Page 1

” Spin-Klin Battery 2016 Page 1 of 13

Arkal Spin-Klin

3” Battery

Installation, Operation and Maintenance

Instructions

Ref- 910101-000494 / 2016

Page 2

3” Spin-Klin Battery 2016 Page 2 of 13

Arkal Spin-Klin 3” Battery – User Manual

This Arkal 3” Spin Klin battery is an automatic self-cleaning filter designed for non-hazardous liquids only

and within the pressure and temperature framework described in the specifications table.

Page 3

3” Spin-Klin Battery 2016 Page 3 of 13

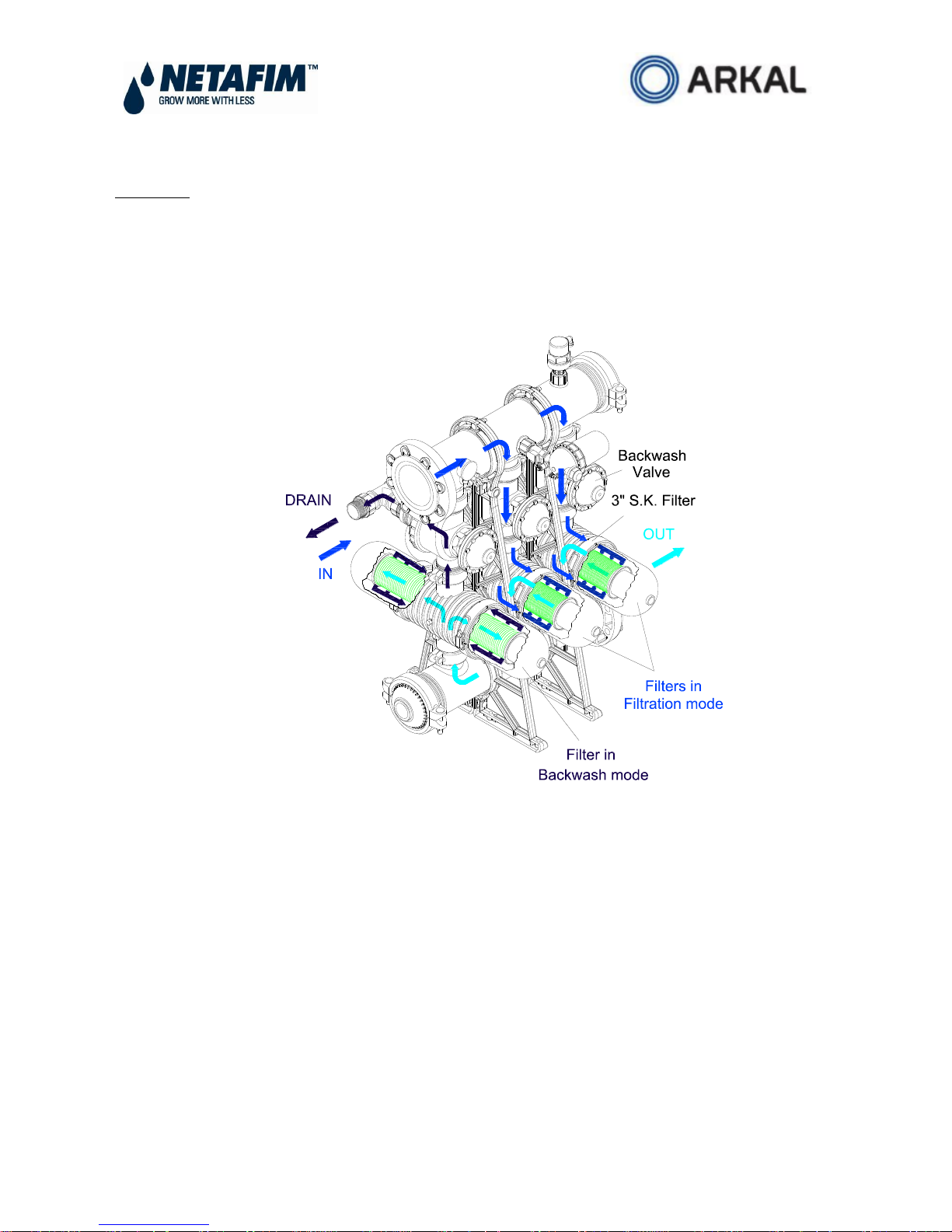

Operation

During the filtration stage, water flows through the INLET manifold and is distributed through the 3” x 2” back-flush

