Page 1

NetaJet NMC user and installation

manual

Manual version: 1.00

Date of issue: March 2005

Publisher: Netafim

TM

(A.C.S.) Ltd.

© Copyright 2003, Netafim

No part of this publication may be reproduced, stored in an automated data file or made

public in any form or by any means, whether electronic, mechanical, by photocopying,

recording or in any other manner without prior written permission of the publisher.

Although Netafim takes the greatest possible care both with its products and the

associated manuals, there may be deficiencies in them.

Netafim will not however accept responsibility for damage resulting from the use of

Netafim products or damage resulting from the use of this manual. Netafim also

reserves the right to make changes and improvements to its products or to the

associated manuals without notice.

Page 2

NetaJet Dosing Unit

Table of contents

Table of contents.........................................................................................................2

Introduction..................................................................................................................4

What is the system intended for...................................................................................4

Advantages..................................................................................................................4

NetaJet ........................................................................................................................4

Applications .................................................................................................................6

Structure & Specifications:...........................................................................................7

NetaJet dosing unit basic materials: ............................................................................7

Schemes and Drawings:..............................................................................................7

Inlet / Outlet Dimensions..............................................................................................9

Water supply:...............................................................................................................9

Fertilizer dosing capacity ...........................................................................................10

Installation..................................................................................................................11

Environmental conditions...........................................................................................11

Hydraulic installation..................................................................................................12

General requirements................................................................................................12

NetaJet Installation Instructions.................................................................................13

Electrical and controller installation............................................................................188

Electrical Grounding...................................................................................................188

Supply power.............................................................................................................20

PH Transmitter & Sensor connection and calibration ................................................22

EC Transmitter & Sensor connection and calibration ................................................24

NNM-64 Installation - Getting started.........................................................................27

NetaJet Commissioning.............................................................................................29

Installation requirements............................................................................................30

Pressure sustaining valve..........................................................................................30

Maintenance..............................................................................................................31

2

Page 3

NetaJet NMC User & Installation Manual Table Of Contents

Parts list & Description...............................................................................................32

Venturis & Booster Pump Specifications....................................................................35

Tips for calibrations ………………… ………………………………………………………39

Warrenty And safety...……………………………………………………………………...42

Safety instructions...………………………………………………………………………...42

Installation and maintenance…...………………………………………………………….42

Preparing the stock of acid/lye...………………………………………………………….42

3

Page 4

NetaJet Dosing Unit

Introduction

This manual details the installation, commissioning and maintenance of Netafim’s

NetaJet dosing units. The aim of this manual is to assist and enable technicians and

skilled growers to install, commission and maintain the NetaJet dosing unit.

What is the system intended for

Netafim’s Netajet dosing units enable growers to precisely control their fertilizer and

acid quantities as well as their irrigation water quantities.

Advantages

Netafim’s next-generation dosing systems meet the most demanding modern irrigation

and fertilization needs. Netafim’s dosing unit based on a precise, efficient Venturi

injector with no moving parts assures reliability and system longevity. For control, the

systems employ unique quick action valves developed specially for the chemical

industry. PH monitoring and control is standard, EC measurement and control is

optional and can be easily added to the systems.

• Fast and accurate fertilizer and acid control.

• Minimum expenses and intervention.

• Attractive price / performance ratio.

• Compact design – reduced shipment coasts.

Netajet

A Netajet injection unit designed to provide accurate fertilizer and acid control with

minimum expense and intervention. Each dosing channel is equipped with a visual flow

meter that can be adjust manually to deliver the required flow rate.

The nominal flow rate of each fertilizer’s venturi injector is 60 Gallon/Hour and the acid

venturi injector is 15 Gallon/Hour.

4

Page 5

NetaJet NMC User & Installation Manual Introduction

Hydraulic principle:

EC

pH

Netajet

OPTIONAL

Figure 1- Hydraulic principle

Notice: pH measurement and control is standard nevertheless the systems can

be supplied with EC measurement if required.

5

Page 6

NetaJet Dosing Unit

Applications

The most common application of the NetaJet is the direct distribution method: the

dosing unit circulates the nutrient solution to the various crop sections.

With this direct distribution method, the NetaJet is only active during Fertigation. The

NetaJet can be used for overhead irrigation, drip irrigation, etc’.

With large areas where the flow rate is greater than 1000 GPM, the fertilizer injection of

60 GPH/channel needs to be verified by the purchaser, as an adequate injection rate

.

For Greenhouse and nursery applications where there is a wide range of flow, the

NetaJet can have a turndown of 60% and still maintain a uniform concentration. With

turndowns >60% a mixing tank is required to maintain uniform concentration. i.e.. If the

high rate of flow on the system is 500 GPM, the minimum flow for uniform concentration

is (500 X (1-60%)= 200 GPM).

6

Page 7

NetaJet NMC User & Installation Manual Structure & Specifications

Structure & Specifications:

This chapter describes the structure of the Netajet dosing unit, its main components,

sizes and dimensions. The role of the various components is explained.

NetaJet dosing unit basic materials:

The NetaJet is equipped with the following components:

• Aluminum frame with adjustable legs.

• All necessary PVC piping.

• Goulds Booster pump used to drive the venturis.

• Venturis and dosing valves.

• Visual flow meters (rotameters) for fertilizer and acid flow indication.

• Switch board with mains voltage components and controller parts.

• Pressure switch to protect the Booster pump.

• pH sensors and transmitters (Ec is optional and can be add easily).

• NMC-64 controller with 24VAC outputs, digital and analog inputs and surge

suppression card.

