Page 1

Page 2

NMC-PRO

© COPYRIGHT 2011, NETAFIM

NO PARTS OF THIS PUBLICATION MAY BE REPRODUCED, STORED IN AN AUTOMATED DATA FILE OR MADE PUBLIC IN

ANY FORM OR BY ANY MEANS, WHETHER ELECTRONIC, MECHANICAL, BY PHOTOCOPYING, RECORDING OR IN ANY

OTHER MANNER WITHOUT PRIOR WRITTEN PERMISSION OF THE PUBLISHER.

ALTHOUGH NETAFIM TAKES THE GREATEST POSSIBLE CARE IN DE S IGNING AND PRODUCING BOTH ITS PRODUCTS

AND THE ASSOCIATED DOCUMENTATION, THEY MAY STILL INCLUDE FAULTS.

NETAFIM WILL NOT ACCEPT RESPONSIBILITY FOR DAMAGE RESULTING FROM THE USE OF NETAFIM'S PRODUCTS OR

THE USE OF THIS MANUAL.

NETAFIM RESERVES THE RIGHT TO MAKE CHANGES AND IMPROVEMENTS TO ITS PRODUCTS AND/OR THE

ASSOCIATED DOCUMENTATION WITHOUT PRIOR NOTICE.

User Manual

Page 2

Page 3

NMC-PRO

CONTENTS

Table of Contents

1 General Information ................................................................................................................................................ 5

1.1 Keyboard .............................................................................................................................................................. 5

1.2 Hot Screens ......................................................................................................................................................... 5

1.3 Main Menu Icons .................................................................................................................................................. 6

1.4 Introduction to Irrigation Programs ....................................................................................................................... 7

1.5 Operation Mode ................................................................................................................................................... 7

2 PROGRAM MENU ......................................................................................................................................................... 9

2.1 Run Time Program ............................................................................................................................................... 9

2.2 Dosing Program ................................................................................................................................................. 11

2.2.1 Proportional Quantity ................................................................................................................................. 11

2.2.2 Proportional Time ...................................................................................................................................... 12

2.2.3 Time ........................................................................................................................................................... 12

2.2.4 Quantity ..................................................................................................................................................... 13

2.2.5 EC Pre-Control .......................................................................................................................................... 16

2.3 Irrigation Program .............................................................................................................................................. 17

2.3.1 Setting Valve Sequence ............................................................................................................................ 18

2.3.2 Adjusting the Water Quantity Based on Weather Conditions ................................................................... 20

2.3.3 Configuring the Irrigation Cale ndar ........................................................................................................... 21

2.4 Irrigation Based on External Conditions ............................................................................................................. 22

2.4.1 Setting the Dry Contacts ........................................................................................................................... 23

2.4.2 Configuring the Analog Sensor s ................................................................................................................ 24

2.5 Irrigation Based on Radiation Sum .................................................................................................................... 27

2.6 Irrigation Based on VPD Sum ............................................................................................................................ 28

2.7 Introduction to the Influence Program ................................................................................................................ 29

2.8 Using the Influences ........................................................................................................................................... 29

2.8.1 Setting the Influences ................................................................................................................................ 29

2.8.2 Radiation Influence on Target EC ............................................................................................................. 30

2.8.3 Drainage Influence on Target Radiation Sum ........................................................................................... 31

2.8.4 Drain Influence on Minimum Time ............................................................................................................. 32

2.8.5 Drainage EC Level Influence on Target EC .............................................................................................. 33

2.8.6 VPD Influence on Target EC ..................................................................................................................... 35

2.8.7 Temperature Influence on Target EC ........................................................................................................ 36

2.9 Agitator ............................................................................................................................................................... 37

2.10Selector................................................................................................................................................................. 38

2.11Filter Flushing ....................................................................................................................................................... 38

2.12Cooling.................................................................................................................................................................. 41

2.13Misting .................................................................................................................................................................. 42

User Manual

Page 3

Page 4

NMC-PRO

CONTENTS

2.14Water Heating ....................................................................................................................................................... 42

3 MANUAL MENU ......................................................................................................................................................... 43

3.1 System Pause .................................................................................................................................................... 43

3.2 Start/Stop Program ............................................................................................................................................ 43

3.3 Start/Stop Valve ................................................................................................................................................. 44

3.4 Manual Filter Flush ............................................................................................................................................. 45

4 ALARM MENU ............................................................................................................................................................ 46

4.1 Reset .................................................................................................................................................................. 46

4.2 Alarm History ...................................................................................................................................................... 47

4.3 Alarm Definition .................................................................................................................................................. 47

4.4 Alarm Setting ...................................................................................................................................................... 49

4.5 EC/pH Alarm Definition ...................................................................................................................................... 49

4.6 EC/pH Alarm Setting .......................................................................................................................................... 49

4.7 Radio System Alarm Definition .......................................................................................................................... 50

4.8 Radio System Alarm View .................................................................................................................................. 50

4.9 Sms Subscription ............................................................................................................................................... 51

5 HISTORY MENU ......................................................................................................................................................... 52

5.1 Irrigation Log ...................................................................................................................................................... 53

5.2 RAD. & VPD SUM & Drain Log .......................................................................................................................... 54

5.3 Uncompleted Irrigation ....................................................................................................................................... 55

5.4 Uncompleted Program s ..................................................................................................................................... 56

5.5 Daily Irrigation .................................................................................................................................................... 56

5.6 Irrigation Accumulation ....................................................................................................................................... 57

5.7 Aux Meter Accumulation .................................................................................................................................... 57

5.8 Accumulation Reset ........................................................................................................................................... 57

5.9 Filters .................................................................................................................................................................. 58

5.10 Cooling ............................................................................................................................................................... 58

5.11 Sensor Log ......................................................................................................................................................... 59

5.12 Event Log ........................................................................................................................................................... 59

5.13 System Log ........................................................................................................................................................ 59

User Manual

Page 4

Page 5

NMC-PRO

GENERAL INFORMATION

1 0BGENERAL INFORMATION

• Keyboard

• Hot Screens

• Main Menu Icons

• Introduction to Irrigation Programs

• Operation Mod e

1.1 5BKeyboard

Numer keys: Use these ke ys to enter values or quantities. In addition, they act as

shortcuts to selections (see the following section).

+/- Key: Toggles between positive and negative values and marks check boxes' option

selection. In a History screen, use this key to toggle between quantities and time

format.

Arrows: Scroll up, down, left, and right to select menus.

MENU: Press to get to the main menu; also acts as "ESC" and "Back" keys.

ENTER: Enter menu, submenu, value, open window, and confirm a value or change.

ZONE LOG IN: Access Mode

DELETE: Erases s t yp in g mistake.

1.2 6BHot Screens

Press MENU from the Main Menu to see Read-On ly overview running processes. Press MENU again to return to the

Main Menu.

There are 10 Hot Screens / Keys:

• 0: Hot Key- Icon of active actions/processes

• 1: Main Screen/System Status

• 2: Irrigation Process

• 3: Irrigation Program Status

• 4: Water, EC/pH, Dosing

• 5: Filter Flushing Status

• 6: Temperature & Humidity measurement

• 7: Weather Station measurement

• 8: System Pressure

• 9: Drain Status

User Manual

Page 5

Page 6

NMC-PRO

GENERAL INFORMATION

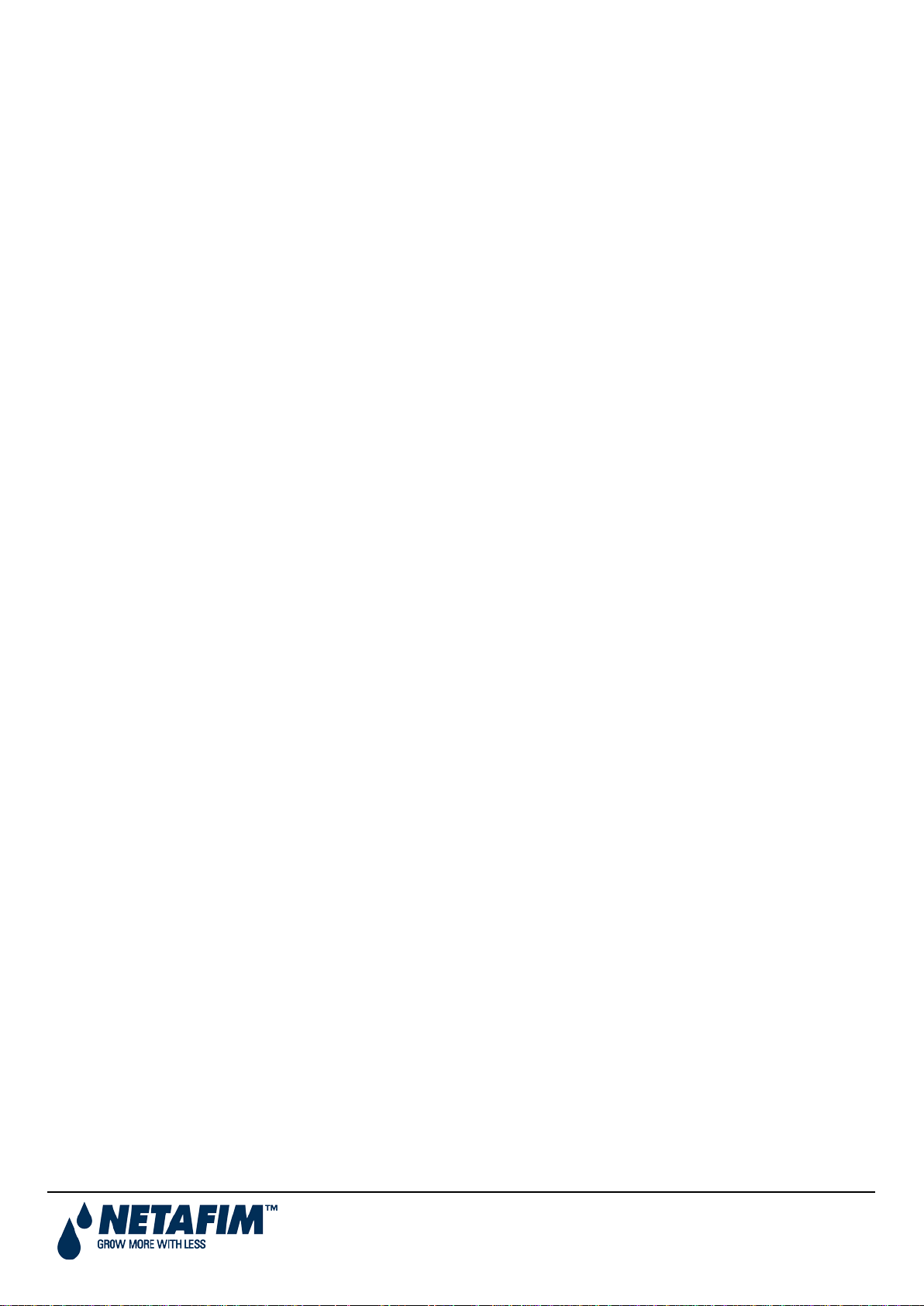

1.3 7BMain Menu Icons

Data log-

Programs:

Conduct manual

Set alarm

For

measurements

Manually test

1.Program

2.Manual

3.Alarm

4.History

5.Test

6.Setup

7.Config

8.Install

irrigation process,

filter flush, system

pause

threshold, and

reset

irrigation

regimen,

dosing recipe,

filter flushing,

entire program

field devices

(valves,

pumps…),

sensor values

(EC, pH, temp,

hum…)

System set-up,

time/date,

sensors

calibration, unit

irrigation log,

water meter,

and system

event log

professional

technical use

only

For

professional

technical use

only

User Manual

Page 6

Page 7

NMC-PRO

GENERAL INFORMATION

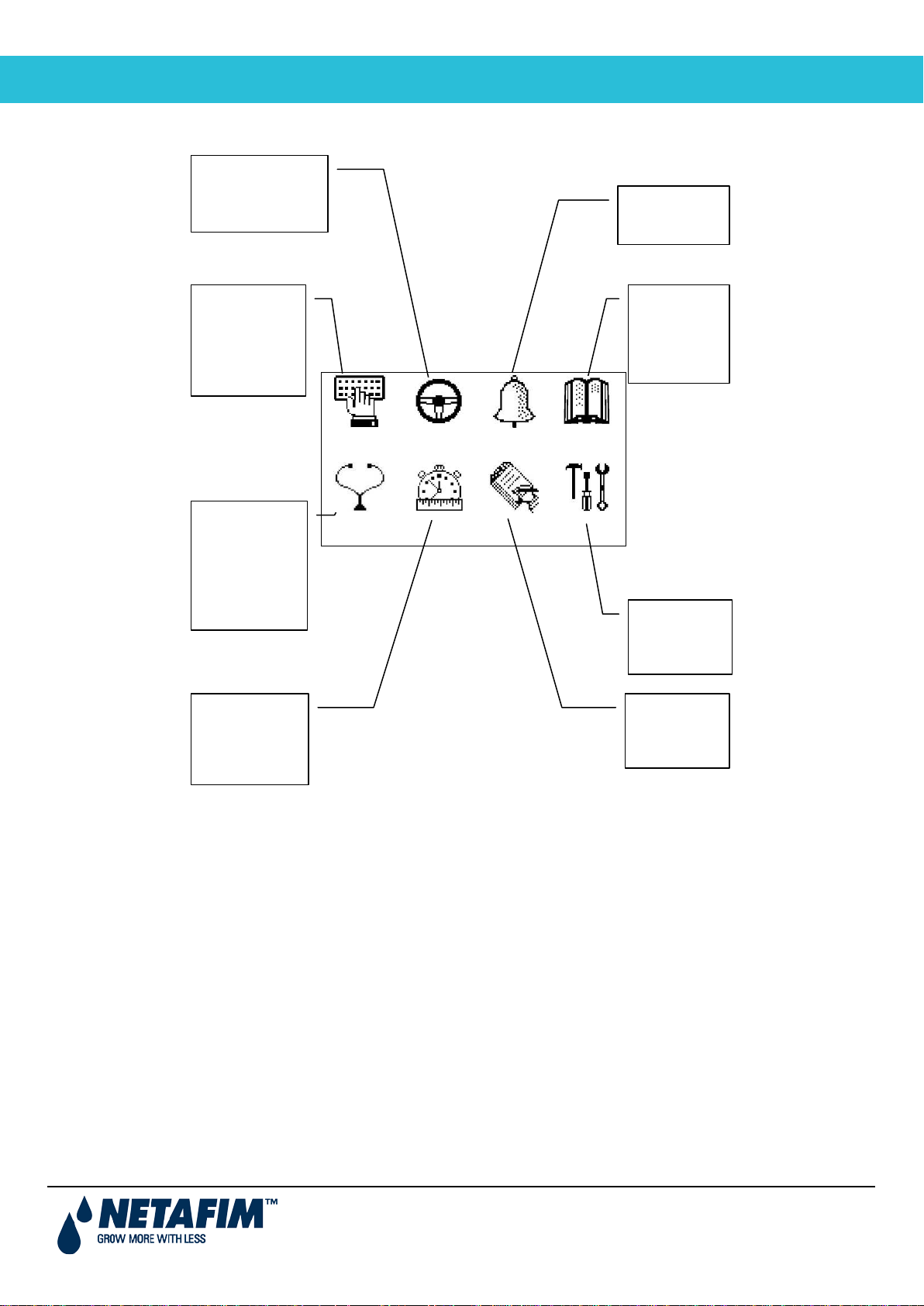

1.4 8BIntroduction to Irrigation Programs

To set an irrigation program-regiment/strategy, the grower must select the necessary valves and set the Run Time

and Dosing programs. The grower can define one or more programs for one or more valves. Refer to PROGRAM

MENU, page 9 for detailed information on these programs.

