Page 1

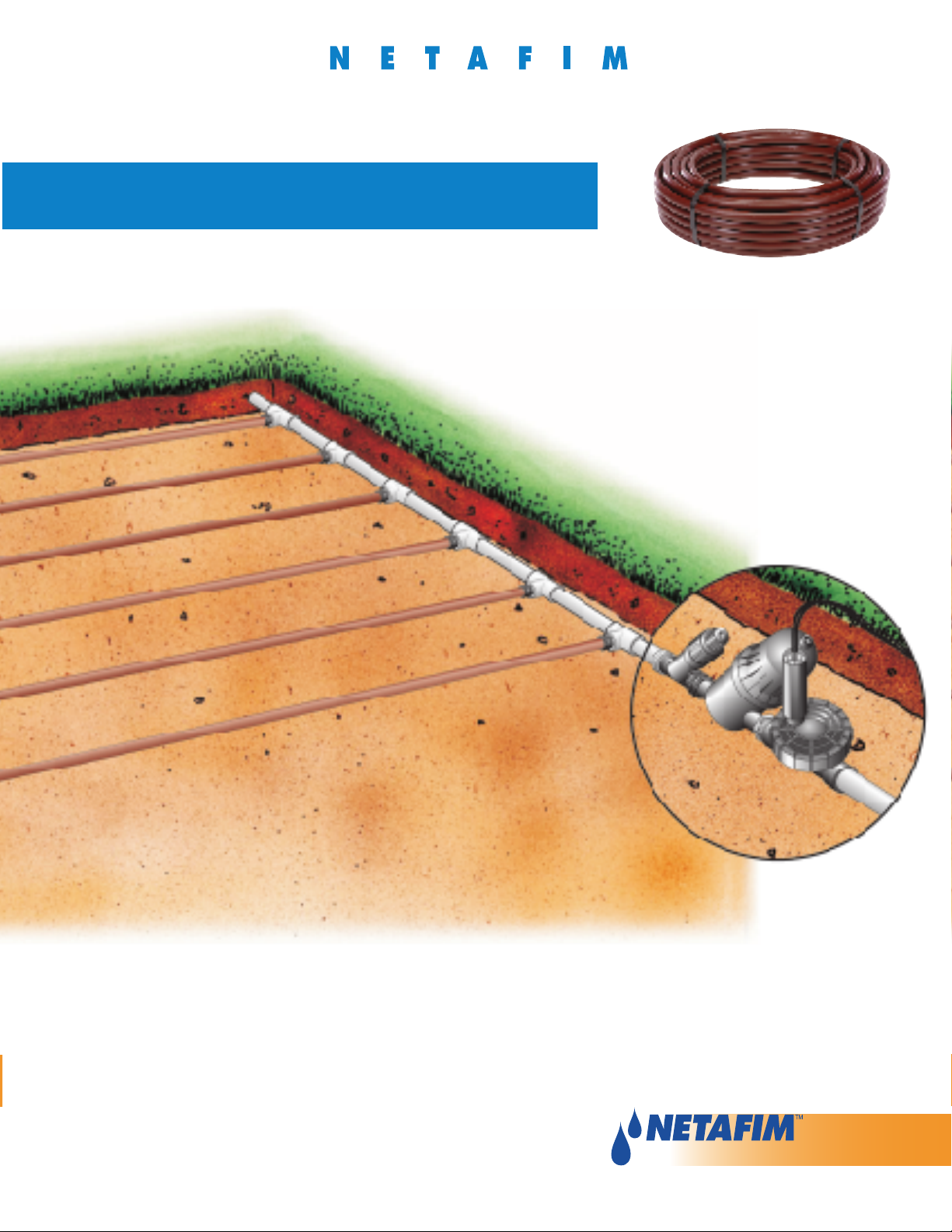

Techline® CV Design Guide

Subsurface or On-Surface

Pressure Compensating Dripperline

with Check Valve

Page 2

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

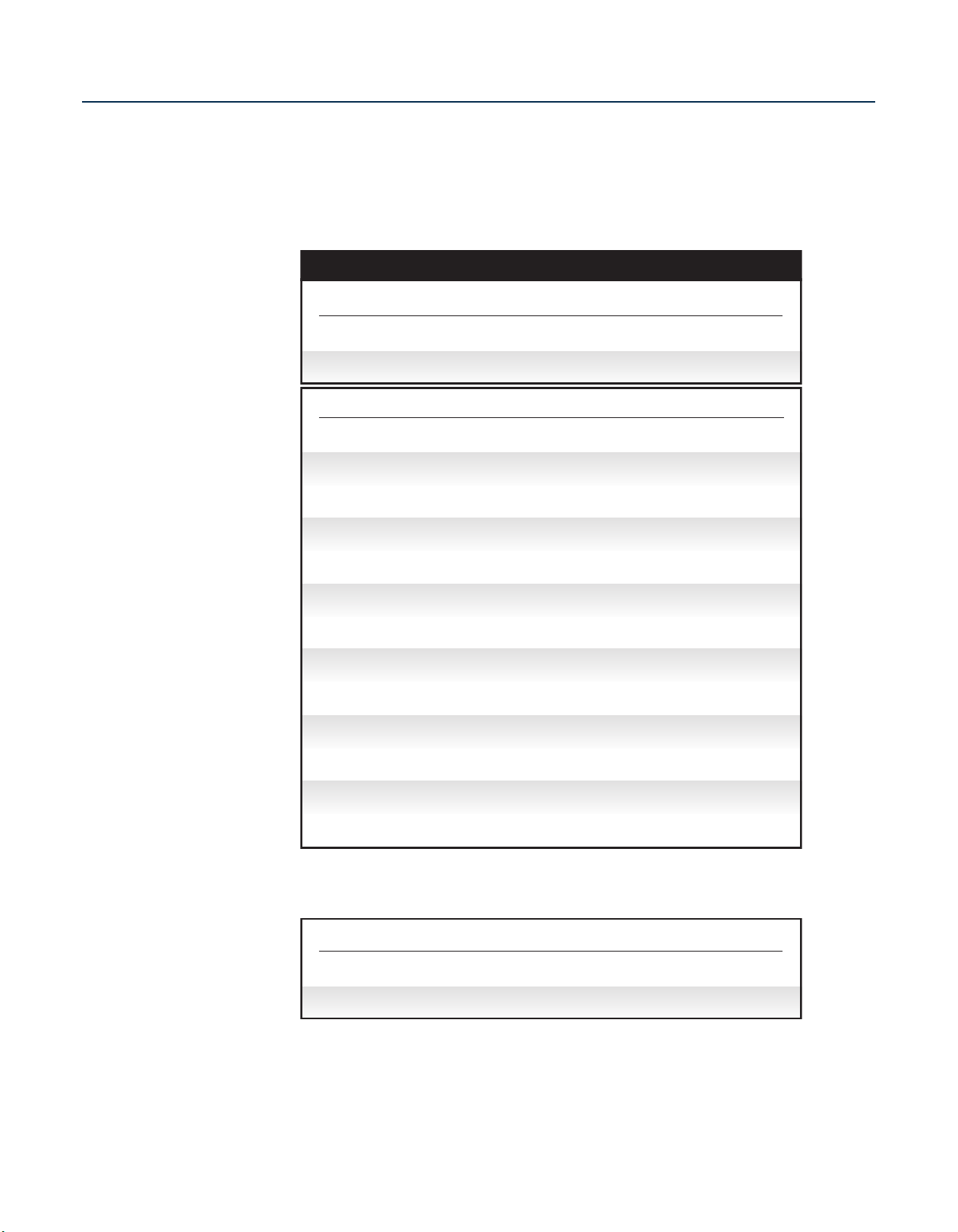

TABLE OF

CONTENTS

INTRODUCTION

Overview ....................................................................................................................... 3

DESIGN CRITERIA

Site Survey ................................................................................................................... 4

Point of Connection ...................................................................................................... 4

BASIC DESIGN STEPS

When Should You Use Techline CV ..............................................................................

Choosing the Proper Techline CV ................................................................................ 5

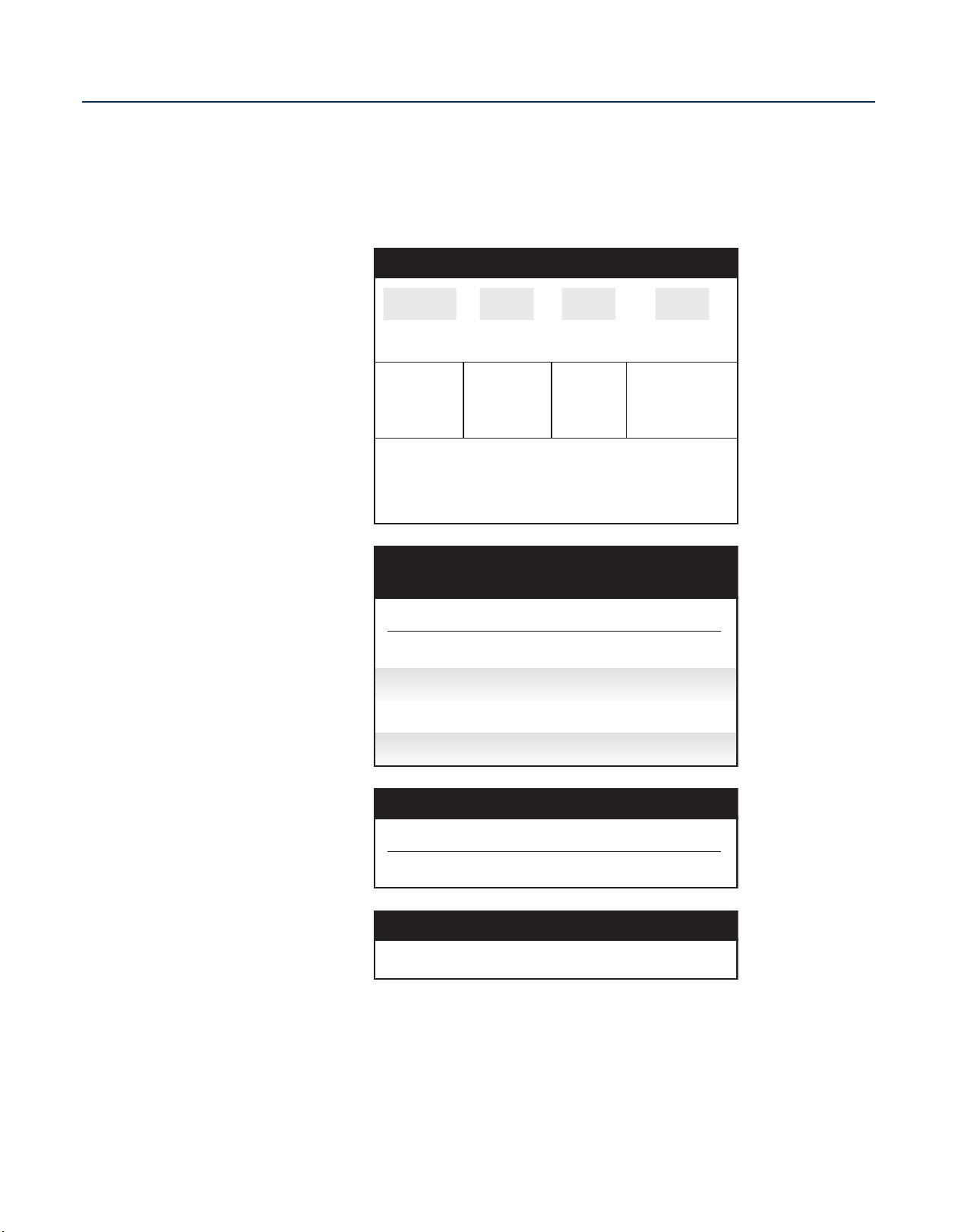

Techline CV General Guidelines Chart ......................................................................... 5

Types of Layouts .......................................................................................................... 6

"GRID" Layout .............................................................................................................. 6

"Lite" Layout ................................................................................................................. 6

What Do These Layouts Have in Common? ................................................................ 6

Basic Grid Layout ......................................................................................................... 7

Basic Lite Layout .......................................................................................................... 7

How to Calculate Equal Techline CV Row Spacing ...................................................... 7

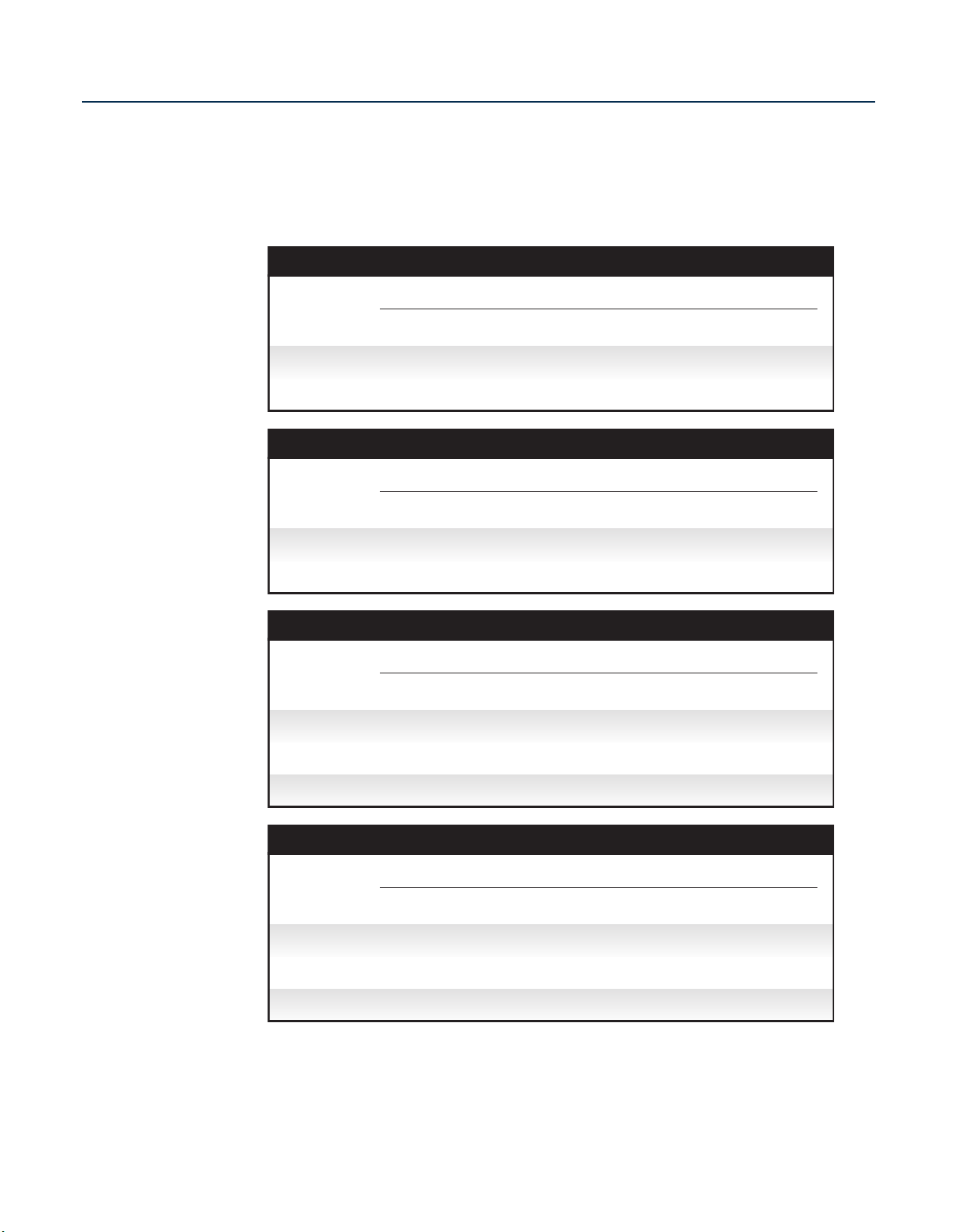

Length of Techline CV Rows ........................................................................................ 8

