Promina® Series

Multiservice Access Platform

Promina 800 Installation and

Maintenance

Part Number: 037037-405 Rev A

Copyright © 2009 Network Equipment Technologies, Inc. All rights reserved.

NETWORK EQUIPMENT TECHNOLOGIES, INC. (hereinafter referred to as "N.E.T."), PROVIDES THIS

DOCUMENT AS IS, WITHOUT WARRANTIES OF ANY KIND, EITHER EXPRESSED OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY AND FITNESS

FOR A PARTI C ULAR PURPOSE.

No part of this publication may be stored in a retrieval system, transmitted or reproduced in any way, including photocopy, photograph, magnetic, or other record, without the prior written permission of N.E.T. Unpublished-rights

reserved under the copyright laws of the United States.

Trademarks

The N.E.T. logo, PanaVue, PrimeSwitch, Promina, SCREAM, Service Creation Manager, and SHOUTIP are

registered trademarks, and CellXpress, FrameXpress, Frame Relay Exchange, IPNX, LAN/WAN Exchange, Network

Equipment Technologies, N.E.T., the net.com logo, net.com, netMS, PortExtender, PrimeVoice, SCREAMvue, and

SHOUT are trademarks of Network Equipment Technologies, Inc.

SunOS and Solaris software copyright is held by Sun Microsystems, Inc. Sun Microsystems is a registered trademark

and Sun, SunOS, OpenWindows, Solaris, and Ultra are trademarks of Sun Microsystems, Inc. UNIX is a registered

trademark of The Open Group.

All other trademarks and registered trademarks are the sole property of their respective owners.

This document constitutes the sole Specifications referred to in N.E.T.'s Product W arranty for the products or services

described herein. N.E.T.’s Product Warranty is subject to all the conditions, restrictions, and limitations contained

herein and in the applicable contract. N.E.T. has made reasonable efforts to verify that the information in this document is accurate, but N.E.T. reserves the right to correct typographical errors or technical inaccuracies. N.E.T.

assumes no responsibility for any use of the information contained in this document or for any infringement of patents or other rights of third parties that may result from the use of this document. Networking products cannot be

tested in all possible uses, configurations or implementations, and interoperability with other products cannot be

guaranteed. The customer is solely responsible for verifying the suitability of N.E.T.'s products for use in its network.

Local market variations may apply. This document is subject to change by N.E.T. without notice as additional information is incorporated by N.E.T. or as changes are made by N.E.T. to hardware or software.

U.S. Government Rights, Government Use rs

The software accompanying this documentation is furnished under a license and may only be used in accordance with

the terms of such license. This documentation is "commercial computer software documentation" as that term is used

in 48 CFR 12.212. Unless otherwise agreed, use, duplication, or disclosure of this documentation and any related

software by U.S. Government civilian agencies is subject to restrictions as set forth in 48 CFR 52.227-14 (ALT III)

and 48 CFR 52.227-19, and use, duplication, or disclosure by the U.S. Department of Defense is subject to restrictions as set forth in 48 CFR 227.7202-1(a) and 48 CFR 227.7202-3(a) or, if applicable, 48 CFR 252.2277013(c)(1)(ii) (OCT 1988).

Released

November 2009

Network Equipment Technologies, Inc.

6900 Paseo Padre Parkway

Fremont, CA 94555 U.S.A.

http://www.net.com

ii Promina 800 Installation and Maintenance

Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Promina® Series ............................................................................................................................ i

Preface.......................................................................................................................................... xiii

Document Conventions ...............................................................................................................iii-xv

Technical Assistance Information ...........................................................................................iii-xviii

Chapter 1 Promina Systems Overview

The Promina Network .................................................................................................................... 1-2

Private Networks ...................................................................................................................... 1-3

Interface and Device Compatibility ......................................................................................... 1-4

Hardware Features ......................................................................................................................... 1-5

Physical Interfaces ................................................................................................................... 1-5

Call Configuration .........................................................................................................................1-5

Network Management .................................................................................................................... 1-6

Chapter 2 Standard Equipment Modules

Overview ........................................................................................................................................ 2-2

Promina Controller Modules Overview ................................................................................... 2-3

Promina 800 Standard Equipment Configuration .......................................................................... 2-4

Standard and Expansion Shelves ....................................................................................... 2-5

High-Speed Shelf (HSS) .................................................................................................... 2-5

SX-2 Port-to-Shelf Configuration ...................................................................................... 2-5

Promina Standard Equipment Connectivity .................................................................................. 2-6

Promina 800 Node Standard Equipment Redundancy .................................................................. 2-7

Domain and System Redundancy ............................................................................................ 2-7

Nonredundant Configurations .................................................................................................. 2-8

Timing Sources ............................................................................................................................ 2-10

Chapter 3 Card Descriptions

Promina 800 standard Equipment Modules ................................................................................... 3-2

PPM Module ............................................................................................................................ 3-2

Master and Coprocessor Functions .................................................................................... 3-3

