Page 1

V 002.01 - JULY 2017

MEGANET

TM

USER MANUAL

ROTATING IMPACT

SPRINKLER

Page 2

© COPYRIGHT 2016, NETAFIM™

NO PARTS OF THIS PUBLICATION MAY BE REPRODUCED, STORED IN AN AUTOMATED DATA FILE OR MADE PUBLIC IN

ANY FORM OR BY ANY MEANS, WHETHER ELECTRONIC, MECHANICAL, BY PHOTOCOPYING, RECORDING OR IN ANY

OTHER MANNER WITHOUT PRIOR WRIT TEN PERMISSION OF THE PUBLISHER.

ALTHOUGH NETAFIM™ TAKES THE GREATEST POSSIBLE CARE IN DESIGNING AND PRODUCING BOTH ITS PRODUCTS

AND THE ASSOCIATED DOCUMENTATION, THEY MAY STILL INCLUDE FAULTS.

NETAFIM™ WILL NOT ACCEPT RESPONSIBILIT Y FOR DAMAGE RESULTING FROM USE OF NETAFIM'S PRODUCTS OR

USE OF THIS MANUAL.

NETAFIM™ RESERVES THE RIGHT TO MAKE CHANGES AND IMPROVEMENTS TO ITS PRODUCTS AND/OR THE

ASSOCIATED DOCUMENTATION WITHOUT PRIOR NOTICE.

FOREIGN LANGUAGES

If you are reading this manual in a language other than the English language, you acknowledge and

agree that the English language version shall prevail in any case of inconsistency or contradiction in

interpretation or translation.

NOTE

All the drawings in this document are for the purpose of illustration only. The actual product details

and infrastructure condition may differ in any actual application.

Page 3

CONTENTS

Introduction

Use of symbols

Aim of this manual

Safety instructions

MegaNet™ rotating impact sprinkler

Description

Applications

Features and benefits

Specifications

Technical data

Performance

Max. lateral length - 10% flow variation

Sprinkler water trajectory

Head loss in riser tube

Installation

Introduction

Various installation configurations

Maintenance

Rinsing the filter

Checking the turbine and the cover

Cleaning the nozzle

Parts and complementary products

Parts

Complementary products

Models for specific uses

Appendix 1: Special applications

Special model for cement connection

Special model with anti-drain valve

Adding a PRV

Road protector

Warranty

4

4

4

5

5

5

6

7

9

11

11

12

12

13

14

15

17

18

19

20

21

21

22

23

Page 4

4

MegaNet

TM

USER MANUAL

INTRODUCTION

WARNING

The following text contains instructions aimed at preventing bodily injury or direct damage to

the crops, the product and/or the infrastructure.

CAUTION

The following text contains instructions aimed at preventing unwanted system operation,

installation or conditions that, if not followed, might void the warranty.

ATTENTION

The following text contains instructions aimed at enhancing the effective use of the instructions

in the manual.

NOTE

The following text contains instructions aimed at emphasizing certain aspects of the installation

or operation of the product.

SAFETY FOOTWEAR

The following text contains instructions aimed at preventing foot injury.

TIP

The following text provides clarification, tips or useful information.

Use of symbols

The symbols used in this manual refer to the following:

Aim of this manual

The aim of this manual is to guide the user in setting up, installation, operaton and maintenance of the

MegaNet™ sprinkler in its various applications.

Safety instructions

• All applicable safety instructions and regulations must be observed and applied.

• The effectiveness of the equipment may be jeopardized or impaired if the equipment is used in a manner

other than that specified by the manufacturer.

WARNING

In an agricultural environment - always wear protective footwear.

CAUTION

When opening or closing any manual valve, always do so gradually, to prevent damage to the

system by water hammer.

Page 5

MegaNetTM USER MANUAL

5

MEGANET™ ROTATING IMPACT SPRINKLER

Description

Applications

High water trajectory angle - 24D

- for vegetables and open field crops, open field nurseries,

crops germination, frost mitigation, cooling fruit orchards and roof dust cleaning.

Low water trajectory angle - 15D

- for under-tree irrigation and shade/net houses.

Features and benefits

Ensures high and uniform yield

• The MegaNet™ has a symmetrical structure that splits the water into two equal jets. That

contributes to the balanced of the sprinkler, providing very high water distribution uniformity.

Increased germination percentage

• Thanks to the gentle water jet, and relatively small drops near the ground, the MegaNet™ does not

groove the soil along the whole irrigation event (including startup and shut off), which prevents the

seeds from being exposed - out of the soil.

Reduced maintenance cost

• The MegaNet™ has a popup mechanism that opens only during irrigation, this mechanism protects

the nozzle and protects the sprinkler's moving parts by preventing insects and dirt particles from getting

inside the sprinkler.

• Each MegaNet™ sprinkler has an integral filter that ensures clean water inside the nozzle. In addition,

this filter can be easily cleaned if needed.

• Extended product life achieved by superior raw material composition resistant the chemicals, fertilizers,

and exposure to sunlight.

Cover

Base

Upper

body

½" male thread

Pin

Cement connector Non-leakage valve

Thread connector model Cement connector model

ISO C 20 mm / ASTM C ½"

Thread connector model

with non-leakage valve

Page 6

6

MegaNet

TM

USER MANUAL

MEGANET™ ROTATING IMPACT SPRINKLER

Specifications

• 7 different nominal flow rates: 200, 250, 350, 450, 550, 650, 750 l/h.

Nominal flow rates at 2.3 bar pressure.

• Recommended working pressure: 2.0 to 3.0 bar (at the sprinkler head).

• Can be installed on solid sets or in removable field stands.