Techline CV Maximum Length of Laterals Chart .......................................................... 8

Center Feed Grid Layouts ............................................................................................ 8

Other Grid Layout Considerations ............................................................................... 9

Zone Water Requirements .......................................................................................... 10

Techline CV Flow per 100' Chart ................................................................................ 10

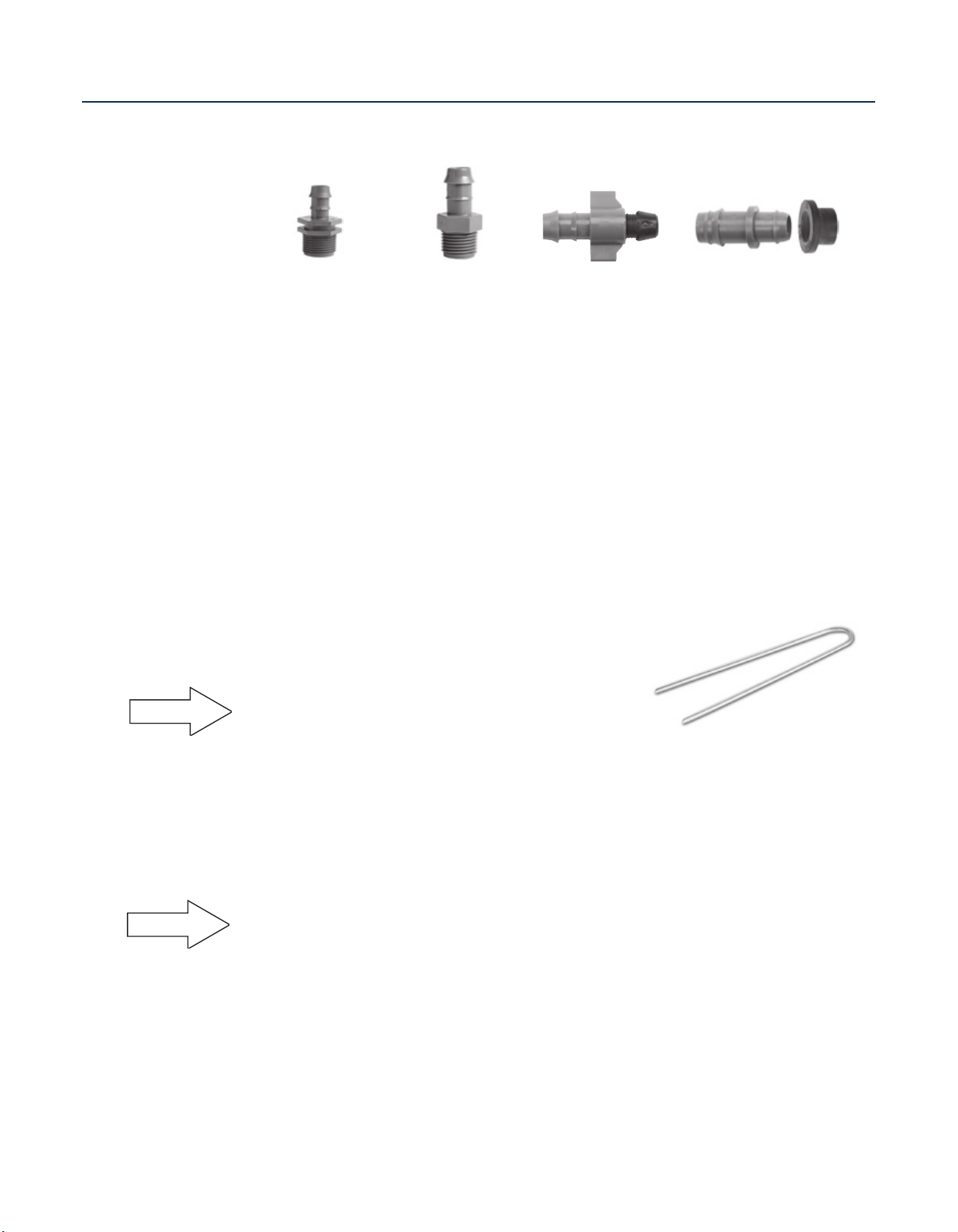

Fittings ........................................................................................................................ 11

Staples ....................................................................................................................... 11

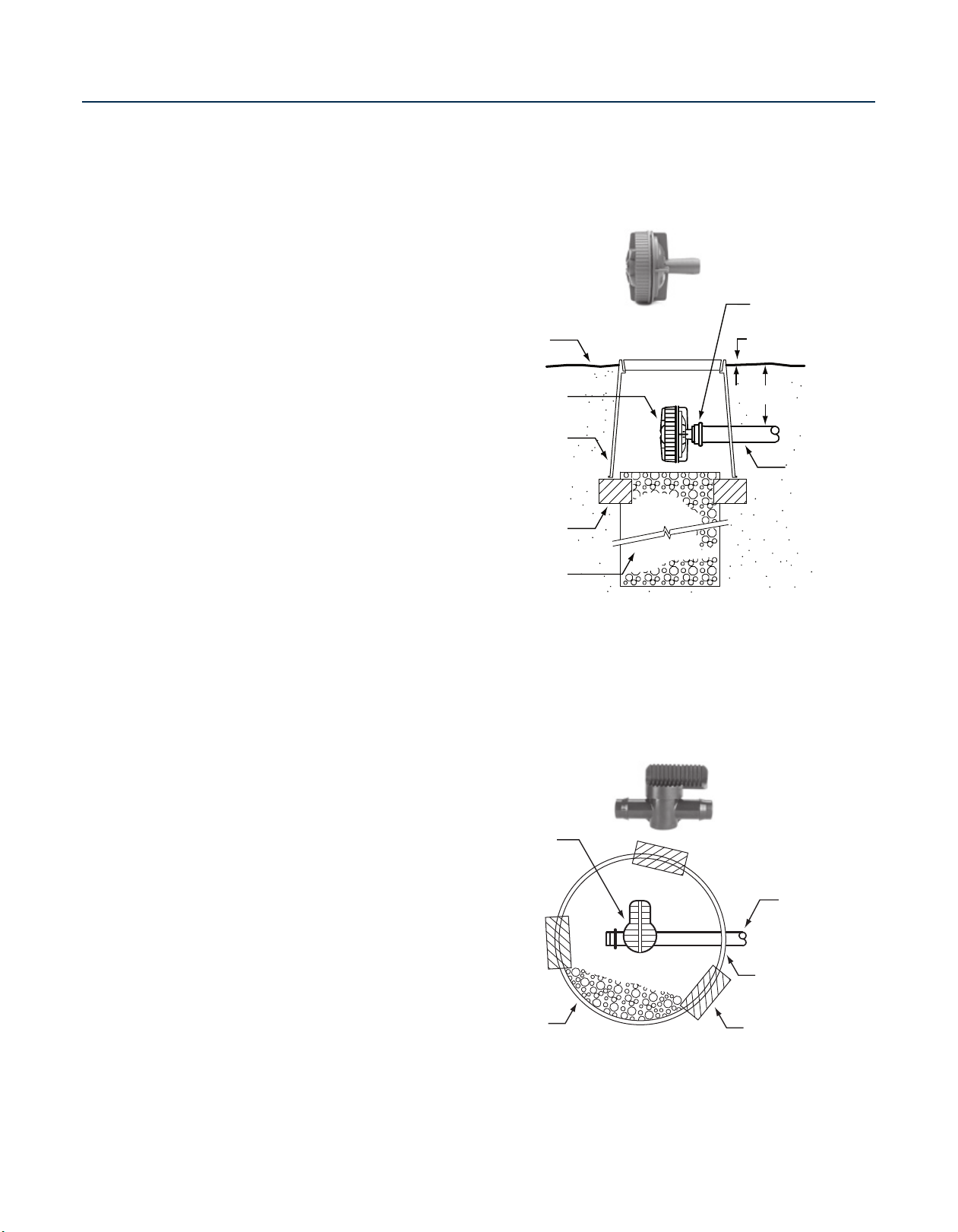

Line Flushing Valves ................................................................................................... 11

If An Automatic Line Flushing Valve is Desired .......................................................... 12

If An Automatic Line Flushing Valve is Not Desired ................................................... 12

Air/Vacuum Relief Valves ............................................................................................ 13

Filters .......................................................................................................................... 14

Pressure Regulating Valves (PRV’S) ........................................................................... 14

Low Volume Control Zone - Low Flow ....................................................................... 15

Low Volume Control Zone - High Flow ...................................................................... 15

Slopes and Berms ...................................................................................................... 16

Techline Check Valve .................................................................................................. 16

Trees ........................................................................................................................... 16

Pressure & Flow Checks ............................................................................................ 17

Calculating Precipitation Rates .................................................................................. 17

5

1

Page 3

2

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TABLE OF

CONTENTS

(continued)

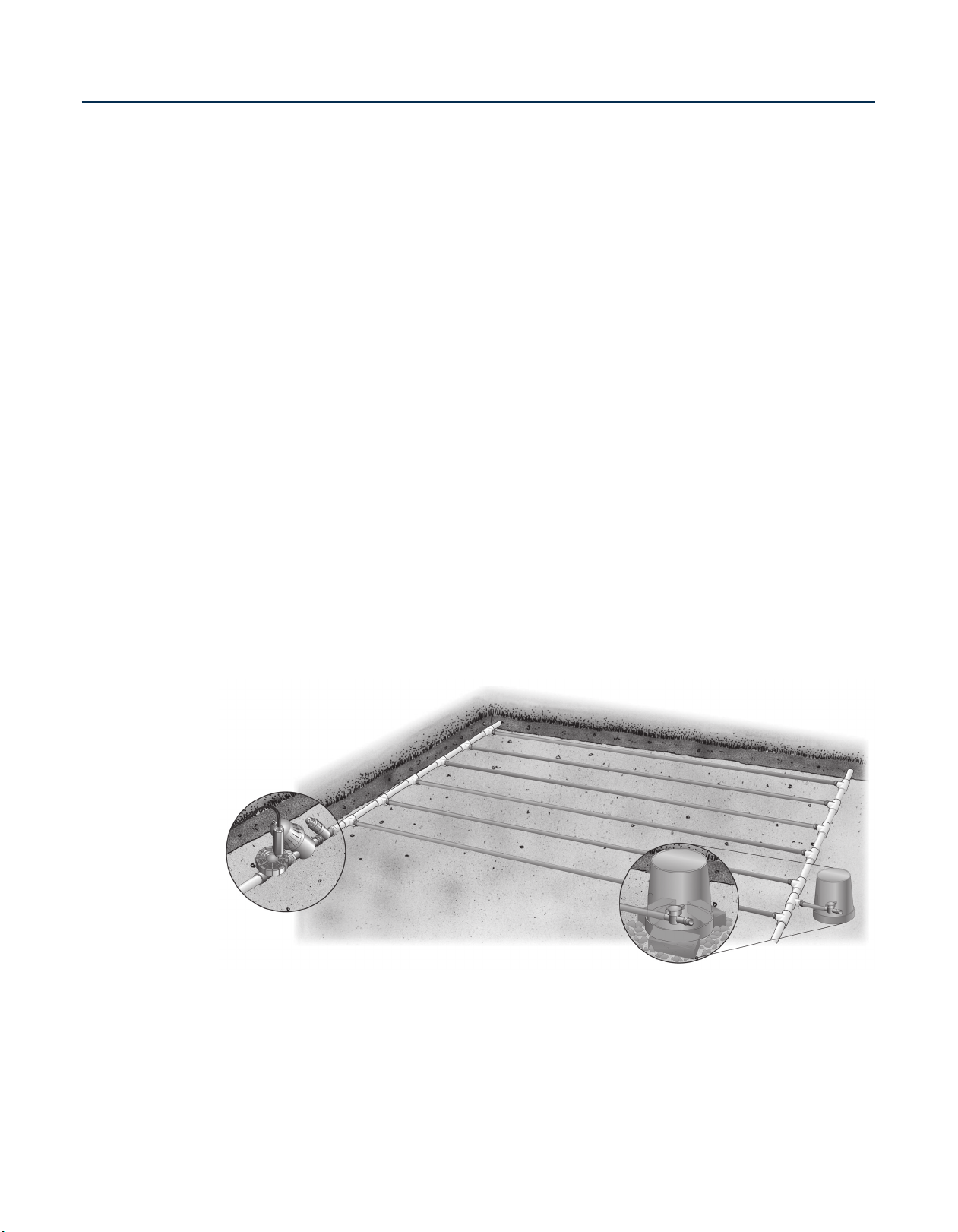

TECHLINE CV IN TURF

Techline CV in Turfgrass ............................................................................................. 18

Where and Why to Use Techline CV in Turf ................................................................ 18

Tips for Using Techline CV in a Newly-Sodded Lawn ................................................ 19

SPECIAL APPLICATIONS AND TIPS

Parking Lot Islands ..................................................................................................... 20

Electrical Grounding ................................................................................................... 20

Techline CV Above and Below Grade ........................................................................ 20

TECHLINE CV WINTERIZING INSTRUCTIONS

Techline CV Winterizing Instructions ..........................................................................

Manual Winterization .................................................................................................. 21

Compressed Air Winterization .................................................................................... 21

TECHLINE CV TECHNICAL DATA

Applications, Specifications and Features/Benefits ...................................................

Exploded View of Techline CV Dripper from Above and Below ................................. 23

Design Formulas ........................................................................................................ 24

Specifications ............................................................................................................. 25

Techline CV Application Rate Tables .......................................................................... 26

Techline CV General Guidelines ................................................................................. 27

Techline CV Maximum Length of a Single Lateral ...................................................... 27

Techline CV Flow ........................................................................................................ 27

Disc Filter Sizing ......................................................................................................... 28

Techline CV with Techfilter .......................................................................................... 29

Techfilter Installation and Mounting Instructions ........................................................ 29

Techfilter Use and Replacement Guidelines .............................................................. 29

Techfilter Specifying Information ................................................................................ 30

Techline CV Minimum & Maximum Feet for Each Filter Size ..................................... 30

Techfilter with Techline CV Model Number Descriptions ........................................... 31

Techline CV End Feed Layout .................................................................................... 34

Techline CV Center Feed Layout ................................................................................ 35

21

22

Installation Checklist ......................................................................................... 36

System Inspection Checklist ........................................................................... 37

Fittings ..................................................................................................................... 38

MOST FREQUENTLY USED CHARTS

Techline CV General Guidelines .................................................................................

Techline CV Maximum Length of a Single Lateral ...................................................... 39

Techline CV Flow ........................................................................................................ 39

39

Page 4

3

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

INTRODUCTION

This manual covers the basics of design, installation, and maintenance of Techline CV integral

dripperline. Included are design steps, technical data, design layouts, as well as some design and

installation details and checklists using both the “Grid” and “LITE” layout methods.

