Netafim WATER METERS Maintenance Manual

INSTALLATION, OPERATION

AND MAINTENANCE GUIDE

‘M’ SERIES

WATER METERS

WATER METERS

METAL ‘M’ SERIES

WATER METER

PLASTIC ‘M’ SERIES

WATER METER

MAINTENANCE REQUIREMENTS

1. Inlet side basket filter should be removed and cleaned every 90 days or as needed based on

the water quality at the site (see Figure 5).

2. Inlet side basket filter must remain in place during normal operation in order to avoid debris

entering and clogging the metering chamber.

3. Teflon tape should be used on pipe fittings and connections as needed to prevent leaks.

WARNING:

Units must not be subjected to system ‘blow out’ using compressed air. Subjecting the water

meter to this procedure will result in product failure and the resulting damage is not covered under

warranty. It is recommended that the water meter be installed in systems or portions of systems

that will gravity drain for winterization only.

If the unit is installed in a system which will be winterized with compressed air, please do one of

the following:

Install manual ball valves on each side of the water meter to isolate the water meter

from the system blow out procedure. Close the manual ball valve on one side of the

water meter, perform the blow out procedure and then open the manual ball valve.

Repeat process on the other side.

Remove the water meter before the blow out procedure and replace it with a section of

PVC/Polyethylene tubing. When the blow out procedure is complete, reinstall the water

meter.

Cleaning Inlet Side

Basket Filter

‘M’ SERIES WATER METER WARRANTY

Netafim ‘M’ Series Water Meters are individually tested, calibrated and inspected to ensure they

meet the highest quality standards and the testing documents are included with each meter. They

also have the industry’s longest warranty.

WARRANTY

Netafim USA’s ‘M’ Series Water Meters are used as sub-meters for residential or commercial

applications and the industry’s smallest multi-jet water meter. The multi-jet principle assures an

equally distributed load on the impeller minimizing wear and maintaining accuracy. These meters

offer the best cost and performance, long-life flow measurement instruments. Wide clearances in

the measuring chamber and negligible area of contact between static and moving parts are the

main reasons for the high reliability of this design even in hard water.

‘M’ SERIES WATER METERS

INDUSTRY’S SMALLEST WATER METERS

FEATURES:

Only one moving part - the impeller - in

contact with the water for minimum wear

and utmost reliability

Magnetically driven sealed registers with

stainless steel/composite encapsulated

and guaranteed against fogging due to

moisture

Very accurate over a wide range of

flows for flexible and efficient water

management

3/4”

1”

0.2 GPM

0.3 GPM

0.9 GPM

1.2 GPM

11 GPM

15.4 GPM

14 GPM

20 GPM

PERFORMANCE DATA

LOWEST FLOW

WITHIN ± 5%

ACCURACY

LOWEST FLOW

WITHIN ± 2%

ACCURACY

NOMINAL FLOW

WITHIN ± 2%

ACCURACY

MAXIMUM FLOW

WITHIN ± 2%

ACCURACY

SIZE

3/4” PLASTIC

3/4” METAL

1” PLASTIC

1” METAL

11 1/4”

11 1/4”

14 3/4“

14 3/4”

3 3/4“

3 3/4”

4 1/4“

4 1/4”

4 1/4”

4 1/4”

4 1/4“

4 1/4”

1.3 lbs.

5.0 lbs.

2.4 lbs.

7.2 lbs.

DIMENSIONS AND WEIGHT

LENGTHSIZE/BODY WIDTH HEIGHT WEIGHT

INTRODUCTION

3/4” AND 1”