• Made of UV-protected materials, durable to all climate conditions and nutrients injected in agricultural

applications

• 2 types of water trajectory:

• High, 24 degrees

• Low, 15 degrees

• Inlet connector:

• 1/2" Threaded inlet connector

• 20 MM ISO inlet connector (to be glued to PVC)

• 1/2" ASTM inlet connector (to be glued to PVC)

• Code-colored locking pins and caps for easy identification.

• 2 balanced water jets.

• Individual filter in each sprinkler.

• MegaNet™ sprinklers meet ISO 8026 standards (SI 1406) with production certified by the

Israel Standards Institute (SII).

• Recommended filtration: 400 micron / 40 mesh.

Selection of the filtration method should be based on the kind and concentration of dirt particles in the

water.

ATTENTION

• For water containing over 2 ppm of sand, a hydrocyclone sand separator must be installed

upstream from the main filter.

• For water containing over 100 ppm of sand/silt/clay solids, pretreatment must be performed

according to the instructions of the Netafim™ expert team.

Page 7

MegaNetTM USER MANUAL

7

TECHNICAL DATA

Performance

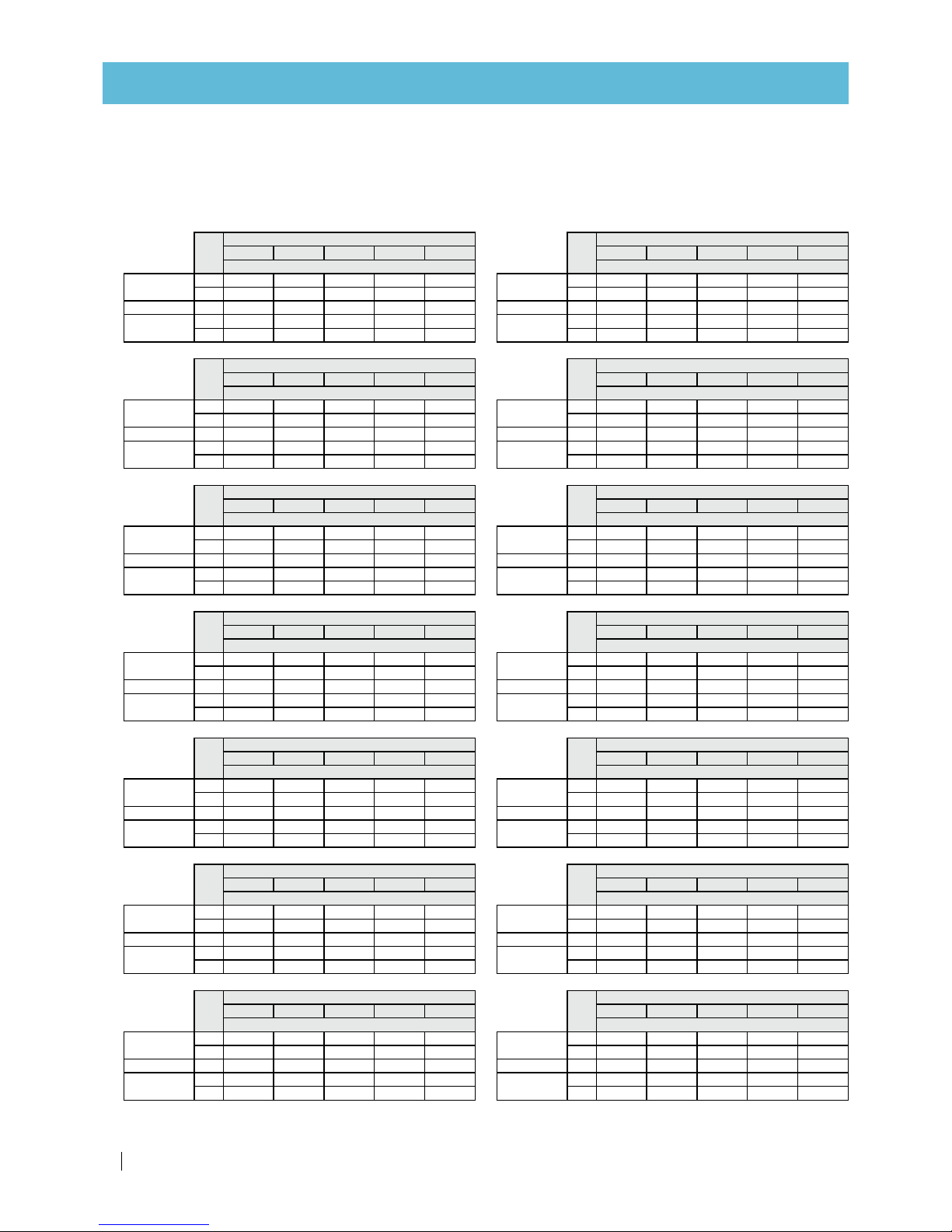

Rectangular spacing

MegaNet™ 15D

Water trajectory angle: 15 degrees. Pin color code: Gray

Nozzle

size

(mm)

Color

code

Working

pressure

(bar)

Flow

rate

(l/h)

Wetted

diameter

*

(m)

Spacing - rectangular (m x m)

7 x 8 8 x 8 9 x 8 10 x 8 9 x 9 9 x 10 10 x 10

Precipitation rate (mm/h)

2.44 Green

2.5 362

14

6.4 5.6 5.0 4.5 4.4 4.0 3.6

3.0 396 7.1 6.2 5.5 5.0 4.9 4.4 4.0

2.79 Blue

2.5 461

16

8.3 7.2 6.4 5.8 5.7 5.1 4.6

3.0 505 9.0 7. 9 7.0 6.3 6.2 5.6 5.0

3.08 Brown

2.5 553

16

9.9 8.6 7.7 6.9 6.8 6.1 5.5

3.0 605 10.8 9.5 8.4 7.6 7. 5 6.7 6.1

3.37 Orange

2.5 678

16

12.1 10.6 9.4 8.5 8.4 7. 5 6.8

3.0 74 3 13.3 11.6 10.3 9.3 9.2 8.3 7. 4

3.68 Red

2.5 785

17

14.0 12.3 10. 9 9.8 9.7 8.7 7. 9

3.0 860 15.3 13.4 11. 9 10.7 10.6 9.5 8.6

* Performance table prepared under laboratory conditions, sprinkler head 0.5 meter above ground.