OVERVIEW:

• Netafim is the world leader in low volume irrigation. Since the early 1960ʼs Netafim has pioneered

the science of subsurface, on-surface and point source irrigation and manufacturing. Serving

more than 100 countries worldwide, Netafim products are sold into the Landscape & Turf market,

as well as agriculture, greenhouse and nursery, wastewater, mining and forestry.

• The Techline family of products have been used successfully in landscape since 1987 in North

America. Techline CV allows for even more water conserving designs because check valves are

built into every dripper.

• Landscape Architects, Contractors, Nurserymen, Designers and Consultants recognize the

benefits of using low volume and drip irrigation for new plantings because of its accelerated plant

growth compared to overhead spray and rotor irrigation. Coupling the rapid growth with dramatic

water savings and low volume irrigation becomes an important part of any irrigation system.

• With the flexibility and quality of Netafim products, architects, designers, and contractors have

highly sophisticated solutions to client and installation issues by bringing drip and subsurface

components together to grow plants, trees, shrubs, groundcover, and yes, even turf.

Page 5

4

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

DESIGN

CRITERIA

• Designing with Techline CV follows the same basic rules as designing with Techline, sprays and rotors.

• Point of connection, static and operating pressures, flow rates, and type of materials being irrigated are

the same.

• Designing similar areas into a zone and not mixing products with different application rates is just like

sprinkler design.

• The essential differences include knowing the type of soil you are working with, and the method of

layout you use in the design.

SITE SURVEY:

• Obtain or draw a scaled plan of the site to be irrigated. Identify all slopes on the plan.

• Identify the type of soil (sand, loam or clay).

• Determine types of materials to be irrigated, turf, groundcover, shrubs, plants, and trees.

POINT OF CONNECTION:

• Type of water, potable, well, pump, effluent, etc.

• Pressure & volume available - Static and operating tests.

Note: For Techline CV Technical Product Application & Specifications, see page 22.

Page 6

5

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

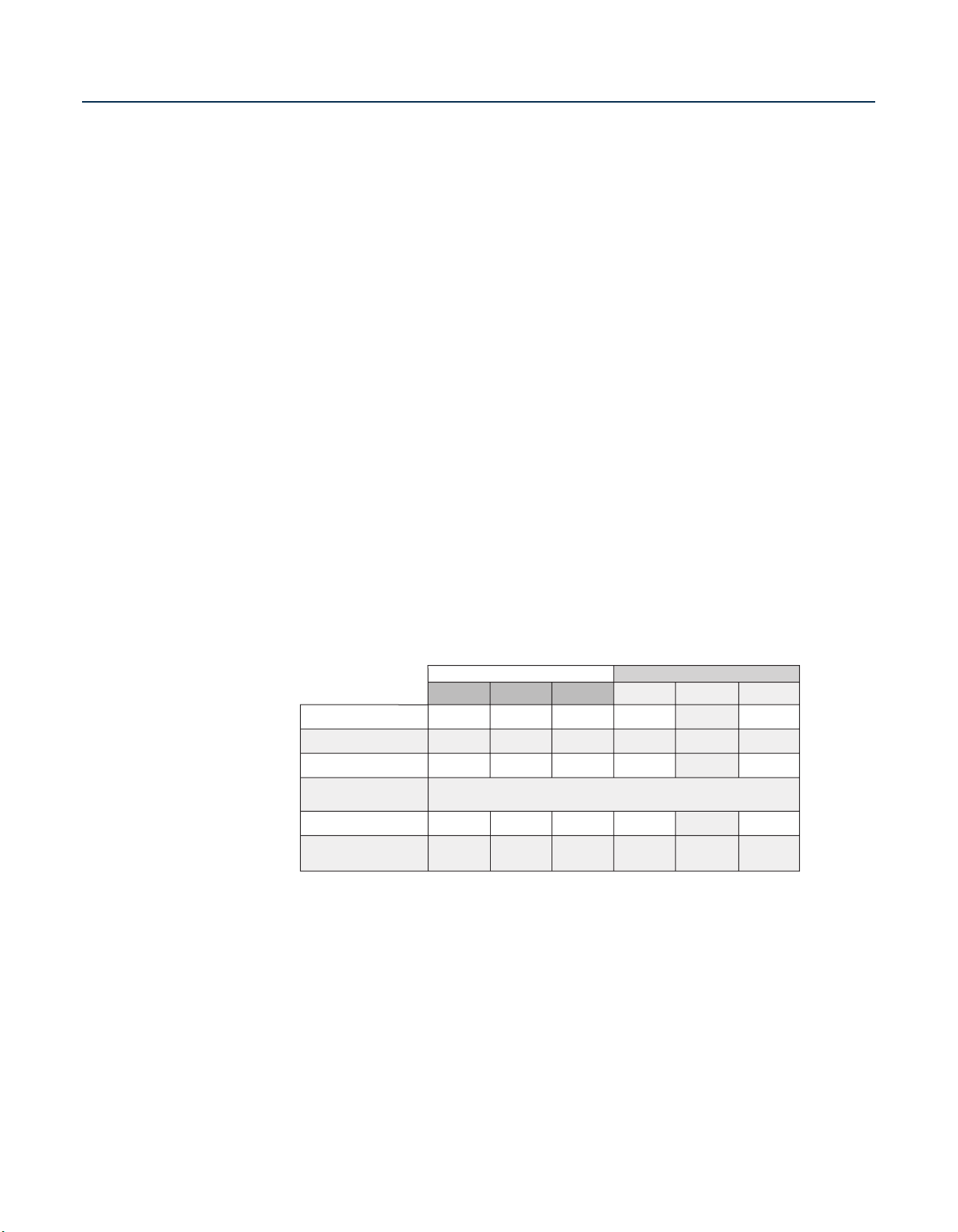

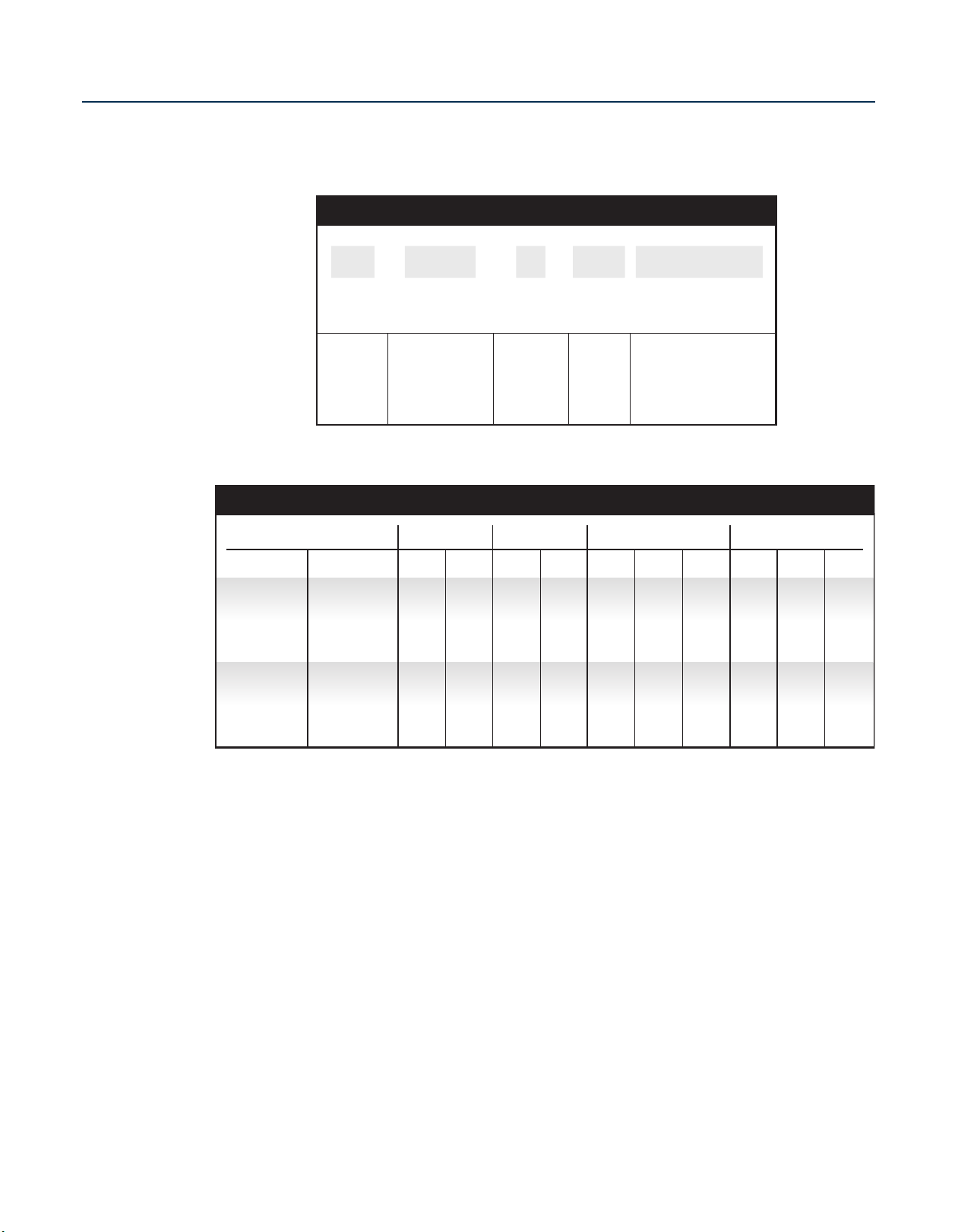

BASIC

Dripper Flow

Dripper Interval

Lateral (Row) Spacings

Burial Depth

Application Rate (in./hr.)

Time to Apply 1/4"

of Water (in minutes)

Clay Soil

0.26 GPH

18"

18" - 22"

.19 - .15

79 - 100

Loam Soil

0.4 GPH

12"

18" - 22"

.43 - .35

35 - 43

Sandy Soil

0.6 GPH

12"

12" - 16"

.96 - .72

16 - 21

Clay Soil

0.26 GPH

18"

18" - 24"

.19 - .14

79 - 107

Sandy Soil

0.6 GPH

12"

16" - 20"

.72 - .58

21 - 26

Loam Soil

0.4 GPH

18"

18" - 24"

.29 - .21

52 - 71

SHRUB and GROUND COVERTURF

TECHLINE® CV General Guidelines

Maximum spacing recommendations: Following these spacing guidelines, dripper flow selection can be increased if desired by the designer.

On-surface or bury evenly throughout the zone to a maximum of 6 inches

DESIGN

STEPS

WHEN SHOULD YOU USE TECHLINE CV?

• Anytime you want to create an even wetted pattern of water throughout an area.

• Since the object of sprinklers is also to create an even wetted pattern, you can use Techline CV

anytime you can use sprinklers.

CHOOSING THE PROPER TECHLINE CV:

• From Table 1, answer two questions:

1. Are you irrigating a Shrub & Groundcover area or Turf?

2. Is the soil Clay, Loam or Sandy?

• Follow the proper column listed under TURF or SHRUB & GROUNDCOVER to identify the proper

Techline CV. Example - If you choose Shrub & Groundcover, with loam soil, 0.4 GPH/18” Techline CV is

the proper choice. (Each dripper will deliver 0.4 GPH and the drippers, mounted inside the tubing, are

spaced 18” apart.)

• What other information is in the General Guidelines Chart?

1. How far to spread out the laterals is listed on the “Lateral (Row) Spacings” line.

(For this example, rows should be evenly spaced anywhere from 18” - 24” apart.)

2. The corresponding application rates and time to apply are listed under the Lateral Spacings

line. (With rows of 0.4 GPH/18” Techline CV every 18” apart, the application rate is 0.29 inches

1

per hour and it will take 52 minutes to apply

rate is 0.21 inches per hour, and it will take 71 minutes to apply

/4” of water. If the rows are 24” apart, the application

1

/4” of water. For other row

spacings, see page 26.)

TABLE 1

Page 7

6

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

BASIC

Exhaust Header

Supply Header

TECHLINE CV

DESIGN

STEPS

(continued)

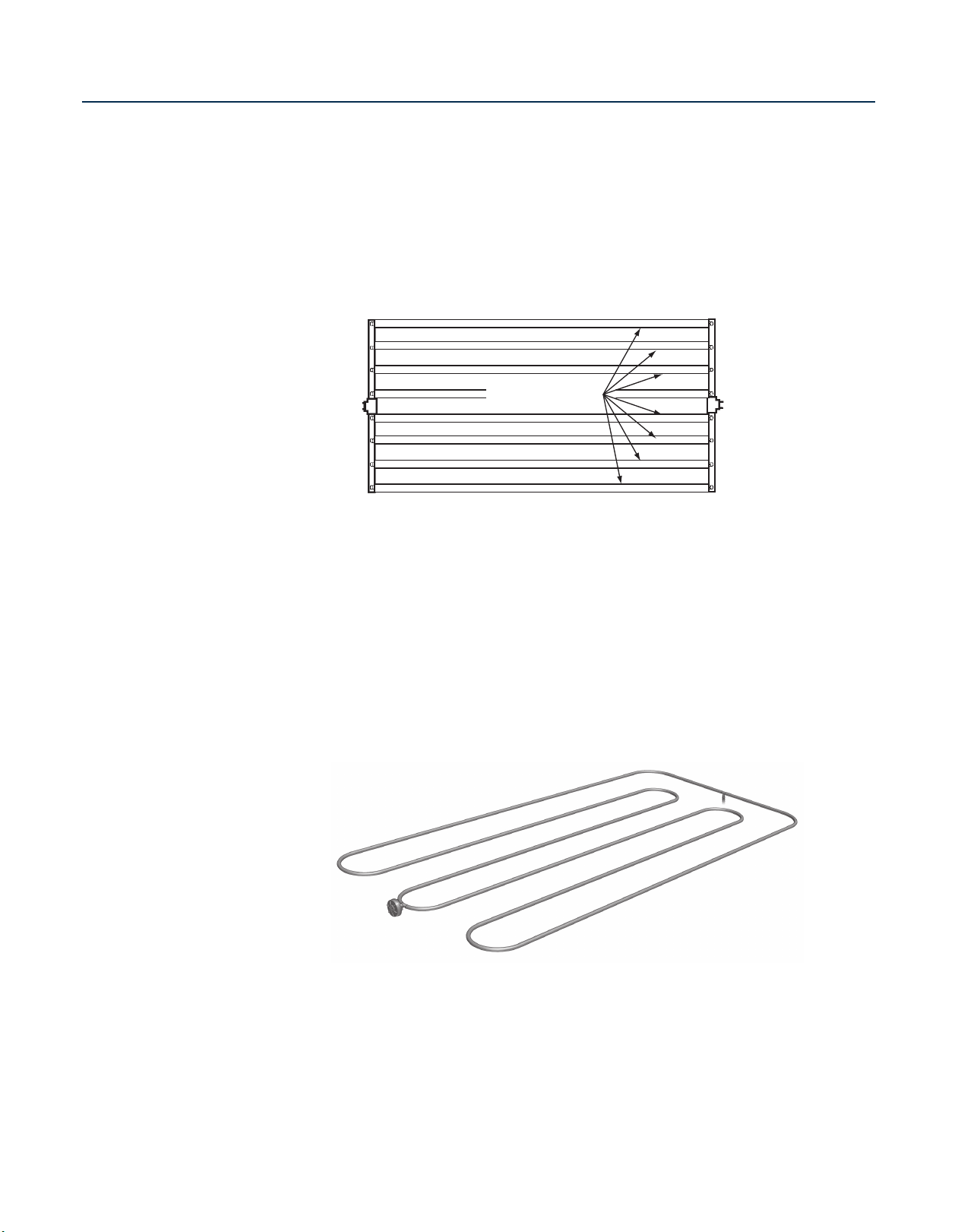

TYPES OF LAYOUTS:

There are two layout methods we recommend - “GRID” and “LITE”. Both accomplish the same goal, but

one method will be the preferred method based on what and how you are irrigating.

