCP

To have the

NETLink

®

Switch receive its IP parameters automatically via DHCP, set a checkmark in the field ‘Get IP address auto-

matically (DHCP).’

This then enables the ‘DHCP Timeout (s)’ input field. Enter the

maximum waiting time here. If the NETLink

®

Switch does not receive any parameters from the DHCP server within this time, it

will use the stored static parameters to ensure that the device is

accessible in the network and can be configured if necessary.

Times shorter than 30 seconds are replaced by the default value

(30 seconds) because most DHCP servers require 12 to 20 seconds

to assign valid parameter sets.

Clicking the ‘Save in NETLink

®

’ button saves the parameters in the

NETLink

®

Switch.

DHCP has the drawback that a NETLink

®

Switch parameterized by

this method could theoretically be assigned a different IP address

from the DHCP every time it is switched on.

The system administrator responsible for the DHCP server can

counter this informing the DHCP server of the MAC address of

the NETLink

®

Switch. However, this is additional work for the sys-

tem administrator.

5.2.5 Additional features

The ‘NETLink PRO Family propertie

s’ input form contains a ‘Net-

Link PRO Family properties’ group box with further options that are

explained here:

• Name:

Here a name can be given to the NETLink

®

Switch that identifies it better when it is shown in the search window. The name

is stored in the device.

The name may designate the location (e.g. conveyor HG1), the

user (e.g. Mr. Example), or anything else.

• Web interface active:

If there is a checkmark in this checkbox, the parameterization

of the NETLink

®

Switch can be viewed and changed, if necessary, in any standard Browser (e.g. IE, Firefox, Opera …) as long

as the password (if one has been set) is known.

Section 7 provides more detailed information about what

you

can do with the web interface.

• Changing the password:

Here you can change the actual password.

It is only possible to change the configuration of the NETLink

®

Switch with the password.

NETLink

®

Switch 29

This applies to parameterization both via the driver and via the

web interface.

Clicking the ‘Save in NETLink

®

’ button saves the parameters in the

NETLink

®

Switch in this case, too.

5.3 Options of the driver

Under the options of the NETLink-S7-NET driver, it is possible to

set the language of the output and help texts of the driver.

It is also possible to read out the version numbers of the driver

files used.

5.3.1 Language setting of the display elements

The langu

ages German and English are currently available.

After switching over the language, the setting window must be

opened again to apply the changes.

5.3.2 Version information

The name

s and version number of all driver files are listed here.

If support is needed, this data is used to obtain information about

the components used quickly and effectively.

i

The default password is

‘admin.’

NETLink

®

Switch 30

5.4 Diagnostics

For rudimentary diagnostics of the connected bus two sub functions are available:

• Display bus nodes

• Display bus parameters

Before the diagnostics functionality is used, a valid station must

be created and a plausible bus configuration set.

5.4.1 Bus members

A list of all

available nodes at the bus will be generated by clicking

the button ‘Read.’

With activating the option ‘Read MLFB number’ the order numbers

of all devices supporting this function will be displayed too.

The possibility to detect all connected nodes depends on the

parameterization of the PG/PC Interface. It is recommended to

enable auto baud functionality at MPI and PROFIBUS.

5.4.2 Bus parameters

If it

is possible a list of all bus parameters will be displayed by

clicking the button ‘Read.’

The possibility to detect the bus parameters depends on the

parameterization of the PG/PC Interface.

NETLink

®

Switch 31

It is recommended to enable auto baud functionality at MPI and

PROFIBUS.

5.5 Teleservice

If you want to use the NETLink® Switch for teleservice, you should

consult the network administrators of both the locations involved.

There are various ways of implementing teleservice via a WAN.

Here are some suggestions:

• Assignment of a separate, unique IP address with direct access

to the network (WAN).

Advantage: Quick to implement

No intervention by the administrator required

Disadvantage: Few globally available addresses exist,

A separate network with direct WAN access

is required, Security

• Use behind a router by means of NAT/PAT

Advantage: Can be integrated into existing infrastructures.

Administrator can ensure that it

is not visible/usable from outside.

Disadvantage: Network administrators must parameterize

routers and firewalls between the

communicating nodes.

• Use of a dial-up router (e.g. NETLink

®

Router)

Advantage: relatively simple to implement

if a phone connection is available.

Disadvantage: Loss of performance, additional costs due

to

phone charges, IP address can only be queried

remotely via DynDNS services.