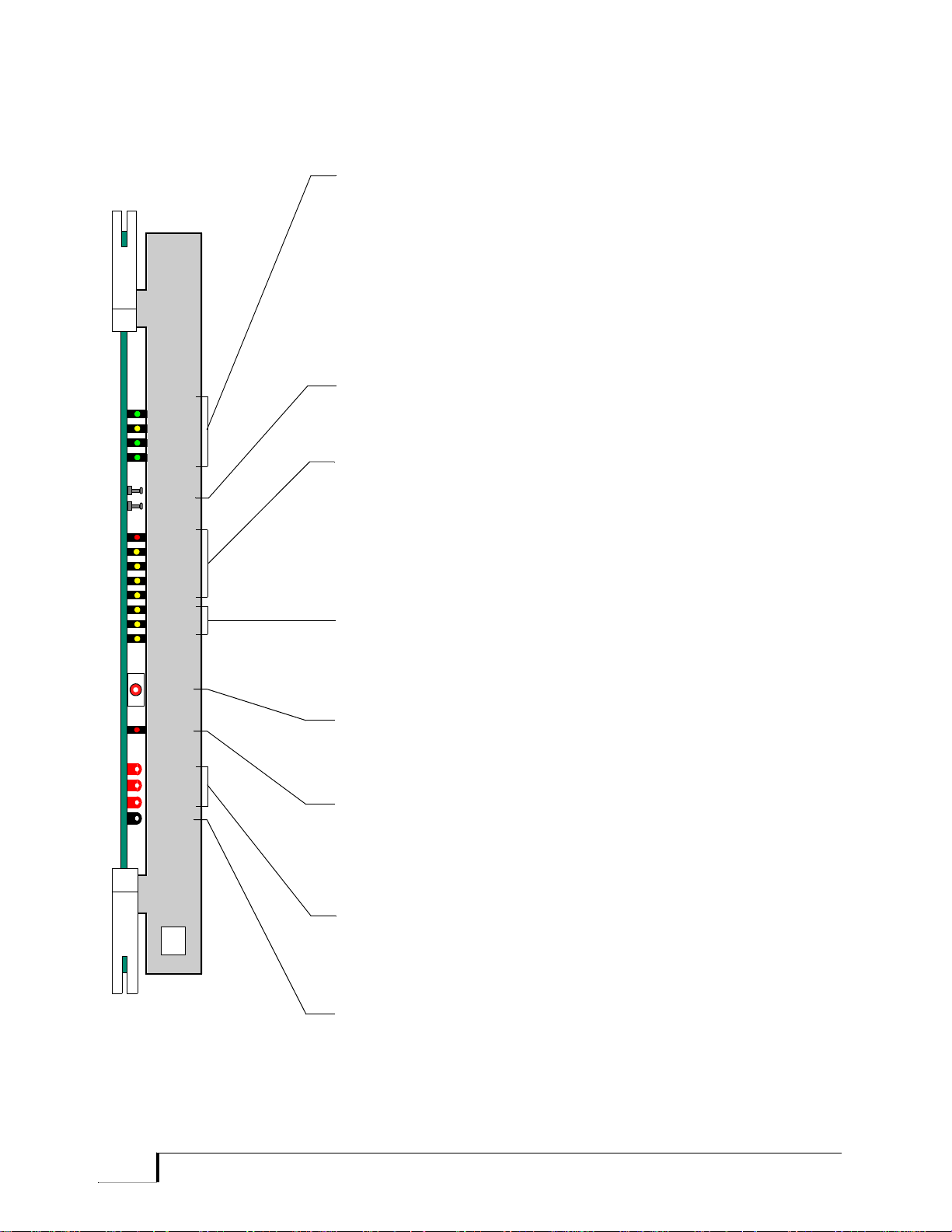

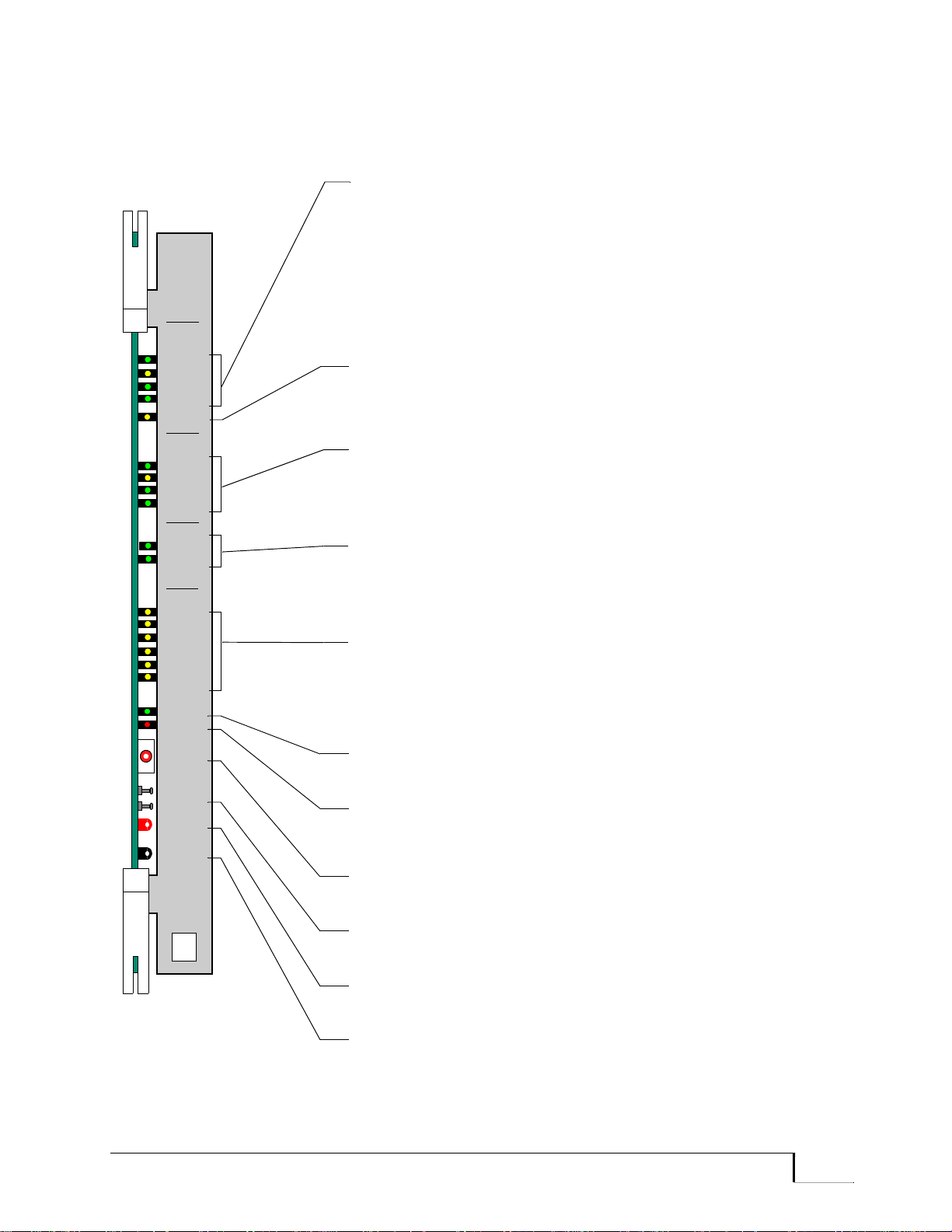

PPM Front Panel ................................................................................................................3-3

PPMI Card ...............................................................................................................................3-5

SX-2 Module ............................................................................................................................ 3-6

Promina 800 Installation and Maintenance Promina Series iii

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SX-2 Front Panel ...............................................................................................................3-6

