NESTOR MARTIN S33, H33, X33, R33 Operating Instructions Manual

Manufactured by:

Fonderies du Lion Development

11 Rue du Lion

5660 Couvin, Belgium

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

INSTALLATION AND OPERATING INSTRUCTIONS

S33

H33 R33

X33

EPA-CERTIFIED NONCATALYTIC WOODSTOVES

WITH WOODBOX© TECHNOLOGY

S33##1710A

Dear Customer,

We would like to thank you for purchasing a Nestor Martin heating appliance. For over 150 years, we have provided

our customers with high-quality, worry-free products that stand the test of time. We work hard so that you can enjoy

the warmth of your new stove for years to come.

If you have questions that are not covered in this manual, please feel free to contact your local Nestor Martin dealer

for more information.

Rudy Cyris

President

2

Table Of Contents

Page

Safety Notice 3

Product Specifications 3

Installation Guide 4

Dimensions S33 and H33 4

Clearances to Combustibles S33 and H33 4

Dimensions X33 and R33 5

Clearances to Combustibles X33 and R33 5

Floor Protection Requirements 6

Types of Chimneys 6

Chimney Inspection 6

Draft Requirements 7

Chimney Height 7

Standard Installation Procedure 8

Freestanding Installations 8

Above a Fireplace 9

Wall Pass-Throughs 9

Acceptable Types of Connector Pipe 10

The Woodbox Combustion System 11

Air Distribution System 11

Controlling Components 11

The Air Intake Controls 12

Operating Instructions 13

Lighting a Fire 13

Use of the Remote Control 14

Refuelling the Stove 14

Overnight Burning 14

Ash Removal 15

Guidelines for Safe Operation 15

Flue Gas Temperature 15

Unattended Fires 16

In Case of a Chimney Fire 16

Choice of Firewood 17

Maintenance 17

Integrated Airwash System 17

Manual Cleaning of the Glass 17

Cleaning the Stove Body 17

Creosote Formation 18

Summer Shut Down 18

Door Handle Adjustment 19

Ash Pan Door Adjustment 19

Spare Parts 20

Spare Parts, S33 20

Spare Parts, H33 22

Spare Parts, X33 24

Spare Parts, R33 26

Safety Labels 28

Warranty 30

Product Specifications

Flue collar size: 6”

Flue position: top

Max burn rate: 59,000 BTU/hr

EPA output range: 8,600 – 37,300 BTU/hr

Emissions rate: 3.43 g/hr

Heating capacity: 1,100 – 1,500 sq ft

Max. burn time: up to 10 hours

Max log length: 17”

Weight: H33: 346 lbs

S33: 358 lbs

R33: 316 lbs

X33: 316 lbs

Safety Listing

Your appliance has been tested following standards :

US Standard: ANSI/UL 1482

Canadian Standard : CAN/ULC-S627

Tests performed by OMNI-Test Laboratories, Inc., Beaverton, Oregon

This stove meet the US Environmental Protection Agency’s emissions limits for wood heaters.

3

Safety Notice

Please read this entire manual before you install and use your new room heater. Failure to follow instructions may result

in property damage, bodily injury or even death.

If your stove is not properly installed, a house fire may result. For your safety, follow the installation directions. Contact

local building or fire officials about restrictions and installation requirements in your area.

The authority having jurisdiction (such as municipal building department, fire department, fire prevention bureau, etc.)

should be consulted before installation to determine the need to obtain a permit.

ENSURE THAT THIS MANUAL REMAINS WITH THE APPLIANCE AND IS PASSED ON TO THE USER AFTER

INSTALLATION. DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE

VICINITY OF THIS APPLIANCE.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause injury or property

damage. Refer to this manual for assistance or consult a qualified (experienced) installer.