Basic Techline CV Grid Layout

“GRID”:

• This is the preferred method for installing Techline CV subsurface

• This method uses supply and exhaust headers with rows of Techline CV connected at each end

• The Supply Header delivers water to each row of Techline CV

• The Exhaust Header forms a continuous loop, or return leg, so all rows of Techline CV are being

supplied from both ends

• This interconnection of the piping network comprises the term “Grid layout.” This evens out the flow,

helps ensure water is being delivered downstream of any break in the laterals, and allows for much

easier repairs of any line breaks.

Basic Techline CV Lite Layout

“LITE”:

• The LITE layout is used exclusively on-surface

• It is the fastest and easiest layout method because no supply and exhaust headers are used

• The dripperline simply weaves back and forth throughout the zone in evenly spaced rows.

WHAT DO THESE LAYOUTS HAVE IN COMMON?

• Both methods assume even row spacings will be maintained

• Both methods are designed to flow water in a loop manner

Page 8

7

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TECHLINE CV

2" to 4" Setback from Edge

5' 52"

BASIC

DESIGN

STEPS

(continued)

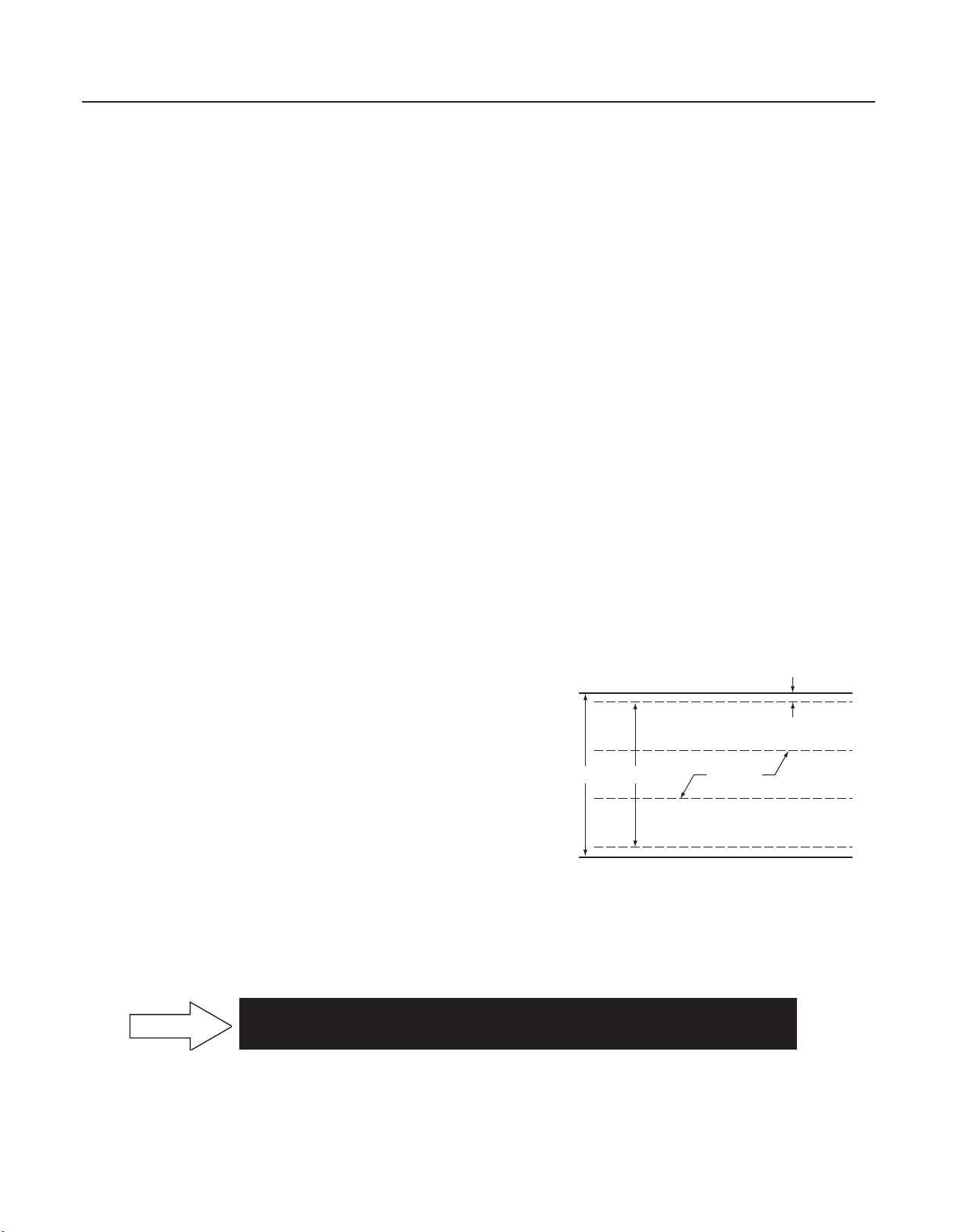

BASIC “GRID” LAYOUT:

• Headers should be indented 2” - 4” from hardscapes and planting areas.

• Headers may be PVC, polyethylene or in zones under 5-GPM, Techline CV or Techline CV Blank

Tubing.

• Headers must be sized to accommodate the flow of the zone without exceeding 5 feet per second

velocity. (Zone Water Requirement calculations are on page 10).

• Start rows of Techline CV 2” - 4” away from the edge of hardscapes, and move across the area with

equal row spacing that does not exceed the recommendations of Table 1.

provide enough moisture to prevent heat damage to plant material generated by hardscapes such as

asphalt). Start rows about 4” away from planting beds.

BASIC “LITE” LAYOUT:

• Water being supplied to the zone is split with a Techline fitting into two directions.

Use a TL075FTEE or TL2W075MA fitting.

• Weave the Techline CV back and forth throughout the planting area with evenly spaced rows.

• Indent the tubing 2” - 4” from hardscapes and planting areas.

• Because water is being split into two separate paths that meet in the middle, the maximum length of the

lateral can be twice the stated limit in Table 2.

• Therefore, to determine the maximum amount of Techline CV you can use in the zone, simply double

the maximum length stated in Table 2.

(The 2” setback will help

NOTE

How to Calculate Equal Techline CV Row Spacing

Example:

• 5 feet x 12 inches = 60 inches

• 60 inches - 8 inches (2 edges x 4” setback) = 52”

• Following recommended Techline CV Row Spacing

for this example, assume 18 inches from Table 1

• 52” ÷ 18” = 2.89 spaces between Techline CV rows

• 2.89 is not a whole number, so round up to the next

whole number, which is 3 (spaces)

• Add 1 (one) to the number of spaces to determine

the number of Techline CV rows

• Determine equal spacing between Techline CV rows. 52 inches ÷ 3 = 17.3 inches

HOW TO QUICKLY DETERMINE THE AMOUNT OF TECHLINE CV IN A ZONE

(Square Footage of Zone x 12) ÷ Minimum Recommended Row Spacing

Page 9

8

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

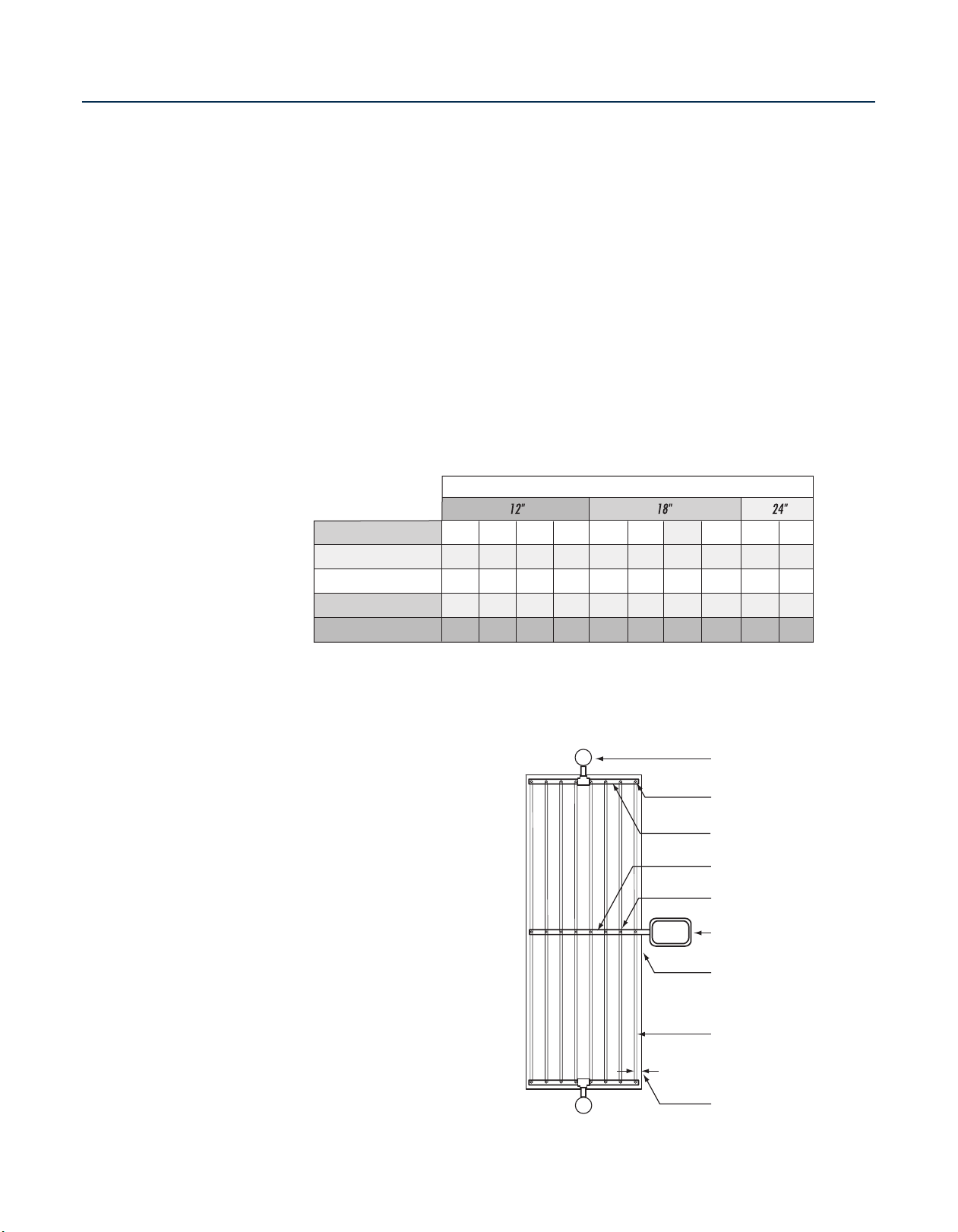

BASIC

Manual Line Flushing Valve

Plumbed to PVC or Poly

Techline Start Connection

Male Adapter

Remote Control Valve with

Disc Filter and PRV

Techline® CV Tubing Lateral

PVC or Poly Exhaust Heade

r

LF

LF

Techline Start Connection

PVC or Poly Supply Header

Area Perimeter

Perimeter Laterals

2" to 4" From Ed

g

e

109

325

409

469

0.4

86

256

322

369

0.6

127

427

539

618

0.26

65

194

244

280

0.9

151

459

579

664

0.4

91

274

346

397

0.9

152

458

580

666

0.6

116

348

440

506

0.9

15

25

35

45

Dripper Flow Rate (GPH)

INLET PRESSURE (psi)

120

361

456

523

0.6

177

604

763

877

0.26

TECHLINE CV DRIPPER SPACING

TECHLINE® CV Maximum Length of a Single Lateral (feet)

DESIGN

STEPS

(continued)

LENGTH OF TECHLINE CV ROWS:

• As with overhead irrigation, friction losses through pipe determine how long a length of pipe can be.

• You do not need to go through friction loss calculations for Techline CV laterals. It has already been

done for you.

• Table 2 shows the maximum length of a single Techline CV lateral within a zone.

• The chart also determines what the operating pressure of the zone needs to be. Example - If you

have a 322ʼ lateral of 0.6 GPH/12” Techline CV, it will need 35 psi to operate properly. If it is from

323ʼ- 369ʼ, it will need 45 psi. Note: We will discuss how to regulate your pressure in the Pressure

Regulating Valve section on page 14.

• Once the zone is laid out, note the pressure you will need somewhere on the design. We will need

this information later to size the Pressure Regulating Valve.

TABLE 2

CENTER FEED GRID LAYOUTS:

• You can increase the length of

laterals by center-feeding the zone.

By doing so, you can have a length

of Techline CV as called out in Table

2 going in each direction, effectively

doubling the maximum lateral

length. This is just like we discussed

with the LITE layout on page 6.

• Where layout flexibility exists,

Center Feed layouts are an

excellent design method.

• They allow for the most even flow of

water through the zone.

• They are an excellent option for

median strips and other large,

homogenous areas.

Techline CV

Center Feed Layout

Page 10

9

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

BASIC

Exhaust Header

Supply Header

Check longest

lateral agains

t

Table 2 for

maximum

lateral length.

Exhaust Header

Supply Heade

r

Total the combined

length of these

Techline CV laterals

and compare it

against the maximum

lateral length allowed

in Table 2.