• Run Time Programs

Based on Time or Quantity

Set water before and after dosing process (fertilizer injection)

• Dosing Programs (Fertilizer)

Up to eight dosing channels per program

Each channel can be defined by:

o Quantity

o Proportional Quantity

o Time

o Proportional Time

• Irrigation Timing Based on External Condition Programs

Supports up to 15 programs

Each program defines:

o Time frame

o Trigger

o Trigger Type (for example one time only or multiple shots)

1.5 9BOperation Mode

There are three operation levels:

• Read Only (restricted): All the parameters and menus are visible, but cannot be modified

• User (partially restricted): Menus 1-6 are fully accessible and can be modified. Menus 7 and 8 can be

viewed but not modified

• Technician (unrestricted): All menus are fully accessible (no restrictions)

User Manual

Page 7

Page 8

NMC-PRO

GENERAL INFORMATION

To change the operation mode, press the LOG IN key

MODE

PASSWORD

OPERATION MODE

OPERATION MODE – USER

?

1

2

3

OPERATION MODE

WRONG PASSWORD

Please Try Again.

Click the MODE icon and insert the password

Please Enter Password

The controller recognizes the operation mode according to the password that is entered:

Read Only 0000

User 9785 or 0101

If an incorrect password is entered, this screen appears.

The Operation mode can be configured to automatically return to the “Read-Only” mode after a certain amount of

time.

Note: Refer to the SYSTEM SETUP section in the Installation Manual.

SYSTEM SETUP

History Resolution ► 1 HOUR

Controller Function ► LOCAL

Automatic return to RO mode ► NO

Return period to RO mode ► 00:10

Controller Number ► 1

Lower Port – Protocol ► NMC NET

Lower Port – BaudRate ► 9600

Upper Port – Protocol ► NONE

Upper Port – BaudRate ► 9600

HISTORY

WEATHER STATION

OPERATION MODE

COMMUNICATION

• To perform a cold start or firmware upgrade, the controller must be in the “Technician” mode.

• If there is a power failure, the controller powers up with the last used mode.

User Manual

Page 8

Page 9

NMC-PRO

PROGRAM MENU

2 1BPROGRAM MENU

The Program Menu is used to configure the irrigation programs. Configuration is a multistep process consisting of

setting the following:

• Run Time Program (length of irrigation time or quantity of water to be distributed), page 9

• Dosing Program (fertilizer distribution program), page 11

• Irrigation (time frame and other parameters), page 17

In addition (or as alternative) to starting the irrigation based on time, irrigation can be set to begin based on:

• Irrigation Based on External Conditions, page 22

• Irrigation Based on Radiation Sum, page 27

• Irrigation Based on VPD Sum, page 28

Furthermore, you can adjust the irrigation process based on environmental factors such as the amount of radiation,

the temperature, or other factors. Refer to Introduction to the Influence Program and Introduction to the Influence

Program, page 29 for more details.

Lastly, use this menu to configure the following functions:

• Agitator, page 37

• Selector, page 38

• Filter Flushing, page 38

• Cooling, page 41

• Misting, pag e 42

• Water Heating, page 42

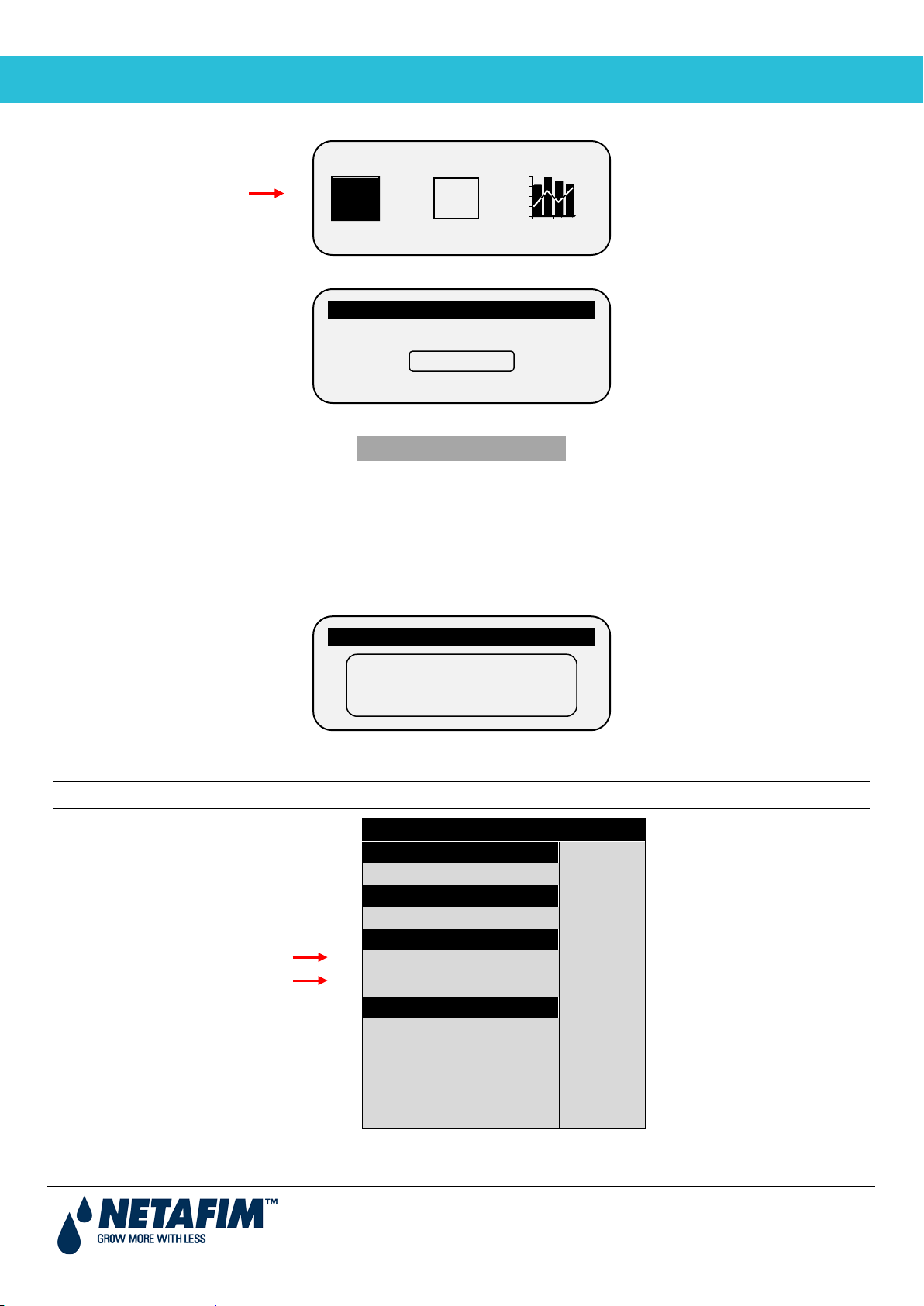

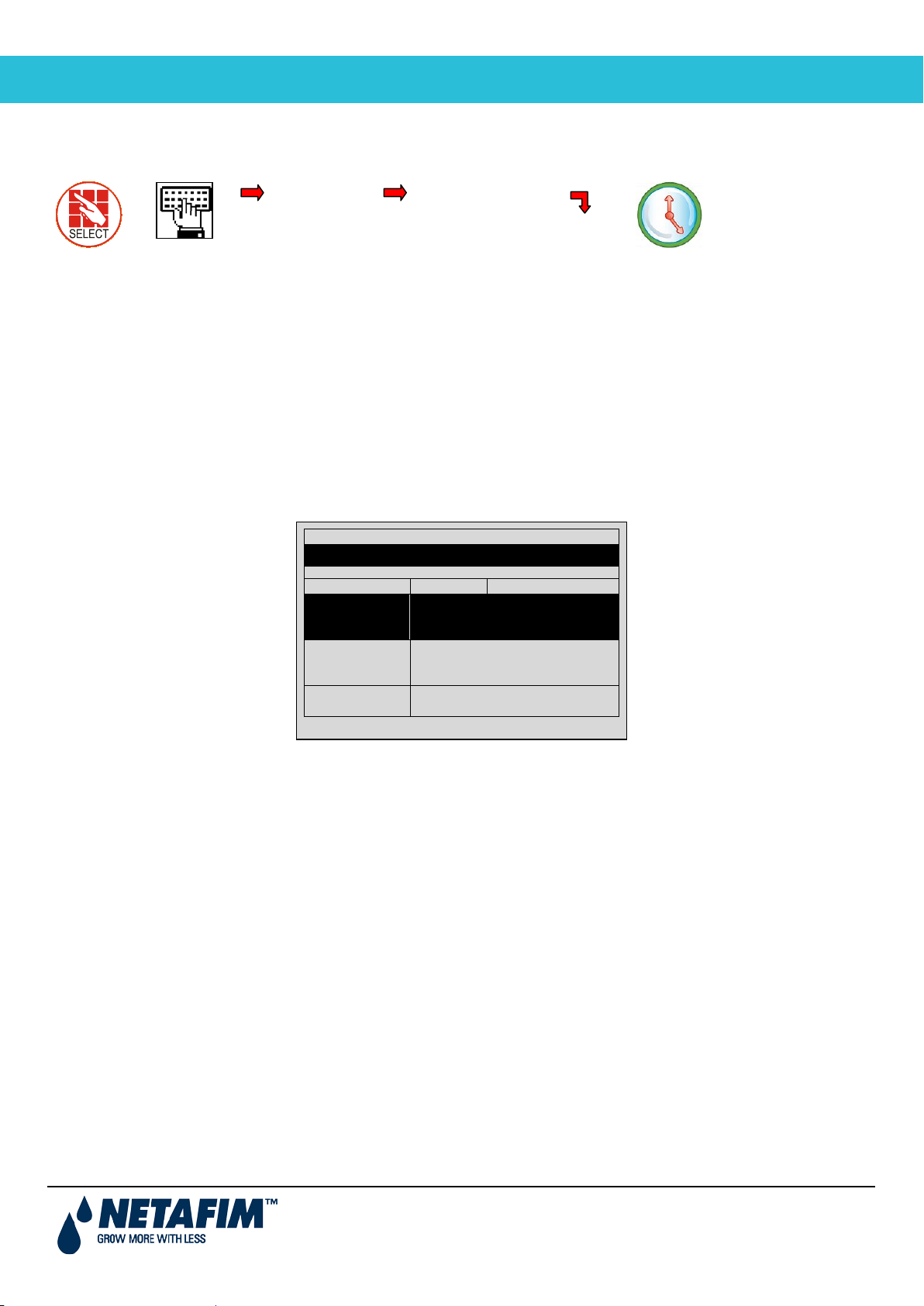

2.1 10BRun Time Program

For every irrigation program, define a Run Time program, which defines the how much water to distribute. Run Time

can be based on either length of time or quantity of water. You can define up to 60 Run Time programs.

As an option, you can configure irrigation to run for a certain amount of time or quantity before dosing begins and/or

after dosing ends. This process rinses the irrigation pipes of any residual matter.

To set the irrigation Run Time:

1. Go to Program > Water Run Time.

2. Select QTY or TIME.

3. Enter the water quantity/total run time.

4. Enter the Before and/or After quantity/time (optional).

5. Repeat as required for each program.

User Manual

Page 9

Page 10

NMC-PRO

PROGRAM MENU

2. Water Run Time

Define

#

Method

Water

Before

After

1

QTY.

10.000

0.000

0.000

QTY.

TIME

#

Method

Water

Before

After

1

TIME

00:15:00

00:00:00

00:00:00

1. Program

Qty.

# Method Water Before After

2

3

4

5

6

7

8

WATER RUN TIME PROGRAM

QTY.

QTY.

QTY.

QTY.