Installation Guide

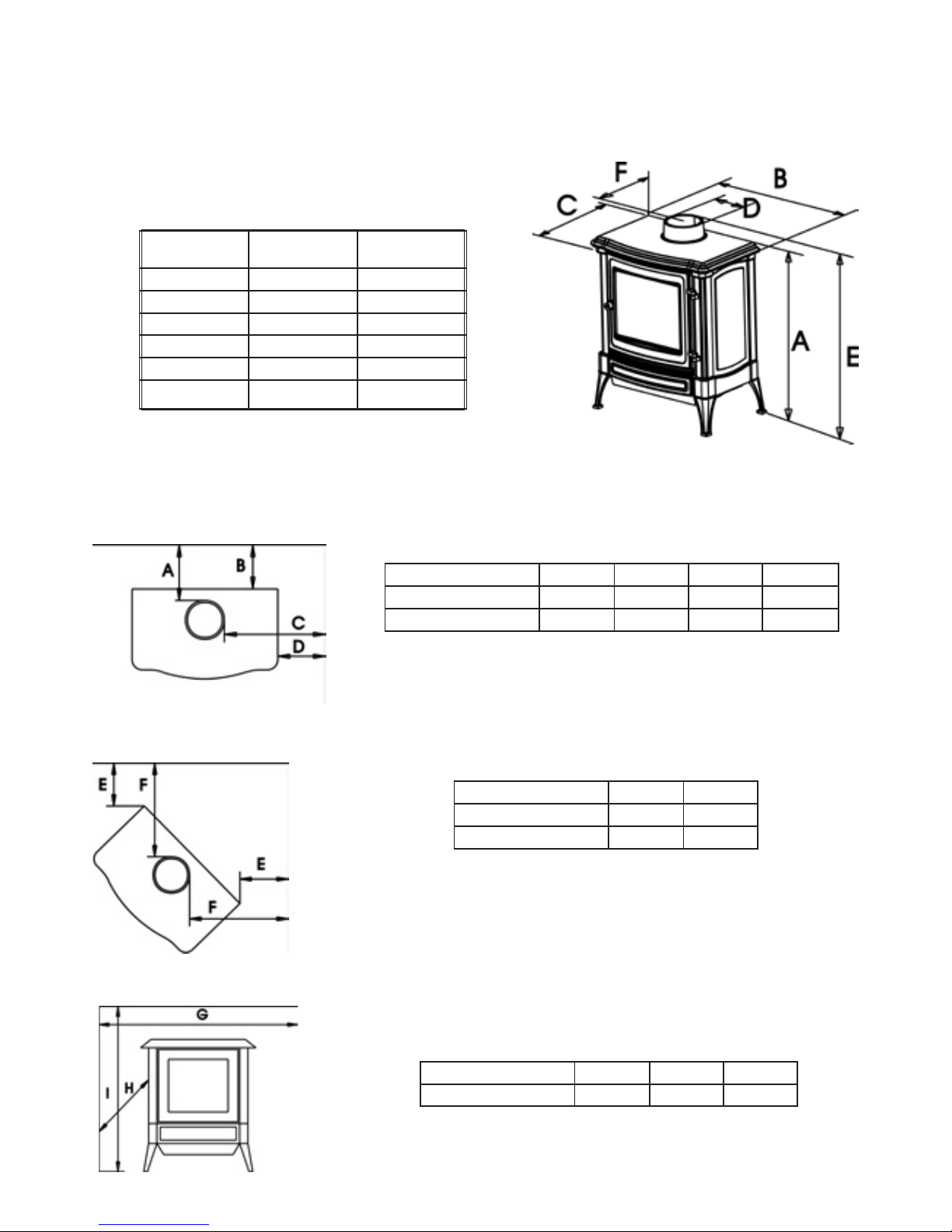

S33 H33

A 30” (751mm) 28” (716mm)

B 25” (631mm) 26” (649mm)

C 16” (395mm) 15” (370mm)

D 6” (150mm) 6” (150mm)

E 32” (816mm) 31” (781mm)

F 5” (113mm) 5” (113mm)

S33 and H33 cast iron models

Dimensions

Clearances to Combustible Materials

Back and side wall clearances

Corner clearances

Alcove clearances

Connector pipe A B C D

Single wall 14” 13” 18” 9”

Double wall 13” 12” 18” 9”

Minimum ceiling height: 30” (unit to ceiling)

Connector pipe E F

Single wall 10½” 19”

Double wall 7” 15½”

Minimum ceiling height: 30” (unit to ceiling)

Connector pipe G H I

Double wall 48” 28” 60”

The following clearances may only be reduced by means approved by the regulatory authority.