At least 0.5 mm/h.

MegaNet™ 24D

Water trajectory angle: 24 degrees. Pin color code: Black

Nozzle

size

(mm)

Color

code

Working

pressure

(bar)

Flow

rate

(l/h)

Wetted

diameter

*

(m)

Spacing - rectangular (m x m)

7 x 8 8 x 8 8 x 10 9 x 9 10 x 10 10 x 11 10 x 12

Precipitation rate (mm/h)

1.85 Yell ow

2.5 210

11

3.6 3.3

3.0 230 3.8 3.6

2.06 Purple

2.5 258

12

4.4 4.0

3.0 283 4.8 4.4

2.44 Green

2.5 362

14

5.9 5.6 4.5 4.4 3.6

3.0 396 6.5 6.2 5.0 4.9 4.0

2.79 Blue

2.5 461

17

8.1 7. 2 5.8 5.7 4.6 4.2 3.9

3.0 505 8.7 7. 9 6.3 6.2 5.0 4.6 4.2

3.08 Brown

2.5 553

18

10.0 8.6 6.9 7. 2 5.5 5.0 4.6

3.0 605 10 .1 9.5 7.6 7. 5 6 .1 5.5 5.1

3.37 Orange

2.5 678

18

11. 5 10.6 8.5 8.4 6.8 6.2 5.7

3.0 74 3 12. 3 11. 6 9.3 9.2 7. 4 6.8 6.2

3.68 Red

2.5 785

18

13.4 12. 3 9.8 9.7 7. 9 7.1 6.6

3.0 860

19

15.0 13. 4 10.7 10.6 8.6 7. 8 7.2

* Performance table prepared under laboratory conditions, sprinkler head 1.0 meter above ground.

At least 0.5 mm/h.

%CU

≥ 92% ≥ 88% and < 92% ≥ 86% and < 88% < 86%

(a)

(b)

Sprinkler

Lateral

* Nominal flow rate at 2.3 bar working pressure.

**Sprinkler height above ground: 15D = 0.5 m, 24D = 1.0 m. At least 0.5 mm/h.

Page 8

8

MegaNet

TM

USER MANUAL

Performance (cont'd)

Triangular spacing - isosceles**

MegaNet™ 15D

Water trajectory angle: 15 degrees. Pin color code: Gray

Nozzle

size

(mm)

Color

code

Working

pressure

(bar)

Flow

rate

(l/h)

Wetted

diameter

*

(m)

Spacing - triangular (m x m)

7 x 8 8 x 8 9 x 8 10 x 8 9 x 9 9 x 10 10 x 10

Precipitation rate (mm/h)

2.44 Green

2.5 362

14

6.4 5.6 5.0 4.5 4.4 4.0 3.6

3.0 396 7.1 6.2 5.5 5.0 4.9 4.4 4.0

2.79 Blue

2.5 461

16

8.3 7.2 6.4 5.8 5.7 5.1 4.6

3.0 505 9.0 7. 9 7.0 6.3 6.2 5.6 5.0

3.08 Brown

2.5 553

16

9.9 8.6 7.7 6.9 6.8 6.1 5.5

3.0 605 10.8 9.5 8.4 7.6 7. 5 6.7 6.1

3.37 Orange

2.5 678

16

12.1 10.6 9.4

3.0 74 3 13.3 11.6 10.3

3.68 Red

2.5 785

17

14.0 12. 3 10.9 9.8 9.7 8.7

3.0 860 15.3 13.4 11.9 10.7 10.6 9.5

* Performance table prepared under laboratory conditions, sprinkler head 0.5 meter above ground.

At least 0.5 mm/h.

MegaNet™ 24D

Water trajectory angle: 24 degrees. Pin color code: Black

Nozzle

size

(mm)

Color

code

Working

pressure

(bar)

Flow

rate

(l/h)

Wetted

diameter

*

(m)

Spacing - triangular (m x m)

7 x 8 8 x 8 8 x 10 9 x 9 10 x 10 10 x 11 10 x 12

Precipitation rate (mm/h)

1.85 Yell ow

2.5 210

11

3.6 3.3

3.0 230 3.8 3.6

2.06 Purple

2.5 258

12

4.4 4.0

3.0 283 4.8 4.4

2.44 Green

2.5 362

14

5.9 5.6 4.5 4.4 3.6

3.0 396 6.5 6.2 5.0 4.9 4.0

2.79 Blue

2.5 461

17

8.1 7. 2 5.8 5.7 4.6 4.2 3.9

3.0 505 8.7 7. 9 6.3 6.2 5.0 4.6 4.2

3.08 Brown

2.5 553

18

10.0 8.6 6.9 7. 2 5.5 5.0 4.6

3.0 605 10 .1 9.5 7.6 7. 5 6 .1 5.5 5.1

3.37 Orange

2.5 678

18

11. 5 10.6 8.5 8.4 6.8 6.2 5.7

3.0 74 3 12. 3 11. 6 9.3 9.2 7. 4 6.8 6.2

3.68 Red

2.5 785

18 13.4 12. 3 9.8 9.7 7. 9 7.1 6.6

3.0 860

19

15.0 13. 4 10.7 10.6 8.6 7. 8 7.2

* Performance table prepared under laboratory conditions, sprinkler head 1.0 meter above ground.