Schemes and Drawings:

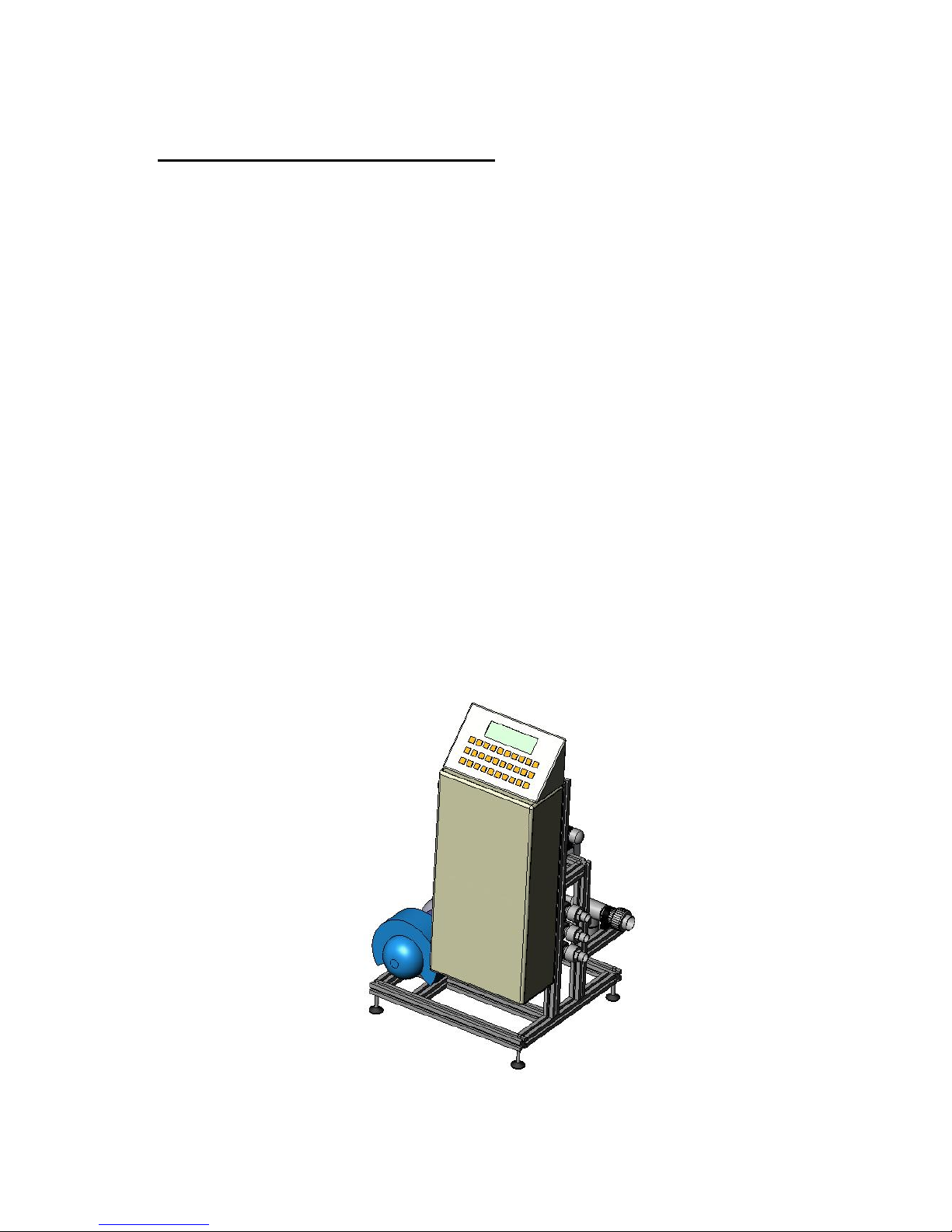

Figure 2 - Netajet Front View

7

Page 8

NetaJet Dosing Unit

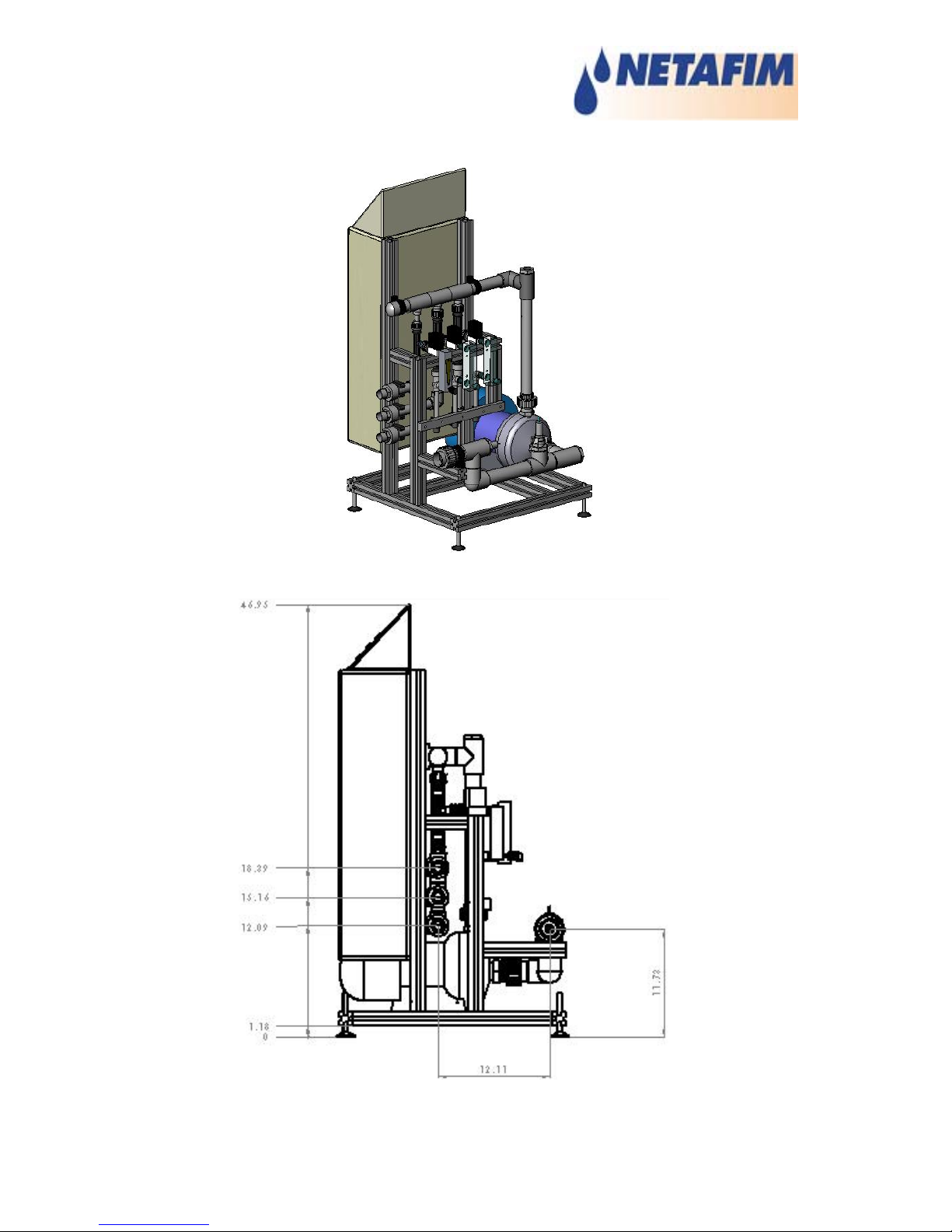

Figure 3 - Netajet Back View

Figure 3 – Side drawing (inches dimensions)

8

Page 9

NetaJet NMC User & Installation Manual Structure & Specifications

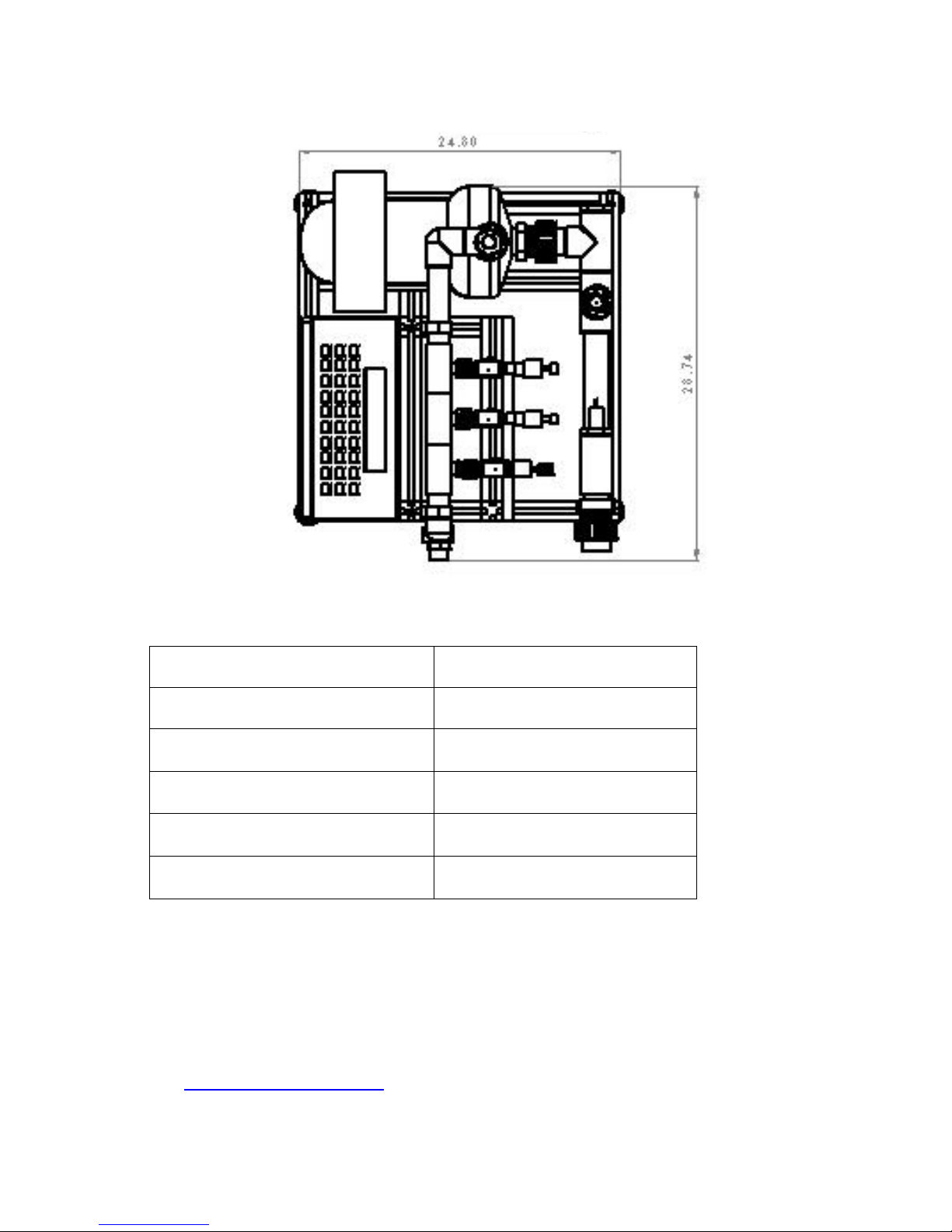

Figure 4 – Upper drawing (inches dimensions)

Inlet / Outlet Dimensions

Netajet

Inlet Diameter 1½ inch NPT male thread

Fertilizer A Outlet Diameter 1 inch NPT male thread

Fertilizer B Outlet Diameter 1 inch NPT male thread

Acid Outlet Diameter 1 inch NPT male thread

Fertilizers & Acid supply ½ inch BSP male thread

Water supply:

The supply water to the NetaJet has to be:

• No more than 72 PSI.