4

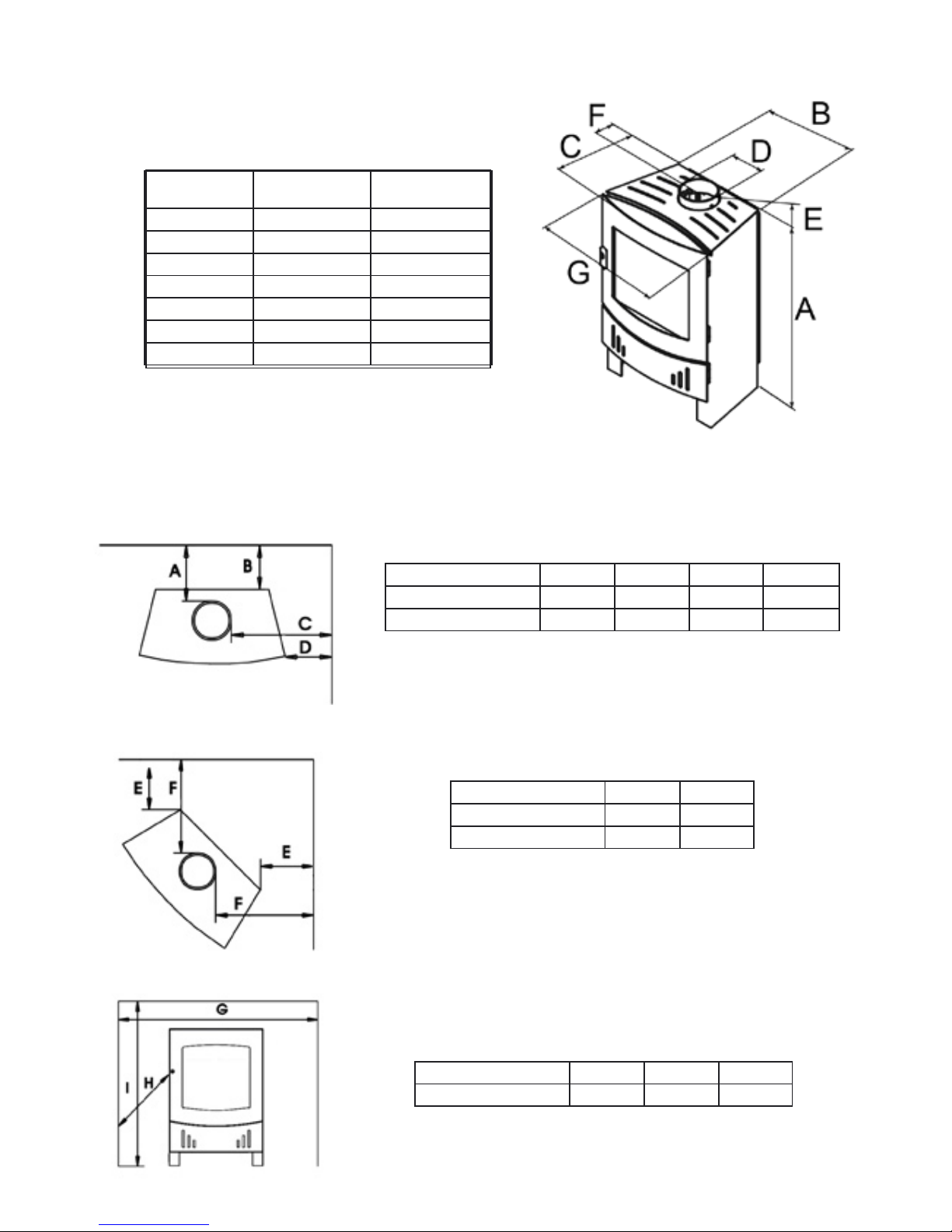

X33 R33

A 31¾” (807 mm) 31¾” (807 mm)

B 16¼” (390 mm) 16¼” (390 mm)

C 16” (404 mm) 15¾” (400 mm)

D 6” (150 mm) 6” (150mm)

E 37” (942 mm) 37” (942 mm)

F 5¼” (132 mm) 5” (113mm)

G 21” (542 mm) 21” (542 mm)

X33 and R33 steel body models

Dimensions

Clearances to Combustible Materials

Back and side wall clearances

Corner clearances

Connector pipe A B C D

Single wall 11” 10” 24” 18½”

Double wall 8” 7” 23” 17½”

Alcove clearances

Minimum ceiling height: 30” (unit to ceiling)

Connector pipe E F

Single wall 10” 15½”

Double wall 9½” 15”

Minimum ceiling height: 30” (unit to ceiling)

Connector pipe G H I

Double wall 48” 28” 60”

The following clearances may only be reduced by means approved by the regulatory authority.