NETLink

®

Switch 32

6 The Tool: ‘NETLink

®

PRO Family Configuration’

If no Simatic engineering tool is available on the parameterization

computer that has installed the PG/PC interface, it is possible to

configure the NETLink

®

Switch via the integrated web interface

(see Section 7.3) or via the separate configuration tool.

The tool is accessible under ‘Start/

Programs/Systeme Helm-

holz/NETLink-S7-NET/NETLink PRO Family Configuration’ after the

NETLink-S7-NET driver has been installed.

After this program has been called, the network will be searched

for connected NETLink

®

MAC addresses:

The scan can be repeated at any time by pressing the “Scan” button again. Having chosen any NETLink

®

adapter out of the pro-

vided list, it is possible to configure the device after clicking ‘Pa-

rametrize…’ as described in Section 5.

An extended function enables direct parameterization across network boundaries. To do this, activate the radio button and enter

the known IP address of the NETLink

®

(the example includes the

optional address of the port – separated by a colon) in the empty

field. The corresponding configuration menu then opens when

"Parameterize..." is clicked.

i

The set IP address of the

connected

NETLink

®

devices

is not relevant for search

function. The search function uses the device-specific

M

AC addresses. All other

data in the list is for information only.

NETLink

®

Switch 33

7 Possibilities of the Web Interface

If it has not been deactivated by the user, the web interface of the

NETLink

®

Switch can be opened with any standard browser (e.g.

Internet Explorer, Firefox, Opera, etc.)

The web interface is intended to support the user intuitively with

information and configuration tasks.

7.1 Home page

The home page, which is located at ‘http://<ip-address>,’ is a basic

address and navigation starting point for the user.

From this page you can go to the status page, to the Basic Configuration page, to the security page and, if the computer is connected to the Internet, to the web site of Systeme Helmholz

GmbH.

The page also shows the contact data, such as postal address,

phone and fax number, e-mail and web address.

i

The NETLink® PRO

Compact has the IP address 192.168.4.49 on

delivery from the factory.

NETLink

®

Switch 34

7.2 Status page

The status page, accessible via a link on the home page, provides

the user with information without allowing unauthorized reconfiguration of the NETLink

®

Switch.

The page provides general information (e.g. firmware version,

number of possible connections, etc.), and specific information

(baud rate, active stations, DHCP status, etc.). A “Diagnostic Page”

is also implemented, which can be useful for troubleshooting, for

NETLink

®

Switch 35

example. To make use of this function, “Go Online” must be activated for the NETLink

®

Switch on the bus system. This can be

done with an engineering tool such as STEP7 or by using the “Go

Online” button on the status page. This function can also be

switched on permanently on the “Basic Configuration” page (see

Section 7.3).

When the "Diagnostic Page" button is pressed, if the bus system is

correctly connected, a list of the currently most important communications parameters will be shown. For a better overview, the

table can be emptied with the "Clear List" function before a new

list is requested.

Because the NETLink

®

Switch is also active as a single master, it is

also possible to search for passive stations only. The search is

started by clicking “Search Passive Stations.” The updated status of

verified stations is then displayed.

i

The values shown here

are volatile!

NETLink

®

Switch 36

The result is entered in line: List of passive stations.

NETLink

®

Switch 37

All displayed elements are shown below in the form of a table.

All the relevant contents appear in the displayed configuration,

which means that the NETLink

®

Switch has signed onto the bus

system (is online).

Device-specific parameters:

Product name NETLink® Switch

Product order number 700-884-MPI21

Firmware version e.g. V2.30

BIOS version e.g. V2.240

Serial number e.g. T00008797

MAC address e.g. 00:06:71:19:22:5D

Device name

This shows the freely selectable name of the NETLink®

Switch, if a name has been assigned.

Bus-specific parameters:

Own station address

If the NETLink® Switch is active on the bus, this is the

device’s own station address.

Online bus parameters

If the NETLink® Switch is active on the bus, this is the

explanation of the bus parameter set, this is transmitted by a CPU.

List of active stations

If the NETLink® Switch is active on the bus, this is the

list of the stations that are currently active. The device’s

own address is shown in red.

List of passive stations

After a search request by a user, a list of passive stations

is output here.

Currently used connections

If the NETLink® Switch has opened at least one bus

connection, the exact count of open connections will

be displayed.

TCP-specific parameters:

IP Address

The currently used IP address of the NETLink® Switch is

shown (e.g. 192.168.4.44).