• No less than 30 PSI.

• Constant in terms of pressure (not fluctuating). If there are fluctuations of more than

10 PSI in supply water pressure, a pressure sustaining valve must be installed (see

Pressure sustaining valve).

9

Page 10

NetaJet Dosing Unit

Fertilizer dosing capacity

• Maximum dosage capacity will be achieve in the minimum operating pressure of 30

PSI (in the main line), at this pressure, the dosage capacity per fertilizer channel is

60 Gallon/hour and per acid channel is 15 Gallon/hour.

• The dosage capacity is virtually independent of the operating pressure above the

specified minimum 30 PSI.

• Minimum dosage capacity of a dosing channel is 10% of the maximum dosage

capacity.

• Maximum and minimum dosing capacity can be adjusted per channel via the pinvalve located on the visual flow meter.

• Motive flow per fertilizer channel is around 700 Gallon/h and per acid channel is

around 235 Gallon/hour.

Notice: Motive and Suction flow of the venturis depends in the inlet and outlet

pressure of the venturi (

see venturis table).

10

Page 11

NetaJet NMC User & Installation Manual Installation

Installation

This chapter details the hydraulic and electrical installation instructions for the Netajet

dosing unit. The aim of this chapter is to enable and assist technicians and skilled

growers to install and commission the Netajet dosing unit.

Environmental conditions

The Netajet dosing unit has been designed for installation in service room or a shaded

area.

When installing the complete dosing unit, including water supply, fertilizer tanks, etc’

the following rules must be observed:

1. Install the dosing unit in a shaded area and make sure that it is not exposed to

direct sunlight, especially the electrical cabinet.

2. Install the dosing unit in an area with an ambient temperature of between 40 °F and

105 °F and a maximum relative air humidity of 85 % (without condensation). Make

sure it is properly ventilated.

3. Install the dosing unit in a dry area protected from splashes, direct spraying with

water or chemicals.

4. The dosing unit must be installed on a hard, leveled floor.

5. Ensure that suitable electrical power supply is available in the vicinity of the

installation for connection of the Netajet dosing unit.

6. Ensure that there is an electrical socket available in the Netajet vicinity both for

installation and for maintenance.

11

Page 12

NetaJet Dosing Unit

Hydraulic installation

There are a few rules and recommendation that must observed when installing the

Netajet dosing units:

General requirements

Water supply

Prior to Netajet installation the following points must be observed and dealt with:

• Filtering:

An 80-mesh filter must be installed before the Netajet dosing unit. Moreover it is

recommended that a filter that removes solid contaminants of more than 500 µm

should be installed before the Netajet. This will significantly reduce the risk of

gradual build-up of contaminants in the area of the pH measurement, venturi inlets,

etc’ and will reduce the risk of malfunctions associated with this.

• Water temperature:

It is important to verify that the irrigation water temperature is always kept in the

allowed values of 40°

to 105° F.

• Chemical conditioning:

In case of high levels of bicarbonate concentrations in the supply water it will be

practically impossible to accurately control the pH levels, moreover there will be a

difference between the levels measured by the Netajet to the levels measured in the

field. In this case it is recommended to pre-treat the supply water by means of

acidification. Acid pre treatment of the water is only desirable if the

bicarbonate/"dissolved carbon dioxide" concentration is too high, then injecting acid

into a storage tank can solve the problem. The reaction of the acid with the

bicarbonate will result in the release of CO

2

. It is essential that the CO2 be properly

removed before the water is injected with the fertilizers to prevent it from taking part

in the chemical reactions.

• Pressure:

• Maximum 72 PSI.

• Minimum 30 PSI.

• Constant, not fluctuating; If there are fluctuations of more than 0.5 bar in

supply water pressure a pressure sustaining valve must be installed (see

Pressure sustaining valve)

• Suitable for field requirements.

Fertilizer supply:

• Fertilizer tanks:

In order to ensure maximum and even fertilizer capacity the following rules

must be observed:

12

Page 13

NetaJet NMC User & Installation Manual Installation

• The fertilizer tanks must be installed as close as possible to the Netajet. It is

recommended to keep a maximum pipe length of 10 meters. Nevertheless

there has to be enough space between the fertilizer tanks themselves and

between the Netajet so that inspection and maintenance operations can be

carried out.

• The fertilizer tanks must be at least the same level as Netajet if not higher.

• Piping and fittings for all dosing channels must be kept as similar as possible

in terms of dimensions and length.

• All supply lines for water and fertilizer and output lines for fertilizer and acid

can be plumbed using PVC (Schedule 80 preferred), Flexible PVC hose (must

be protected from UV radiation) or polyethylene hose.

• For acid, the supply lines are normally installed and maintained by the acid

supplier. Teflon is the best material for acid supply lines. PVC and Stainless

Steel are acceptable but have a shorter life. No nylon, brass, galvanized or

steel fittings can be used.

• It is recommended that the suction from the fertilizer tanks be done about 5-10

cm higher than the bottom of the tank. This prevents suction of sediment and

reduces the risk of clogging and blockage.

• Filtering:

It is essential to ensure proper filtering before the Netajet dosing channels; the

minimum filter should be of 120-mesh screen. All sand must be removed from the

water.