At least 0.5 mm/h.

**Do not confound isosceles with equilateral:

• An isosceles triangle is a triangle in which two sides are of equal length. The distance between 2

adjacent sprinklers on the same lateral (a) is not equal to the distance between 2 sprinklers on adjacent

laterals. The height of the triangle represents the distance between adjacent laterals (b).

Isosceles is usually referred to in open-field applications.

• An equilateral triangle is a triangle in which all three sides are equal. The distance between 2 adjacent

sprinklers on the same lateral is equal to the distance between 2 sprinklers on adjacent laterals.

Equilateral is occasionally referred to in orchards due to the tree planting pattern.

(a)

(b)

Sprinkler

Lateral

%CU

≥ 92% ≥ 88% and < 92% ≥ 86% and < 88% < 86%

TECHNICAL DATA

Page 9

MegaNetTM USER MANUAL

9

TECHNICAL DATA

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 102 112 120 126 140

1% 108 119 128 14 4 150

Flat terrain 0 120 133 144 153 170

Downhill

-1% 126 140 152 171 180

-2% 132 147 160 180 190

Nominal

flow rate:

200 l/h*

Max. lateral length - 10% flow variation

Inlet pressure: 3.0 bar

Lateral: PE 32 mm ID: 27.2 mm Lateral: PE 40 mm ID: 36.8 mm

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 90 98 112 117 120

1% 96 10 5 120 126 13 0

Flat terrain 0 102 119 12 8 135 150

Downhill

-1% 10 8 126 136 144 160

-2% 114 126 14 4 15 3 17 0

Nominal

flow rate:

250 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 78 84 88 99 100

1% 84 91 96 108 11 0

Flat terrain 0 84 98 10 4 108 120

Downhill

-1% 90 98 112 117 130

-2% 96 105 112 126 130

Nominal

flow rate:

350 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 66 77 80 90 90

1% 72 77 88 90 100

Flat terrain 0 72 84 88 99 100

Downhill

-1% 78 84 96 99 11 0

-2% 78 91 96 108 120

Nominal

flow rate:

450 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 60 70 72 81 80

1% 66 70 80 81 90

Flat terrain 0 66 77 80 90 90

Downhill

-1% 72 77 88 90 100

-2% 72 77 88 99 10 0

Nominal

flow rate:

550 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 54 63 64 72 80

1% 60 63 72 72 80

Flat terrain 0 60 63 72 81 80

Downhill

-1% 60 70 72 81 90

-2% 60 70 80 81 90

Nominal

flow rate:

650 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 54 56 64 63 70

1% 54 56 64 72 70

Flat terrain 0 54 63 64 72 80

Downhill

-1% 54 63 72 72 80

-2% 60 63 72 81 80

Nominal

flow rate:

750 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 15 0 161 176 180 190

1% 174 189 200 216 230

Flat terrain 0 198 217 240 252 270

Downhill

-1% 216 238 264 288 310

-2% 234 259 288 315 340

Nominal

flow rate:

200 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 13 8 147 160 171 18 0

1% 15 6 168 184 198 210

Flat terrain 0 174 189 208 225 240

Downhill

-1% 18 6 210 232 252 270

-2% 204 224 248 270 290

Nominal

flow rate:

250 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 120 12 6 13 6 14 4 150

1% 12 6 14 0 152 162 170

Flat terrain 0 138 154 168 180 200

Downhill

-1% 150 168 184 198 220

-2% 162 17 5 200 216 230

Nominal

flow rate:

350 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 102 112 12 0 126 140

1% 114 126 136 14 4 150

Flat terrain 0 120 13 3 14 4 162 170

Downhill

-1% 126 14 0 160 171 180

-2% 138 15 4 168 180 200

Nominal

flow rate:

450 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 96 10 5 112 117 13 0

1% 10 2 112 120 126 14 0

Flat terrain 0 108 119 128 14 4 150

Downhill

-1% 114 126 14 4 153 160

-2% 120 133 14 4 162 170

Nominal

flow rate:

550 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 84 91 104 108 11 0

1% 90 98 112 117 120

Flat terrain 0 96 105 120 12 6 130

Downhill

-1% 102 112 12 0 135 140

-2% 108 119 128 14 4 150

Nominal

flow rate:

650 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 78 84 96 99 110

1% 84 91 96 108 11 0

Flat terrain 0 90 98 10 4 117 120

Downhill

-1% 90 105 112 126 130

-2% 96 105 120 126 140

Nominal

flow rate:

750 l/h*

*Nominal flow rate at 2.3 bar working pressure.