QTY.

QTY.

QTY.

25.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

Time

2

3

4

5

6

7

8

WATER RUN TIME PROGRAM

QTY.

QTY.

QTY.

QTY.

QTY.

QTY.

QTY.

25.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

WATER RUN TIME PROGRAM

1

TIME

2

QTY.

3

QTY.

4

QTY.

5

QTY.

6

QTY.

7

QTY.

8

QTY.

o Define value for "before" and "after" time program

00:15:00

25.000

0.000

0.000

0.000

0.000

0.000

0.000

00:0200

5.000

0.000

0.000

0.000

0.000

0.000

0.000

00:01:00

5.000

0.000

0.000

0.000

0.000

0.000

0.000

Note: Whatever figure you enter in Before/After is deduc ted f rom the total run time/quantity. For example if the

run time is 15 minutes, a Before time of two minutes and After time of one minute, then the net dosing time is

12 minutes.

User Manual

Page 10

Page 11

NMC-PRO

PROGRAM MENU

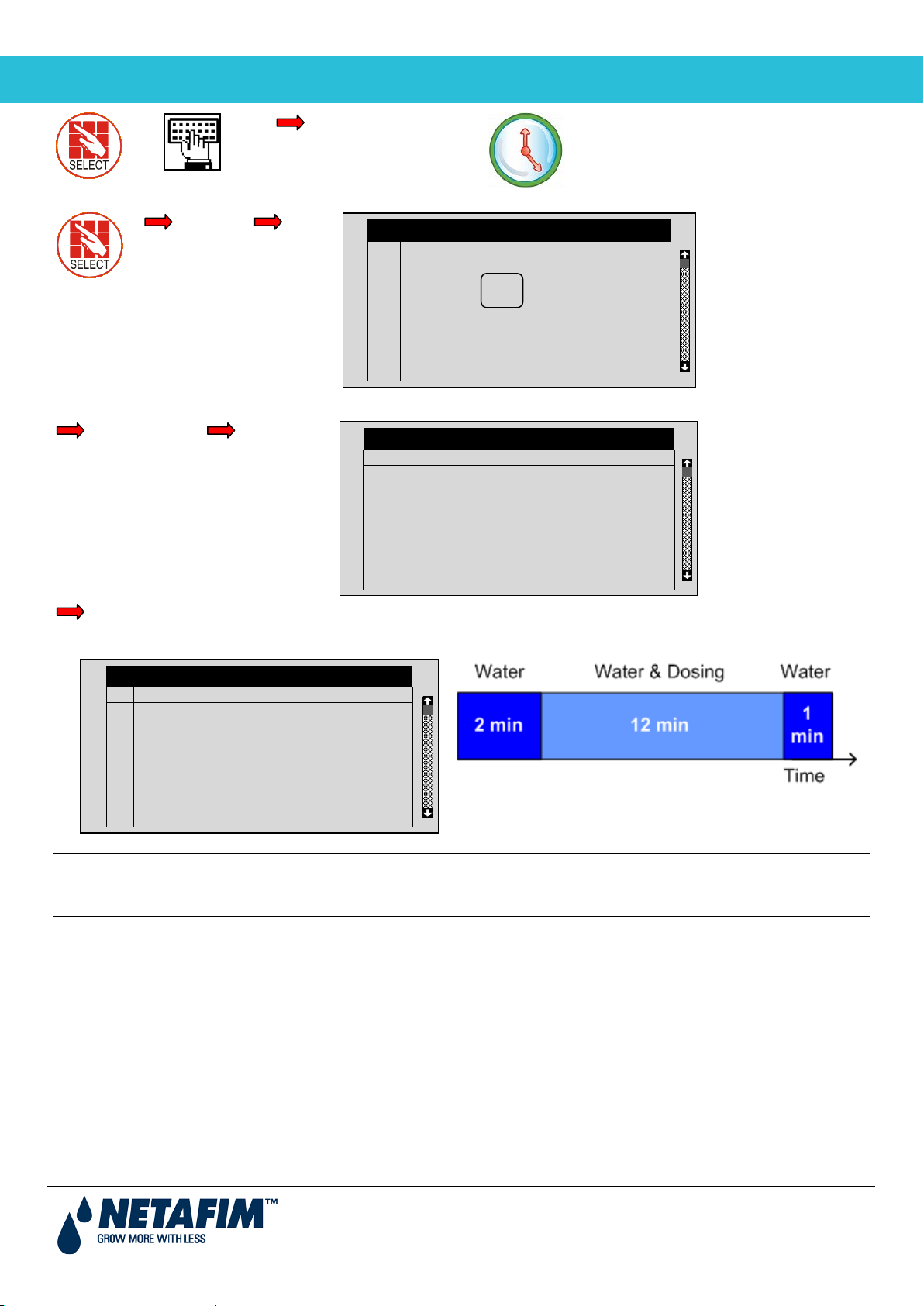

2.2 11BDosing Program

3. Dosing

Program: 1

EC Dosing Method

P.TIME

P. QTY

Program: 1

1

2

3

---

1. Program

For every irrigation program, define a Dosing Program that defines the quantity of fertilizer per channel and its delivery

method. You can define up to 10 Dosing Programs.

Note: If there is more than one fertilizer tank for the selected dosing channel, refer to Selector, page 38.

DOSING PROGRA M

INJECTION PER DOSING CHANNEL

EC

5.00

EC Dosing Method

PH Dosing Method

EC

5.00

ACID

5.00

P.QTY

P.QTY

---

---

Dosing can be according to one of the following:

• Proportional quantity • Proportional time

• Quantity • Time

2.2.1 50BProportional Quantity

Proportional Quantity is the quantit y of fertilizer distributed per quantity of water. The proportion can be one of the

following:

• Liters per cube of water

• Gallons per 1000 gallons of water

DOSING PROGRA M

INJECTION PER DOSING CHANNEL

1

EC

5:00

PH Dosing Method

2

EC

6:00

3

ACID

0.00

P. TIME

P.QTY

TIME

---

---

---

User Manual

Page 11

Page 12

NMC-PRO

PROGRAM MENU

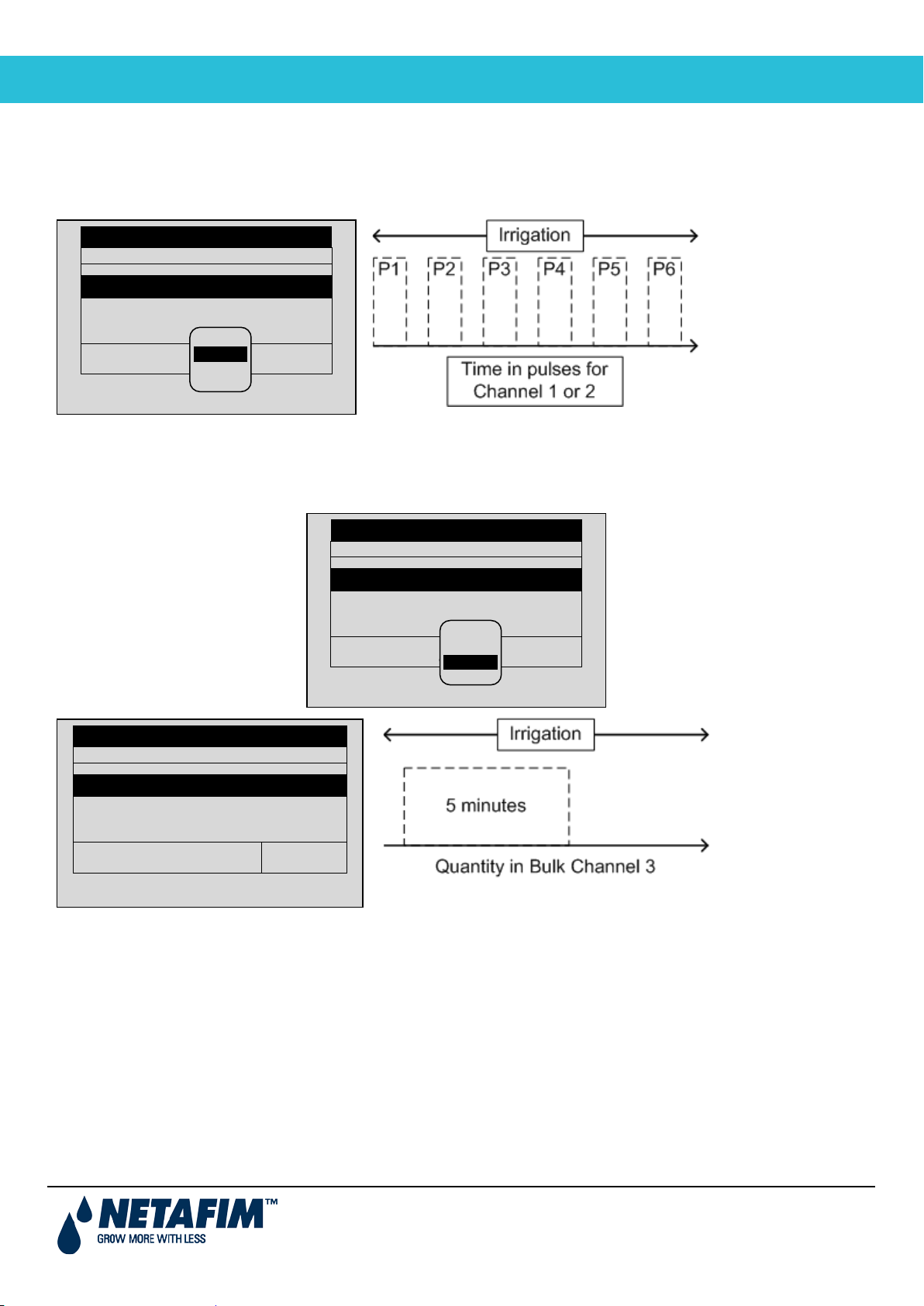

2.2.2 51BProportional Time

Example: In Channel 3, P1 = 5 minutes.

Program: 1

1

2

3

---

P. QTY

Program: 1

1

2

3

---

P. QTY

Program: 1

1

2

3

---

Proportional Time takes the required dosing time and spreads out each dose over the irrigation program in open/close

pulses per channel. The diagram below shows how each the fertilizer is distributed over the total run time; a dose (P)

is injected during irrigation according to the calculated schedule.

DOSING PROGRA M

INJECTION PER DOSING CHANNEL

EC

00:10

EC Dosing Method

PH Dosing Method

EC

00:00

P. TIME

TIME

ACID

0.00

P.TIME

P.QTY

---

---

2.2.3 52BTime

When using the Time delivery method, fertilizer is injected once, for the length of time defined in this screen.

DOSING PROGRA M

INJECTION PER DOSING CHANNEL

DOSING PROGRAM

INJECTION PER DOSING CHANNEL

EC

00:10

EC Dosing Method

PH Dosing Method

EC

00:00

P. TIME

TIME

ACID

0.00

P.TIME

P.QTY

---

---

EC

00:15

EC Dosing Method

PH Dosing Method

EC

00:10

(one pulse)