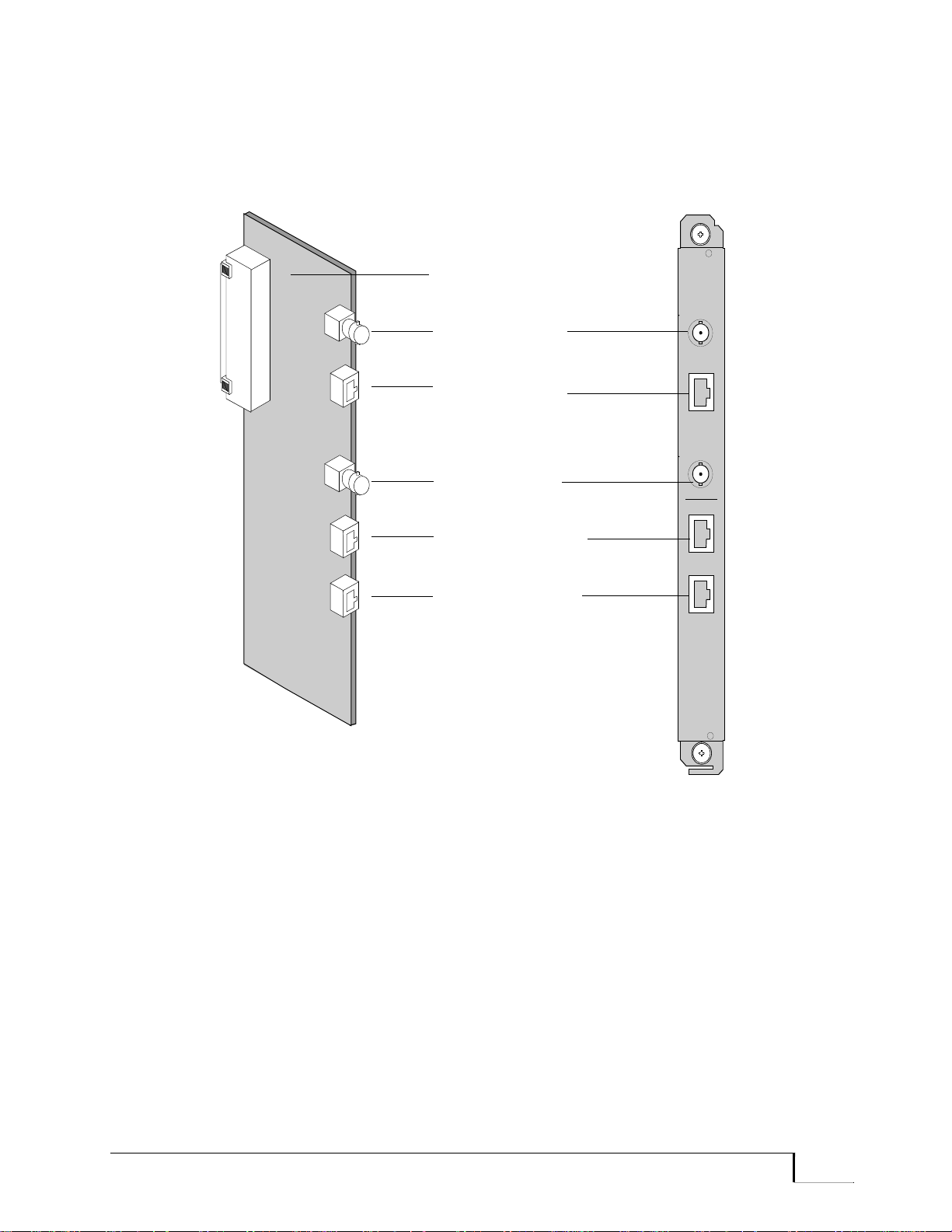

SXI-2 Card ............................................................................................................................... 3-8

SXI-2 Connectors .............................................................................................................. 3-8

SBI Card ................................................................................................................................ 3-10

BX Front Panel ......................................................................................................................3-10

BXI Connectors .....................................................................................................................3-12

Promina Server Module ......................................................................................................... 3-13

PSM Redundancy ............................................................................................................ 3-13

PSM Front Panel .............................................................................................................. 3-14

Promina Server Module Interface .......................................................................................... 3-16

Bus Terminator ...................................................................................................................... 3-18

Dial-in Access Modem ................................................................................................................3-19

Chapter 4 Software Configuration

Card Installation ............................................................................................................................. 4-2

Card Installation After Node Initialization .............................................................................. 4-2

Standard Equipment Parameters .................................................................................................... 4-6

Processor Card Parameters ......................................................................................................4-6

[0] Alarm/Monitor Interface .............................................................................................. 4-6

[5] PPP on Aux Port ........................................................................................................... 4-6

[6] PPP Baud Rate ............................................................................................................. 4-7

[7] PPP Local IP ................................................................................................................ 4-7

[8] PPP Remote IP ............................................................................................................. 4-7

[9] PPP TyCo Device ......................................................................................................... 4-7

[10] MTU Size ................................................................................................................... 4-7

PSM Card Parameters .............................................................................................................. 4-7

[0/1] Console/Auxiliary Baud Rate ...................................................................................4-7

[2] External IP .................................................................................................................... 4-8

[4] Subnet Mask ................................................................................................................. 4-8

[5/6] PSM1/2 Assigned CardID ......................................................................................... 4-8

[10] PPP on Aux Port ......................................................................................................... 4-8

[11] PPP Baud Rate ........................................................................................................... 4-9

[12] PPP Local IP ..............................................................................................................4-9

[13] PPP Remote IP ........................................................................................................... 4-9

[14] PPP TyCo Device ....................................................................................................... 4-9

iv Promina Series Promina 800 Installation and Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[15] MTU Size ................................................................................................................... 4-9

Card Query Displays .................................................................................................................... 4-10

Processor Card Configurations .............................................................................................. 4-10

Card Configuration Descriptions ........................................................................................... 4-12

Alarm Panel I/F ................................................................................................................4-12

Auxiliary Port Configuration ........................................................................................... 4-12

Bytes of RAM Left .......................................................................................................... 4-12

CBUS Interrupts/Sec ........................................................................................................ 4-12

Code Version ...................................................................................................................4-12

Console Port Configuration ............................................................................................. 4-12

CPU Restart Count ........................................................................................................... 4-13

CPU Status ....................................................................................................................... 4-13

Current GMT ...................................................................................................................4-13

DB Checksum .................................................................................................................. 4-13

DB Status ......................................................................................................................... 4-13

External IP .......................................................................................................................4-14

Gateway IP Addr ............................................................................................................. 4-14

HW Revision ....................................................................................................................4-14

HW Serial No ...................................................................................................................4-14

Idle Time (%) ................................................................................................................... 4-14

Internal IP (Address) ........................................................................................................ 4-14

Internal IP Addr ...............................................................................................................4-14

Load Units ........................................................................................................................ 4-14

Local IP ............................................................................................................................ 4-14

MAC Addr .......................................................................................................................4-15

Master CPU ...................................................................................................................... 4-15

MTU Size ......................................................................................................................... 4-15

Number of Installed SSC Ports ........................................................................................ 4-15

Perm Boot Version ........................................................................................................... 4-15

Power Up .........................................................................................................................4-15

PPP Baud Rate ................................................................................................................. 4-15

PSM Card ID ................................................................................................................... 4-15

Remote IP ........................................................................................................................ 4-15

Restart .............................................................................................................................. 4-16

RTC Overruns .................................................................................................................. 4-16

Promina 800 Installation and Maintenance Promina Series v

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Number ..................................................................................................................4-16

Slot Type .......................................................................................................................... 4-16

Status ................................................................................................................................ 4-16

Subnet Mask ....................................................................................................................4-16

Task Distribution ............................................................................................................. 4-16

Task Restart Count ........................................................................................................... 4-17

TyCo Device ....................................................................................................................4-17

Wrt Boot Version ............................................................................................................. 4 -17

Query PSM Displays ................................................................................................................... 4-18

PSM Card Configuration Descriptions .................................................................................. 4-19

Database ........................................................................................................................... 4-19

Ext IP Addr ...................................................................................................................... 4-19

Int IP Addr ....................................................................................................................... 4-19