Page 10

10

MegaNet

TM

USER MANUAL

TECHNICAL DATA

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 192 203 216 225 230

1% 234 252 272 288 300

Flat terrain 0 282 308 336 360 390

Downhill

-1% 318 357 392 423 460

-2% 348 392 432 477 520

Nominal

flow rate:

200 l/h*

Max. lateral length - 10% flow variation (cont'd)

Inlet pressure: 3.0 bar

Lateral: PE 50 mm ID: 45.4 mm Lateral: FlexNet™ 2" ID: 50.4 mm

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 174 18 9 200 207 220

1% 210 224 240 261 270

Flat terrain 0 246 273 296 315 340

Downhill

-1% 276 308 336 369 400

-2% 300 336 376 405 440

Nominal

flow rate:

250 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 15 0 161 176 180 190

1% 174 189 208 216 230

Flat terrain 0 198 217 240 261 280

Downhill

-1% 222 245 272 297 320

-2% 234 266 296 324 350

Nominal

flow rate:

350 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 13 8 147 160 171 18 0

1% 15 6 168 184 189 210

Flat terrain 0 174 189 208 225 240

Downhill

-1% 18 6 210 232 252 270

-2% 198 224 248 270 290

Nominal

flow rate:

450 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 126 13 3 14 4 153 160

1% 138 15 4 168 180 190

Flat terrain 0 156 168 184 198 210

Downhill

-1% 16 8 18 2 200 216 240

-2% 174 196 216 234 260

Nominal

flow rate:

550 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 114 126 136 144 150

1% 12 6 13 3 14 4 16 2 170

Flat terrain 0 138 147 160 180 190

Downhill

-1% 144 161 176 18 9 210

-2% 156 16 8 19 2 207 220

Nominal

flow rate:

650 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 10 8 112 120 13 5 140

1% 114 126 136 14 4 160

Flat terrain 0 126 14 0 15 2 162 170

Downhill

-1% 132 147 160 171 19 0

-2% 138 15 4 168 189 200

Nominal

flow rate:

750 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 210 224 232 243 250

1% 264 287 304 324 340

Flat terrain 0 336 371 400 432 460

Downhill

-1% 390 434 480 522 560

-2% 432 483 536 585 640

Nominal

flow rate:

200 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 19 8 210 216 225 230

1% 240 259 280 297 310

Flat terrain 0 294 322 352 378 410

Downhill

-1% 336 378 416 450 490

-2% 372 413 464 504 550

Nominal

flow rate:

250 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 174 182 192 207 210

1% 204 224 240 252 270

Flat terrain 0 240 259 288 306 330

Downhill

-1% 264 294 328 360 380

-2% 288 322 360 396 430

Nominal

flow rate:

350 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 15 6 16 8 176 18 9 200

1% 180 196 208 225 240

Flat terrain 0 204 224 248 270 280

Downhill

-1% 228 252 280 297 320

-2% 246 273 304 333 360

Nominal

flow rate:

450 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 14 4 15 4 168 171 180

1% 16 2 175 19 2 207 220

Flat terrain 0 180 203 216 234 250

Downhill

-1% 19 8 224 248 270 290

-2% 216 238 264 288 310

Nominal

flow rate:

550 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 132 140 15 2 162 170

1% 14 4 161 168 180 190

Flat terrain 0 162 175 192 207 220

Downhill

-1% 174 19 6 216 234 250

-2% 186 210 232 252 270

Nominal

flow rate:

650 l/h*

Slope

Distance between sprinklers (m)

6 7 8 9 10

Max. lateral length (m)

Uphill

2% 120 13 3 14 4 153 160

1% 132 147 16 0 171 180

Flat terrain 0 150 161 176 18 9 210

Downhill

-1% 156 17 5 192 207 230

-2% 168 189 208 225 240

Nominal

flow rate:

750 l/h*

*Nominal flow rate at 2.3 bar working pressure.

Page 11

MegaNetTM USER MANUAL

11

TECHNICAL DATA

Sprinkler water trajectory

A

B

A. Distance

- Distance of max. trajectory height from sprinkler nozzle.

B. height

- Elevation of max. trajectory height above ground.

Trajectory height above sprinkler nozzle

The maximum trajectory height above the sprinkler nozzle is relevant in the following cases:

• When sprinklers are used under the canopy to prevent wetting the foliage.

• When sprinklers are used in a net-house or inside a roofed structure such as a glasshouse, to prevent

wetting the net or the ceiling.

* Nominal flow rate at 2.3 bar working pressure.

Flow

rate

*

(l/h)

Nozzle

size

(mm)

Color

code

MegaNet

™

15D

Water trajectory angle: 15 degrees

Pin color code: Gray

MegaNet™ 24D

Water trajectory angle: 24 degrees

Pin color code: Black

Height (m) Distance from head (m) Height (m) Distance from head (m)

200 1. 85 Yellow

1.0 0 4.75 1.42 4.88250 2.06 Purple

350 2.44 Green

450 2.79 Blue

1.11 5.13 1.61 5.47

550 3.08 Brown

650 3.37 Orange

750 3.68 Red

Riser tube: OD ½"

, ID 15.0 mm

Riser tube: OD ¾"

, ID 20.5 mm

Head loss in riser tube

Riser tube: OD 12.0 mm

, ID 9.0 mm

Flow

rate*

(l/h)

Riser tube length (m)

1.2

Head loss (bar)

200

0. 017

250

0.025

350

0.045

450

0.070

550

0.10 0

650

0.134

750

0.172

Flow

rate*

(l/h)

Riser tube length (m)

0.4 0.8 1.2

Head loss (bar)

200

0.000 0.001 0.001

250

0.001 0.001 0.002

350

0.001 0.003 0.004

450

0.002 0.004 0.006

550

0.003 0.006 0.009

650

0.004 0.008 0.012

750

0.005 0.010 0.015

Flow

rate*

(l/h)

Riser tube length (m)

0.4 0.8 1.2

Head loss (bar)

200

0.000 0.000 0.000

250

0.000 0.000 0.000

350

0.000 0.001 0.001

450

0.000 0.001 0.001

550

0.001 0.001 0.002

650

0.001 0.002 0.003

750

0.001 0.002 0.003

Page 12

12

MegaNet

TM

USER MANUAL

INSTALLATION

Introduction

CAUTION

Assembly must be done gently. Do not overtighten or use excessive force.