ACID

00:05

TIME

TIME

---

---

User Manual

Page 12

Page 13

NMC-PRO

PROGRAM MENU

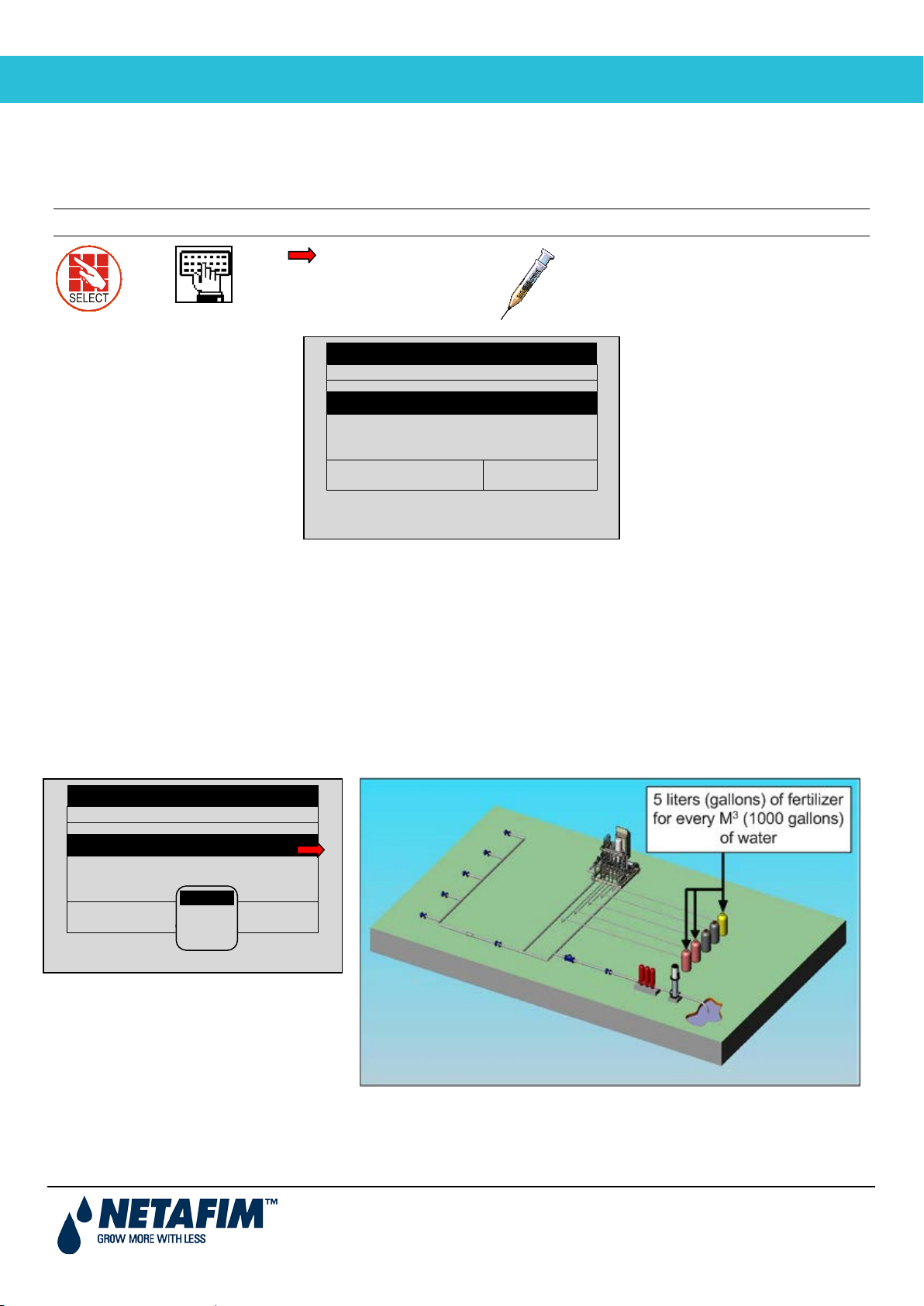

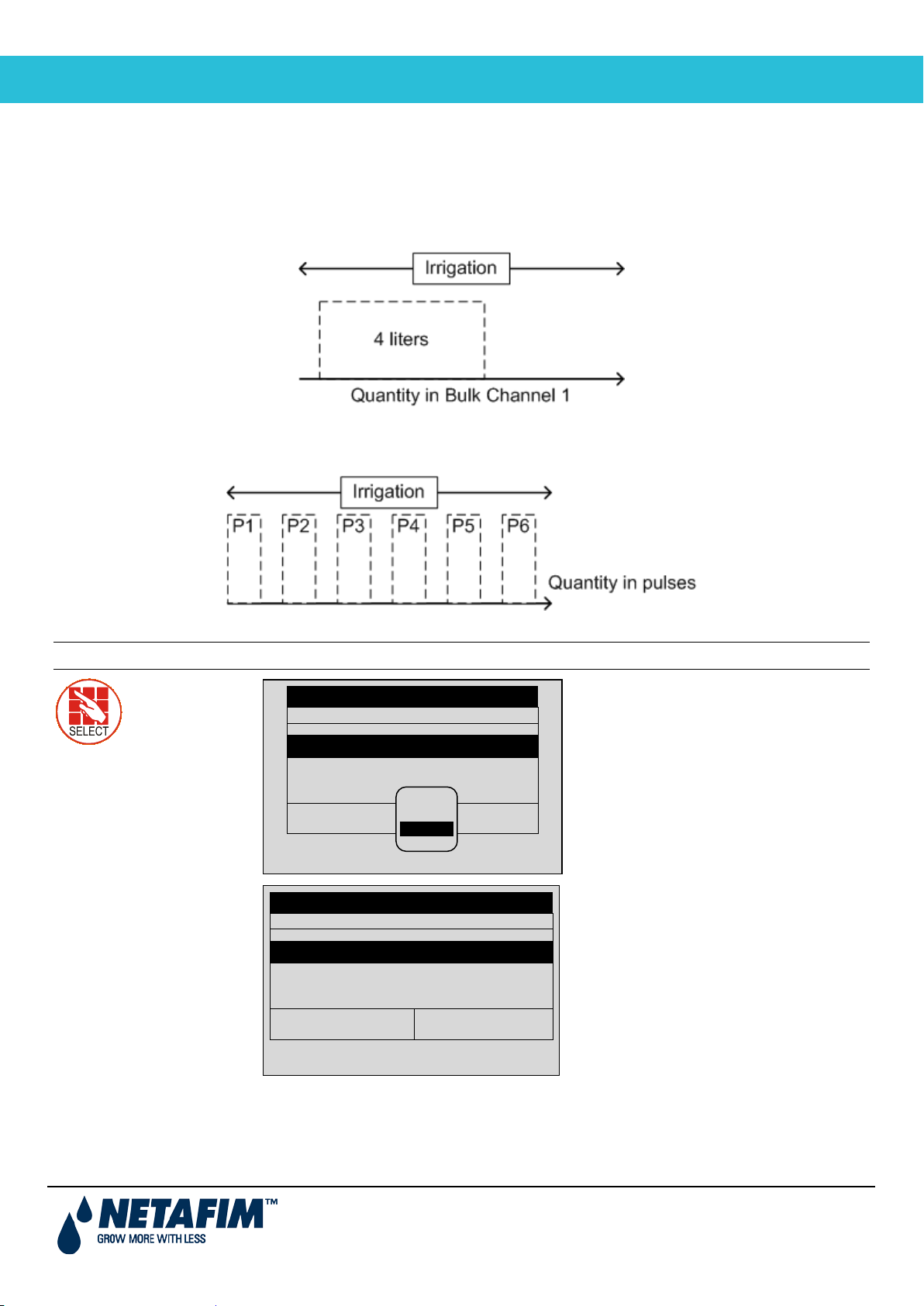

2.2.4 53BQuantity

Program: 1

1

2

3

--EC Dosing Method

QTY.

EC Dosing Method

P.TIME

P. TIME

The Quantity method injects a fixed amount of fertilizer in the irrigation water. When using the Quantity method, there

are two options:

• Option A: Bulk (similar to Time method). In this option, fertilizer is injected once, with the quantity defined in

this screen.

Example: Channel 1, P1 = four liters in one pulse

• Option B: Spread (according to dosing configuration set by a technician). Option B is similar to Proportional

Time. In this method, fertilizer is spread out by quantity over the irr igat ion run time.

Example: Channel 1 = P1 + P2 + P3…+ Pn = 4 liters

Note: The example below shows liters; in the USA use gallons.

Qty.

Program: 1

INJECTION PER DOSING CHANNEL

1

EC

00:10

PH Dosing Method

INJECTION PER DOSING CHANNEL

EC

4.00

PH Dosing Method

DOSING PROGRA M

2

EC

00:00

DOSING PROGRA M

EC

5.00

TIME

QTY.

ACID

2.00

QTY.

3

ACID

0.00

P.QTY

---

---

---

---

---

When installing the NMC Pro Controller, the installation technician selects the required option. The user defines the

quantity in the above screen.

User Manual

Page 13

Page 14

NMC-PRO

PROGRAM MENU

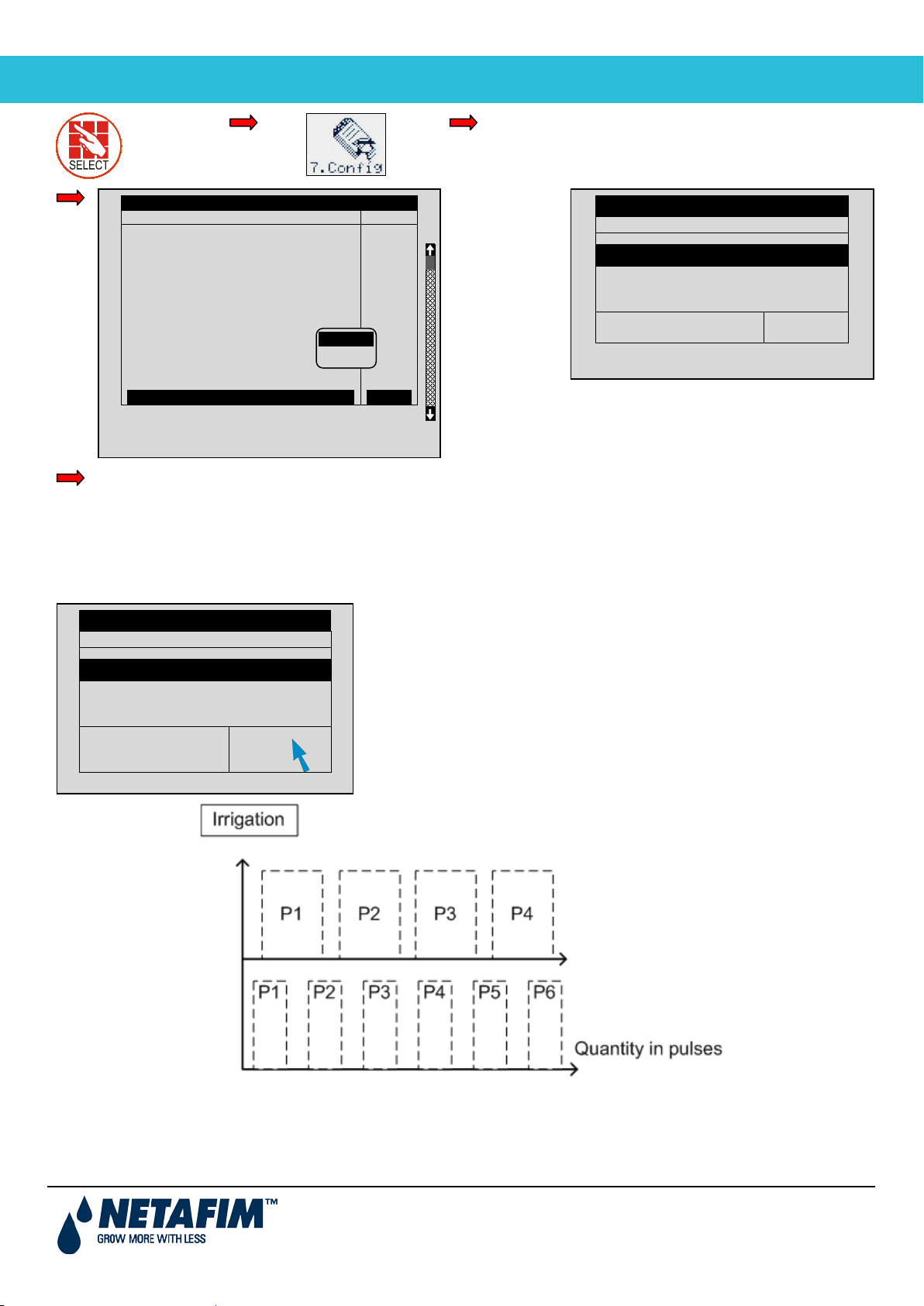

Main

Define

Back in Dosing Program menu, define Injection

Target PH

5.50

Program: 1

1

2

3

---

PH Dosing Method

QTY.

DOSING CONFIGURATION

EC Alarms

NO

BULK

Menu

7. Dosing Configuration

pH Alarms

Minimum On Time (sec)

Minimum Off Time (sec)

EC Coarse Tuning (0-10)

EC Fine Tuning (0-10)

pH Coarse Tuning (0-10)

pH Fine Tuning (0-10)

Control Cycle (sec)

EC/pH Averaging (0-Low, 20-High)

Dosing Boost. Off Delay (mm:ss)

Dosing by QTY. Method

SPREAD

NO

1.0

1.0

5

5

5

5

6

3

00:10

BULK

according to

Bulk or

Spread

DOSING PROGRA M

INJECTION PER DOSING CHANNEL

EC

4.00

EC Dosing Method

EC

5.00

ACID

2.00

QTY.

per Dosing Channel.

2.2.4.1 63BExample of Dosing by Quantity (Spread)

Using Quantity (Spread) is normally done in an open field. The following is an example of a Quantity (Spread)

configuration.

Program: 1

INJECTION PER DOSING CHANNEL

1

PASSIV

4.00

DOSING PROGRA M

2

PASSIV

5.00

3

ACID

2.00

---

---

---

---

---

Passive Method

PH Dosing Method

QTY.

P.QTY.

Ch. 1

Ch. 2

Spread Qty. = 4 liters

Spread Qty. = 5 liters

User Manual

Page 14

Page 15

NMC-PRO

PROGRAM MENU

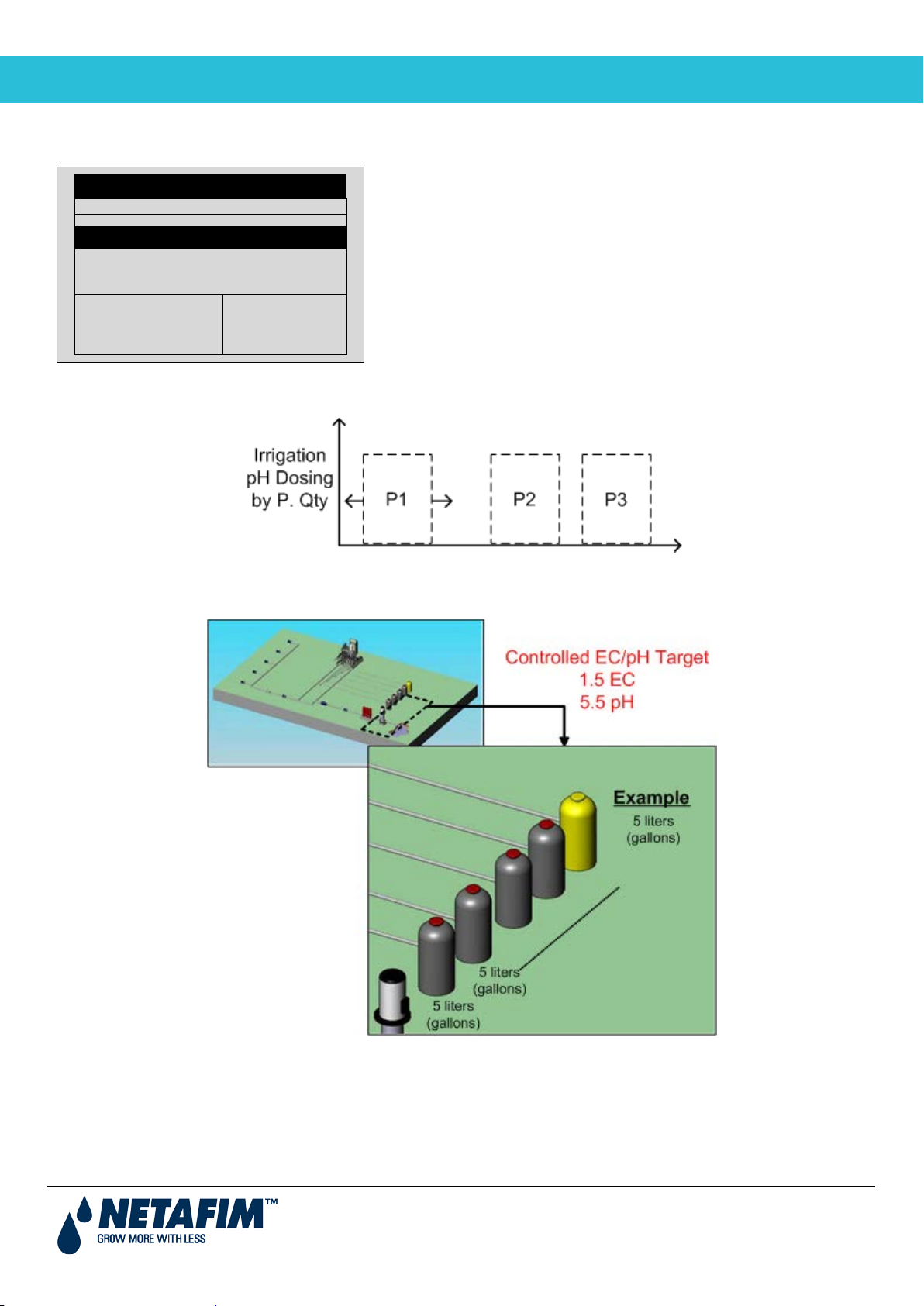

2.2.4.2 64BExample of Controlled EC/pH Based on Proportional Quantity

Define dosing program: Nutrient amount and desired EC/pH levels

Program: 1

1

2

3

---

The following is an example of how to configure the controller so that the pH is maintained at a certain level.