Techline fittings

and dripperline

PVC or

Poly Piping

DESIGN

STEPS

(continued)

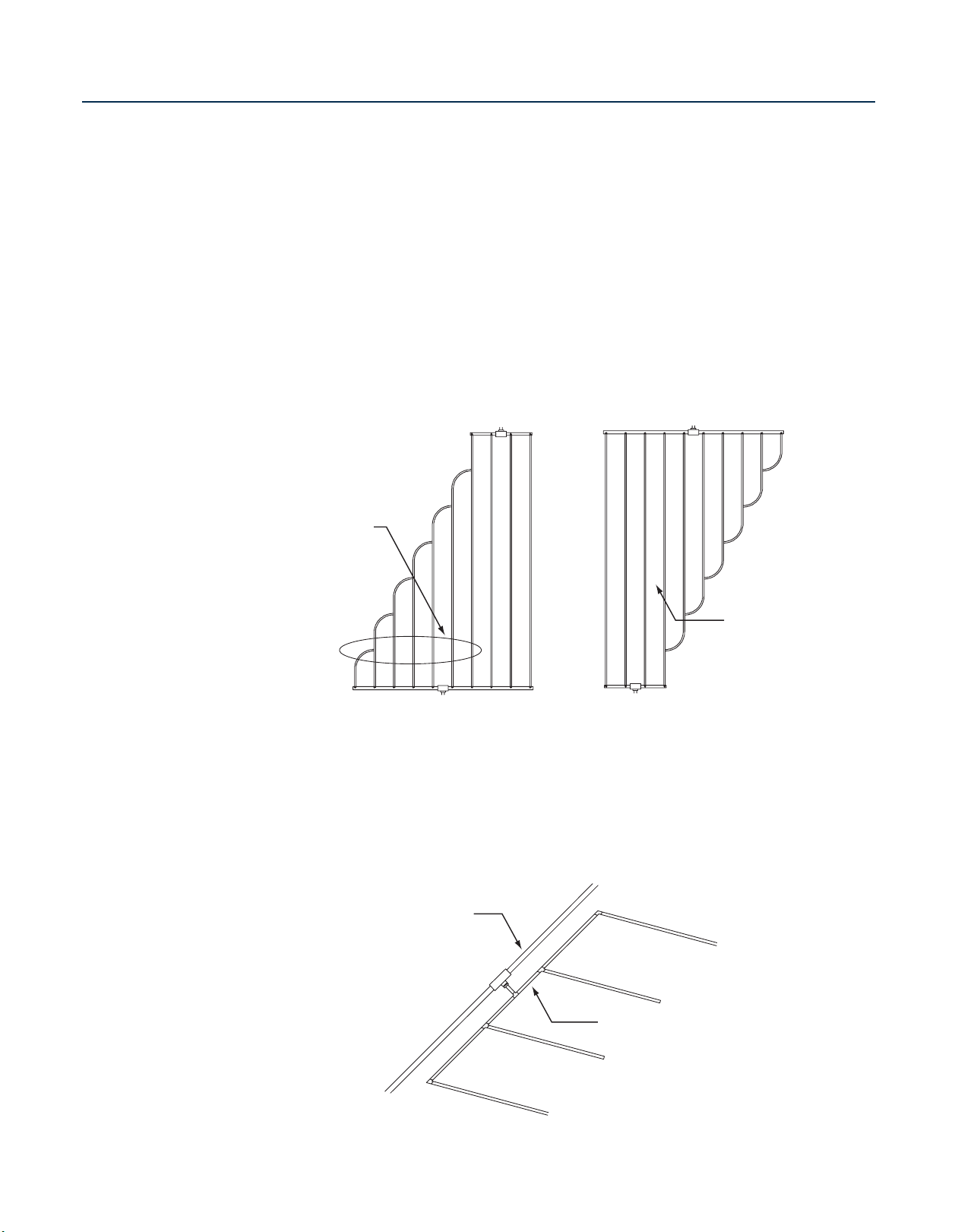

OTHER GRID LAYOUT CONSIDERATIONS:

• When branching out or joining rows of Techline CV, one of two rules apply:

Rule #1: When branching out Techline CV from the supply header, add up all “branched out”

dripperline and check it against the maximum lateral length listed in Table 2.

Rule #2: When joining laterals from the supply header, check only the longest lateral against the

maximum allowable in Table 2.

Branching Out

Techline CV Laterals

• To reduce the number of glue joints, saddles or insert fittings in a header, transition to Techline CV

and Techline fittings to make up subheaders.

• Make sure to follow the guideline of not exceeding 5 GPM in the “sub-header” zone.

Techline CV Laterals

Joining

Creating Sub-Headers to

Reduce Glue/Saddle Joints

Page 11

10

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

BASIC

0.26 GPH Dripper 0.9 GPH Dripper

26.40 GPH

17.58 GPH

Not Available

0.44 GPM

0.29 GPM

Not Available

0.4 GPH Dripper

40.OO GPH

26.67 GPH

Not Available

0.67 GPM

0.44 GPM

Not Available

61.00 GPH

41.00 GPH

31.00 GPH

92.00 GPH

61.00 GPH

46.00 GPH

1.53 GPM

1.02 GPM

0.77 GPM

12"

18"

24"

0.6 GPH Dripper

1.02 GPM

0.68 GPM

0.51 GPM

TECHLINE® CV Flow

(per 100 feet)

DRIPPER SPACING

DESIGN

STEPS

(continued)

ZONE WATER REQUIREMENTS:

• Once the Techline CV is laid out, we need to identify total zone flow. This will help determine

mainline, submain as well as supply and exhaust header sizing, valve, filter, and pressure regulator

selection.

• There are two ways to determine the flow in a Techline CV zone.

• Because Techline CV is pressure-compensating, the flow rate per 100' is the same over a wide

pressure range.

• Table 3 shows an easy way to determine total zone flow:

– Add up the amount of Techline CV

(in hundreds of feet) and

– Multiply that figure by the corresponding dripperline GPM to determine zone flow.

Calculating Total Zone Water Demand

• Multiply Total Feet x 12” = Total inches of Techline CV

• Total Inches of Techline CV ÷ Dripper Spacing = Number of Drippers

• Multiply Number of Drippers x Dripper Flow Rate (GPH) = Total GPH Flow

• Total GPH Flow ÷ 60 = Total GPM in the Zone

Example:

Ten 100ʼ rows of Techline CV with Dripper Spacing of 18”, Flow Rate is 0.6 GPH.

100ʼ x 10 = 1,000ʼ

1,000ʼ x 12” = 12,000” 12,000” ÷ 18” = 667 Drippers

667 Drippers x 0.6 GPH = 400 GPH Total Flow

400 GPH ÷ 60 = 6.67 GPM Flow in the Zone

TABLE 3

Page 12

11

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

BASIC

DESIGN

STEPS

(continued)

NOTE

TL075MA

3/4" Male

Adapter

FITTINGS:

When laying out Techline CV, you will need to use fittings. If you have chosen a GRID layout, you may

need a transition fitting from the supply piping to the Techline CV. Further, you will use Techline CV

fittings to connect the rows of Techline CV to the headers. If you are using a LITE layout, you will also

use a transition fitting from the supply piping, as well as a fitting at the end or midpoint of the zone so

that a flush point can be installed.

Netafim 17mm barbed insert fittings are designed to speed the installation as well as offer you a broad

range of choices, (see page 38).

The barbed end(s) of all Techline CV fittings is raised and sharp. This allows the fitting to be used with

operating pressures up to 50-psi without clamps. If pressures are expected to exceed 50-psi, a clamp

is recommended. Ensure that the clamp is secured over the raised barb.

Fittings are simply pressed into the tubing. No special tools are required. As with all polyethylene pipe,

do not heat the tubing before inserting the fittings. It is not necessary and it can damage the pipe.

STAPLES:

Techline CV staples (TLS6) are used to hold dripperline in place.

While most commonly used when Techline CV is laid on-surface

or under a mulch cover, staples are also valuable when a layout

is being assembled sub-grade before being covered with dirt.

Rule of Thumb: Use a minimum of one staple for every:

• 3 feet of dripperline in sand

• 4 feet of dripperline in loam

• 5 feet of dripperline in clay

Further, use 2 staples “xʼed” over each other with any change-of-direction fittings such as tees, elbows

or crosses.

TL050MA

1/2" Male

Adapter

TLIAPE

TLIAPVC

TLS6

LINE FLUSHING VALVES:

NOTE

Techline CV has a check valve in each dripper designed to hold back a 41/2 foot column of water (2-psi

dripper closing pressure). Therefore, it may not be desirable to use an automatic Line Flushing Valve with

Techline CV, since it could allow water to drain from the dripperline after zone shutdown.

• Line Flushing Valves are used to provide a cleansing action in dripperline each time the zone is turned

on.

• When the zone is turned on, the flush valve begins dumping water into a sump located under it.

• The dumping of water (additional flow) allows the velocity of water inside the dripperline to increase

momentarily helping to clean the inside walls of the tubing.

• This action moves sediments out of the zone and into the sump.

Page 13

12

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

BASIC

Techline Shut-Off

Valve #TLSOV

(blank tubing may be

attached to outlet)

Techline CV Lateral

(or Exhaust Header

)

Valve Box

(Install Per Specs)

Brick Supports

(Three)

3/4" Gravel Sump

(1 Cubic Foot)

Compression Ring

(Provided)

1"

See Specs

Techline

17mm Tubin

g

Finish Grade

Valve Box

(see specs)

Brick Supports (3)

3/4" Gravel Sump

(1 cubic foot)

Line Flushing

Valve (TLFV-1)

DESIGN

STEPS

(continued)

IF AN AUTOMATIC

LINE FLUSHING VALVE IS

DESIRED:

• It is because the desire to have

a cleansing action outweighs the

desire to hold the water inside

the tubing when the zone is off.

• As such, place a Line Flushing

Valve (one per each 15 GPM

of zone flow) as far away from

the source as possible. This will

typically be somewhere along

the exhaust header in a GRID

layout and at the midpoint of the

tubing in a LITE layout.

• When Center Feed layouts are

used, install at least one Line

Flushing Valve on each exhaust

header.

• Line Flushing Valves should

be buried in a valve box with a

gravel sump adequate to drain

approximately one gallon of

water.

• See Air/Vacuum Relief Valves on

page 13.

Netafim Line Flushing Valve

IF AN AUTOMATIC LINE

FLUSHING VALVE IS

NOT DESIRED:

• It is because holding the

water in the Techline CV is

desired and,

• Procedures have been

established to manually

flush the lines during the

season.

• In this case, Techline

Shut-Off Valves

Figure 8 Line Ends (TLFIG8)

should be located along the

exhaust header, or at the

midpoint of a LITE layout.

(TLSOV) or

Techline CV Manual Line

Flush Valve

Page 14

13

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

Techline Start

Connection

Line Flushing Valve Plumbed to PVC,

Poly or Techline CV

Area Perimeter

Techline CV Lateral Tubing

Blank Tubing

Centered on mound

or berm

Supply Header

Remote Control Valve

with Disc Filter and PRV

Exhaust

Header

Techline Tee

Air/Vacuum Relief Valve

(Plumbed to Techline CV,

one at each high point)

LF

AR

6" Round Valve Box

Air/Vacuum Relief Valve

Techline 180 2-Way

Adapter Tee - TL075FTEE

3/4"M x 1/2"F

Reduction Bushing

Finish Grade

Techline CV Tubin

g

3/4" Crushed

Gravel Sump

Brick Supports (3)

BASIC

DESIGN

STEPS

(continued)

NOTE

NOTE

AIR/VACUUM RELIEF

VALVES:

Because Techline CV is designed

to keep water in the tubing, an

A/VRV would only be used in

conjunction with an automatic

Line Flushing Valve as described

in the previous section.

If you want to hold the water

inside the dripperline after

zone shutdown, (you are using

a TLSOV or FIG8 in lieu of an

automatic Line Flushing Valve)

disregard this section.

An Air/Vacuum Relief Valve

freely allows air into a zone

VRV)

after shutdown. It also ensures

a vacuum doesnʼt draw debris

into the dripperline. Further, they

also provide a means of releasing

air from the dripperline when the

zone is turned on, thus eliminating

air pockets and speeding up

dripperline operation. (Because

water stays in a Techline CV zone

anytime the elevation across the

zone is less than

not an issue).

• On zones where an Air/Vacuum

Relief Valve is desired, they are

installed at the highest point(s) in

the zone.

• To ensure that all of the

rows of the dripperline can

take advantage of the Air/

Vacuum Relief Valve,

it/them along a lateral that

runs perpendicular to the

dripperline laterals. This may

be an exhaust header, or a

special lateral connecting all

the rows of dripperline, such as

going over a berm.

In large scale irrigation systems

where pumps and large diameter

pipe are used, air that has been

created must be expelled. As

such, the use of Continuous

Air Vents may be required

on continuously and noncontinuously pressurized lines.

41/2

(A/

feet, this is

install

Netafim Air/Vacuum

Relief Valve (TLAVRV)

Installing A/VRV

To Laterals

Page 15

14

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

BASIC

DESIGN

STEPS

(continued)

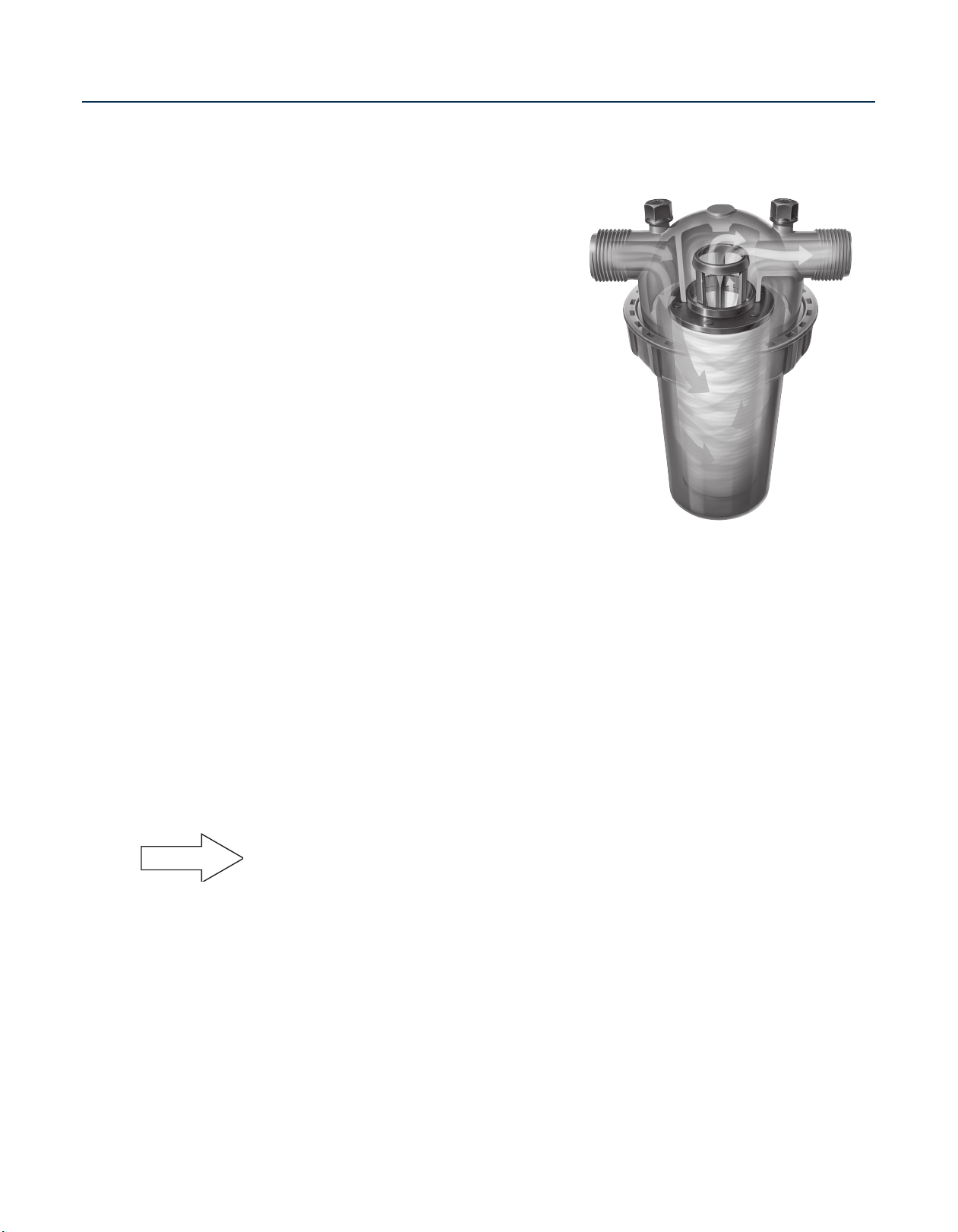

FILTERS:

• Just like overhead irrigation, dripperline needs protection against dirt and debris. (In sprinkler heads,

filters are placed under the drive assembly or nozzle. With drip and dripperline, one filter is placed at

the beginning of the zone, or at the POC).

• Filters are normally installed immediately downstream of the remote control valve.