• Piping:

The hose connection of the Netajet is suitable for a ½ inch flexible hose. Make sure

the hose used is chemical resistant. It is recommended to tighten the hose with a

stainless steel hose clip.

NetaJet Installation Instructions

• The ratio between irrigation water flow / Bypass water flow should be no less than

1.5 and no more than 100. This is essential because of the solubility of the

fertilizers in the Bypass water flow

Flow through the NetaJet should be calculated as follows:

• Flow per fertilizer channel is around 760 Gallon/h (700 Gallon/h motive flow +

60 Gallon/h fertilizer suction).

• Flow per acid channel is around 250 Gallon/h (235 Gallon/h motive flow + 15

Gallon/h acid suction).

13

Page 14

NetaJet Dosing Unit

• A distance of about 6.5 foot should be maintained between inlet and outlet

connections of the NetaJet to the irrigation mainline (see drawing below).

• It is important to ensure proper turbulent flow between Bypass water and irrigation

water in the mainline. There are a few alternatives to achieve the required turbulent

flow, for example:

• Adding a mixing chamber such as a filter on the mainline (see

Figure 6 -

Installation with Filter)

• Adding an injection tube fitted in the inlet and outlets of the irrigation mainline.

• Typically pH adjusting flow is injected upstream of filtration and fertilizer is

downstream of filtration. If products are injected upstream of filtration the increased

flow must be included in filtration design for total flow as the NetaJet flow will be

filtered twice.

water

meter

5 D

6.5 ft

5 ft

Figure 5 - NetaJet Hydraulic Installation

14

Page 15

NetaJet NMC User & Installation Manual Installation

water

meter

5 D

ACID

FERT A

FERT B

Figure 6 - Installation with Filter

15

Page 16

NetaJet Dosing Unit

Typical installation

16

Page 17

NetaJet NMC User & Installation Manual Installation

17

Page 18

NetaJet Dosing Unit

Electrical and controller installation

Electrical Grounding

Electrical equipment can be destroyed or slowly damaged by voltage spikes, lightning

hits, etc’. Proper electrical grounding in combination with the NMC-64 internal

protections is essential to protect the system, reduce the risk of damage and prolong its

lifetime.

Correct selection and installation of equipment will protect your system and reduce the

risk of human injury.

Proper grounding provides an easy path for electrical current to return to its source.

A grounding system should tie all non-current carrying conductors to earth ground (0

volts). The grounding system should present a minimum resistance to current flow.

Make sure all items used are in proper condition, for example, a corroded wire clamp

attaching a ground wire to a ground rod might add 100 ohms or more resistance to a

system.

Less than 5 ohm will be considered as a good ground.

A very good ground needs to be supplied using a minimum of 2 grounding rods

and 4 Gauge standard wire connecting the grounds to the NetaJet.

Ground Rods

Ground rods are used to efficiently connect the system to earth where current may be

dissipated in the soil.

• Material:

Ground rods should be copper clad.

• Diameter:

Minimum 5/8”, preferably 3/4”. Generally the larger the rod diameter, the lower it’s

resistance to current flow.

• Length:

Minimum 8 feet, preferably 10 foot. A longer ground rod will reach a soil with higher

moisture content. Moist soil carries current much better than drier soil.

• Single grounding:

It is important that there is only one grounding location where a rod or series of rods

are connected to each other using a ground wire.

18

Page 19

NetaJet NMC User & Installation Manual Installation

Independent ground rods will increase the risk of current, from a lightning strike for

example, being dissipated through one rod and reentering the system through an

adjacent rod.

• Location;

Close to the main circuit breaker panel and in moist soil. For example in an area

that is usually wet from a drip or a low spot where water drains. Make sure the area

is well protected from damage by lawnmowers, tractors, etc’.

• Rod installation

Drive the rod into the earth until about 10 cm (4 inches) is left above grade. If it is

impossible to drive the rod to the proper depth, it is acceptable to lay the rod

horizontally, 2.5 feet below grade.

In case the rod is exposed to damage, for example by lawnmowers or tractors it can

be installed in a hole, about 8 inches deep so that the rod is about 0.3 feet under

grade and 0.3 feet above hole level.

Notice: The National Electric Code (NEC) mandates two ground rods unless you

can show less than 10 ohms resistance with one rod.

Ground Wire

The ground wire is a large copper wire that connects the main circuit breaker panel to

the ground rod.

• Diameter:

Typically, 6-gauge copper standard wire is sufficient. If the wire run is greater than

20 feet, 4 - gauge wire should be used.

The ground wire should be protected from damage by lawnmowers, tractors, etc’. It

should be buried minimum 6 inches under grade for protection and enter the house as

soon as possible. It is important that the wire not be cut; it should remain continuous.

Ground Clamps

Ground wires should not be merely wrapped around a ground rod. Ground clamps are

used to attach a ground wire to a ground rod. The most common clamp is known as an

acorn clamp.

Make sure the ground clamps you select are rated for outdoor use. Do not use pipe

clamps rated for inside water lines or hose clamps to attach the ground wire.

19

Page 20

NetaJet Dosing Unit

Ground connection

What Should Be Grounded?

Any equipment that is or could become energized, even accidentally, should be

grounded. Current from lightning, strikes objects in a random fashion. Accounts of

lightning strikes reveal scenarios most of us could not predict.

Electric circuits should be wired with a 3-wire conductor consisting of hot, neutral and

grounding wires. The grounding wire should be attached cleanly and securely to

devices or systems to be grounded. The other end of the grounding wire should be

attached to the ground bus on the main panel.

Supply power

Installer needs to supply power to NetaJet in conduit with disconnects. The NetaJet

includes power protection for the controller and motor controls for the motor.

Electrical connection to NetaJet divided per 2:

• Controller - 1Phase, 2 amps at 120 VAC with disconnect.