DOSING PROGRA M

INJECTION PER DOSING CHANNEL

EC

5.00

Target EC

Target PH

EC Dosing Method

PH Dosing Method

EC

5.00

1.50

5.50

P.QTY

P.QTY

ACID

5.00

---

---

**Channel 3 (Acid channel): pH is controlled at 5.50. To keep pH levels on target, the Pulse width (meaning the

quantity in each pulse) fluctuates according to controller calculations.

3 liter

1m³

pH Target = 5.5

User Manual

Page 15

Page 16

NMC-PRO

PROGRAM MENU

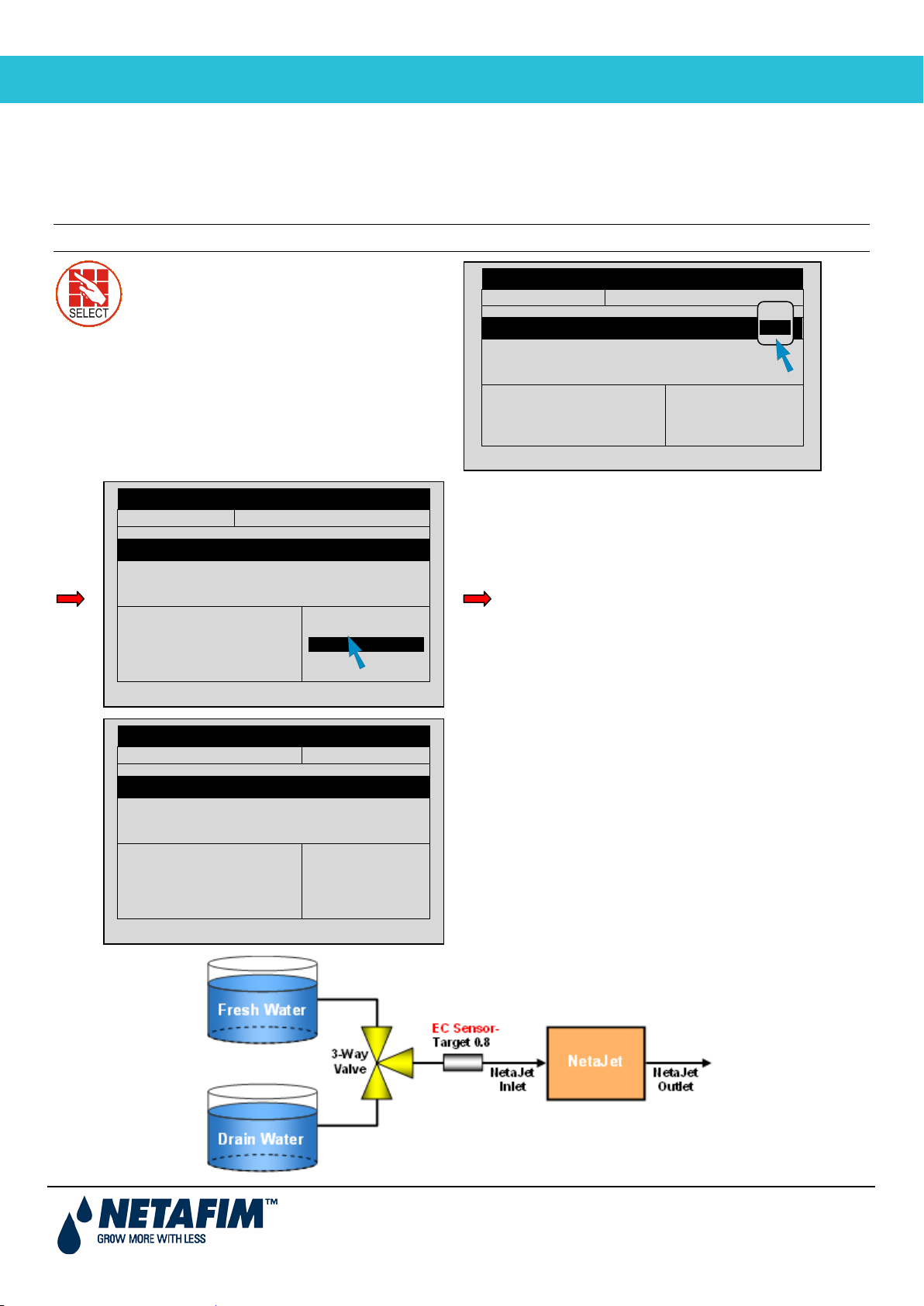

2.2.5 54BEC Pre-Control

EC Pre-Control ON (this enables

Program: 1

EC Pre-Control: ON

1

2

3

--Program: 1

EC Pre-Control:

1

2

3

---

Target EC

1.50

Program: 1

EC Pre-Control: ON

1

2

3

---

Target EC

1.50

Use this option in hydraulic pre-control systems in greenhouses. When collecting excess water from drains, the

grower can set an EC target before water goes through an irrigation system. This method reuses excess fertilizer and

water, recycling them for a second irrigation run.

Note: An EC Pre-Control valve relay must be defined by a technician at installation.

the control)

INJECTION PER DOSING CHANNEL

EC

2.00

Target EC

Target PH

EC Dosing Method

PH Dosing Method

DOSING PROGRA M

EC

ACID

5.00

3.00

1.50

5.50

P.QTY

P.QTY

OFF

ON

---

---

DOSING PROGRA M

INJECTION PER DOSING CHANNEL

EC

2.00

Target PH

Target EC Pre-Control

EC Dosing Method

PH Dosing Method

EC

5.00

ACID

3.00

5.50

-----

P.QTY

P.QTY

---

---

Define pre-controlled EC target

DOSING PROGRA M

INJECTION PER DOSING CHANNEL

EC

2.00

Target PH

Target EC Pre-Control

EC Dosing Method

PH Dosing Method

EC

5.00

ACID

3.00

5.50

0.80

P.QTY

P.QTY

---

---

User Manual

Page 16

Page 17

NMC-PRO

PROGRAM MENU

2.3 12BIrrigation Program

1. Irrigation

Select program

1. Program

DATE : 19-Apr-07 TIME : 16:12:32

Program: 4

Priority:

Const. 0%

Start Time

08:00 10:00

Day: 01/01

In the Irrigation Program screen, complete the irrigation setup.

.

In this screen define the following:

• Start time: This parameter defines the irrigation program time period. Each period begins at the defined time

and runs until the next defined time. Define up to six periods for each irrigation program. For example:

If you enter one time, the time period is 24 hours, starting from the time entered.

If you enter two times, the first period goes from first time defined until the second time. The second

period then starts and continues until the first time. For example in the screen below, the first period

starts at 8:00 and continues until 10:00. The second period begins at 10:00 and continues until 8:00

(the next day).

• Clock Start: This parameter defines the number of irrigation cycles within each time period. In the example

below, there are two cycles between 8:00 – 10:00 and three cycles from 10:00 – 8:00.

• Min. Time: The minimal amount of time between cycle starts

IRRIGATION PROGRAM

Clock Start

Min. Time

Valve #

Run Time #

Dosing Prog

2 3

01:00 01:00

001

1

1

Dose/Water 1 D

• Valve #: Select which irrigation valve(s) open(s) (refer to Setting Valve Sequence, page 18).

• Run Time #: Select the required Run Time Program (refer to Run Time Program, page 9).

• Dosing Prog: Select the required Dosing Program (refer to Dosing Progr am, page 11).

• Day: Type the current day/number of days in cycle (refer to Configur ing the Ir rigat ion Calendar, page 21).

• Dose/Water: For each day define the irrigation regime (refer to Configuring the Irrigation Calendar, page 21).

• Irrigation Adjustments: Along with irrigation programs based on time, NMC enables adjusting or running

irrigation based on the following:

Adjusting the Water Quantity Based on Weather Conditions, page 20

Irrigation Based on External Conditions, page 22

Irrigation Based on Radiation Sum, page 27Irrigation Based on VPD Sum , page 28

Introduction to the Influence Program, page 29

User Manual

Page 17

Page 18

NMC-PRO

PROGRAM MENU

2.3.1 Setting Valve Sequence

Example 2: Cycling Irrigation Program for Group of Two Valves

In this example, two valves operate simultaneously (valves operating together is a called a group). All other

DATE : 19-Apr-07 TIME : 16:12:32

Program: 4

Priority:

Const. 0%

Start Time

08:00

Day: 01/01

The following section provides examples on how to set the val ves’ sequence.

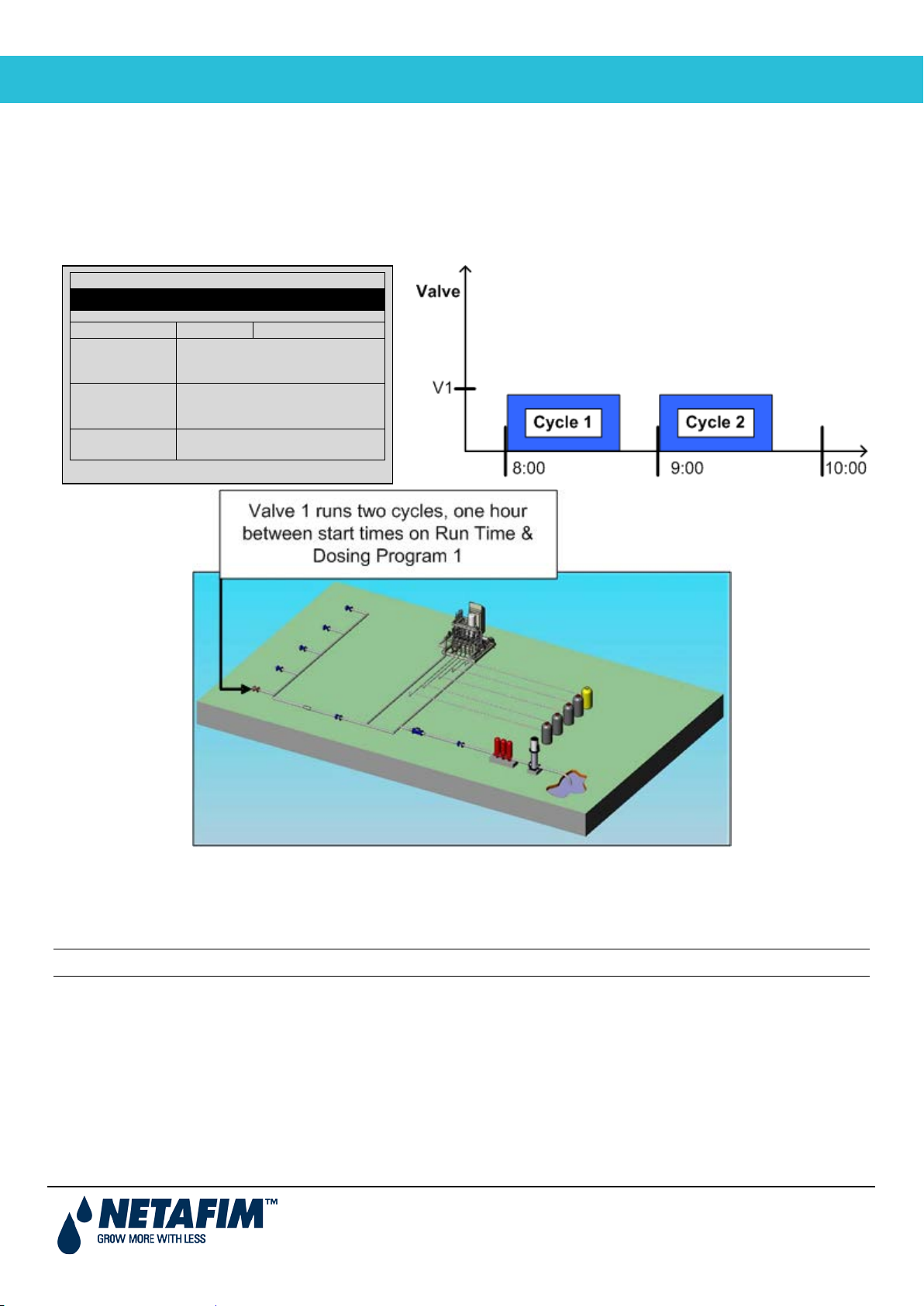

Example 1: Cycling Irrigation Program for One Valve

In the following example, Irrigation Program 4 begins running at 8:00 AM. There are two cycles, with one hour in

between each cycle. Irrigation is from one valve. Run Time program 1 and Dosing Program 1 are used.

