Page 1

[Type text]

Page 2

NMC-JUNIOR PRO User Manual

© COPYRIGHT 2011, NETAFIM

NO PARTS OF THIS PUBLICATION MAY BE REPRODUCED, STORED IN AN AUTOMATED DATA FILE OR MADE PUBLIC IN

ANY FORM OR BY ANY MEANS, WHETHER ELECTRONIC, MECHANICAL, BY PHOTOCOPYING, RECORDING OR IN ANY

OTHER MANNER WITHOUT PRIOR WRITTEN PERMISSION OF THE PUBLISHER.

ALTHOUGH NETAFIM TAKES THE GREATEST POSSIBLE CARE IN DESIGNING AND PRODUCING BOTH ITS PRODUCTS

AND THE ASSOCIATED DOCUMENTATION, THEY MAY STILL INCLUDE FAULTS.

NETAFIM WILL NOT ACCEPT RESPONSIBILITY FOR DAMAGE RESULTING FROM THE USE OF NETAFIM'S PRODUCTS OR

THE USE OF THIS MANUAL.

NETAFIM RESERVES THE RIGHT TO MAKE CHANGES AND IMPROVEMENTS TO ITS PRODUCTS AND/OR THE

ASSOCIATED DOCUMENTATION WITHOUT PRIOR NOTICE

VERSION 9.06 REV 1.0 110363

.

Page 2

Page 3

NMC-Junior Pro Installation Manual

CONTENTS

Table of Contents

1 General Instructions ................................................................................................................................................ 7

1.1 Basic Requirements for On-Site Preparation ....................................................................................................... 7

1.2 Frequency Inverters ............................................................................................................................................. 7

1.3 General Dimensions ............................................................................................................................................. 7

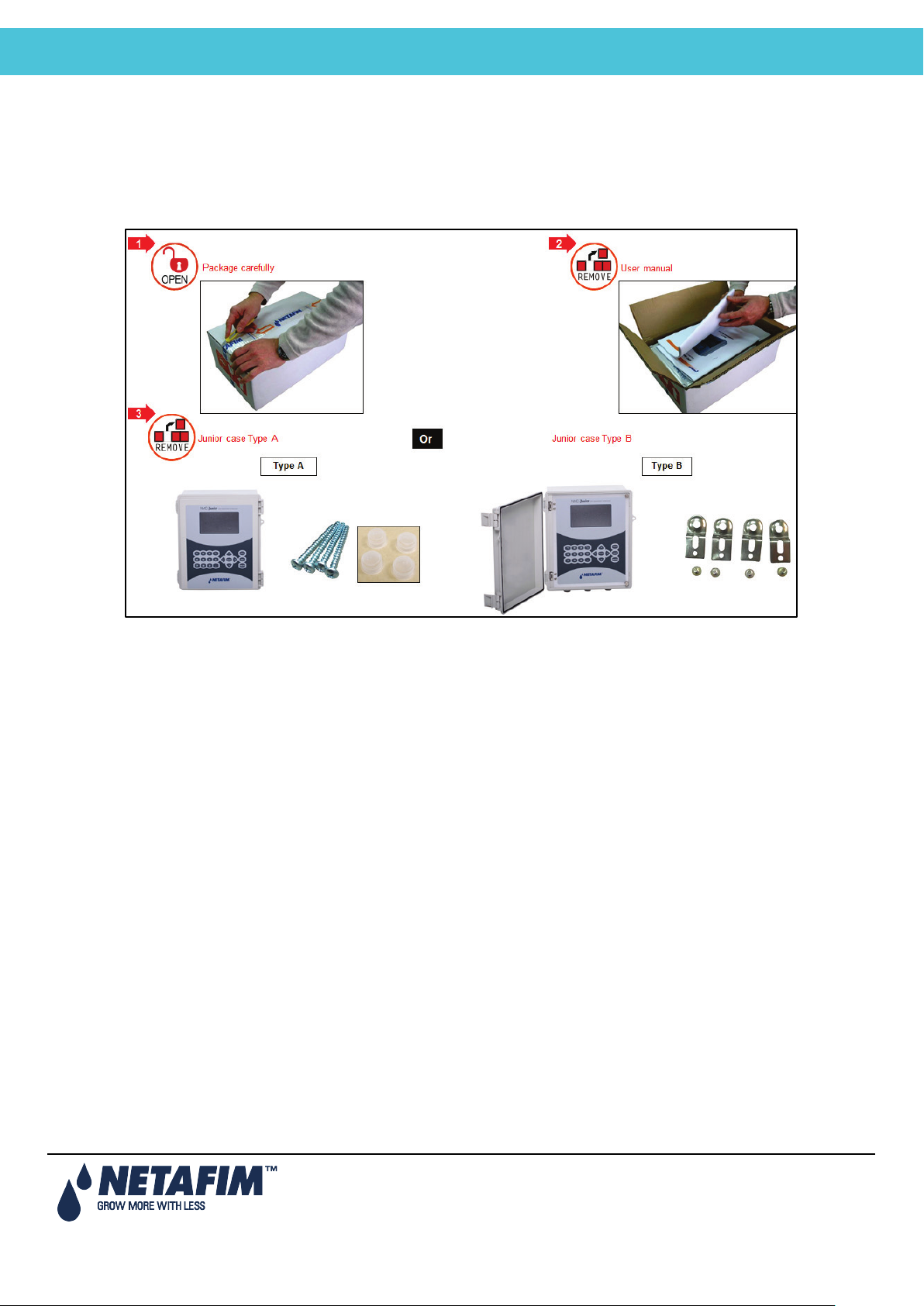

2 Unpacking and Mounting ........................................................................................................................................ 8

2.1 Unpacking ............................................................................................................................................................ 8

2.2 Box Installation ..................................................................................................................................................... 8

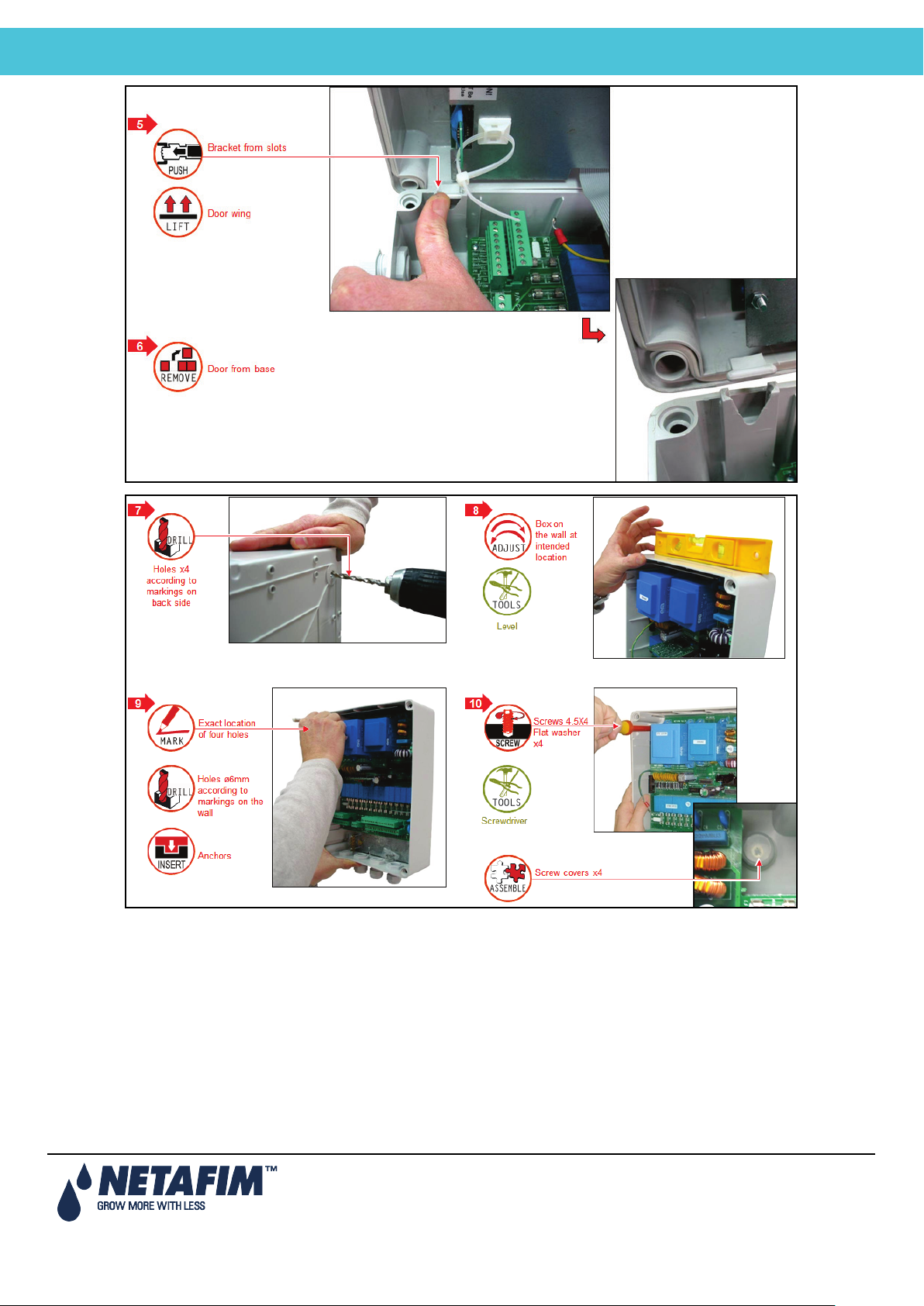

2.2.1 Option A ....................................................................................................................................................... 9

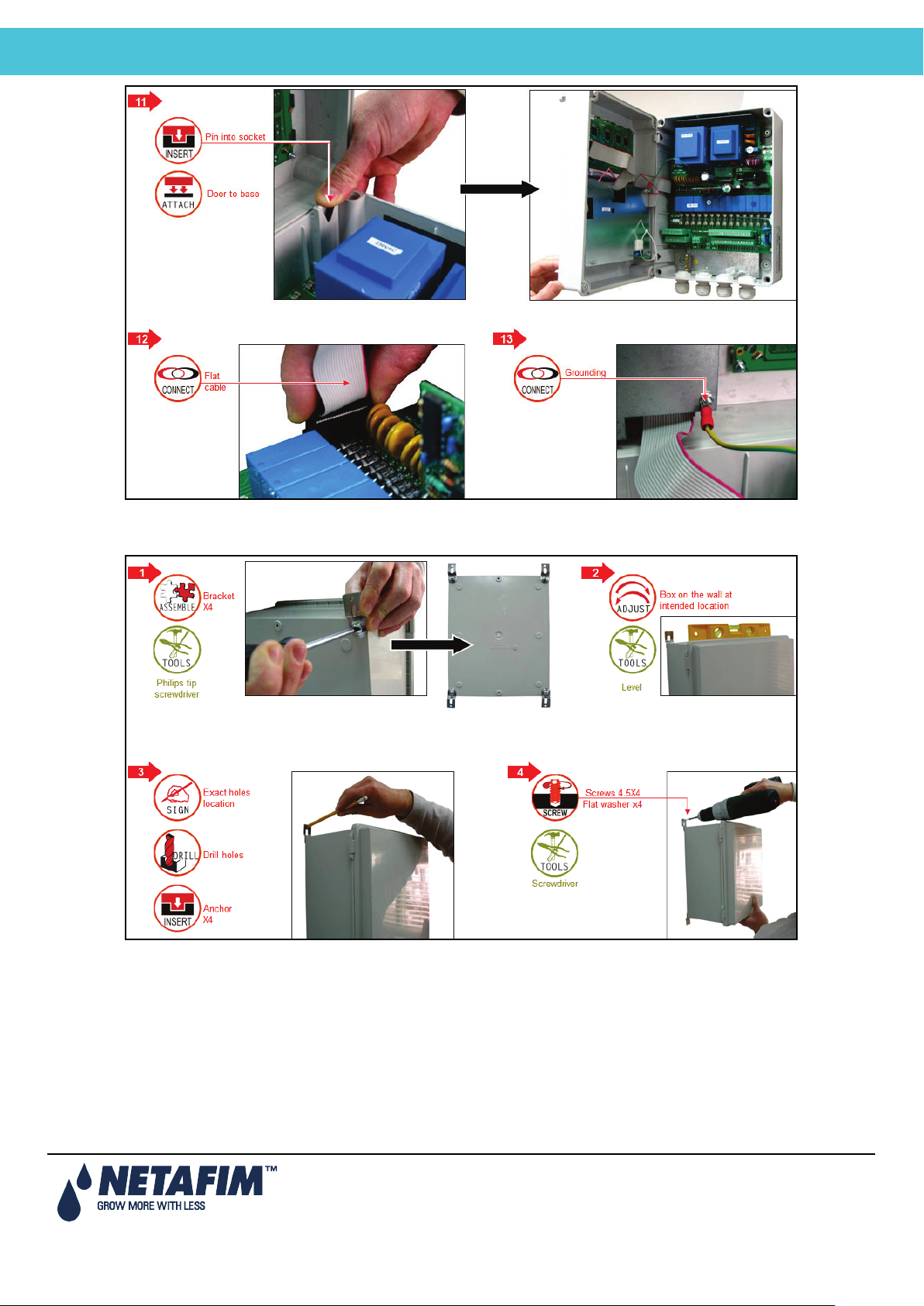

2.2.2 Option B ..................................................................................................................................................... 11

3 Power Supply WIring ............................................................................................................................................. 12

3.1 Main Power Wiring ............................................................................................................................................. 12

3.2 Electrical Test ..................................................................................................................................................... 14

3.3 Firmware Upgrade ............................................................................................................................................. 16

3.3.1 Accessing the Application ......................................................................................................................... 16

3.3.2 Running the Application ............................................................................................................................ 16

4 Electrical Installation ............................................................................................................................................. 18

4.1 Input/Output Layout ............................................................................................................................................ 18

4.2 Output Terminals ................................................................................................................................................ 19

4.2.1 Output Terminal Wiring ............................................................................................................................. 19

4.2.2 Example of Output Wiring ......................................................................................................................... 19

4.3 Input Terminals .................................................................................................................................................. 20

4.3.1 Input Terminal Wiring ................................................................................................................................ 20

4.3.2 Digital Input Examples ............................................................................................................................... 21

4.4 PC and Inter-Controller Communication ............................................................................................................ 23

4.4.1 Card Installation ......................................................................................................................................... 23

4.4.2 Wiring and Controller Setup ...................................................................................................................... 24

5 Controller Setup ..................................................................................................................................................... 27

5.1 Start-Up .............................................................................................................................................................. 27

5.2 Device Layout .................................................................................................................................................... 27

5.3 Device List .......................................................................................................................................................... 28

5.4 Digital Input ........................................................................................................................................................ 28

5.5 Analog Input ....................................................................................................................................................... 29

5.6 Hot Keys and Status Screens ............................................................................................................................ 30

6 Controller Test Procedure..................................................................................................................................... 32

6.1 Relays ................................................................................................................................................................ 32

6.2 Digital Input ........................................................................................................................................................ 32

6.3 Analog Input ....................................................................................................................................................... 33

Page 3

Page 4

NMC-Junior Pro Installation Manual

CONTENTS

6.4 Temperature ....................................................................................................................................................... 34

6.5 Humidity ............................................................................................................................................................. 34

7 System Configuration Procedure ......................................................................................................................... 35

7.1 Device Delay Configuration................................................................................................................................ 35

7.1.1 Example of Device Startup & Shutdown Order ......................................................................................... 36

7.1.2 Example of Stagger Valve Delay – Multiple Shifts .................................................................................... 37

7.2 Pump Station Configuration ............................................................................................................................... 38

7.3 Valve Configuration ............................................................................................................................................ 39

7.4 Valve Flow Rate ................................................................................................................................................. 40

7.5 Water Meter........................................................................................................................................................ 41

7.6 Dosing Channel Configuration ........................................................................................................................... 42

7.7 Dosing Configuration .......................................................................................................................................... 43

7.8 Drainage Configuration ...................................................................................................................................... 44

7.9 EC/pH Configuration .......................................................................................................................................... 44

7.10 Cooling Configuration .................................................................................................................................... 45

7.11 Misting Configuration ..................................................................................................................................... 45

7.12 History Resolution .......................................................................................................................................... 45

7.13 System Nutrigation™ Check .......................................................................................................................... 46

7.13.1 Check if EC/pH is on Target ...................................................................................................................... 46