Tools required

• 20 mm spanner

• 30 mm spanner

Various installation configurations

Netafim™ sprinklers can be installed at a convenient height in different configurations, to suit the needs of

various crops and field conditions.

Among the various installation options:

•

Mega Stand™

- a ½" diameter robust and durable modular sprinkler stand suitable for a variety of

agriculture and mining irrigation applications.

•

IMP SPR stand™

- a ½" diameter stand, satisfactorily used by farmers all over the globe for many years.

It became a classic in open field and orchard irrigation due to its durability, simplicity and versatility.

It can accommodate any type of ½" sprinkler.

•

Solid set

- Netafim™ offers a comprehensive range of sockets and reducer couplings dedicated to

the proper connection of sprinklers to solid-set riser pipes (PVC or other rigid pipes). Usage of these

accessories ensures appropriate, safe operation and longevity of the sprinklers.

See the installation manual for each one of the above installation options at

http://www.netafim.com/irrigation-products-technical-materials

Page 13

MegaNetTM USER MANUAL

13

To assure proper operation of the sprinkler, a simple inspection and maintenance procedure should be

carried out regularly.

Rinsing the filter

Frequency:

Before the beginning of each growing season

or in case one the following symptoms occurs:

• The sprinkler doesn't emit water.

• The flow of water emitted is low.

Action:

1.

Open the sprinkler by unscrewing the upper body of the

sprinkler from its base.

2.

Detach the filter by pulling it down.

3.

Clean the filter from the inside with a water jet or pressurized air.

4.

Put the filter back in place.

CAUTION

Never operate the sprinkler without the filter.

Failure to comply with this instruction will clog the sprinkler,

and may damage it and void the warranty.

5.

Reassemble the sprinkler.

MAINTENANCE

1

2

3

Page 14

14

MegaNet

TM

USER MANUAL

MAINTENANCE

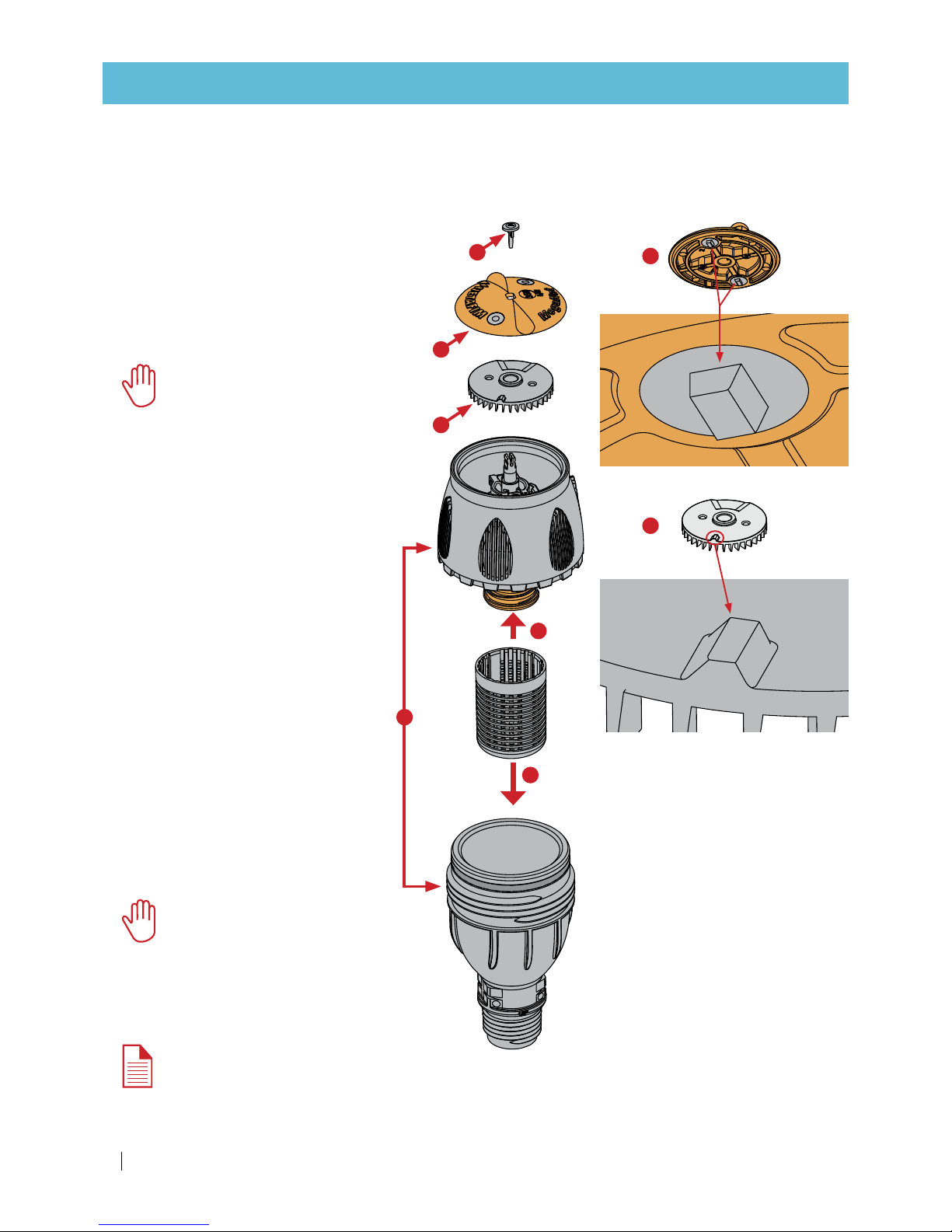

Checking the turbine and the cover

Frequency:

Before the beginning of each growing season

Action:

1.