• Booster pump – 2 HP at 240 VAC or 480 VAC 3 phase (optional) with

disconnect.

Electrical connection – 2X240VAC

Main power

t

o

the Net

aJe

t

Supply power

to the NMC

controlle

r

Power to the

Booster pump

20

Page 21

NetaJet NMC User & Installation Manual Installation

Electrical connection – 3X480VAC

Pictures will be change

21

Page 22

NetaJet Dosing Unit

PH Transmitter & Sensor connection and calibration

Typically the pH transmitter will be supplied wired and connected to the NMC-64,

nevertheless it should be checked and calibrated after system installation.

Connecting pH sensor to Transmitter:

1. Connect wire (HI) to connector 10.

2. Connect shield (LO) to connector 11.

Warning!

•

Do not remove resistors from connectors 3-4 and 5-6.

• Do not switch between shield and wire connections.

• Do not connect/press “wire ends” on the sensor’s cable.

pH Transmitter Calibration

The calibration procedure requires calibration fluids of two levels, the recommended

values are: pH 7 for the high-level calibration fluid and pH 4 for the low-level calibration

fluid. If calibration fluids of these values are not available other calibration values can

be used.

1. Remove the sensor from its socket and wipe fluids off it.

2. Insert the sensor into the higher-level calibration fluid, for instance with a pH value

of 7 (Milwaukee pH 7.01 buffer).

3. Using the ZERO (and according to measured temp) adjust the reading to fit the pH

value as on the calibration fluid (example – if temp is 25C°, the pH value shall be

7.01).

4. Wipe the sensor and insert it to the lower value calibration fluid, for instance with pH

4 (Milwaukee pH 4.01 buffer). Keep the sensor in the buffer for 1 minute before

starting calibrate.

5. Calibrate with the SENS until the pH reading is as on the calibration fluid, according

to 25

o

C (example – using 4.01 buffer and temp is 25C°, the pH value shall be 4.01).

6. Carefully insert the sensor back to its socket.

7. Repeat sensor calibration every two weeks.

Warning!

The pH should not be dry, make sure to put it in fluid immediately after calibrating.

22

Page 23

NetaJet NMC User & Installation Manual Installation

Allowing the PH sensor to dry out, will damage and is not covered by warenty.

Connecting pH transmitter to NMC-64 controller

1. Connect pH transmitter to NMC-64 analog input card as follows:

2. pH transmitter’s connector 1 to analog card’s connector Red.

3. pH transmitter’s connector 2 to analog card’s connector T6.

4. Check that analog card’s jumper 2 (from left) is set to 4-20mA.

Figure 7 – pH sensor & transmitter’s connections to Analog input card

23

Page 24

NetaJet Dosing Unit

EC Transmitter & Sensor connection and calibration

Typically the EC transmitter will be supplied wired and connected to the NMC-64

(if ordered as option), nevertheless it should be checked and calibrated after system

installation.

Connecting EC sensor to Transmitter:

1. Remove resistors from connectors 3-4 and 5-6.

2. Connect Green wire to connector 4.

3. Connect Red wire to connectors 5 and 6.

4. Connect Black wire to connectors 10 and 11.

5. Connect White wire to connectors 12 and 13.

6. Adjust the Dip-switches (white ON) as follow:

EC Transmitter Calibration

1. Remove the sensor from its socket and wipe fluids off it.

2. Using the ZERO, bring the reading to 0 (no calibration fluid is needed here).

3. Insert the sensor into the calibration fluid (Milwaukee 1413 µS/cm solution).

4. Calibrate with the SENS until the EC reading is as on the calibration fluid and

according to 25

o

(example – using Milwaukee 1413 µS/cm solution transmitter

should be calibrated to show a value of 1.41 mS).

5. Insert the sensor back to the socket and tighten it.

6. Repeat sensor calibration once every two months.

Connecting EC transmitter to NMC-64 controller

1. Connect EC transmitter to NMC-64 analog input card as follows:

2. EC transmitter’s connector 1 to analog card’s connector Red.

3. EC transmitter’s connector 2 to analog card’s connector T5.

4. Check that analog card’s jumper 1 (from left) is set to 4-20mA.

24

Page 25

NetaJet NMC User & Installation Manual Installation

12VDC

Red

Inpu

t

2

1

Figure 8 – EC sensor & transmitter’s connections to Analog input card

25

Page 26

NetaJet Dosing Unit

NMC-64 EC & pH definitions and calibration

1. Menu 8.2 - Install / Analog Input 1:

Define pH sensor No. 1 on input number 6.

2. Menu 7.7 - CONFIGURATION / EC pH SENSOR RANGE:

Define table as follows:

Sensor 4 mA 20 mA

EC (Ms) 0 20

pH 0 14

3. Menu 6.6 - SETUP / EC pH CALIBRATION:

Change factor by pressing on the right and left arrows until value displayed on

controller screen is identical to the value displayed on transmitter screen:

Sensor Value Factor

EC 1.41 0.00

pH 7.00 0.00

26

Page 27

NetaJet NMC User & Installation Manual Installation

NNM-64 Installation - Getting started

This paragraph briefly explains how to get started with the NMC-64 software setup

procedure. For further explanations please refer to the NMC-64 User & Installation

Manual.

For initial configuration of the controller start with Menu 6: Setup.

Later steps might depend on earlier ones; therefore it is essential to go through all the

steps.

You can use the following chart for assistance.

Table # Table description NMC-64

Setup

6.1 Time & date Set your local Time and Date

6.2 System Setup Define system definitions such as measurement

units, PC communication etc’.

Installation

8.1 Device Definition Define which devices are needed in you application.

8.2 Device Layout Assign an output (Relay) to each device.

8.3 Analog Input Assign inputs to analog sensors, for example

EC/pH, temp sensors etc’.