7.13.2 Water Run Time ........................................................................................................................................ 46

7.13.3 Start/Stop Valve ......................................................................................................................................... 47

8 Controller Advanced Settings .............................................................................................................................. 48

8.1 Pump Station Configuration ............................................................................................................................... 48

8.2 Multiple Water Meters ........................................................................................................................................ 48

8.3 Various Dosing Configurations........................................................................................................................... 49

8.3.1 Method 1 .................................................................................................................................................... 49

8.3.2 Method 2 .................................................................................................................................................... 49

8.3.3 Method 3 .................................................................................................................................................... 49

8.4 Dosing Configuration .......................................................................................................................................... 50

8.4.1 EC/pH Control Step 1 ................................................................................................................................ 50

8.4.2 EC/pH Control Step 2 ................................................................................................................................ 50

9 Program Menu ........................................................................................................................................................ 51

9.1 Irrigation ............................................................................................................................................................. 51

9.1.1 Setting Irrigation that is Longer than 24 Hours .......................................................................................... 55

9.2 Influence Program .............................................................................................................................................. 55

9.2.1 Using the Influences .................................................................................................................................. 55

9.2.2 Setting the Influences ................................................................................................................................ 55

9.3 Water Run Time ................................................................................................................................................. 60

Page 4

Page 5

NMC-Junior Pro Installation Manual

CONTENTS

9.4 Dosing ................................................................................................................................................................ 61

9.4.1 Dosing Program ......................................................................................................................................... 61

9.4.2 Dosing Injection Methods .......................................................................................................................... 61

9.5 Ext. Condition ..................................................................................................................................................... 63

9.6 Agitator ............................................................................................................................................................... 64

9.7 Selector .............................................................................................................................................................. 65

9.8 Filter Flushing ..................................................................................................................................................... 65

9.9 Cooling ............................................................................................................................................................... 66

9.10 Misting ............................................................................................................................................................ 68

9.11 Water Heating ................................................................................................................................................ 69

10 Manual Operation Menu .................................................................................................................................. 70

10.1 Irrigation Pause .............................................................................................................................................. 70

10.2 Start/Stop Program ........................................................................................................................................ 70

10.3 Start/Stop Valve ............................................................................................................................................. 71

10.4 Filter Flushing ................................................................................................................................................ 72

11 Setup Menu ....................................................................................................................................................... 73

11.1 Time and Date ............................................................................................................................................... 73

11.2 System Setup................................................................................................................................................. 74

11.3 Temperature Calibration ................................................................................................................................ 75

11.4 Humidity Calibration ....................................................................................................................................... 75

11.5 EC/pH Calibration .......................................................................................................................................... 76

11.5.1 Calibration of the EC/pH Monitor Transmitter ........................................................................................... 76

11.5.2 EC/pH Transmitter Monitor & NMC-Junior Pro Correlation....................................................................... 78

11.6 Sensors Logging ............................................................................................................................................ 78

11.7 Write to Data Plug .......................................................................................................................................... 79

11.8 Read from Gold Data Plug ............................................................................................................................. 79

12 Appendix A: NMC-Junior Pro Parts List ........................................................................................................ 80

13 Appendix B: Troubleshooting ........................................................................................................................ 81

13.1 Controller Display is Off ................................................................................................................................. 81

13.2 Output Malfunction ......................................................................................................................................... 82

14 Appendix C: Replacements and Additional Installations ............................................................................ 84

14.1 Power Supply Card ........................................................................................................................................ 84

14.2 Relay Card ..................................................................................................................................................... 85

15 Appendix D: Sensor Installation and Definition............................................................................................ 86

15.1 EC – pH Sensor Connection .......................................................................................................................... 86

15.1.1 EC Sensor Calibration ............................................................................................................................... 87

15.1.2 pH Sensor Calibration ............................................................................................................................... 88

15.2 Temperature/Humidity Sensor Connection ................................................................................................... 90

Page 5

Page 6

NMC-Junior Pro Installation Manual

CONTENTS

15.2.1 Humidity Sensor Definition ........................................................................................................................ 91

15.3 Sensor and Cable Specifications ................................................................................................................... 91

16 Appendix E: Technical Specifications ........................................................................................................... 92

16.1 Technical Specifications ................................................................................................................................ 92

16.2 Controller Components .................................................................................................................................. 92

16.2.1 Keyboard & Display ................................................................................................................................... 93

16.2.2 Hardware Components ............................................................................................................................. 93

16.2.3 Power Supply Card.................................................................................................................................... 95

16.2.4 Input and Output Card ............................................................................................................................... 98

17 Appendix F: Main Menu Tree .......................................................................................................................... 99

18 Warranty .......................................................................................................................................................... 100

Page 6

Page 7

NMC-Junior Pro Installation Manual

GENERAL INSTRUCTIONS

1 GENERAL INSTRUCTIONS

• Installation should be performed by authorized technicians only.

• Verify that field components are working properly.

• Apply all safety regulations.

• Do not apply force or pressure on components during the installation procedure.

• Refer to your supervisor if problems occur during installation procedure.

1.1 Basic Requirements for On-Site Preparation

• Verify power source between 115 VAC or 220 VAC ± 10%

• Verify grounding connection < 10Ω

• Environment temperature between -10° C / 14° F to +60° C / 140° F

• Verify protection from damaging climate conditions

1.2 Frequency Inverters

• Frequency inverters can cause severe electrical and electromagnetic interference. Therefore, when

employing a frequency inverter, it is critical that you carefully follow the manufacturer's installation

instructions.

• In particular verify:

that the cable shielding between the inverter and any motor meets industry standards

proper grounding of the inverter's chassis and motor power cable

proper grounding of low voltage cable shield wire

that the controller and inverter cables are kept in separate conduits or wire bundles

1.3 General Dimensions

Page 7

Page 8

NMC-Junior Pro Installation Manual

UNPACKING AND MOUNTING

2 UNPACKING AND MOUNTING

• Unpacking

• Box Installation

2.1 Unpacking

2.2 Box Installation

• Option A, page 9

• Option B, page 11

Page 8

Page 9

NMC-Junior Pro Installation Manual

UNPACKING AND MOUNTING

2.2.1 Option A

Page 9

Page 10

NMC-Junior Pro Installation Manual

UNPACKING AND MOUNTING

Page 10

Page 11

NMC-Junior Pro Installation Manual

UNPACKING AND MOUNTING

2.2.2 Option B

Page 11

Page 12

NMC-Junior Pro Installation Manual

Power Supply Wiring

3 POWER SUPPLY WIRING

• Main Power Wiring

• Electrical Test

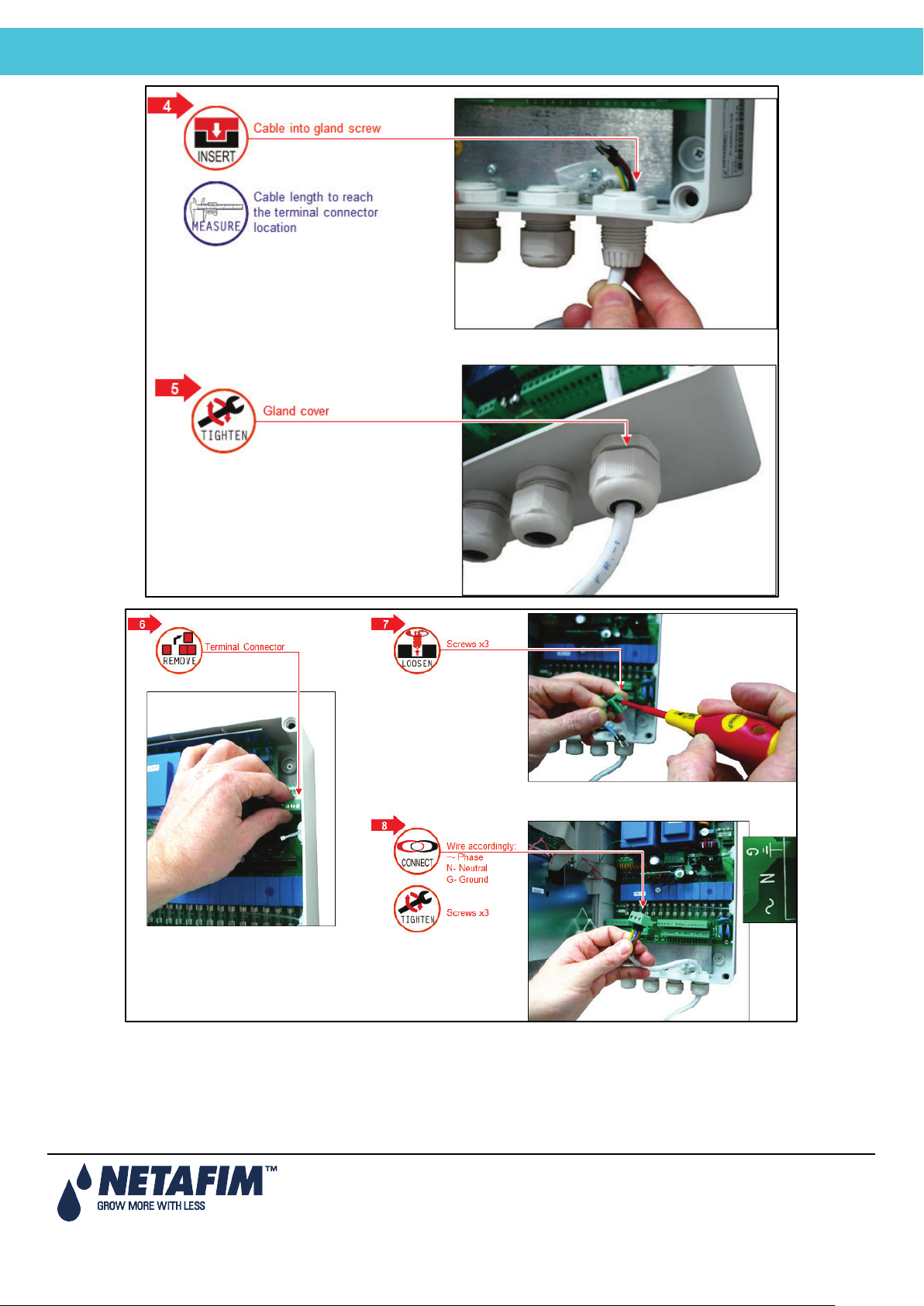

3.1 Main Power Wiring

Page 12

Page 13

NMC-Junior Pro Installation Manual

Power Supply Wiring

Page 13

Page 14

NMC-Junior Pro Installation Manual

Power Supply Wiring

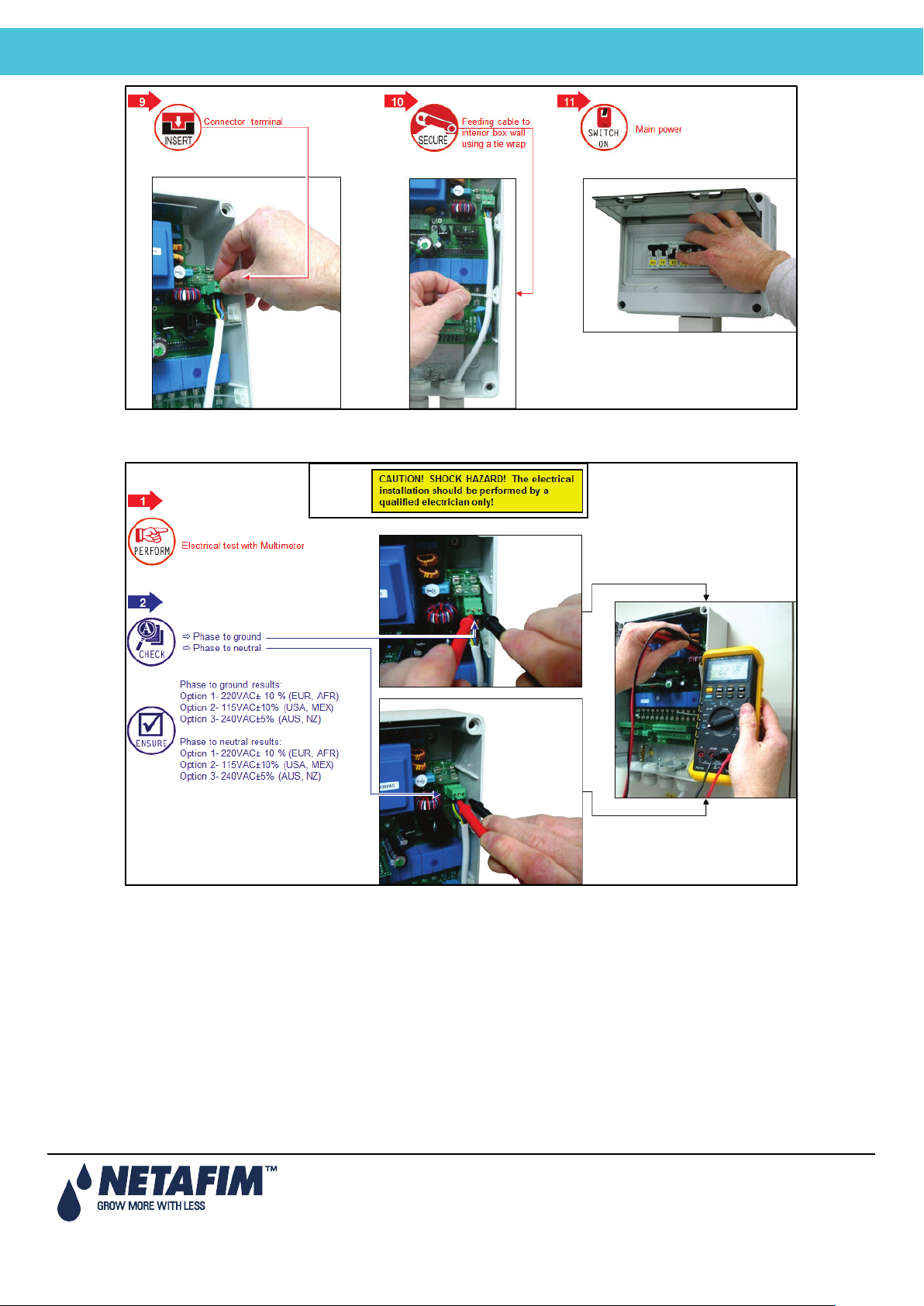

3.2 Electrical Test

Page 14

Page 15

NMC-Junior Pro Installation Manual

Power Supply Wiring

Page 15

Page 16

NMC-Junior Pro Installation Manual

Power Supply Wiring

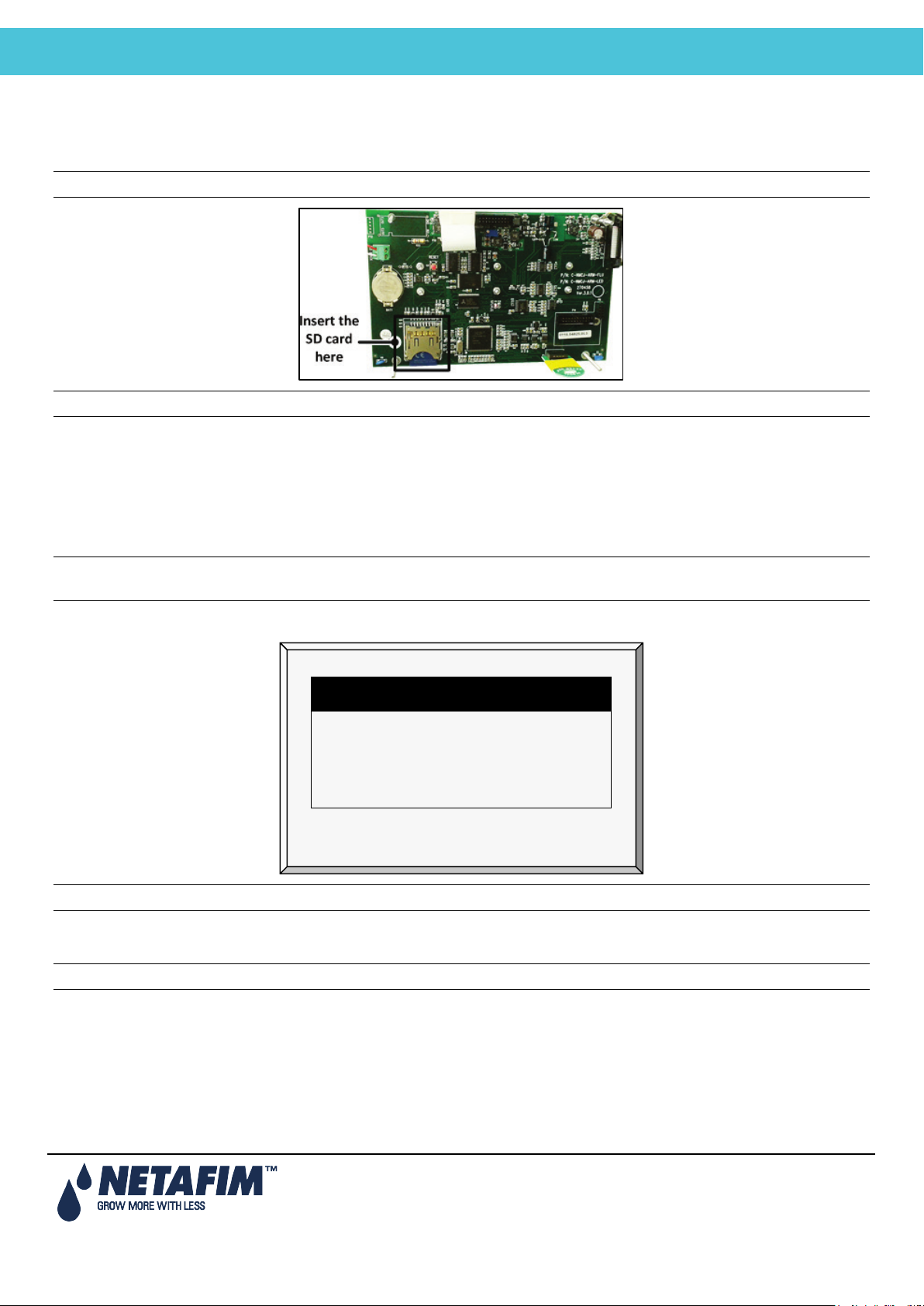

3.3 Firmware Upgrade

SELECT AN OPTION

Hardware Firmware

Hardware Test

Cancel Update

The Bootloader application enables installing or updating the system firmware. The application is menu based and

simple to use and enables updating the firmware from an SD card.