Subnet Mask

The currently used subnet mask of the NETLink® Switch

is shown (e.g. 255.255.0.0).

Gateway Address

If it has been set by the user, the standard gateway

currently used will be displayed here (e.g.

192.168.1.1).

Listen on Port

Port or ports via which the NETLink® Switch can be

reached by the PG/PC interface.

DHCP

(- DHCP timeout)

Shows whether the DHCP is activated or not (ON or

OFF). In active mode, the DHCP timeout is also dis-

played here.

Connected to client address

IP address of the computer that has just established a

connection to the NETLink

®

Switch.

Security interface

ON/OFF

Indicates whether the IP address access protection is

activated.

Currently used TCP

connections

If the NETLink® Switch has opened at least one TCP or

RFC1006, the exact count of open TCP connections

will be displayed here (maximum value shown in

brackets).

NETLink

®

Switch 38

Bus-specific settings:

- Go online after boot up

Shows whether the function for automatic connection

is activated or not (ON or OFF).

- Own station address

Indicates the local station address. This is the address

with which the NETLink

®

Switch will participate in the

bus cycle.

- Rack/Slot mode ON/OFF

Indicates whether R/S mode (ON) or addressed mode

(OFF) is used (for details, see Section 9.2).

- Currently used RFC connections

If the NETLink® Switch has opened at least one TCP or

RFC1006, the exact count of open connections will be

displayed here (maximum value shown in brackets).

7.3 Configuration page

The configuration page, accessible via a link on the home page, is

a configuration interface for the user.

Before this page is opened, the user name (default: NETLink

Switch, if no user-defined user name is entered) and the password

(admin if no user-defined password has been set) must be entered.

The confirmation prompt is case sensitive. So you must remember

which upper and lower case letters you used.

i

The default user name is

“NETLink Switch”

The default password is

‘admin.’

NETLink

®

Switch 39

As soon as you have answered the security query, you will have

write access to all parameters.

NETLink

®

Switch 40

The bus parameters can also be adapted to the single master functionalities. For further details on the RFC1006 function see Section 8.

Device-specific parameters:

Device name

Name consisting of max. 20 alphanumeric characters.

TCP parameters:

Static IP address

IP address that is used if DHCP is deactivated or

the DHCP timeout elapses.

Static subnet mask

Subnet mask that is used if DHCP is deactivated or

the DHCP timeout elapses.

Static gateway

Gateway that is used if DHCP is deactivated or the

DHCP timeout elapses.

Alternative NETLink Port

In addition to the standard port, a further freely

selectable port can be stored here in the NETLink

®

Switch.

DHCP ON/OFF

Automatic fetching of address parameters from a

DHCP server ON or OFF.

DHCP Timeout (in seconds)

Possible range: 30 to 65535 seconds. Timeout is

deactivated at 65535. In this case, there is no fallback mechanism, i.e. it is essential that a DHCP

server is accessible!

Web-Interface ON/OFF Web interface is ON or OFF

Bus-specific parameters:

Go online after boot up

ON/OFF

The need to go “online” immediately is largely

only relevant when CPU-to-CPU communication

is used.

NETLink MPI/PB Address

This is where the address with which the NETLink

®

Switch will participate in the bus cycle is entered.

Any address assigned at another location (e.g. by

the SHS7-Net driver) is then ignored.

Single Master bus parameters

The bus parameters specified here are used if the

single master function is active.

Rack/Slot modus ON/OFF

Indicates whether R/S mode (ON) or addressed

mode (OFF) is used (for details, see Section 9.2).

Fix destination address for

R/S mode

If R/S mode is activated, all incoming RFC1006

requests are routed to the bus address parameterized here.

User/password settings:

User

User name needed to sign on to the security-relevant pages of the NETLink

®

Switch

New password Password of max. eight characters

Retype new password

The password of max. eight characters must be

entered a second time

Please remember that the user names/passwords that you have defined for this configuration interface cannot be reset by any “master reset”. Please contact our technical support if you are no

longer able to access the safety-relevant pages of the Web interface with the access data known to you.

i

F

or further information,

see Section 9

NETLink

®

Switch 41

If you click the ‘Submit’ button, the inputs are checked for plausibility. You may then be shown which inputs are incorrect and

what correct input would look like at this point.

If all entries are consistent, the changes are displayed again as

they will now be stored non-volatilely in the NETLink

®

Switch

when you click the ‘Store’ button again.