PSM Code ........................................................................................................................ 4-19

MAC Addr .......................................................................................................................4-19

Status ................................................................................................................................ 4-19

SX-2 Card Configuration ............................................................................................................. 4-20

Active Domain ................................................................................................................. 4-20

DB Status ......................................................................................................................... 4-20

Domain ............................................................................................................................. 4-20

Firmware Revision ........................................................................................................... 4-21

Redundant SX .................................................................................................................. 4-21

Serial Number ..................................................................................................................4-21

Slot Type .......................................................................................................................... 4-21

Status ................................................................................................................................ 4-21

System Components ........................................................................................................ 4-21

BX Card Configuration ................................................................................................................ 4-22

Active Domain ................................................................................................................. 4-22

DB Status ......................................................................................................................... 4-22

Domain ............................................................................................................................. 4-22

Serial Number ..................................................................................................................4-22

Slot Type .......................................................................................................................... 4-22

Status ................................................................................................................................ 4-23

Redundant BX .................................................................................................................. 4-23

SX-2 Port .........................................................................................................................4-23

vi Promina Series Promina 800 Installation and Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Console Port Settings ................................................................................................................... 4-24

Chapter 5 SSC, HTC, and SCLP Ports

SSC Ports on the PPM, PLM, and IPLM ....................................................................................... 5-1

TBus Allocation ....................................................................................................................... 5-2

HTC Ports and SNMP Manageability ........................................................................................... 5-4

SSC Port Installation ..................................................................................................................... 5-5

SSC Port Parameters ................................................................................................................ 5-7

[0] Orig/Ans Mode ............................................................................................................. 5-8

[1] Destination Port ............................................................................................................ 5-8

[2] Call/Preempt Priority ................................................................................................... 5-8

[3] Secondary Call/Preempt Priority .................................................................................. 5-9

[4] Port Type ...................................................................................................................... 5-9

[5] Port Speed ....................................................................................................................5-9

[7] Routing Options ........................................................................................................... 5-9

[8] Primary Selected Path ................................................................................................ 5-10

[10] Selected Path Required ............................................................................................ 5-10

[11] IP Only ..................................................................................................................... 5-10

[14] Max Link Cost ......................................................................................................... 5-11

[15] Secondary Selected Path .......................................................................................... 5-11

[16] Primary Selected Gateway ....................................................................................... 5-11

[17] Secondary Selected Gateway ................................................................................... 5-11

[18] Gateway Required .................................................................................................... 5-11

HTC Port Installation ................................................................................................................... 5-12

HTC Port Parameters ............................................................................................................. 5-15

[0] Orig/Ans Mode ........................................................................................................... 5-16

[1] Destination Port .......................................................................................................... 5-16

[2] Call/Preempt Priority ................................................................................................. 5-16

[3] Secondary Call/Preempt Priority ................................................................................ 5-16

[4] Port Type .................................................................................................................... 5-16

[5] Port Speed ..................................................................................................................5-17

[7] Routing Options ......................................................................................................... 5-17

[8] Selected Path ..............................................................................................................5-17

[10] Selected Path Required ............................................................................................ 5-17

[12] IP .............................................................................................................................. 5-17

Promina 800 Installation and Maintenance Promina Series vii

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[13] Master-only .............................................................................................................. 5-18

SCLP/SSC Port Query Displays .................................................................................................. 5-19

PPM, PLM,

and IPLM Configurations ...................................................................................................... 5-19

Port Configuration Descriptions ............................................................................................ 5-20

ATM Routing ................................................................................................................... 5-20

Call Priority ...................................................................................................................... 5-20

Call State .......................................................................................................................... 5-20

Card Status ....................................................................................................................... 5-21

Card Type ........................................................................................................................ 5-21

Destination Port ...............................................................................................................5-21

Encry Routing ..................................................................................................................5-21

Fiber Routing ................................................................................................................... 5-21

GW Required ................................................................................................................... 5-21

Installed Port .................................................................................................................... 5-21

Last Disconnect ................................................................................................................5-21

Link Status ....................................................................................................................... 5-22

Orig/Ans Mode ................................................................................................................ 5-22

Pkts Recvd .......................................................................................................................5-22

Pkts Sent .......................................................................................................................... 5-22

Port Speed ........................................................................................................................ 5-22

Port Status ........................................................................................................................ 5-23

Port Type .......................................................................................................................... 5-23

Preempt Prty .................................................................................................................... 5-23

Pri Sel GW ....................................................................................................................... 5-23

Pri Sel Path ....................................................................................................................... 5-23

SCLX Routing ................................................................................................................. 5-23

Sec Call Priority ............................................................................................................... 5-23

Sec Prmt Priority ..............................................................................................................5-23

Sec Sel GW ...................................................................................................................... 5-23

Sec Sel Path ..................................................................................................................... 5-23

Terr Routing ..................................................................................................................... 5-24

HTC Port Query Displays ............................................................................................................ 5-25

Chapter 6 Promina 800 System

Promina 800 Configurations .......................................................................................................... 6-2

viii Promina Series Promina 800 Installation and Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STS Shelf ................................................................................................................................. 6-2

EXS Shelf ................................................................................................................................ 6-2

System Hardware ........................................................................................................................... 6-3

Configuration Specifications ......................................................................................................... 6-4

Load Units ................................................................................................................................ 6-4

Logical Slots ............................................................................................................................6-5

Module Power Consumption ................................................................................................... 6-5

Electrical and Environmental Specifications ........................................................................... 6-6

Physical Dimensions ...................................................................................................................... 6-7

Rack-mount System ................................................................................................................. 6-9

Cabinet-

mounted Systems ..................................................................................................................... 6-9

Cabinet Grounding ........................................................................................................... 6-14

Promina 800 Shelves ................................................................................................................... 6-15

Shelf Configurations .............................................................................................................. 6-15

Optional Cabinet Equipment ................................................................................................. 6-15

Shelf and Slot Numbering ...................................................................................................... 6-16

Slot Restrictions ............................................................................................................... 6-17

HSS-2 Shelf ...........................................................................................................................6-18

HSS-2 Shelf Door ............................................................................................................ 6-18

HSS-2 Backplane ............................................................................................................. 6-19

STS Shelf ............................................................................................................................... 6-22

STS Shelf Front Panel ...................................................................................................... 6-22

STS Backplane ................................................................................................................. 6-25

Setting the STS Backplane Jumper .................................................................................. 6-26

EXS Shelf .............................................................................................................................. 6-27

EXS Backplane ................................................................................................................ 6-27

Setting the EXS Backplane Jumper ................................................................................. 6-28

Power Supplies ............................................................................................................................ 6-29

System Power and BTU Output ............................................................................................. 6-29

Power Distribution Units ............................................................................................................. 6-30

Cabinet/Rack Mounted PDUs ................................................................................................ 6-30

-48 and -60 V DC PDU .................................................................................................... 6-30

Connection to DC Power Source ..................................................................................... 6-35

100 to 240 V AC PDU ..................................................................................................... 6-38