Note: Verify that the card is in place before starting.

Note: Junior Pro supports up to 4 GB SD cards.

3.3.1 Accessing the Application

1. Press and hold the Left and Down arrow keys.

2. Turn on the unit.

In the screen that appears, enter the password: 38845.

Note: If you enter the wrong password, an error message appears and the program goes to the Main Screen.

Repeat the process.

3. Press Enter. The screen below appears.

Note: Hardware Test is used for quality control only.

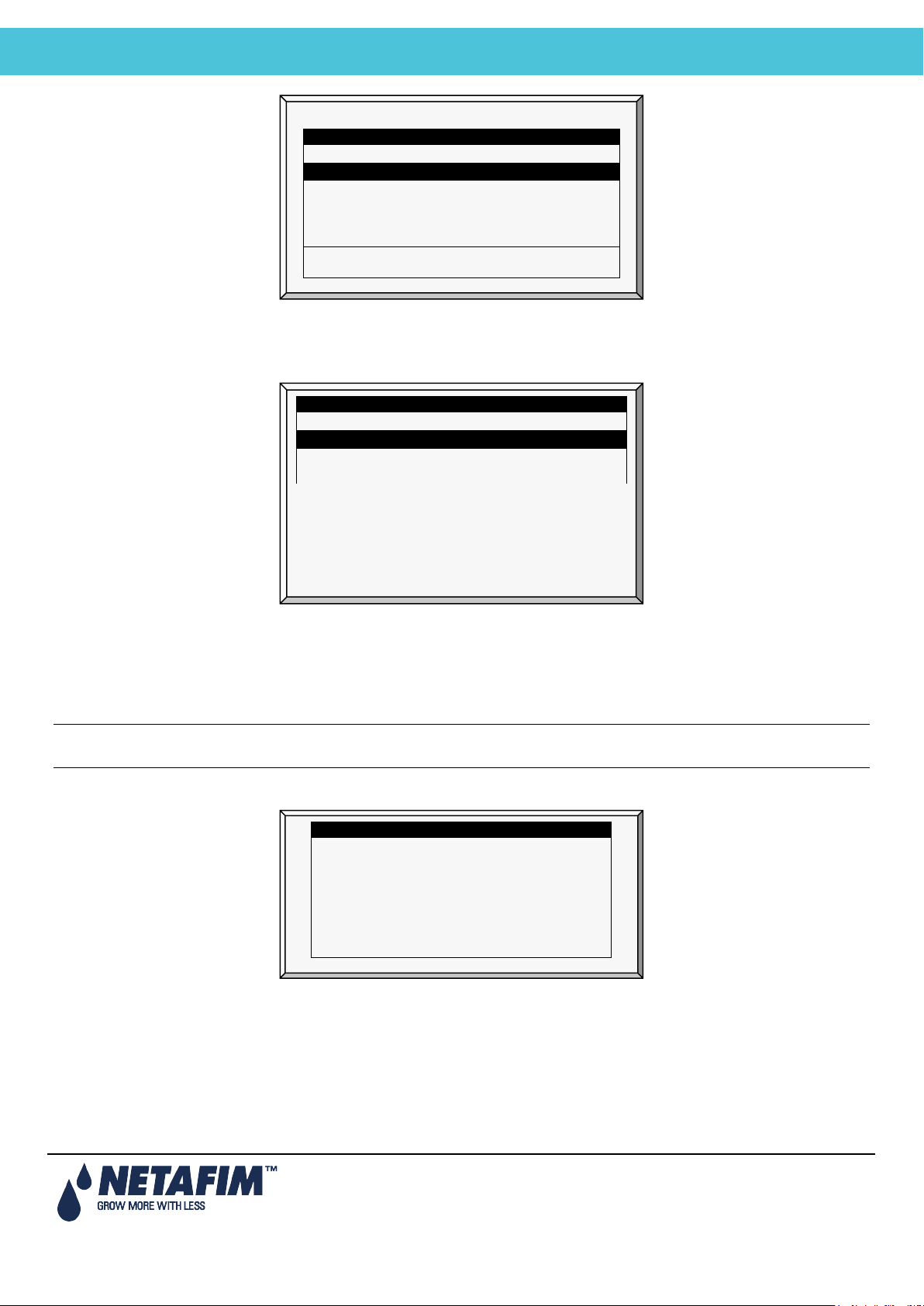

3.3.2 Running the Application

Note: Pressing Exit or ESC takes you to the previous menu.

1. Select Hardware Firmware. The following screen appears (example only):

Page 16

Page 17

NMC-Junior Pro Installation Manual

Power Supply Wiring

SELECT A FILE

Path: /

NMC_PRO <DIR> 13/Oct/2009

NEWPRO~1

<DIR>

12/Sept/2014

SELECT A FILE

Path: /

NETAFIMHEX1.04

<DIR>

12/Sept/2014

New Software Version

New Software Found

COLD START REQUIRED!!

New Version:

8.02.49

NETAFIM <DIR> 12/Sept/2014

Press ENTER to confirm selection or MENU to return.

2. Select the required directory.

3. Press Enter.

The following screen appears:

NMC_PRO <DIR> 13/Oct/2009

NETAFIMHEX1.06 <DIR> 12/Sept/2014

4. Select the required software version.

5. Press Enter.

6. A confirmation message appears. Select Yes.

7. Press Enter.

Note: Do not turn the unit off during the update! If there is an interruption (for example a power outage), restart the

process.

At the end of the process, the following screen appears (the version numbers are examples only):

Old Version: 8.02.00

Press ENTER To Continue.

8. Press Enter and perform a Cold Start.

Page 17

Page 18

NMC-Junior Pro Installation Manual

ELECTRICAL INSTALLATION

4 ELECTRICAL INSTALLATION

• Input/Output Layout, page 18

• Output Terminals, page 19

• Input Terminals, page 20

• PC and Inter-Controller Communication, page 23

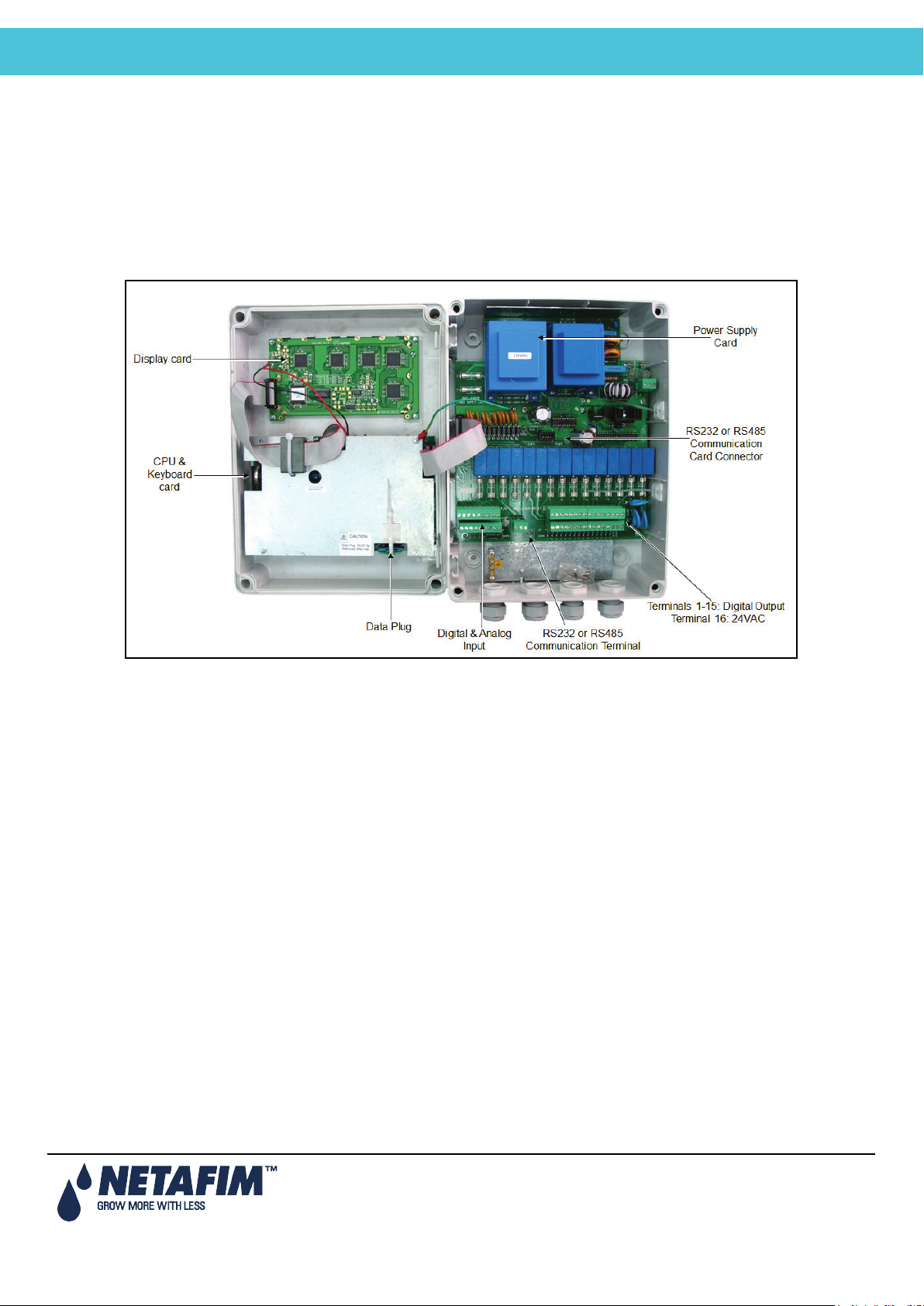

4.1 Input/Output Layout

Page 18

Page 19

NMC-Junior Pro Installation Manual

ELECTRICAL INSTALLATION

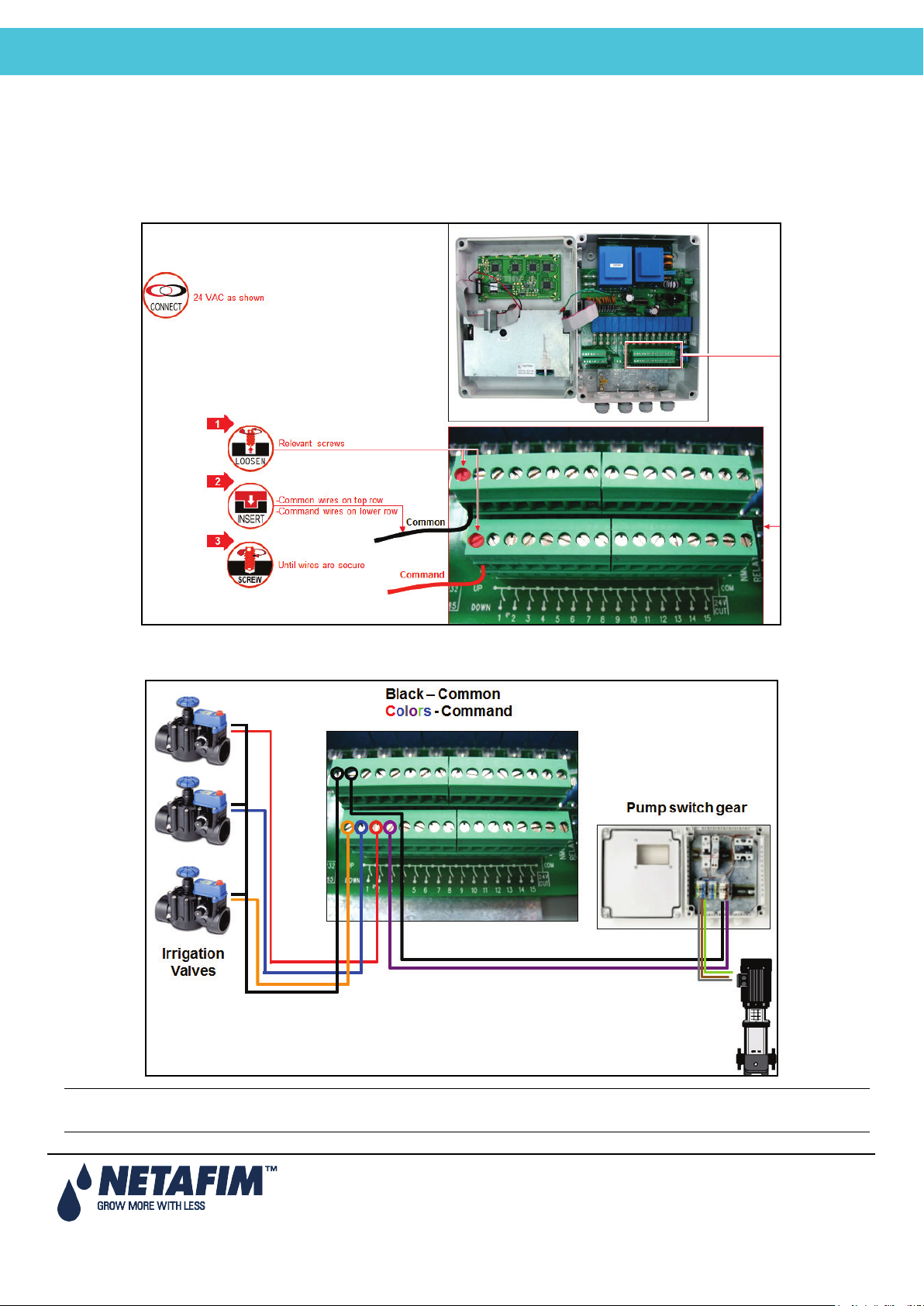

4.2 Output Terminals

• Output Terminal Wiring

• Example of Output Wiring

4.2.1 Output Terminal Wiring

4.2.2 Example of Output Wiring

Note: Before switching the controller on, the technician should verify that there is no short circuit on each output.