140 PSI

UP TO 122° F

CORROSION-PROOF COPPER ALLOY

COMPOSITE

MALE PIPE THREAD

AVAILABLE SIZES

MAXIMUM WORKING PRESSURE

MAXIMUM LIQUID TEMPERATURE

BODY MATERIAL - METAL

BODY MATERIAL - PLASTIC

CONNECTIONS

SPECIFICATIONS

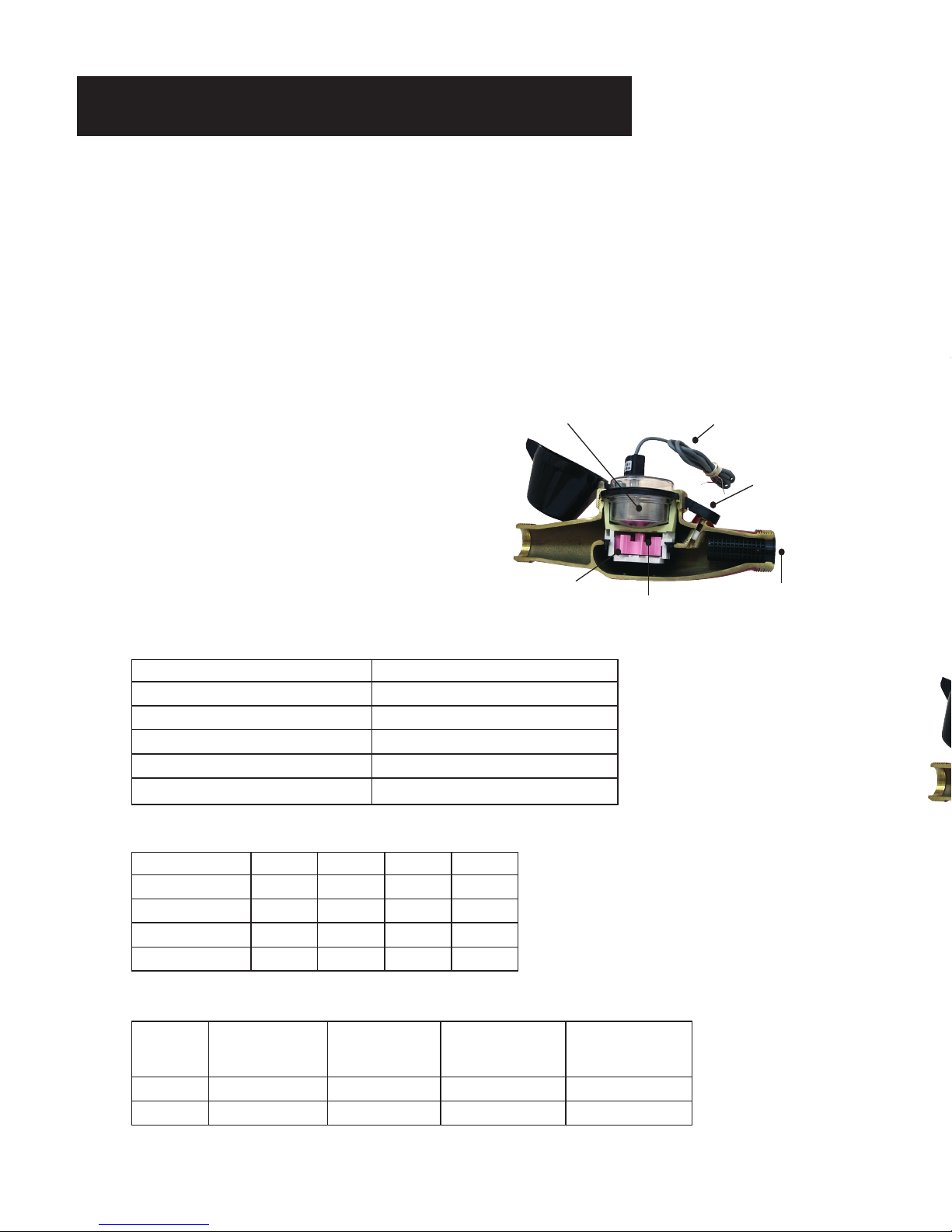

Inlet Side

Basket Filter

Measuring

Chamber

Impeller

Pulse Reed

Switch

Sealed

Register

TamperProof Tab

2 • ‘M’ SERIES WATER METERS

‘M’ SERIES WATER METERS • 3

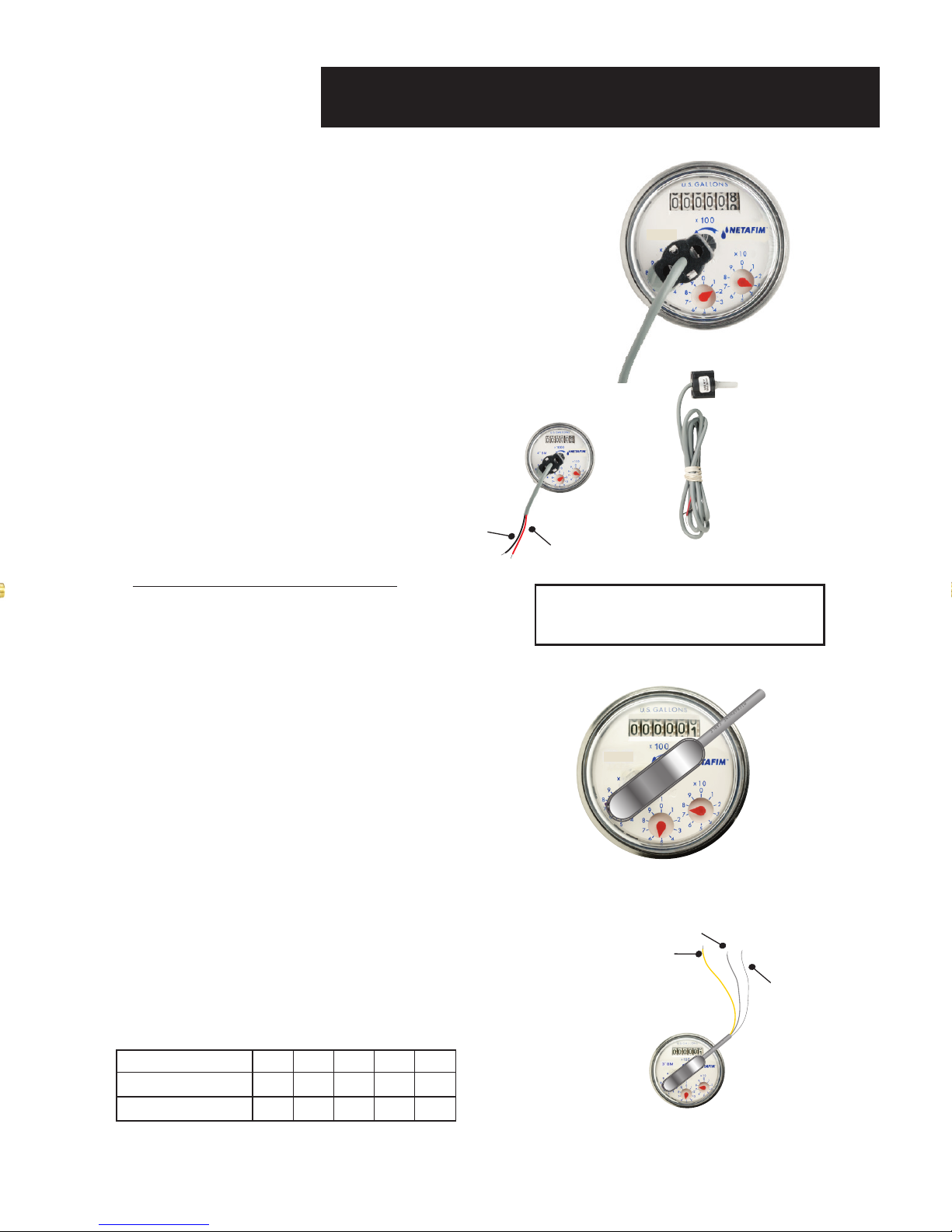

REGISTERS

REED SWITCH REGISTER

The Reed Switch Register is a dry contact or simple switch

closure for communicating with control and monitoring

equipment. Registers are interchangeable and easily

replaced with common tools. They are removable even when

the meter is operating. A leak indicator in the center of the

dial registers the lowest flow through the meter. Flows are

totalled in U.S. Gallons and each dial face indicates the

multiplication factor.

Magnetic coupling activates the reed switch

creating a pulsed output.

Dry contact uses very little electric power.

Calculates volume related functions such as

data recorders or simple counters.

Maximum contact current is 50mA and

maximum contact voltage is 48VDC.

Red Wire = Positive

Black Wire = Negative

PHOTO DIODE REGISTER

The Photo Diode Register has a photo coupler

sensor that provides pulse output for communicating

with control and monitoring equipment. Registers are