After the changed parameterization data have been stored, the

NETLink

®

Switch is restarted to activate the desired configuration.

With the Web interface, NETLink

®

Switch can be started both locally and remotely, as required. This is done by clicking the ‘De-

vice Reboot’ button.

7.4 Security page

The security page, which is also accessible via a link on the home

page, is a configuration interface available to the user for limiting

access.

After the security query (see 7.3) has been correctly answered, the

user has write-access to all parameters that are implemented for

TCP security etc.

If the TCP access list is switched on by entering ‘ON,’ stations,

TCP connections can be established with the NETLink

®

Switch

only from stations that have addresses configured in the table

‘TCP address 1’ to ‘TCP address 12’ (white list).

The IP addresses must be entered in the four-octet pattern (e.g.

‘192.168.4.36.’) To clear or reset the TCP address setting, ‘OFF’

must be entered.

TCP/IP addresses that are not in the white list have read-only access to the web interface. MPI, PPI, or PROFIBUS functionalities

cannot be used. The configuration of the NETLink

®

Switch is also

prevented.

It is also possible to activate additional write protection for any

bus nodes connected to the NETLink

®

Switch. If the NETLink®

Switch is used, for example, as a communications adapter for representing visualization values, only data from the connected controllers can be read out if write protection is active. In this way,

manipulation of the CPU sequential program is ruled out.

This assumes, of course, that the access data for the NETLink

®

Switch web interface are secure.

Attention: To prevent their use by unauthorized persons, any

proxy servers that exist in company networks may not be entered

in the white list. If so, safe use of the NETLink

®

Switch is not

guaranteed.

i

R

ebooting can take up to

15 seconds.

!

Notice deviation by usage

of proxy servers.

NETLink

®

Switch 42

With the button ‘Factory defaults’ it is possible to restore all parameters to the as-delivered state of the NETLink

®

Switch. All user-

defined configurations will be deleted by this function.

If you click the ‘Submit’ button, the inputs are checked for plausibility. You may then be shown which inputs are incorrect and

what correct input would look like at this point.

If all entries are consistent, the changes are displayed again as

they will now be stored non-volatile in the NETLink

®

Switch

when you click the ‘Store’ button again.

NETLink

®

Switch 43

After the new parameterization data have been stored, the NETLink

®

Switch is restarted to activate the new configuration.

Parameters of the TCP access list:

TCP access list

ON/OFF

Switch ON/OFF the functionality of the TCP access list.

TCP/IP address

1 and 2

First and second IP addresses that are allowed to

access the NETLink

®

Switch.

TCP/IP address

3 and 4

Third and fourth IP addresses that are allowed to

access the NETLink

®

Switch.

TCP/IP address

5 and 6

Fifth and sixth IP addresses that are allowed to

access the NETLink

®

Switch.

TCP/IP address

7 and 8

Seventh and eighth IP addresses that are allowed

to access the NETLink

®

Switch.

TCP/IP address

9 and 10

Ninth and tenth IP addresses that are allowed to

access the NETLink

®

Switch.

TCP/IP address

11 and 12

Eleventh and twelfth IP that are allowed to access

the NETLink

®

Switch.

SPS write Protection PLC write-protection ON or OFF

NETLink® Switch can be started both locally and remotely via the

security interface. This is done by clicking the ‘Device Reboot’ button.

7.5 Observing variables

In addition to the “Observing Variables” function in the Simatic

engineering tools, NETLink

®

Switch also provides this function via

the web interface.

Setting parameters of the observe variables function:

MPI address

An active MPI/PB address is selected using the

dropdown menu.

Number of Variables

The number of variables to be observed can be

selected from 1 to 10 for a clearer view.

No. Consecutive numbering.

Address Area

The following viewable items are supported: OB,

OW, OD, IB, IW, ID, MB, MW, MD, DBB, DBW,

DBD, counter, and timer.

Address Index*

Address of the bytes to be displayed. * On the

case of data blocks with the form

“Datablock.Offset”

Result Value

If one of the buttons is pressed, the output value

will be displayed here

Display Format Display formats: decimal, hexadecimal, or binary

Description Freely selectable description (max. 32 chars)

i

R

ebooting can take up to

15 seconds.

NETLink

®

Switch 44

The operating menu can be accessed via the ‘Observe Variables’

link. An RFC 1006 communications channel is assigned for these

functions.