(Resistance test)

Page 19

Page 20

NMC-Junior Pro Installation Manual

ELECTRICAL INSTALLATION

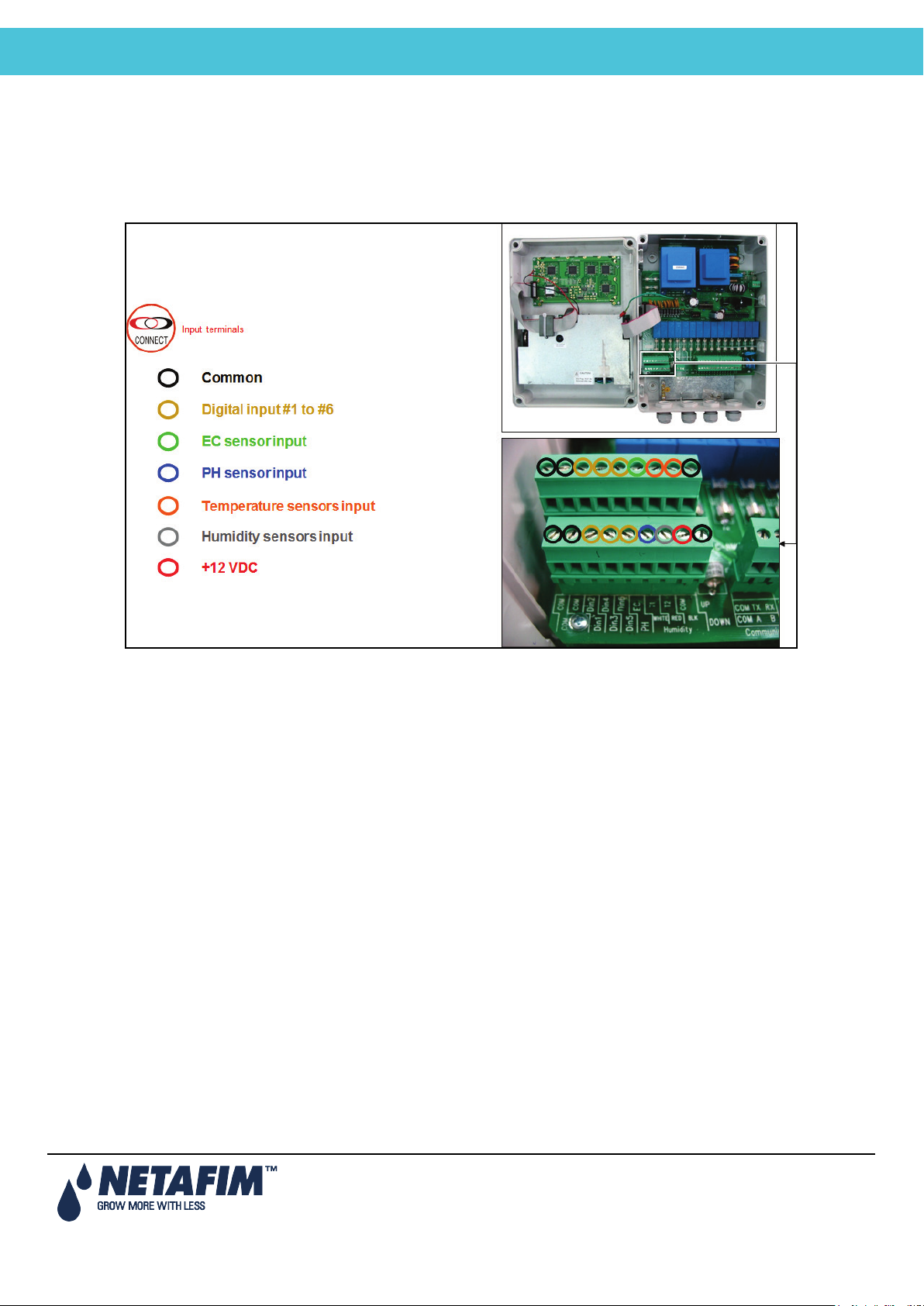

4.3 Input Terminals

• Input Terminal Wiring

• Digital Input Examples

4.3.1 Input Terminal Wiring

Page 20

Page 21

NMC-Junior Pro Installation Manual

ELECTRICAL INSTALLATION

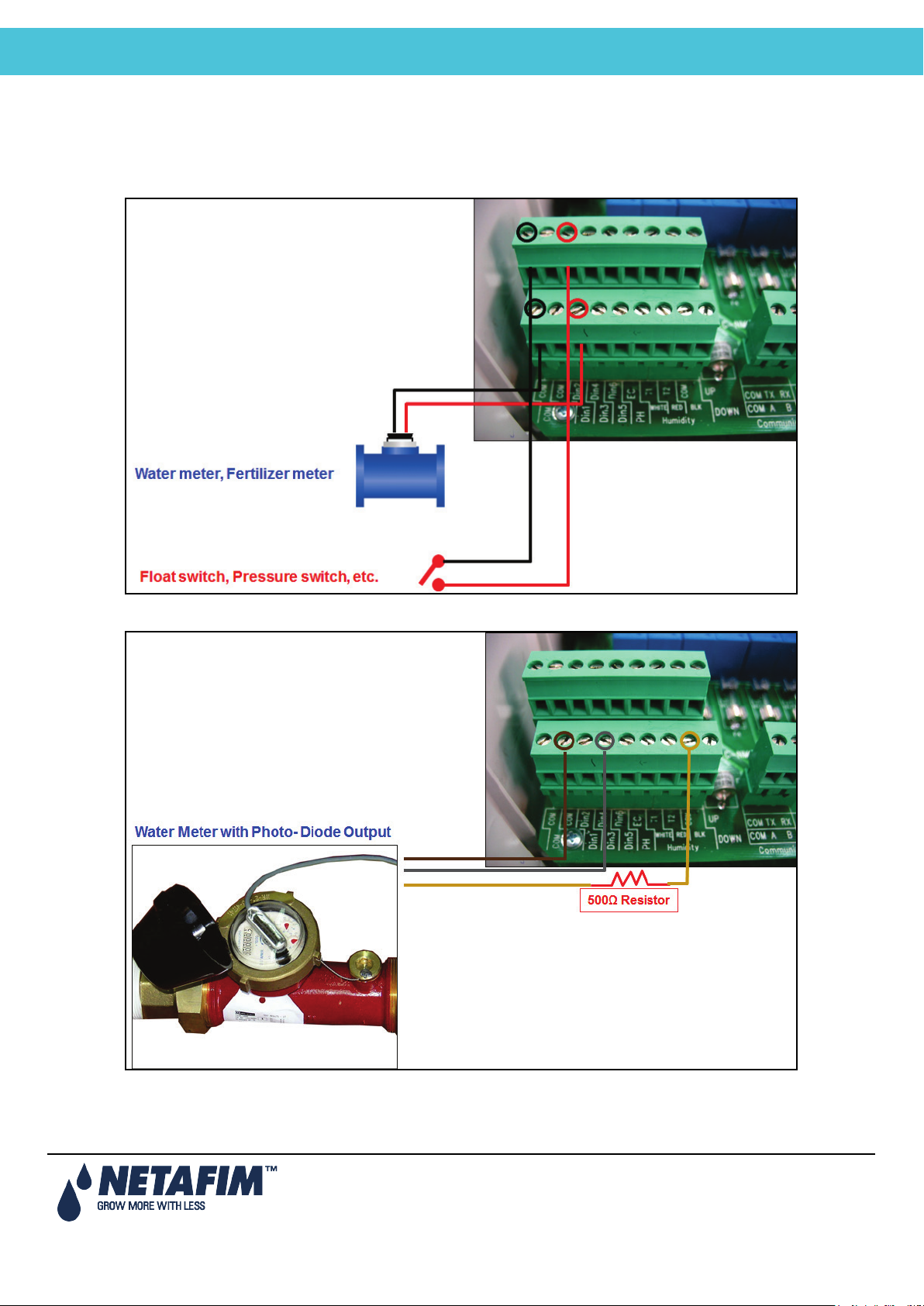

4.3.2 Digital Input Examples

• Example A

Digital input 1: Water meter, Fertilizer meter

Digital input 2: Float switch, Pressure switch

Digital Input 3: Water Meter with Photo-Diode Output

Page 21

Page 22

NMC-Junior Pro Installation Manual

ELECTRICAL INSTALLATION

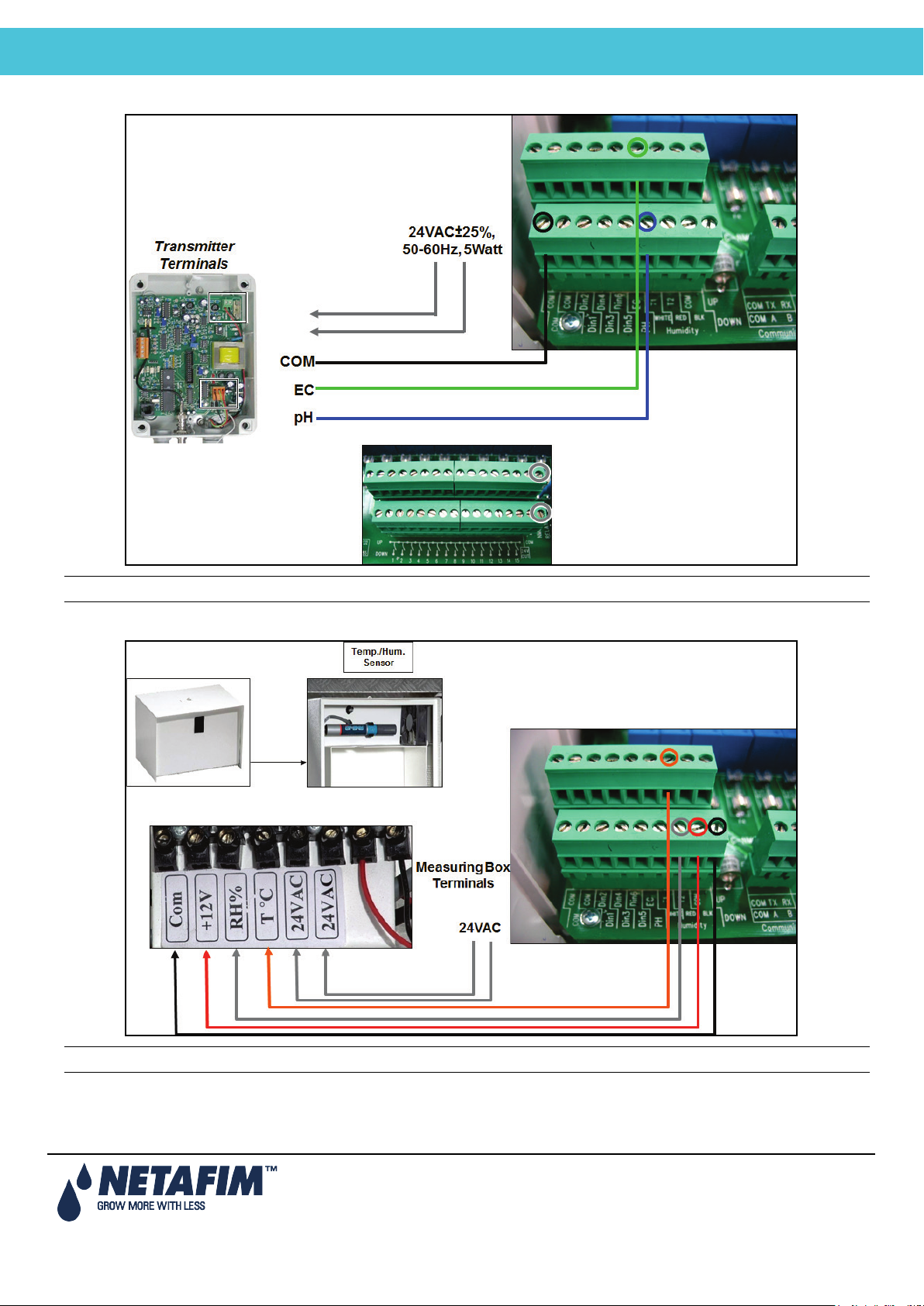

• Example B: EC / pH sensors

Can wire EC/pH main power source to 24VAC on the output terminals.

• Example C: Temperature / Humidity Sensors

Can wire 24VAC source in same way as on previous page.