8.5 Digital Input Assign inputs to digital sensors, for example water

meters, Dry contact, etc’.

Configuration

7.1 Pump Valve Delay Choose whether to start first with pump or valve and

define operation order.

7.2 Valve Configuration Configure a valve to a pump, mainline and water

meter. .

7.3 Valve Flow Rate Define valve flow rate.

7.4 Water meter Define volume per pulse of the water meter.

7.5 Fertilizer Setting Define fertilizer channel definitions; pump type,

operation method, ratio etc’.

27

Page 28

NetaJet Dosing Unit

7.6 EC/pH Setting Define whether fertigation is according to EC/pH

and set injection definitions.

Table # Table description NMC64

Setup

6.6 EC PH calibration Adjust the calibration factor so that the Value is

similar to the value shown on the EC&pH

transmitters

Test

5.1 Relays Verify the functionality of each output/device.

Program

1.2 Run Time program Define water programs; method (quantity/time),

total water quantity/time, water before and

water after.

Notice: water before/after are deducted from

total water quantity/time.

1.3 Fertilizer Program Define fertilizer programs; method (proportional

quantity/time, total quantity/time), quantities/time

per channel and EC/pH set points.

1.1 Irrigation Program Define irrigation program; start times, number of

cycles, time between cycles, participant valves,

run-time programs, fertilizer program, etc’.

Manual start

2.3 Manual Start Valve Manually start each valve and verify that the set

nominal flow rate is similar to the measured one.

2.2 Manual Start Program Manually start the programs to check whether

they are operative as set/expected. The

program can manually be shut down after

proper operation has been verified.

For detailed explanations please refer to NMC-64 User & Installation Manual.

28

Page 29

NetaJet NMC User & Installation Manual Installation

NetaJet Commissioning

When commissioning the NetaJet, keep to the following procedure:

• Ensure that the outlet of the NetaJet to the water distribution system is closed;

• Fully bleed the NetaJet pump. The pump must not run dry. Consult the pump

supplier's documentation for how to bleed the pump.

• Open the NetaJet switch box and start the NetaJet pump manually (see below in

this paragraph on how to start the NetaJet manually);

• Verify that the NetaJet pump is rotating in the correct direction (see arrow on pump

casing).

• Check the pressure in the venturi with the pressure gauge on the NetaJet. When the

NetaJet outlet for the water distribution is closed, the pressure must agree with the

value indicated in the documentation for the NetaJet pump;

• Ensure that the fertiliser lines are filled completely with fertiliser up to the venturis;

When commissioning is concluded, clean the filter on the NetaJet running

towards the EC tubes and the venturis

29

Page 30

NetaJet Dosing Unit

Installation requirements

Pressure sustaining valve

The pressure sustaining valve is used to ensure that the NetaJet works against

constant pressure and should be added to the system whenever the mainline pressure

fluctuates more than 0.5 bars.

The pressure sustaining valve (PSV) is installed on the main line after the NetaJet inlet

and ensures the pressure doesn’t drop below the set value.

Install that PSV on the mainline after the NetaJet.

1. Check the maximum pressure on the main line, this can be done by making sure all

pumps are operative and opening the smallest crop section to be irrigated at once.

In case the water supply is from a municipal source or a source that supplies to a

few systems at once make sure you check the pressure when the pressure is

maximal, this will usually be when a minimal number of consumers are operative.

2. Calibrate the PSV so that it maintains a pressure that is 3-4 meters higher than the

maximal pressure measured on the mainline.

PSV

Inlet valve

(Optional)

Figure 11 - PSV Installation

30

Page 31

NetaJet NMC User & Installation Manual Installation

Maintenance

In order to ensure reliable and optimal operation and extend system life cycle regular

maintenance must be cried out.

The NetaJet dosing unit and its immediate environment must be kept clean by

removing dust, water and chemicals from the dosing unit. It is important that all filter

elements on and in the vicinity of the NetaJet are cleaned regularly.

The NetaJet, supply water and irrigation water system must be checked regularly for

leaks, air bubbles in fertilizer and/acid/alkali lines and the pump pressure.

Description How often See link

PH sensor calibration Every 2 –4 weeks

EC sensor calibration Every 2 months

Fertilizer filters cleaning Once a week

Supply water filters cleaning Once a week

Leak inspection Once a week

Winterization:

• Pump draining

• PH & EC sensors

• Plumbing drain

31

Page 32

NetaJet Dosing Unit

Parts list & Description

Item Description Netafim serial # USA Part #

1 Goulds Pump N/A

2 Switch Board N/A

3 Controller’s display N/A

4 Aluminum frame 45000-008740

5 Half union 50

Adaptor nipple 50x1½”

77300-019660

77300-012200

6 EC&PH inlet manifold 33000-005550

7 Geka PVC connector 3/4" Male

Geka PVC connector 3/4" Female

77300-022700

77300-022800

8 Half union 50

Adaptor nipple 50x1¼”

77300-019660

77300-012100

9 Half union 40

Adaptor nipple 40x1”