To display the desired values, you can use the ‘1x fetch’ button for

a single value update or ‘cyclic fetch’ for a permanent online

query.

With ‘Save Configuration’, it is possible to store the screen form

you have created with all the variables and their descriptions in

the NETLink

®

Switch.

NETLink

®

Switch 45

An example of display of various variables:

The value update is currently permanently set to 0.5 seconds.

Even if multiple stations access this function from the TCP/IP

end, only one connection resource is ever assigned in the NETLink

®

Switch. Moreover, data exchange via MPI/PB and/or RFC

1006, the ‘Observe Variables’ action has the lowest priority. The

update time in the Web interface therefore depends on the concurrent bus load.

NETLink

®

Switch 46

8 RFC1006 Function (S7-TCP/IP)

As an additional option, the NETLink® Switch can implement the

RFC1006 protocol (also known as S7-TCP/IP or as ISO on top of

TCP). RFC mode is always active and does not have to be specifically enabled. The NETLink

®

Switch automatically goes “online” as

soon as it detects an RFC frame.

Because many visualization system manufacturers have implemented this protocol to implement connections with CPs from

Siemens (e.g. CP343 or CP443), NETLink

®

Switch with RFC1006 is

a low-cost alternative to communication with these visualization

systems.

The RFC1006 functionality of the NETLink

®

Switch is also sup-

ported by S7-200 systems.

The following software packages with RFC1006 support have so

far been tested in conjunction with the NETLink products:

• WinCC V6.0/V7.0 (Siemens AG)

• WinCC flexible 2005/2007/2008 (Siemens AG)

• ZenOn V6.2 (COPA-DATA)

• PROCON-Win V3.2 (GTI Control)

• S7-OPC Server, V3.1 and higher (Systeme Helmholz GmbH)

• AGLink V4.0 (DELTALOGIC Automatisierungstechnik GmbH)

• INAT-OPC-Server (INAT GmbH)

• WinCE 5.0 Terminal TP21AS (Sütron Electronic GmbH)

• KEPserverEx V4.0 (KEPware Inc.)

• InTouch V9.5 (Wonderware GmbH)

Systeme Helmholz GmbH provides additional documentation on

the subject of SCADA, HMI, and OPC (example applications) (for

information see 11.3).

!

Please also observe

the application-specific

instructions in Troubleshooting and possibly in

other relevant documentation

NETLink

®

Switch 47

9 Bus Parameters in Single Master Operation

If the NETLink® Switch is connected to a bus system on which no

other master is active, the NETLink

®

generates the token itself. In

which case it is then usually also necessary to adapt the relevant

bus parameters.

The bus address with which the NETLink

®

Switch signs onto the

bus is entered in field “NETLink MPI/PB Address”.

The value for this address may be anywhere in the range 0

through 126. It is a precondition for this that the selected address

is not larger than the HAS (highest station address) and is not already being used for another device on the bus.

9.1 Storing specified bus parameters

For bus profiles MPI and PPI, no other adaptations besides the

baud rate are usually necessary. However, the DP setting must be

configured carefully.

When parameterizing, please note that all parameters for

PROFIBUS are interdependent. That is, if a parameter, e.g. the

baud rate, is changed, all the other parameters usually also

change.

For MPI, on the other hand, all parameters besides the baud rate

are fixed. That is, if an MPI connection of increased from, say,

from 187.5 Kbps to 12000 Kbps, all other parameters can/must

remain unchanged.

The following parameters must be taken into account:

• Baud rate: The required baud rate is entered in

Kbps. For example ‘187.5’

or ‘12000’.

The possible values are:

9.6; 19.2; 45.45; 93.75; 187.5; 500;

1500; 3000; 6000, and 12,000.

• HSA The highest station address is entered

here. For MPI generally ‘31’

and for PROFIBUS ‘126.’ However, any values

can be used that are not equal

to the default values.

• TSlot_Init This value is always ‘415’ for MPI –

whatever the baud rate. For PROFIBUS

the appropriate value should be read

from the PROFIBUS project.

• Ttr This value is always ‘9984’ for MPI –

whatever the baud rate. For PROFIBUS

the appropriate value should be read

from the PROFIBUS project.

• Max. Tsdr This value is always ‘400’ for MPI –

whatever the baud rate. For PROFIBUS

NETLink

®

Switch 48

the appropriate value should be read

from the PROFIBUS project.