Page 22

Page 23

NMC-Junior Pro Installation Manual

ELECTRICAL INSTALLATION

4.4 PC and Inter-Controller Communication

• Card Installation

• Wiring and Controller Setup

4.4.1 Card Installation

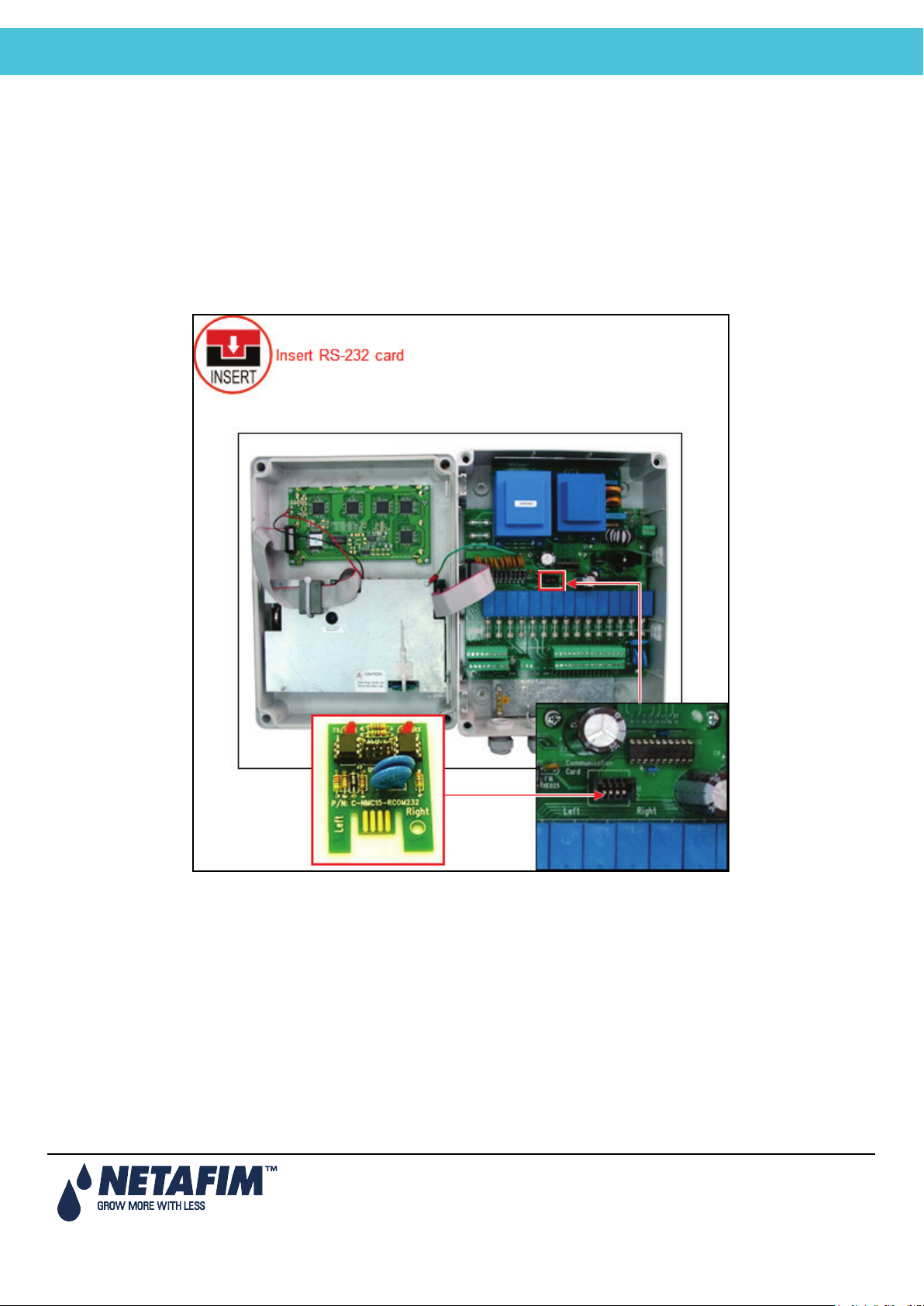

• Option A: RS-232 Card

• Option B: RS-485 Card

4.4.1.1 Option A: RS-232 Card

Page 23

Page 24

NMC-Junior Pro Installation Manual

ELECTRICAL INSTALLATION

4.4.1.2 Option B: RS-485 Card

4.4.2 Wiring and Controller Setup

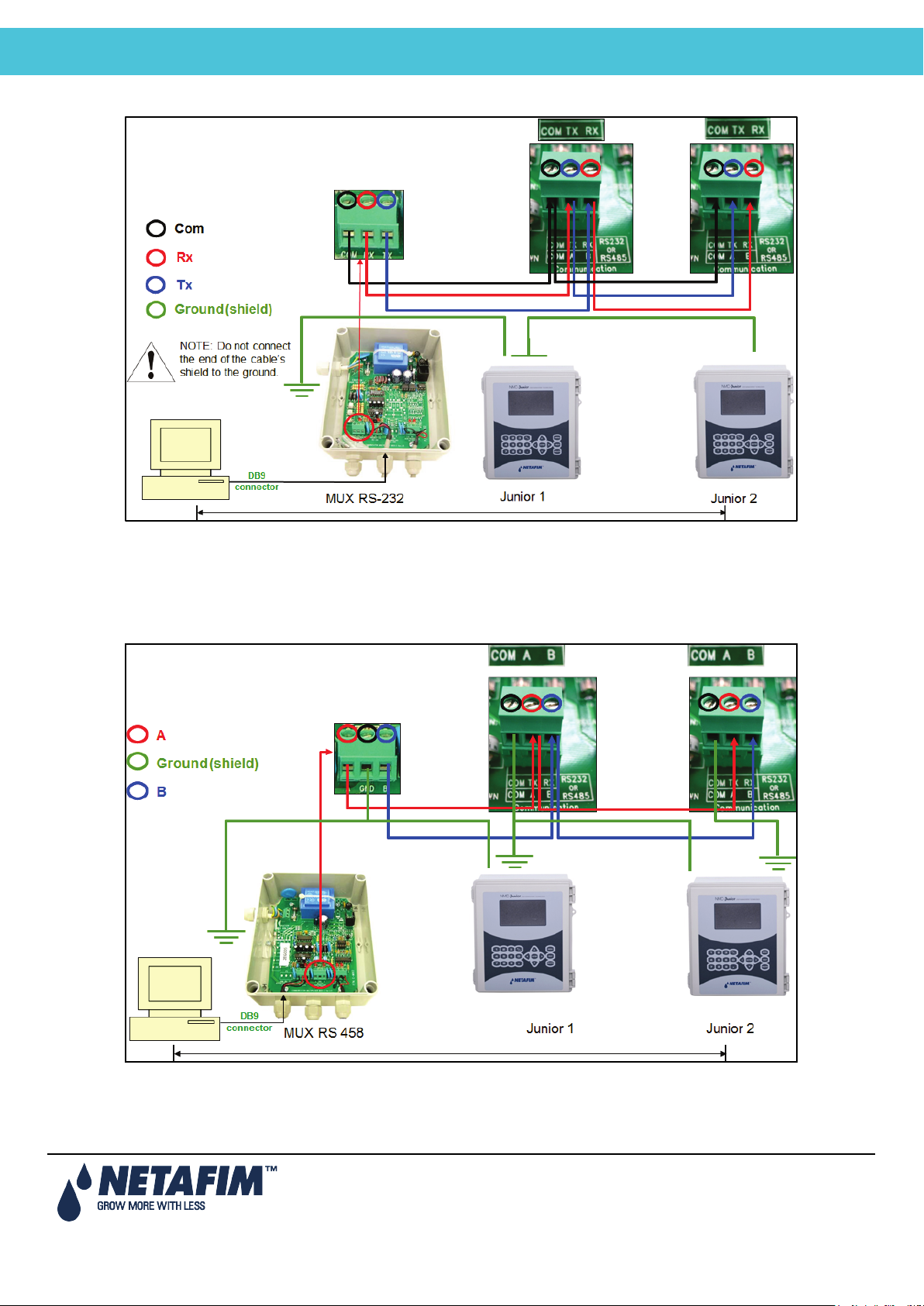

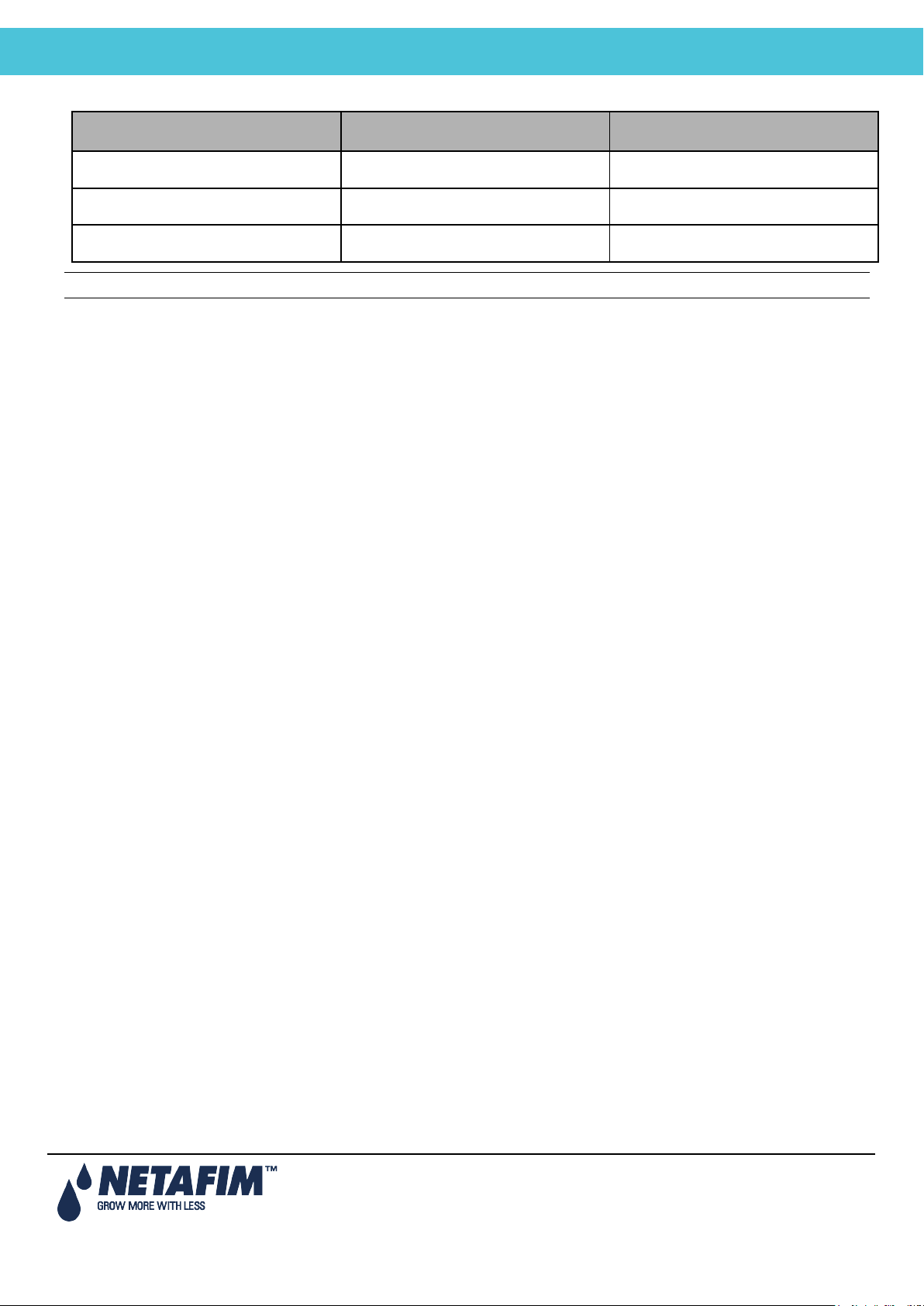

• Option A: RS-232 Setup

• Option B: RS-485 Setup

• Communication Distance and Baud Rate

Page 24

Page 25

NMC-Junior Pro Installation Manual

ELECTRICAL INSTALLATION

4.4.2.1 Option A: RS-232 Setup

• Use 3 wire shielded communication cable

• Do not connect the end of the cable’s shield to the ground.

• Refer to 4.4.2.3Communication Distance and Baud Rate.

4.4.2.2 Option B: RS-485 Setup

• Use 2 wire shielded communication cable.

• Do not connect the end of the cable’s shield to the ground.

• Refer to 4.4.2.3Communication Distance and Baud Rate.

Page 25

Page 26

NMC-Junior Pro Installation Manual

ELECTRICAL INSTALLATION

4.4.2.3 Communication Distance and Baud Rate

Baud rate is dependent on cable length and number of controllers.

10 Controllers 1 Controller Baud Rate

1200 meter / 0.75 mile 2000 meter / 1.25 mile 9600 BPS

1800 meter/ 1.12 mile 2500 meter / 1.55 mile 4800 BPS

2400 meter /1.49 mile 3000 meter / 1.86 mile 2400 BPS

Page 26

Page 27

NMC-Junior Pro Installation Manual

CONTROLLER SETUP

5 CONTROLLER SETUP

INSTALLATION

• Start-Up

• Error! Reference source not found.

• Error! Reference source not found.

• Error! Reference source not found.

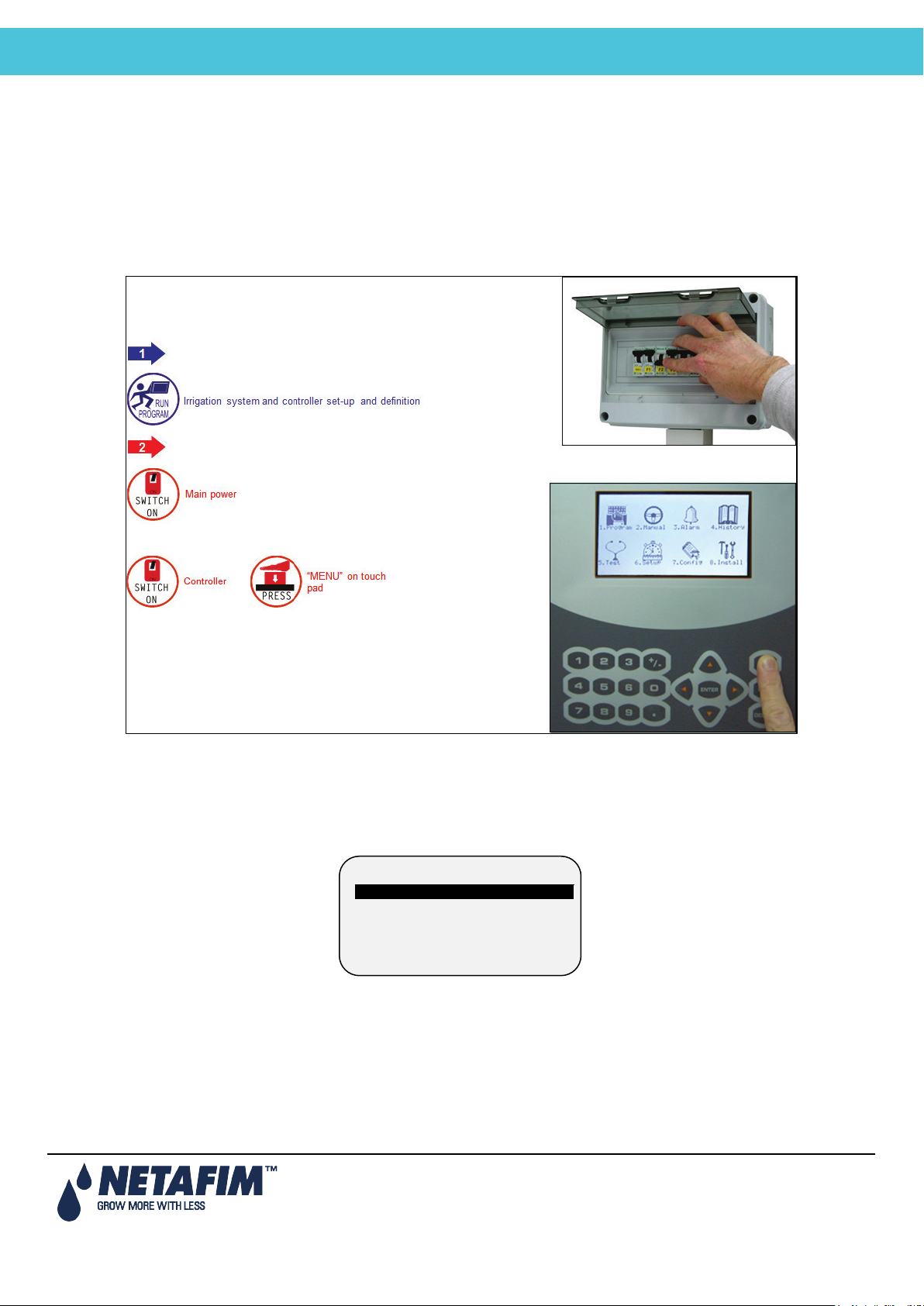

5.1 Start-Up

• Device Layout, page 27

• Device List, page 28

• Digital Input, page 28

5.2 Device Layout

1. DEVICE LAYOUT

2. DEVICE LIST

3. DIGITAL INPUT

4. ANALOG INPUT

The device layout screen allows you to assign functions to each output (relay).

1. Place the cursor on the Function column, use the arrow keys to reach the relevant line, and press ENTER. A

selection list including all available devices will appear.

2. Choose the required device and confirm by pressing ENTER. The cursor will move to the No. column.

3. Specify the number of the device in the controller and press ENTER to confirm.

4. If you wish to define several devices of the same type, for example valves 1 to 10, configure the first one and

press ENTER a few times until you reach the required amount. The NMC-Junior Pro automatically continues

with the same device until instructed otherwise, or until reaching the system limitation for that device.

Page 27

Page 28

NMC-Junior Pro Installation Manual

CONTROLLER SETUP

Note: If 'Radio' is selected in table 6.2, the screen contains at least 64 outputs.

Relay

Function

No

1

Valve

99

2

Valve

00

3

Valve

01

4

Valve

02

5

Valve

03

6

Valve

04

7

Valve

05

8

None

--

9

Valve

06

10

Pump

1

D-In

Input Function

1

Water Meter 1

2

Dosing Meter 1

3

Dosing Meter 2

4

< None >

5

< None >

6

Water Meter 2

DEVICE LAYOUT

Note: After making changes, be sure to exit and return again to check for errors. The NMC-Junior Pro will delete

and replace conflicting assignments with ‘---‘.

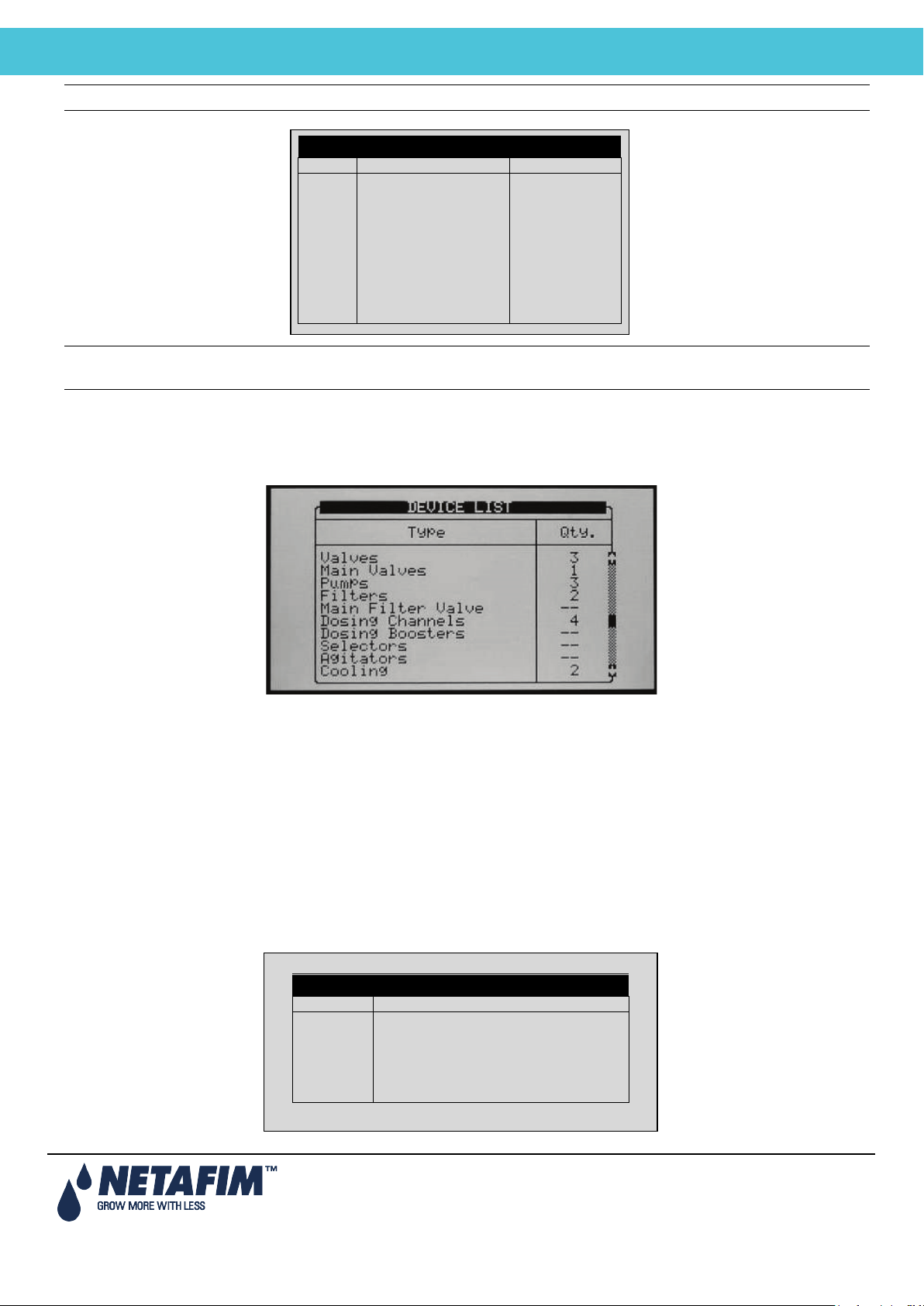

5.3 Device List

The Device List screen allows you to view what type, and how many devices are currently defined. This screen

automatically updates depending on the devices set in the 7.1 screen.