IRRIGATION PROGRAM

Clock Start

Min. Time

Valve #

Run Time #

Dosing Prog

Dose/Water 1 D

2

01:00

001

1

1

specifications are the same as those found in Example 1.

Note: Valves in the same group must have the same run time.

User Manual

Page 18

Page 19

NMC-PRO

PROGRAM MENU

Example 3: Irrigation Program for a Group and Individual Valve

DATE : 19-Apr-07 TIME : 16:12:32

Program: 4

Priority:

Const. 0%

Start Time

08:00 10:30 12:30

Day: 01/03

1 2 3

DATE : 19-Apr-07 TIME : 16:12:32

IRRIGATION PROGRAM

Program: 4

Priority:

Const. 0%

Start Time

08:00

Day: 01/01

Clock Start

Min. Time

Valve #

Run Time #

Dosing Prog

Dose/Water 1 D

2

01:00

001 + 002

1 1

1 1

In this example, Valves 1 and 2 are designated as a group. Valve 3 is designated as an individual valve. There are

different/interchangeable delays (multiple start time) dividing the day into periods.

The first cycle’s (C1) run time begins at 8:00 (Valve 1 and 2). Valve 3 begins operating at its run time. In this example,

Valve 3 begins operating after Valve 1 and 2 finishes. This process is repeated once (C2), with a break of one hour

between cycle start times.

Cycle 3 (C3) begins at 10:30. In this cycle, there is a 30 minute break between cycles (C4). The process continues as

shown in the graph below.

Clock Start

Min. Time

Valve #

Run Time #

Dosing Prog

Dose/Water

IRRIGATION PROGRAM

2 2 2

01:00 00:30 01:00

001 + 002 003

1 1 2

1 1 2

D W D

User Manual

Page 19

Page 20

NMC-PRO

PROGRAM MENU

Start Time

Min. Time

08:00 10:30

01:00 00:30

Valve #

001+002 003

2.3.2 Adjusting the Water Quantity Based on Weather Conditions

The NMC Irrigation Pro enables you to manually increase or decrease the quantity of water on any given day.

Depending on the weather c ondit ions , you can change the quantity of water emitted from valves without changing the

program.

Example 4: Increasing Irrigation

In this example, water is supplemented by 20% to compensate for an increase in heat. If the regular run time is 10

minutes, the actual run time will be 12 minutes. All other specifications are the same as those found in Example 3.

Note: The change to the programs affects both Valves 1 and 2, and Valve 3.

Note: Dosing is not affected when using this function, only the quantity of water.

There are two options:

• Daily: Program adjustment is for one day only. Regular program resumes the following day.

• Const: Program adjustment continues until changed.

DATE : 19-Apr-07 TIME : 16:12:32

IRRIGATION PROGRAM

Program: 4 Priority: Daily 20%

Clock Start

2 2

Run Time #

Dosing Prog

Day: 01/01

Dose/Water

1 1 2

1 1 2

1 2 3

D W -

User Manual

Page 20

Page 21

NMC-PRO

PROGRAM MENU

Example 5: Decreasing Irrigation

1 2 3 4 5 6 7 X X X X

X

Irrigation by dosing or water

DATE : 19-Apr-07 TIME : 16:12:32

Program: 4

Priority:

Daily -10%

Valve #

001+002 003

Dose/Water

D -

DATE : 19-Apr-07 TIME : 16:12:32

Program: 4

Priority:

Daily 20%

Start Time

08:00 10:30

Day: 04/07

Dose/Water

1 2 3 4 5 6 7

D - D W D - D

In this example, irrigation is decreased by 10% to compensate for a decrease in heat. If the regular run time is 10

minutes, the actual run time is nine minutes.

IRRIGATION PROGRAM

Start Time

Clock Start

Min. Time

Run Time #

Dosing Prog

Day: 01/01

08:00 10:30

2 2

01:00 00:30

1 1 2

1 1 2

1

2.3.3 Configuring the Irrigation Calendar

NMC-Pro enables scheduling irrigation programs by:

• Daily calendar

• Irrigation by dosing or water

When setting up a schedule, configure the following:

• Day: X/Y

X represents the first day that the cycle begins. For example, if you want to define the first day of

the cycle as day 4, define X as 4.

Y represents the length of the cycle. If the length is 7 days, define Y as 7. You can schedule up

to 14 days.

• Dose/Water: For each day, define what the regime type for each day:

Dose: Water and dosing

Water: Water only

None: No irrigation

Clock Start

Min. Time

Valve #

Run Time #

Dosing Prog

IRRIGATION PROGRAM

2 2

01:00 00:30

001+002 003

1 1 2

1 1 2

AND

Select the daily calendar

User Manual

Page 21

Page 22

NMC-PRO

PROGRAM MENU

D - D W D - D

DATE : 19-Apr-07TIME : 16:12:32

IRRIGATION PROGRAM

Program: 4

Priority: --

Daily 20%

Start Time

08:00 10:30

Day: 04/07

1 2 3 4 5 6 7

Dose

In this example, the seven day cycle begins on the

fourth day (04/07). On the fourth day, the irrigation is

water only (no dosing).

1 2 3 4 5 6 7

Clock Start

Min. Time

Valve #

Run Time #

Dosing Prog

Dose/Water

2 2

01:00 00:30

001+002 003

Water

1 1

None

1 1

D - D W D - D

2.4 13BIrrigation Based on External Conditions

Irrigation can be controlled by input from dry contact or analog sensor triggers.

• If the Irrigation Program is active, these programs can only function after the Irrigation Program is completed.

• If the Irrigation Program is inactive, these programs can function during the defined time frame.

• In both cases, irrigation begins only when external conditions meet the user-defined requirements.

Irrigation programs can be controlled via dry contact input or analog sensors from peripheral equipment (for example,

filling a water tank according to level float switch). When using dry contacts or analog sensors, set the following:

• Time frame that the program can operation

• Which trigger input starts and stops irrigation

• The trigger type:

One Shot: Irrigation runs once

Multi Shot: Irrigation continues to run until a stop signal is received

Only If On: Used when there is one switch only. Irrigation continues as long as switch remains on

NMC Pro supports up to 15 extension programs defining which trigger initiates irrigation. In each program, the start

and stop trigger must be the same type (meaning both must be dry contact or analog sensor).

User Manual

Page 22

Page 23

NMC-PRO

PROGRAM MENU

To configure an irrigation program triggered by external condition:

1. Irrigation

Select dry contact to start and stop

DATE : 1-May-07 TIME : 10:12:09

Const.

1. Program

Start

Trigger

Stop

1

7

Dry Con 1

<NONE>

One Shot

One Shot

Dry Con

<NONE>

One Shot

1. Program

1

07:00

18:00

Dry Con 1

Start

Trigger

Stop

1

8

Dry Con 1

<NONE>

One

Shot

Dry Con 2

<NONE>

IRRIGATION PROGRAM

Program: 1 Priority: -- Cond. 1

Start Time

Clock Start

Contact

Min. Time

Max. Time

Valve #

Run Time #

Dosing Prog

07:00

1

ON

--:--

--:--

001

1

1

For Next Screen Press The DOWN Arrow

The following sections detail how to set up the dry contact and analog sensor triggers.

2.4.1 55BSetting the Dry Contacts

The following section details how to set dry contact to control irrigation.

4. Ext.

Condition

This is the

time frame

in which the

condition (if

true) can

operate

EXTERNAL CONDITION PROG RA M

#

2

3

4

5

6

7

8

From

hh:mm

--:--

--:--

--:--

--:--

--:--

--:--

--:--

08:00

-300

00:30

--:--

To

hh:mm

--:--

--:--

--:--

--:--

--:--

--:--

--:--

10:00

--

150

Daily

00:20

Cond.

--:--

Rad Sum

Start

Dry Cont.

<NONE>

<NONE>

<NONE>

<NONE>

<NONE>

<NONE>

<NONE>

1

----

--:-

-

--:-

-

Select trigger type

EXTERNAL CONDITION PROGRAM

#

Dry Cont.

2

<NONE>

3

<NONE>

4

<NONE>

5

<NONE>

6

<NONE>

external condition program.

Type

One Shot

One Shot

One Shot

One Shot

One Shot

Dry

Cont.

Multi Shot

2

<NONE>

<NONE>

<NONE>

<NONE>

EXTERNAL CONDITION PROG RA M

#

2

3

4

5

6

7

Dry Cont.

<NONE>

<NONE>

<NONE>

<NONE>

<NONE>

<NONE>

Type

Shot

One

Shot

One

Shot

One

Dry Cont.

<NONE>

<NONE>

<NONE>

<NONE>

<NONE>

<NONE>

User Manual

Page 23

Page 24

NMC-PRO

PROGRAM MENU

Num.

Sensor Type

Min Value

Max Value

3

ECh20

7

45

4

Netasense

7

45

Gen. Sensor

Temperature

Num.

Sensor Type

Min Value

Max Value

2

->

->

-> 3 ->

->

->

Example of Tank Filling:

Water Tank with Floats

2.4.2 56BConfiguring the Analog Sensors

The following section details how to configure analog sensors to control irrigation.

Note: In general, a technician performs steps 1 and 2 during installation. The user only begins from step 3.

1. In Setup > Analog Conversion Table:

a. Select the sensor type. Each sensor has default values assigned to it.

Netasense: 7 – 45

ECH20: 0 – 60

General Sensor: 0.2 - 10

b. If required, edit the values.

ANALOG CONVERSION TABLE

1

4

->

->

->

->

->

->

2. In Test > Analog Sensor, view the actual sensor values.

ANALOG CONVERSION TABLE

1 7 45

2 <NONE> 7 45

User Manual

Page 24

Page 25

NMC-PRO

PROGRAM MENU

c. Define The Trigger Type.

d. Under Stop An. Dry Con., define the input type.

3

Ana. Sen 2

Dry Con 14

---

4

Ana. Sen 3

<NONE>

---

6

Ana. Sen 5

<NONE>

---

7

Ana. Sen 6

<NONE>

---

8 <NONE>

---

3

One Shot

Dry Con 14

Multi Shot

4

One Shot

<NONE>

Only If On

5

One Shot

<NONE>

---

6

One Shot

<NONE>

---

7

One Shot

<NONE>

---

8

One Shot

<NONE>

---

3

Ana. Sen 2

13:00

Dry Con 1

4

Ana. Sen 3

--:--

<NONE>

6

Ana. Sen 5

--:--

<NONE>

7

Ana. Sen 6

--:--

<NONE>

8 --:--

<NONE>

2

11:00

12:00

Dry Con 1

5

--:--

--:--

<NONE>

6

--:--

--:--

<NONE>

7

--:--

--:--

<NONE>

8

--:--

--:--

<NONE>

ANALOG SENSOR

1

Netasense

11

3

Netasense

33

6

ECh20

25

8

ECh20

51

9

Temperature

21

No. Type Value

2 Netasense 22

4 Gen. Sensor 7

5 Gen. Sensor 3

7 ECh20 32

10 Temperature 21

3. In Program > Ext Condition, configure the External Condition Program for the analog sensors.

a. Enter the beginning and ending time for each

program

EXTERNAL CONDITION PROG RA M

# From

hh:mm

1 10:00 12:00 Ana. Sen 1

3 12:00 13:00 Dry Con 1

4 --:-- --:-- <NONE>

EXTERNAL CONDITION PROG RA M

# Trigger Type Stop An

1 Multi Shot Ana. Sen 2 --2 Multi Shot Dry Con 2 One Shot

To hh:mm Start An.

Dry Cont.

Dry Cont.

Oper.

to Start

b. Under Start An. Dry Cont., define the input type.

EXTERNAL CONDITION PROG RA M

# From

hh:mm

1 12:00 Ana. Sen 1

2 Ana. Sen 1 12:00 Dry Con 1

5 Ana. Sen 4 --:-- <NONE>

To

hh:mm

Start An.

Dry Cont.

EXTERNAL CONDITION PROGRAM

# Trigger Type Stop An

Dry Cont.

1 Ana. Sen 2 --2 Ana. Sen 1 Dry Con 2 ---

Oper.

to Start

5 Ana. Sen 4 <NONE> ---

User Manual

Page 25

Page 26

NMC-PRO

PROGRAM MENU

e. Under Oper. to Start, choose the required symbol. f. Under Oper. To Stop, choose the required symbol.

Symbol

Definition

---

No operation

=

The analog sensor function value is equal to the start/stop value. There is a ± 1%

#

Start

Oper.

Stop

1

25 = 20

3

---

---

---

4

---

---

---

6

---

---

---

7

---

---

---

#

Oper.

Start Value

Oper.

1 25

=

2

---

---

---

5 = ---

---

6 > ---

---

7

>=

---

---

#

Stop An

Oper.

Start

1

Ana. Sen 2 >

2

Dry Con 2

---

---

5

<NONE>

---

=

6

<NONE>

---

>

7

<NONE>

---

>=

EXTERNAL CONDITION PROG RA M

Dry Cont.