5

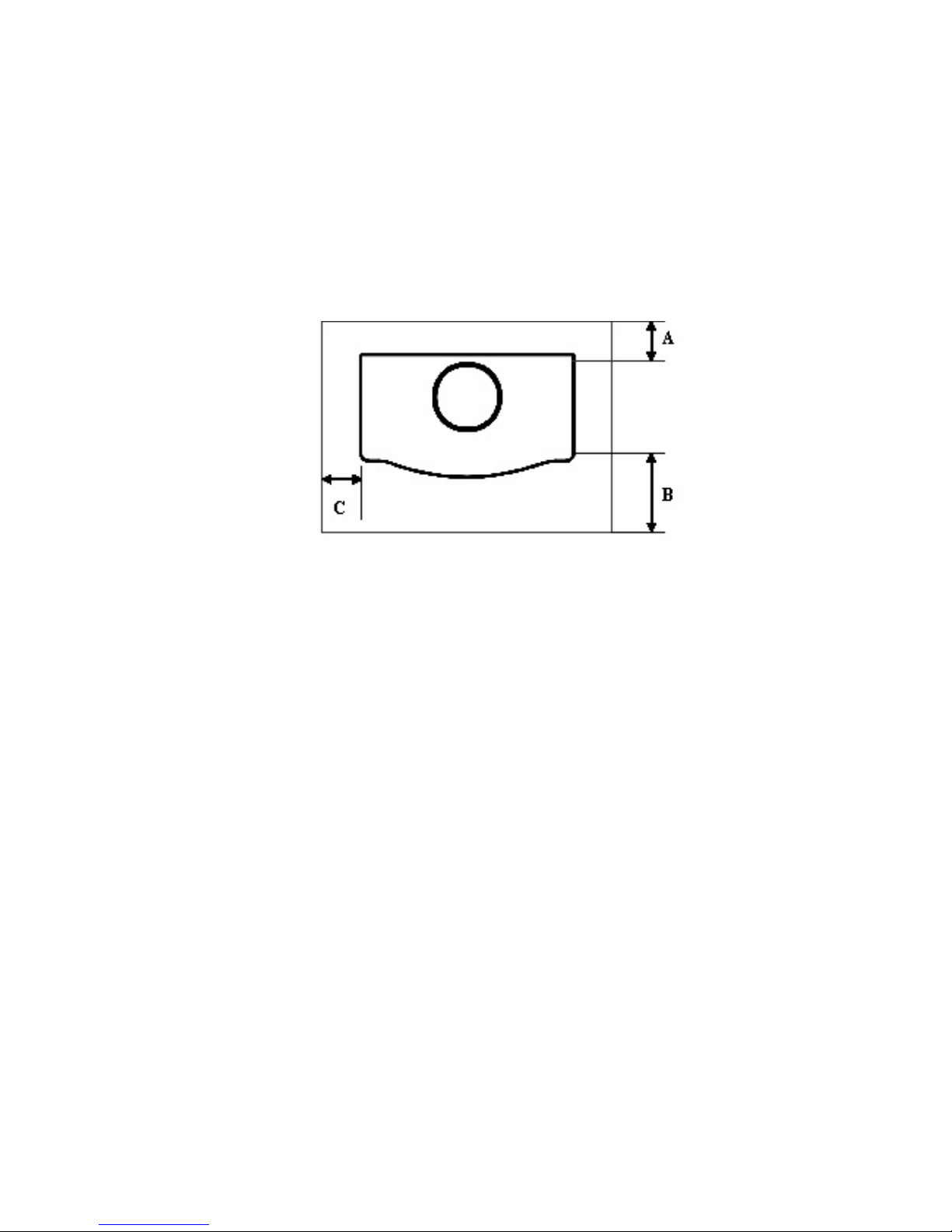

Floor Protection Requirements

A non-combustible floor protector (hearth extension) must be installed under the unit.

Check with local building authorities as to what other materials are acceptable.

The floor protector must extend:

1. Beyond the front door, a minimum of 16 inches (400 mm) in USA and 18 inches (450 mm) in Canada. See

measurement “B” on the floor protection drawing below.

2. On both sides of the unit, a minimum of 5 inches (125 mm) in USA and 8 inches (200 mm) in Canada. See

measurement “C” below.

3. On the back of the unit, a minimum of 0” (0 mm) in USA and 8 inches (200 mm) in Canada. See

measurement “A” below.

Notice: In case of installation with horizontal pipe, the floor protection must be extended beyond the back of the

appliance under the chimney connector and 2” (50 mm) beyond each side of the chimney connector.

Minimum requirements for floor protection on combustible floors

Types of Chimneys

The Chimney is a vital part of your stove installation. Your stove must be connected to either a code-approved

masonry chimney (a flue liner may be required), or a 6-inch diameter factory built chimney complying with the UL

requirements for Type HT chimneys (regulation UL 103 and ULC S629).