Open the sprinkler by unscrewing the

upper body of the sprinkler from its base.

2.

Detach the filter by pulling it down.

3.

Remove the pin by pulling it up with your

fingernail or with a small screwdriver.

CAUTION

Be sure not to lose the pin. It is

esential to the operation of the

sprinkler. Aside from indicating

the sprinkler trajectory angle it

also serves to hold the cover

and the turbine in place.

4.

Push the sprinkler's top mechanism

up and hold it.

5.

Remove the colored cover

by pulling it up.

6.

Remove the turbine by pulling it up.

7.

Visually check the 2 black tabs on

the underside of the colored cover

for wear.

8.

Visually check the tab on the

top side of the turbine for wear.

If any of them is worn, replace both

parts - the cover and the turbine.

9.

Put the filter back in place.

10.

Reassemble the sprinkler.

CAUTION

Do not forget to put the pin

back in place. It is esential to

the operation of the sprinkler.

1

2

3

4

5

6

7

8

NOTE

It is recommended to replace the

cover and the turbine every 2000

irrigation hours.

Page 15

MegaNetTM USER MANUAL

15

Cleaning the nozzle

CAUTION

Never operate the sprinkler without the filter.

Failure to comply with this instruction will clog the sprinkler, and may damage it and void the warranty.

If the above instruction is followed, the sprinkler nozzle should never get clogged.

In the event that the sprinkler has been operated without the filter in place, it is possible to clean the nozzle.

Follow the instructions below:

NOTE

The drawings below present the sprinkler's upper body without the pin, the colored cover and the

turbine, to show the actions described. In practice, these 3 parts are connected to the top of the

diverter throughout the dismantling and reassembling process, and do not interfere with it.

NOTE

2 service keys are supplied with each box of MegaNet™ sprinklers. Additional service keys can be

ordered separately (Cat. No. 63620-004500).

1.

Open the sprinkler by unscrewing the upper body of the sprinkler from its base (see page 21, step 1).

2.

Push the sprinkler's top mechanism up and hold it (see page 21, step 4).

MAINTENANCE

Groove

TabTab

Slot

3.

Insert the slotted end of a service key

underneath the diverter holder.

4.

Push the far end of the service key down to the horizontal

position with the groove underneath the key resting on the rim

of the sprinkler's upper body. In this position, the service key

should hold in place.

ATTENTION

There are 2 opposing tabs on the underside

of the diverter holder. Make sure that the

slot of the service key holds one of the tabs.

Page 16

16

MegaNet

TM

USER MANUAL

MAINTENANCE

Diverter

5.

Release the diverter using the other end of the

second service key.

Clean

6.

Clean the nozzle from the top with a water jet or

pressurized air.

7.

To reassemble the sprinkler perform the

steps above in reverse order.

When putting the diverter back in place, turn the

key clockwise until the diverter snaps in place.

A click should be heard.

CAUTION

When reassembling the sprinkler, do not

forget to put the filter in place to avoid

clogging the nozzle in the future.

Hold the first service key in place and turn the

second service key counterclockwise to release the

diverter.

Page 17

MegaNetTM USER MANUAL

17

Parts

MegaNet™ -

½" threaded inlet connector,

head only

Flow

rate*

(l/h)

Nozzle

size

(mm)

Color

code

Catalog number

24D 15D

200 1.8 5 Yel low 63600-001700 63600-004900

250 2.06 Purple 63600-0 01750 63600-004950

350 2.44 Green 63600-001000 63600-005000

450 2.79 Blue 63600-002000 63600-006000

550 3.08 Brown 63600-003000 63600-007000

650 3.37 Orange 63600-004000 63600-008000

750 3.68 Red 63600-004500 63600-009000

* Nominal flow rate at 2.3 bar working pressure.

Packaging data

MegaNet™

Units

p/box

Box size

(cm)

Box weight

(Kg)

Boxes

p/pallet

Total unit s

p/pallet

Pallet weight

(Kg)

Head only 200 18 x 34 x 79 11. 0 20 4000 232

MegaNet™ cover

Flow

rate*

(l/h)

200 250 350 450 550 650 750

Color

code

Yellow Purple Green Blue Brown Orange Red

Catalog

number

63620

-

004850

63620

-

004900

63620

-

005000

63620

-

005100

63620

-

005200

63620

-

005300

63620

-

005400

* Nominal flow rate at 2.3 bar working pressure.

MegaNet™ parts

PARTS AND COMPLEMENTARY PRODUCTS

Part description Catalog number

Turbine (black)

for 24D models

with flow rates 200-350 l/h

63600-002000

Turbine (grey)

for all 15D models

and 24D models

with flow rates 450-750 l/h

63600-006000

Part description Catalog number

Pin for 24D (black) 63600-00175 0

Pin for 15D (grey)

63600-004950

Part description Catalog number

Filter 63620-004400

Page 18

18

MegaNet

TM

USER MANUAL

PARTS AND COMPLEMENTARY PRODUCTS

MegaNet™ accessories

Product

description

Road protector

Catalog

number

63620-007000

Product

description

Ser vice key

Catalog

number

63620-004500

Complementary products

Product

description

In-line pressure regulator,

¾" female - ½" female.

2.5 bar nominal outlet pressure.