• Min. Tsdr This value is always ‘20’ for MPI –

whatever the baud rate. For PROFIBUS

the appropriate value should be read

from the PROFIBUS project.

• Tset This value is always ‘12’ for MPI –

whatever the baud rate. For PROFIBUS

the appropriate value should be read

from the PROFIBUS project.

• Tqui This value is always ‘0’ for MPI –

whatever the baud rate. For PROFIBUS

the appropriate value should be read

from the PROFIBUS project.

• Gap This value is always ‘5’ for MPI –

whatever the baud rate. For PROFIBUS

the appropriate value should be read

from the PROFIBUS project.

• Retry This value is always ‘2’ for MPI –

whatever the baud rate. For PROFIBUS

the appropriate value should be read

from the PROFIBUS project.

Please note that under unfavorable circumstances an incorrectly

parameterized NETLink

®

Switch can interfere with the bus to the

extent that regular bus operation is no longer possible.

9.2 Addressing (rack/slot mode ON/OFF)

RFC1006 connections are virtual point-to-point links, that is,

links from the PC to the programmable controller (possible

branching within the programmable controller is handled by the

CPU => Routing).

Because NETLink

®

Switch is a point-to-multipoint communication

adapter (‘PC to NETLink

®

Switch ’ on the one hand and ‘NETLink®

Switch to many bus stations’ on the other hand), it was necessary

to implement different addressing methods to permit all communication variations.

The addressing methods are ‘Addressed Mode’ (see Section

9.2.1)

and ‘Rack/Slot Mode’ (see Section 9.2.2).

These two addressing

methods, which are mutually exclusive,

permit most types of communication that are also possible via the

NETLink-S7-NET.

I

ncorrect bus parameters

can interfere with the bus

considerably!

NETLink

®

Switch 49

9.2.1 Addressed mode

If di

fferent CPUs are to be accessed on the same MPI/PROFIBUS

via RFC1006, addressed mode is suitable.

If this mode is used, the following setting must be parameterized

on the configuration page of the Web interface.

• ‚Rack/slot mode’ must be deactivated (OFF)

Ö Addressed Mode is active

The destination address now has to be entered in the RFC1006

driver of the Windows application (e.g. WinCC, see Section 9.3.1)

ins

tead of the rack and slot.

Please note that the rack and slot together fill only one byte

which is divided as follows:

• Rack fills the upper three bits

(11100000

bin

for Rack 7, Slot 0)

• Slot fills the lower five bits

(00011111

bin

for Rack 0, Slot 31)

If you now want to communicate with destination address 2, the

following has to be entered:

Rack 0, Slot 2.

If you want to communicate with destination address 49, on the

other hand, the following has to be set:

Rack 1, Slot 17.

Section 11.5 contains a table were you can read off already converted values for the rack and slot.

There are also parameterization tools that do not provide fields

with names like rack and slot. These tools normally have a

parameterization field with a name such as Remote TSAP that is

usually two bytes long and in hex format. This field, in which

only the lower byte is of interest, is parameterized as follows:

If you want to communicate with destination address 2, the following has to be entered:

Remote TSAP 0202

hex

.

If you want to communicate with destination address 49, on the

other hand, the following has to be set:

Remote TSAP 0231

hex

.

Section 11.5 contains a table were you can read off already converted values for the Remote TSAP.

The formula Rack * 32 + Slot = Address can be used for simplicity.

9.2.2 Rack/slot mode

In r

ack/slot mode, it is possible to access specific modules of the

automation system.

NETLink

®

Switch 50

This is achieved by only communicating directly with one, preparameterized station. This station routes the data packets not intended for it to the required rack/slot and routes the response

back to the NETLink

®

Switch.

This makes it possible, for example, to communicate in S7-400

systems with more than one CPU on a rack (ÖMulticomputing)

without having to attach further CPUs to the bus.

To use this functionality, it is necessary to parameterize the following on the configuration page of the Web interface:

• ‚Rack/slot mode’ must be enabled (ON)

• For ‘Fix destination address for R/S mode’, the address of the re-

quired communication partner must be entered.

No special aspects have to be observed in the visualization system. The settings for the rack and slot or remote TSAP must be

made as the described for the specific visualization system.

Section 9.3.1 explains addressed mode using WinCC as an example.

9.3 Example of configuration for WinCC V7.0

The basic parameterization of RFC1006 connections in visualization systems is explained here using the example of the WinCC

V7.0 tool from Siemens AG.