valves into the Spin Klin filters. The water then passes through the filter elements to the outlet manifold for consumer

use.

Description of the Back-Flushing Process

1. The controller transmits an electrical command to the first solenoid per either differential pressure or time.

2. The solenoid then sends a pressure command to the back-flush valve, moving it from the filtration mode to the

back-flushing mode.

3. Filter #1 is then back-flushed with water from the outlet manifold that has been filtered by the other filters in the

system. Contaminated water and impurities flow out through the drain manifold.

4. On completion of the allotted back-flush time the controller releases the back-flush command. Filter #1 return to

the filtration mode.

5. Filter #2 then enters the back-flush mode, and the process is repeated until all the filters in the system have been

back-flushed.

6. After all the filters have been back-flushed the system returns to the filtration mode, until the next back-flush

cycle.

Page 4

3” Spin-Klin Battery 2016 Page 4 of 13

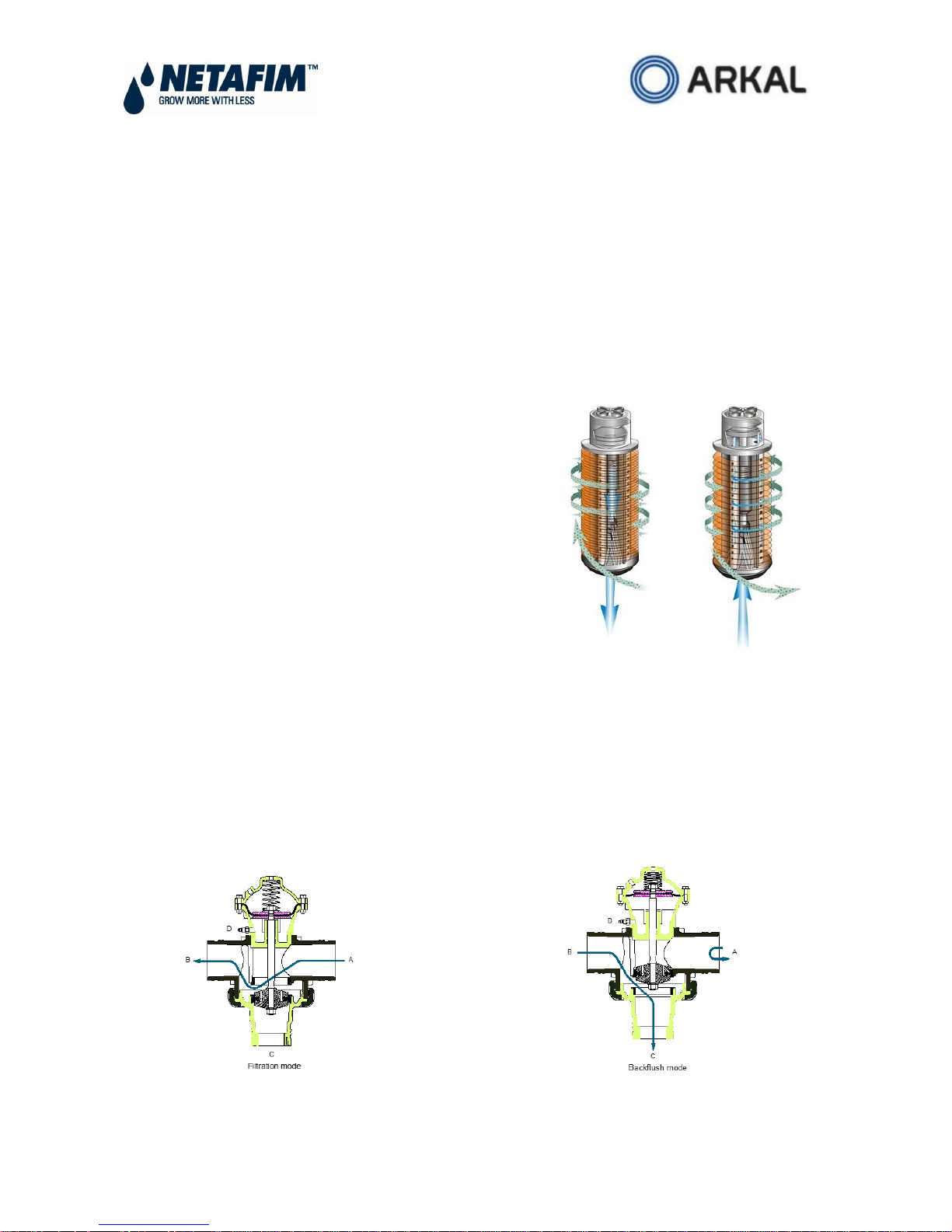

Spin Klin Technology - Spin Klin Spine

General:

The Spin Klin discs are stacked on the Spin Klin spine.

The discs are color-coded by micron size, and are assembled according to your water filtration requirements. The spine

assembly has a spring compression unit and an internal piston which are used to alternately compress and release the

discs during filtration and back-flush cycles.

Filtration Mode:

During the filtration process the filter discs are tightly compressed

together by the spring and the differential pressure, forcing the

water to flow through the grooves and traps of the discs.

Back-flush Mode:

During back-flush the discs are released by releasing the inlet hydraulic

pressure. Multi-jet nozzles provide tangential spray on the loosened

discs, causing them to spin, and release the retained solids, which are

flushed out to the drain.

3” x 2” Back-flush Valve

Filtration Position:

Water flows from port [A] (main supply) to port [B] (filter connection). Port [C] (drain water outlet) is closed by the seal.

Back-flush Position:

Command pressure is applied to the top side of the diaphragm through port [D]. The diaphragm moves down, pushing

the sealed body by the shaft. Port [A] is closed by the seal, preventing flow to the filter. Port [C] is now open allowing

flushing water to flow from port [B] (filter connection) to the drain.

Filtration Mode

Outlet

Inlet

Back-flush Mode

To Drain

Back-flush

Water Inlet

Page 5

3” Spin-Klin Battery 2016 Page 5 of 13

System Installation and Startup

Technical Data

10 bar at (25⁰ C)

145 psi

Maximum Pressure

2.8 bar

38 psi

Minimum Pressure

20 m

³/h

88 gpm

Back-flush Flow Rate per unit

70⁰C

158⁰F

Maximum Temperature

4-11

4-11

pH

3” Spin Klin Battery with Bermad Valves

Installation

A. Make sure that the inlet and outlet orientation is correct (shown by arrows on filter).

B. Prior to start-up check for any transport damage to the unit (system operates under pressure!).

C. Connect back-flush drainage line.

D. Cover clamps need to be properly closed.

Start-up Operation

Start the back-flush cycle, making sure that all system components function correctly.

Filter Load-up during Start-up

Close the downstream (flow control) valve (if available).

Flush until clean with repeated cycles.

Slowly reopen the downstream valve.

If the pressure difference remains high, check and see if the flow rate is too high.

An excessive flow rate through the filter causes excessive pressure loss.

?160

?160

TYP.

2"

6"

6"

250 [9 27/32"]

DRAIN

IN

OUT

REF. 947 [37 5/16"]

285 [11 7/32"]

535 [21 1/16"]

6"

OUT

1047 [41 7/32"]

REF. 1291 [50 13/16"]

560 [22 1/16"]

820 [32 9/32"] (IN-OUT)

DRAIN

6"

IN

180 [7 3/32"]

REF. 865 [34 1/16"]

PRESSURE GAUGE

AIR RELEASE VALVE

3" S.K. FILTER

BACKFLUSH VALVE

CONTROL FILTER

Page 6

3” Spin-Klin Battery 2016 Page 6 of 13

Control

Refer to the controller’s manufacturer user manual before installing the controller.