HSS-2 PDUs .......................................................................................................................... 6-42

Promina 800 Installation and Maintenance Promina Series ix

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-48 and -60 V DC PDU (dual feed) ................................................................................. 6-42

100 to 240 V AC PDU (Dual Feed) ................................................................................. 6-43

STS PDUs .............................................................................................................................. 6-44

-48 and -60 V DC Single/Dual Feed PDU ....................................................................... 6-44

Connection to DC Power Source ..................................................................................... 6-46

100 to 240 V AC PDU ..................................................................................................... 6-49

Fan Tray Assemblies ................................................................................................................... 6-50

Alarm Panel/Auxiliary Fan Assembly ................................................................................... 6-50

Jackfield Fan Assembly .........................................................................................................6-51

Intake Fan Assembly ............................................................................................................. 6-51

Thermostatic Controlled Fan Assembly ................................................................................ 6-52

Standard Equipment Modules ...................................................................................................... 6-53

HSS-2 Shelf Modules ............................................................................................................6-54

Reserved Card Slots ............................................................................................................... 6-55

System Redundancy ............................................................................................................... 6-56

Promina Processor Module .............................................................................................. 6-57

Promina Server Module ................................................................................................... 6-58

STS Shelf Modules ................................................................................................................ 6-58

STS Feature Modules ....................................................................................................... 6-59

EXS Shelf Modules ............................................................................................................... 6-60

Chapter 7 Promina System Components

Power Supplies .............................................................................................................................. 7-2

250 W Power Supplies ............................................................................................................. 7-2

Maximum Output Currents ................................................................................................ 7-5

Power Supply Specifications ............................................................................................. 7-5

400 W Power Supplies ............................................................................................................. 7-5

Maximum Output Currents ................................................................................................ 7-9

Power Supply Specifications ............................................................................................. 7-9

Aux Power Supply Tray .............................................................................................................. 7-10

Fan Trays ...............................................................................................................................7-11

Wattage and BTU Output ............................................................................................................ 7-12

Module Power Consumption .......................................................................................................7-13

Load Units .................................................................................................................................... 7-14

Logical Slots ................................................................................................................................ 7-15

x Promina Series Promina 800 Installation and Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Minimum Load Board ................................................................................................................. 7-16

System Load Current Requirements ...................................................................................... 7-17

Configuration Requirements .................................................................................................. 7-18

Bus Cards ............................................................................................................................... 7-18

T1 Jackfield .................................................................................................................................. 7-19

Alarm Panel Assembly ................................................................................................................7-20

Front Alarm Panel-2 ....................................................................................................................7-21

Alarm Panel-2 Connections ................................................................................................... 7-21

Rear Alarm Connectors ................................................................................................... 7-22

Serial Port Interface ..................................................................................................................... 7-23

Cross Connects ...................................................................................................................... 7-24

Baud Rates ............................................................................................................................. 7-24

Serial Port Pinouts ................................................................................................................. 7-24

Determining Bandwidth ............................................................................................................... 7-27

Transparent Signaling Overhead ........................................................................................... 7-27

Trunk Asynchronous Bandwidth ........................................................................................... 7-27

Pass-Through Timing ............................................................................................................7-27

Synchronous Timing .............................................................................................................. 7-27

Chapter 8 Operator Interface Commands

Expert Mode Command Summary ................................................................................................ 8-2

Appendix A Card Installation

Module Installation Requirements ................................................................................................ A-2

Load Units ............................................................................................................................... A-2

Logical Slots ........................................................................................................................... A-2

Promina 800 Card Installation ...................................................................................................... A-3

Interface Card Installation ............................................................................................................ A-5

Installing an Interface Card in an HSS-2 ................................................................................ A-5

Installing an Interface Card in an STS or an EXS .................................................................. A-5

Rear Interface Card Replacement ................................................................................................. A-9

Front Card Installation ................................................................................................................ A-10

Front Card Replacement ............................................................................................................. A-12

Connecting Interface Cards .................................................................................................. A-13

Installing Front Cards ........................................................................................................... A-13

Replacing Front Cards ..........................................................................................................A-13

Promina 800 Installation and Maintenance Promina Series xi

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B PanaVue Configuration for HTC Port Use

Typical Ethernet-Based Configuration ..........................................................................................B-2

HTC Configuration ..................................................................................................................B-3

Index..................................................................................................................................................1

xii Promina Series Promina 800 Installation and Maintenance

Preface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Document

This document is for use in the installation and management of Promina

Series nodes. It provides information about standard equipment modules

and how to install standard equipment cards in the configuration

database.

Before using this document the reader should have a working knowledge

of data communications, and basic trunking and transmission concepts.

The user also needs to be aware of the hazards associated with electronic

equipment and electricity, a detailed discussion of which is beyond the

scope of this document.

This document provides screen displays as examples of output from the

Operator Interface. Because the displayed information is dependent on

each node’s configuration, the examples may not correspond exactly to

the information displayed by another node. Differences in software

releases can also account for differences in displayed information.

Document Organization

The document contains the following sections:

Section Title Description

Chapter 1 Promina Systems

Overview

Chapter 2 Standard Equipment

Modules

Chapter 3 Card Descriptions Describes the standard equipment modules

Chapter 4 Software Configuration Describes installing standard equipment cards

Chapter 5 SSC, HTC, and SCLP

Ports

Provides an overview of the Promina systems.

Provides basic information about the standard

equipment modules in Promina 800

and includes illustrations of the front panel

and rear cards with information on front panel

components and rear card ports.

in the configuration database through the

Operator Interface and includes descriptions

of card and port parameters.

Describes operation and usage of SSC

(Secondary Signaling Channel), HTC (HDLC

TBus Channel), and SCLP (Signaling Channel

Link Protocol) ports, used to communicate

network management information, control

signals and system updates between

domains.

Promina 800 Installation and Maintenance Promina Series xiii

Preface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section Title Description

Chapter 6 Promina 800 System Describes the hardware configurations an d

specification for the rack- and

cabinet-mounted Promina 800 systems.

Chapter 7 Promina System

Components

Chapter 8 Operator Interface

Commands

Appendix A Card Installation Installation and replacement procedures for

Appendix B PanaVue Configuration

for HTC Port Use

Describes Promina 800 Hardware

components.

Contains the Operator Interface commands

used for the configuration of modules.

CE cards in the Promina 800 systems.

Describes how to configure a PanaView

workstation for IP connectivity to a promina

network.

xiv Promina Series Promina 800 Installation and Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface

Document Conventions

The following conventions are used in this document:

Convention Example Description

Key name Press DELETE. Refers to non-printing keys on the

keyboard that you press.

Simultaneous

Key

bold Caution: Used for emphasis.

bold courier Type exit Indicates a command to be typed.

Enter Enter add ndp 2 Indicates that after typing the information,

Italic Use breakers rated for

Screen shot YYYY/MM/DD Refers to date used in screen shot.