Catalog

number

31000-002200

Pressure regulator

Page 19

MegaNetTM USER MANUAL

19

PARTS AND COMPLEMENTARY PRODUCTS

Special model for cement connection (blue base)

Product description

20 mm ISO inlet connector ½" ASTM inlet connector

Flow

rate*

(l/h)

Nozzle

size

(mm)

Color

code

Catalog number Catalog number

24D 15D 24D 15D

200 1.8 5 Yel low

** ** ** **

250 2.06 Purple

** ** ** **

350 2.44 Green

** ** ** **

450 2.79 Blue

**

63600 -010100

**

63600-010500

550 3.08 Brown

**

63600-010200

**

63600-010600

650 3.37 Orange

** ** ** **

750 3.68 Red

** ** ** **

Models for specific uses, head only

Special model with anti-drain valve

Product description

½" threaded inlet connector + AD

Flow

rate*

(l/h)

Nozzle

size

(mm)

Color

code

Catalog number

24D 15D

200 1.8 5 Yel low 63600-001720

**

250 2.06 Purple

** **

350 2.44 Green 63600-001900

**

450 2.79 Blue 63600-002010 63600-005010

550 3.08 Brown 63600-003010 63600-006010

650 3.37 Orange 63600-004010

**

750 3.68 Red 63600-004510

**

* Nominal flow rate at 2.3 bar working pressure.

**Missing catalog numbers available upon request.

Page 20

20

MegaNet

TM

USER MANUAL

Special model for cement connection (blue base)

Can be cemented to the end of a PVC riser tube in solid set installations. Effective for theft prevention.

2 types are available:

• ISO C 20 mm

• ASTM C ½"

Cementing to a ½" (or 20 mm) PVC pipe

NOTE

Read and understand all the instructions before performing this procedure.

1.

Use WELD-ON 717 PVC cement and P68 primer or their equivalents.

2.

Trim the application brush to the desired shape.

3.

Dip the application brush in the P68 primer. Squeeze the brush to remove excess solvent.

4.

Using the brush, clean the inner surface of the socket with the primer.

5.

Using the brush, clean the outer surface of the sprinkler housing with the primer.

6.

Wait 60 seconds for the primer to dry befor applying the cement and then neatly apply the cement to

the outer surface of the sprinkler housing.

7.

Apply the cement to the cylindrical part of

the sprinkler housing below the circular rib.

8.

Insert the sprinkler housing into the socket

in a rotational motion (1/4 turn) to spread the

cement over the entire surface. Make sure

the sprinkler is fully inserted into the socket.

9.

Hold the sprinkler and socket together

for about 30 seconds to make sure they are

firmly connected.

10.

Remove any excess cement with a dry cloth.

11.

Repeat all the steps above when cementing

the socket to the riser tube.

12.

Wait at least 6 hours for the cement to fully

solidify before running water through the

sprinkler.

APPENDIX 1: SPECIAL APPLICATIONS

8 11 12

Page 21

MegaNetTM USER MANUAL

21

Special model with anti-drain valve

For use in slopped fields in order to prevent drainage of the distribution pipe and

possible over-saturation of the soil, unwanted puddles or landslide.

Features and benefits

• Automatic end-of-irrigation shut-off valve.

• Prevents water backflow or drainage of the system into low areas.

• Eliminates the need for system water refill at the beginning of the next irrigation cycle.

• Shut-off pressure: 0.6 bar

Installation

The installation process of this model is similar to that of the regular model

(see pages 10-19).

Screwing and tightening of the sprinkler can be done by hand. The use of a 20 mm

spanner is not necessary.

Adding a PRV (pressure regulating valve)

Install a PRV at the sprinkler inlet when a 100% flow rate and

distribution uniformity is required.

The presented model is suitable for an exit pressure of 2.5 bar.

For other exit pressure values, contact your local Netafim™

representative.

Installation

The installation process of the sprinkler and PRV is similar to that

of installation on solid set riser pipes (see page 12).

Screwing and tightening of the PRV should be done by hand.

ATTENTION

Make sure the PRV is connected to the sprinkler

with the arrow pointing towards the sprinkler (up).

NOTE

The PRV bottom thread is ¾" female. To connect the PRV to

a riser with a thread that is not ¾" male, use an apropriate

adapter/reducer from the vast selection offered by Netafim™

(see page 26 and at XXX).

APPENDIX 1: SPECIAL APPLICATIONS

Arrow

¾" male

thread

Page 22

22

MegaNet

TM

USER MANUAL

Road protector

To avoid wetting the roads around the field, Netafim™ offers a road protector to be used on the sprinklers

at the boundaries of the field.

Installing the road protector

1.

Place the road protector on top of the

sprinkler with its back side facing the

road you want to protect from water.

2.

Push the road protector down onto the

sprinkler head. Clicks should be heard.

3.

Slightly rotate the road protector until

more clicks are heard.

Removing the road protector

1.

Push the 2 ears outwards and up to release the road protector from the sprinkler.

APPENDIX 1: SPECIAL APPLICATIONS

CLICK!

CLICK!

2 3

Page 23

MegaNetTM USER MANUAL

23

WARRANTY

Netafim™ warrants all the components of the MegaNet™ sprinkler to be free of substantial defects in

material and workmanship for a period of 1 (one) year from the date of purchase.

If a defect is discovered during the applicable warranty period, Netafim™ will repair or replace, at its

discretion, the product or the defective part.

This warranty does not extend to repairs or replacements of a MegaNet™ sprinkler or part resulting from

misuse, negligence, alteration, force majeure, lightning, improper installation or improper maintenance,

including any maltreatment of the MegaNet™ sprinkler or any part of the irrigation systems.

If a defect arises in your Netafim™ product during the warranty period, contact your Netafim™ supplier.

Limited warranty

This warranty is subject to the terms and conditions contained in Netafim's official warranty statement in

force at the time of application.

For the full text of Netafim's official warranty statement, go to:

http://www.netafim.com/irrigation-products-technical-materials

Page 24

GROW MORE WITH LESS

WW W.NE TAFIM.COM

Loading...

Loading...