Make sure that the voltage of both the solenoid unit and controller are correct.

Set the manual operation button to automatic.

Check that the ∆P hydraulic switch HIGH and LOW pressure lines are correctly connected to the appropriate ports.

Set the starting back-flush switch to ∆P 5meters (7psi).

Set the controller to a flush time of 30 seconds and a dwell time of 10 seconds. These settings may require

adjustment to conform to local water conditions. Typically, a 1 to 3-hour interval between back-flush cycles is

recommended.

Page 7

3” Spin-Klin Battery 2016 Page 7 of 13

Spin Klin – System Maintenance

Monthly Maintenance

Check inlet /outlet pressures:

In case the pressure differential is above 5 m / 7 PSI.

Activate automatic back-flush of the Spin Klin filter battery.

If the pressure differential remains high check for possible failures.

Check for leakages from the drain manifold:

In case there is a leakage of water during the filtration stage, check for possible failure at the back-flush valve seals.

Back-flush controller performance:

Check that the controller timing parameters are correctly adjusted and activate automatic back-flush cycle. In the event

of possible failure at the back-flush controller, check for possible failures.

Cleaning of the Command Filter:

Close the command filter inlet valve, release the pressure trapped at the command filter and remove the cover.

Thoroughly clean the filtration element and then reinstall the command filter element and cover, then open the inlet

valve.

Winterization:

To prevent the filter battery becoming damaged during water freezing - drain all the water from the filter battery and the

command filter and leave the drain valve open.

Page 8

3” Spin-Klin Battery 2016 Page 8 of 13

Seasonal Maintenance – Cleaning the Discs

When manual cleaning of the discs is required, please

follow the steps described below: Make sure that

system is not under pressure! Release the clamp and

remove the cover (Figures 1, 2)

Unscrew the butterfly-nut on the filtration element

(Figure 3) Remove the tightening cylinder (Figure 4)

Remove the discs (for convenience we recommend

using a plastic bag) (Figures 5, 6)

Tie each set on a string and place them in a cleaning

solutions (HCL, Chlorine, or other) refer to “Cleaning

Recommendations Clogged Filtration Discs”.

Thoroughly wash the discs with fresh water (Figure 7)

Reassemble the discs on the spines; check that the

correct quantities of discs are assembled on the spine:

when the discs are pressed with two hands, the top

disc should be level with the imprinted circle on

the outside of the spine (Figure 8)

Put on the tightening cylinder and tighten the

butterfly-nut, then reassemble the filter cover and

tighten the clamp (Figures 9, 10)

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

Figure 8

Figure 10

Figure 9

Page 9

3” Spin-Klin Battery 2016 Page 9 of 13

Cleaning Recommendations for Clogged Filtration Discs

Water-formed deposits may cause clogging of the filter discs. The formation of these deposits depends on the quality of

the filtered water and environmental conditions like temperature, pH, light, duration of filtration and more.

Common water-formed deposits are:

Biological or organic deposits (mostly mucous or oily to the touch, beige, brown or green in color)

Iron oxide (rust) or other metal oxides

Carbonates (white or gray deposit)

Combinations of the above

If these deposits cannot be eliminated by pretreatment of the water, we recommend the following cleaning procedure:

Material and Equipment

A well ventilated working place.

2 small containers (1 liter), 2 large containers (15 liter) and a stirring stick, all resistant to chemicals, preferably of

polypropylene.

Plastic rope to tie up the disc.

Sodium Hypochlorite NaOCl - Strong oxidizing liquid, commercial concentration: 10%. Oxidizes and removes

organic and biological deposits.