Module module The term module refers to card systems,

Press Shift+F1. Refers to non-printing keys on the

keyboard that need to be pressed

simultaneously.

press the Return or Enter key.

Refers to a new term that is defined in the

fast trip on supply

circuits.

For more information,

see the Hardware

Description manual.

text or glossary.

Refers to a document or book title.

except where the word card is used as

part of the name for the module.

Promina 800 Installation and Maintenance Promina Series xv

Preface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The following icons are used in this document to provide important

information:

Icon Description Definition

Note Directs the reader’s attention to important

information.

Caution Provides information on how to avoid possible

loss of packet traffic or damage to files or

equipment. Also, provides information on how to

avoid a potentially hazardous non-electrical

situation.

Caution Provides information about ho w to pr ot ect

against fire hazards.

Warning Provides information on how to avoid a

potentially hazardous electrical situation that, if

not avoided, could result in serious injury or

death.

Warning Provides information on how to avoid potentially

hazardous laser or LED radiation emission that,

if not avoided, can damage your eyes.

Safety Ground

Symbol

ESD Ground

Symbol

This symbol represents the Safety Ground

Connection connection on the Promina Series

chassis. This symbol has a circle around the

outside of the icon.

This symbol represents the ESD Ground

Connection on the Promina Series chassis. This

symbol does not have a circle around the

outside of the icon.

xvi Promina Series Promina 800 Installation and Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface

Associated Documents

The following manuals in the Promina Series documentation set provide

additional information.

Promina Series Manuals

Safety

System Hardware

Trunk Modules

Feature Modules

Management

Reference

Reader’s Response

Promina 800

Installation and

Maintenance

NX1000 Installation

and Maintenance

Channelized Trunk

Modules

IP Modules

Port

Extender

Analog Voice

Modules

Terminology

Reference

Compliance and Safety

Promina 200/400

Installation and

Maintenance

NX1000 Quick

Installation Guide

Trunk

Modules

Data

Modules

Digital Voice

Modules

Node

Management

Quick

Reference

Promina 100 Installation

and Maintenance

ATM

Modules

Packet

Modules

Quad Basic Rate

Interface

Alarms

and Events

We encourage comments on the content of this document. Please address

any comments to:

Manager, Technical Publications

N.E.T.

6900 Paseo Padre Parkway

Fremont, California 94555

tech_pubs@net.com

N.E.T. may use or distribute, without incurring any obligation, and in any

way it believes appropriate, any information supplied.

Promina 800 Installation and Maintenance Promina Series xvii

Preface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Assistance Information

If there is a problem installing or using N.E.T. products, call N.E.T.

Technical Assistance Center (TAC) at the following numbers:

For North America, call 1.800.800.4638

For International collect calls, use 1.703.948.7999

TAC engineers are available by telephone 24 hours a day, seven days a

week. Warranty and contract customers receive first consideration in the

scheduling of technical resources.

Before contacting TAC for help, review and verify the provisions

contained in your warranty or contract. Depending on those provisions,

there might be a charge for service.

When authorized, TAC engineers can diagnose most network problems

remotely, using dial-up connections. When a service technician is

required, TAC will dispatch the nearest N.E.T. or third-party service

engineer.

Note: Technical problems can be diagnosed and resolved more quickly if you

have remote access, such as a dial-in modem. Use a modem rated at 9600bps

or greater, or an ISDN connection, for dial-in net.com TAC supp ort and

incoming PPP connections. For other remote access methods, contact net.com

TAC.

xviii Promina Series Promina 800 Installation and Maintenance

1Chapter 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1Promina Systems

Overview

A Promina system is a Multiservice Access Platform, the engine of a

multiservice backbone network. On a single platform, a Promina system

fully integrates the functions of a voice and data networking multiplexer ,

an Integrated Services Digital Network (ISDN) switch, a frame-relay

switch, a multiprotocol router , and a network management system. The

operating system software features a high degree of networking

intelligence which is distributed among all Promina nodes. In addition to

providing all these functions, Promina systems offer the flexibility of

using all existing customer Integrated Digital Network Exchange (IDNX)

feature cards.

This chapter provides an overview to the N.E.T. Promina hardware

system in the following sections:

• The Promina Network on page 1-2.

• Hardware Features on page 1-5.

• Call Configuration on page 1-5.

• Network Management on page 1-6.

Promina 800 Installation and Maintenance Promina Series 1 - 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Promina Systems Overview

The Promina Network

Promina nodes are high performance systems that support internodal

trunks operating over subrated and nonsubrated T1, T3, E1, E3 and OC-3

transmission facilities. A Promina node provides the power and features

required for low speed (16 kbps) to high speed (T3/E3/OC-3) networking

over transmission facilities that range in speeds up to 155 Mbps. The

Promina node supports these feature modules:

• trunk

• voice, including voice compression server modules

• circuit-, frame-, and packet-based exchange

• data

For details on the Promina feature modules, refer to the specific module

manual; for example, T runk Modules, Voice Modules, and Data Modules.

Also refer to the Packet Module Manual (for FRX, LWX or

PrimeSwitch).

1 - 2 Promina Series Promina 800 Installation and Maintenance

Promina Systems Overview

Promina 400

Promina 400

Promina 800

Paris

London

New York

Promina 800

Berlin

Promina 400

Tokyo

Singapore

Sydney

Promina 800

Promina 200

Rio de

Janeiro

Mexico

City

Promina 400

Hong

Kong

Promina 400

Promina 200

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Private Networks Figure 1-1 shows an example of an N.E.T. private network, consisting of

several nodes and topologies. In a network, the Promina 800, 400, 200,

and 100 are referred to as nodes. The logical connections between nodes

are called links. Trunks are the digital transmission facilities over which

voice, data, and video are transmitted.

Figure 1-1 Exam ple of an N.E.T. Pr ivate Network

Promina 800 Installation and Maintenance Promina Series 1 - 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Promina 800

Promina 800

Promina 800

Promina 400

T1

T3

T3T3

T1

T1

T1

Graphics

Workstation

Host

Host

Video

Tape

Drive

PBX

Promina 800

Ethernet

Token Ring

Token Ring

Ethernet

Promina Systems Overview

Interface and

Device

Compatibility

A Promina node is compatible with many public network services. It also

supports a wide range of applications by providing transparency to

protocols for specific applications and permitting connections to most

major types of voice, data, and image equipment (Figure 1-2).

Figure 1-2 Equipment Supported by Promina Systems

1 - 4 Promina Series Promina 800 Installation and Maintenance

Promina Systems Overview

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Features

The Promina processor subsystems provide features and interfaces such

as:

• mass storage provided by the PSM (Promina Server Module)

• non-volatile storage for boot code, run-time code, and the

configuration database

• real time clock

• Ethernet ports

– internal Ethernet port for intranodal communications

– external Ethernet port for Network Management System (NMS)

connectivity

• serial ports

Physical

Interfaces

Call Configuration

Promina nodes uses industry standard physical interfaces to connect with

customer devices. The Promina nodes provide connections for:

• data terminal equipment

• voice equipment compatible to industry standards

• video transmittal and receiving equipment.