• Netafim uses a non-collapsing stack of flat grooved discs that effectively capture contaminants.

• They are easily removed from the filter body and flushed clean under a faucet or in a pail of clean

water.

• Disc filters come in a variety of sizes and filtering capacities.

• Rule of Thumb: Use 120 or 140 mesh filters for Techline CV designs. Techline CV only requires 120

mesh filtration. If a finer mesh filter is used, it may require more frequent cleanings.

• Refer to “DISC FILTER SIZING CHART” on page 28 to properly size the filter.

PRESSURE REGULATING VALVES (PRV’S):

Pressure Regulating Valves reduce the operating pressure so that Techline CV zones operate

between 15 and 45 psi.

• PRVʼs are normally installed immediately downstream of the disc filter and remote control valve.

Often all three components are in the same valve box, and the distance from the PRV to the Techline

CV is limited so additional friction is not incurred.

3

• The two most popular sizes of PRV are both

range of 0.25 - 4.4 GPM. The

from

11/2

" - 3” are also available for zones with flows up to 200 GPM.

• To select the correct PRV, choose the model that has the correct flow range based on total zone flow.

• Then select the correct pressure rating based on the following:

1. If you used the “Maximum Length of a Single Techline CV Lateral” chart, (Table 2) match the PRV

to the same pressure rating you used for your maximum lateral length calculation,

OR

2. Simply use a 45 psi PRV. (Because Techline CV is pressure-compensating, there is no reason to

intentionally reduce the pressure below 45 psi).

NOTES:

1. If the PRV is remotely located from the supply header, remember to account for any friction loss

that occurs through the piping to the supply header.

2. Low Volume Control Zone Kits:

• These preassembled kits speed installation and have all of the components needed for a low

volume zone.

• Kits are sized for a specific flow range

High Flow version has a flow range of 3.5 - 17.6 GPM. Other sizes

/4" units. One is a Low Flow version that has a flow

Page 16

15

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

BASIC

DESIGN

STEPS

(continued)

LOW VOLUME CONTROL ZONE - LOW FLOW

LVCZ10075-LF

• Hunter 24VAC PGV-100JT-G 1” valve

• Netafim DF075-140 Filter

• Netafim PRV075LF45V2K PRV

• For zones ranging from 0.25 - 4.4 GPM

Low Volume

Control Zone Kit

(LVCZ10075-LF)

0.25 - 4.4 GPM

Flow Selection for PRV

Low Flow PRV Operates from

0.25 to 4.4 GPM

LOW VOLUME CONTROL ZONE - HIGH FLOW

LVCZ10075-HF

• Hunter 24VAC PGV-100JT-G 1” valve

• Netafim DF070-140 Filter

• Netafim PRV075HF45V2K PRV

• For zones ranging from 3.5 - 17.6 GPM

High Flow PRV Operates from

3.5 to 17.6 GPM

Low Volume

Control Zone Kit

(LVCZ10075-HF)

3.5 - 17.6 GPM

Page 17

16

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

BASIC

PVC or Poly Supply Header,

(continues to next tree)

Estimated

Dripline of

Mature Tre

e

Valve, Filter

PRV Assembly

Tree Rootball

Techline CV Tubing

(dimensions per plans)

Line Flushing Valve

with Gravel Sum

p

LF

Techline® Tee

18" at Top

Up To

+25%

22 1/2" at Botto

m

2/3

1/3

DESIGN

STEPS

(continued)

SLOPES AND BERMS:

Taller Slope Irrigation Method

Techline CV has a check valve built into each

dripper. This allows the dripperline to hold

back up to a

41/2

feet column of water. As

such, designing Techline CV on slopes and

berms is very easy.

• Techline CV should be installed

perpendicular to (across) slopes

• In the upper 2/3 of the slope, space Techline

CV per TABLE 1, page 5, 27 or 39.

1

• In the lower

/3 of the slope, increase the

distance between rows by 25%.

• For every

41/2

feet of elevation change,

either:

- Split the slope into separate zones, or

- Install a Netafim “TLCV” inline check

valve.

Techline Check Valve (TLCV):

• Designed to hold back up to a 13ʼ column of water

• Rule of Thumb: Every 1ʼ of water exerts 0.433 psi of pressure at the base of the column.

As such, a 100ʼ column of water exerts 43.3 psi at the base.

TLCV Specifications:

• Flow Range: 0.9 - 4.4 GPM

(200 - 1,000 I/h)

• Closing Pressure: 5.7 psi (4m)

• Opening Pressure: 7.1 psi (5m)

• Can hold back a 13ʼ column of water (5.7 ÷ .433)

• Connection: 17mm insert

TREES:

• It is important to provide trees

Techline CV Tubing and

Accessories for Tree Planting

with adequate water at the

rootball, while also planning for

the treeʼs needs as it grows.

NOTE: When trees are

transplanted, the soil in the rootball

and the native soil are different.

You must ensure that there are

sufficient drippers irrigating both

soils because water will not

migrate from one soil type to the

other.

• A loop of Techline CV close to

the rootball, with more Techline

CV surrounding the estimated

dripline of the tree when mature

will provide sufficient water.

Page 18

17

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

BASIC

DESIGN

STEPS

(continued)

PRESSURE & FLOW CHECKS:

• One of the best means of ensuring a Techline CV zone is operating properly is to test the pressure at

regular intervals.

• By taking and recording the pressure while the zone is running, you can ensure that the zone is

working as installed.

• Take the reading as far away from the source as possible to ensure that pressures throughout the rest

of the zone are at least that high.

• If readings are lower than normal, a line break, clogged filter, dirty remote control valve, clogged PRV,

or reduced line pressure are possible causes.

NOTE: Always take the readings at the same time of day, from the same spot. This reduces the chance

of faulty readings due to other factors.

• If a water meter is available, check the flow of each zone.

• Record the information at least once per year on a “System Inspection Checklist” (an example is

provided on page 37).

CALCULATING PRECIPITATION RATES:

• Method 1: See the “Techline CV Application Rate Tables” on page 26.

• Method 2: If there is some variation in your design, (for instance, when we had to decrease the

distance between the rows in our earlier example) then rely on the formula below.

CAUTION: Though the precipitation rates of rotors, fixed sprays and Techline CV can be very close in

many situations, we do not recommend tying dripperline into spray or rotor zones. Techline CV has an

irrigation application rate efficiency greater than sprays or rotors. Even when calculations make it appear

that the application rates are the same, a Techline CV zone will actually be delivering more water since

none of it is evaporating or landing where it canʼt be used.

Determining Techline CV Application Rate

Application Rate (inches per hour) =

231.1 x Dripper Flow Rate (GPH)

Dripperline Row Spacing (inches) x Techline CV Dripper Spacing (inches)

Example:

• Dripperline Row Spacing = 17.3” apart

• Techline CV Dripper Spacing = 18”

• Dripper Flow Rate = .6 GPH

231.1 x .6 (GPH)

17.3 inches x 18 inches

= .45 inches per hour

Page 19

18

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TECHLINE CV

IN TURF

TECHLINE CV IN TURFGRASS:

Background: Netafim products have been used successfully in turfgrass since the 1980's. It is a

popular choice for a variety of residential and commercial general-use and specialized-use turf areas,

and has been used very successfully in sports turf, as well as composition and grass tennis courts.

WHERE AND WHY TO USE TECHLINE CV IN TURF:

• Long, odd-shaped or narrow areas:

– Allows greater landscape design freedom to use curvilinear layouts that cannot be utilized when

overhead irrigation is used

– Eliminates wet roads and sidewalks

– Helps save water

– Reduces slipping and tripping hazards

– Reduces wet surface hazards to vehicle traffic

– The ability to irrigate areas with less water in long narrow areas where either getting the water is

hard, or zoning the area is difficult

– Overspray is eliminated

• Areas close to buildings and at-grade windows:

– Stops windows from getting wet

– Allows the use of turfgrass close to a building without damage to facades

– Reduces deterioration and discoloration of building facades

• Athletic fields:

– No exposed sprinklers reduces impact injuries

– On tight-soil fields:

• Can be irrigated and softened prior to play without wetting the surface

• Helps reduce impact injuries from hard soil surfaces

– Because water window issues are eliminated, time of play increases

• Auto dealerships and other parking areas:

– No overspray reduces the cost of auto detailing

– Reduces slipping and tripping hazards

– Reduces wet surface hazards to vehicle traffic

• High wind, or constant wind areas:

– Overspray and wasted water is eliminated

– Water gets where it is supposed to be regardless of wind

• High liability areas:

– Tripping and other liability issues are significantly reduced

– Maintenance costs to repair broken sprinkler heads are greatly reduced

• Vandal-prone areas:

– “Out of sight, out of mind”

– Maintenance costs and potential liability of unrepaired problems is greatly reduced

Page 20

19

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TECHLINE CV

IN TURF

• Wood hardscapes:

– Bleaching of hardscapes such as wooden fences is eliminated

– Aesthetics of the wood hardscapes is maintained

• Steep slopes:

– Allows turf to be used on slopes

– Water is easily managed on slopes with dripperline

– Wash outs are eliminated

• Locales where the cost of water is too expensive for overhead irrigation:

• Unlike spray or rotor irrigation, which does not have an even application rate across its pattern,

Techline CV has an extremely well-balanced application rate in the entire area. As such, you do not

need to overwater to make sure the driest area receives enough water.

– Techline CV uses about half of the water of an overhead system

– Techline CV is about 90% efficient vs. overhead irrigation, which is about 60% efficient

• Techline CV seals in 1.3 gallons of water for every 100', saving water from draining out of the

dripperline each time the zone shuts off.

• Water window issues:

– Irrigate whenever necessary because there is no exposed spray

• Recycled/reclaimed water or fertigation applications where spraying water is illegal:

– Allows for use of nutrient-rich water, often at a greatly reduced cost

– Saves potable water supplies

TIPS FOR USING TECHLINE CV IN A NEWLY-SODDED LAWN:

• Follow Table 1 General Guidelines recommendations for turf,

• Bury the Techline CV approximately 4” below final grade

• In areas where mechanical aeration will be used, bury the Techline CV 6” below final grade and

ensure aeration does not exceed 4"

• When installing the sod:

– It is important that the final grade is smooth, ensuring that the sod makes solid contact with the soil

– Properly “knit” the edges together

– Thoroughly wet the sod with overhead irrigation

– Roll the sod to ensure good contact

• If the irrigation system is automatic:

– Set the zone to run several times daily

– Keep wetted from above as necessary until the roots establish

• Once you cannot pull the edges of the sod up, discontinue overhead watering

• Irrigate on a daily or every-other-day basis

• Protection against root intrusion

– For years of trouble-free system performance, and a limited lifetime warranty against root intrusion,

use Netafim Techfilter with Techline CV,

see pages 29 - 33.

see pages 5, 27 or 39.

Page 21

20

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

SPECIAL

APPLICATIONS

AND TIPS

PARKING LOT ISLANDS:

If islands are small, consider tying several of them together on the same zone.

• Once you have determined that the conditions of the islands are similar enough to interconnect them,

design each for the same precipitation rate by using the same Techline CV and spacing.

• Use one Low Volume Control Zone kit at the source, and install a TLSOV or TLFIG8 either at the end

of the last island or, if the islands dead-end, on each island.

• Connections between the islands should be PVC, or as called out by the designer or local codes.

ELECTRICAL GROUNDING:

• The effectiveness of electrical grounding is dependent on the soil and its moisture content. In moist

soil, grounding is more effective than in dry soil.

• One method of ensuring moist soil is to install a length of Techline CV along a length of unclad

copper wire being used for grounding purposes. The Techline CV is installed in the usual method.

Run it from a separate station on the controller to give you maximum control.

• Techline CV can also be installed over the top of a grounding plate or ground rod.

TECHLINE CV ABOVE AND BELOW GRADE:

Techline CV is designed to be used in a variety of ways:

• It can be laid on the surface, (it’s UV resistant!) and held in place with Techline Staples (TLS6),

• It can be laid on the surface, stapled into place and covered with mulch, or

• It can be buried below grade.

NOTE: When using Techline CV above grade with staples, use enough staples to firmly hold the tubing

in place, especially in freezing climates.

Page 22

21

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TECHLINE CV

WINTERIZING

INSTRUCTIONS

TECHLINE CV WINTERIZING INSTRUCTIONS:

Winterizing an irrigation system involves removing enough water to ensure that

components do not crack or break during freezing weather.

Because Techline CV is designed to keep water sealed inside the tubing between

irrigations, it is important that these simple steps be followed.

NOTE

MANUAL WINTERIZATION

• A drain port must be present at all low points in the zone.

• Ports may be a tee or elbow with a threaded plug, a Netafim TLFIG8 or TLSOV

which, when opened, will allow water to drain. If a Netafim “automatic” Line

Flushing Valve has been used, disassemble it.

• If the Techline CV zone is a grid or closed system, the supply and exhaust

headers may contain a significant amount of water because they are either blank

Techline CV tubing, PVC, or poly pipe. It is important to provide drain ports for

these components.

• If the Techline CV laterals dead-end, and are not connected to an exhaust header,

the lateral ends should be opened to drain at the lowest point(s).

• In the event that some water remains in the system, the disc filter should be

disassembled, and the discs removed to allow any water to exit. Leave the filter

disassembled in the event that some water remains in the system.

• In systems where elevation is a concern, install a drain port upstream of the filter to

ensure as much water as possible is drained.

• Follow manufacturer instructions for any automatic zone valves.

COMPRESSED AIR WINTERIZATION

Follow the same initial procedures for a Techline CV zone as you would for a zone of

overhead sprinklers.

Note: Techline CV fittings are rated to 50 psi without clamps, so the air pressure

must be adjusted according. It is air volume, not pressure that is effective when

winterizing in this manner.

• The pressure regulator, which is normally installed in the valve box along with

the zone valve and filter regulates water, not air pressure. Air pressure should be

regulated to 50 psi or less.

• The drain ports, (a fitting with a threaded plug, a Netafim TLSOV, TLFIG8, or

Netafim Line Flushing Valve), which are normally installed as far away from the

water source of the zone as possible, must be open. Unscrew and disassemble

any “automatic” Line Flushing Valves.

• With all drain ports open, compressed air should be applied until no water is seen

exiting the zone.

(no compressed air blow-out)

Page 23

22

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TECHNICAL

DATA

Techline CV

Dripperline

APPLICATIONS:

• Subsurface or on-surface installations

• Slopes

• Curved, angular or narrow areas

• High traffic/high liability areas

• Areas subject to vandalism

• High wind areas

• Turf, shrubs, trees, flowers

• At-grade windows

• Sports turf

• Tennis courts

FEATURES/BENEFITS:

• Each Dripper has a built-in, 2 psi Check Valve:

- All drippers turn on and off at the same time

- Minimizes water loss

41/2

- Holds back up to

- No low drainage; great on slopes

- More precise watering - Entire lateral begins operating at the same time

• Built-in Physical Root Barrier: Drippers are protected from root intrusion without chemical reliance

• Dark Brown Color: Visually identifies Techline CV, better blending into surrounding colors of the

landscape

• Pressure Compensation: All drippers deliver equal flow across the length of the lateral

• Unique Flow Path: Turbonet technology allows for better control of water flow and less chance of

clogging

• Single hole dripper outlet from tubing:

- Better protection against intrusion

- Allows the dripperline to be used in subsurface applications without chemical protection

• Water is captured from the center of the tubing, ensuring that only the cleanest water is used

• No Air/Vacuum Relief Valve is required: Installations are faster and less expensive

• No Automatic Line Flushing Valve is required: Because the dripperline is designed to hold water in

the tubing after shut-down, a manual flush may be used

• Techline Compatible: Same ID/OD as Techline, works with all Techline fittings and no pipe clamps

are needed under 50 psi

• Installations are faster and less expensive

• Techfilter Compatible: Provides a limited lifetime warranty against root intrusion

feet of water

SPECIFICATIONS:

• Dripper Flow Rates

• Dripper Spacings:, 12", 18", 24" (24" is available in 0.6

& 0.9 GPH flow rates)

• Pressure Compensation Range: 14.7 to 70 psi

• Maximum System Pressure: 50 psi

• Tubing Diameter: 0.66” O.D., 0.56" I.D.