interchangeable and easily replaced with common tools.

They are removable even when the meter is operating.

Flows are totalled in U.S. Gallons and each dial face

indicates the multiplication factor.

A sensor combines an IR light source and a light

sensitive diode in one package. Signals are created

when the light beam created by the IR light is

interrupted by a rotating element.

Requires a constant supply of DC power.

Minimum contact current is 15mA to a maximum of 25mA

DC through a resistor and maximum voltage is 28VDC.

Yellow Wire = Positive (20-30mA through a resistor)

Transparent Wire = Output (open collector, max. load 2mA)

Bare Wire = Ground

TRANSPARENT : OUTPUT (npn) - MAX 2mA-25V

SHIELD: GROUND MAX. VOLTAGE : 25 VDC

5 YELLOW-MIN 15mA - MAX 25mA DC

Black Wire

Red Wire

TRANSPARENT : OUTPUT (npn) - MAX 2mA-25V

SHIELD: GROUND MAX. VOLTAGE : 25 VDC

5 YELLOW-MIN 15mA - MAX 25mA DC

Yellow

Wire

Transparent

Wire

Bare

Wire

RESISTOR VALUE - Ω

RESISTOR VALUE - W

180

0.25

220

0.25

330

0.25

470

0.5

1,000

1.0

RECOMMENDED RESISTOR VALUES

VOLTAGE › 5

6

9 12 24

Note: Correct polarity

of the leads should be

checked carefully to

prevent damage of the

sensor. Register will not

function properly if the

register lid is not closed

during operation.

Reed

Switch

Only

NOTE: Always refer to the controller

manufacturer’s instructions for proper

installation and connection requirements.

Loading...

Loading...