All chimneys must be installed either according to the local building codes in the case of a masonry chimney or

according to the chimney manufacturer’s instructions in the case of a factory-built metal chimney. See the chimney

manufacturers instructions for exact specifications. An oversized chimney may result in less than optimum

performance. Installations into a large, masonry chimney may require a liner to improve performance.

Chimney Inspection

Existing chimneys must be inspected before installing your stove. Consult your local building department for chimney

code requirements. A masonry chimney should have a code-approved liner. This liner must not have broken or

missing pieces. Some non-code masonry chimneys may be brought up to code by being relined. (Consult your dealer

or qualified chimney sweep.) Factory built metal chimneys should also be inspected, first for creosote deposits (which

would be removed), and then for integrity of the stainless steel liner. Look for obvious bulges in the lining, which may

indicate the need to replace that section (use a bright flashlight). Also inspect the attic to see that the chimney has

proper clearance to combustible framing members.

6

Draft Requirements

The appliance is merely one component of larger system. The other equally important component

is the venting system. This is necessary for achieving the required flow of combustion air to the

fire chamber and for safely removing unwanted combustion by-products from the appliance. If the

venting system’s design does not promote these ends, the system may not function properly. Poorly

functioning venting systems may create performance problems, as well as be a safety hazard

(i.e. an oversized chimney may result in less than optimum performance. Installations into a large

masonry chimney may require a liner to improve performance).

THE RECOMMENDED DRAFT REQUIREMENTS FOR YOUR STOVE IS NO LESS THAN -.04

AND NO GREATER THAN -.08. OPERATION OF YOUR STOVE WITH A DRAFT GREATER

THAN -.08 CAN POSSIBLY CAUSE DAMAGE TO THE STOVE AND VOID THE WARRANTY.

SPECIAL NOTE: A barometric damper is recommended for installations of stoves in areas that

may have high winds, which can affect the draft. The installation must be only in units with a newly

constructed chimney, free of creosote deposits. The barometric damper is an automatic device

designed to regulate the draft in a heating appliance, which in turn, stabilizes the chimney temperatures,

lessening the potential of over-firing. Do not place the barometric damper greater than 24 inches (610 mm) above the

unit. Excessive draft will lead to poor control of the burn rate, possible over-firing of the stove and damage to the cast

iron components of the firebox. Most barometric dampers are calibrated in inches of water column and can be set to

draft requirements of -.03 to -.08 inches (-7.5 to -20 Pa). It is recommended that the barometric dampers to be set

between -.05 and -.06 inches.

Chimney Height requirements

According to the American National Standards Institute ANSI/NFPA 211-92, draft 1-7, a chimney or vent shall be so

designed and constructed to develop a flow sufficient to completely remove all flue and vent gases to the outside

atmosphere. The venting system shall satisfy the draft requirements of the connected appliance in accordance with

the manufactures instructions.

The “3-foot, 2-foot, 10-foot rule” on chimney height states that a chimney must be:

1. At least 3 feet higher than the highest part of the roof opening through which it passes,

2. and at least 2 feet higher than any part of the roof within 10 feet, measured horizontally.

Due to prevailing winds, local terrain, adjacent tall trees, a hill or ravine near the home, or adjacent structures,

additional chimney height or a special chimney cap may be required to assure optimum performance.

.02

.01

.03

.04

.05

.06

.07

.08

.09

.05

.1

.2

.3

.4

.5

.6

.7

.8

.9

1.0

IN.OF WATERDRAFTOR PRESSURE-LOW RANGE

IN.OF WATERDRAFTOR PRESSURE-HIGH RANGE

Draft gauge

7

Standard Installation Procedure

1. Position the unit no closer than the minimum clearances to combustible materials. Check that no overhead

cross members in the ceiling or roof will be cut. Reposition unit if necessary, being careful not to move closer

than the minimum clearances.

2. Mark the position of the required floor protector on the floor. Remove the unit and install the floor protector.

3. Position the unit on the floor protector at the proper clearances.

4. Install a 6-inch diameter, minimum 24 MSG black or 26 MSG blued steel connector pipe on the flue collar of

the unit.

5. The stove is NOT to be connected to any air distribution duct or system. A chimney connector shall not

pass through an attic or roof space, closet or similar concealed space, or a floor, or ceiling. Where passage

through a wall or partition of combustible construction is desired, the installation shall conform to CAN/CSA B365, Installation Code for Solid-Fuel-Burning Appliances and Equipment. (Canadian installations only).

6. Use a 6” chimney connector adapter to connect the chimney connector up to the chimney. The small ends of

the chimney connector should all point down to ensure a drip-free installation.