Hydrochloric Acid HCl - Very corrosive liquid, commercial concentration: 30%. Dissolves and removes carbonates,

iron oxide, and other deposits.

Safety equipment: safety glasses, gloves, long pants, long sleeved shirt and shoes.

ATTENTION!

While working with chemicals protect yourself with the necessary safety equipment:

Safety glasses, gloves, protective clothing

Work in a well-ventilated area

Follow the manufacturer’s instructions

Page 10

3” Spin-Klin Battery 2016 Page 10 of 13

Cleaning Organic and Biological Deposits

Open the filter and remove dirty discs.

Attention – Never open the filter before the pressure has been released.

Arrange the discs loosely on the plastic rope

Prepare a 5% Sodium Hypochlorite solution:

1. Pour 5 liters of water into one of the large containers.

2. Add 5 liters of Sodium Hypochlorite (10%) into the water.

Soak the discs in the solution so that both sides are covered. To achieve maximum cleaning, agitate the discs

several times with a stirring stick.

Contact time with cleaning solution: up to 8 hours

Remove the discs carefully from the solution, put them in the second large container and rinse them very well with

clean water before placing them back in the filter.

We recommend flushing the cleaned discs again in the filter to ensure that all chemical residues are removed.

The cleaning solution can be used for several sets of discs. As the cleaning activity of the solution deteriorates, it may be

necessary to soak the discs for a longer time.

Cleaning Carbonates and Iron Deposits

Open the filter and remove the dirty discs.

Arrange the discs loosely on the plastic rope.

Prepare a 5% Solution of Hydrochloric Acid:

1. Pour 10 liters of water into one of the large containers.

2. Carefully add 2 liters of Hydrochloric Acid (30%) into the water.

Soak the discs in the solution so that both sides will be covered.

PLEASE NOTE: Carbonates react violently with hydrochloric acid (foaming, gas evolution).

To achieve maximum cleaning, agitate the discs several times with a stirring stick.

Contact time with cleaning solution: 1 - 8 hours.

Remove the discs carefully from the solution and rinse them well with clean water before placing them back in the

filter.

We recommend flushing the cleaned discs again in the filter to ensure that all chemical residues are removed.

The cleaning solution can be used for several sets of discs. It may be necessary to soak the discs for a longer period of

time as the cleaning activity of the solution deteriorates.

Page 11

3” Spin-Klin Battery 2016 Page 11 of 13

Cleaning Complex Deposits

If the composition of the deposit is not known, perform the following test:

Take 5 discs for the test.

Soak 2 discs in a 5% Sodium Hypochlorite Solution.

Preparation of the solution:

Pour 1 cup of water into a small container, then add 1 cup of Sodium

Hypochlorite (10% NaOCl)

Soak 2 discs in a 5% Hydrochloric Acid Solution.

Preparation of the solution:

Pour 2½ cups (= 500ml) of water into a small container, then add carefully

½ cup (= 100ml) of Hydrochloric Acid (30% HCl).

Keep one disc as a control.

Observe the cleaning process:

If one of the solutions removes all the deposit, clean the discs in that solution per the instructions above.

If neither solution removes the deposit completely, continue with the test procedure.

Remove the discs from both solutions, rinse them well with water and soak them in the second solution: put the

two discs, which have been in the Sodium Hypochlorite Solution, in the Hydrochloric Acid Solution, and the other

way around.

Check the cleaning process:

If one of the treatments removes all the deposit, clean all the discs following the same two-step procedure in the

exact same order. Rinse the discs well between the two cleaning processes.

If the deposit hasn’t been completely removed, send a set of untreated discs to the laboratory for further

examination.

Page 12

3” Spin-Klin Battery 2016 Page 12 of 13

Identifying Malfunctions in the 3” Spin Klin system

No Back-flush Operation

Important note: Command filter exists only in pressurized air controlled systems

Page 13

3” Spin-Klin Battery 2016 Page 13 of 13

Continuous or Non-stop Back-flushing

Loading...

Loading...