5.4 Digital Input

1. Go to Installation > Digital Input

2. Place the cursor on the relevant line and press ENTER. A selection list will open. Choose the required sensor and

press ENTER to confirm.

Inputs 1-32 are according to the following:

• Card no. 1: inputs 1 – 8

• Card no. 2: inputs 9 – 16

• Card no. 3: inputs 17 – 24

• Card no. 4: inputs 25 - 32

DIGITAL INPUT

Page 28

Page 29

NMC-Junior Pro Installation Manual

CONTROLLER SETUP

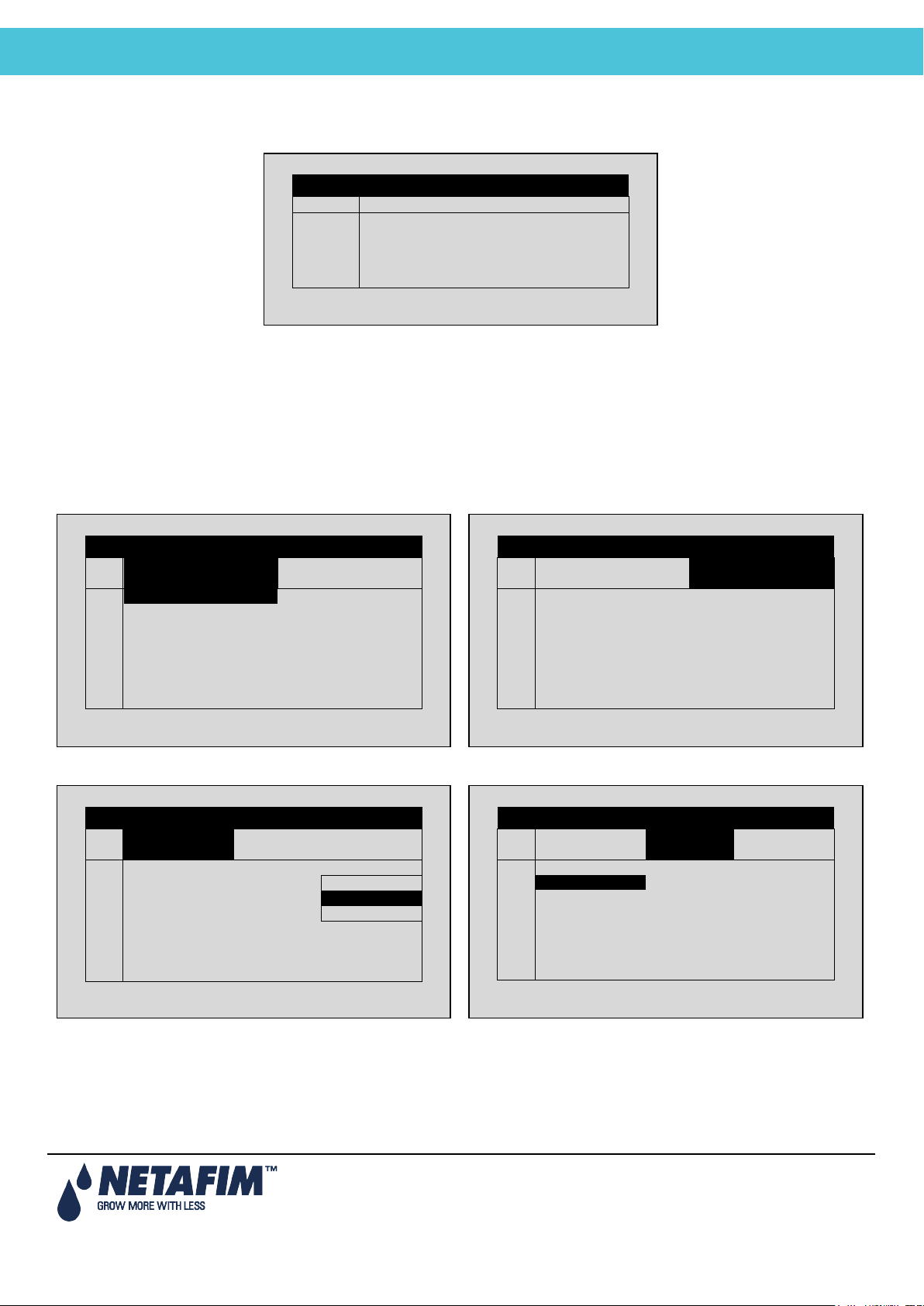

5.5 Analog Input

a. Enter the beginning and ending time for each

b. Under Start An. Dry Cont., define the input type.

c. Define The Trigger Type

d. Under Stop An. Dry Con., define the input type.

Channel

Input Function

Valid

1

pH Sensor

NO

2

EC Sensor

YES

3

Humidity Sensor

YES

4

Temp. Sensor 1

YES

5

Temp. Sensor 2

YES

#

From

hh:mm

To hh:mm

Start An.

Dry Cont.

1

10:00

12:00

2

11:00

12:00

Dry Con 1

3

12:00

13:00

Dry Con 1

4

--:--

--:--

<NONE>

5

--:--

--:--

<NONE>

6

--:--

--:--

<NONE>

7

--:--

--:--

<NONE>

8

--:--

--:--

<NONE>

#

From

hh:mm

To

hh:mm

Start An.

Dry Cont.

1 12:00

2 12:00

Dry Con 1

3 13:00

Dry Con 1

4 --:--

<NONE>

5 --:--

<NONE>

6 --:--

<NONE>

7 --:--

<NONE>

8 --:--

<NONE>

#

Trigger Type

Stop An

Dry Cont.

Oper.

to Start

1

Multi Shot

---

2

Multi Shot

Dry Con 2

One Shot

3

One Shot

Dry Con 14

Multi Shot

4

One Shot

<NONE>

Only If On

5

One Shot

<NONE>

---

6

One Shot

<NONE>

---

7

One Shot

<NONE>

---

8

One Shot

<NONE>

---

#

Trigger Type

Stop An

Dry Cont.

Oper.

to Start

1

---

2 Dry Con 2

---

3 Dry Con 14

---

4 <NONE>

--- 5

<NONE>

---

6 <NONE>

---

7 <NONE>

---

8 <NONE>

---

1. In Installation > Analog Input, define input function(s) as Analog Sensors.

ANALOG INPUT

2. In Setup > Analog Conversion Table:

a. Select the sensor type

b. Under Valid, select YES.

3. In Test > Analog Sensor, view the actual sensor values.

4. In Program > Ext Condition, configure the External Condition Program for the analog sensors.

program.

EXTERNAL CONDITION PROGRAM

EXTERNAL CONDITION PROGRAM

EXTERNAL CONDITION PROGRAM

EXTERNAL CONDITION PROGRAM

Page 29

Page 30

NMC-Junior Pro Installation Manual

CONTROLLER SETUP

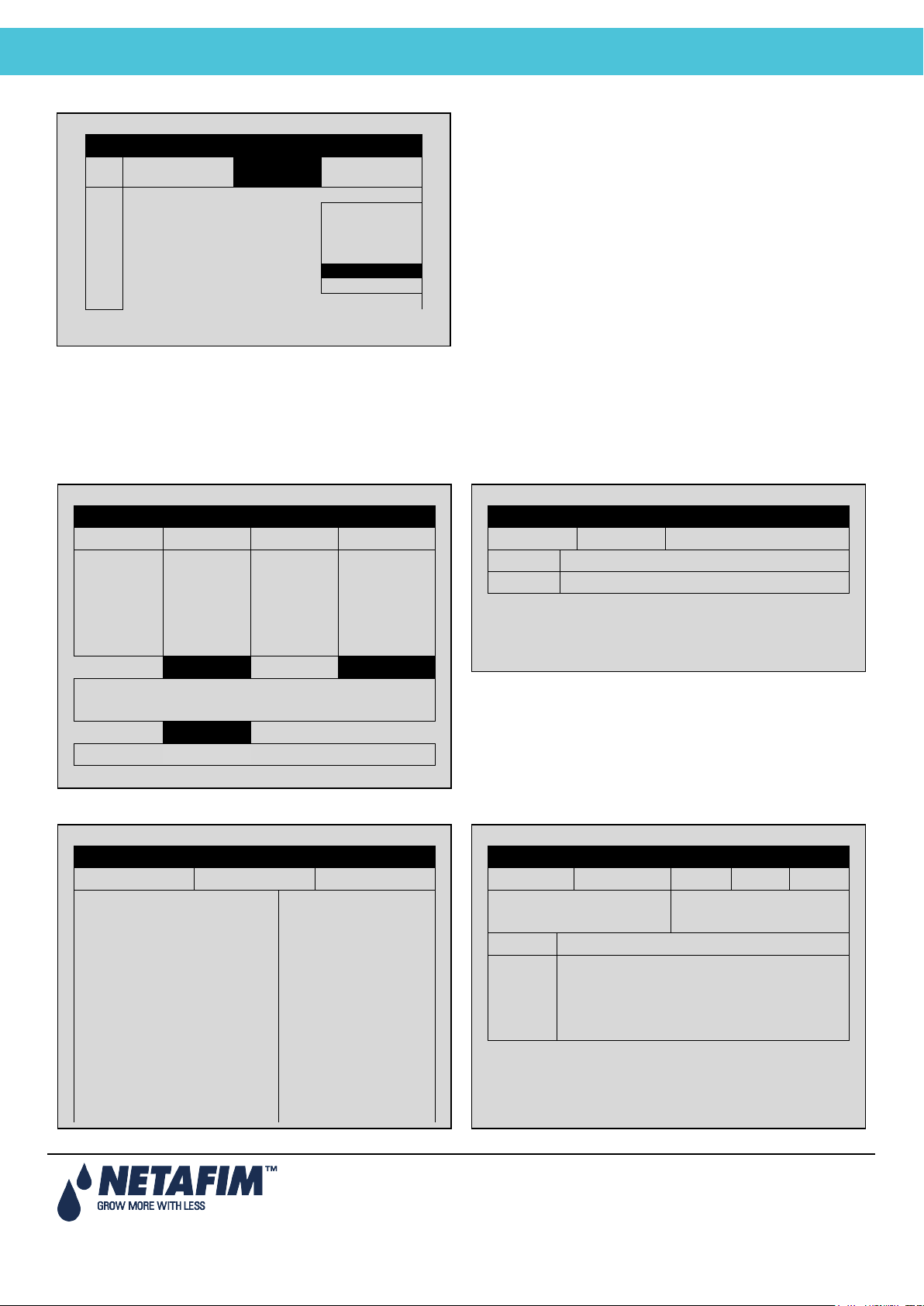

e. Under Oper. to Start, choose the required symbol.

f. Under Start Value, enter the required value to start

EXTERNAL CONDITION PROGRAM

#

Stop An

Dry Cont.

Oper.

to Start

Start

Value

1

<NONE> >

2

Dry Con 2

---

3

Dry Con 14

---

4

<NONE>

---

5

<NONE>

---

6

<NONE>

---

7

<NONE>

---

8

<NONE>

---

the analog sensor. Under Stop Value, entered the

required value to stop the analog sensor.

5.6 Hot Keys and Status Screens

Hot Key 1: Next Irrigation Hot Key 2: Irrigation Process

SYSTEM SETUP

SET ACTUAL

CYCLE 1 1 START AT

WATER 00:10:00 00:10:00

FLOW 100.00 100.00

EC 1.5 LEFT

pH 5.3

STATUS ACTIVE

PROGRAM: 07:43:23 IRRIGATION

VALVE: 03-Apr-13 ALARM

MESSAGE

Hot Key 3: Program Status Hot Key 4: Water Flow & EC/pH Status

PROGRAM STATUS

Program: 1 3-Apr-13 09:12:35

Status Wait

Time - Minimum ---

Time - Maximum ---

Rad Sum – Measured/Limit —/—

Clock Starts – Given/Set —/—

Starts Due to Rad Sum ---

Starts Due to Max Time ---

Total Cycles Given 1

Last Start 12:00

Elapsed Time 3:00

Next Start 15:43

IRRIGATION PROCESS

Prog: Valve: Time: 08:07:23

Set Actual Flow Valve

Water

WATER EC/pH

Status Wait EC pH

Nom. Flow ------ Target --- ---

Act. Flow ------ Actual --- ---

Open(%) Min(%) Prg(%) Max(%)

Chan. 1 --- --- --- ---

Chan. 2 --- --- --- ---

Chan. 3 --- --- --- ---

Chan. 4 --- --- --- ---

Page 30

Page 31

NMC-Junior Pro Installation Manual

CONTROL TEST PROCEDURE

Hot Key 5: Filter Flushing Status Hot Key 6: Temperature and Humidity Status

FILTER FLUSHING STATUS

Item

Flush Status OFF

Time to Next Flush --:--:--

Delta Pressure (Digital) OFF

Flushing Filter No. --

Remaining Filters Qty. 0

Delay 00:00

Current Delta Pressure ----

TEMP & HUMIDITY

No. Temp. Humidity

1 <NONE> <NONE>

2 <NONE> ----

AVG. <NONE> <NONE>

Sen#T H VPD VPD SUM

<NONE> 0.0

Page 31

Page 32

NMC-Junior Pro Installation Manual

CONTROL TEST PROCEDURE

6 CONTROLLER TEST PROCEDURE

TEST

OUTPUT

FUNCTION

STATUS

1

DOSING CHANNEL 1

OFF

2

DOSING CHANNEL 2

OFF

3

DOSING CHANNEL 3

OFF

4

DOSING CHANNEL 4

OFF

5

DOSING CHANNEL 5

OFF

6

DOSING CHANNEL 6

OFF

7

DOSING CHANNEL 7

OFF

8

DOSING CHANNEL 8

OFF

1. RELAYS

2. DIGITAL INPUT

3. ANALOG INPUT

4. TEMPERATURE

5. HUMIDITY

The Test menu provides a quick way of verifying functionality.

• Relays, page 32

• Digital Input, page 32

• Analog Input, page 33

• Temperature, page 34

• Humidity, page 34

6.1 Relays

The Relays Test screen allows you to check the current output status and verify proper operation.

TEST RELAYS

The setting switches automatically between ON and Off depending on device actual status.

To manually test relay functionality, move the cursor to required device using the arrow keys and press ENTER; the

device is turned on and the setting shows MAN.

Press ENTER again to return to automatic operation.

• OFF: The output is not active.

• ON: The output is automatically turned on by the relevant program.

• Man: Manual operation of the output. The manual operation resets after 30 minutes of being idle, to prevent

you from forgetting to set it back to automatic operation.

• Load Output Level: Output level in A/D values. The value is constantly updated in accordance to relay

operation and output level change. This value is used to calculate the A/D threshold value to be considered as

a short circuit.

6.2 Digital Input

The Digital Input test screen allows you to verify the proper operation of digital inputs and sensors. Digital inputs are

defined as meters (water meters, dosing meters, etc.) that count the number of closed contacts from 0 to 255 and

Page 32

Page 33

NMC-Junior Pro Installation Manual

CONTROL TEST PROCEDURE

automatically restart back from 0. Other digital inputs (Dry contact, Ext. Pause, etc.) show either 0 when the contact is

DIGITAL VALUE

Channel

Value 1 59

2

0

3

0

4 0 5

0

6

0

Channel

Value

pH

564

EC

345

Hum.