It is assumed you are familiar with the development environment

of WinCC, so that only points relating specifically to the connection need to be mentioned.

Because it is the Windows RFC1006 driver that is parameterized,

all elements you will see in the WinCC example can also be

found in similar form on other visualization systems/OPC servers

that support RFC1006.

To explain the special aspects of communication with the NETLink

®

Switch, the same connection is explained once for addressed mode (see Section 9.3.1) and again in rack/slot mode (see

Section 9.3.2).

9.3.1 Using addressed mode

For

the basics of addressed mode at the NETLink

®

Switch end, see

Section

9.2.1.

To parameterize a RFC1006 link in a WinCC project, a new

TCP/IP link must first be created in the ‘SIMATIC S7 PROTOCOL

SUITE.’

NETLink

®

Switch 51

Here, this connection is called ‘NETLink.’

A click on ‘Properties’ takes us to a setting form in which the IP

address of the NETLink

®

Switch and the rack/slot combination of

the destination have to be entered.

In this case, the NETLink

®

Switch has the IP address 192.168.4.49.

The destination CPU with which we want to communicate has

the PROFIBUS address 49. Because addressed mode is to be used,

we can read off the correct value for the rack and slot from the

table in Section 11.5.

Under this connection we have just configured, we now have to

create a variable.

i

The NETLink® PRO Com-

p

act has the IP address

192.168.4.49 on

delivery

NETLink

®

Switch 52

This is done by right-clicking to open the context menu of the

new connection and selecting ‘New variable…’.

In the properties window of the variable, which was named

‘MB0_over_NETLink’ in this case, we can now select the type of

variable by clicking the ‘Select’ button.

Marker byte 0 is configured here.

NETLink

®

Switch 53

The following screenshot shows that a variable named

‘MB0_over_NETLink’ now exists under the ‘NETLink’ connection.

If this variable is now included in the initial screen of the WinCC

project, for example, a connection will be established to the CPU

with address 49 via the NETLink

®

Switch to read or write marker

byte 0 from this address.

Further variables of different types can, of course, be created and

used according to the same scheme.

It is also possible to create additional TCP/IP connections in order

to communicate not only with the CPU with bus address 49 but

also with other CPUs.

9.3.2 Use of rack/slot mode

For t

he basics of rack/slot mode at the NETLink

®

Switch end, see

Section 9.2.2.

To paramet

erize a RFC1006 link in WinCC, a new TCP/IP link

must first be created in the ‘SIMATIC S7 PROTOCOL SUITE.’

NETLink

®

Switch 54

Here, this connection is called ‘NETLink.’

A click on ‘Properties’ takes us to a setting form in which the IP

address of the NETLink

®

Switch and the rack/slot combination of

the destination have to be entered.

In this case, the NETLink

®

Switch has the IP address 192.168.4.49.

The destination CPU with which we want to communicate is in

Rack 0 on Slot. Because rack/slot mode we are going to use,

WinCC does not have to announce the CPU address. Instead, the

real values for rack and slot are specified, in this case rack 0 and

slot 2.

Please note that the destination address, 49 in this case, must now

be announced to the NETLink

®

Switch via the Web interface.

Under this connection we have just configured, we now have to

create a variable.

i

The NETLink® PRO Com-

p

act has the IP address

192.168.4.49 on

delivery

!

R

emember to param-

eterize the NETLink

®

P

RO Compact.

NETLink

®

Switch 55

This is done by right-clicking to open the context menu of the

new connection and selecting ‘New variable…’.

In the properties window of the variable, which was named

‘MB0_over_NETLink’ in this case, we can now select the type of

variable by clicking the ‘Select’ button.

Marker byte 0 is configured here.

NETLink

®

Switch 56

The following screenshot shows that a variable named

‘MB0_over_NETLink’ now exists under the ‘NETLink’ connection.

If this variable is now included in the initial screen of the WinCC

project, for example, a connection will be established to the CPU

with address 49 via the NETLink

®

Switch to read or write marker

byte 0 from this rack 0, slot 2.

Further variables of different types can, of course, be created and

used according to the same scheme.

It is also possible to create additional TCP/IP connections in order

to communicate not only with rack 0 / slot 2, for example, but

also with rack 0 / slot3. However, all the communication must go

via bus address 49.

NETLink

®

Switch 57

10 Troubleshooting

The points described here show some typical errors that can occur

in day-to-day work with the NETLink

®

Switch.