• Coil Lengths: 100', 250', 1,000'

(TLSOV or TLFIG8)

(GPH): 0.26, 0.4, 0.6, 0.9

Page 24

23

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TECHNICAL

Labyrinth

Dripper Cover

Diaphragm

Raised lip surrounding the exit hole,

along with the air gap between the exit

hole in the dripper and the tubing,

provides physical root barrier.

Labyrinth

Dripper Cover

Diaphragm

Filtration Surfac

e

DATA

Techline CV – Exploded View of

Dripper from Above and Below

Above View

Below View

Page 25

24

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TECHNICAL

DATA

DESIGN FORMULAS

Formula 1.1

Formula 1.2

Formula 1.3

Estimated Total Length of Dripperline =

Irrigated Area x 12

Minimum Recommended Lateral Spacing (inches)

In Which:

Estimated Total Length of Dripperline = Total Footage of Dripperline in a Zone

Irrigated Area = Total Area in Square Feet

Minimum Recommended Lateral (Row) Spacing = The minimum row spacing from the

General Guidelines Chart in inches

Application Rate (inches per hour) =

231.1 x Dripper Flow Rate (GPH)

Dripperline Row Spacing (inches) x Dripper Spacing (inches)

In Which:

Application Rate is = Inches per Hour of Water Being Applied

Dripper Flow Rate = Gallons per Hour Flow of One Dripper

Dripper Spacing = Spacing in Inches of Drippers Inside Tubing

Dripperline Row Spacing = Inches Between Techline CV Laterals (Rows)

Number of Drippers in a Zone =

Total Dripperline x 12

Dripper Spacing

In Which:

Number of Drippers = Number of Drippers

Total Dripperline = Length of All Dripperline in a Zone in Feet

Dripper Spacing = Spacing in Inches of Drippers Inside Tubing

Formula 1.4

Number of Drippers x Dripper Flow Rate (GPH)

In Which:

Flow per Zone = Total Gallons per Minute

Number of Drippers = Number of Drippers

Dripper Flow Rate = Gallons per hour of one dripper

GPH = Gallons per Hour Flow of One Dripper

Formula 1.5

(

Dripper Spacing (inches) x Dripperline Spacing (inches)

In Which:

Estimated Total Zone Flow = Gallons per Minute in Zone

Irrigated Area = Total Area in Square Feet

Dripper Spacing = Distance Between Dripperline in Inches

Dripperline Spacing = Distance Between Dripperline in Inches

Dripper Flow Rate = Gallons per Hour of One Dripper

Irrigated Area (square feet) x 144

Flow per Zone =

60

Estimated Total Zone Flow =

)

x Dripper Flow Rate (GPH) ÷ 60

Page 26

25

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TECHNICAL

Dripper

Flow Rate

26 = 0.26 GPH

4 = 0.4 GPH

6 = 0.6 GPH

9 = 0.9 GPH

Dripper

Spacing

12 = 12"

18 = 18"

24 = 24"

Coil

Length

01 = 100 feet

025 = 250 feet

10 = 1,000 feet

Techline CV

Dripperline

TLCV

TLCV

X X

X X

X X

TECHLINE CV Specifying Information

For blank tubing use: TLCV010=1,000', TLCV0025=250', TLCV001=100'

Techline CV Ordering Example:

TLCV26-12025 is Techline CV, .26 GPH, 12" Spacing, 250' Coil.

TLCV010 is Techline CV Blank Tubing, 1,000' Coil.

TECHLINE CV Dripper Flow Passage

and Filtration Recommendations

Dripper Flow Depth Width Length Minimum Filtration

0.26 GPH 0.029" 0.033" 1.57" 120 Mesh

0.4 GPH 0.028" 0.050" 1.57" 120 Mesh

0.6 GPH 0.039" 0.050" 1.57" 120 Mesh

0.9 GPH 0.063" 0.045" 1.57" 120 Mesh

TECHLINE CV Tubing Dimensions

Inside Diameter Outside Diameter Wall Thickness

0.560" 0.660" 0.050"

TECHLINE CV Minimum Bending Radius

7 Inches

DATA

Specifications

Page 27

26

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TECHNICAL

TECHLINE CV 0.4 GPH Dripper Flow

(in inches per hour)

Techline CV Row Spacing

Dripper Spacing 12" 13" 14" 15" 16" 17" 18" 19" 20" 22" 24"

12" 0.64 0.59 0.55 0.51 0.48 0.45 0.43 0.41 0.39 0.35 0.32

18" 0.43 0.40 0.37 0.34 0.32 0.30 0.29 0.27 0.26 0.23 0.21

TECHLINE CV 0.26 GPH Dripper Flow

(in inches per hour)

Techline CV Row Spacing

Dripper Spacing 12" 13" 14" 15" 16" 17" 18" 19" 20" 22" 24"

12" 0.42 0.38 0.36 0.33 0.31 0.29 0.28 0.26 0.25 0.23 0.21

18" 0.28 0.26 0.24 0.22 0.21 0.20 0.19 0.18 0.17 0.15 0.14

TECHLINE CV 0.6 GPH Dripper Flow

(in inches per hour)

Techline CV Row Spacing

Dripper Spacing 12" 13" 14" 15" 16" 17" 18" 19" 20" 22" 24"

12" 0.96 0.89 0.83 0.77 0.72 0.68 0.64 0.61 0.58 0.53 0.48

18" 0.64 0.59 0.55 0.51 0.48 0.45 0.43 0.40 0.39 0.35 0.32

24" 0.48 0.44 0.41 0.39 0.36 0.34 0.32 0.30 0.29 0.26 0.24

TECHLINE CV 0.9 GPH Dripper Flow (in inches per hour)

Techline CV Row Spacing

Dripper Spacing 12" 13" 14" 15" 16" 17" 18" 19" 20" 22" 24"

12" 1.44 1.33 1.24 1.16 1.08 1.02 0.96 0.91 0.87 0.79 0.72

18" 0.96 0.89 0.83 0.77 0.72 0.68 0.64 0.61 0.58 0.53 0.48

24" 0.72 0.67 0.62 0.58 0.54 0.51 0.48 0.46 0.43 0.39 0.36

DATA

Techline CV Application Rate Tables

Page 28

27

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

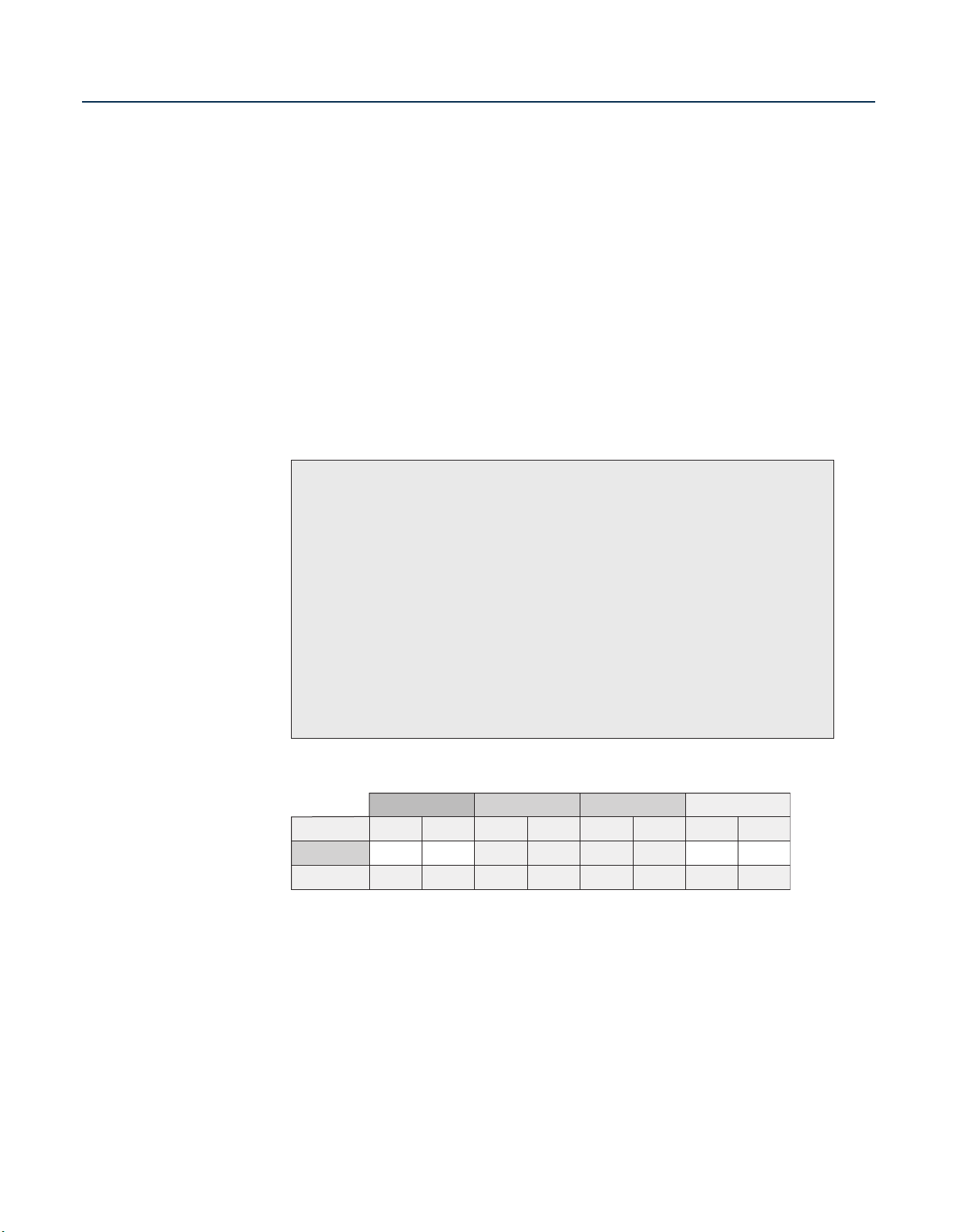

TECHNICAL

Dripper Flow

Dripper Interval

Lateral (Row) Spacings

Burial Depth

Application Rate (in./hr.)

Time to Apply 1/4"

of Water (in minutes)

Clay Soil

0.26 GPH

18"

18" - 22"

.19 - .15

79 - 100

Loam Soil

0.4 GPH

12"

18" - 22"

.43 - .35

35 - 43

Sandy Soil

0.6 GPH

12"

12" - 16"

.96 - .72

16 - 21

Clay Soil

0.26 GPH

18"

18" - 24"

.19 - .14

79 - 107

Sandy Soil

0.6 GPH

12"

16" - 20"

.72 - .58

21 - 26

Loam Soil

0.4 GPH

18"

18" - 24"

.29 - .21

52 - 71

SHRUB and GROUND COVERTURF

TECHLINE® CV General Guidelines

Maximum spacing recommendations: Following these spacing guidelines, dripper flow selection can be increased if desired by the designer.

On-surface or bury evenly throughout the zone to a maximum of 6 inches

109

325

409

469

0.4

86

256

322

369

0.6

127

427

539

618

0.26

65

194

244

280

0.9

151

459

579

664

0.4

91

274

346

397

0.9

152

458

580

666

0.6

116

348

440

506

0.9

15

25

35

45

Dripper Flow Rate (GPH)

INLET PRESSURE (psi)

120

361

456

523

0.6

177

604

763

877

0.26

TECHLINE CV DRIPPER SPACING

TECHLINE® CV Maximum Length of a Single Lateral (feet)

0.26 GPH Dripper 0.9 GPH Dripper

26.40 GPH

17.58 GPH

Not Available

0.44 GPM

0.29 GPM

Not Available

0.4 GPH Dripper

40.OO GPH

26.67 GPH

Not Available

0.67 GPM

0.44 GPM

Not Available

61.00 GPH

41.00 GPH

31.00 GPH

92.00 GPH

61.00 GPH

46.00 GPH

1.53 GPM

1.02 GPM

0.77 GPM

12"

18"

24"

0.6 GPH Dripper

1.02 GPM

0.68 GPM

0.51 GPM

TECHLINE® CV Flow (per 100 feet)

DRIPPER SPACING

DATA

TABLE 1

TABLE 2

TABLE 3

Page 29

28

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TECHNICAL

DISC FILTER Recommended Filter Sizing

Filter Size

3

/4" 1" 1 1/2" 1 1/2" Super 2"

Filter Volume (cubic inches) 5.8 26.8 26.8 36.1 75

Filtration Area (square inches) 24.8 48.9 49 77.8 148

Mesh 40 80 120 140 200

Micron 400 200 130 115 75

Disc Color Blue Yellow Red Black Green*

Flow Rate (GPM) Friction Loss (psi)

4.4 0.40 0.14 – – –

8.8 1.46 0.54 – – –

13 3.40 1.34 – – –

17 – 2.10 – – –

22 – 3.24 1.10 1.10 –

26 – – 1.30 1.20 –

31 – – 1.70 1.20 –

35 – – 2.30 2.50 –

44 – – – 4.20 0.30

66 – – – – 0.63

88 – – – – 1.03

110 – – – – 1.47

132 – – – – 2.13

Losses shown are for a 140 mesh filtration element tested in potable water. The maximum recommended flow for each

filter is listed. Example: The maximum recommended flow for a 3/4" filter is 13 GPM. The maximum recommended

flow for a 1" filter is 22 GPM.

*Green not available for 3/4".

Disc Filter Sizing

DATA

Page 30

29

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TECHNICAL

DATA

TECHLINE CV WITH TECHFILTER

Filters are an integral part of every drip system.

No system should be designed or assembled

without proper filtration. The primary function

is to filter out contaminants that could plug the

small orifices of the drippers. Netafimʼs Techfilter

serves a secondary purpose of protecting

against roots invading the system.

Triflurex® is incorporated into the replaceable

disk ring assemblies inside the filter housing.

When water passes through the filter, a very

low concentration of Trifluralin

level) is transmitted throughout the system.

The operation of this technology provides

very precise and even distribution of Trifluralin

through the piping network which will inhibit root

growth into the dripper outlets. No other uses

or claims are made for the use of this product

beyond the protection of the system from root

intrusion.

TECHFILTER INSTALLATION AND MOUNTING INSTRUCTIONS:

The installation of the Techfilter is no different than any other filter. It is advisable to install the filter so

the filter rings are easily removed for periodic cleaning of contaminants and replacement of the rings at

the end of their affectivity. The filter should be mounted so the cover can be easily disassembled and

the ring set, when removed, will not drop dirt or particle contaminants back into the filter body. Do not

install the filter in direct sunlight. The Techfilter should be mounted to avoid direct sunlight. Mounting in

an irrigation valve box, meter box or inside a building is preferred.