376

Temp1

511

Temp2

453

open or 1 when the contact is closed.

Note that the card number is set according to its jumpers regardless to its location (local or extension box).

• Perform a dry test. Using a magnet, get a pulse. Attach the magnet to get a pulse from the read of the cable.

• Verify the water, fertilizer and any auxiliary meters.

Delta pressure: 1 = ON, 0 = OFF

6.3 Analog Input

Analog inputs will show values from 0 to 1023.

ANALOG INPUT

pH sensor

EC sensor

Humidity sensor

Temp sensor

Sensor type Description

pH = 0 – A/D = 205

pH = 7.0 – A/D = 615

pH = 14.0 – A/D = 1023

EC = 0 – A/D = 205

EC = 2.0 – A/D = 370

EC = 10.0 – A/D = 1024

RH% = 0 – A/D = 0

RH% = 50 – A/D = 308

RH% = 100 – A/D = 620

T°C = 0 – A/D = 768

T°C = 25 – A/D = 489

T°C = 50 – A/D = 250

Page 33

Page 34

NMC-Junior Pro Installation Manual

CONTROL TEST PROCEDURE

6.4 Temperature

No.

Value

1

27.3

2

28.6

No.

Value

1

57.3

This table shows the current temperature sensor readings in degrees (Celsius or Fahrenheit depending on the setup

in the screen).

TEMPERATURE

6.5 Humidity

This table shows the current humidity sensor readings in percentage relative humidity.

HUMIDITY

Page 34

Page 35

NMC-Junior Pro Installation Manual

SYSTEM CONFIGURATION PROCEDURE

7 SYSTEM CONFIGURATION PROCEDURE

CONFIGURATION

1. DEVICE DELAY CONFIGURATION

2. PUMP STATION CONFIGURATION

3. VALVE CONFIGURATION

4. VALVE FLOW RATE

5. WATER METER

6. DOSING CHANNEL CONFIGURATION

7. DOSING CONFIGURATION

8. DRAINAGE CONFIGURATION

9. EC/PH CONFIGURATION

10. COOLING CONFIGURATION

11. MISTING CONFIGURATION

• Device Delay Configuration, page 35

• Pump Station Configuration, page 38

• Valve Configuration, page 39

• Valve Flow Rate, page 40

• Water Meter, page 41

• Dosing Channel Configuration, page 42

• Dosing Configuration, page 43

• Drainage Configuration, page 44

• EC/pH Configuration, page 44

• Cooling Configuration, page 45

• Misting Configuration, page 45

• History Resolution, page 45

• System Nutrigation™ Check, page 46

7.1 Device Delay Configuration

The Device Delay Configuration screen enables defining the startup and shutdown order of the irrigation process.

• On (mm:ss): On is the definition of the startup order. The set times are taken from procedure startup. The

device with the shortest time will be started first and shifted to procedure startup. Therefore it is recommended

that the device that is to be started first be set as 00:00 (automatically changes to --:--).

• Off (mm:ss): Off is the definition of the shutdown order of the irrigation process. The set times are taken from

procedure shutdown. The device with the shortest time will be stopped first and shifted to procedure

shutdown. Therefore it is recommended that the device that is to be stopped first be set as 00:00

(automatically changes to --:--).

Page 35

Page 36

NMC-Junior Pro Installation Manual

SYSTEM CONFIGURATION PROCEDURE

7.1.1 Example of Device Startup & Shutdown Order

Stagger

1:00

1:30

00:20

VALVE 1

VALVE 2

MAIN

PUMP

• Startup: According to the settings above, the pump will be turned on first (on procedure startup). The main

valve will be opened after 1 minute later (one minute from procedure startup) the valve.

• Shutdown: According to the settings above the valve will be turned off first (on procedure shutdown). The

main valve will be closed after 15 seconds and the pump will be closed 20 seconds later (35 seconds from

procedure shutdown).

Note: It is recommended that the device that should be started (stopped) first be defined as zero

(will appear as --:--).

IN-PROGRAM DELAYS

• Shift delay (sec): Define the time (in seconds) between each valve change. The shift delay can also be a

shift advance by inserting a negative value. This means that the next valve will start before the previous one.

• Stagger delay (sec): Define the time (in seconds) for the first shift and the last shift delay between valves

(inside of group).

Stagger

00:20

0:15

00:35

mm:ss

Page 36

Page 37

NMC-Junior Pro Installation Manual

SYSTEM CONFIGURATION PROCEDURE

7.1.2 Example of Stagger Valve Delay – Multiple Shifts

Page 37

Page 38

NMC-Junior Pro Installation Manual

SYSTEM CONFIGURATION PROCEDURE

7.2 Pump Station Configuration

Pump

No.

Capacity

m3/h

Stability

mm:ss

Off Delay

mm:ss

1

----

--:--

--:--

Pump

No.

Capacity

m3/h

Stability

mm:ss

Off Delay

mm:ss

1

5.00

00:20

00:00

The NMC-Junior Pro can include up to six pumps. Each valve (irrigation, cooling or misting) can be connected to one

of the pumps or to the pump station. The pump station is a group of pumps (out of the six possible pumps) that will be

started in accordance with the required flow. The Pump Station configuration screen allows you to define which pumps

are part of the station, the capacity of the various pumps and their startup and shutdown delays.

Pump Station Configuration

Pump Station Configuration

The NMC-Junior Pro automatically calculates the expected flow and determines which pump (or pumps) should be

started (see Valve Configuration for additional information regarding flow calculation). The NMC-Junior Pro will start

the minimal number of pumps required to supply the calculated flow rate.

If several pumps should be started, the NMC-Junior Pro starts from the largest to the smallest and will turn them off

from the smallest to the largest.

• Pump No.: Pump number.

• Capacity: Define pump capacity in m3 or gallon. This will be the maximum pump capacity, above which the

NMC-Junior Pro will turn on another pump (if available).

• Stability (mm:ss): Define stability time. Stability time is the startup time required for current pump before next

pump can be started up. Stability time is usually used to prevent voltage drop down and water hammer (see

Pump Startup Order

• Off Delay (mm:ss): Define off delay. Off delay will be the delay time for current pump to stop after last pump

has stopped. This delay is usually used to prevent water hammer (see Pump Shutdown Order

• Station (Yes/No): Define whether the pump is part of the pump station.

The following is a startup and shutdown order schema according to the settings above and a calculated flow rate of 60

3

/h:

m

schema).

schema).

Pump 1

Pump 2

Pump 3

00:20

00:20

Figure 1: Pump startup & shutdown order

00:20

00:10

00:10

mm:ss

Page 38

Page 39

NMC-Junior Pro Installation Manual

SYSTEM CONFIGURATION PROCEDURE

7.3 Valve Configuration

Valve configuration allows you to configure devices such as pumps, main valves and drainage measurement of

valves.

• Valve No.: Indication of the valve number.

• Pump: Define which pump or pump station should be started when irrigating this valve. When choosing

Station, the NMC-Junior Pro will choose which and how many pumps should be started to supply the required

(calculated) flow. See

• Pump Station Configuration on page 38 for more information).

• Main Valve: Define which main valve should be opened when starting each valve.

• Water Meter: Configure a water meter to each valve. This option is only possible when the flow calculation

(water meter type) is Standard.

Note: Make sure that you define an operative water meter. There is no protection against defining a water meter

that isn’t properly defined in the system.

Note that when operating using Water Source (refer to Water Meter, page 41) a valve is not configured to a specific

water meter. In this case, all water meters set in the system are relevant for each irrigation; their pulses are calculated

for the flow rate. Therefore the Water Meter column is irrelevant in the Valve Configuration table.

Note: Make sure that you define an operative water meter. There is no protection against defining a water meter

that isn’t properly defined in the system.

Note: When using more than one water meter only start two valves that are configured to the same water meter;

the NMC-Junior Pro uses only the water meter connected to the leading valve and does not sum the flow from

the rest of the water meters. Dosing in this manner can create unexpected alarms and malfunctions!

• Drain Meter: Define which drain meter this valve is connected to.

• Drain Type: Define drainage type:

Total: Drainage is collected from the complete valve area.

Sample: Drainage is collected from a representing part of the valve area.

Note that it is possible to set several valves to the same drain meter when working by 'Total'. The system does not

allow operating several valves on the same meter when operating by 'Sample'.

• Sample %: When using sample drainage measurement it is required to define the ratio of the sample area to

the complete valve area.

Page 39

Page 40

NMC-Junior Pro Installation Manual

SYSTEM CONFIGURATION PROCEDURE

7.4 Valve Flow Rate

• Nominal: Define nominal valve flow rate (m3/h or gallon/min). The NMC-Junior Pro uses the set nominal flow

rate for calculating the ratio between valves when starting a few valves together, the boundaries for alarms,

the total flow rate for calculating how many pumps to start, etc. Therefore it is recommended to try and set the

nominal flow rate as close as possible to the actual flow rate.

• Minimum: Minimum valve flow rate, under which the system will generate a low flow alarm. When changing

the Nominal flow rate this setting is automatically set to 25% under the nominal flow, and can be manually

changed.

• Maximum: Maximum valve flow rate, above which the system will generate a high flow alarm. When changing

the nominal flow rate this setting is automatically set to 25% above the nominal flow, and can be manually

changed.

Note: When starting several valves simultaneously the system will sum their nominal, minimal and maximal flow

rates. An alarm will be generated only if the measured flow rate is lower than the total minimum, or higher than

the total maximum.

Note: When starting several valves simultaneously, the quantities between them will be divided based on the

ratio of their nominal flow.

Page 40

Page 41

NMC-Junior Pro Installation Manual

SYSTEM CONFIGURATION PROCEDURE

7.5 Water Meter

Description

Ratio

Type

Water Meter 1(L/P)

10.000

W.SOURCE

Water Meter 2(L/P)

20.000

W.SOURCE

Water Meter 3(L/P)

50.000

W.SOURCE

AUX Meter 1 (L/P)

----

--------

AUX Meter 2 (L/P)

----

--------

AUX Meter 3 (L/P)

----

--------

AUX Meter 4 (L/P)

----

--------

AUX Meter 5 (L/P)

----

--------

AUX Meter 6 (L/P)

----

--------

Description

Type

Sum

Water Meter 1(L/P)

W.SOURCE

+

Water Meter 2(L/P)

W.SOURCE

+

Water Meter 3(L/P)

W.SOURCE

+

AUX Meter 1 (L/P)

-------

--------

AUX Meter 2 (L/P)

STANDARD

--------

AUX Meter 3 (L/P)

W.SOURCE

--------

AUX Meter 4 (L/P)

--------

--------

AUX Meter 5 (L/P)

--------

--------

AUX Meter 6 (L/P)

--------

--------

Description

Ratio

Type

Water Meter 1(L/P)

10.000

STANDARD

Water Meter 2(L/P)

20.000

STANDARD

Water Meter 3(L/P)

50.000

STANDARD

AUX Meter 1 (L/P)

----

--------

AUX Meter 2 (L/P)

----

--------

AUX Meter 3 (L/P)

----

--------

AUX Meter 4 (L/P)

----

--------

AUX Meter 5 (L/P)

----

--------

AUX Meter 6 (L/P)

----

--------

• Ratio: Set volume per pulse of each water meter or auxiliary meter.

• Type: Define type of flow calculation:

Standard: In this function valves which are operated in a group should be connected to the same water

meter.

Note: If a few valves configured to different water meters will be started simultaneously, the NMC-Junior Pro

uses the flow measured by the water meter connected to the leading valve.

Water source: The NMC-Junior Pro will sum or deduct flow measured simultaneously from a few water

meters. When choosing this function an additional column called ”SUM” will appear, this column

enables to define which water meters should be summed and which deducted from the total measured

flow.

Note: Flow calculation type is a general definition for all water meters, therefore when changing type of water

meter for one of the water meters the type will be changed for all water meters.

Note: When setting flow calculation (water meter type) to Water source it is not possible to configure valves to

water meters.

• Sum: Define whether flow measured by each water meter should be added to the total measured flow or

deducted:

“+” Flow measured by this water meter will be added to the total measured flow.

“–” Flow measured by this water meter will be deducted from the total measured flow.

Note: Since flow cannot be negative, if the controller measures negative flow it will show zero.

Note: If all valves are set to "–" the system ignores the measured flow and will use the nominal flow (based on

the nominal flow).

WATER METER

WATER METER

WATER METER

Page 41

Page 42

NMC-Junior Pro Installation Manual

SYSTEM CONFIGURATION PROCEDURE

Note: It is very important to choose the correct flow meter for the application. Choosing a wrong flow meter might

result in measurement errors or an inaccurate control. For instructions regarding how to choose the correct water

meter see NMC-Junior Pro Irrigation > General > Flow meter determination.

7.6 Dosing Channel Configuration

• Pump: Select the type of dosing pump:

Venturi: The dosing unit consists of Venturi driven injectors. The dosing booster will be turned on when

fertigation is active.

Hydraulic: The dosing unit consists of hydraulic fertilizer pumps. The dosing booster is not needed and

will not be turned on when Fertigation is active. When working with hydraulic pump, the method can

only be Liter/Pulse and EC & pH control is not possible.

Electric: The dosing unit consists of electrical fertilizer pumps. The dosing booster is not needed and

will not be turned on when Fertigation is active.

• Method: Select the operating method:

Liter/Pulse: Define whether a dosing meter is connected to this channel and used for control purposes.

Set the volume per pulse on the Ratio column.

Time (cc/sec): Define whether the calculated flow rate of the dosing channel is in CC (gallons) of

fertilizer per second.

Time (Liter/min): Define whether the calculated flow rate of the dosing channel is in liters (gallons) per

minute.

Time (Liter/Hour): Define whether the calculated flow rate of the dosing channel is in liters (gallons) per

Hour.

• Ratio

Method is Time: Define calculated flow rate, this will be the flow rate of the channel when completely

open.

Method is Liter/Pulse: Define the volume per pulse.

• React: Set the required use of the channel:

EC: The channel is used to increase measured EC, meaning it will be opened more when the measured

EC is lower than the set EC.

pH: The channel is used to decrease measured pH, meaning it will be opened more when the

measured pH is higher than the set pH.

Passive: The channel does not respond to changes in measured EC/pH, meaning it will be opened as

set in the dosing program regardless of the EC/pH values.

Alkali: The channel is used to increase measured pH, meaning it will be opened more when the

measured pH is lower than the set pH.

Note: If EC/pH control is off, or the channel is used for proportional injection only (for example in order to inject

chemicals) set reaction to passive.

• High %: set an injection percentage limit. This percentage will limit the deviation from set dosing recipe when

NMC-Junior Pro is injecting more than specified in order to try and reach the target EC/pH values.

• Low %: set an injection percentage limit. This percentage will limit the deviation from set dosing recipe when

NMC-Junior Pro is injecting less than defined in order to try and reach the target EC/pH values.

Page 42

Page 43

NMC-Junior Pro Installation Manual

SYSTEM CONFIGURATION PROCEDURE

• V/P(L/G): This parameter is disabled when operating by Liter/Pulse. Define the volume per pulse of the

dosing meter (liters or gallons). Only required when using a dosing meter for measurement and alarm

purposes. When using a dosing meter for control purposes the volume per pulse of the dosing meter should

be defined on the Ratio column. The letter between the brackets indicates whether the volume units are in

Liter or Gallon.

7.7 Dosing Configuration

• EC Control: Define whether EC control should be operative.

• pH Control: Define whether pH control should be operative.

• EC Alarms: Define whether EC related alarms are operative. When EC control is set to ‘Yes’, EC Alarms are

automatically set to ‘Yes’ and cannot be changed.

• pH Alarms: Define whether pH related alarms are operative. When pH control is set to ‘Yes’ pH Alarms are

automatically set to ‘Yes’ and cannot be changed.

• Minimum On Time (sec): Define the minimum time the dosing regulator can be open. This feature is used to

protect the regulator from being excessively turned on and off. The minimum allowed on time is 0.4 seconds.

• Minimum Off Time: Define the minimum time the dosing regulator can be off. This feature is used to protect

the regulator from being excessively turned on and off. The minimum off time allowed is 0.4 seconds.