If any condition during operation is not described here and this

manual does not provide any information on how to remedy it,

the support of Systeme Helmholz GmbH is available to help you.

Q: I don’t know the IP address of my computer.

A: Enter the command ‘ipconfig’ after the prompt to show the

configuration of the Ethernet interfaces of your computer.

Q: My computer has a firewall. Which ports must I release?

A: The NETLink-S7-NET driver communicates with the NETLink

®

Switch via TCP port 7777.

UDP ports 25342 and 25343 are also used to search for the NETLink

®

Switch devices.

Please release at least port 7777 so that the basic functionality of

the driver is available.

If you use the RFC1006 functionality (also known as S7-TCP/IP),

port 102 must also be released.

ATTENTION: If you want to use the driver option ‘Internet teleser-

vice’ (see Section 5.2.1), the specific ports configured there must

also

be released because this port will be used instead port 7777.

Q: Both the configuration tool and the web interface ask me for a

password and a user name. But I have never assigned a user name

or password.

A: If no user name and/or password were/are specified, the default user name ‘NETLink Switch’ and the default password ‘admin’

are applied.

Q: Once the configured PROFIBUS slaves have been added on my

CPU, communication between NETLink

®

Switch and STEP7 be-

comes markedly slower.

A: The user can influence the allocation of ‘cycle load due to com-

munication [%]’ under object properties of the CPU in the hard-

ware configuration. The default value is 20 %.

Q: I get an error message when I access the controller.

i

The default user name is

“NETLink Switch”

The default password

is ‘admin.’

NETLink

®

Switch 58

A: The problem may be the setting of the PG/PC interface (e.g.

PROFIBUS instead of MPI, address already allocated, etc.) or the

NETLink

®

Switch if it is not connected or not accessible at this IP

address.

Make sure you have set the IP address correctly in the driver configuration. Please also enter the command PING <IP address> at

the DOS prompt to check whether the NETLink

®

Switch can also

be accessed physically via the network.

Q: The setting dialog boxes are not appearing in the Simatic Manager:

A: Please note that after initial installation the NETLink-S7-NET

driver must be added to the PG/PC interfaces.

Make sure you had administrator rights during installation. Reboot your PC after installation if prompted to do so.

You need at least version 5.1 of the Simatic Manager.

Q: The Starter program has problems accessing a Micromaster

drive.

A: When you request a ‘control priority’ for the Micromaster drive,

please increase the Failure monitoring from 20ms to 200ms and

the Application monitoring from 2000ms to 5000ms, so that the

Starter software remains operable.

Q: Every time I execute a certain function, it fails and the red LED

flashes.

A: An exception has occurred in communication. Please contact

support and describe how the error can be triggered. The support

team will attempt to solve the problem as quickly as possible.

Q: If I set the NETLink

®

Switch to auto baud in the PG/PC interface and try to go online, the active LED lights up briefly before a

message appears telling me that the bus parameters cannot be determined.

A: Either the CPU used does not support the cyclic transmission

of bus parameters (disabled via parameterization or function does

not exist), or the CPU is so busy with general communication

tasks that the lower-priority bus parameter frame is transmitted

too infrequently and cannot be detected by the NETLink

®

Switch.

Please deactivate the auto baud functionality in the NETLink-S7NET driver (PG/PC interface) and set the correct baud rate and the

correct profile.

i

The NETLink® has the IP

address 192.168.4.49 on

deliver

y f

rom the factor

y

.

NETLink

®

Switch 59

Q: The variables from my S7 200 CPU are not updated in my

WINCC project.

A: The default settings of the system parameters in register SIMATIC S7 for Cycle Formation, Sign-of-Life Monitoring and CPU-Stop

Monitoring must be deactivated.

Q: I use the rack/slot mode of the RFC1006 interface (rack/slot

mode = ON) and have specified address 2 for my existing CPU in

the Web interface in ‘Fix destination address for R/S mode.’

Although NETLink

®

Switch online is active (active LED lights up),

my visualization system tells me that no link can be established.

A: Make sure you have assigned the correct values to rack and slot

in the parameterization. For example, to communicate with a

CPU in a 300 rack, you must enter '0' for rack and '2' for slot.

Many visualization system manufacturers have grouped together

the two fields. In that case, there may be a field with the name

'Remote TSAP' containing a hex value such as '0102.' In this case,

the hex value '02' stands for rack 0 and slot 2.

Q: I would like to use addressed mode of the RFC1006 interface