For Promina system configurations, features, and options, contact your

local N.E.T. sales representative.

Once the Promina system is installed and tested, the Promina node is

configured.

The number of voice and data calls that can be supported by the Promina

node depends on the following:

• the number of redundant modules

• the number of available logical and physical slots on the node

• the maximum number of database ports

Promina 800 Installation and Maintenance Promina Series 1 - 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Promina Systems Overview

Network Management

Using the processor modules, the Promina operator can access the

Operator Interface software to configure the node, monitor the network,

and diagnose network problems from any ASCII asynchronous terminal.

1 - 6 Promina Series Promina 800 Installation and Maintenance

1Chapter 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2Standard Equipment

Modules

This chapter contains an overview of the standard equipment modules for

Promina Series nodes. It includes the following topics:

• Overview on page 2-2.

• Promina Controller Modules Overview on page 2-3.

• Promina 800 Standard Equipment Configuration on page 2-4.

• Promina Standard Equipment Connectivity on page 2-6.

• Promina 800 Node Standard Equipment Redundancy on page 2-7.

• Domain and System Redundancy on page 2-7.

• Nonredundant Configurations on page 2-8.

• Timing Sources on page 2-10.

Promina 800 Installation and Maintenance Promina Series 2 - 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Equipment Modules

Overview

The standard set of equipment modules that are part of every Promina

800 model include node processor modules, modules that provide

connection between node shelves, and cards that terminate system buses.

Other standard operating equipment include power supplies, chassis, and

cabinets. You can find procedures for installation of standard equipment

modules in Appendix A, Card Installation.

The types of standard equipment modules vary depending on the type of

node. All standard equipment modules consists of front cards, interface

cards, or both. Table 2-1 lists the cards for standard equipment modules

for each type of node and briefly describes each module.

Node Front Card Interface Card Description

Table 2-1 Promina 800 Standard Equipment Modules

Promina 800

only

Promina 800

(required)

Promina 400

(optional)

Promina

Processor

Module (PPM)

Switching

Exchange

(SX-2)

N/A Shelf Bus

Bus Extender

(BX)

N/A Bus Terminator Terminates system buses (STS only).

Promina

Server Module

(PSM)

PPM Interface

(PPMI)

SX Interface

(SXI-2)

Interface (SBI-2)

BX Interface

(BXI)

PSM Interface

(PSMI)

• PPM resides in the high-speed shelf

(HSS) and controls the node.

• PPMI provides an Ethernet port, an

RS-232/RJ-45 port, and an Alarm

port.

SX-2 provides the switch matrix and

clocking on the node, as well as

communication between shelves.

SBI-2 connects the SX-2 modules to the

HSS.

BX provides the communication link

between the expansion shelf (EXS) or

standard shelf (STS) and the SX-2 on the

HSS-2.

• PSM serves as the node file system

manager and the focal point for local

network management and remote

access administrative and service

communications.

• PSMI provides two Ethernet ports and

two RS-232/RJ-45 ports to support

these PSM functions.

2 - 2 Promina Series Promina 800 Installation and Maintenance

Standard Equipment Modules

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Promina

Controller

Modules Overview

The Promina node processor modules (PPM) and Promina node storage

module (PSM) control the internal logic and communication for the node

and provide the central processing and memory storage for the node. The

controller modules also provide the connections for access to the operator

interface.

The PPMs are high-performance controller cards using the Motorola

68LC060. The PLMs are multifunction controller cards using the

Motorola 68LC040.

The PSM has a 68EC040 microprocessor; it incorporates a hard disk

drive for storage of system code, configuration database, event logs, and

feature module code for Frame Relay Exchange (FRX), LAN-WAN

Exchange (LWX), and ISDN Exchange (ISDNX, also known as

PrimeSwitch Module). The combination of these high-speed

microprocessors and the onboard memory design on the Promina

controller cards enables fast system boot up and a high level of call

performance.

The Promina controller cards use a real time operating system. The

Promina operating system also includes these advanced features:

• DOS-compatible filing system for easy access to files

• Internet Protocol (IP) routing system for accessing files over Promina

and IDNX networks

• Local and remote Simple Network Management Protocol (SNMP)

agent for network management systems

• Internet applications:

– Network File System (NFS) client and server system

– File Transfer Protocol (FTP)

– Remote login (RLogin)

– PPP (Point-to-Point Protocol) access to nodes via modem

For more information on each of the Promina controller modules refer to

Chapter 3, Card Descriptions. You can find the procedures for standard

equipment module installation in Appendix A, Card Installation.

Promina 800 Installation and Maintenance Promina Series 2 - 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Space

HSS-0

PPM Cards

SX-2 Cards

SX-2 Cards

Trunk Card

PSM Card

EXS 2

EXS 3

Alarm Panel (optional) / Fan

Power Supplies

Power Supplies

T1-Jackfield (optional)/Fans

Voice Card

Power Supply Tray

EXS 1

T3-Jackfield (optional)

Air Space

BX Cards

Standard Equipment Modules

Promina 800 Standard Equipment Configuration

A Promina 800 node must have one high-speed shelf (HSS) and one

standard shelf (STS) or expansion shelf (EXS) with any combination of

additional STS or EXS shelves, up to a maximum of seven shelves. For

more information on these shelves, refer to the Promina System

Components on page 7-1. Also see Appendix A, Card Installation.

A Promina 800 node may consist of either a nonredundant or redundant

configuration of PPM, PSM, SX-2, and BX cards and power supplies.

Refer to Promina 800 Node Standard Equipment Redundancy on page

2-7 for further detail.

A Promina 800 node with three EXS shelves and with redundant PPMs,

SX-2, and BX cards is illustrated in Figure 2-1.

Figure 2-1 Promina 800 standard Equipment Configuration

2 - 4 Promina Series Promina 800 Installation and Maintenance

Standard Equipment Modules

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard and Expansion Shelves

The Bus Extender (BX) cards and PSM modules must be installed in an

STS or an EXS. The BX card must reside in the leftmost slots in an STS

(for example, slots 16 and 17) or the rightmost slot in an EXS (for

example, slots 30 and 31).

The PSM can be installed in any slot in an STS or EXS except slots

reserved for BX cards.

High-Speed Shelf (HSS)

The PPM module and Switched Exchange (SX-2) cards must be installed

in an HSS-2 (shelf 0). These cards cannot function in any other type of

shelf.

The SX-2 cards must be installed in the leftmost slots (slots 0 and 1) and

the redundant SX-2 cards must be installed in the rightmost slots (slots 14

and 15). PPM cards can be installed in any HSS slot not reserved for

SX-2 cards.

SX-2 Port-to-Shelf Configuration

Each SX-2 card has four spigots numbered 0 to 3 starting with the bottom

connector. Each spigot provides 16 logical slots: 32 Mbps of bandwidth

per spigot for a total of 128 Mbps per SX-2 card, and a maximum of 256

Mbps with two SX-2 cards.