(parts per billion

®

EFFECTIVE USE AND REPLACEMENT GUIDELINES:

The Techfilter can effectively protect the system from root intrusion for 200 hours of use, but not longer

than 2 years of service. We recommend replacing the filter cartridge following the above guidelines.

®

is manufactured by Agan Chemical Manufacturers Ltd.

NOTE

Triflurex

Techfilter with Techline CV is sold together for use on a new installation as a part number as

shown on pages 31 - 33. Techfilter cannot be sold without the proper amount of Techline CV.

Page 31

30

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

Filter

Size

075 = 3/4"

10 = 1"

10L = 1" Long

15L = 1 1/2" Long

20 = 2"

Dripper

Flow

26 = 0.26 GPH

4 = 0.4 GPH

6 = 0.6 GPH

9 = 0.9 GPH

Dripper

Spacing

12 = 12"

18 = 18"

24 = 24"

Quantity

of Techline CV

Length of Techline CV

supplied with each

filter ordered.

See chart below.

Techfilter

TF XXX

XXXCVX

XX

TECHFILTER Specifying Information

TF

TECHLINE CV Minimum & Maximum Feet for Each Filter Size

0.4 GPH 0.6 GPH 0.9 GPH

Model Flow (GPM) 12" 18"

3

/4"

1"

1" Long or

1 1/2" Long

2"

Min. - 1

Max. - 7

Min. - 3

Max. - 22

Min. - 8

Max. - 40

Min. - 14

Max. - 90

448

3,284

1,194

5,970

2,089

13,433

682

5,000

1,818

9,090

2,181

20,454

294

2,157

784

3,922

1,373

8,824

441

3,235

1,176

5,882

2,059

13,235

588

4,314

1,569

7,843

2,745

17,647

196

1,438

523

2,614

915

5,882

294

2,157

784

3,922

1,373

8,824

390

2,857

1,039

5,195

1,818

11,688

149

1,044

227

1,590

12" 18"

98

686

147

1,029

24"

196

1,373

Use the flow rate of the zone or the number of feet of Techline CV to determine what size filter to use. Example: If you have a 7.37 GPM zone of .4/12"

Techline CV (7.37 GPM = 1,100' of dripperline) use the 1" Techfilter. Note: One or more Techfilter sizes may work for your application.

0.26 GPH

12" 18"

638

4,681

1,702

8,511

2,979

19,149

1,034

7,586

2,758

13,799

4,827

31,034

213

1,489

345

2,413

12" 18"

65

45898686

24"

130

909

TECHNICAL

DATA

Page 32

31

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TECHFILTER with TECHLINE CV Model Number Descriptions

Filter Size Model Number

Description

1" TF10912-200CV 1" Techfilter w/200' .9 gph 12" Techline CV

1" TF10912-1000CV 1" Techfilter w/1,000' .9 gph 12" Techline CV

1" TF10918-300CV 1" Techfilter w/300' .9 gph 18" Techline CV

1" TF10918-1000CV 1" Techfilter w/1,000' .9 gph 18" Techline CV

1" TF10612-300CV 1" Techfilter w/300' .6 gph 12" Techline CV

1" TF10612-1000CV 1" Techfilter w/1,000' .6 gph 12" Techline CV

1" TF10618-350CV 1" Techfilterw/350' .6 gph 18" Techline CV

1" TF10618-1000CV 1" Techfilter w/1,000' .6 gph 18" Techline CV

1" TF10412-400CV 1" Techfilter w/400' .4 gph 12" Techline CV

1" TF10412-1000CV 1" Techfilter w/1,000' .4 gph 12" Techline CV

1" TF10418-600CV 1" Techfilter w/600' .4 gph 18" Techline CV

1" TF10418-1000CV 1" Techfilter w/1,000' .4 gph 18" Techline CV

1" TF102612-400CV 1" Techfilter w/400' .26 gph 12" Techline CV

1" TF102612-1000CV 1" Techfilterw/1,000' .26 gph 12" Techline CV

1" TF102618-600CV 1" Techfilter w/600' .26 gph 18" Techline CV

1" TF102618-1000CV 1" Techfilter w/1,000' .26 gph 18" Techline CV

3

/4" TF075912-100CV

3

/4" Techfilter w/100' .9 gph 12" Techline CV

3

/4" TF075912-1000CV

3

/4" Techfilter w/1,000' .9 gph 12" Techline CV

3

/4" TF075918-100CV

3

/4" Techfilter w/100' .9 gph 18" Techline CV

3

/4" TF075918-1000CV

3

/4" Techfilter w/1,000' .9 gph 18" Techline CV

3

/4" TF075612-100CV

3

/4" Techfilter w/100' .6 gph 12" Techline CV

3

/4" TF075612-1000CV

3

/4" Techfilter w/1,000' .6 gph 12" Techline CV

3

/4" TF075618-200CV

3

/4" Techfilter w/200' .6 gph 18" Techline CV

3

/4" TF075618-1000CV

3

/4" Techfilter w/1,000' .6 gph 18" Techline CV

3

/4" TF075412-100CV

3

/4" Techfilter w/100' .4 gph 12" Techline CV

3

/4" TF075412-1000CV

3

/4" Techfilter w/1,000' .4 gph 12" Techline CV

3

/4" TF075418-200CV

3

/4" Techfilter w/200' .4 gph 18" Techline CV

3

/4" TF075418-1000CV

3

/4" Techfilter w/1,000' .4 gph 18" Techline CV

3

/4" TF0752612-100CV

3

/4" Techfilter w/100' .26 gph 12" Techline CV

3

/4" TF0752612-1000C

3

/4" Techfilter w/1,000' .26 gph 12" Techline CV

3

/4" TF0752618-200CV

3

/4" Techfilter w/200' .26 gph 18" Techline CV

3

/4" TF0752618-1000C

3

/4" Techfilter w/1,000' .26 gph 18" Techline CV

TECHNICAL

DATA

Page 33

32

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TECHNICAL

1" Long TF1OL912-500CV 1" Long Techfilter w/500' .9 gph 12" Techline CV

1" Long TF1OL912-1000CV 1" Long Techfilter w/1,000' .9 gph 12" Techline CV

1" Long TF1OL918-800CV 1" Long Techfilter w/800' .9 gph 18" Techline CV

1" Long TF1OL918-1000CV 1" Long Techfilter w/1,000' .9 gph 18" Techline CV

1" Long TF1OL612-800CV 1" Long Techfilter w/800' .6 gph 12" Techline CV

1" Long TF1OL612-1000CV 1" Long Techfilter w/1,000' .6 gph 12" Techline CV

1" Long TF1OL618-900CV 1" Long Techfilter w/900' .6 gph 18" Techline CV

1" Long TF10L618-1000CV 1" Long Techfilter w/1,000' .6 gph 18" Techline CV

1" Long TF1OL412-1100CV 1" Long Techfilter w/1,100' .4 gph 12" Techline CV

1" Long TF1OL412-1000CV 1" Long Techfilter w/1,000' .4 gph 12" Techline CV

1" Long TF10L418-1700CV 1" Long Techfilter w/1,700' .4 gph 18" Techline CV

1" Long TF10L418-1000CV 1" Long Techfilter w/1,000' .4 gph 18" Techline CV

1" Long TF10L2612-1000C 1" Long Techfilter w/1,000' .26 gph 12" Techline CV

1" Long TF10L2618-1000C 1" Long Techfilter w/1,000'.26 gph 18" Techline CV

1 1/2" Long TF15L912-500CV 1 1/2" Techfilter w/500' .9 gph 12" Techline CV

1 1/2" Long TF15L912-1000CV 1 1/2" Techfilter w/1,000' .9 gph 12" Techline CV

1 1/2" Long TF15L918-800CV 1 1/2" Techfilter w/800' .9 gph 18" Techline CV

1 1/2" Long TF15L918-1000CV 1 1/2" Techfilter w/1,000' .9 gph 18" Techline CV

1 1/2" Long TF15L612-800CV 1 1/2" Techfilter w/800' .6 gph 12" Techline CV

1 1/2" Long TF15L612-1000CV 1 1/2" Techfilter w/1,000' .6 gph 12" Techline CV

1 1/2" Long TF15L618-900CV 1 1/2" Techfilter w/900' .6 gph 18" Techline CV

1 1/2" Long TF15L618-1000CV 1 1/2" Techfilter w/1,000' .6 gph 18" Techline CV

1 1/2" Long TF15L412-1100CV 1 1/2" Techfilter w/1,100' .4 gph 12" Techline CV

1 1/2" Long TF15L412-1000CV 1 1/2" Techfilter w/1,000' .4 gph 12" Techline CV

1 1/2" Long TF15L418-1700CV 1 1/2" Techfilter w/1,700' .4 gph 18" Techline CV

1 1/2" Long TF15L418-1000CV 1 1/2" Techfilter w/1,000' .4 gph 18" Techline CV

1 1/2" Long TF15L2612-1000C 1 1/2" Techfilter w/1,000' .26 gph 12" Techline CV

1 1/2" Long TF15L2618-1000C 1 1/2" Techfilter w/1,000' .26 gph 18" Techline CV

TECHFILTER with TECHLINE CV Model Number Descriptions

Filter Size Model Number

Description

DATA

Page 34

33

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TECHNICAL

TF075

3

/4" Techfilter Replacement Cartridge

TF100 1" Techfilter Replacement Cartridge

TF100L 1" Long and 1 1/2" Techfilter Replacement Cartridge

TF200 2" Techfilter Replacement Cartridge

2" TF20912-1000CV 2" Techfilter w/1,000' .9 gph 12" Techline CV

2" TF20918-1400CV 2" Techfilter w/1,400' .9 gph 18" Techline CV

2" TF20918-1000CV 2" Techfilter w/1,000' .9 gph 18" Techline CV

2" TF20612-1400CV 2" Techfilter w/1,400' .6 gph 12" Techline CV

2" TF20612-1000CV 2" Techfilter w/1,000' .6 gph 12" Techline CV

2" TF20618-1600CV 2" Techfilter w/1,600' .6 gph 18" Techline CV

2" TF20618-1000CV 2" Techfilter w/1,000' .6 gph 18" Techline CV

2" TF20412-2000CV 2" Techfilter w/2,000' .4 gph 12" Techline CV

2" TF20412-1000CV 2" Techfilter w/1,000' .4 gph 12" Techline CV

2" TF20418-3000CV 2" Techfilter w/3,000' .4 gph 18" Techline CV

2" TF20418-1000CV 2" Techfilter w/1,000' .4 gph 18" Techline CV

2" TF202612-2000CV 2" Techfilter w/2,000' .26 gph 12" Techline CV

2" TF202618-3000CV 2" Techfilter w/3,000' .26 gph 18" Techline CV

TECHFILTER with TECHLINE CV Model Number Descriptions

Filter Size Model Number

Description

DATA

Page 35

34

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TECHNICAL

Remote Control Valve

with Disc Filter and PRV

Perimeter Laterals

(2" to 4" from edge)

PVC or Poly Supply Header

Techline CV Tubing Lateral

Area Perimeter

Manual Line Flushing Valve

Plumbed to PVC or Pol

y

PVC or Poly Exhaust Heade

r

LF

Techline Start Connection

Male Adapter

DATA

Techline CV End Feed Layout

Page 36

35

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

TECHNICAL

Manual Line Flushing Valve

Plumbed to PVC or Poly

Perimeter Laterals

(2" to 4" from edge)

Techline Start Connection

PVC or Poly Supply Header

Techline Start Connection

Male Adapter

Techline CV Tubing Lateral

Area Perimeter

PVC or Poly Exhaust Heade

r

LF

LF

Remote Control Valve

with Disc Filter and PRV

DATA

Techline CV Center Feed Layout

Page 37

36

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

INSTALLATION

CHECKLIST

Project:

Date:

1. Assemble and install remote control valve and pressure regulator as indicated in

Netafim detail(s) .

2. Assemble and install supply header as indicated in Netafim detail(s)

. Tape or plug all open connections.

3. Assemble and install exhaust header as indicated in Netafim detail(s)

. Tape or plug all open connections.

4. Install Techline CV laterals beginning at the start connection(s) indicated in Netafim

detail(s) . Type and layout of laterals are to be

installed as specified, and/or as indicated in Netafim detail(s) .

Tape or plug all open ends.

5. If required, install an air/vacuum relief valve at the point(s) of highest elevation in the

zone as indicated in Netafim detail(s) .

6. Make all Techline CV to fitting connections while flushing the system. Make

connections as indicated in Netafim detail(s) .

7. While flushing, connect Techline CV laterals to the exhaust header as indicated in

Netafim detail(s) .

8. Install line flushing valve(s) as indicated in Netafim detail(s) .

9. Install other Netafim accessories as indicated in Netafim detail(s) .

10. Operate and inspect the system. Record system data for historical record. Use

Netafim System Inspection Checklist.

Page 38

37

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

SYSTEM

INSPECTION

CHECK LIST

Techline CV Dripper Spacing 12” 18” 24”

Techline CV Lateral Spacing 12” 18” 24” Other "

Dripper Flow Rate 0.26 GPH 0.4 GPH 0.6 GPH 0.9 GPH

Type of Installation On-Surface Subsurface Depth below grade (inches)

Type of Pressure Regulator 3/4” Low Flow (0.25 to 4.4 GPM ) 3/4” High Flow (3.5 to 17.6 GPM )

1 1/2” Other

15 psi 25 psi 35 psi 45 psi

Disc Filter Size 3/4” 1” 1 1/2” 2”

Disc Filter Mesh 80 120 140 200

Project:

Date:

Operating Pressure psi

Pressure at Flush Valve psi

If More Than One Flush Valve psi psi psi

Controller Data

Station # Frequency x Per Week Run Time: Minutes Flow GPM

Station # Frequency x Per Week Run Time: Minutes Flow GPM

Station # Frequency x Per Week Run Time: Minutes Flow GPM

Station # Frequency x Per Week Run Time: Minutes Flow GPM

Station # Frequency x Per Week Run Time: Minutes Flow GPM

Station # Frequency x Per Week Run Time: Minutes Flow GPM

Station # Frequency x Per Week Run Time: Minutes Flow GPM

Station # Frequency x Per Week Run Time: Minutes Flow GPM

Page 39

38

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

Techline TELL

Elbow

Techline TLCOUP

Coupling

Techline TL075MA or TL050MA

Male Adapter

Techline TL075FTEE

2-Way Adapter Tee

Techline TLTEE

Tee

Techline TLCROSS

Cross

Techline TLW075MA

"V" 2-Way Adapter

Techline TLPLUG

Dripper Plug Ring

Techline TLFIG8

Line End

Techline TLTUBEADP

Micro-Tubing Adapter

3

/4" High Flow PRV

Pressure Regulating Valve

3

/4" Low Flow PRV

Pressure Regulating Valve

1 1/2" PRV

Pressure Regulating Valve

TLS6

6" Wire Staple

TLSOV

Shut-Off Valve (Barb x Barb)

DF-075

3/4" Disc Filter

TLAVRV

Air/Vacuum Relief Valve

TLIAPE

Insert Adapter for

1" or Larger

PE to Techline

TLIAPVC

Insert Adapter and

Grommet for 1 1/2" or Larger

PVC to Techline

TLCV

Inline Check Valve

FITTINGS

Page 40

39

N E T A F I M T E C H L I N E® C V D E S I G N G U I D E

MOST

Dripper Flow