7. Check that all clearances are still within the allowable tolerances.

8. Secure adjoining sections of chimney connector to each other using three equally spaced sheet metal screws.

Secure the connector pipe to flue collar using three equally spaced sheet metal screws. DO NOT secure

chimney connector to chimney with screws.

9. The unit must be connected to either:

• a code-approved masonry chimney with a flue liner, or

• a 6 inch diameter factory built chimney complying with the requirements for Type HT chimneys in the

standard UL 103 and ULC S629.

WARNING:

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE.

UNIT MUST BE INSTALLED ACCORDING TO ALL LOCAL CODES. A BUILDING PERMIT MUST BE OBTAINED

BEFORE INSTALLING.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

DO NOT INSTALL IN A MOBILE HOME.

READ ALL INSTRUCTIONS CAREFULLY BEFORE STARTING THE INSTALLATION.

UNIT MUST BE PROPERLY INSTALLED OR LISTING WILL BE VOID.

INSTALLATIONS OTHER THAN THOSE SPECIFICALLY COVERED HEREIN HAVE NOT BEEN CONFIRMED BY

TEST AND ARE NOT COVERED BY THE LISTING.

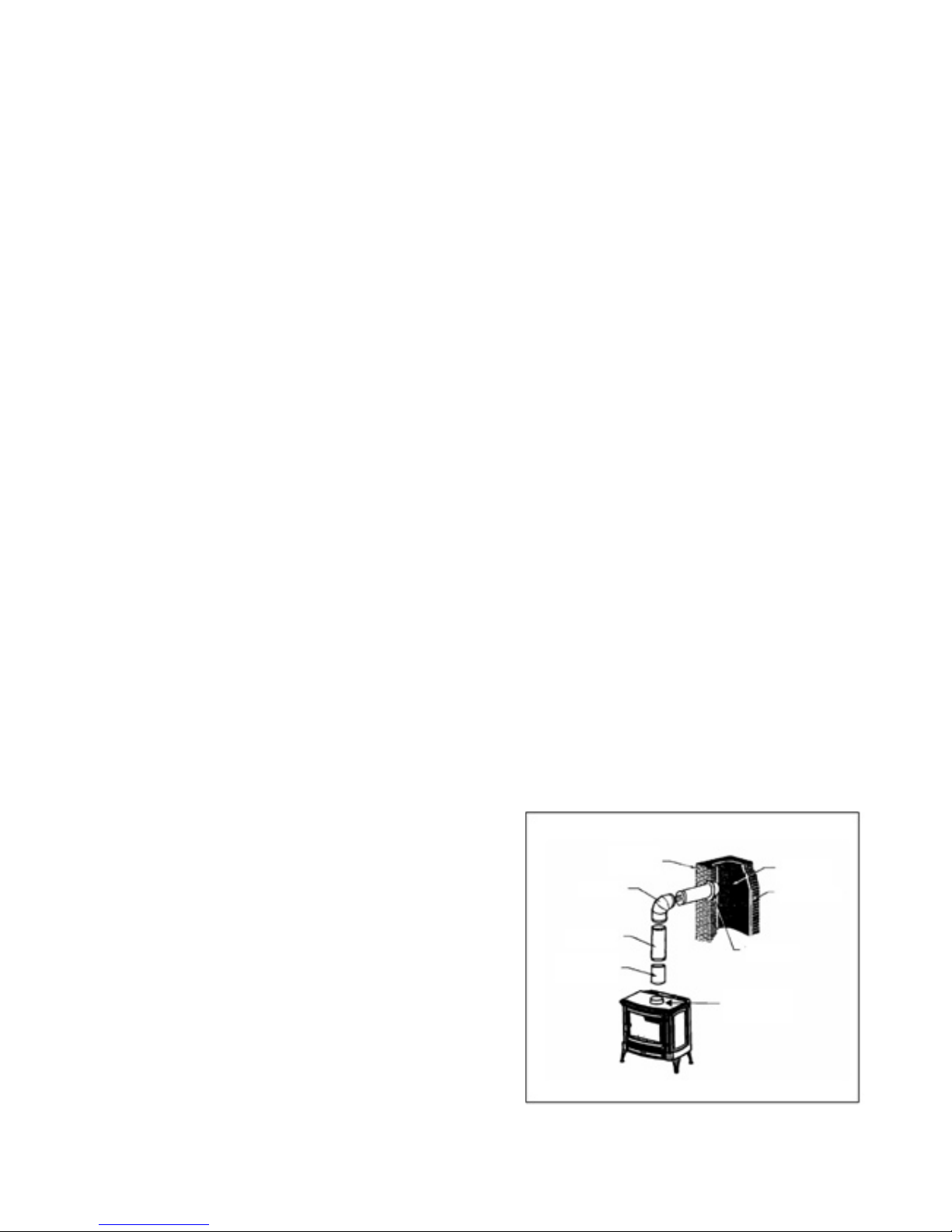

Freestanding Installations

If the chimney connector must pass through a combustible wall to reach the chimney, follow the recommendations in

the Wall Pass-Through section that follows.