77300-019950

77300-013600

10 Upper manifold 33000-005600

11 Acid outlet 33000-005650

12 Fertilizer B outlet 33000-005700

13 Fertilizer A outlet 33000-005750

14 1” Rubber washer 77300-029200

15 3/4” Rubber washer 77300-003050

16 Adaptor nipple ¼” x ¾” 77300-022600

17 Half union for dosing valve 77300-011550

77300-021400

18 Half union (Nut) for dosing valve 77300-021100

19 Burkert dosing valve, type 124 77800-004000

20 Nipple ¼” x ¼” 77300-011200

32

Page 33

NetaJet NMC User & Installation Manual Installation

21 Inlet unit for Fertilizers and Acid

channels

33000-005800

22 Glass flow meter for Acid channel 77540-008300

23 Flow meter for fertilizer channel 77540-007500

24 EC sensor (optional) 45000-006660

25 PH sensor 45000-006680

26 Tube clip 50mm = 2” 77300-024300

27 Tube clip 32mm = 1¼” 77300-024150

28 Tube clip 40mm = 1½” 77300-024200

29 Mazzei injector 878 1”, 60 Gallon/hour 77800-003470

30 Mazzei injector 484-A ¾”, 15 Gallon/hour 77800-003450

31 Tube clip 16mm 77300 - 024000

33

Page 34

NetaJet Dosing Unit

Figure 12 – Service parts

34

Page 35

NetaJet NMC User & Installation Manual Installation

Venturis & Booster Pump Specifications

Water Suction Capacity – Injector Inlet Pressure 5 – 50 PSI

* Number in parenthesis indicate the injector outlet pressure when suction stop (Zero Suction Point)

35

Page 36

NetaJet Dosing Unit

Water Suction Capacity – Injector Inlet Pressure 60 – 120 PSI

* Number in parenthesis indicate the injector outlet pressure when suction stop (Zero Suction Point)

36

Page 37

NetaJet NMC User & Installation Manual Installation

Goulds Pump – Model NPE

37

Page 38

NetaJet Dosing Unit

D2

D3

D4

D1

H 1

H 2

H 3

Dimensions and weight

System type D 1

[Inch]

D 2

[Inch]

D 3

[Inch]

D 4

[Inch]

H 1

[Inch]

H 2

[Inch]

H 3

[Inch]

NetaJet NMC 1 ½ 1 1 1 46.95 28.34 24.8

System type Package Net weight (lb) Gross weight (lb)

NetaJet NMC

38

Page 39

NetaJet NMC User & Installation Manual Installation

Tips for calibrations

Before running the NetaJet, a calculation has to be done in order to understand what

are the dosing capabilities.

The following data is part of the calibration process and has to be consider before the

system operation:

• Minimum and Maximum flow rate that required from the field.

• Suction capacity of each venturi which is influenced by the pressures around the

system.

• Fertilizers concentrations which is influence on the EC value of the irrigated

water.

Example A: System calculation according a specific case

Data:

Flow rate demand from the field: 1500 Gallon/min

Fertilizer injection capacity: 60 Gallon/hour =

mi

n

60

/60 hourGallon

= 1 Gallon/min

Acid injection capacity: 15 Gallon/hour =

mi

n

60

/15 hourGallon

= 0.25 Gallon/min

Calculation:

Fertilizer injection capacity

Maximum quantity that can be delivered by a fertilizer channel:

mi

n

/

1500

min/1

Gallon

Gallon

=

Main line capacity

Gallon

Gallon

1500

1

Gallon

Gallon

X

Gallon

Gallon

1000

67.0

1000

1500

1

=

This formula is demonstrate how to calculate the higher limit of a fertilizer channel,

means when the NMC controller will open the Dosing Valve for 100% the NetaJet

will inject 0.67 Gallon from the fertilizer channel to every 1000 Gallons of water that

flows through the main line to the field.

39

Page 40

NetaJet Dosing Unit

The same calculation can be done for the acid channel:

Acid injection capacity

Maximum quantity that can be delivered by an acid channel:

=

mi

n

/

1500

min/25.0

Gallon

Gallon

Main line capacity

Gallon

Gallon

1500

25.0

1000

1500

25.0

X

Gallon

Gallon

=

Gallon

Gallon

1000

17.0

Example B: Ec calibration according the system capabilities

After the calculations in Example A, Ec definition can be done as follow:

Data:

Maximum quantity of fertilizers that can be delivered by the NetaJet per every 1000

Gallons of water that flows through the main line to the field:

0.67 X 2 channels = 1.34 Gallon

Because Ec reaction is linear, the following procedure can be implement in order to

know the Ec value that will be reached after the NetaJet:

0.67 Gallon = 86 Ounce

• Take sample of 86 ounce from each fertilizer tank and mix it in sample of 1

Gallon from the water source.

• Measured by Ec meter the Ec value of the mixed solution.

This is the maximum Ec that will be achieved according to the examples above.

TANK B

86 Ounce 86 Ounce

TANK A

1 Gallon

When the fertigation process is done by the proportional quantity method, always

keep a difference to be able to make corrections up or down in order to control the

Ec value.

40

Page 41

NetaJet NMC User & Installation Manual Installation

The recommended value is between 50% - 70% of the fertilizer channel limitation,

means: 0.67 X 70% = 0.47 Gallon of fertilizer from each channel to be inject per

1000 Gallons that flows through the main line.

Notice: Do not use too concentrated fertilizers in order to achieve a higher Ec

value, using too concentrated fertilizers can bloke the injectors (venturies) because

of solidification.

41

Page 42

NetaJet Dosing Unit

Warranty and safety

Safety instructions

This chapter describes the safety instructions that should be applied when installing,

using and maintaining all NetaJet dosing units.

Installation and maintenance

The dosing unit must always be switched off before installation or maintenance work

is carried out on it.

If installation work has to be carried out on the supply, the lighting circuit group to

which the dosing unit has been or is connected must first be isolated from the

supply.

Preparing the stock of acid/lye

Observe the following rules when working with acids:

• Protect your eyes: wear safety goggles!

• Never add water to acid or lye, but always acid to water! This is because of the

large amount of heat developed and the danger of acid splashes when you add

water to acid.

• Never allow water to back flow or enter acid tank. This will cause a severe reaction

and possibly melt the acid holding tank if it is made of plastic.

42

Loading...

Loading...