3 Dry Con 14 --- <

4 <NONE> --- <=

8 <NONE> ---

to Start

Value

g. Under Start Value, enter the required value to start

the analog sensor. Under Stop Value, entered the

required value to stop the analog sensor.

EXTERNAL CONDITION PROG RA M

Value

2 --- --- ---

5 --- --- ---

to Stop

Value

EXTERNAL CONDITION PROG RA M

to Start

3 < --- --4 <= --- ---

8 --- --- ---

to Stop

8 --- --- ---

In the examples given above, irrigation has been set to start when the analog input is greater than 25 and irrigation

stops when the input is 20.

Oper. to Start and Oper. to Stop require a logical operation. The following table defines these symbols:

<, <= The analog sensor function value is less than/less than or equal to the start/stop

value.

allowable deviation.

>, >= The analog sensor function value is greater than/greater than or equal to the

start/stop value.

User Manual

Page 26

Page 27

NMC-PRO

PROGRAM MENU

2.5 14BIrrigation Based on Radiation Sum

Valve #

001

DATE : 1-May-07 TIME : 10:12:09

Program: 1

Priority: --

Rad Sum

Start Time

07:00

08:00

10:00

Valve #

001

1. Program

NMC Pro enables setting an irrigation trigger based on a radiation sum limit (joul/cm² = energy).

When using this option, set the following:

• Start Time: Start Time is when the unit begins measuring radiation levels to implement the irr igat ion pr ogram.

• Clock Start: Number of cycles. 0 (zero) means that this program is disabled. 1 (one) means that this program

runs one time after time-based irrigation is completed. 2 (two) means that the program runs twice, and so on.

• Radiation Sum Limit: This parameter determines the minimal amount of accumulated radiation required for

irrigation to start.

• Minimum Time: When irrigation begins, NMC Pro erases the current radiation sum and restarts the count.

Minimum time is the minimal amount of time between irrigation starts, even if the radiation sum has reached

its limit.

• Maximum Time: This parameter determines the maximum amount of time between irrigation starts, even if

the sum limit has not been reached.

1. Irrigation

Clock Start

Rad Sum Li.

Min. Time

Max. Time

IRRIGATION PROGRAM

1

100

--:--

--:30

-300

00:30

--:--

--

Const.

150

Daily

00:20

Cond.

--:--

Rad Sum

1

----

--:-

-

--:-

-

Run Time #

Dosing Prog

DATE : 1-May-07 TIME : 10:12:09

Program: 1 Priority: -- Rad Sum

Start Time

Clock Start

Rad Sum Li.

Min. Time

Max. Time

Run Time #

Dosing Prog

1

1

For Next Screen Press The DOWN Arrow

IRRIGATION PROGRAM

07:00

1

100

--:--

--:30

1

1

For Next Screen Press The DOWN Arrow

08:00

-300

00:30

01:00

10:00-

150

00:20

01:00

16:00

--

----

--:--

--:--

User Manual

Page 27

Page 28

NMC-PRO

PROGRAM MENU

In the example below, between 8:00 – 10:00, the Radiation Sum Limit is 300; between 10:00 – 16:00 the limit is 150.

1. Irrigation

1. Program

DATE : 1-May-07 TIME : 10:12:09

Program: 1

Priority: --

VPD Sum

Start Time

07:00

08:00

10:00

DATE : 1-May-07 TIME : 10:12:09

Program: 1

Priority: --

VPD Sum

Max. Time

--:--

01:00

01:00

--:--

Valve #

001

Since during the afternoon hours there is a greater amount of sunlight, the user lowered the limit to ensure that they

receive sufficient amounts of irrigation.

2.6 15BIrrigation Based on VPD Sum

NMC Pro enables setting an irrigation trigger based on Vapor Pressure Deficit (kPa•min). The Vapor Pressure Deficit

(VPD) is a measurement which incorporates both the relative humidity (RH) and the temperature. When the VPD is

high, that means that the RH is low or the temperature is high. Irrigation begins when the VPD reaches the userdefined limit.

Irrigation based on VPD Sum can take place only during the VPD time frame. Refer to 6.1 SETUP > TIME & DATE to

define the start and end time for VPD Sum. Normally, this parameter is defined during installation.

Clock Start

Rad Sum Li.

Min. Time

Max. Time

Valve #

Run Time #

Dosing Prog

IRRIGATION PROGRAM

1

----

--:--

--:- 001

1

1

-30

00:30

--:--

Daily

Cond.

Rad Sum

--

VPD Sum

150

00:20

--:--

1

----

--:--

--:--

Start Time

Clock Start

VPD Sum Li.

Min. Time

Run Time #

Dosing Prog

For Next Screen Press The DOWN Arrow

IRRIGATION PROGRAM

07:00

1

----

--:--

1

1

08:00

-30

00:30

10:00

-15

00:20

16:00

--

----

--:--

• Start Time: Start Time is when the unit begins measuring and calculating VPD levels to implement the

irrigation program.

• Clock Start: Number of cycles. 0 (zero) means that this program is disabled. 1 (one) means that this program

runs one time after time-based irrigation is completed. 2 (two) means that the program runs twice, and so on.

User Manual

Page 28

Page 29

NMC-PRO

PROGRAM MENU

• VPD Sum Limit: This parameter determines the minimal (accumulated) VPD required for irrigation to start.

• Minimum Time: When irrigation begins, NMC Pro erases the current VPD sum and restarts the count.

Minimum time is the minimal amount of time between irrigation starts, even if the radiation sum has reached

its limit.

• Maximum Time: This parameter determines the maximum amount of time between irrigation starts, even if

the VPD limit has not been reached.

2.7 16BIntroduction to the Influence Program

Irrigation Pro enables adjusting irrigation settings according the following factors (labeled “Influences” on the screen):

• Solar radiation

• Amount of drainage

• Amount of fertilizer present in the drainage

• VPD

• Temperature

These Influences can adjust the following irrigation settings:

• EC

• Radiation Sum (RadS)

• Minimum Rest Time (MinT)

For example, a grower may want to increase the EC based on the Solar Radiation. Alternatively, he may want to

decrease the MinT based on the drainage.

2.8 17BUsing the Influences

• Set an Influence to increase or decrease the setting.

• Changes to the setting are in percentages (for example, a 10% increase in the EC level).

• Several Influences adjust the EC setting. The final adjustment amount is based on the sum total of the

different Influences.

• You enter up to three points for each Influence setting. Irrigation Pro automatically calculates the curve based

on these points.

• You can program up to 15 different programs (corresponding to the 15 irrigation programs)

• After configuring an Influence, you must enable it (under ACTIVE/SOURCE).

2.8.1 57BSetting the Influences

1. Go to Install > Device Layout .

2. Define relays as dosing channels, as required.

3. Go to Program > Irrigation.

4. Using the arrow keys, scroll down to Screen 2. The following screen appears.

User Manual

Page 29

Page 30

NMC-PRO

PROGRAM MENU

DATE: 2 –Feb-12 TIME 12:52-08

IRRIGATION PROGRAM

INFLUENCE

TABLE

ACTIVE/SOURCE

Radia./EC

NO

Drain/RadS

NO

Drain/MinT

NO

EC Drain/EC

NO

Program: 1 Priority: -- Const. 0%

VPD/EC

Temp/EC

Screen 2 of 2 – In order to view the

NO

NO

5. Set the required Influences to YES.

The following sections detail each Influence.

Note: The following sections include examples. These examples are not meant to be actual numbers used in

practice; they simply illustrate the operating principles. Consult with your local extension agent for actual

specifications.

2.8.2 Radiation Influence on Target EC

This function enables adjusting the EC based on solar radiation. Solar radiation increases the greenhouse

temperature. Adjust the EC according to your crops’ requirements.

To set the Radiation Influence:

1. In Installation > Analog Input , define a sensor as EC.

2. In Configuration > Dosing Channel Configuration, set React to EC.

3. In Configuration > Dosing Configuration > EC Control to Yes .

4. In Program > Irrigation, select Radia./EC.

5. Define the Radiation set points (w/m2).

6. Define the EC change in percentages.

7. Set ACTIVE/SOURCE to Yes.

8. Press Menu and confirm changes.

9. In Program > Dosing Program, set:

a. the Target EC

b. EC Dosing Method to Qty

User Manual

Page 30

Page 31

NMC-PRO

PROGRAM MENU

Example: As sunlight increases, a crop needs lower EC levels. The following screen illustrates increasing in the EC

DATE: 2 –Feb-12 TIME 12:52-08

Program: 1

Priority: --

Const. 0%

INFLUENCE

TABLE

ACTIVE/SOURCE

Drain/RadS

(w/m2)

(%)

Drain/MinT

200

0

VPD/EC

800

-20

Temp/EC

Screen 2 of 2 – In order to view the

based on radiation. Since Irrigation Pro calculates the decrease in EC proportionally, there will be a 15% decrease

when the radiation reaches 600 w/m2.

IRRIGATION PROGRAM

Radia./EC

Radia. EC

EC Drain/EC

400 -10

2.8.3 58BDrainage Influence on Target Radiation Sum

Irrigation can be triggered by the Radiation Sum (Rad Sum). This Influence enables adjusting the Rad Sum based on

the amount of drainage.

To set the Drainage Influence on Rad Sum:

1. In Program > Irrigation, set Contr. to Rad Sum.

2. In Installation > Digital Input , define which digital input is the drain meter.

Note: The drainage must be defined correctly! You can check the drainage meter status using Hot key 9.

3. In Configuration > Valve Configuration define which valve number corresponds to which drainage meter.

4. In Configuration > Drainage Configuration, define the drainage meter’s Ratio Liter/Pulse.

User Manual

Page 31

Page 32

NMC-PRO

PROGRAM MENU

5. In Program > Irrigation, select Drain/RadS.

DATE: 2 –Feb-12 TIME 12:52-08

Program: 1

Priority: --

Const. 0%

INFLUENCE

TABLE

ACTIVE/SOURCE

Drain/RadS

(%)

(%)

Drain/MinT

20

-10

VPD/EC

55

30

Temp/EC

Screen 2 of 2 – In order to view the

a. Define the Drainage percentage set points.

b. Define the RadS percentage set points.

6. Set ACTIVE/SOURCE to Yes.

7. Press Menu and confirm changes.

Example: A user set irrigation to be triggered by the radiation sum. As can be seen, the increases are not

proportional.

IRRIGATION PROGRAM

Radia./EC

DRAIN% RadS

EC Drain/EC

30 10

2.8.4 59BDrain Influence on Minimum Time

Minimum time defines the minimum break between irrigations. Even if the Rad/VPD sum limit / condition limit has

been reached irrigation does not take place until this time has passed. This function enables adjusting the Minimum

Time based on the drainage.

To set the Drainage Influence on the Minimum Time:

1. In Installation > Digital Input , def ine which digital input is the drain meter.

Note: The drainage must be defined correctly! You can check the drainage meter status using Hot key 9.

2. In Configuration > Valve Configuration define which va lv e num ber corresponds to which drainage meter.

3. In Configuration > Drainage Configuration, define the drainage meter’s Ratio Liter/Pulse.

4. In Program > Irrigation, select Drain/MinT.

a. Define the Drainage percentage set points.

User Manual

Page 32

Page 33

NMC-PRO

PROGRAM MENU

b. Define the MinT percentage set points.

DATE: 2 –Feb-12 TIME 12: 52-08

Radia./EC

DRAIN%

MinT

Drain/RadS

(%)

(%)

Drain/MinT

20

-25

Temp/EC

5. Set ACTIVE/SOURCE to Yes.

6. Press Menu and confirm changes.

Example: When drainage is low, a user wants to decrease the Minimum Time. He sets 20% drainage to a MinT of

-25%. As drainage increases, the time between irrigation increases. In this scenario, if the MinT is set to 60 minutes,

40% drainage adjusts the time to 75 minutes.

IRRIGATION PROGRAM

Program: 1 Priority: -- Const. 0%

INFLUENCE TABLE ACTIVE/SOURCE

EC Drain/EC

VPD/EC

40 25

2.8.5 60BDrai na ge E C Level Inf luence on Target EC

If you have installed an EC sensor in the drainage, you can adjust the Target EC level based on the drainage EC

level. This can be used, for example, to lower the EC input if EC levels in the drainage are above specifications.

To set the EC Drainage Influence on the EC:

User Manual

Page 33

Page 34

NMC-PRO

PROGRAM MENU

1. In Installation > Analog Input:

DATE: 2 –Feb-12 TIME 12:52-08

Program: 1

Priority: --

Const. 0%

Radia./EC

EC Drain / EC

Drain/MinT

1

0

EC Drain/EC

2

-10

Temp/EC

Screen 2 of 2 – In order to view the

a. Define a sensor as EC.

b. Define a sensor as EC drain.

2. In Installation > Digital Input define which digital input is the drain meter.

Note: The drainage must be defined correctly! You can check the drainage meter status using Hot Key 9.

3. In Configuration > Valve Configura tio n def ine which va lv e num ber corr es ponds t o which dra in age m eter.

4. In Configuration > Dosing Channel Configuration set React to EC.

5. In Configuration > Dosing Configuration > EC Control to Yes .

6. In Configuration > Drainage Configuration, define the drainage meter’s Ratio Liter/Pulse.

7. In Program > Irrigation, select EC Drain/EC.

a. Define the EC Drain percentage set points.

b. Define the EC percentage set points.

8. Set ACTIVE/SOURCE to Yes.

9. Press Menu and confirm changes.

10. In Program > Dosing Program set the Target EC.

Note: You can disable this function by disabling EC Control (Configuration > Dosing Configuration).

IRRIGATION PROGRAM

INFLUENCE TABLE ACTIVE/SOURCE

Drain/RadS

VPD/EC

mS/cm (%)

3 -20

Example: A user wants to maintain an EC level of 1.5. To this end, he measures the drainage EC. When the drainage

EC falls below 1.5, he increases the EC input. As it rises above 1.5 ms/cm, he decreases the input.