The opening through the chimney wall to the flue (the “breach”) must be lined with either a ceramic or metal cylinder,

called a “thimble”, which is securely cemented in place.

Fig. A: Chimney connection in a freestanding installation

8

Most chimney breeches incorporate thimbles, but the fit must

be snug and the joint between the thimble and the wall must be

cemented firmly (Fig. A)

A special piece called the “thimble sleeve”, slightly smaller in

diameter than standard connectors and most thimbles, will

facilitate the removal of the chimney connector system for

inspection and cleaning. Thimble sleeves are available from

your local dealer.

To install a thimble sleeve, slide it into the breech until it is flush

with the inner flue wall. Do not extend it into the actual flue

passage, as it could interfere with the draft.

The thimble sleeve should protrude 1-2” (25-50 mm) into the

room. User fire cement and thin gasketing to seal the sleeve

in place in the thimble. Secure the chimney connector to the

outer end of the sleeve with sheet metal screws.

Chimney

Elbow

Slip Pipe

Standard

Connector

Flue Liner

Flue Liner

Thimble

Flue Collar

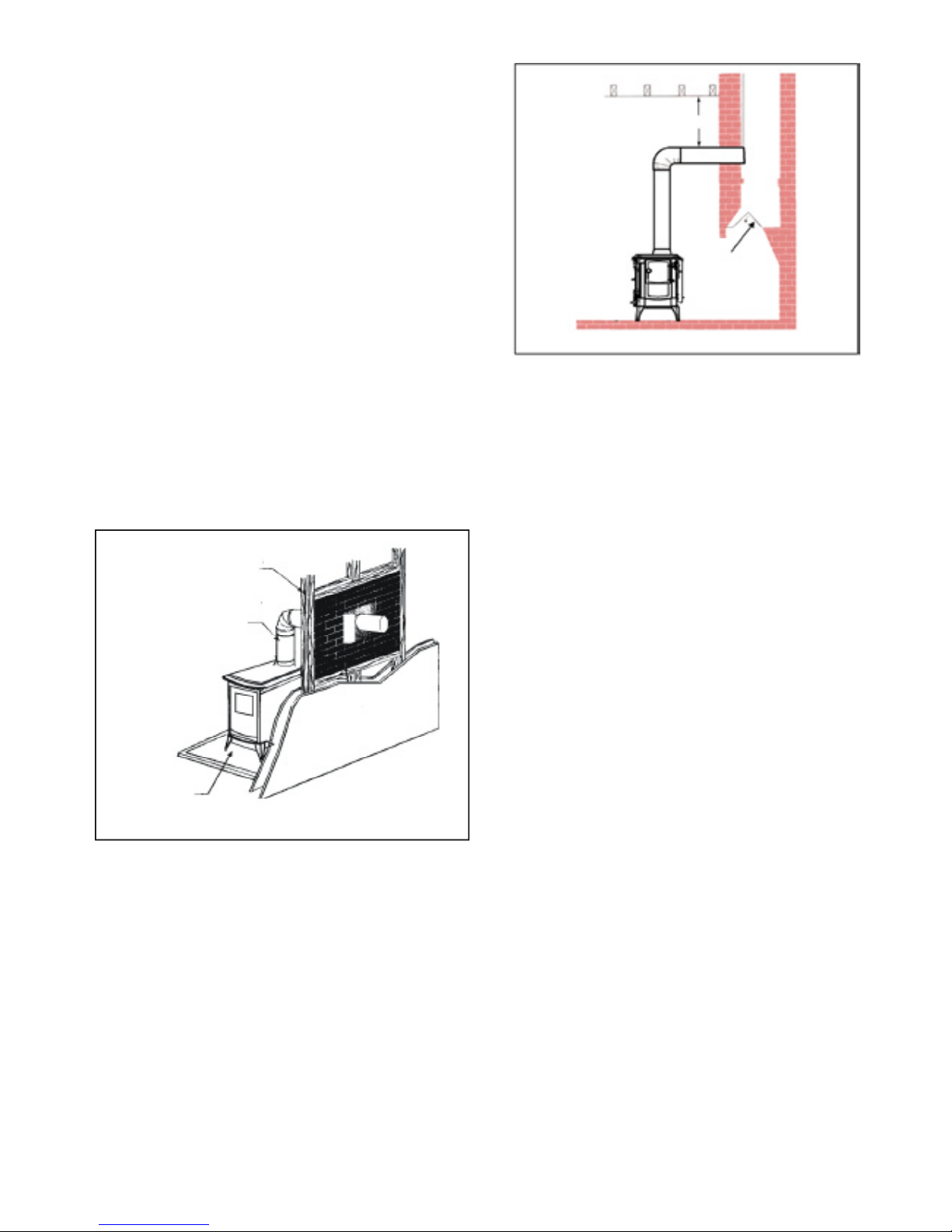

Above a Fireplace

In this type of installation, the chimney connector rises

from the stove, turns 90°, and then goes into the fireplace

chimney (Fig. B) The liner of the fireplace chimney should

extend at least to the point at which the chimney connector

enters the chimney. Follow all the guidelines for installing

a chimney connector into a freestanding masonry chimney,

and pay special attention to these additional points:

• Double check the connector clearance from the

ceiling: 18” minimum.

• The fireplace damper must be closed and sealed

to prevent room air from being drawn up the flue,

thereby reducing the draft. However, it must

be possible to re-open the damper in order to

inspect the chimney.

Fig. B: Chimney connector enters the chimney above a fireplace

Wall Pass-Through

Whenever possible, design your installation so that the wall connector does not pass through a combustible wall. If

you are considering a wall pass-through in your installation, check with your building inspector before you begin. Also

check with the chimney connector manufacturer for any specific requirements. Accessories are available for use as

wall pass-throughs. If using one of these, make sure it has been tested and listed for use as a wall pass-through.

Fig. C: An example of an approved wall pass-through

9

Chimney connector enters chimney above the

Wall Stud

The National Fire Protection Association (NFPA) has

established guidelines for passing chimney connectors

through combustible walls. Many building code