• EC Coarse Tuning (0-10): EC Coarse Tuning is used to adjust the speed and strength of the EC control. A

higher value will result in faster correction but might lead to over shooting (see Appendix 1 – General > EC/pH

correction adjustment for further information).

• EC Fine Tuning (0-10): EC Fine Tuning is used to fine tune the EC control shooting (see NMC-Junior Pro

Irrigation > Part 2 > General > EC/pH correction adjustment for further information).

• pH Coarse Tuning (0-10): pH Coarse Tuning is used to adjust the speed and strength of pH control. A higher

value will result in faster correction but might lead to over shooting (see NMC-Junior Pro Irrigation > Part 2 >

General > EC/pH correction adjustment for further information).

• pH Fine Tuning (0-10): pH Fine Tuning is used to fine tune pH control shooting (see NMC-Junior Pro

Irrigation > Part 2 > General > EC/pH correction adjustment for further information).

• Control Cycle (sec): Define the control cycle for EC/pH control. This should be the time it takes the system

since it injected fertilizer/acid until the change in recognized by the system.

• EC/pH Averaging (0-Low, 20-High): Averaging factor for EC/pH measurement. EC/pH averaging should be

used to enable correction when injection is not homogenous.

• Dosing Booster Off Delay (mm:ss): Define the time that the dosing booster should be left on after dosing

has ended. This time is usually used to circulate the acid and nutrients in order to prevent high concentrations

in the area of the venturies and dosing booster when the system is idle.

• Dosing by QTY. Method:

Bulk: All channels set to QTY (quantity) dosing method will inject the set quantity in one bulk, starting

after water before quantity/time has elapsed.

Spread Out: The set dosing quantity of all channels set to QTY (quantity) dosing method will be spread

throughout the irrigation.

Page 43

Page 44

NMC-Junior Pro Installation Manual

SYSTEM CONFIGURATION PROCEDURE

7.8 Drainage Configuration

Sensor

4 mA

20 mA

EC 0 10

pH 0 14

• Ratio: Define volume per pulse of the drainage meters (liter/pulse or gallon/pulse).

• On Delay: Define how long a valve, which is configured to this drainage measurement, should be open before

the measured drainage is related to this valve. All drainage measured before this time has elapsed (although

the valve is open) will still be related to the previous opened valve that was configured to this drainage sump.

• Off Delay: Define how long after irrigation has finished, the measured drainage should still be related to the

previous irrigation. This value is used to “tell” the NMC when to stop relating drainage to the previous irrigation

and write it to all relevant history tables.

7.9 EC/pH Configuration

EC/pH CONFIGURATION

Define the range of the EC/pH transmitters.

• Default settings for Netafim EC/pH transmitters is:

EC: zero to 10 mS

PH: zero to 14 ppm

• EC Control Sensor: Define which EC sensor should be used for control. When setting EC 1 + EC 2, EC1 will

be used for control, and EC2 will be used for verification.

• pH Control Sensor: Define which pH sensor should be used for control. When setting pH 1 + pH 2, pH1 will be

used for control, and pH2 will be used for verification.

Page 44

Page 45

NMC-Junior Pro Installation Manual

SYSTEM CONFIGURATION PROCEDURE

7.10 Cooling Configuration

1. Select Controller number (in case of multiple controllers in the network, name each controller with a different

SETUP

The cooling configuration screen will only be visible after one (or more) cooling valves have been defined in the

DEVICE LAYOUT

• Pump: Configure a pump to each cooling valve. This setting is not necessary if the cooling pump is not

controlled by the NMC-Junior Pro.

• Main Valve: Configure a main valve to each cooling valve. This setting is not necessary if the cooling doesn’t

have a main valve.

table.

7.11 Misting Configuration

• Pump: Configure a pump for each misting valve. This setting is not necessary if the misting pump is not

controlled by the NMC-Junior Pro.

• Main Valve: Configure a main valve to each misting valve. This setting is not necessary if the misting doesn’t

have a main valve.

7.12 History Resolution

Program how often the computer collects sensor data (keep in mind that lower resolution fills the memory in short

period and overwrites the old data).

1. TIME & DATE

2. SYSTEM SETUP

3. TEMPE RATURE CALIBRATION

4. HUMIDITY CALIBRATION

5. EC/PH CALIBRATION

6. SENSOR LOGGING

7. WRITE TO DATA P LUG

8. READ FROM DATA PLUG

number

Page 45

Page 46

NMC-Junior Pro Installation Manual

SYSTEM CONFIGURATION PROCEDURE

2. Select the communication baud rate between controllers and the PC

SYSTEM SETUP

Language

Temperature Unit

°C

Volume Unit

Metric

Maximum Cooling Parallel

1

Maximum Misting Parallel

1

STOP IRRIGATION

During Filter Flushing

No

During Cooling Process

No

During Misting Process

No

STOP DOSING

During Filter Flushing

No

Main Screen

Default Hotkey Number

5

History

History Resolution

1 Hour

Weather Station

Controller Function

LOCAL

Operation Mode

Automatic return to RO mode

NO

Return period to RO mode

00:10

Communication

Controller Number

1

Port Protocol

NMC NET

Baud Rate

9600

7.13 System Nutrigation™ Check

• Check if EC/pH is on Target

• Water Run Time

• Start/Stop Valve

7.13.1 Check if EC/pH is on Target

SYSTEM SETUP

1. Go to Program > Dosing.

2. Enter required amount of fertilizer to inject per dosing channel in l/m³ (USA: Gallon/1000 gallon)

3. Enter required target EC/PH levels.

7.13.2 Water Run Time

Page 46

Page 47

NMC-Junior Pro Installation Manual

SYSTEM CONFIGURATION PROCEDURE

7.13.3 Start/Stop Valve

Page 47

Page 48

NMC-Junior Pro Installation Manual

CONTROLLER ADVANCED FEATURES

8 CONTROLLER ADVANCED SETTINGS

• Pump Station Configuration

• Multiple Water Meters

• Various Dosing Configurations

• Dosing Configuration

• Error! Reference source not found.

• Hot Keys and Status Screens

8.1 Pump Station Configuration

8.2 Multiple Water Meters

Only one water meter can be measured at a time.

Page 48

Page 49

NMC-Junior Pro Installation Manual

CONTROLLER ADVANCED FEATURES

8.3 Various Dosing Configurations

• Method 1

• Method 2

• Method 3

8.3.1 Method 1

• Dosing pump control = Fert. Meter

• Dosing pump measurement = Fert. Meter

• Dosing pump type = Venturi or Electric

8.3.2 Method 2

• Dosing pump control = Nominal Flow Rate

• Dosing pump measurement = Calculate dosing pump flow rate

• Dosing pump type = Venturi or Electric

8.3.3 Method 3

• Dosing pump control = Fert. meter

• Dosing pump measurement = Fert. Meter

• Dosing pump type = Hydraulic

Page 49

Page 50

NMC-Junior Pro Installation Manual

CONTROLLER ADVANCED FEATURES

8.4 Dosing Configuration

• EC/pH Control Step 1

• EC/pH Control Step 2

8.4.1 EC/pH Control Step 1

System injects ± depending on EC levels, auto-adjust to meet target levels. Set limits for controller adjustments when

levels are too high/low/

Example: If dosing Channel 1 is set by the grower to inject 10 liter/m3, the controller auto adjust range is 5 to 15

liter/m3 in order to meet the EC level.

8.4.2 EC/pH Control Step 2

• EC/pH coarse tuning: When way off target, faster/stronger correction

• EC/pH fine tuning: Off target is low, slow/light correction

• Control cycle: Delay time from fertilizer/Acid injection point to EC/pH sensors reading

• EC/pH averaging: Balanced reading from EC/pH sensors

• Dose boost off delay: Time clear water circulated through system after fertigation stops and Venturi closes

Page 50

Page 51

NMC-Junior Pro Installation Manual

PROGRAM MENU

9 PROGRAM MENU

In the Main Menu screen, place the cursor on the program icon and press ENTER, or press '1' to enter the Program

Menu.

• Irrigation, page 51

• Using the Influences, page 55

• Setting the Influences, page 55

• Water Run Time, page 60

• Dosing, page 61

• Ext. Condition, page 63

• Agitator, page 64

• Selector, page 65

• Filter Flushing, page 65

• Cooling, page 66

• Misting, page 68

• Water Heating, page 69

Note: To enter any of the menus, press the corresponding numeric key or scroll to the desired item using the

up/down arrow keys and press ENTER: a new window will appear. The first menu under Program is Irrigation.

9.1 Irrigation

The Irrigation Program screen includes all the settings for configuring automatic irrigation start. It depends heavily on

the Water Run Time and dosing program screens; therefore it is recommended to configure these screens before

irrigation takes place.

The NMC-Junior Pro consists of 15 irrigation programs.

Page 51

Page 52

NMC-Junior Pro Installation Manual

PROGRAM MENU

• Program: Select a program by entering the program number and confirm by pressing ENTER.

• Priority: Priority determines the order in which programs will take place. If start time is the same, higher

priority programs come first. Higher priority programs do not stop currently operative programs.

If start time and priority are the same, irrigation programs with a lower number are executed first. Priority

ranges are between 0 and 15, 15 being the highest (See NMC-Junior Pro Irrigation – Part 2 > Priority

specifications for further information).

• Const / Daily / Cond. / Rad Sum / VPD Sum:

CONST.: Increase or decrease the amount of water for all valves included in this program. 0% means

the quantities will be as specified in the Water Run Time program, 100% will be twice the amount and

–50% will be half the amount specified in the Water Run Time Program. To decrease enter the

required percentage of change, press the +/- key and confirm with the ENTER key. The percentage of

change is active until you specify otherwise.

DAILY: Increase or decrease the amount of water for all valves included in this program. 0% means the

quantities will be as specified in the Water Run Time program, 100% will be twice the amount and –

50% will be half the amount specified in the Water Run Time Program.

To decrease, enter the required percentage of change, press +/- key and confirm with the ENTER key.

The percentage of change will be active only for the present day and will change automatically back to

zero on End Day time.

Note: CONST. % and DAILY % does not change Quantity / time of water before and water after settings, nor

dosing quantities.

Note: When setting watering program and using 'Spread' the percentage affects not only the water but also the

dosing.

Cond.: Specify whether the Condition program can trigger irrigations, and choose a Condition program

to start/stop irrigations. Irrigations will be started and stopped according to the settings of the relevant

Condition program (see Ext. Condition, page 63, for additional information). If irrigation is not triggered

due to Condition program until Max time has elapsed irrigation will be performed due to Max time.

When choosing Condition, the screen will be split in two. To view the day sequence, press the Down

arrow when the cursor is placed on the bottom of the screen.

The Condition program has the third priority after active irrigation and uncompleted irrigation (See

NMC-Junior Pro Irrigation – Part 2 > Priority specifications for further information).

Page 52

Page 53

NMC-Junior Pro Installation Manual

PROGRAM MENU

Note: It is impossible to set the same Condition program for two different programs.

DATE : 1-May-12 TIME : 10:12:09

Program: 2

Priority: --

Rad Sum

Start Time

Max. Time

07:00

02:00

12:00

--:--

16:00

--:--

Valve #

Dosing Prog

001

1

051+052

2 2

115

3

255

2

DATE : 1-May-12 TIME : 10:12:09

Program: 2

Priority: --

Rad Sum

Day: 04/06

1 2 3 4

5 6

Rad Sum / VPD Sum: Choose whether irrigations can be triggered by the radiation or VPD sum. The

specific Rad Sum trigger is specified per period (see Rad Sum Li.

Rad/VPD Sum until Max time has elapsed irrigation will be performed due to Max time.

). ). If irrigation is not triggered due to

IRRIGATION PROGRAM

Clock Start

Rad Sum Li.

Min. Time

Run Time #

Screen 1 of 3 – In order to view the

1

200

01:00

1

--

--00:30

2 2

-100

--:--

2

Dose / Water

---

IRRIGATION PROGRAM

D - D W

Screen 2 of 3 – In order to view the

D W

Note: When choosing Rad/VPD Sum the screen will be split in two. To view the day sequence, press the Down

arrow on the bottom part of the screen.

• Start time (hh:mm): ENTER up to six start times (periods) per day for each program.

• Clock Start: Set the number of time-based irrigation cycles that will be performed in this cycle. The first cycle

starts at the specified start time; subsequent cycles will start after the specified Min. Time.

• Cond. Starts (appears only when Cond. Is selected): On/Off.

On: Irrigations can be triggered by the Condition program, when the specified Condition program

settings are met (Condition program active).

Off: Irrigations will not be triggered by the condition program, regardless of the Condition program

status.

• Rad/VPD Sum Li.: Specify the radiation/VPD sum limit at which irrigation will take place. The Rad/VPD Sum

counter of the specific program is automatically reset when irrigation is performed. If Rad/VPD sum limit is '0'

it is ignored.

• Min. Time:

In Rad/VPD sum and condition modes determine the minimum time allowed between irrigations.

Even if the Rad/VPD sum limit / condition limit has been reached irrigation will not be performed until

that time has passed.

Page 53

Page 54

NMC-Junior Pro Installation Manual

PROGRAM MENU

In clock starts the minimum time is the delay between start of a cycle until the start of the next cycle.

+

Dose

DATE : 1-May-12 TIME : 10:12:09

Program: 1

Priority: --

Const. 50%

Start Time

Min. Time

07:00

01:00

12:00

00:30

16:00

--:--

Valve #

Dosing Prog

051+05

1 1

004+116

3 3

115

4

255

4

Day: 04/06

1 2 3 4

5 6

For example if Clock Start is set to 2, the set Run Time is 30 minutes and the Min. Time is 45 minutes.

The second cycle will start 15 minutes after the end of the first cycle.

• Max. Time: The maximum time between two subsequent cycles. This value is used to limit the time between

two cycles when using dynamic irrigation triggers such as Rad/VPD Sum or the Condition program. When the

specified Max. Time from the beginning of the previous cycle has elapsed; irrigation will take place regardless

of the Rad/VPD Sum level or the Condition program status.

• Valve #: The NMC-Junior Pro can operate valves in any required order. Set the valve number and press

enter. The following window appears:

_

Select ‘blank’ and press ENTER to set the valve to operate alone, or ‘+’ (plus) to operate together with the next

valve. Several valves can be set to work together, as a group. A valve set (group) will have the same Run Time

program and the same dosing program. Each irrigation program can include a maximum of 100 valves

(columns) in any required order (all of them together, one after the other, a few groups-max. 100 groups, etc.).

The same valve can be entered several times with different settings.

• Run Time #: attach a Run Time Program to a valve or a group of valves. When setting valves to work

individually, a Run Time Program should be set for each valve. When setting a few valves to work together

(“+” mark between them) a Run Time Program should only be set for the first valve, the rest of the valves will

follow this setting.

Note: The quantity set in the Run Time Program will be the quantity given for all valves set to operate together,

not per valve (for further specifications of the Run Time Program see Water Run Time, page 55).

• Dosing Program: Attach a Dosing Program to a valve or a group of valves. When setting valves to work

individually, a Dosing Program should be set for each valve. When setting a few valves to work together (with

“+” mark between them) a Dosing Program should only be set for the first valve, the rest of the valves will

follow this setting.

• Day (xx/xx): Allows defining whether the program should irrigate water only, dose or be turned off on different

days.

(xx/xx): The right setting defines the day’s cycle.

(xx/xx): The left setting defines the current day of the cycle.

Select Dose, Water or None and press ENTER. ‘Dose’ means Fertigation (water + dosing), ‘Water’ means

irrigation without dosing and ‘None’ means the program is idle in that day.

IRRIGATION PROGRAM

Water

None

Clock Start

Run Time #

Dose / Water

2

1 1

D W - D

1

2 2

W D

1

2

--2

Page 54

Page 55

NMC-Junior Pro Installation Manual

PROGRAM MENU

The figure above shows “Day: 04/06”, meaning the number of the days in the cycle is 6, and the current day is day 4.

Day 1 and 5 are set to dose, day 3 is set to irrigate water only, and on days 2, 4 and 6 the program is idle.

9.1.1 Setting Irrigation that is Longer than 24 Hours

If a cycle day is 1 and the irrigation length is over 24 hours, the irrigation will repeat itself continuously, which means

continuous irrigation.

Note: Dosing operates according to ('D-W') for the same day and not according to the setting when the irrigation

has started. If irrigation starts at 18:00 and on this day dosing is set ('D'), the irrigation crosses midnight to a day

where no dosing is set ('W'), dosing stops at midnight!

9.2 Influence Program