User Manual

Page 34

Page 35

NMC-PRO

PROGRAM MENU

2.8.6 61BVPD Infl ue nc e on Target EC

You can adjust the EC based on the VPD Sum (air temperature and humidity). As the VPD rises or falls, the program

can increase or decrease the EC level according to your requirements.

1. In Installation > Analog Input define:

a. a sensor as EC.

b. an air temperature sensor.

c. a humidity sensor.

Note: You can verify the EC status using Hot Key Screen, the temperature and humidity sensors status using Hot

Key Screen 6.

2. In Setup > VPD Sensor Setup, enable VPD Temperature and VPD Humidity sensors.

3. In Configuration > Dosing Channel Configuration set React to EC.

4. In Configuration > Dosing Configuration > EC Control, set EC Control to Yes.

5. In Program > Irrigation, select VPD/EC.

a. Define the VPD sum points.

b. Define the EC percentage set points.

6. Set ACTIVE/SOURCE to Yes.

7. In Program > Dosing Program:

a. Set the Target EC.

b. Set EC Dosing Method to Qty.

User Manual

Page 35

Page 36

NMC-PRO

PROGRAM MENU

Example: A grower wants to lower the EC as the kPa decreases. He sets this screen to reduce the increase in EC to

DATE: 2 –Feb-12 TIME 12:52-08

Program: 1

Priority: --

NO

0%

INFLUENCE

TABLE

OUT temp

Drain/RadS

Temp 3

Drain/MinT

Temp 4

VPD/EC

NO

Temp/EC

NO

DATE: 2 –Feb-12 TIME 12:52-08

INFLUENCE

TABLE

ACTIVE/SOURCE

Radia./EC

VPD

EC

EC Drain/EC

10

4

VPD/EC

5

2

Temp/EC

Screen 2 of 2 – In order to view the

match the decreasing VPD levels.

IRRIGATION PROGRAM

Program: 1 Priority: -- Const. 0%

Drain/RadS

Drain/MinT

(kPa) (%)

15 7

2.8.7 62BTemperature Influence on Target EC

You can adjust the EC based on the air temperature. As the temperature rises or falls, the program can increase or

decrease the EC level according to your requirements.

1. In Installation > Analog Input define:

a. a sensor as EC

b. an air temperature sensor

Note: You can verify the EC status using Hot Key Screen 4, the temperature sensor status using Hot Key

Screen 6.

2. In Configuration > Dosing Channel Configuration set React to EC.

3. In Configuration > Dosing Configuration > EC Control, set EC Control to Yes.

4. In Program > Irrigation, select Temp/EC.

a. Define the Temperature sum points.

b. Define the EC percentage set points.

5. Set ACTIVE/SOURCE, select the temperature sensor number.

IRRIGATION PROGRAM

Temp 1

Radia./EC

EC Drain/EC

Screen 2 of 2 – In order to view the

Temp 2

N/A

6. In Program > Dosing Program:

a. set the Target EC.

b. set EC Dosing Method to Qty.

Example: A grower’s flower crop requires higher EC levels when the temperature goes above room temperature 22°

C). Using this screen, he can adjust the levels accordingly.

User Manual

Page 36

Page 37

NMC-PRO

PROGRAM MENU

5. Agitator

Define On/Off time during dosing

DATE: 2 –Feb-12 TIME 12:52-08

IRRIGATION PROGRAM

INFLUENCE

PRIORITY

ACTIVE/SOURCE

Radia./EC

Temp

EC

Drain/RadS

(°C/F))

(%)

Drain/MinT

25

2

EC Drain/EC

27

5

Screen 2 of 2 – In order to view the

1. Program

mm:ss

mm:ss

Dosing Active

Operation Mode

Parallel

On

Off

Dosing Active

01:00

05:00

mm:ss

mm:ss

Dosing Active

01:00

05:00

Operation Mode

Serial

Parallel

Program: 1 Priority: -- Const. 0%

VPD/EC

Temp/EC

30 7

TEMP1

2.9 18BAgitator

Use this screen to operate fertilizer tanks equipped with mixing devices.

and when system is idle

On

Dosing Not

Active

Dosing Not Active

Operation Mode Parallel

AGITATOR

--:--

--:--

AGITATOR

mm:ss

05:00

Serial

Off

--:--

--:--

mm:ss

60:00

• Select Parallel to operate

more than one agitator

simultaneously

• Select Serial if not enough

power to operate more than

one agitator at a time

AGITATOR

On

Off

Dosing Not Active

05:00

60:00

User Manual

Page 37

Page 38

NMC-PRO

PROGRAM MENU

2.10

19B

6. Selector

20B

7. Filter

1. Program

1. Program

Dosing Prog.

Time Between Flushing (hh:mm)

02:00

Water Fill Up (min)

1

Selector

Use this screen to operate more than one fertilizer tank (containing different fertilizers) attached to a single dosing

channel. The program enables taking fertilizer from different tanks (according to the dosing program).

2.11

Filter Flushing

Use this screen to program filter flushing during irrigation.

Flushing

1

2

3

4

5

6

7

8

9

Flushing Time (mm:ss)

Delay Between Filters (mm:ss)

Delta Pressure (Digital)

Delta Pressure Valve (bar)

Delay Delta Pressure (mm:ss)

Delta P ressure Reiteration

Dwell Time Main (mm:ss)

FILTER FLUSHING PROGRAM

SELECTOR

S1 S2

00:10

00:05

YES

0.5

00:06

3

00:10

Item Description

Time Between Flushing

Flush Time Flush time per filter.

Delay Between Filters Set delay between the flushing of each filter (to bui ld up pressur e).

Note: Filter flush process can start only after main water line is full. The default time is one minute; see Menu 3.3.

ALARM DEFINITION

Water Leak (m3)

Water Leak Period (hh:mm)

Identify Leak-Subtr. Meter?

Dosing Channel Leak Delay(s)

Dosing Channel Leak (Pulse)

Dosing Flow Difference (%)

Missing Pulses For No Flow

Stop System Cons. Flow Alarm s

# of Irrig. Without Drainage

1.000

00:30

NO

3

10

25

10

-3

Note: See graph on next page for further information on these fields.

Flush occurs after the accumulated irrigation time (between all valves). Break

time between irrigation are not included. Only one filter is cleaned at a time.

Delta Pressure

Set flush by pressure sensor. Pressure at filter inlet/outlet, if there is a significant

difference, a filter may be blocked.

User Manual

Page 38

Page 39

NMC-PRO

PROGRAM MENU

Item Description

Delta Pressure Value (sensor) If there is a differential, (DP signal or Analog DP value), a flush is needed.

Delta Pressure Delay Set delay to verify if there is a definite blockage.

Delta Pressure Reiteration

Dwell Time Main

Set to give signal after XX flushes. If Delta Pressure still indicates a blockage, an

alarm will be raised.

Open main filter valve before flush to balance pressure for a reliable flushing

process.

User Manual

Page 39

Page 40

NMC-PRO

PROGRAM MENU

User Manual

Page 40

Page 41

NMC-PRO

PROGRAM MENU

2.12

21B

8. Cooling

Set On/Off time and select sensors

Temp. Sens. 1

Hum. Sens. 1

+1 of each sensor: uses average of both

Dynamic cooling: 2 temp. threshold, same Hum

On time is set.

1. Program

Cooling

This screen sets a cooling program for cooling/humidification process in greenhouses. This program operates

according to temperature, humidity or time (to reduce temperature, increase humidity.)

Program: 1 Status: Cooling

Below RH On Off

1

2

Cool# 1 2 - - - - - - - -

Temp. Sens.: 1 -- Hum. Sens.: 1 --

Program: 1 Status: Cooling

From To Above t°

1

2

Cool# 1 2 - - - - - - - -

Temp. Sens.: 1 2-- Hum. Sens.: 1 2

Program: 1 Status: Cooling

Below RH On Off

1

2

Cool# 1 2 - - - - - - - Temp. Sens.: 1 2-- Hum. Sens.: 1 2

COOLING/HUMIDIFICATION PROGRAM

80

---

COOLING/HUMIDIFICATION PROGRAM

80

80

COOLING/HUMIDIFICATION PROGRAM

80

80

00:00:10

--:--:--

16:00

16:00

00:00:10

00:00:10

00:00:10

--:--:--

25.0

35.0

00:00:10

00:00:10

OR

COOLING/HUMIDIFICATION PROGRAM

Program: 1 Status: Cooling

Below RH On Off

1

2

Cool# 1 2 - - - - - - - -

Temp. Sens.: 1 2 Hum. Sens.: 1 2

80

---

00:00:10

--:--:--

00:00:10

--:--:--

COOLING/HUMIDIFICATION PROGRAM

Program: 1 Status: Cooling

To Above t° Below RH

1

2

Cool# 1 2 - - - - - - - -

Temp. Sens.: 1 2-- Hum. Sens.: 1 2

16:00

16:00

25.0

35.0

80

80

Off time can be controlled according to temp.

High temp.= less off time

Low temp.= more off time

User Manual

Page 41

Page 42

NMC-PRO

PROGRAM MENU

2.13

22B

9. Misting

23B

10. Water

1. Program

1. Program

Misting

Use this screen to control misting in the greenhouse using a timer.

# No. Start

Define Start/End time

Define Misting On/Off

time

1

2

3

4

5

6

7

8

9

1

--

--

--

--

--

--

--

--

MISTING PROGRAM

hh:mm

08:00

--:--

--:--

--:--

--:--

--:--

--:--

--:--

--:--

End

hh:mm

16:00

--:--

--:--

--:--

--:--

--:--

--:--

--:--

--:--

On

hh:mm:ss

00:00:10

--:--:--

--:--:--

--:--:--

--:--:--

--:--:--

--:--:--

--:--:--

--:--:--

Off

hh:mm:ss

00:00:05

--:--:--

--:--:--

--:--:--

--:--:--

--:--:--

--:--:--

--:--:--

--:--:--

2.14

Water Heating

Use this screen to heat water in cold areas/seasons.

Heating

Define Start/End time

Define Water Temp. ±

Difference (dead band)

to stop

Define sensors

WATER HEATING

From Time

To Time

Water Temperature

Difference

Temp. Sensor #1

Temp. Sensor #2

08:00

16:00

20.0

2.0

1

2

User Manual

Page 42

Page 43

NMC-PRO

MANUAL MENU

3 2BMANUAL MENU

1. Irrigation pause

To resume, reverse steps above and select NO

2. Start/Stop

Select Program

Yes

To resume, reverse steps above and select NO

Program:

1

2. Manual

YES

2. Manual

SET

ACTUAL

LEFT

CYCLE

0

0

0

STATUS

ACTIVE

PROGRAM: PAUSE

This menu enables manual control over various functions.

• System Pause, page 43

• Start/Stop Program, page 43

• Start/Stop Valve, page 44

• Manual Filter Flush, page 45

3.1 24BSystem Pause

Use this function to manually pause the system during an irrigation program; for example if you need to calibrate the

EC/pH or fix the pipes.

WATER

FLOW

EC

Ph

15:38:16

VALVE: 1 25-Apr-07

Pause Irrigation? YES

ACTIVE IRRIGATION

00:15:00

100.000

1.5

5.5

IRRIGATION PAUSE

00:01:00

0.000

4.5

3.3

00:14:01

IRRIGATION

DOSING

3.2 25BStart/Stop Program

IRRIGATION PAUSE

Pause Irrigation? YES

NO

YES

Menu

START/STOP PROGR AM

Program

User Manual

Page 43

Page 44

NMC-PRO

MANUAL MENU

Note: Start one cycle only

3. Start/Stop

Select Valve and corresponding Run

Menu

Yes

To resume, reverse steps above and

Valve

2

2. Manual

#

Method

Water

Before

After

1

TIME

00:10:00

00:00:00

00:00:00

Program: 1

1

2

3

4

5

DATE : 1-May-07 TIME : 10:12:09

Program: 1

Priority: -

Rad Sum

from Program 1.

IRRIGATION PROGRAM

Start Time

Clock Start

Rad Sum Li.

Min. Time

Max. Time

Valve #

Run Time #

Dosing Prog

For Next Screen Press The DOWN Arrow

3.3 26BStart/Stop Valve

Use this screen to manually start/stop a valve.

START/STOP VALVE

Run Time #

Dosing Program

1

1

Valve

07:00

1

----

--:--

--:- 001

1

1

08:00

-300

00:30

01:00

Time/Dosing program

10:00

-150

00:20

01:00

select NO

13:00

-300

00:30

01:00

WATER RUN TIME PROGRAM

2

QTY.

3

QTY.

4

QTY.

5

QTY.

6

QTY.

7

START/STOP VALVE

Valve

Run Time #

Dosing Program

2

1

1

QTY.

8

QTY.

9

QTY.

10

QTY.

INJECTION PER DOSING CHANNEL

EC

5.00

Target EC

Target PH

EC Dosing Method

PH Dosing Method

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

DOSING PROGRA M

EC

5.00

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

EC

5.00

1.60

5.50

P.QTY

P.QTY

EC

5.00

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

ACID

3.00

Run Time Program

(1)

Dosing Program (1)

User Manual

Page 44

Page 45

NMC-PRO

MANUAL MENU

3.4 27BManual Filter Flush

4. Filter Flush

Select filters (usually all)

Yes

Menu

Hot Screen 5 to view

Which Filter

<None>

<None>

2. Manual

Flush Status

ON

Water Fill Up (min)

1

Use this screen to activate m anual filter flush. Us this function only when the system is irrigating.

MANUAL FILTER FLUSHING

All Filters

Filter 01

Filter 02

MANUAL FILTER FLUSHING

Which Filter to Flush? All Filters