inspectors follow these guidelines when approving

installations.

The methods approved by the NFPA are:

• Cutting away all combustible material in the

wall a sufficient distance from the single wall connector,

to provide the required 12” (300 mm) clearance for the

connector. Any material used to close the opening must

be non-combustible (as in Fig . C).

• Using a section of double-wall chimney with a

9” (230 mm) clearance to combustibles.

• Placing a chimney connector pipe inside

a ventilated thimble, which is then separated from

combustibles by 6” (150 mm) of fibreglass insulating

material.

• Placing a chimney connector pipe inside a section

of 9” (230 mm) diameter, solid-insulated factory built

chimney, with two inches of air space between the

chimney section and the combustibles.

Chimney Connector

Floor Protection

minimum 18”

seal the damper

Acceptable Types of Connector Pipe

Minimum Flue Diameter: Minimum 6”, Maximum 10”

Minimum recommended chimney height (from appliance to termination): 12’-15’

- When Using Single Wall Pipe: Install a 6-inch diameter, single wall, 24 MSG black steel or 26 MSG blued steel

connector pipe on the flue collar of the unit. The crimped ends of the pipeshould all point down. Additional sections of

single wall pipe should be fastened together with at least three sheet metal screws each section. All pipe connections

must be sealed (using high temperature silicone).

- When connecting to the factory-built ceiling support package, use the manufacturer’s transition piece, usually called

a dripless connector, to join single wall pipe to their factory-built chimney section.

- When using approved double wall pipe: Type L and listed doublewall connector pipe is acceptable. Install any

factory-built brand of pipe according to the manufacturer’s instructions. All pipe connections must be sealed.

- Chimney Connector Adapter - Use a 6-inch chimney connector adapter to connect the chimney connector up to the

chimney. The small ends of the chimney connector should all point down for a drip free installation. Secure adjoining

sections of chimney connector to each other using three sheet metal screws. Secure the connector pipe to flue collar

using three sheet metal screws. DO NOT secure chimney connector to chimney with screws.

- Connection to a factory built chimney - Your stove may be connected to a factory-built chimney conforming

to CAN / ULC – S629, Standard for 650°C Factory-Built Chimneys. All pipe connections must be sealed.

- For Reduced Residential Clearances Using Double Wall Pipe: Type L and listed double wall connector pipe is

acceptable. Install any factory-built brand of pipe according to the manufacturer’s instructions.

10

Loading...

Loading...