The SX-2 connects to each shelf through the BX cards (referred to as

BXA and BXB on redundant systems).

The STS shelf contains 12 slots. To maintain “module 16” consistency,

STS slots are numbered as if there are 16 on each shelf (the four missing

slot numbers are discarded and appear as empty when the database is

queried). For example, if shelf 1 slots are numbered 16 to 27, shelf 2 slot

numbers start at 32.

Note: It is important to connect the SX-2 spigots so that the slot numbers are

consecutive; that is, so there are no gaps. For example, in a three-shelf

configuration, shelf 0 connects to spigot 0, shelf 1 to spigot 1, shelf 2 to spigot 2,

etc. The T3 modules can connect to spigots 6 and 7 regardless of gap s because

of clock reference considerations on spigots 0 through 3.

Promina 800 Installation and Maintenance Promina Series 2 - 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auxiliary Port to

Internal Ethernet

Nodal Modem

Console Ports

External Ethernet

External Ethernet

PPM

Front Card

Interface Card

PSM

PPM

PPM

to Terminals

or Workstation

Console Port

to Terminals

or Workstation

Alarm

Interface

Front Card

Interface Card

NMS /LAN

Terminator

Terminator

Standard Equipment Modules

Promina Standard Equipment Connectivity

The Promina node processor modules provide connectivity between the

node processors (by way of internal Ethernet), to NMS or LAN systems

(by way of external Ethernet), to terminal/workstations, and to a remote

access modem. Figure 2-2 illustrates conceptually the standard

equipment connectivity in a Promina 800 with redundant PPMs and a

nonredundant PSM.

Note: PPMs and PSMs in a Promina 800 must be connected by the internal

Ethernet cable even in a nonredundant configuration. The Ethernet connection

enables code loading from the PSM to the PPM. Each end of the Ethernet

connection (including on any T-connector) must have a terminator installed.

Figure 2-2 Promina 800 standard Equipment Connectivity

2 - 6 Promina Series Promina 800 Installation and Maintenance

Standard Equipment Modules

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Promina 800 Node Standard Equipment Redundancy

A Promina 800 node may have redundant PPM and PSM modules.

Redundant PPMs are configured in a multiprocessing system with one

master PPM and the others serving as coprocessors. PSM modules

provide 1:1 redundancy.

A redundant Promina 800 may have two or four SX-2 cards (two

redundant pairs) to support up to eight system components consisting of

shelves or modules that support direct SX-2 connections such as the T3

module.

Note: Each T3/E3 card takes up one SX-2 spigot. Each CX card optionally

takes up one spigot. Each SCLX card takes from 1-2 spigots.

The redundant SX-2 and BX cards provide 1:1 redundancy.

Domain and

System

Redundancy

Promina 800 nodes with redundant standard equipment can be configured

to provide system redundancy through two domains. The required

equipment for each domain in a Promina 800 node is shown in Table 2-2.

Table 2-2 Domain Equipment in Promina 800

Number Equipment per Domain

1-2 HSS-2 shelf (per node; domain independent)

1 Shelf bus interface card

1-2 SX-2 modules

1-n T3 (1-4) and E3 (1-6) modules (domain dependent when

redundant; domain independent when nonredundant)

1-n CX (1-4) modules with T3/E3/OC3 interface ca rd s

1-4 SCLX modules with OC3 interface cards

1-n BX modules (one per STS or EXS shelf)

1-4 PPMs (per node; domain independent)

Note: HSS-2 and PPMs are standard to both domains and are domain

independent. There can be up to four PPMs per node for load-sharing and not

necessarily for redundancy.

All the shelves (EXS/STS), T3/E3 trunk modules, and CX modules (with

T3/E3 interface cards) are connected to both Domain A and Domain B

through spigots on SX-2 cards. The SX-2 spigot on the HSS-2 shelf,

which is shelf 0 (zero), is connected to Shelf Bus Interface (SBI) ports A

Promina 800 Installation and Maintenance Promina Series 2 - 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Equipment Modules

and B, respectively; thus the node system has redundant standard

equipment via domains, and with one online and the other offline.

If the system is currently on domain A and a failure is detected on a

standard equipment card (for example, an SX-2, BX, T3, or SCLX, if

cabled and configured redundantly) the system will switch to Domain B.

The node has the highest priority, followed by the shelf, followed by the

trunk module. For example, if a Promina 800 is currently using domain A

and a failure occurs on a Domain A BX module, the Promina will switch

to Domain B, even though the redundant T3 card on Domain B is down.

This causes the T3 span to go down but enables the shelf that had the

failed BX to be restored. In this example, the system will still be

nonredundant.

The operator switches the domain online by entering the Switch Domain

command in the OI.

Nonredundant

Configurations

A Promina 800 node may also be configured as a nonredundant system. A

nonredundant configuration of the Promina 800 node consists of the

following:

• One rack

• One HSS-2

• One to 3 EXS

• One power supply per shelf

• One PSM

• One PPM

• One SX-2

• One T3, E3, or CX (with T3/E3 interface) (optional)

A second PPM is used in a nonredundant Promina 800 node, if needed, to

accommodate the number of load units in the node configuration. In this

situation, the second PPM does not provide redundancy.

A second SX-2 may be needed in a nonredundant Promina 800 node

depending on the number of shelves and whether the node has a

high-bandwidth trunk such as a T3, E3, or CX with T3/E3 interface.

Nonredundant Promina 800 configurations also have some restrictions in

supported components and system capabilities.

• Only EXS shelves (to a maximum of three EXS shelves) are

supported.

2 - 8 Promina Series Promina 800 Installation and Maintenance

Standard Equipment Modules

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

• Only one high-bandwidth trunk card such as a T3, E3, or CX (with

T3/E3 interface) is supported.

• A nonredundant configuration cannot support domain redundancy;

the B domain must be disabled in the configuration database to

suppress nonredundant events and alarms.

Promina 800 Installation and Maintenance Promina Series 2 - 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Equipment Modules

Timing Sources

A single, central clocking source is vital to the operation of all digital

networks because it synchronizes transmission between communicating

devices. If the clocking of each element in the network is not

synchronized to a standard source, bit errors and frame slips can occur.

Internal clocking is provided as follows:

Table 2-3 Clocking Sources

Node Card

Promina 800 SX-2

The SX-2 module can provide internal timing by way of the timing

signals generated by the onboard crystal oscillator. These cards can also

provide external timing by phase-locking onto external clock sources (for

example, digital transmission facilities, channel banks, or station clocks).

External clocking from customer equipment can also be provided to the

node through various modules including:

• Trunk cards

• Primary Rate Card (PRC) and Two Megabyte Channelized Port

(TMCP) voice cards

• Universal Synchronous Data (USD) data cards

Note: USD data cards are not supported by the Promina 100.

For more information on setting up clocking, refer to the Node

Management manual.

2 - 10 Promina Series Promina 800 Installation and Maintenance

1Chapter 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3Card Descriptions